Measurement Technique Comparison in the Entire Fracture Surface Topography Assessment for Additively Manufactured Materials

Abstract

1. Introduction

2. Materials and Methods

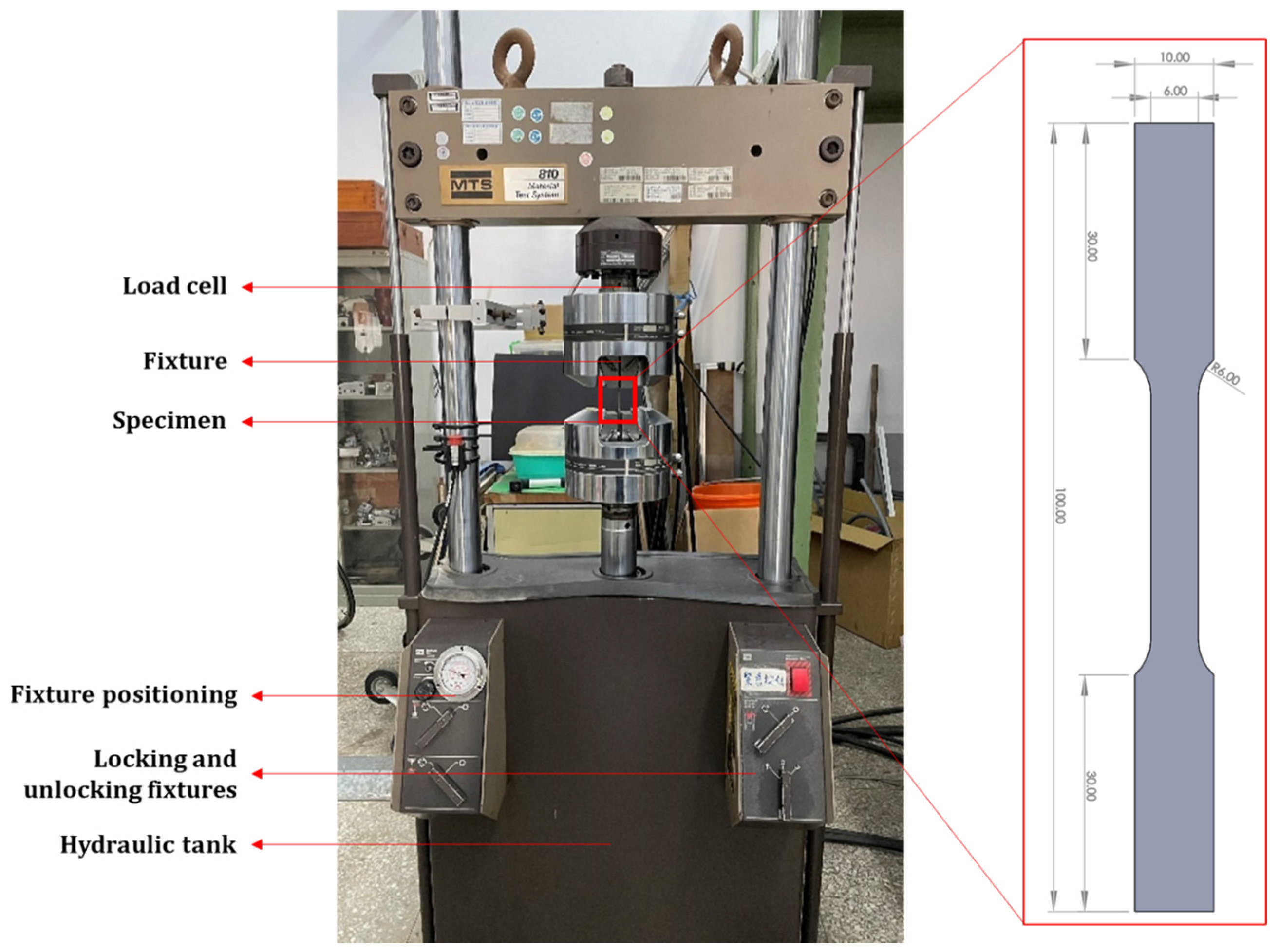

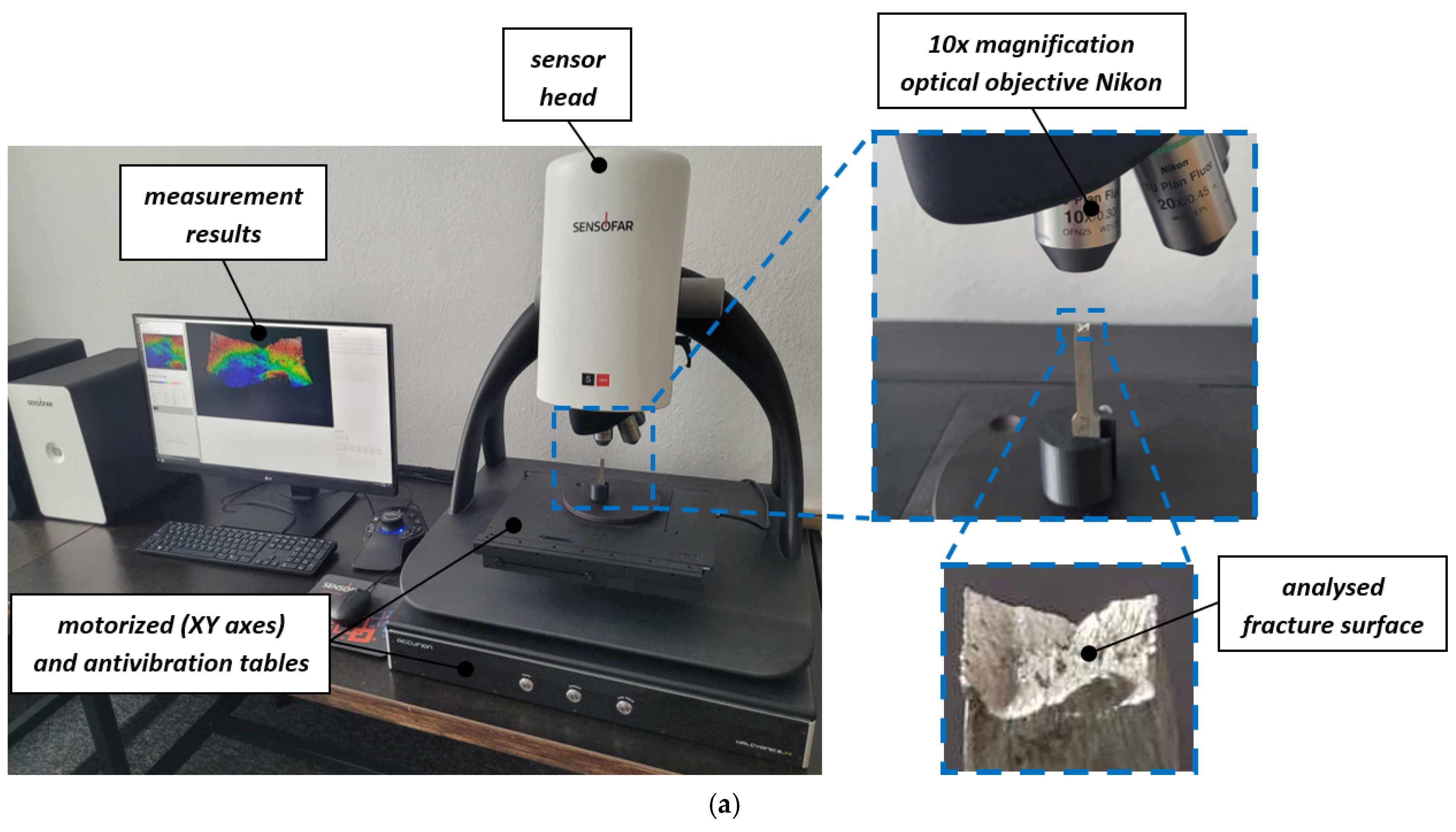

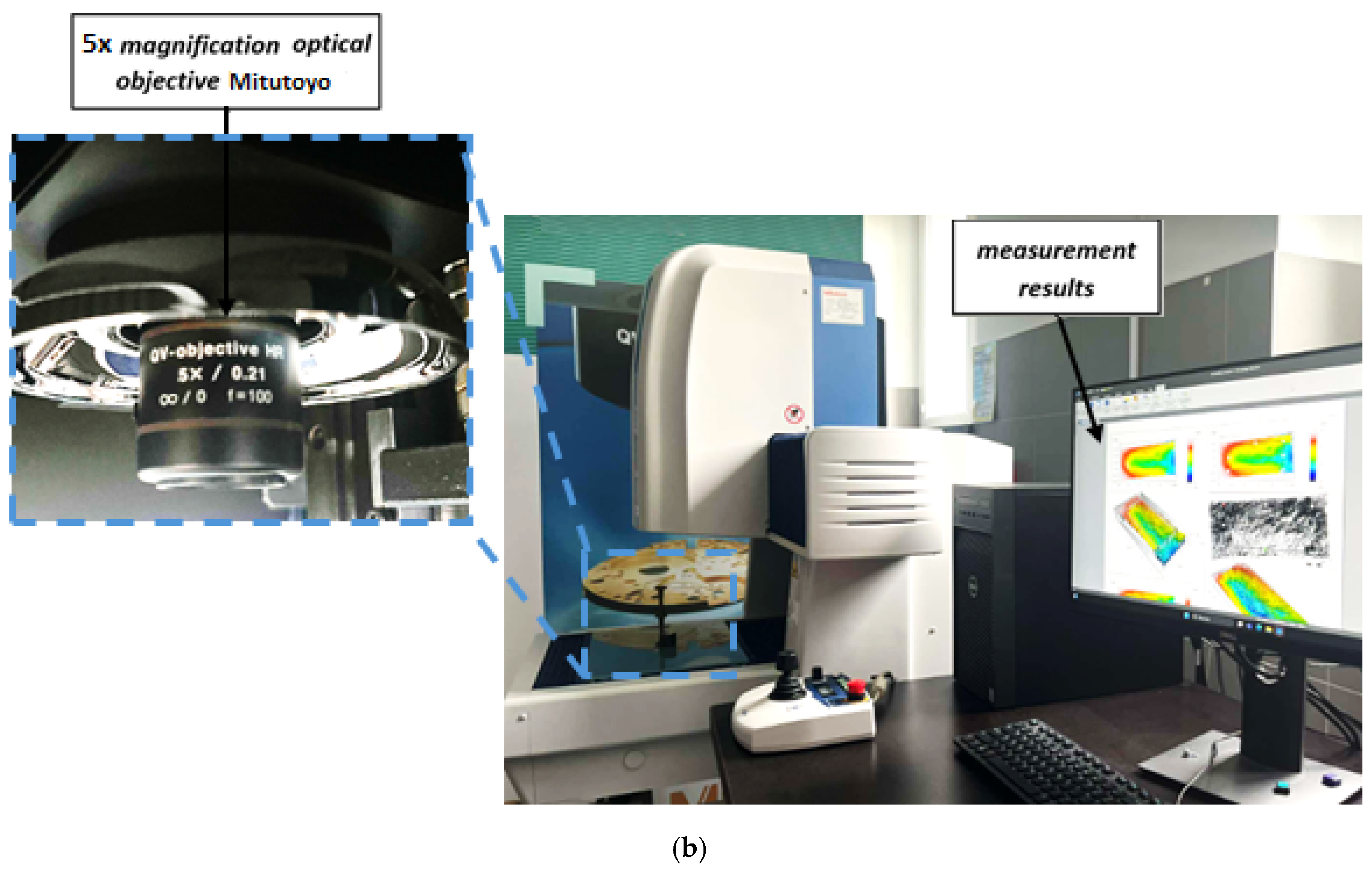

2.1. Characteristics of Test Specimens and Surface Measurement Devices

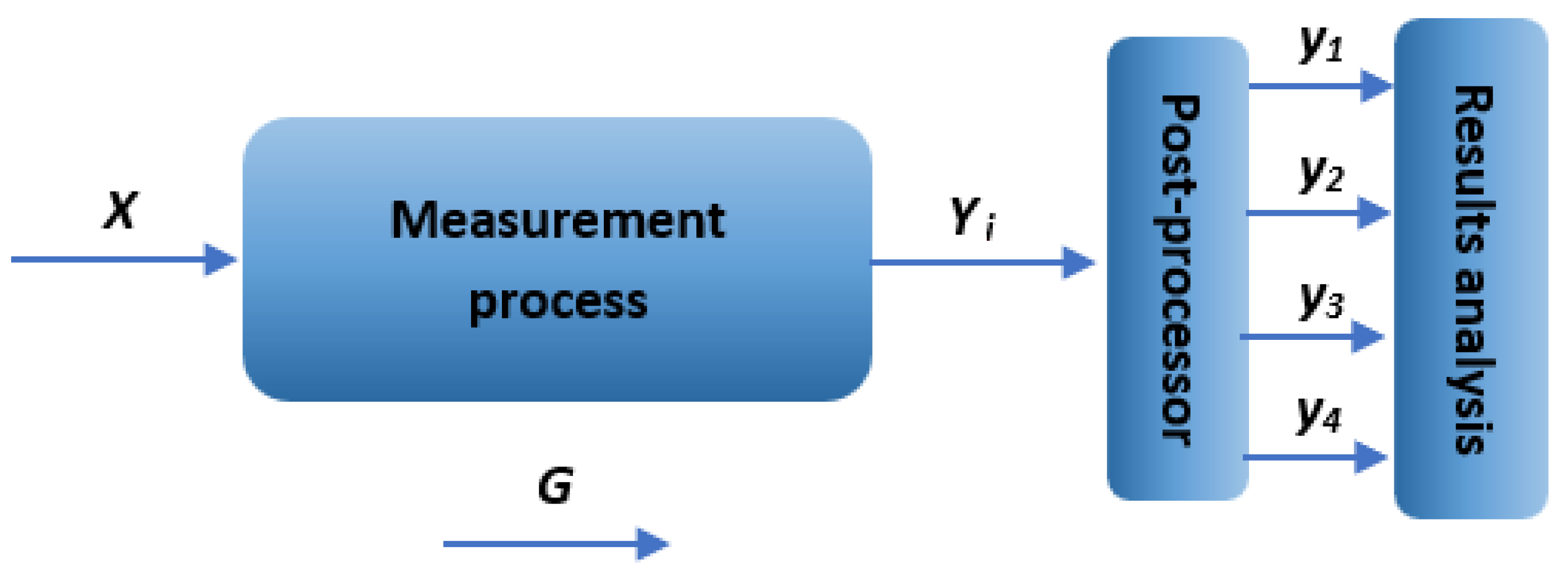

2.2. Measurement Procedure

Characteristics of Factors

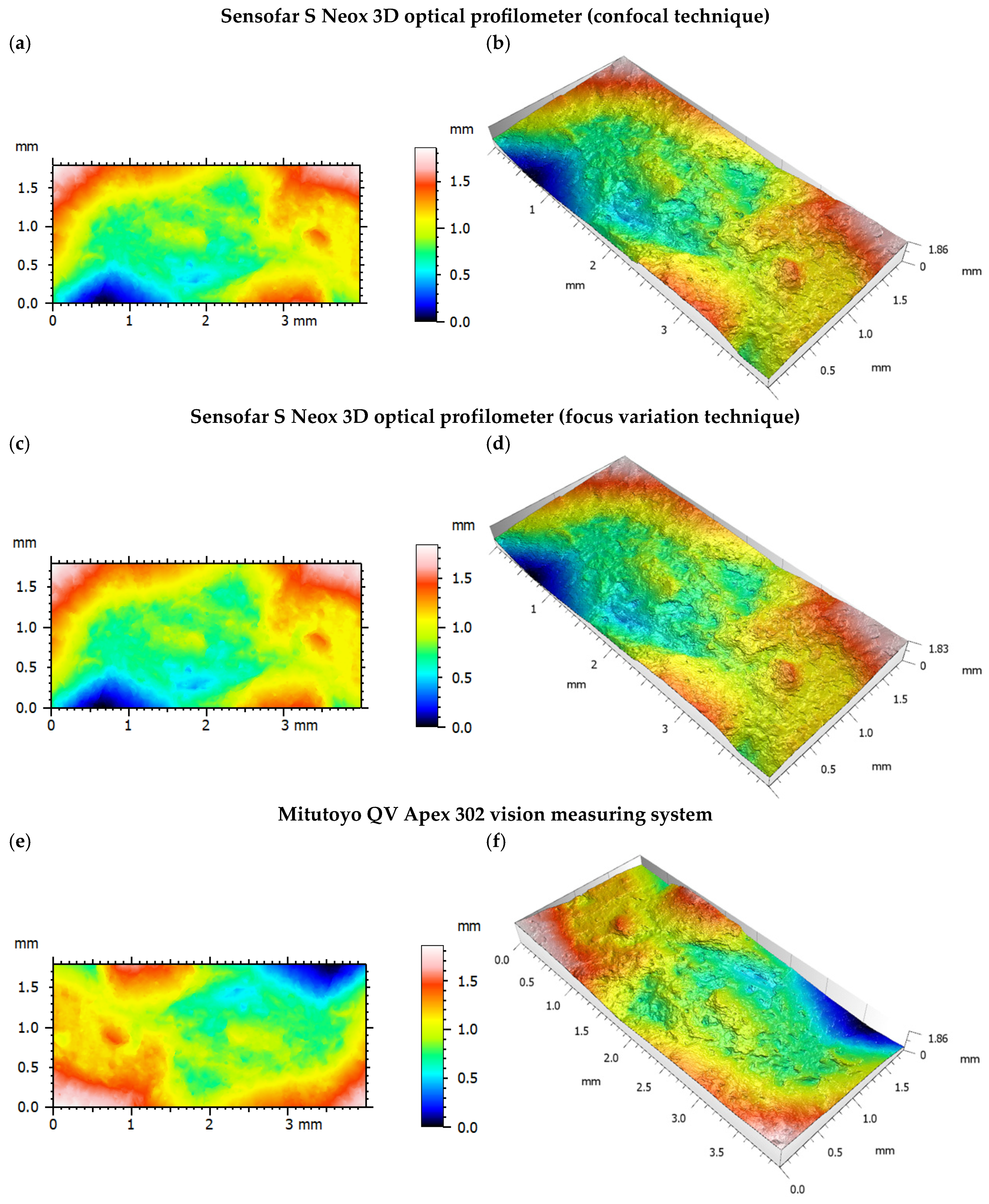

- X—input factors: measurement techniques and methods—Sensofar S Neox 3D optical profilometer (confocal and focus variation microscope techniques), Mitutoyo QV Apex 302 vision measuring system.

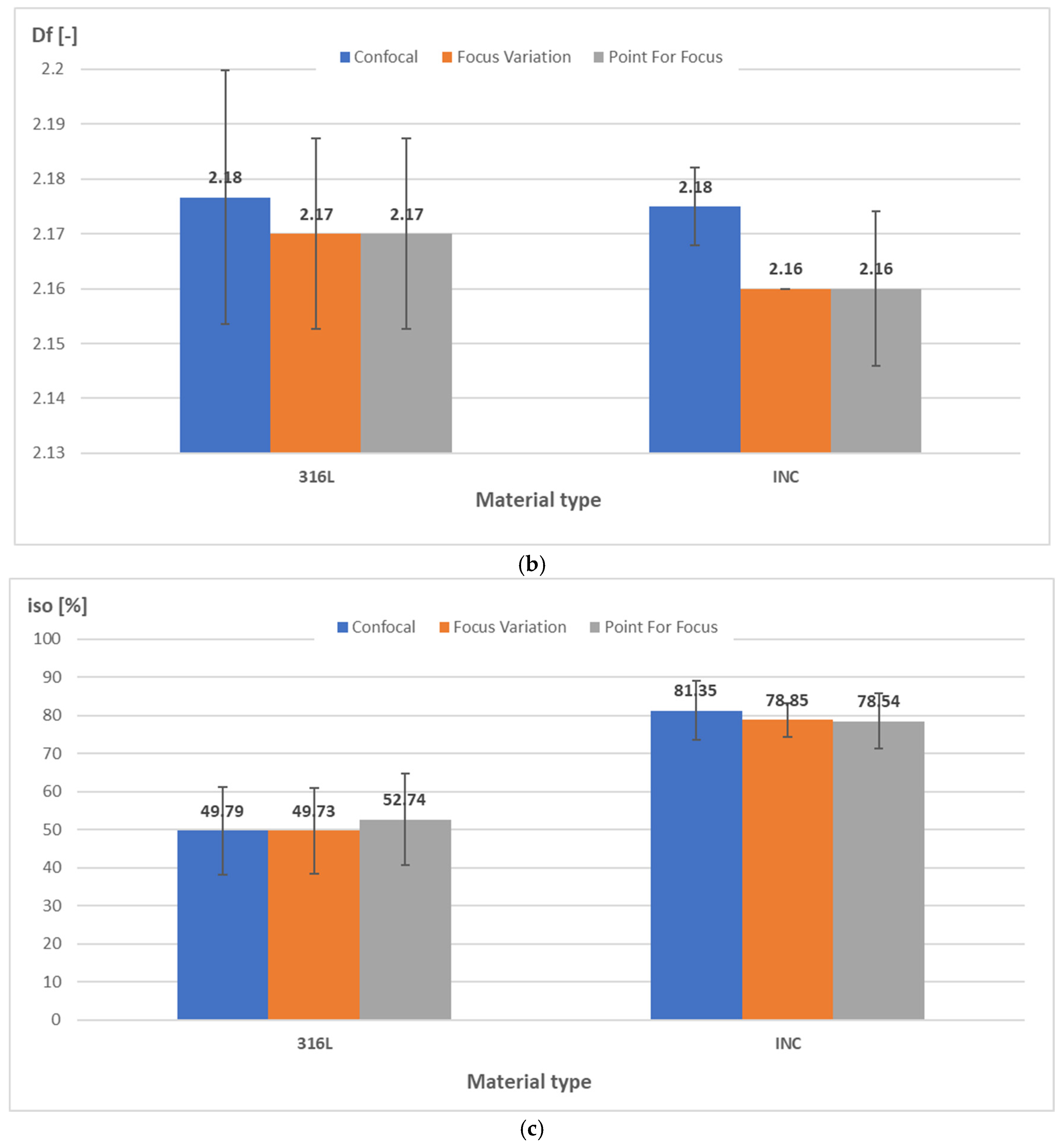

- Y—output factors (analyzed values): y1—void volume Vv [mm³/mm²]; y2—Df enclosing boxes [-]; y3—texture isotropy [%]; y4—general view of the surface topography [isometric images].

- G—constant values: parameters and measurement conditions for each device, etc.

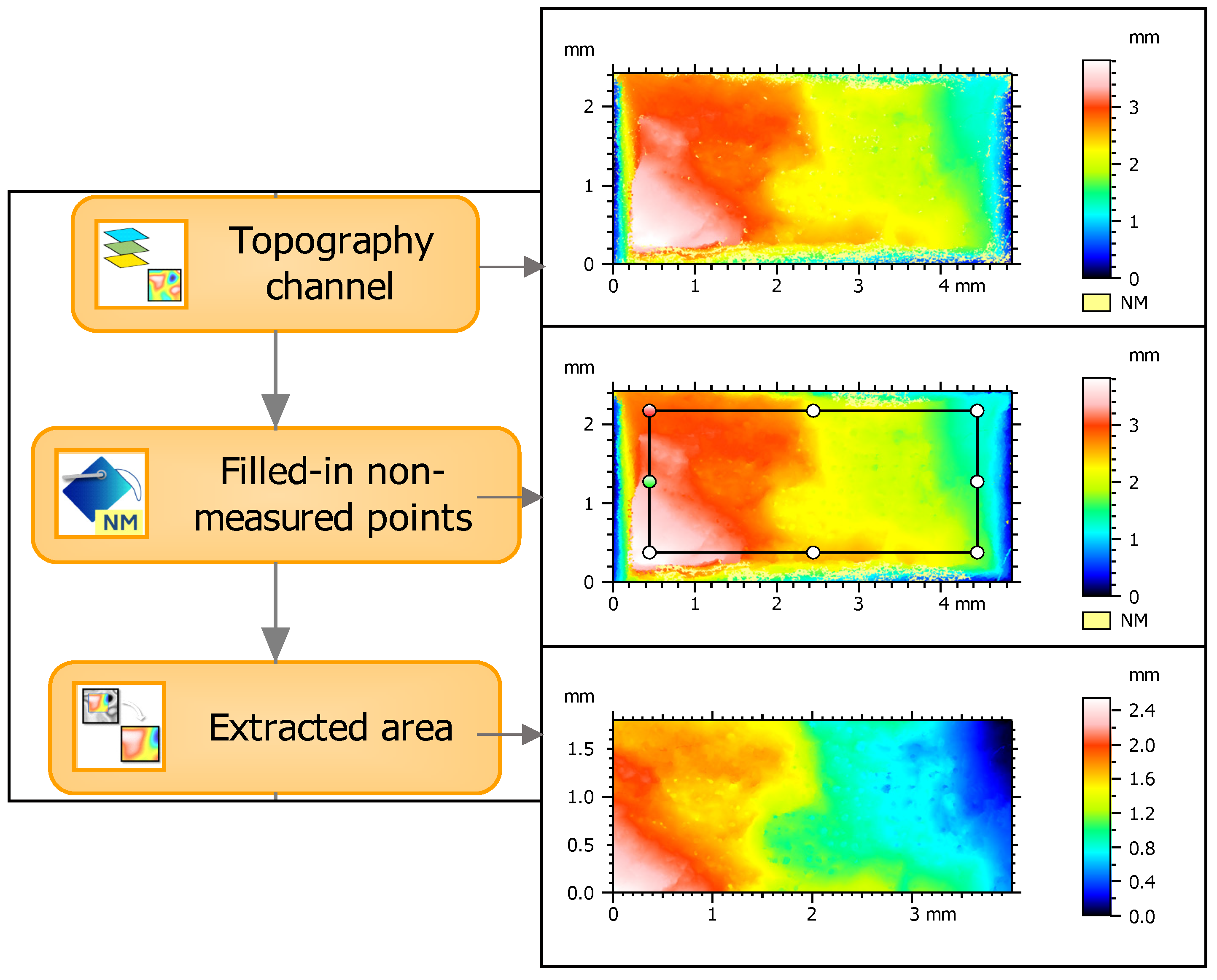

2.3. Measurement Data Analysis Procedure

2.4. Scanning Electron Microscope Observations

3. Results

4. Discussion

5. Conclusions

- The specimens were successfully fabricated using the following laser process parameters: printing power of 200 W, scanning speed of 800 mm/s, hatch spacing of 105 µm, and layer thickness of 50 µm. The specimens were successfully post-processed with the WEDM process.

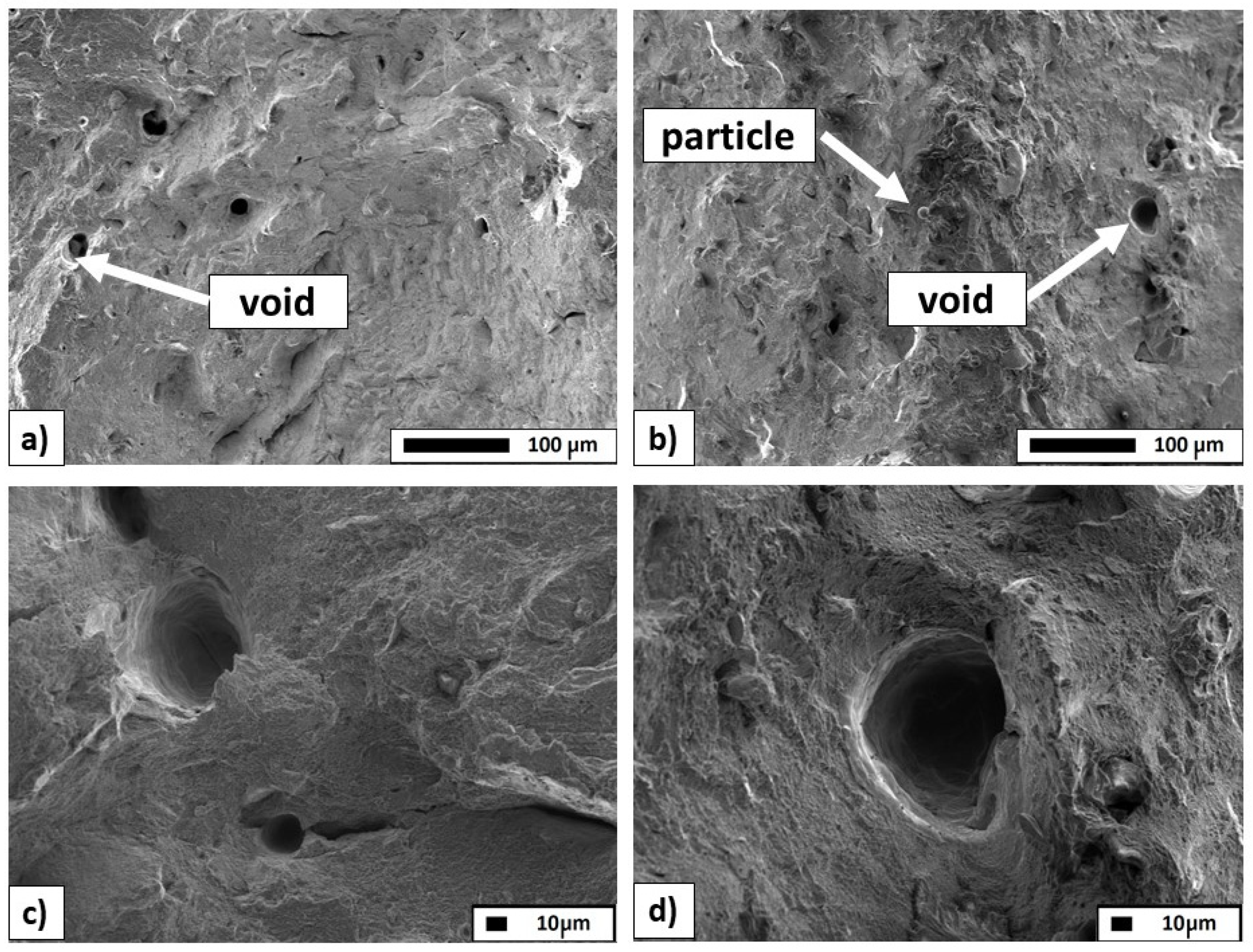

- SEM observations confirm that both materials exhibit ductile fracture modes. In the Inconel 718 specimens, additional porosities and unmelted powder grains were identified, a result of the additive manufacturing process.

- Optical systems allow for the accurate evaluation of irregularly shaped surfaces, such as those analyzed in this paper and the entire fracture surfaces of AM-fabricated materials.

- Obtaining similar results of surface topography measurements for each of the presented devices and measurement techniques indicates a proper assessment of the structure of the entire fracture surface metrology; both measurement devices can therefore be used to measure the topography of this type of surface for additively manufactured materials.

- Both measurement systems and the demonstrated method of analyzing measurement data can be used in an industrial environment to accurately assess irregularly shaped surfaces, such as AM parts.

- Another key point to note is that the entire fracture surface method holds significant promise for analyzing failures in 3D-printed metals functioning under both quasi-static and fatigue conditions. Furthermore, it may greatly assist in understanding the failure mechanisms resulting from various loads.

- Future research directions include testing and detailed analysis of a wider range of AM-fabricated materials, including advanced and hybrid materials. Based on the collected measurement data, it will be possible to further improve current measurement techniques and develop appropriate methods for their analysis.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Whitehouse, D.J. Surface metrology. Meas. Sci. Technol. 1997, 8, 955. [Google Scholar] [CrossRef]

- Magsipoc, E.; Zhao, Q.; Grasselli, G. 2D and 3D Roughness Characterization; Springer: Berlin/Heidelberg, Germany, 2020; Volume 53, pp. 1495–1519. [Google Scholar] [CrossRef]

- Leach, R.; Evans, C.; He, L.; Davies, A.; Duparré, A.; Henning, A.; Jones, C.W.; O’Connor, D. Open questions in surface topography measurement: A roadmap. Surf. Topogr. Metrol. Prop. 2015, 3, 013001. [Google Scholar] [CrossRef]

- Lee, C.O.; Park, K.; Park, B.C.; Lee, Y.W. An algorithm for stylus instruments to measure aspheric surfaces. Meas. Sci. Technol. 2005, 16, 1215. [Google Scholar] [CrossRef]

- Deja, M.; Dobrzyński, M.; Flaszyński, P.; Haras, J.; Zieliński, D. Application of Rapid Prototyping technology in the manufacturing of turbine blade with small diameter holes. Pol. Marit. Res. 2018, 25 (Suppl. S1), 119–123. [Google Scholar] [CrossRef]

- Deja, M.; Zielinski, D. A pilot study to assess an in-process inspection method for small diameter holes produced by direct metal laser sintering. Rapid Prototyp. J. 2019, 26, 418–436. [Google Scholar] [CrossRef]

- Jeyapoovan, T.; Murugan, M. Surface roughness classification using image processing. Measurement 2013, 46, 2065–2072. [Google Scholar] [CrossRef]

- Tsigarida, A.; Tsampali, E.; Konstantinidis, A.A.; Stefanidou, M. On the Use of Confocal Microscopy for Calculating the Surface Microroughness and the Respective Hydrophobic Properties of Marble Specimens. J. Build. Eng. 2021, 33, 101876. [Google Scholar] [CrossRef]

- Niemczewska-Wójcik, M.; Madej, M.; Kowalczyk, J.; Piotrowska, K. A Comparative Study of the Surface Topography in Dry and Wet Turning Using the Confocal and Interferometric Modes. Measurement 2022, 204, 112144. [Google Scholar] [CrossRef]

- Walczak, D.; Krolczyk, J.B.; Chudy, R.; Gupta, M.K.; Pruncu, C.; Krolczyk, G.M. Role of optical measurement systems in analysing the surface topography of an industry standard component. Optik 2023, 283, 170919. [Google Scholar] [CrossRef]

- Leksycki, K.; Królczyk, J.B. Comparative assessment of the surface topography for different optical profilometry techniques after dry turning of Ti6Al4V titanium alloy. Measurement 2021, 169, 108378. [Google Scholar] [CrossRef]

- Podulka, P.; Macek, W.; Rozumek, D.; Żak, K.; Branco, R. Topography measurement methods evaluation for entire bending-fatigued fracture surfaces of specimens obtained by explosive welding. Measurement 2024, 224, 113853. [Google Scholar] [CrossRef]

- ISO 25178–600; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 600: Metrological Characteristics for Areal Topography Measuring Methods. International Organization for Standardization: Geneva, Switzerland, 2019.

- Roos-Hoefgeest, S.; Roos-Hoefgeest, M.; Álvarez, I.; González, R.C. Simulation of Laser Profilometer Measurements in the Presence of Speckle Using Perlin Noise. Sensors 2023, 23, 7624. [Google Scholar] [CrossRef] [PubMed]

- Vanrusselt, M.; Haitjema, H.; Leach, R.K.; de Groot, P. International comparison of noise in areal surface topography measurements. Surf. Topogr. Metrol. Prop. 2021, 9, 025015. [Google Scholar] [CrossRef]

- ISO 25178–700; Geometrical Product Specifications (GPS)—Surface Texture: ArealPart 700: Calibration, Adjustment and Verification of Areal Topography Measuring Instruments. International Organization for Standardization: Geneva, Switzerland, 2022.

- Podulka, P.; Macek, W.; Owsiński, R.; Branco, R.; Trembacz, J. Roughness measurement results evaluation of 6082 aluminium alloy specimens after fatigue bending tests. Precis. Eng. 2024, 91, 77–94. [Google Scholar] [CrossRef]

- Wibisono, A.T.; Jiang, C.P.; Culler, D.; Toyserkani, E. Laser Powder Bed Fusion of Stainless Steel 316L for Rectangular Micropillar Array with High Geometrical Accuracy and Hardness. 3d Print. Addit. Manuf. 2024. [Google Scholar] [CrossRef]

- Jiang, C.P.; Maidhah, A.A.; Wang, S.H.; Wang, Y.R.; Pasang, T.; Ramezani, M. Laser Powder Bed Fusion of Inconel 718 Tools for Cold Deep Drawing Applications: Optimization of Printing and Post-Processing Parameters. Materials 2023, 16, 4707. [Google Scholar] [CrossRef]

- Macek, W.; Branco, R.; Podulka, P.; Kopec, M.; Zhu, S.P.; Costa, J.D. A brief note on entire fracture surface topography parameters for 18Ni300 maraging steel produced by LB-PBF after LCF. Eng. Fail. Anal. 2023, 153, 107541. [Google Scholar] [CrossRef]

- Jiang, C.P.; Masrurotin, M.; Ramezani, M.; Wibisono, A.T.; Toyserkani, E.; Macek, W. Sintering parameter investigation for bimetallic stainless steel 316L/inconel 718 composite printed by dual-nozzle fused deposition modeling. Rapid Prototyp. J. 2024, 30, 1624–1637. [Google Scholar] [CrossRef]

- Cao, L.; Li, J.; Hu, J.; Liu, H.; Wu, Y.; Zhou, Q. Optimization of surface roughness and dimensional accuracy in LPBF additive manufacturing. Opt. Laser Technol. 2021, 142, 107246. [Google Scholar] [CrossRef]

- Podulka, P.; Rudawska, A.; Macek, W. Study of vibrational surface topography measurement errors of LPBF Inconel 718 alloy after shot peening process. Measurement 2025, 243, 116434. [Google Scholar] [CrossRef]

- Macek, W. Fractal Analysis of the Bending-Torsion Fatigue Fracture of Aluminium Alloy. Eng. Fail. Anal. 2019, 99, 97–107. [Google Scholar] [CrossRef]

- Macek, W.; Branco, R.; Szala, M.; Marciniak, Z.; Ulewicz, R.; Sczygiol, N.; Kardasz, P. Profile and Areal Surface Parameters for Fatigue Fracture Characterisation. Materials 2020, 13, 3691. [Google Scholar] [CrossRef] [PubMed]

- Chu, T.; Nguyen, T.; Yoo, H.; Wang, J. A Review of Vibration Analysis and Its Applications. Heliyon 2024, 10, e26282. [Google Scholar] [CrossRef]

- Macek, W. Correlation between Fractal Dimension and Areal Surface Parameters for Fracture Analysis after Bending-Torsion Fatigue. Metals 2021, 11, 1790. [Google Scholar] [CrossRef]

| Machine and Software | |

|---|---|

| 3D printer | Tongtai AMP-160 |

| Software (slicer) | Materialise Magics 23.1 |

| Method and materials | |

| 3D printing method | LPBF |

| Materials | Stainless Steel 316L, Inconel 718 |

| Process parameters | |

| Laser power | 200 W |

| Scanning speed | 800 mm/s |

| Hatch space | 105 µm |

| Layer thickness | 50 µm |

| Post-processing | |

| Wire Electrical Discharge Machining (WEDM) | |

| Parameter | Measurement System | |

|---|---|---|

| Sensofar S Neox 3D | Mitutoyo QV Apex 302 | |

| Light source | LED | LED strobe light |

| Pixel size | 1.38 µm | |

| Optical resolution | 0.46 µm | 0.10 µm |

| Measurement software | SensoSCAN S neox 7.7 | FORMTRACEPAK V6 |

| Magnification | 10 | 5 |

| Measurement technique | Confocal, focus variation | Point for focus |

| Material Type | Measurement Technique | ||

|---|---|---|---|

| Confocal (Sensofar S Neox 3D) | Focus Variation (Sensofar S Neox 3D) | Point For Focus (Mitutoyo QV Apex 302) | |

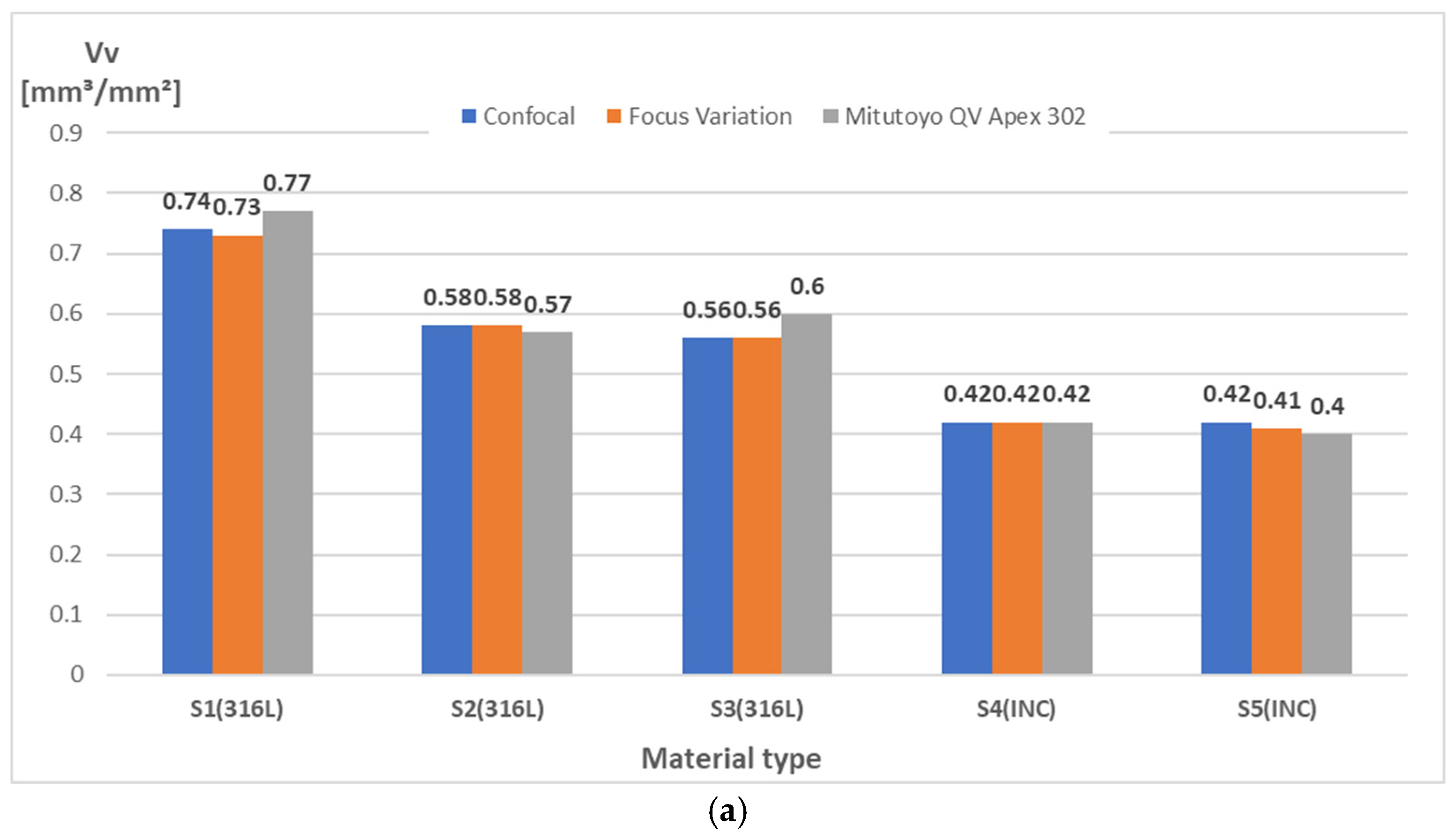

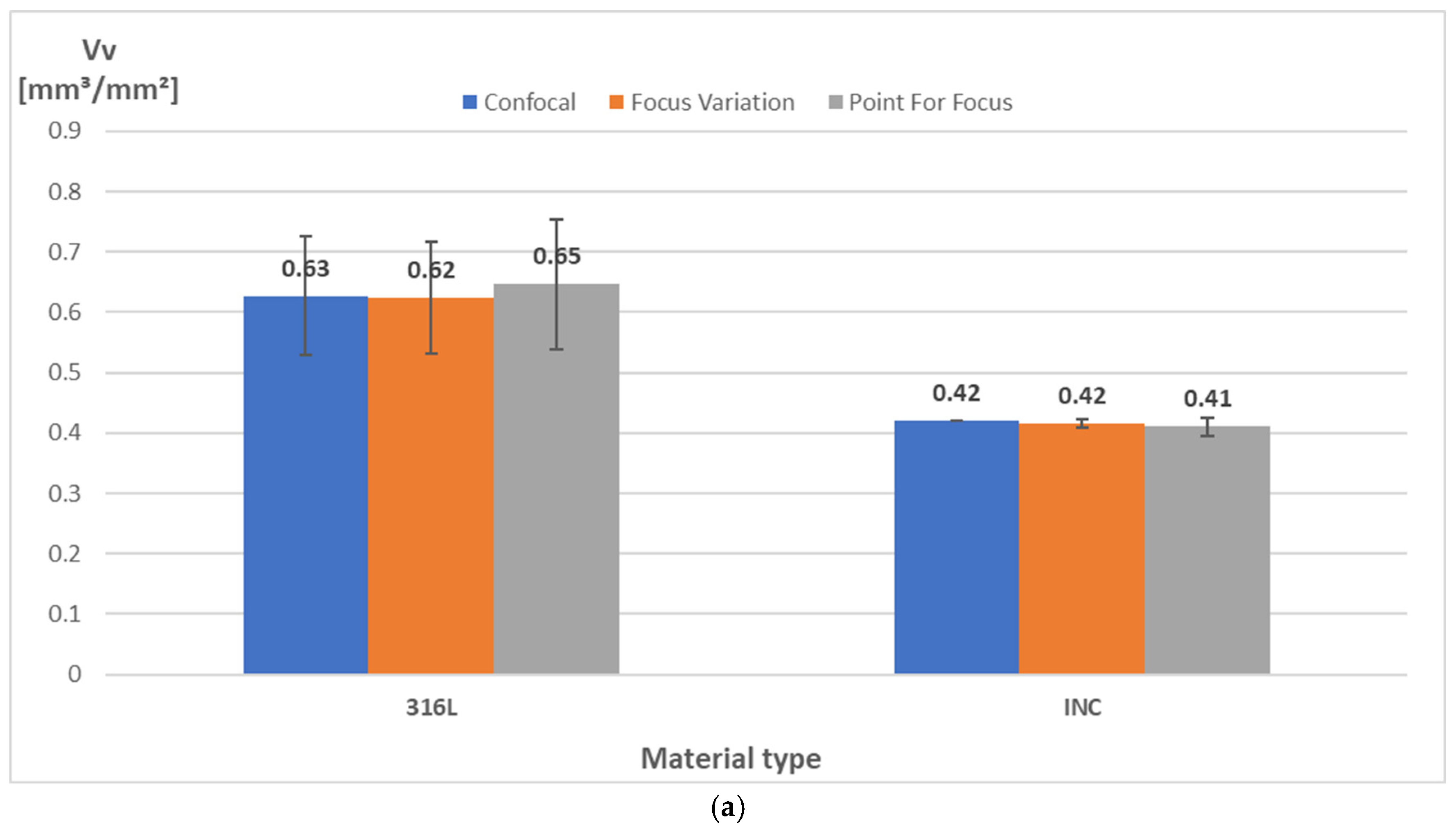

| Analyzed value: Vv—void volume [mm³/mm²] | |||

| S1(316L) | 0.74 | 0.73 | 0.77 |

| S2(316L) | 0.58 | 0.58 | 0.57 |

| S3(316L) | 0.56 | 0.56 | 0.6 |

| S4(INC) | 0.42 | 0.42 | 0.42 |

| S5(INC) | 0.42 | 0.41 | 0.4 |

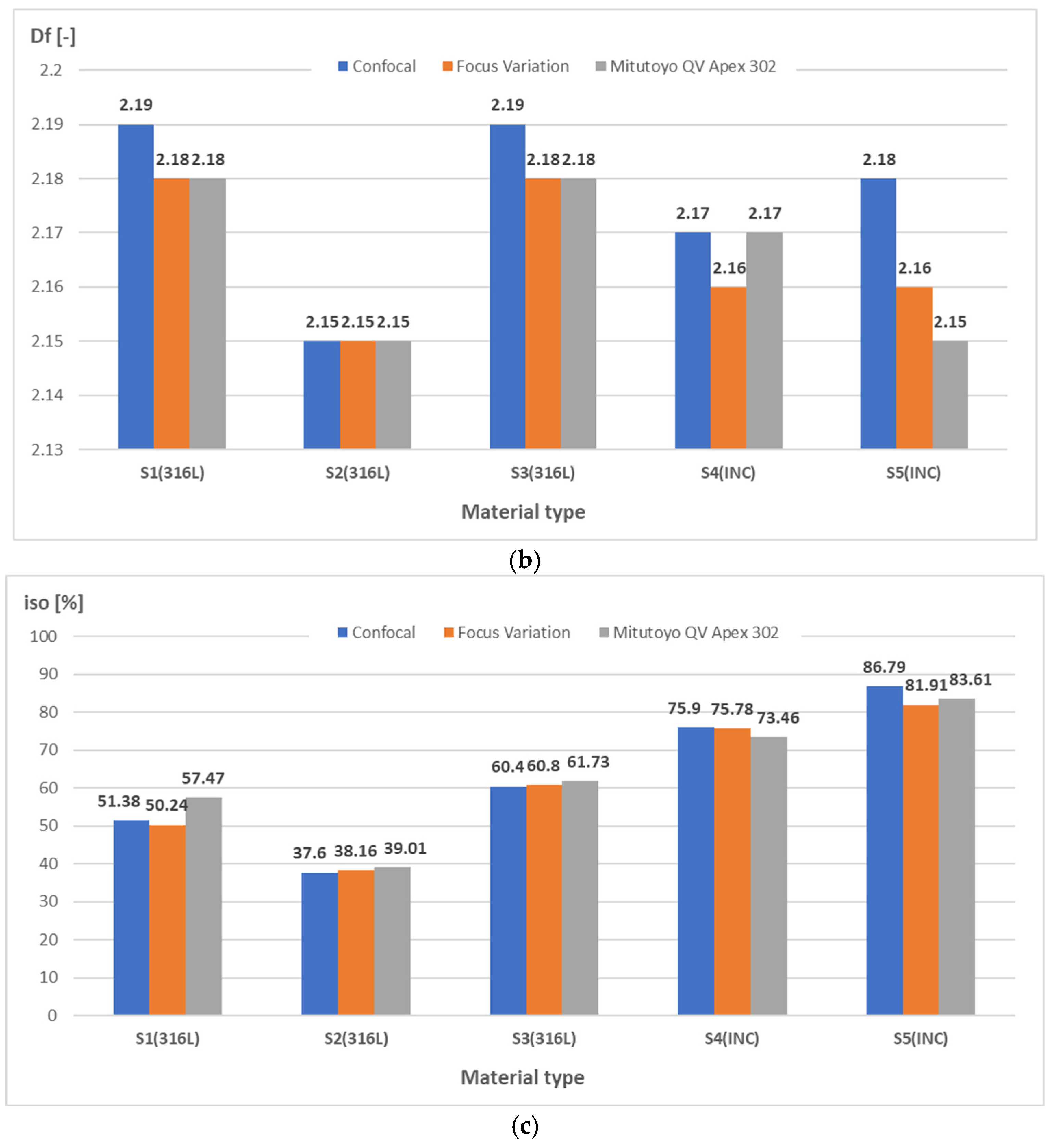

| Analyzed value: Df—enclosing boxes [-] | |||

| S1(316L) | 2.19 | 2.18 | 2.18 |

| S2(316L) | 2.15 | 2.15 | 2.15 |

| S3(316L) | 2.19 | 2.18 | 2.18 |

| S4(INC) | 2.17 | 2.16 | 2.17 |

| S5(INC) | 2.18 | 2.16 | 2.15 |

| Analyzed value: iso—texture isotropy [%] | |||

| S1(316L) | 51.38 | 50.24 | 57.47 |

| S2(316L) | 37.6 | 38.16 | 39.01 |

| S3(316L) | 60.4 | 60.8 | 61.73 |

| S4(INC) | 75.9 | 75.78 | 73.46 |

| S5(INC) | 86.79 | 81.91 | 83.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zieliński, D.; Mirowska, A.; Podulka, P.; Jiang, C.-P.; Macek, W. Measurement Technique Comparison in the Entire Fracture Surface Topography Assessment for Additively Manufactured Materials. Materials 2025, 18, 1355. https://doi.org/10.3390/ma18061355

Zieliński D, Mirowska A, Podulka P, Jiang C-P, Macek W. Measurement Technique Comparison in the Entire Fracture Surface Topography Assessment for Additively Manufactured Materials. Materials. 2025; 18(6):1355. https://doi.org/10.3390/ma18061355

Chicago/Turabian StyleZieliński, Dawid, Aleksandra Mirowska, Przemysław Podulka, Cho-Pei Jiang, and Wojciech Macek. 2025. "Measurement Technique Comparison in the Entire Fracture Surface Topography Assessment for Additively Manufactured Materials" Materials 18, no. 6: 1355. https://doi.org/10.3390/ma18061355

APA StyleZieliński, D., Mirowska, A., Podulka, P., Jiang, C.-P., & Macek, W. (2025). Measurement Technique Comparison in the Entire Fracture Surface Topography Assessment for Additively Manufactured Materials. Materials, 18(6), 1355. https://doi.org/10.3390/ma18061355