Influence of Yield Stress and Material Area Ratio on Bondability and Formability in Drawing Processes of Bimetallic Rods

Abstract

1. Introduction

2. Literature Review

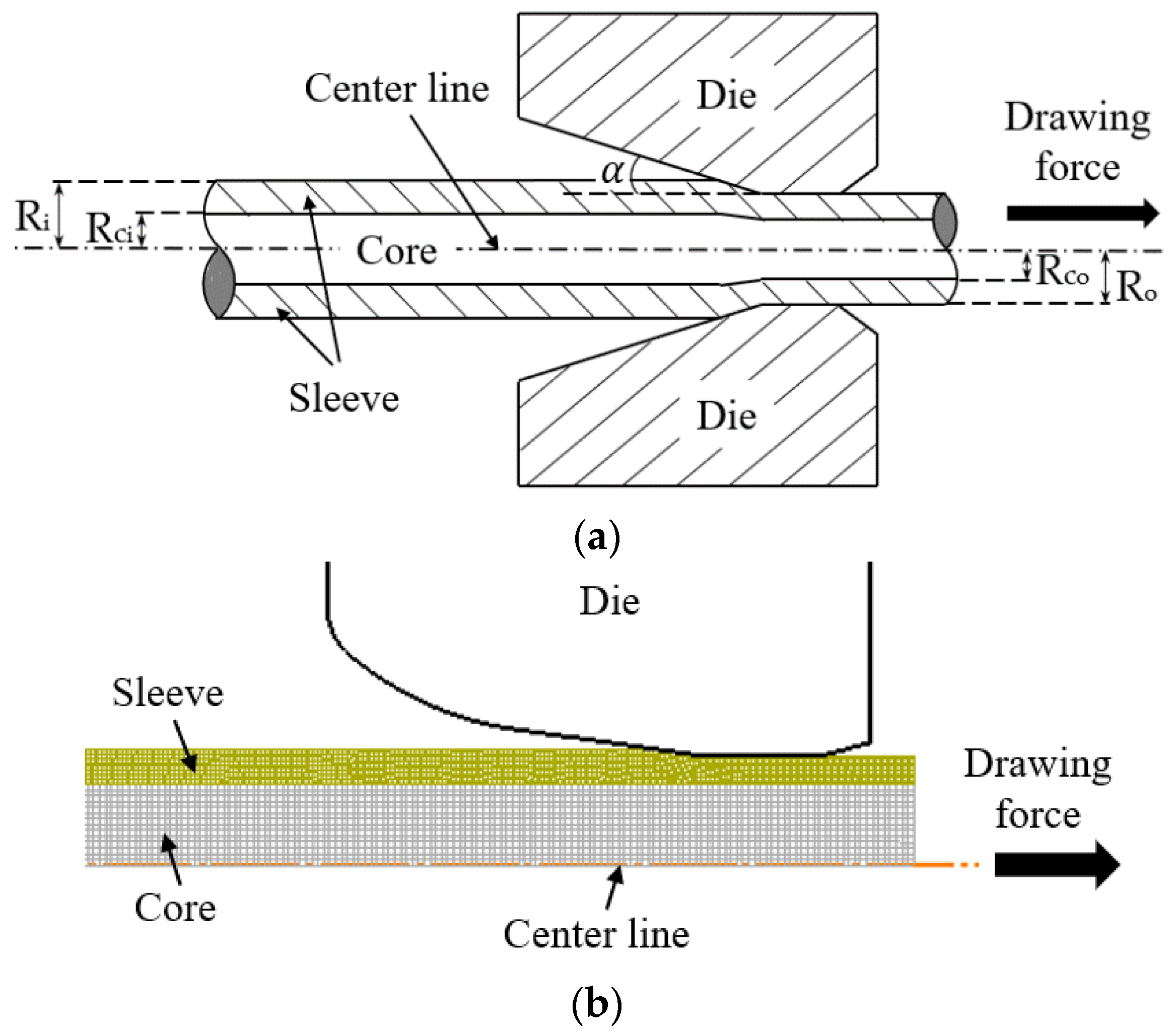

3. Materials and Methods

4. Results

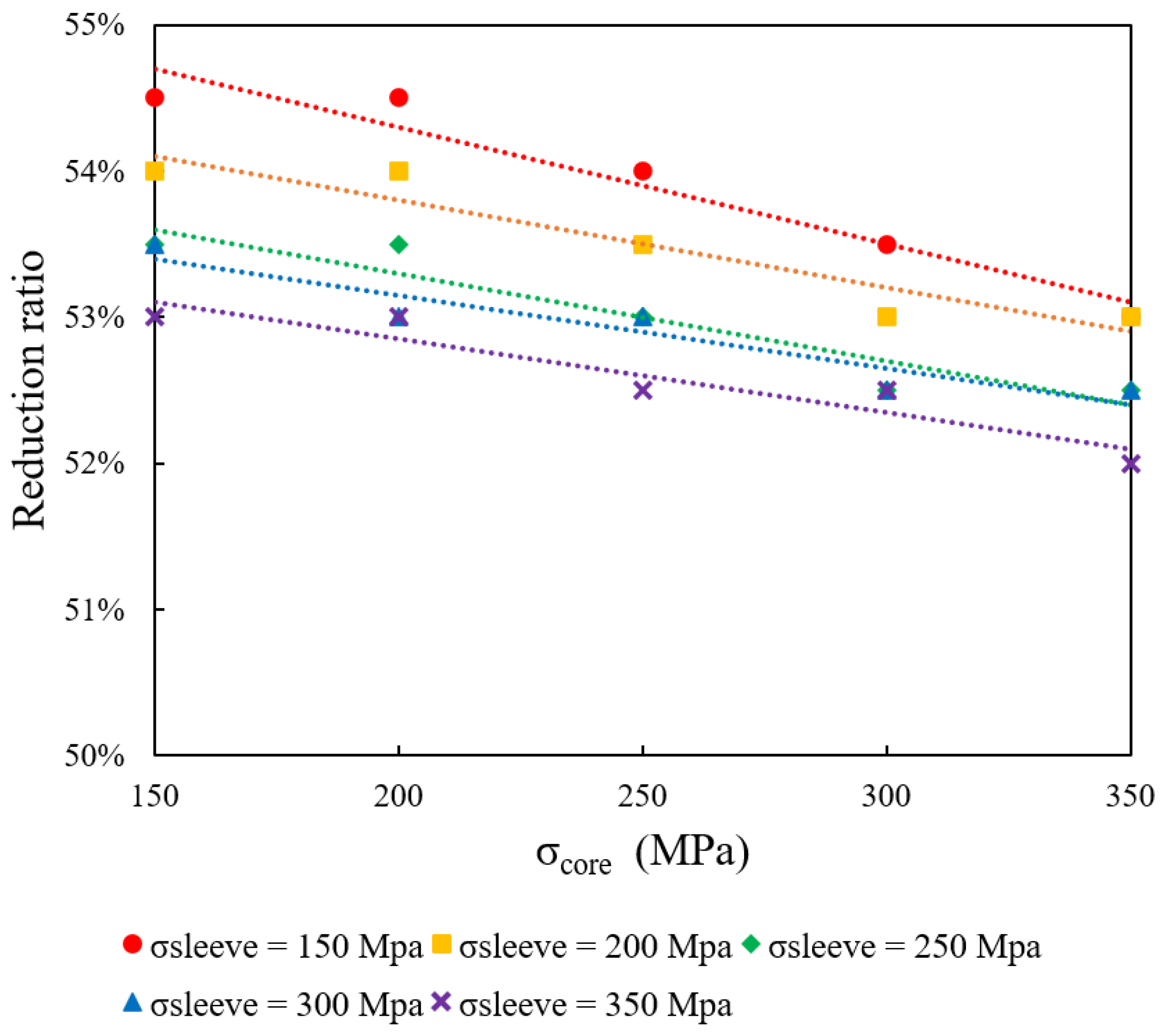

4.1. Influence of Core and Sleeve Yield Stress on Drawing Limit at a Fixed 70% Core Ratio

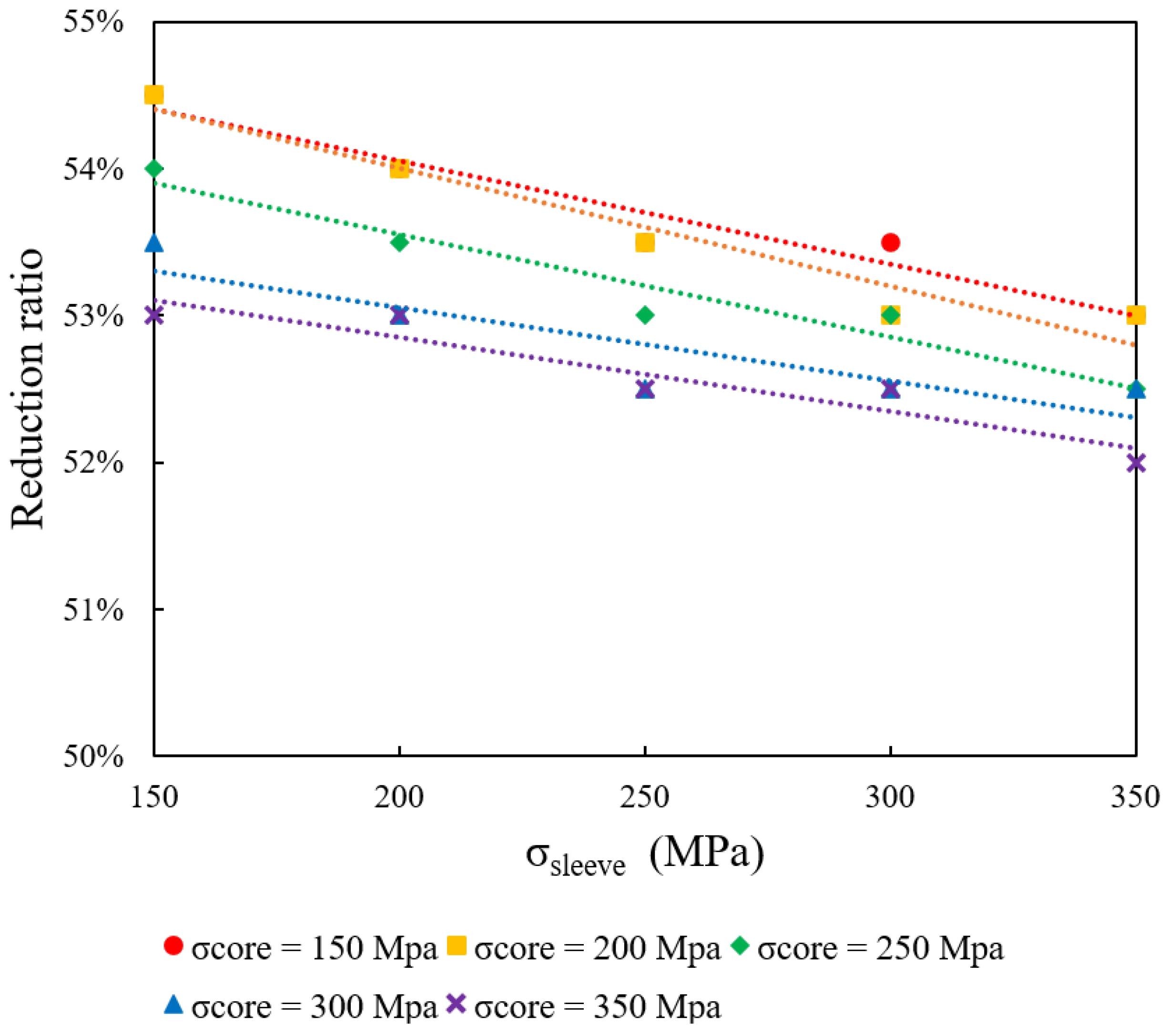

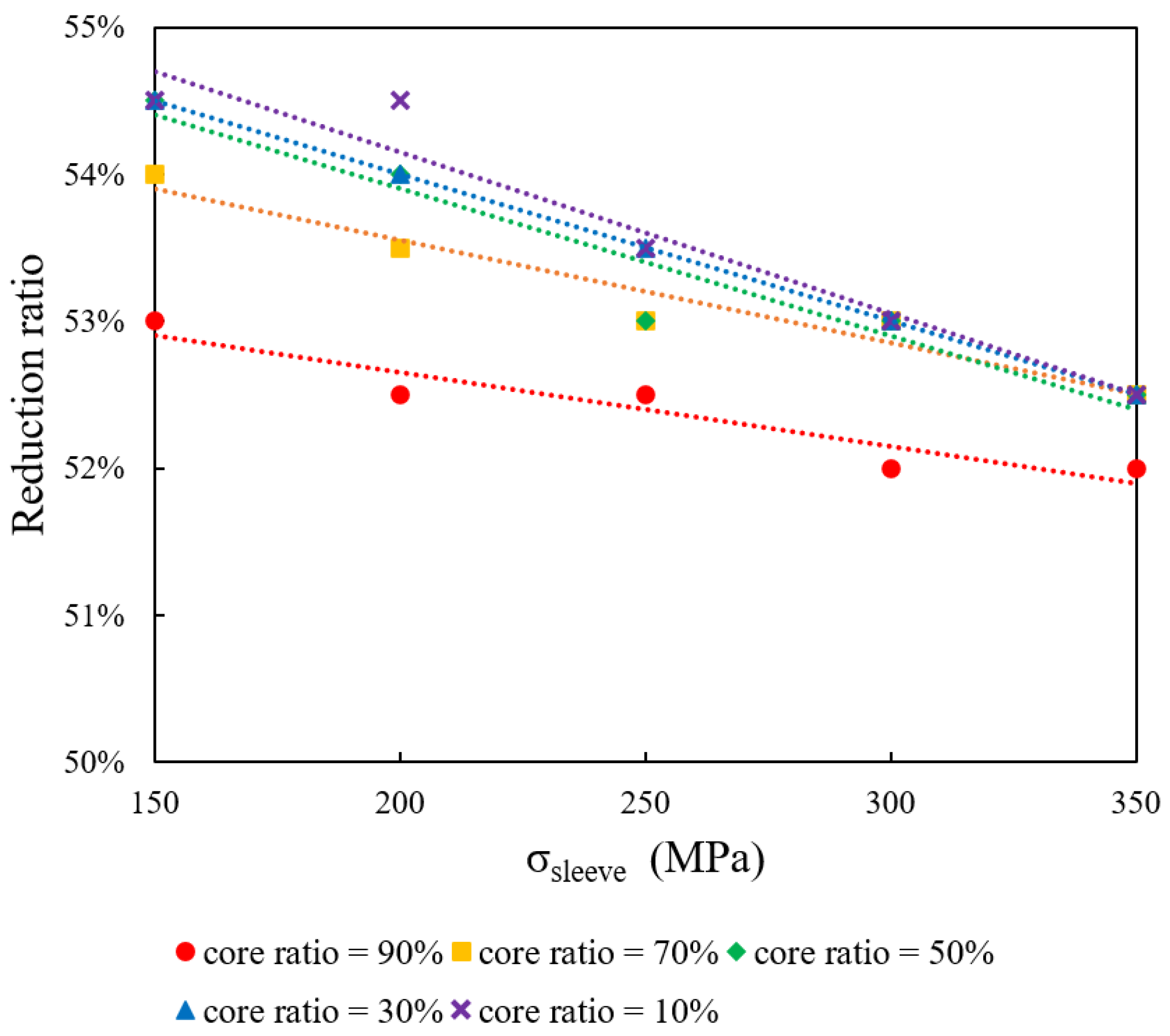

4.2. Impact of Initial Core Ratio on Drawing Limit at Constant Sleeve Yield Stress (250 MPa)

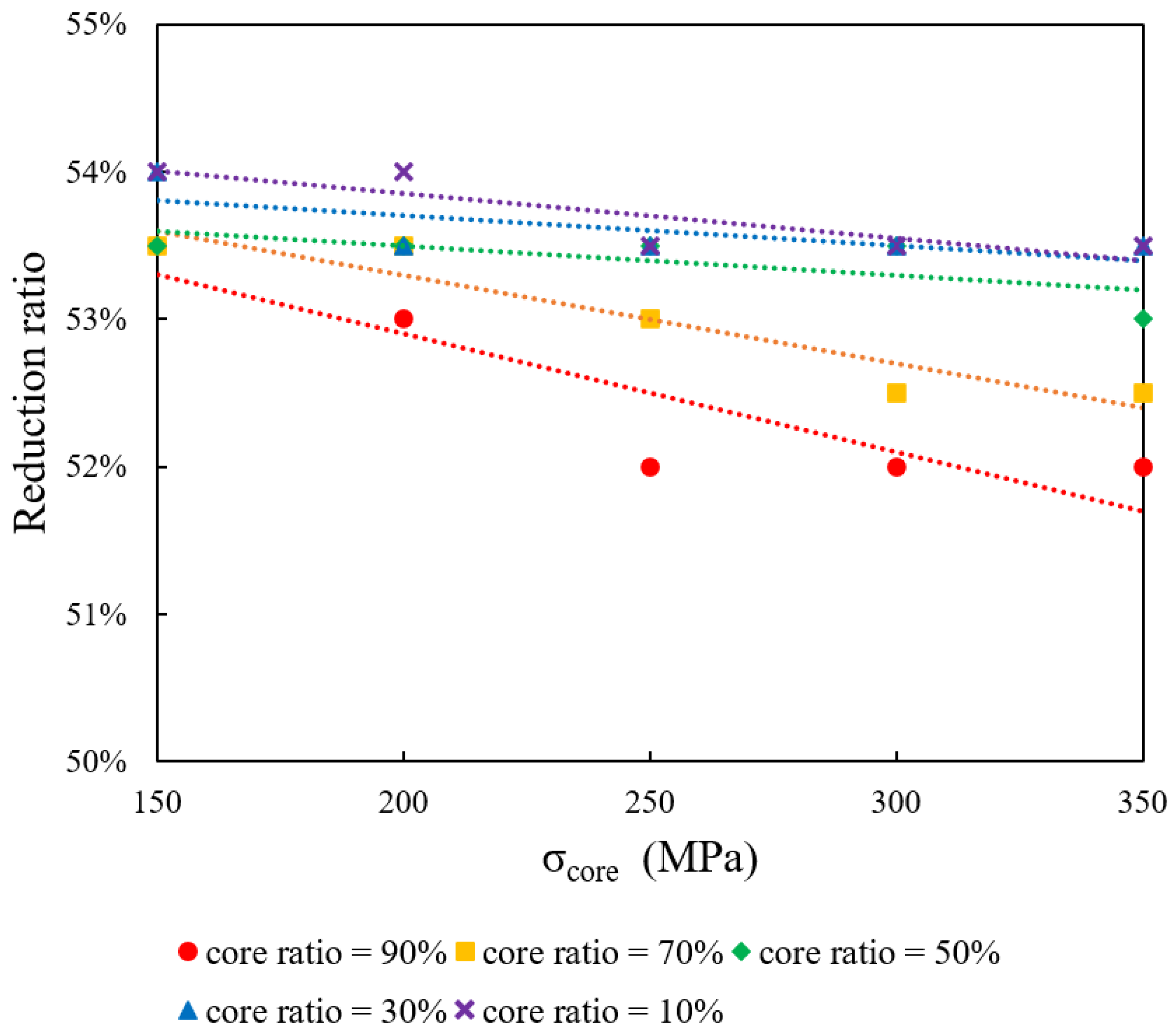

4.3. Impact of Initial Core Ratio on Drawing Limit at Constant Core Yield Stress (250 MPa)

5. Discussion

5.1. Influence of Core and Sleeve Yield Stress on Drawing Limit at a Fixed 70% Core Ratio

5.2. Impact of Initial Core Ratio on Formability and Drawing Limit

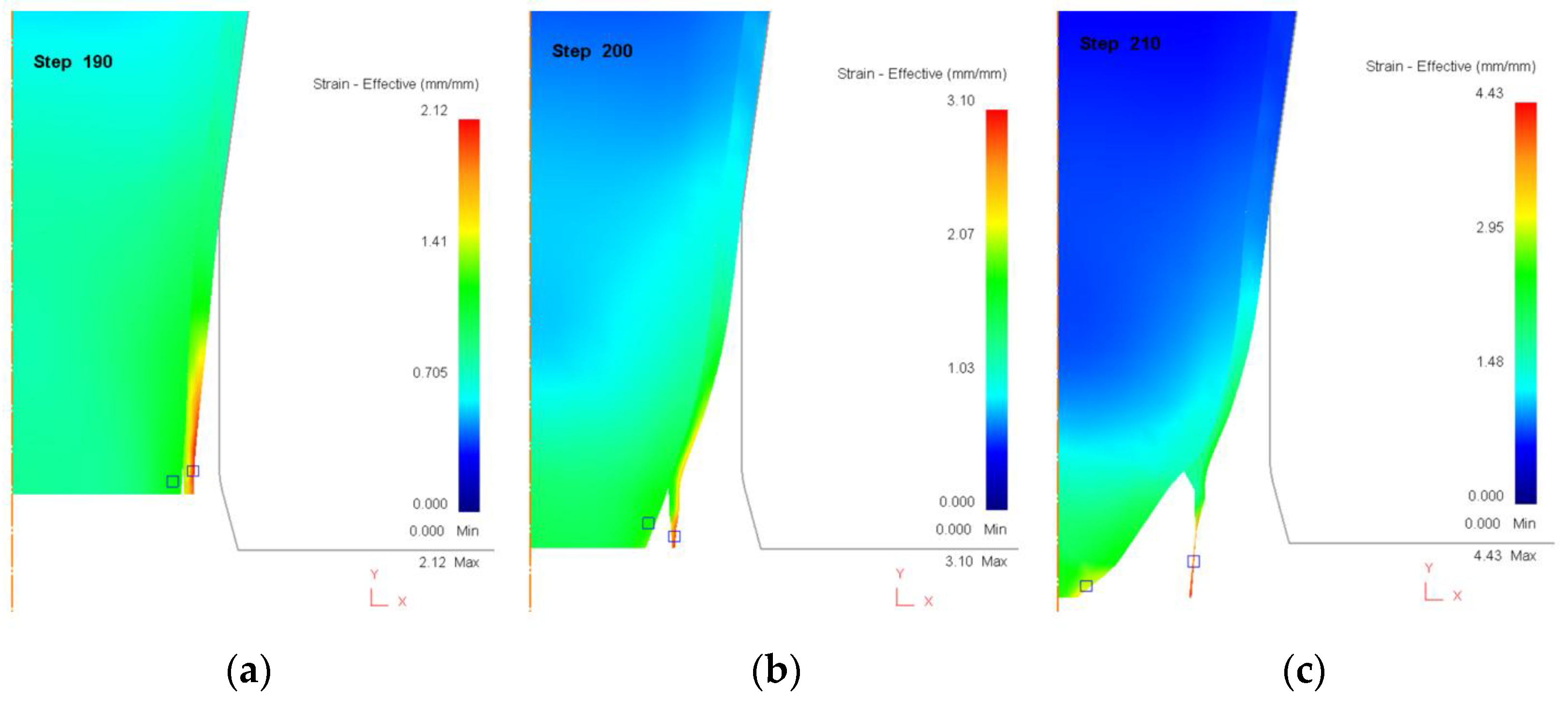

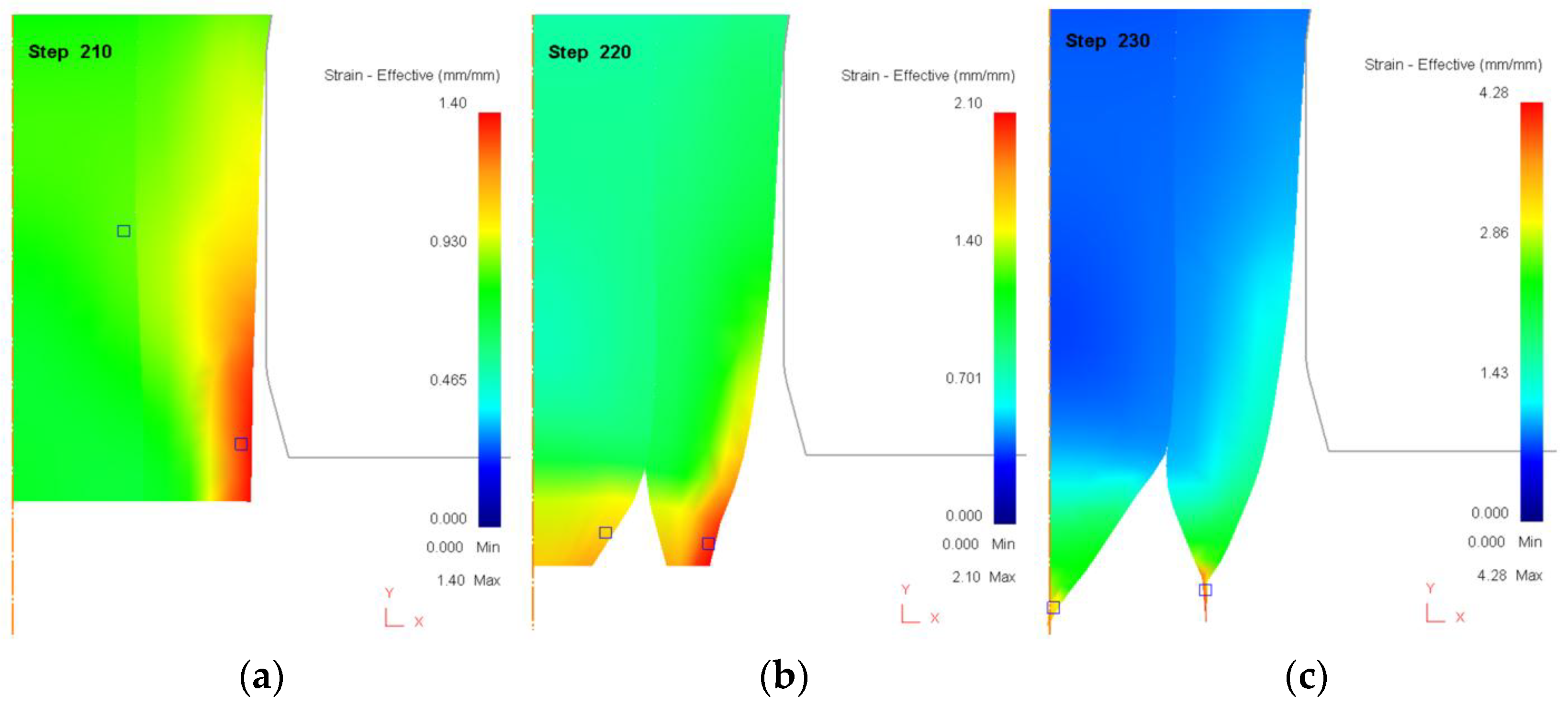

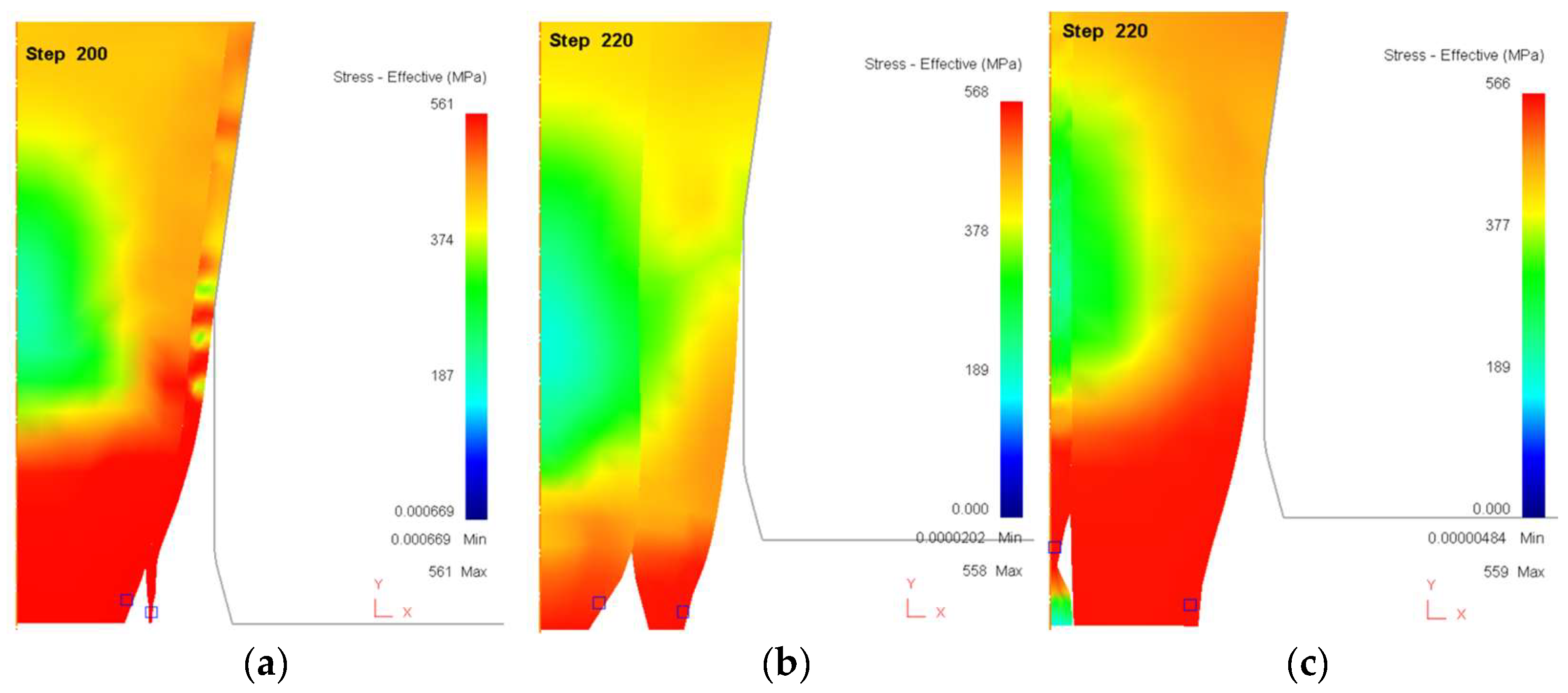

5.3. Influence of Initial Core Ratio on Strain Distribution and Fracture Mechanisms

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, S.; Lee, M.G.; Lee, S.P.; Lee, G.A.; Kim, Y.B.; Lee, J.S.; Bae, D.S. Effect of bonding interface on delamination behavior of drawn Cu/Al bar clad material. Trans. Nonferrous Met. Soc. China 2012, 22–23, 645–649. [Google Scholar] [CrossRef]

- Bykov, A.A. Bimetal production and applications. Steel Tran. 2011, 41, 778–786. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, Y.; Li, Y.; Zhai, W.; Sun, L.; Zhang, C. Review of preparation and application of copper–steel bimetal composites. Emerg. Mater. Res. 2019, 8, 538–551. [Google Scholar] [CrossRef]

- Fei, B.; Fei, M.; Chen, Z. High Electric Conduction Property of Composite Copper-clad Steel Wire. IEEE Trans. Electromagn. Compat. 1999, 41–43, 196–201. [Google Scholar]

- Wu, Q.; Wang, D.; Gao, Y. Effects of Processing Technic on Grain Size of Copper Clad Steel Wire. Adv. Mat. Res. 2012, 567, 116–122. [Google Scholar] [CrossRef]

- Sawicki, S. Properties of Bimetallic “Carbon Steel–Stainless-steel” Bars with Periodic Texture Obtained by Explosive Cladding and Rolling. Met. Sci. Heat Treat. 2012, 54, 303–308. [Google Scholar]

- Pan, S.; Zheng, T.; Yao, G.; Chi, Y.; De Rosa, I.; Li, X. High-strength and high-conductivity in situ Cu–TiB2 nanocomposites. Mater. Sci. Eng. A 2022, 831, 141952. [Google Scholar] [CrossRef]

- Szulc, W.; Pietrzyk, M.; Dyja, H.; Pilarczyk, J.W. Theoretical and experimental analysis of drawing of steel rods covered with copper. J. Mater. Process. Technol. 1994, 45, 401–406. [Google Scholar]

- Ko, D.C.; Lee, S.K.; Kim, B.M.; Jo, H.H.; Jo, H. Evaluation of copper coating ratio in steel/copper clad wire drawing. J. Mater. Process. Technol. 2007, 186, 22–26. [Google Scholar]

- Sasaki, T.T.; Barkey, M.; Thompson, G.B.; Syarif, Y.; Fox, D. Microstructural evolution of copper clad steel bimetallic wire. Mater. Sci. Eng. A 2011, 528, 2974–2981. [Google Scholar]

- Danenko, V.F.; Trykov, Y.P.; Gurevich, L.M.; Bulaeva, S.A. Influence of drawing on the properties of bimetallic wire (Carbon Steel+ 12X18H10T steel). Steel Transl. 2011, 41, 429–433. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, M.; Hu, J.; Zhang, J.; Yang, Y.; Xie, M. FEM Simulation on First-Step Drawing Process of Platinum-Clad Nickel Bars. Metals 2023, 13, 1462. [Google Scholar] [CrossRef]

- Chen, D.C.; Guo, Z.Y.; Wang, S.J. Finite element analysis of double layers alloy wire drawing processes. Int. J. Mater. Form. 2008, 1, 415–418. [Google Scholar] [CrossRef]

- Malaki, M.; Maleki, H.; Malaki, M.; Roohani, H.R. Investigation of the bimetal clad drawing by upper bound method. J. Mater. Eng. Perform. 2013, 22, 943–951. [Google Scholar] [CrossRef]

- Raghebi, M.; Fatehi Sichani, F.; Rahnama, S. Experimental and numerical investigation on interlayer pressure at bimetallic Copper clad Aluminum wire drawing. Modares Mech. Eng. 2017, 17, 253–262. [Google Scholar]

- Dai, Y.M.; Ma, Y.Q.; Dai, Y.J. Theoretical Account for the Bimetallic Bonding of the Copper Clad Aluminum Wire by Clad-Drawing at Room Temperature. Adv. Mater. Res. 2012, 391, 37–41. [Google Scholar] [CrossRef]

- Księżarek, S.; Kazana, W.; Ciura, L.; Marszowski, K.; Woch, M. Bimetallic wires: Technology for their mechanical cold cladding and functional properties. Arch. Metall. Mater. 2011, 56, 891–895. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Morris, R.A.; Thompson, G.B.; Syarif, Y.; Fox, D. Formation of ultra-fine copper grains in copper-clad aluminum wire. Scr. Mater. 2010, 63, 488–491. [Google Scholar] [CrossRef]

- Keller, C.; Moisy, F.; Nguyen, N.; Eve, S.; Dashti, A.; Vieille, B.; Guillet, A.; Sauvage, X.; Hug, E. Microstructure and mechanical properties characterization of architectured copper aluminum composites manufactured by cold-drawing. Mater. Charact. 2021, 172, 110824. [Google Scholar] [CrossRef]

- Song, J.W.; Hong, J.P.; An, Y.J.; Son, S.H.; Park, J.S.; Kim, S.H.; Kang, S.H.; Kang, J.H. Evaluation of the Mechanical and Electrical Properties of Multistage Drawn Copper-Clad Aluminum Wire After Annealing Process. Metals 2024, 14, 1386. [Google Scholar] [CrossRef]

- Alberti, N.; Barcellona, A.; Masnata, A.; Micari, F. Central bursting defects in drawing and extrusion: Numerical and ultrasonic evaluation. CIRP Ann. 1993, 42, 269–272. [Google Scholar] [CrossRef]

- Mcallen, P.; Phelan, P. Ductile fracture by central bursts in drawn 2011 aluminium wire. Int. J. Fract. 2005, 135, 19–33. [Google Scholar]

- Haddi, A.; Imad, A.; Vega, G. The influence of the drawing parameters and temperature rise on the prediction of chevron crack formation in wire drawing. Int. J. Fract. 2012, 176, 171–180. [Google Scholar]

- Roh, Y.H.; Cho, D.; Choi, H.C.; Yang, Z.; Lee, Y. Process condition diagram predicting onset of microdefects and fracture in cold bar drawing. Metals 2021, 11, 479. [Google Scholar] [CrossRef]

| Forming Parameters | Value |

|---|---|

| Initial core ratio, Rci/Ri × 100, % | 10, 30, 50, 70, 90 |

| Reduction ratio, r = (Ri2 − Ro2)/Ri2 × 100, % | 50.0, 50.5, 51.0, 51.5, 52.0, 52.5, 53.0, 53.5, 54.0, 54.5, 55.0 |

| Friction coefficient, µ | 0.1 |

| Semi-die angle, α [°] | 8 |

| Drawing speed, v [mm/s] | 10 |

| Forming Parameters | Value |

|---|---|

| Yield stress of the core, σcore, MPa | 150, 200, 250, 300, 350 |

| Yield stress of the sleeve, σsleeve, MPa | 150, 200, 250, 300, 350 |

| Young’s modulus of the core, GPa | 207 |

| Young’s modulus of the sleeve, GPa | 207 |

| σy of Sleeve (MPa) | σy of Core (MPa) | σy Ratio (σsleeve:σcore) | 50.0% | 50.5% | 51.0% | 51.5% | 52.0% | 52.5% | 53.0% | 53.5% | 53.5% | 54.0% | 55.0% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 150 | 150 | 1.00 | S | S | S | S | S | S | S | S | S | S | F |

| 150 | 200 | 0.75 | S | S | S | S | S | S | S | S | S | S | F |

| 150 | 250 | 0.60 | S | S | S | S | S | S | S | S | S | F | F |

| 150 | 300 | 0.50 | S | S | S | S | S | S | S | S | F | F | F |

| 150 | 350 | 0.43 | S | S | S | S | S | S | S | F | F | F | F |

| σy of Sleeve (MPa) | σy of Core (MPa) | σy Ratio (σsleeve:σcore) | 50.0% | 50.5% | 51.0% | 51.5% | 52.0% | 52.5% | 53.0% | 53.5% | 53.5% | 54.0% | 55.0% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 200 | 150 | 1.33 | S | S | S | S | S | S | S | S | S | F | F |

| 200 | 200 | 1.00 | S | S | S | S | S | S | S | S | S | F | F |

| 200 | 250 | 0.80 | S | S | S | S | S | S | S | S | F | F | F |

| 200 | 300 | 0.67 | S | S | S | S | S | S | S | F | F | F | F |

| 200 | 350 | 0.57 | S | S | S | S | S | S | S | F | F | F | F |

| σy of Sleeve (MPa) | σy of Core (MPa) | σy Ratio (σsleeve:σcore) | 50.0% | 50.5% | 51.0% | 51.5% | 52.0% | 52.5% | 53.0% | 53.5% | 53.5% | 54.0% | 55.0% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 250 | 150 | 1.67 | S | S | S | S | S | S | S | S | F | F | F |

| 250 | 200 | 1.25 | S | S | S | S | S | S | S | S | F | F | F |

| 250 | 250 | 1.00 | S | S | S | S | S | S | S | F | F | F | F |

| 250 | 300 | 0.83 | S | S | S | S | S | S | F | F | F | F | F |

| 250 | 350 | 0.71 | S | S | S | S | S | S | F | F | F | F | F |

| σy of Sleeve (MPa) | σy of Core (MPa) | σy Ratio (σsleeve:σcore) | 50.0% | 50.5% | 51.0% | 51.5% | 52.0% | 52.5% | 53.0% | 53.5% | 53.5% | 54.0% | 55.0% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 300 | 150 | 2.00 | S | S | S | S | S | S | S | S | F | F | F |

| 300 | 200 | 1.50 | S | S | S | S | S | S | S | F | F | F | F |

| 300 | 250 | 1.20 | S | S | S | S | S | S | S | F | F | F | F |

| 300 | 300 | 1.00 | S | S | S | S | S | S | F | F | F | F | F |

| 300 | 350 | 0.86 | S | S | S | S | S | S | F | F | F | F | F |

| σy of Sleeve (MPa) | σy of Core (MPa) | σy Ratio (σsleeve:σcore) | 50.0% | 50.5% | 51.0% | 51.5% | 52.0% | 52.5% | 53.0% | 53.5% | 53.5% | 54.0% | 55.0% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 350 | 150 | 2.33 | S | S | S | S | S | S | S | F | F | F | F |

| 350 | 200 | 1.75 | S | S | S | S | S | S | S | F | F | F | F |

| 350 | 250 | 1.40 | S | S | S | S | S | S | F | F | F | F | F |

| 350 | 300 | 1.17 | S | S | S | S | S | S | F | F | F | F | F |

| 350 | 350 | 1.00 | S | S | S | S | S | F | F | F | F | F | F |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, Y.-M.; Tsui, H.S.R. Influence of Yield Stress and Material Area Ratio on Bondability and Formability in Drawing Processes of Bimetallic Rods. Materials 2025, 18, 1441. https://doi.org/10.3390/ma18071441

Hwang Y-M, Tsui HSR. Influence of Yield Stress and Material Area Ratio on Bondability and Formability in Drawing Processes of Bimetallic Rods. Materials. 2025; 18(7):1441. https://doi.org/10.3390/ma18071441

Chicago/Turabian StyleHwang, Yeong-Maw, and Hiu Shan Rachel Tsui. 2025. "Influence of Yield Stress and Material Area Ratio on Bondability and Formability in Drawing Processes of Bimetallic Rods" Materials 18, no. 7: 1441. https://doi.org/10.3390/ma18071441

APA StyleHwang, Y.-M., & Tsui, H. S. R. (2025). Influence of Yield Stress and Material Area Ratio on Bondability and Formability in Drawing Processes of Bimetallic Rods. Materials, 18(7), 1441. https://doi.org/10.3390/ma18071441