Three-Dimensional-Printed Biomimetic Structural Ceramics with Excellent Tribological Properties

Highlights

- Inspired by biomimetic tribology and the superior properties of ceramics, biomimetic ceramic specimens were fabricated via ink direct writing 3D printing and laser processing.

- Building on this, the tribological performance of biomimetic specimens was studied under varying friction conditions to assess the influence of biomimetic structures on the friction and wear behavior of ceramics.

- MoS₂ films were deposited on biomimetic specimens via physical vapor deposition (PVD) to explore the synergistic lubrication between biomimetic structures and lubricating materials.

Abstract

1. Introduction

2. Materials and Methods

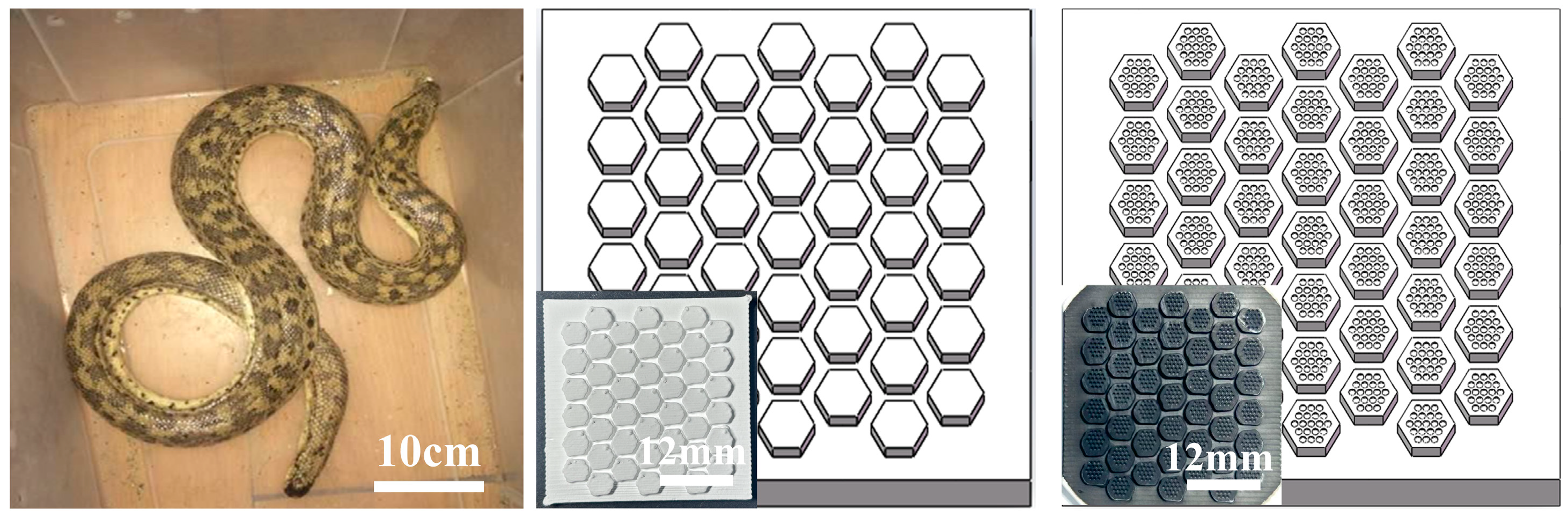

2.1. Bionic Wear-Resistant Prototype and Structural Design

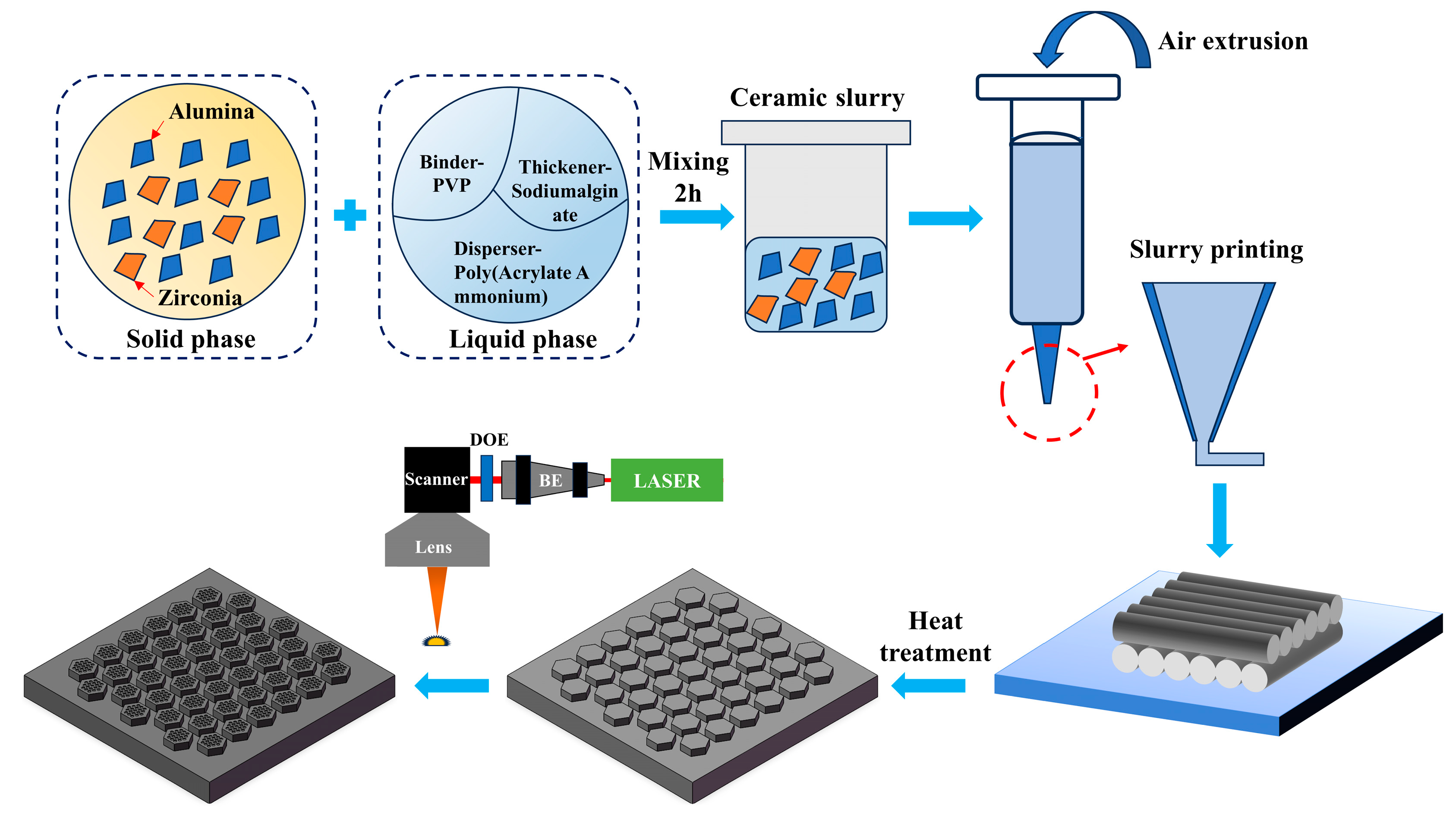

2.2. Preparation of Ceramic Slurry for 3D Printing

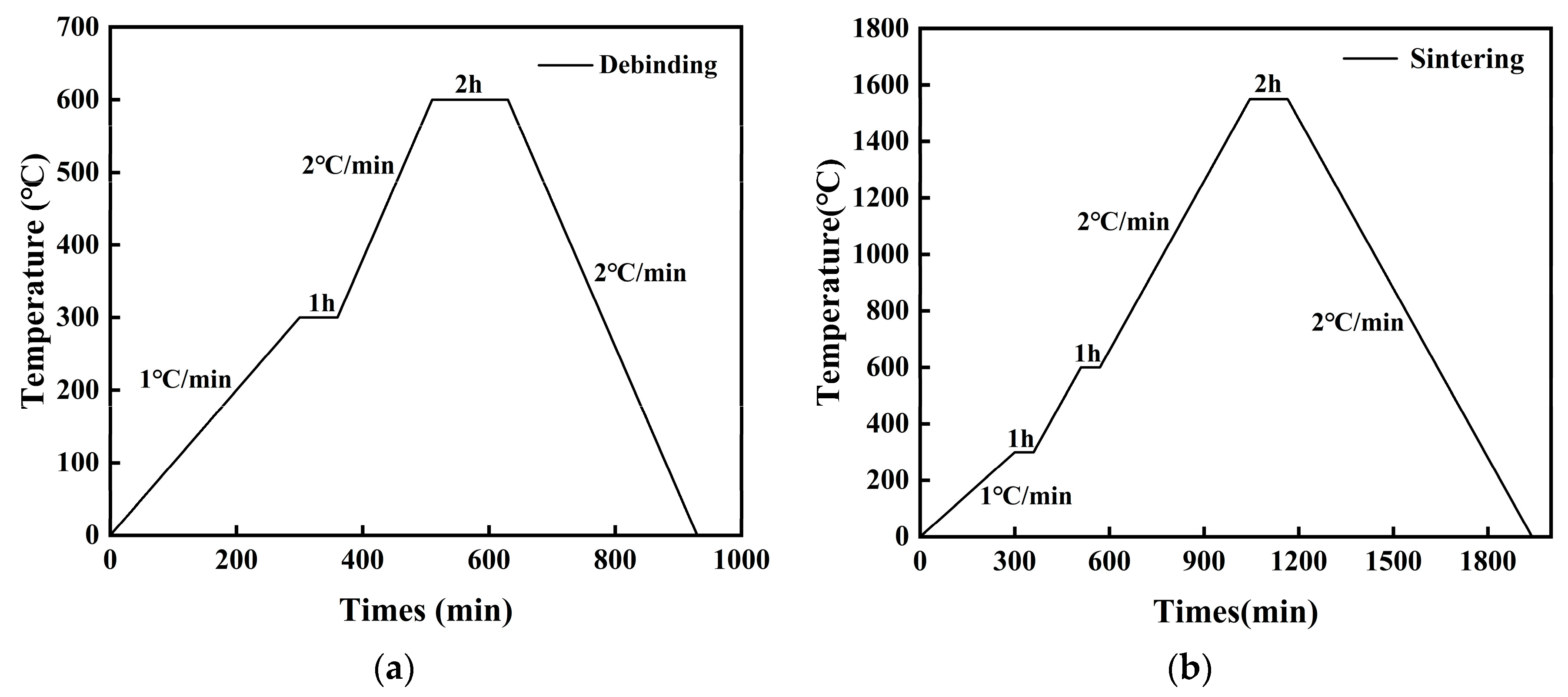

2.3. Preparation of 3D-Printed Bionic Structural Ceramics

2.4. Preparation of Solid Lubricant Coatings

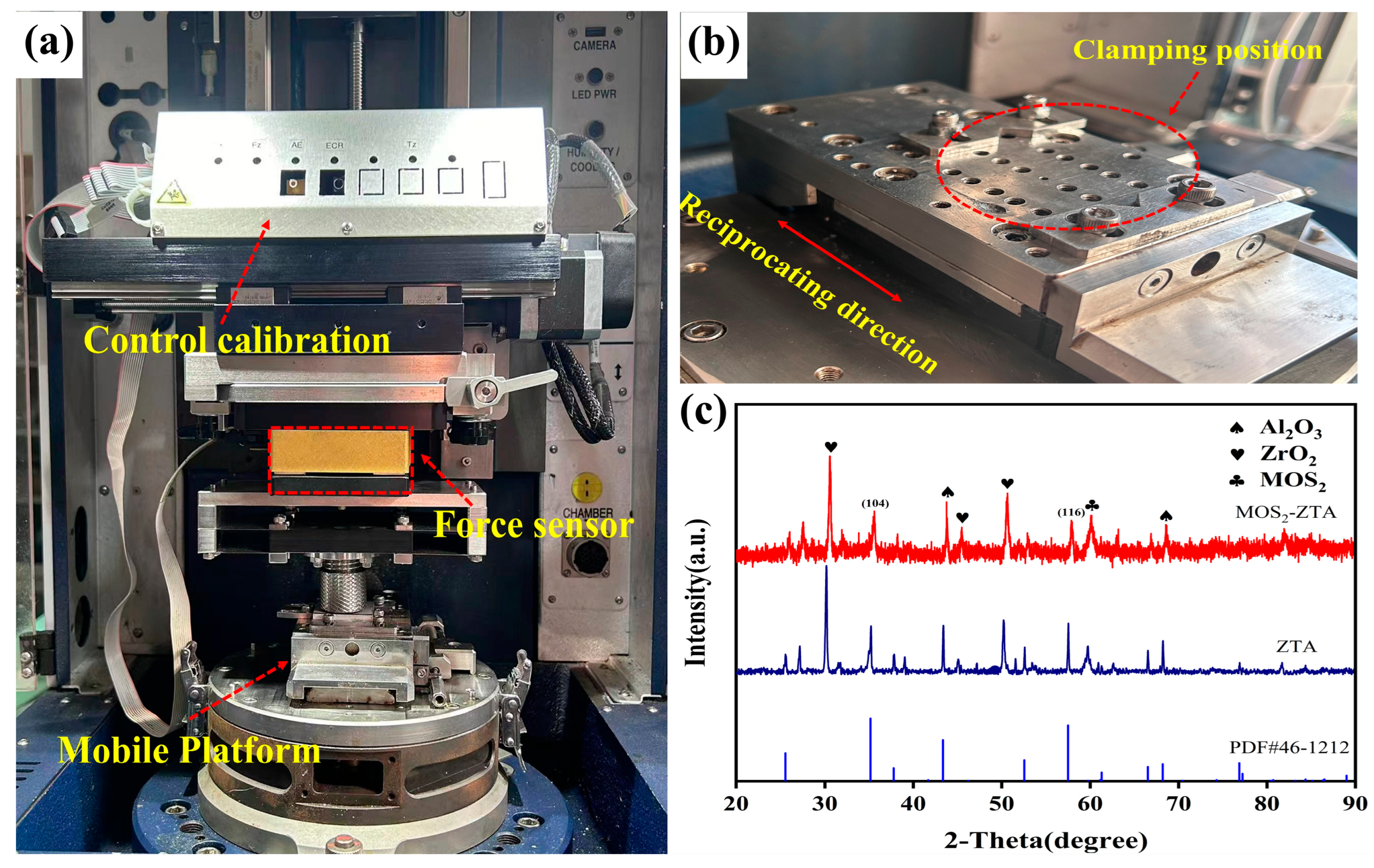

2.5. Tribological Performance Testing

3. Results

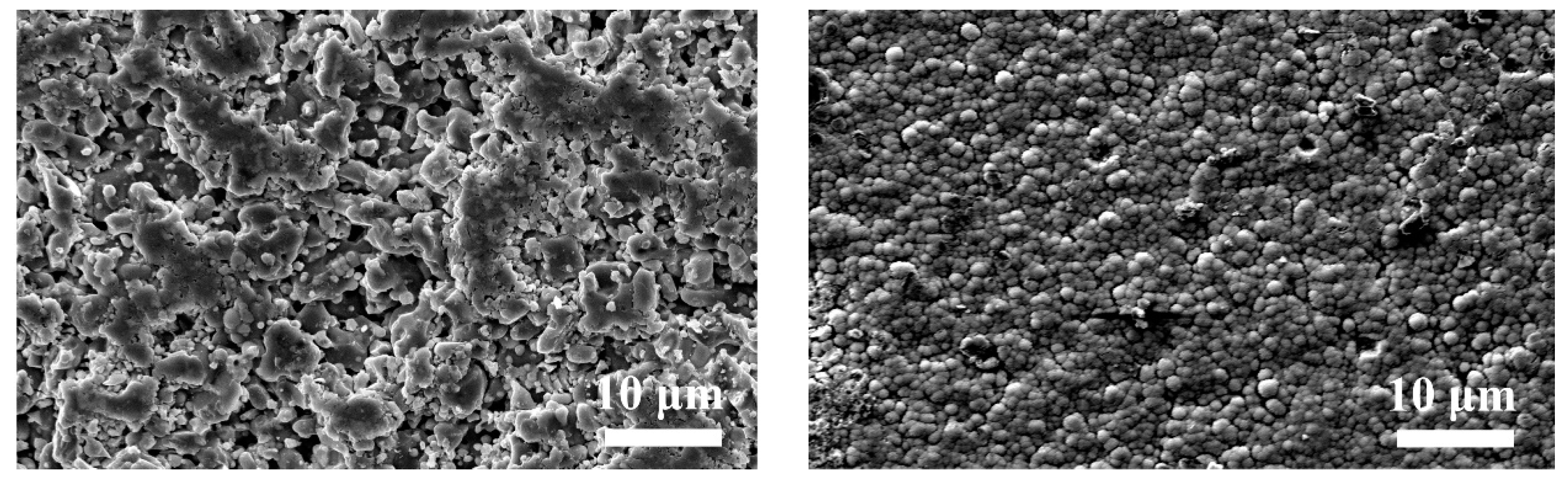

3.1. Microscopic Morphology and Phase Composition Analysis

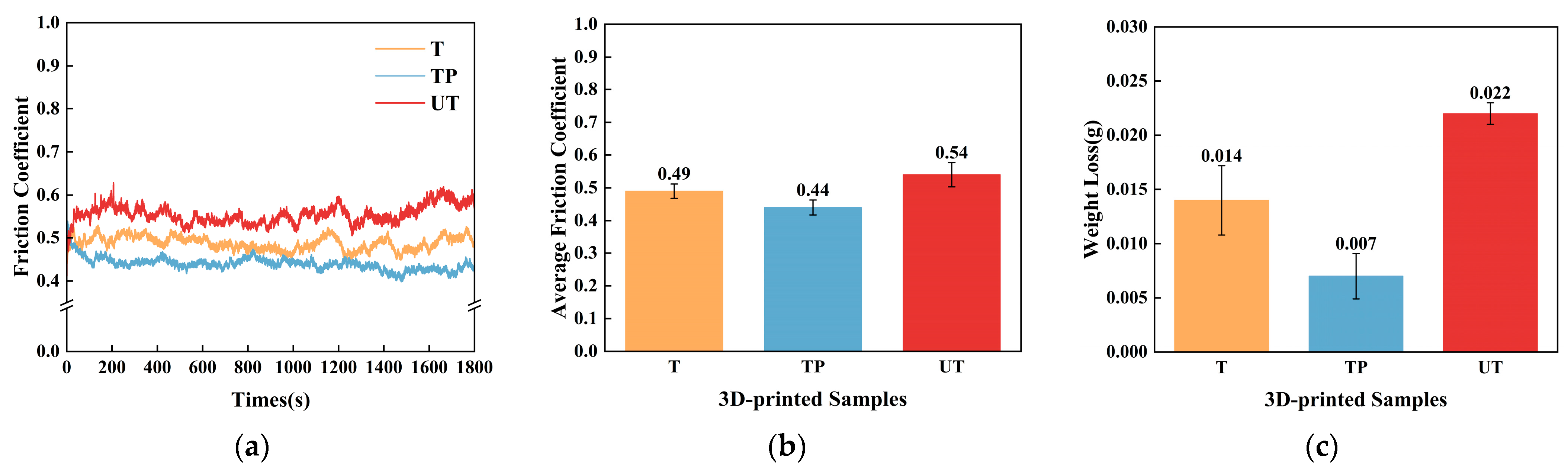

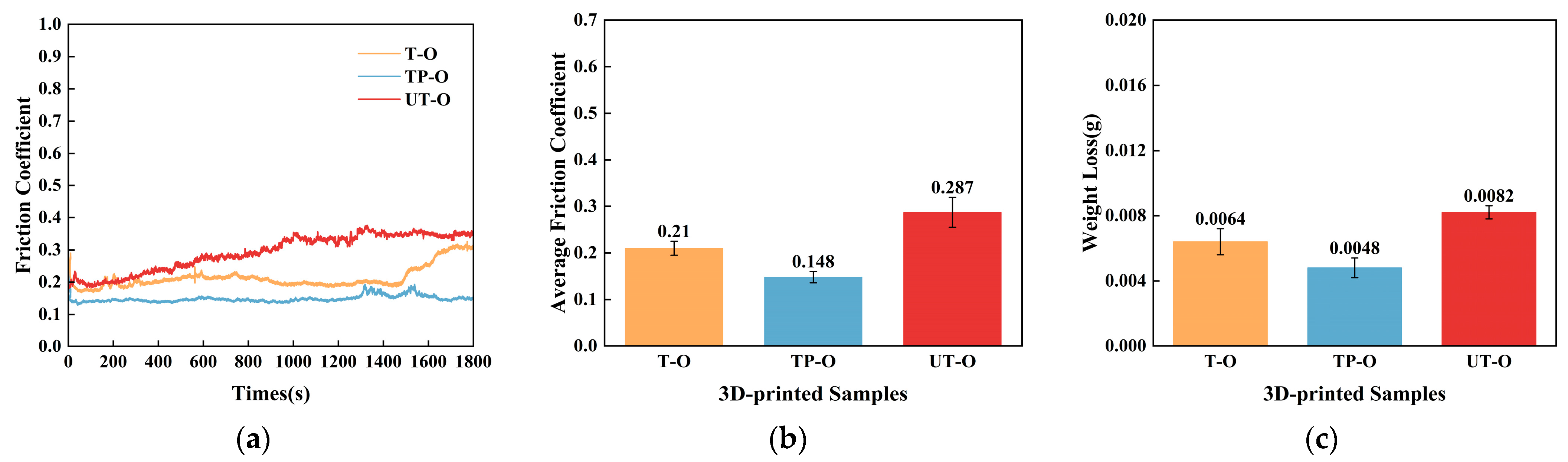

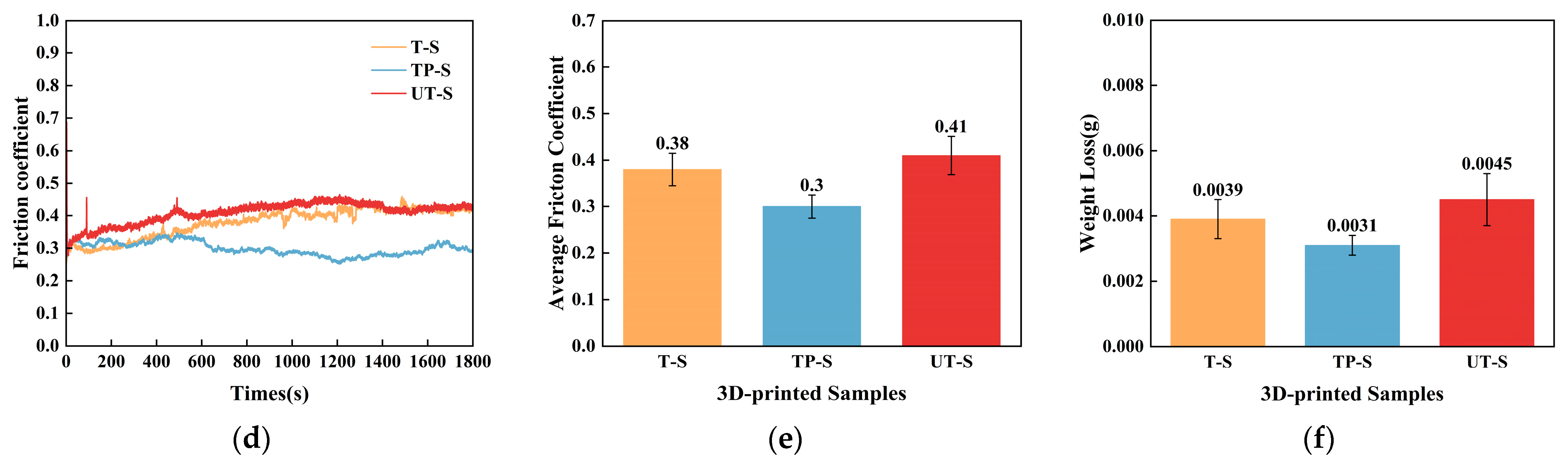

3.2. Tribological Performance Analysis

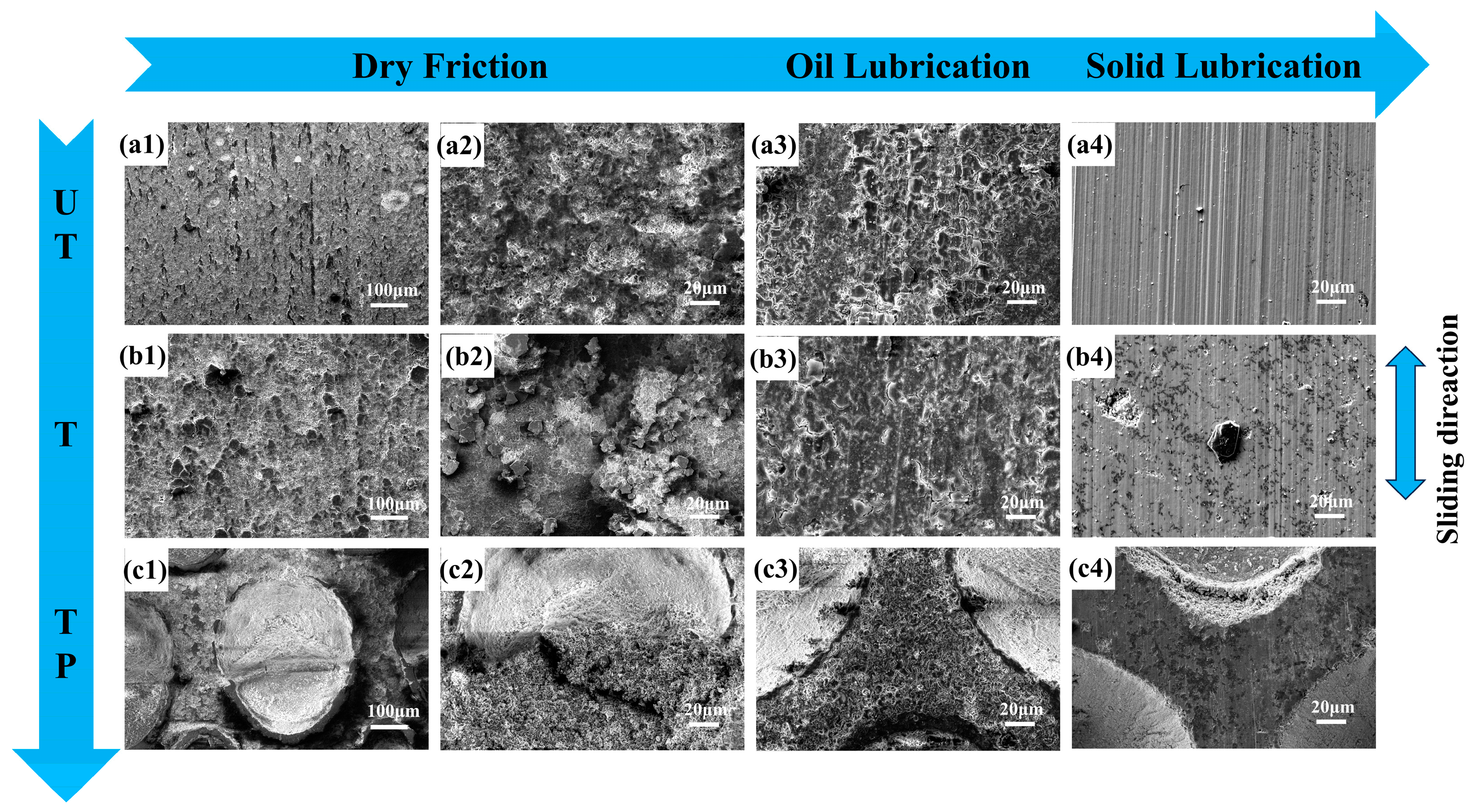

3.3. Wear Surface Morphology Analysis

4. Discussion

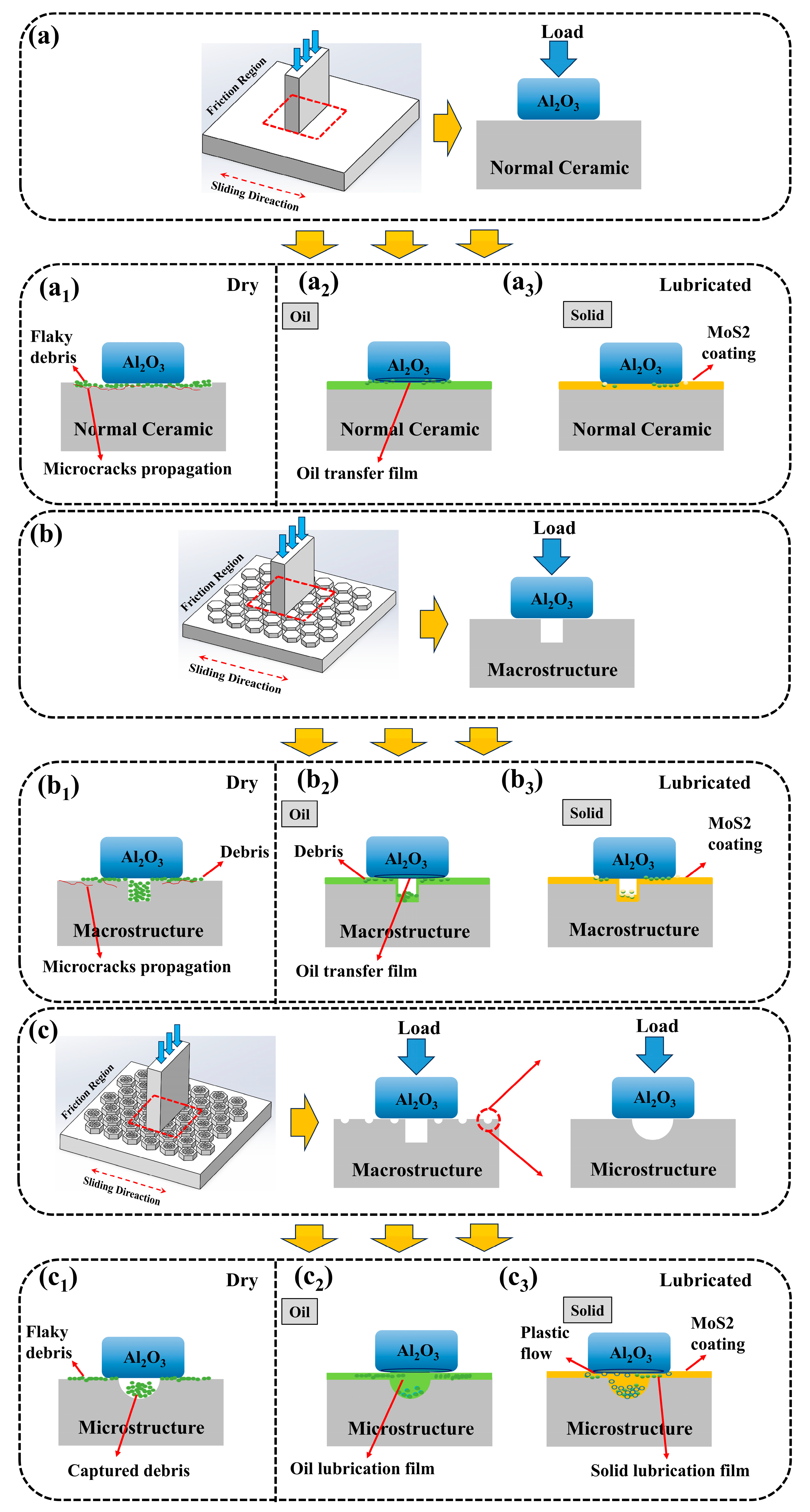

- (1)

- Macroscopic hexagonal biomimetic units effectively disperse contact stress, reducing local stress concentration.

- (2)

- Microscopic dimple structures serve as lubricant reservoirs, releasing lubricant during friction and establishing long-lasting secondary lubrication effects.

- (3)

- MoS2 solid lubricant coating forms a stable lubricating film at the friction interface, significantly lowering the interfacial friction coefficient.

- (4)

- Stress concentration mitigation: The local support provided by the biomimetic structures effectively reduces stress at their edges, preventing crack initiation and propagation.

- (5)

- Debris-trapping and rolling effects: The dimple structures capture wear debris and induce rolling effects, reducing abrasive wear and further enhancing wear resistance.

5. Conclusions

- (1)

- The introduction of biomimetic structures significantly optimizes the tribological properties of the matrix material. Compared to blank specimens, biomimetic-structured specimens demonstrate a reduction in the average friction coefficient by 44.4% and 72.6% under dry and lubricated conditions, respectively, exhibiting excellent friction reduction and wear resistance. The synergistic effect between macroscopic hexagonal biomimetic structures and microscopic dimples significantly reduces the contact area and stress concentration, effectively inhibiting crack propagation, thereby substantially enhancing the wear resistance of ceramic composites.

- (2)

- A notable synergistic effect exists between biomimetic structures and lubricating media. Under oil lubrication conditions, biomimetic structures provide ideal storage and circulation spaces for lubricant, promoting the formation of a stable lubricating film. The incorporation of the MoS2 solid lubricant coating further enhances the material’s lubrication performance, particularly achieving a long-lasting secondary lubrication effect in the microscopic biomimetic units.

- (3)

- The material’s wear mechanism undergoes a significant transformation. The synergistic design of biomimetic structures and solid lubricant provides an innovative and efficient solution for the high-end applications of ceramic materials, not only significantly improving wear resistance and service life but also demonstrating substantial engineering application value.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, K.; Quan, Y.; Ding, D.; Zhuang, J.; Fei, C.; Zhao, J.; Wang, L.; Zhao, T.; Wang, Z.; Zhao, Y.; et al. 3D Printing PMN-PT Textured Ceramics for Transducer Applications. Ceram. Int. 2024, 50, 51870–51876. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, H.; Yao, H.; Zeng, Y.; Chen, J. Preparation, Microstructure, and Properties of ZrO2(3Y)/Al2O3 Bioceramics for 3D Printing of All-Ceramic Dental Implants by Vat Photopolymerization. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100023. [Google Scholar] [CrossRef]

- Qu, X.; Wang, F.; Shi, C.; Zhao, N.; Liu, E.; He, C.; He, F. In Situ Synthesis of a Gamma-Al2O3 Whisker Reinforced Aluminium Matrix Composite by Cold Pressing and Sintering. Mater. Sci. Eng. A 2018, 709, 223–231. [Google Scholar] [CrossRef]

- Katz, R.N. Ceramics for High Performance Rolling Element Bearings: A Review and Assessment. Mater. Des. 1987, 1, 69–79. [Google Scholar] [CrossRef]

- Liao, Y.; Zhang, F.; Pan, X.; Li, K.; Zhou, Y.; Wu, S. A Comparative Study on Tribological Behavior of Al2O3, AlN, Si3N4 and ZrO2 Ceramics Sliding against Polycrystalline Diamond Ball. Wear 2023, 530–531, 205067. [Google Scholar] [CrossRef]

- Alves, P.C.F.; Silva, D.G.D.; Vasconcelos, D.C.L.; Vilela, J.J.; Nascimento, J.F.D.; Melo, D.C.D.; Vasconcelos, W.L. Microstructural Characterization and Mechanical Properties on Al2O3–TiO2 Materials Obtained by Uniaxial Pressing and Extrusion. Ceram. Int. 2021, 47, 24988–24996. [Google Scholar] [CrossRef]

- Fan, H.; Hu, T.; Zhang, Y.; Fang, Y.; Song, J.; Hu, L. Tribological Properties of Micro-Textured Surfaces of ZTA Ceramic Nanocomposites under the Combined Effect of Test Conditions and Environments. Tribol. Int. 2014, 78, 134–141. [Google Scholar] [CrossRef]

- MacDonald, E.; Barnes, A.; Roschli, A.; Feldhausen, T.; Borish, M.; Wang, P. Introduction to Additive Manufacturing. In Motion and Path Planning for Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2024; pp. 1–12. ISBN 978-0-443-15286-3. [Google Scholar]

- Liu, X.; Zou, B.; Xing, H.; Huang, C. The Preparation of ZrO2-Al2O3 Composite Ceramic by SLA-3D Printing and Sintering Processing. Ceram. Int. 2020, 46, 937–944. [Google Scholar] [CrossRef]

- Santoliquido, O.; Camerota, F.; Ortona, A. The Influence of Topology on DLP 3D Printing, Debinding and Sintering of Ceramic Periodic Architectures Designed to Replace Bulky Components. Open Ceram. 2021, 5, 100059. [Google Scholar] [CrossRef]

- Yang, L.; Zeng, X.; Ditta, A.; Feng, B.; Su, L.; Zhang, Y. Preliminary 3D Printing of Large Inclined-Shaped Alumina Ceramic Parts by Direct Ink Writing. J. Adv. Ceram. 2020, 9, 312–319. [Google Scholar] [CrossRef]

- Masuda, H.; Ohta, Y.; Kitayama, M. Additive Manufacturing of SiC Ceramics with Complicated Shapes Using the FDM Type 3D-Printer. J. Mater. Sci. Chem. Eng. 2019, 7, 1–12. [Google Scholar] [CrossRef]

- Ordoñez, E.; Gallego, J.M.; Colorado, H.A. 3D Printing via the Direct Ink Writing Technique of Ceramic Pastes from Typical Formulations Used in Traditional Ceramics Industry. Appl. Clay Sci. 2019, 182, 105285. [Google Scholar] [CrossRef]

- Ellis, J.; Mavromatos, N.E.; Nanopoulos, D.V.; Sakharov, A.S. Cosmology: Synchrotron Radiation and Quantum Gravity. Nature 2004, 428, 386. [Google Scholar] [CrossRef]

- Lamnini, S.; Elsayed, H.; Lakhdar, Y.; Baino, F.; Smeacetto, F.; Bernardo, E. Robocasting of Advanced Ceramics: Ink Optimization and Protocol to Predict the Printing Parameters—A Review. Heliyon 2022, 8, e10651. [Google Scholar] [CrossRef]

- Yun, J.S.; Park, T.-W.; Jeong, Y.H.; Cho, J.H. Development of Ceramic-Reinforced Photopolymers for SLA 3D Printing Technology. Appl. Phys. A 2016, 122, 629. [Google Scholar] [CrossRef]

- Liu, Z.; Yin, W.; Tao, D.; Tian, Y. A Glimpse of Superb Tribological Designs in Nature. Biotribology 2015, 1–2, 11–23. [Google Scholar] [CrossRef]

- Wu, C.; Wu, Y.; Zhao, H.; Li, S.; Ni, J.; Li, X. Influence of Hardness of Nanoparticle Additive in PTFE Solid Lubricant on Tribological Properties of GCr15 Steel with Bionic Texture. Tribol. Int. 2023, 189, 108915. [Google Scholar] [CrossRef]

- Shi, X.; Xue, Y.; Zhang, K.; Wu, C. Optimization of Bionic Textured Parameter to Improve the Tribological Performance of AISI 4140 Self-Lubricating Composite through Response Surface Methodology. Tribol. Int. 2021, 161, 107104. [Google Scholar] [CrossRef]

- Li, X.; Guo, Z.; Huang, Q.; Yuan, C. Application of Bionic Tribology in Water-Lubricated Bearing: A Review. J. Bionic Eng. 2022, 19, 902–934. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, Y.; Mei, H.; Kong, Z.; Mao, M.; Cheng, L. Excellent Lubrication Properties of 3D Printed Ceramic Bionic Structures. Ceram. Int. 2020, 46, 23463–23470. [Google Scholar] [CrossRef]

- Li, X.; Deng, J.; Yue, H.; Ge, D.; Zou, X. Wear Performance of Electrohydrodynamically Atomized WS2 Coatings Deposited on Biomimetic Shark-Skin Textured Surfaces. Tribol. Int. 2019, 134, 240–251. [Google Scholar] [CrossRef]

- Kumar, R.; Antonov, M.; Varga, M.; Hussainova, I.; Rodriguez Ripoll, M. Synergistic Effect of Ag and MoS2 on High-Temperature Tribology of Self-Lubricating NiCrBSi Composite Coatings by Laser Metal Deposition. Wear 2023, 532–533, 205114. [Google Scholar] [CrossRef]

- Furlan, K.P.; De Mello, J.D.B.; Klein, A.N. Self-Lubricating Composites Containing MoS2: A Review. Tribol. Int. 2018, 120, 280–298. [Google Scholar] [CrossRef]

- Zhong, Y.; Zheng, L.; Gao, Y.; Liu, Z. Numerical Simulation and Experimental Investigation of Tribological Performance on Bionic Hexagonal Textured Surface. Tribol. Int. 2019, 129, 151–161. [Google Scholar] [CrossRef]

- Wang, H.; Qiu, H.; Liu, W.; Tian, L.; Zheng, J.; Zhang, Z.; Zhou, Z. Anti-Wear Properties of Multi-Bioinspired Textures with Hierarchical and Superhydrophobic Structures under Water Lubrication. Wear 2023, 532–533, 205124. [Google Scholar] [CrossRef]

- Kumar, R.; Torres, H.; Aydinyan, S.; Antonov, M.; Varga, M.; Rodriguez Ripoll, M.; Hussainova, I. Microstructure and High Temperature Tribological Behaviour of Self-Lubricating Ti-TiBx Composite Doped with Ni Bi. Surf. Coat. Technol. 2022, 447, 128827. [Google Scholar] [CrossRef]

- Kumar, R.; Torres, H.; Aydinyan, S.; Antonov, M.; Varga, M.; Hussainova, I.; Rodriguez Ripoll, M. Tribological Behavior of Ni-Based Self-Lubricating Claddings Containing Sulfide of Nickel, Copper, or Bismuth at Temperatures up to 600 °C. Surf. Coat. Technol. 2023, 456, 129270. [Google Scholar] [CrossRef]

- Kumar, R.; Rezapourian, M.; Rahmani, R.; Maurya, H.S.; Kamboj, N.; Hussainova, I. Bioinspired and Multifunctional Tribological Materials for Sliding, Erosive, Machining, and Energy-Absorbing Conditions: A Review. Biomimetics 2024, 9, 209. [Google Scholar] [CrossRef] [PubMed]

- Bartkowiak, T.; Peta, K.; Królczyk, J.B.; Niesłony, P.; Bogdan-Chudy, M.; Przeszłowski, Ł.; Trych-Wildner, A.; Wojciechowska, N.; Królczyk, G.M.; Wieczorowski, M. Wetting Properties of Polymer Additively Manufactured Surfaces—Multiscale and Multi-Technique Study into the Surface-Measurement-Function Interactions. Tribol. Int. 2025, 202, 110394. [Google Scholar] [CrossRef]

- Hsu, S.M.; Jing, Y.; Hua, D.; Zhang, H. Friction Reduction Using Discrete Surface Textures: Principle and Design. J. Phys. Appl. Phys. 2014, 47, 335307. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Szurdak, A.; Grützmacher, P.G.; Hirt, G.; Mücklich, F. Friction Reduction Induced by Elliptical Surface Patterns under Lubricated Conditions. Adv. Eng. Mater. 2018, 20, 1700731. [Google Scholar] [CrossRef]

- Wu, Z.; Xing, Y.; Huang, P.; Liu, L. Tribological Properties of Dimple-Textured Titanium Alloys under Dry Sliding Contact. Surf. Coat. Technol. 2017, 309, 21–28. [Google Scholar] [CrossRef]

- Schneider, J.; Braun, D.; Greiner, C. Laser Textured Surfaces for Mixed Lubrication: Influence of Aspect Ratio, Textured Area and Dimple Arrangement. Lubricants 2017, 5, 32. [Google Scholar] [CrossRef]

- Ezhilmaran, V.; Vijayaraghavan, L.; Vasa, N.J. Investigation of Nd3+:YAG Laser Aided Surface Texturing to Improve Tribological Characteristics of Piston Ring. J. Laser Micro Nanoeng. 2017, 12, 195–202. [Google Scholar] [CrossRef][Green Version]

- Zheng, L.; Zhong, Y.; Gao, Y.; Li, J.; Zhang, Z.; Liu, Z.; Ren, L. Coupling Effect of Morphology and Mechanical Properties Contributes to the Tribological Behaviors of Snake Scales. J. Bionic Eng. 2018, 15, 481–493. [Google Scholar] [CrossRef]

- Sun, Q.; Hu, T.; Fan, H.; Zhang, Y.; Hu, L. Dry Sliding Wear Behavior of TC11 Alloy at 500 °C: Influence of Laser Surface Texturing. Tribol. Int. 2015, 92, 136–145. [Google Scholar] [CrossRef]

- Spalvins, T. Morphological and Frictional Behavior of Sputtered MoS2 Films. Thin Solid Film. 1982, 96, 17–24. [Google Scholar] [CrossRef]

- Wang, K.; Xiong, D.; Niu, Y. Novel Lubricated Surface of Titanium Alloy Based on Porous Structure and Hydrophilic Polymer Brushes. Appl. Surf. Sci. 2014, 317, 875–883. [Google Scholar] [CrossRef]

- Pauschitz, A.; Roy, M.; Franek, F. Mechanisms of Sliding Wear of Metals and Alloys at Elevated Temperatures. Tribol. Int. 2008, 41, 584–602. [Google Scholar] [CrossRef]

- Wang, Y.M.; Jiang, B.L.; Lei, T.Q.; Guo, L.X. Microarc Oxidation and Spraying Graphite Duplex Coating Formed on Titanium Alloy for Antifriction Purpose. Appl. Surf. Sci. 2005, 246, 214–221. [Google Scholar] [CrossRef]

- Liu, H.; Fine, M.E.; Cheng, H.S. Tribological Behavior of SiC-Whisker/Al2O3 Composites against Carburized 8620 Steel in Lubricated Sliding. J. Am. Ceram. Soc. 1991, 74, 2224–2233. [Google Scholar]

- Fan, H.; Su, Y.; Song, J.; Wan, H.; Hu, L.; Zhang, Y. Surface 3-D Lubrication Structure Design of Al2O3/Ni-Laminated Ceramics to Improve Tribological Properties under Combined Environments. Appl. Surf. Sci. 2019, 480, 572–581. [Google Scholar] [CrossRef]

- Rapoport, L.; Moshkovich, A.; Perfilyev, V.; Lapsker, I.; Halperin, G.; Itovich, Y.; Etsion, I. Friction and Wear of MoS2 Films on Laser Textured Steel Surfaces. Surf. Coat. Technol. 2008, 202, 3332–3340. [Google Scholar] [CrossRef]

| Bulk Density (g·cm−3) | Flexural Strength (MPa) | Fracture Toughness (Mpa/m2) | Vickers Hardness (HV) | Line Shrinkage (%) | ||

|---|---|---|---|---|---|---|

| 4.70 | 126.657 | 2.702 | 172.10 | X | Y | Z |

| 6.13 | 5.96 | 6.94 | ||||

| Samples | Ar Flow (sccm) | RF Power (W) | Deposition Time (min) |

|---|---|---|---|

| UT-S | 45 | 150 | 120 |

| T-S | 45 | 150 | 120 |

| TP-S | 45 | 150 | 120 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Liu, Y.; Jiang, B.; Xin, Z.; Jiao, Z. Three-Dimensional-Printed Biomimetic Structural Ceramics with Excellent Tribological Properties. Materials 2025, 18, 1376. https://doi.org/10.3390/ma18061376

Wang Z, Liu Y, Jiang B, Xin Z, Jiao Z. Three-Dimensional-Printed Biomimetic Structural Ceramics with Excellent Tribological Properties. Materials. 2025; 18(6):1376. https://doi.org/10.3390/ma18061376

Chicago/Turabian StyleWang, Zhaozhi, Yajie Liu, Biao Jiang, Zhiheng Xin, and Zhibin Jiao. 2025. "Three-Dimensional-Printed Biomimetic Structural Ceramics with Excellent Tribological Properties" Materials 18, no. 6: 1376. https://doi.org/10.3390/ma18061376

APA StyleWang, Z., Liu, Y., Jiang, B., Xin, Z., & Jiao, Z. (2025). Three-Dimensional-Printed Biomimetic Structural Ceramics with Excellent Tribological Properties. Materials, 18(6), 1376. https://doi.org/10.3390/ma18061376