Research on Dynamic Mechanical Properties of Silicon Carbide-Modified Concrete

Abstract

1. Introduction

2. Experiment

2.1. Experimental Materials and Sample Preparation

2.2. Experimental Equipment and Methods

3. Results and Analysis

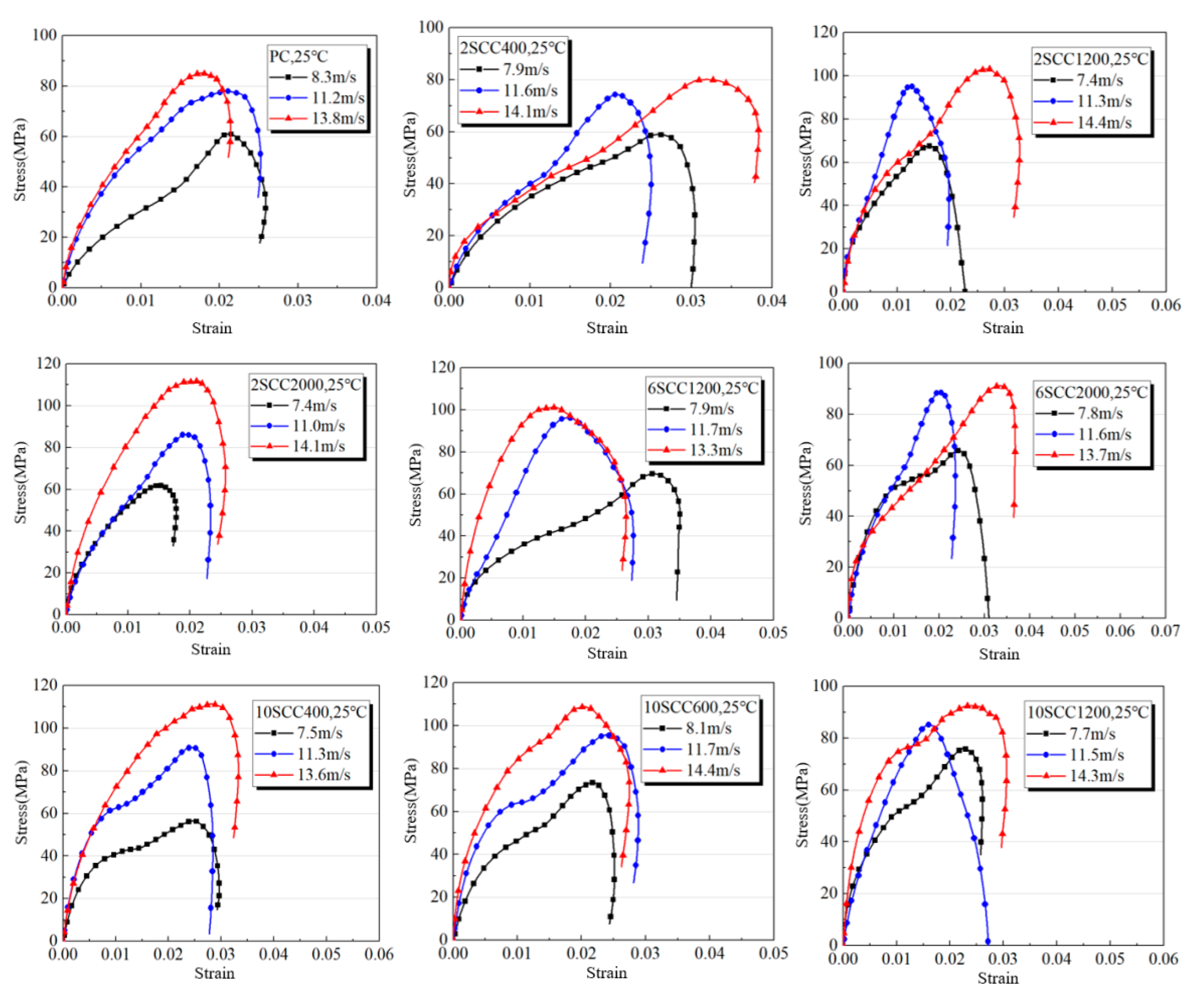

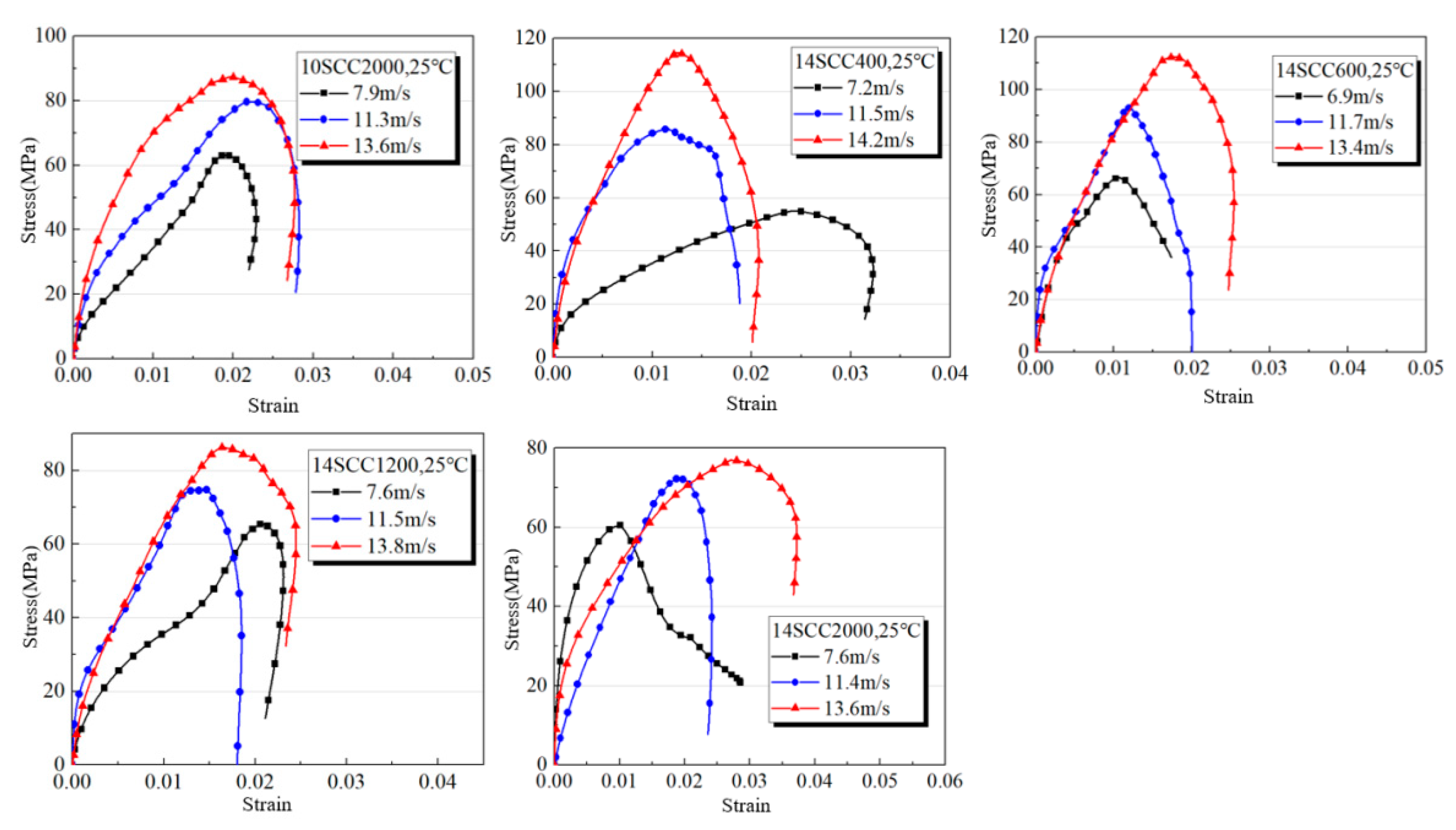

3.1. Stress–Strain Curve

3.2. Dynamic Strength Characteristics

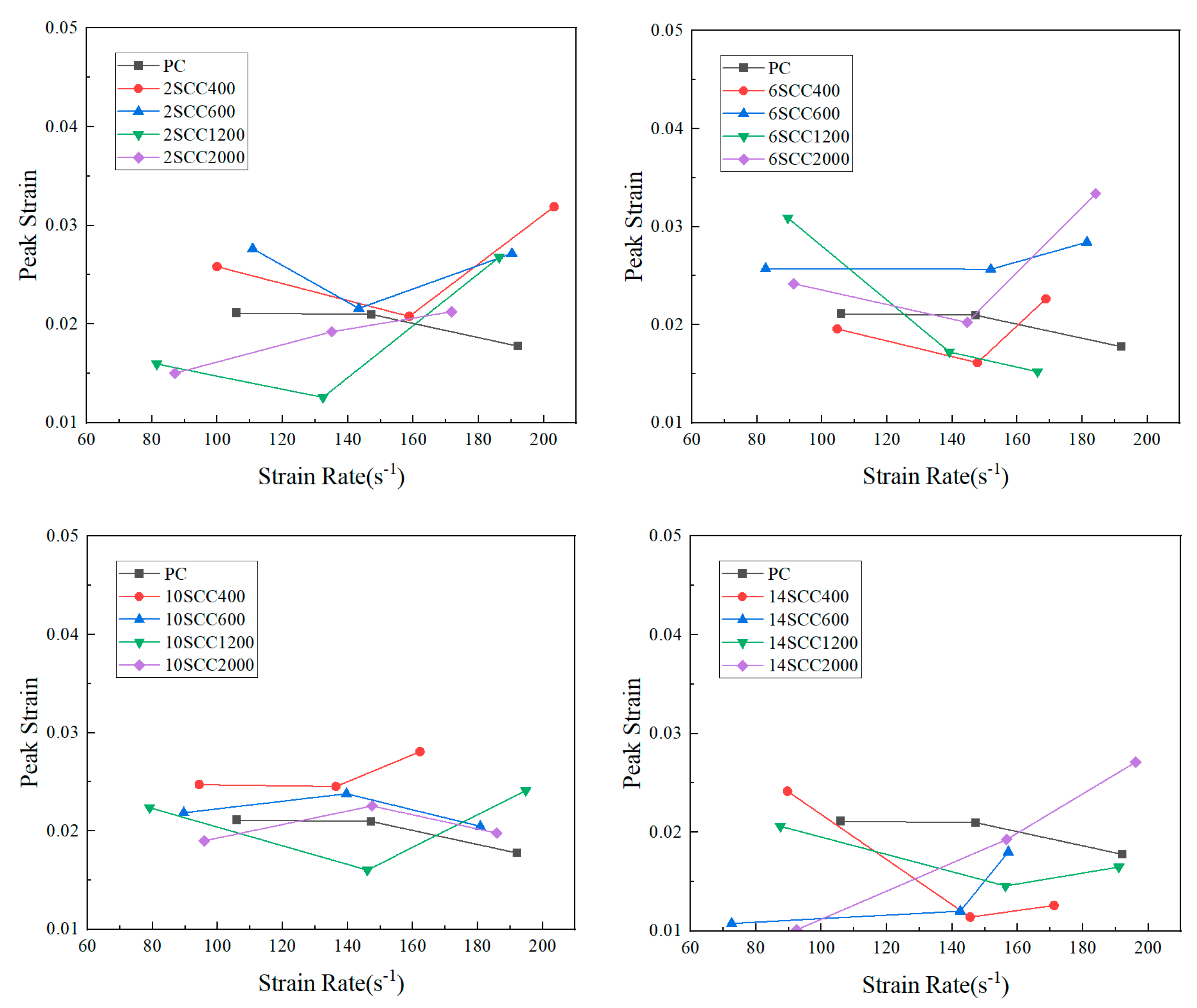

3.3. Deformation Characteristics Analysis

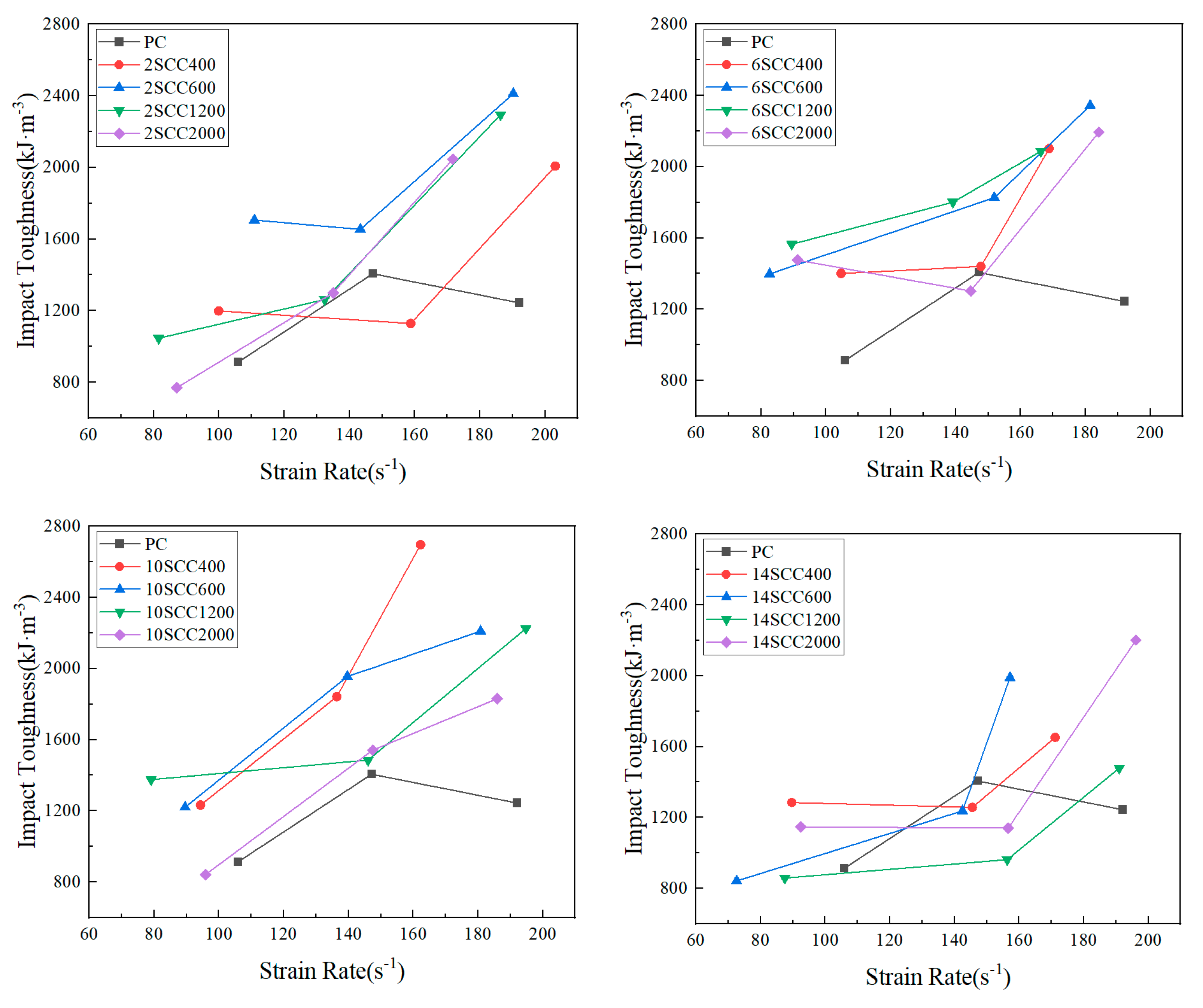

3.4. Energy Characteristics Analysis

3.5. Optimal Content Analysis

3.6. Mechanism of Action Analysis

- Confining Pressure Factor

- 2.

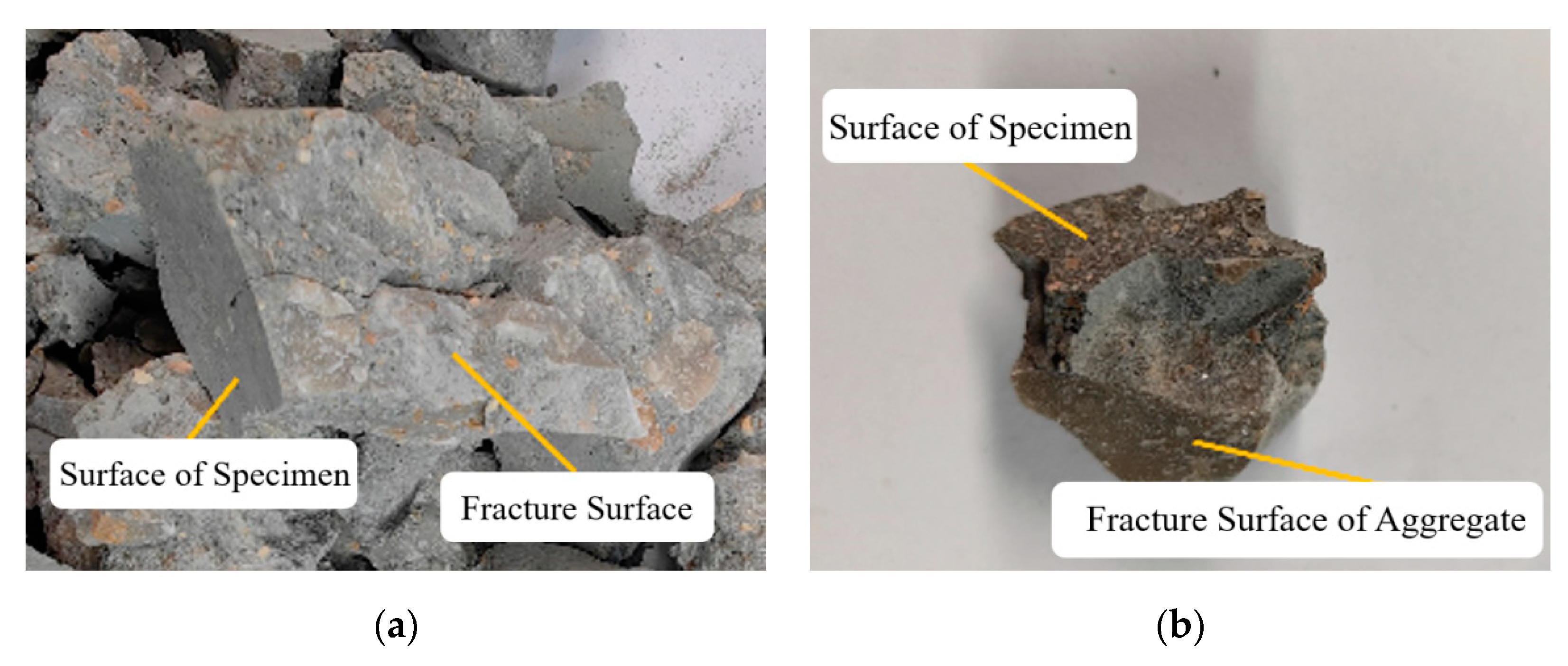

- Aggregate Factor

- 3.

- Crack Factor

- 4.

- Cement Paste Factor

- 5.

- Pore Water Factor

4. Summary

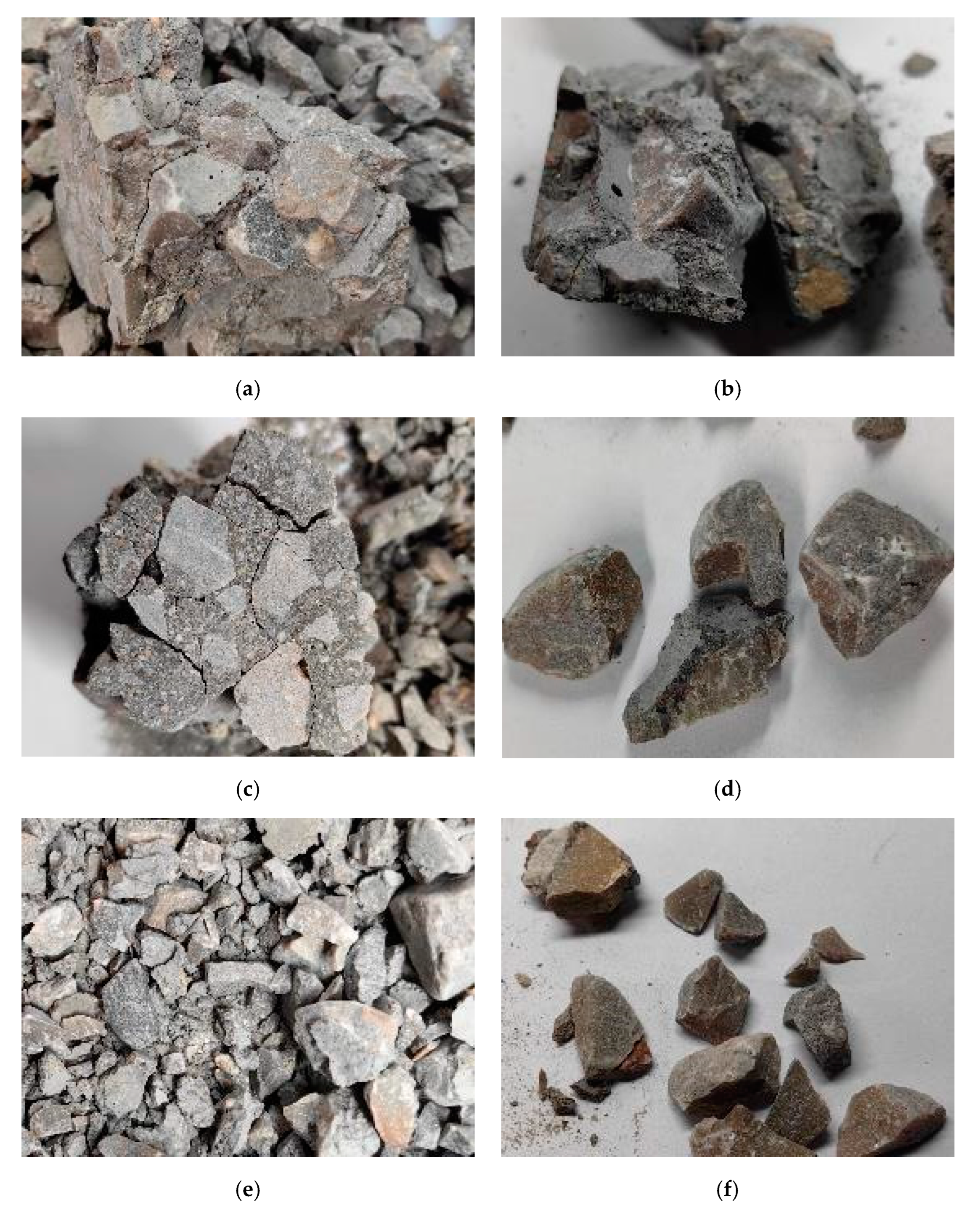

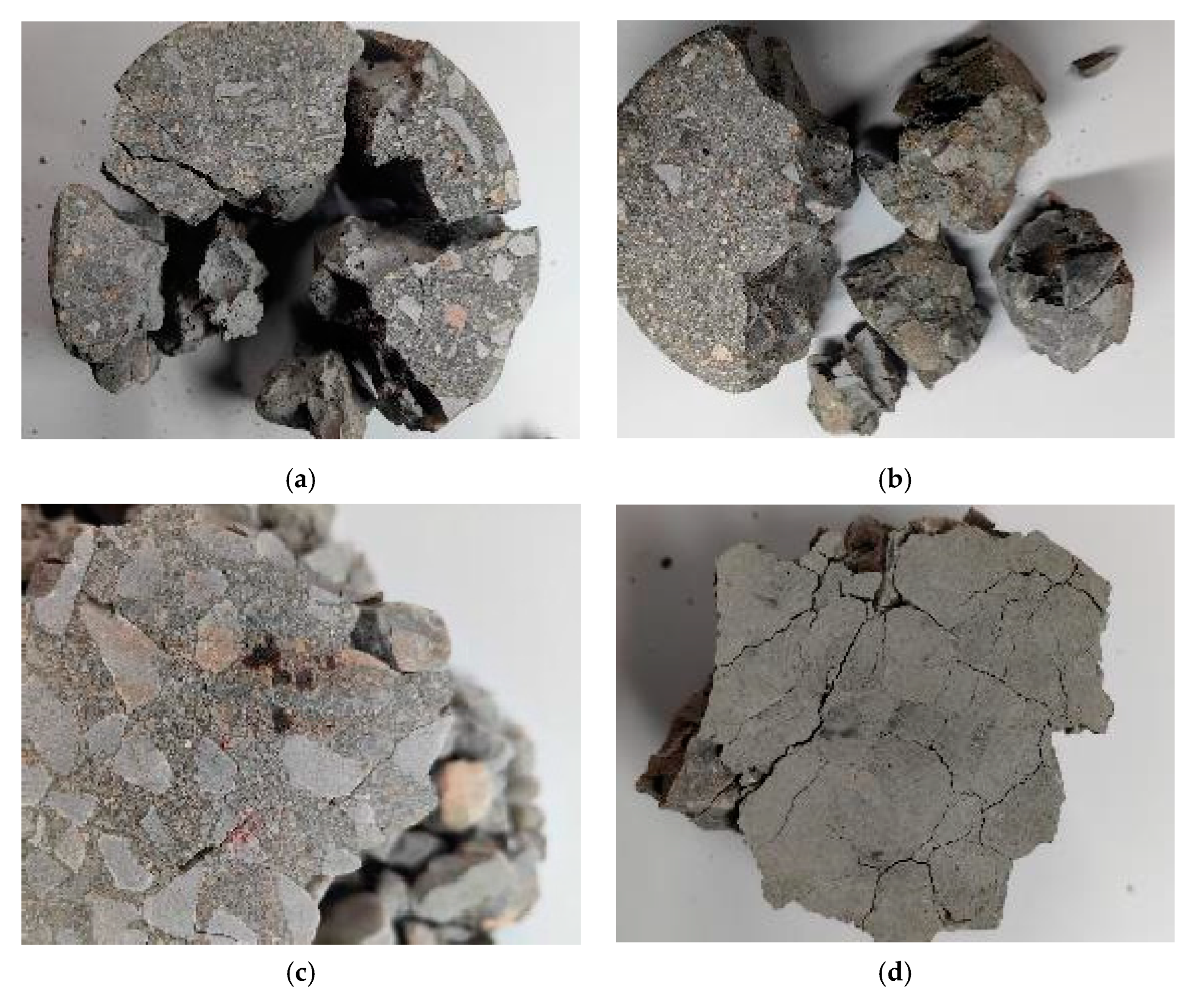

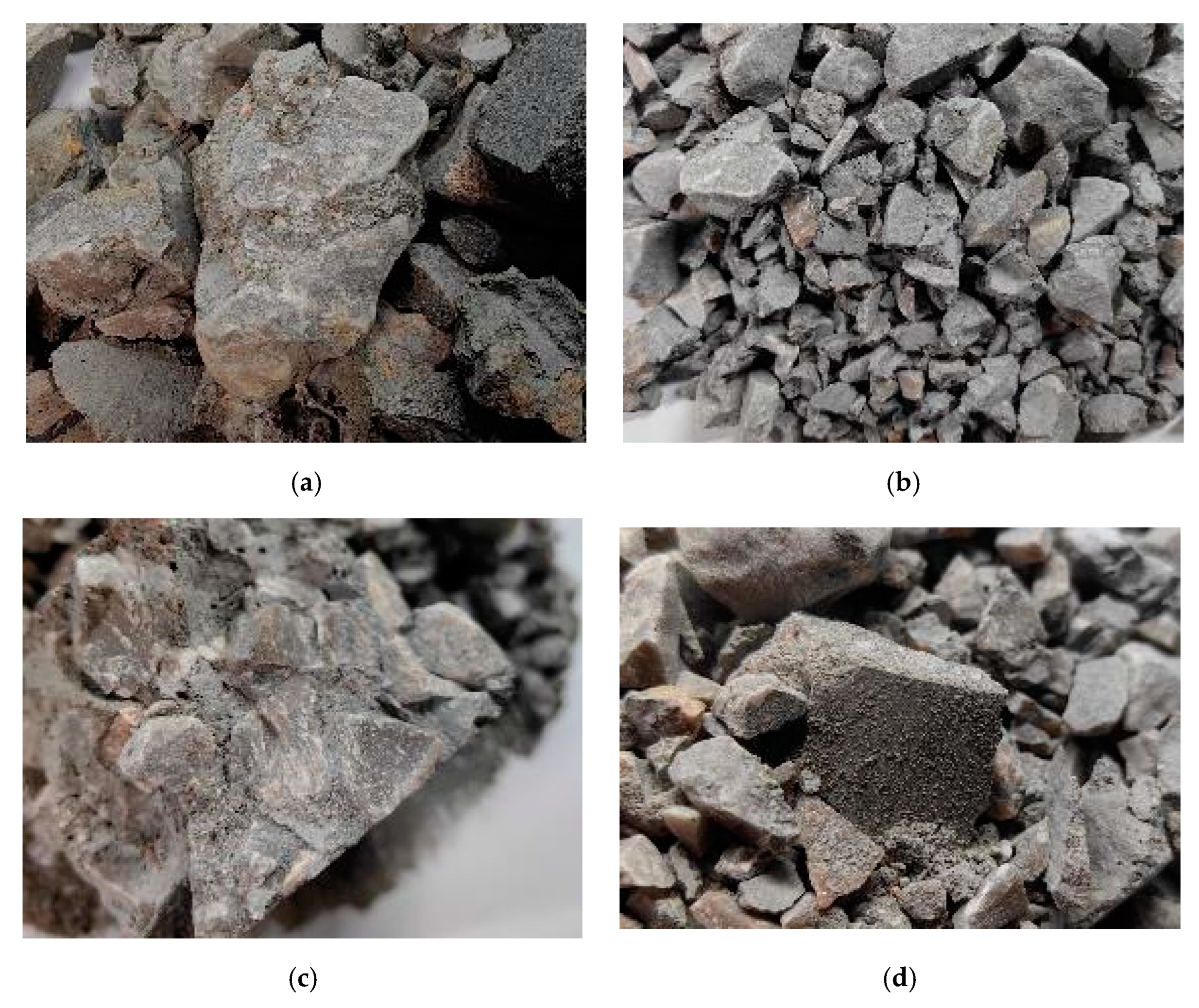

- As the strain rate increased, both ordinary concrete and silicon carbide-modified concrete exhibited a significant strain rate effect, with gradually increasing peak stress, impact toughness, and degree of fragmentation.

- From the perspective of strength characteristics, the optimal content and fineness of silicon carbide varied under different strain rates, but a notable pattern emerged. Within the scope of this study, the higher the strain rate, the greater the optimal content and the coarser the optimal fineness. Specifically, under high strain rates, coarse-grained and high-content silicon carbide exhibited the best modification effect. Overall, the optimal combination of content and fineness was 14SCC400, which, at an impact pressure of 0.4 MPa, achieved a strain rate of 171.17 s−1, and a dynamic peak stress of 114.51 MPa, representing a 34.43% improvement over PC concrete.

- From the perspective of deformation characteristics, as the strain rate increased, the peak strain and ultimate strain of ordinary concrete gradually decreased, whereas those of silicon carbide-modified concrete first decreased and then increased after the strain rate exceeded 140 s−1. This indicated that the incorporation of large-particle high-strength silicon carbide effectively improved the deformation performance of concrete under high strain rates. From the perspective of fragmentation, when the strain rate reached 180 s−1, no cement paste connections between adjacent aggregates were observed, indicating that the cement paste interfaces within the concrete were almost entirely destroyed, and the specimen fragmented into cement paste powder and coarse aggregate pieces.

- The relationship between the load-bearing capacity of concrete and the strength of aggregates became more pronounced under high strain rates. The incorporation of silicon carbide directly enhanced the aggregate strength at the micron level, thereby increasing the load-bearing capacity of concrete under high-speed impact loading. Coarse-grained high-strength silicon carbide particles exhibited more prominent modification effects on the strength and deformation characteristics of concrete under high strain rates.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Multi-scale mechanical and fracture characteristics and early-age strain capacity of high performance carbon nanotube cement nanocomposites. Cem. Concr. Compos. 2010, 32, 110–115. [Google Scholar] [CrossRef]

- Dang, F.; Li, Y.; Ren, J.; Zhou, M. Analysis of dynamic mechanics and energy characteristics of concrete impact failure. Explos. Impact 2022, 42, 63–76. [Google Scholar]

- Lu, S.; Xia, W.; Bai, E.; Ling, L.; Du, Y. Interfacial Modification: The dynamic compression properties and enhancement mechanism of concrete added with micro-nano hierarchical carbon-based fiber. Compos. Part B Eng. 2022, 247, 110340. [Google Scholar]

- Wang, J.; Dong, S.; Dai Pang, S.; Yu, X.; Han, B.; Ou, J. Tailoring anti-impact properties of ultra-high performance concrete by incorporating functionalized carbon nanotubes. Engineering 2022, 18, 232–245. [Google Scholar]

- Yang, Y.; Li, Q.; Qiao, L. Review of SHPB dynamic load impact test characteristics and energy analysis methods. Processes 2023, 11, 3029. [Google Scholar] [CrossRef]

- Butt, H.S.U.; Xue, P. Determination of the wave propagation coefficient of viscoelastic SHPB: Significance for characterization of cellular materials. Int. J. Impact Eng. 2014, 74, 83–91. [Google Scholar]

- Liu, F.; Li, Q.M. Strain-Rate Effect of polymers and correction methodology in a SHPB Test. Int. J. Impact Eng. 2022, 161, 104109. [Google Scholar]

- Gao, G. Stress wave effects and their mechanisms on stress-strain curves in the elastic phase of SHPB tests. Int. J. Impact Eng. 2024, 193, 105061. [Google Scholar]

- Walley, S.M. The Origins of the Hopkinson Bar Technique. In The Kolsky-Hopkinson Bar Machine: Selected Topics; Springer: Cham, Switzerland, 2018; pp. 1–25. [Google Scholar]

- Sharma, S.; Chavan, V.M.; Agrawal, R.G.; Patel, R.J.; Kapoor, R.; Chakravartty, J.K. Split-Hopkinson Pressure Bar: An Experimental Technique for High Strain Rate Tests; Bhabha Atomic Research Centre: Mumbai, India, 2011. [Google Scholar]

- Al-Salloum, Y.; Almusallam, T.; Ibrahim, S.M.; Abbas, H.; Alsayed, S. Rate dependent behavior and modeling of concrete based on SHPB experiments. Cem. Concr. Compos. 2015, 55, 34–44. [Google Scholar]

- Cao, J. Dynamic Constitutive Model and Finite Element Method of Steel Fiber Reinforced Concrete. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2011. [Google Scholar]

- Pham, T.M.; Zhang, X.; Elchalakani, M.; Karrech, A.; Hao, H.; Ryan, A. Dynamic response of rubberized concrete columns with and without FRP confinement subjected to lateral impact. Constr. Build. Mater. 2018, 186, 207–218. [Google Scholar]

- Pham, T.M.; Chen, W.; Khan, A.M.; Hao, H.; Elchalakani, M.; Tran, T.M. Dynamic compressive properties of lightweight rubberized concrete. Constr. Build. Mater. 2020, 238, 117705. [Google Scholar]

- Chen, T.; Wang, Z.; Wang, A.; Bai, E.; Zhu, X. Comparative study on the static and dynamic mechanical properties and micro-mechanism of carbon fiber and carbon nanofiber reinforced concrete. Case Stud. Constr. Mater. 2023, 18, e01827. [Google Scholar]

- Hu, S.; Wang, D.; Liu, J. Experimental Study on Dynamic Mechanical Properties of Concrete Materials. Eng. Mech. 2001, 2001, 115–118, 126. [Google Scholar]

- Liu, X.; Hu, S. Two-dimensional numerical analysis of dispersion effect in large-diameter SHPB. Exp. Mech. 2000, 15, 371–376. [Google Scholar]

- Abderrazak, H.; Hmida, E. Silicon carbide: Synthesis and properties. In Properties and Applications of Silicon Carbide; IntechOpen: Rijeka, Croatia, 2011; pp. 361–388. [Google Scholar]

- Soltys, L.M.; Mironyuk, I.F.; Mykytyn, I.M.; Hnylytsia, I.D.; Turovska, L.V. Synthesis and properties of silicon carbide. Phys. Chem. Solid State 2023, 24, 5–16. [Google Scholar] [CrossRef]

- Long, L.; Zhu, J.; Zhang, D.; Jiang, H.; Wang, R.; Di, Y.; He, H.; Han, T.; Liu, W.; Bi, J.I. Research Progress in Properties of Silicon Carbide Whisker Reinforced Composites. J. Funct. Mater./Gongneng Cailiao 2023, 54, 11091. [Google Scholar]

- Zhou, K.; Xu, M.; Wu, W.; Wang, J. Preparation of Nano Silicon Carbide Modified UV Paint and Its Application Performance on Wood Flooring Surface. Polymers 2023, 15, 4584. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Li, G.; Zhang, X. Electromagnetic wave absorption characteristics of silicon carbide modified concrete applied to protective engineering. Case Stud. Constr. Mater. 2024, 20, e03362. [Google Scholar]

- Wei, J.; Zhang, Y.; Li, X.; Zhang, H.; Guo, Y.; Wang, T.; Qiao, X.; Lei, W. Recent Progress in synthesis, growth mechanisms, and electromagnetic wave absorption properties of silicon carbide nanowires. Ceram. Int. 2022, 48, 35966–35985. [Google Scholar] [CrossRef]

- Idrees, M.; Chaudhary, H.A.; Akbar, A.; Mohamed, A.M.; Fathi, D. Effect of silicon carbide and tungsten carbide on concrete composite. Materials 2022, 15, 2061. [Google Scholar] [CrossRef]

- Kim, H.G.; Qudoos, A.; Jeon, I.K.; Woo, B.H.; Ryou, J.S. Assessment of PCM/SiC-based composite aggregate in concrete: Energy storage performance. Constr. Build. Mater. 2020, 258, 119637. [Google Scholar]

- Pundienė, I.; Korjakins, A.; Pranckevičienė, J.; Kligys, M. Effect of silicon carbide aggregate, prepared by different methods, on the properties of refractory concrete with cenospheres. Ceram. Int. 2018, 44, 15944–15953. [Google Scholar]

- Qiu, H.; Wu, Y.; Chen, H.; Wang, R.; Yu, J.; Lin, Y. Influence of SiC on the thermal energy transfer and storage characteristics of microwave-absorbing concrete containing magnetite and/or carbonyl iron powder. Constr. Build. Mater. 2023, 366, 130191. [Google Scholar] [CrossRef]

- Qiu, H.; Wu, Y.; Chen, H.; Wang, R.; Han, Z.; Wan, Z. Effect of silicon carbide powder on temperature field distribution characteristics and microwave deicing efficiency of cement concrete containing magnetite (Fe3O4) powder. Constr. Build. Mater. 2023, 392, 132005. [Google Scholar]

- Li, Y. Discussion on construction quality control measures of corundum concrete wear-resistant ground. Sichuan Cem. 2016, 2016, 45. [Google Scholar]

- Wang, R.; Wu, G.; Han, C. Study on mix proportion design and mechanical properties of corundum concrete. Highway 2004, 2004, 145–149. [Google Scholar]

- Chen, H.; Xu, J.; Liu, J. Effect of different absorbing admixtures on microwave heating efficiency of concrete pavement. J. Wuhan Univ. (Eng. Ed.) 2020, 53, 773–778. [Google Scholar]

- Wei, Y.; Li, K.; Xu, C.; Wang, L.; Fan, J.; Zhu, J. The effect of strain lag for the flexural enhancement of RC beams strengthened by HMRE under secondary load. Eng. Struct. 2024, 316, 118612. [Google Scholar]

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2011.

- Khosravani, M.R.; Weinberg, K. A review on split Hopkinson bar experiments on the dynamic characterisation of concrete. Constr. Build. Mater. 2018, 190, 1264–1283. [Google Scholar]

- Sarva, S.; Nemat-Nasser, S. Dynamic compressive strength of silicon carbide under uniaxial compression. Mater. Sci. Eng. A 2001, 317, 140–144. [Google Scholar]

- Xie, Y.J.; Fu, Q.; Zheng, K.R.; Yuan, Q.; Song, H. Dynamic mechanical properties of cement and asphalt mortar based on SHPB test. Constr. Build. Mater. 2014, 70, 217–225. [Google Scholar] [CrossRef]

- Kong, X.; Wang, E.; Li, S.; Lin, H.; Zhang, Z.; Ju, Y. Dynamic mechanical characteristics and fracture mechanism of gas-bearing coal based on SHPB experiments. Theor. Appl. Fract. Mech. 2020, 105, 102395. [Google Scholar] [CrossRef]

- Li, J.; Yang, L.; Xie, H.; Wei, P.; Li, D.; Xu, Y.; Zhang, F. Research on impact toughness and crack propagation of basalt fiber reinforced concrete under SHPB splitting test. J. Build. Eng. 2023, 77, 107445. [Google Scholar] [CrossRef]

- Zhao, D.; Li, K.; Fan, J.; Wang, Y.; Zhu, J. Shear behavior of RC beams strengthened with high-strength steel strand mesh reinforced ECC: Shear capacity, cracking and deformation. Eng. Struct. 2024, 298, 117081. [Google Scholar] [CrossRef]

| Cement | Sand | Large Gravel | Small Gravel | Water | Superplasticizer |

|---|---|---|---|---|---|

| 315.0 | 631.0 | 1053.6 | 263.4 | 137.0 | 0.63 |

| 400 Mesh | 600 Mesh | 1200 Mesh | 2000 Mesh | |

|---|---|---|---|---|

| 0 | PC | |||

| 2% | 2SCC400 | 2SCC600 | 2SCC1200 | 2SCC2000 |

| 6% | 6SCC400 | 6SCC600 | 6SCC1200 | 6SCC2000 |

| 10% | 10SCC400 | 10SCC600 | 10SCC1200 | 10SCC2000 |

| 14% | 14SCC400 | 14SCC600 | 14SCC1200 | 14SCC2000 |

| Number | Impact Pressure | Strain Rate | Silicon Carbide Content | |||

|---|---|---|---|---|---|---|

| 2% | 6% | 10% | 14% | |||

| 1 | 0.2 MPa | 70–110 s−1 | 1200 | 1200 | 1200 | 600 |

| 2 | 0.3 MPa | 130–150 s−1 | 1200 | 1200 | 600 | 600 |

| 3 | 0.4 MPa | 160–200 s−1 | 2000 | 400 | 400 | 400 |

| Number | Impact Pressure | Strain Rate | Silicon Carbide Fineness | |||

|---|---|---|---|---|---|---|

| 400 Mesh | 600 Mesh | 1200 Mesh | 2000 Mesh | |||

| 1 | 0.2 MPa | 70–110 s−1 | 2% | 10% | 10% | 6% |

| 2 | 0.3 MPa | 130–150 s−1 | 10% | 10% | 6% | 6% |

| 3 | 0.4 MPa | 160–200 s−1 | 14% | 14% | 2% | 2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.; Chen, Q.; Yu, Y.; Bai, E.; Wang, L.; Guo, Y.; Li, A. Research on Dynamic Mechanical Properties of Silicon Carbide-Modified Concrete. Materials 2025, 18, 1374. https://doi.org/10.3390/ma18061374

Chen T, Chen Q, Yu Y, Bai E, Wang L, Guo Y, Li A. Research on Dynamic Mechanical Properties of Silicon Carbide-Modified Concrete. Materials. 2025; 18(6):1374. https://doi.org/10.3390/ma18061374

Chicago/Turabian StyleChen, Tao, Qingwei Chen, Yang Yu, Erlei Bai, Li Wang, Yanqin Guo, and Ang Li. 2025. "Research on Dynamic Mechanical Properties of Silicon Carbide-Modified Concrete" Materials 18, no. 6: 1374. https://doi.org/10.3390/ma18061374

APA StyleChen, T., Chen, Q., Yu, Y., Bai, E., Wang, L., Guo, Y., & Li, A. (2025). Research on Dynamic Mechanical Properties of Silicon Carbide-Modified Concrete. Materials, 18(6), 1374. https://doi.org/10.3390/ma18061374