Multiscale Analysis of Surface Topography for Engineering Applications in the Casting Industry

Abstract

1. Introduction

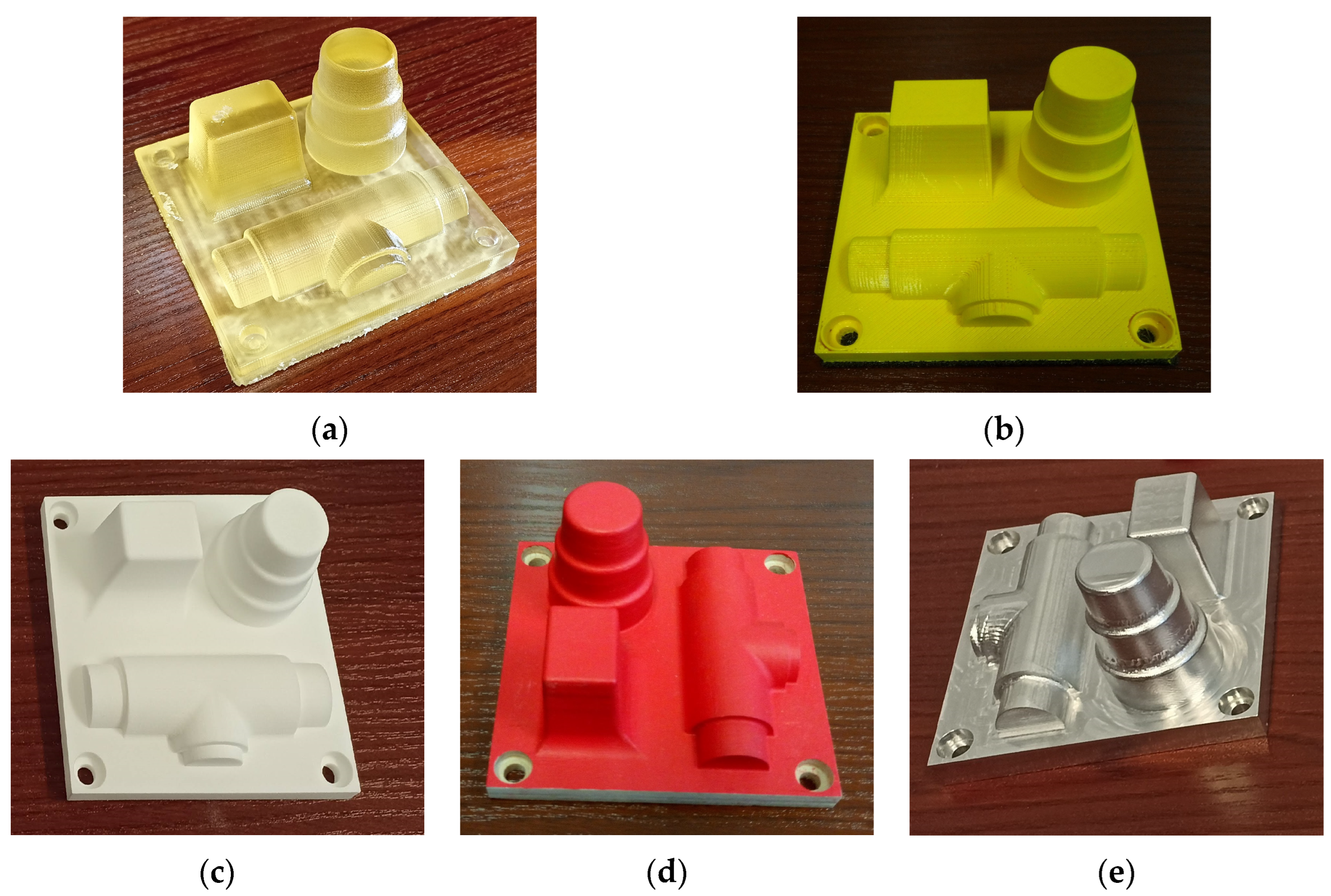

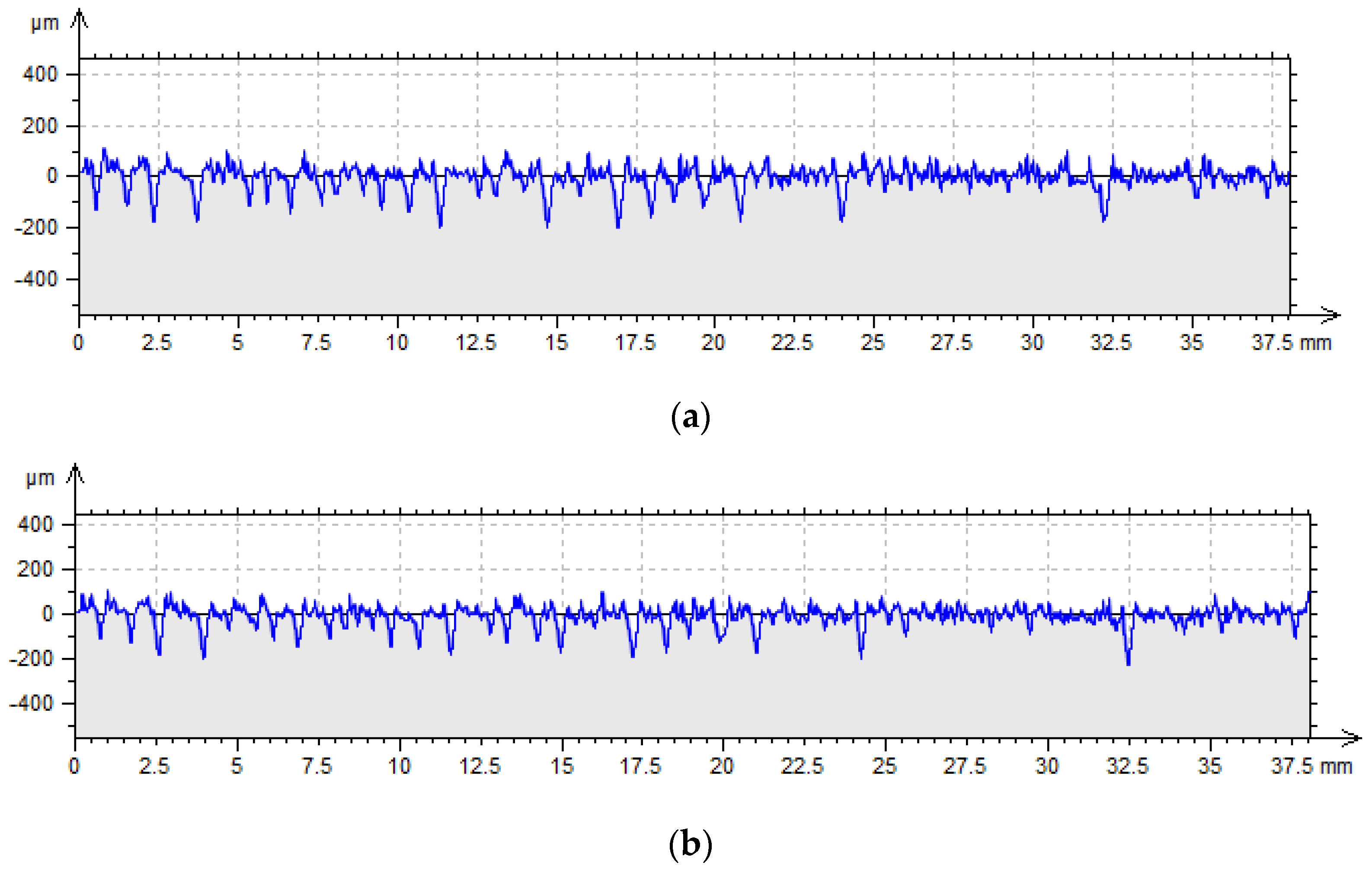

2. Materials and Methods

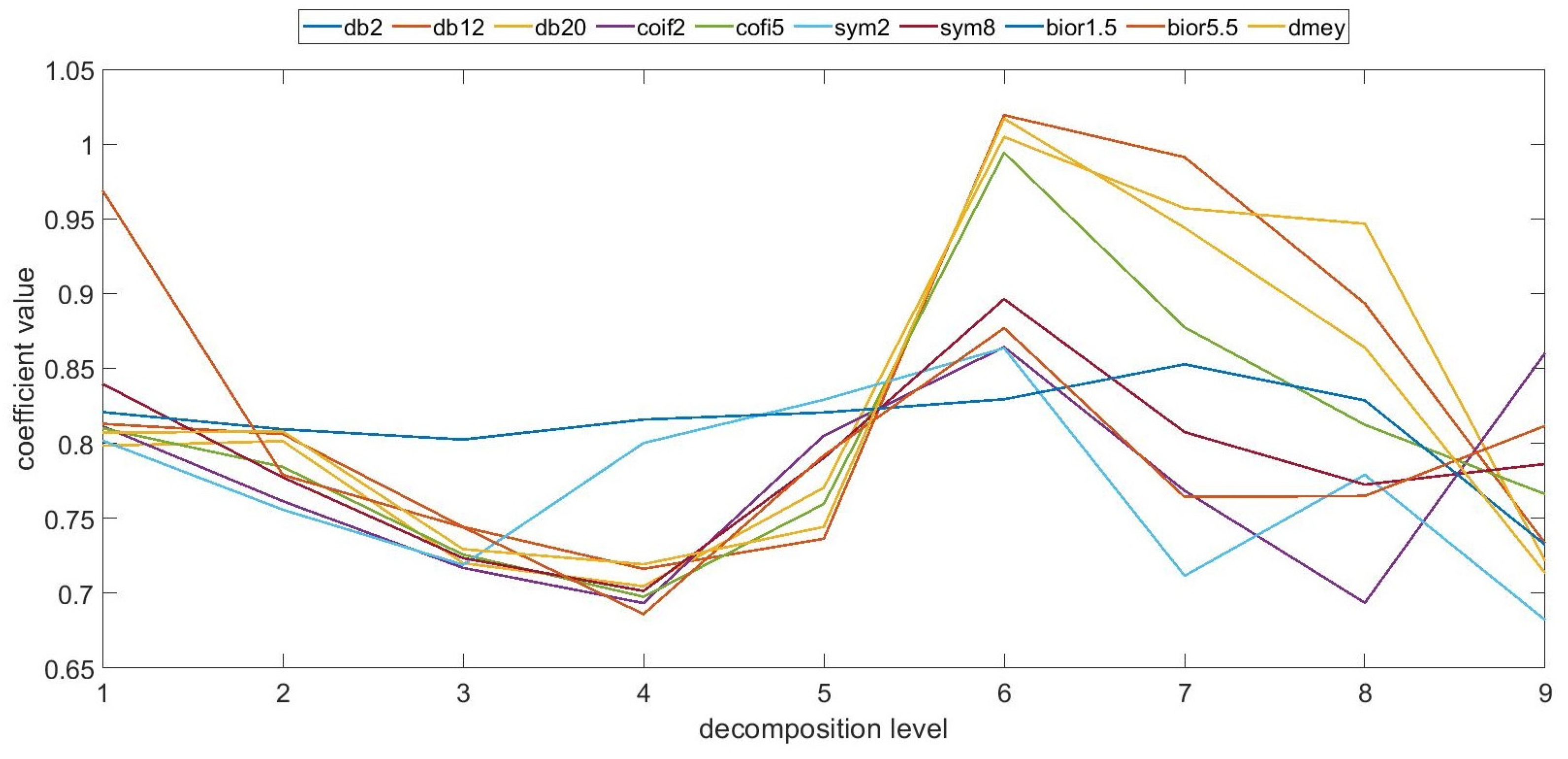

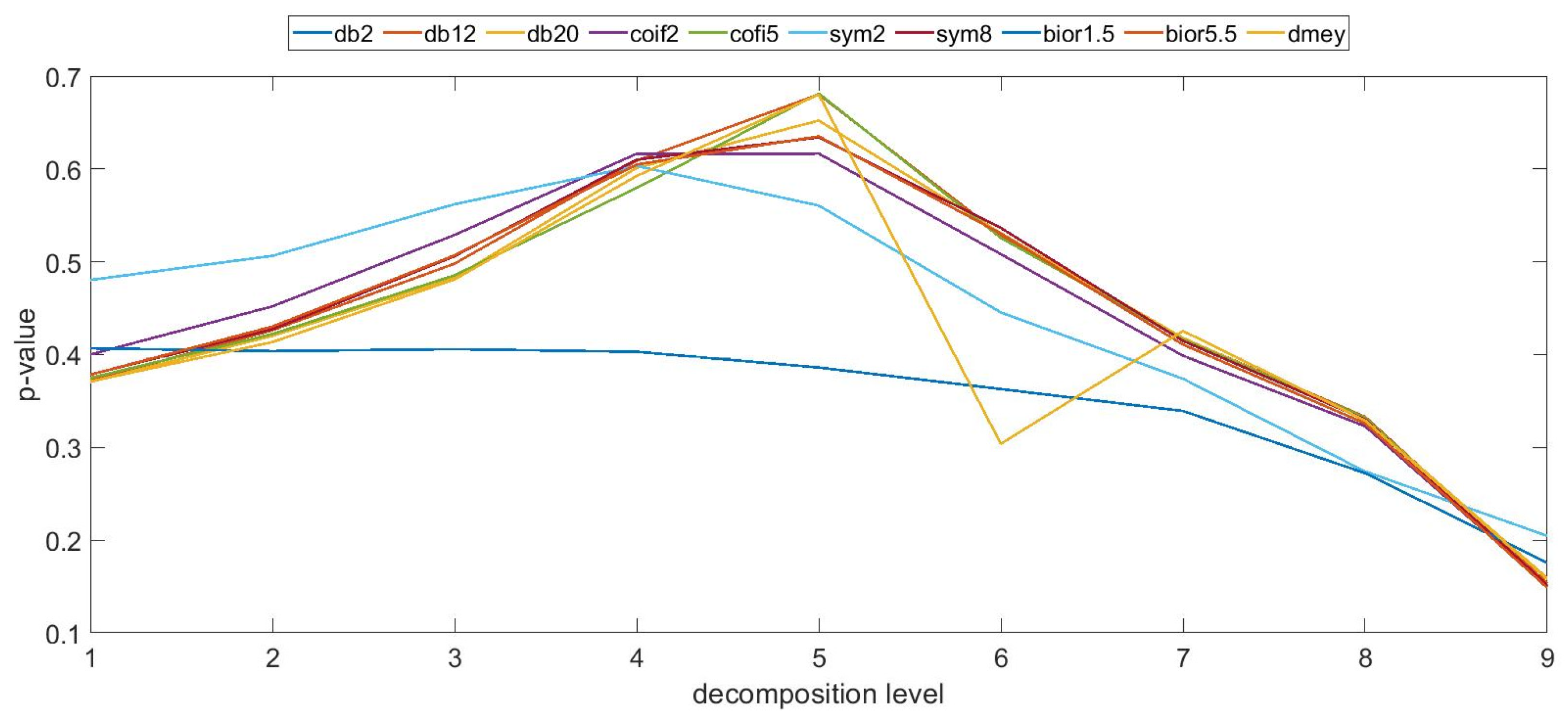

3. Results and Discussion

4. Conclusions

- Studies have shown that the impact of the forming process is relatively small. Changes have been noted for both high-frequency information and low-frequency information, with varying intensity. Changes occurred in the irregularity schedule caused both by the influence of the forming mass and the forming process, and ANOVA statistical tests, among others, showed that conducting one-hundred forming cycles only slightly affected the variability of the surface topography. These changes were noted for the high-frequency components of the surface irregularities; however, local correlations between the profile before and after the molding process were observed, as well as for subsequent levels of decomposition describing low-frequency information, for which the degree of similarity of the profiles statistically decreased. It can be stated that the forming process had a greater influence on the long-term components of the surface profile.

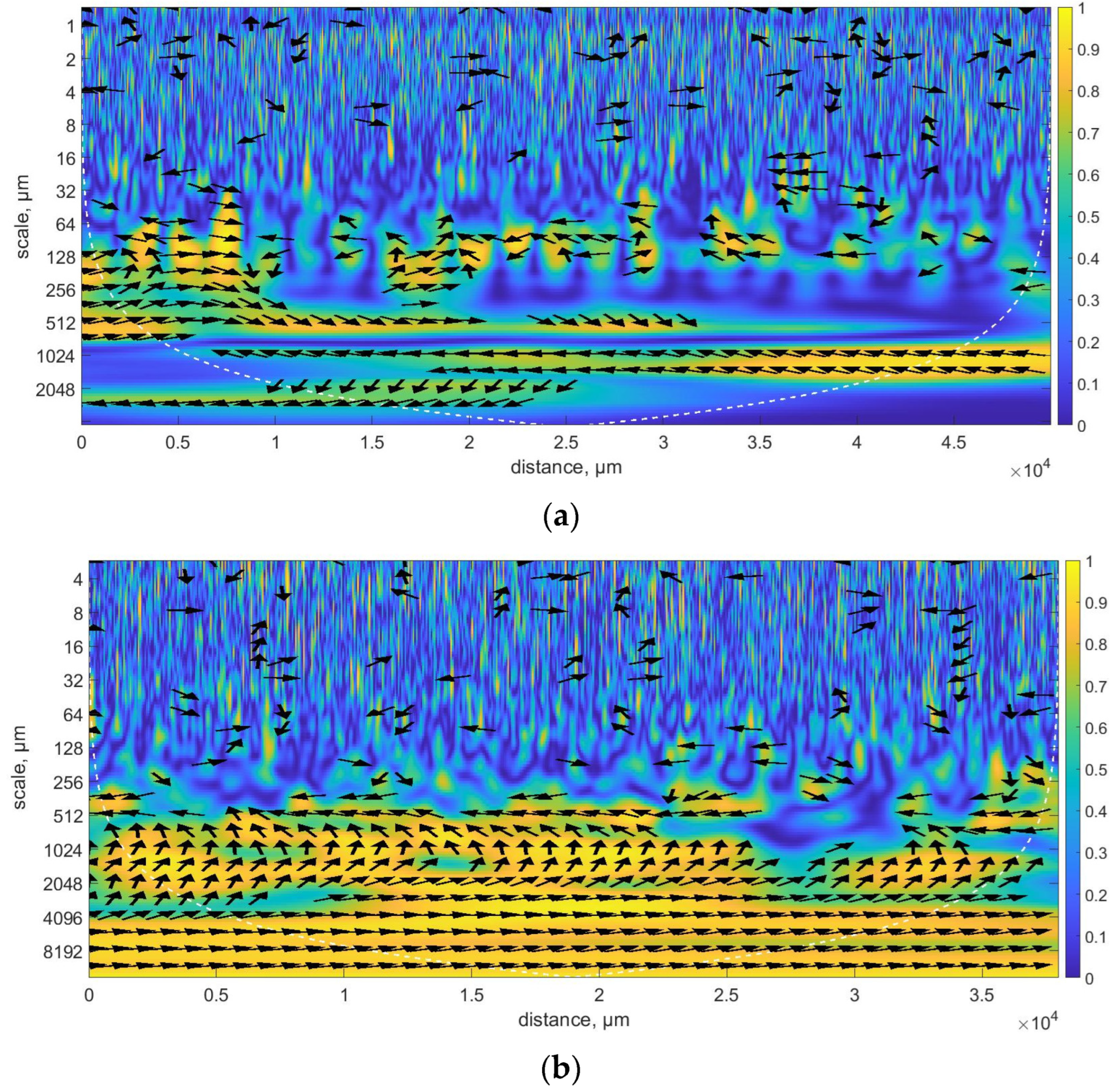

- Assessment of profiles based on continuous wavelet transformation allowed us to conclude that for most of the evaluated samples, high coefficient values were primarily concentrated around the scale of 0.512 mm. Utilizing a continuous approach, it was noted that for low frequencies, there was a phase shift, which could have been reflected in the values obtained in the case of discrete analysis.

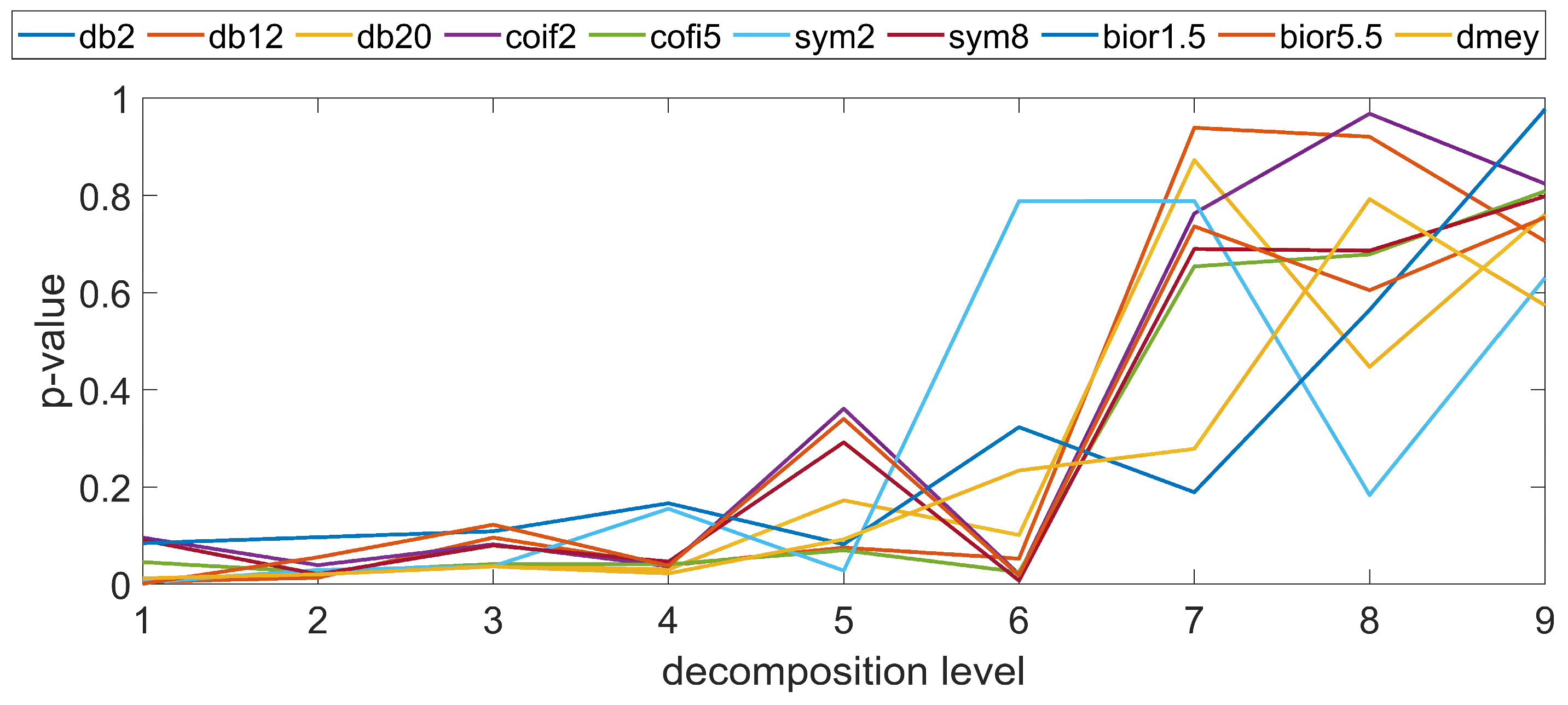

- It should be noted that no significant influence of individual mother wavelets was observed in terms of surface discrimination. The selected forms of wavelets, which were characterized by various properties and filtration capabilities of the profiles, did not allow us to obtain statistically different data for individual levels of wavelet decomposition. The exception was the bior1.5 wavelet, for which significantly different results were obtained, and the dmey wavelet, for which there was an anomaly in the presented values with respect to the other wavelets at the selected level. This may provide a diagnostic indication in terms of the evaluation of the profiles and the impact of the process on the topography variability.

- The studies conducted did not show convergent trends in terms of the impact of the forming process on the variability of the surface topography with respect to the manufacturing method. It can be observed that for individual samples produced using specific technological parameters, the conducted wavelet analysis resulted in the detection of dependencies in individual frequency bands and scales, but functional dependencies did not occur, and individual cases appeared randomly depending on the manufacturing technology and applied parameters. This research enhances the practical applicability of new surface irregularity assessment techniques developed within the framework of Metrology 4.0, and it increases the practical use of additive technologies in relation to their application in the casting industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| biorNr.Nd | Mother wavelet biorthogonal, Nr defines wavelet order of scaling functions used for reconstruction; Nd defines the wavelet order of the functions used for decomposition |

| coifN | Mother wavelet Coiflet, N defines the number of vanishing moments |

| dbN | Mother wavelet Daubechies, N defines the number of vanishing moments |

| dmey | Discrete Meyer wavelet |

| FDM | Fused Deposition Modelling |

| Lt | Layer thickness |

| PJM | PolyJet Matrix |

| SLS | Selective Laser Sintering |

| symN | Mother wavelet Symlet, N defines the number of vanishing moments |

| ψ(x) | Mother wavelet |

References

- Singh, S.; Singh, R. Fused deposition modelling based rapid patterns for investment casting applications: A review. Rapid Prototyp. J. 2016, 22, 123–143. [Google Scholar] [CrossRef]

- Tang, S.-Y.; Yang, L.; Fan, Z.-T.; Jiang, W.-M.; Liu, X.-W. A review of additive manufacturing technology and its application to foundry in China. China Foundry 2021, 18, 249–264. [Google Scholar] [CrossRef]

- Turek, P.; Budzik, G.; Sęp, J.; Oleksy, M.; Józwik, J.; Przeszłowski, Ł.; Paszkiewicz, A.; Kochmański, Ł.; Żelechowski, D. An Analysis of the Casting Polymer Mold Wear Manufactured Using PolyJet Method Based on the Measurement of the Surface Topography. Polymers 2020, 12, 3029. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A review of vat photopolymerization technology: Materials, applications, challenges, and future trends of 3d printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef] [PubMed]

- Mazurkiewicz, M.; Kluczyński, J.; Jasik, K.; Sarzyński, B.; Szachogłuchowicz, I.; Łuszczek, J.; Torzewski, J.; Śnieżek, L.; Grzelak, K.; Małek, M. Bending Strength of Polyamide-Based Composites Obtained during the Fused Filament Fabrication (FFF) Process. Materials 2022, 15, 5079. [Google Scholar] [CrossRef]

- Boontherawara, P.; Chaijareenont, P. Comparing the trueness of 3D printing and conventional casting for the fabrication of removable partial denture metal frameworks for patients with different palatal vault depths: An in vitro study. J. Prosthet. Dent. 2024, 132, 434.e1–434.e6. [Google Scholar] [CrossRef] [PubMed]

- Hobbis, D.; Armstrong, M.D.; Patel, S.H.; Tegtmeie, R.C.; Laughlin, B.S.; Chitsazzadeh, S.; Clouser, E.L.; Smetanick, J.L.; Pettit, J.; Gagneur, J.D.; et al. Comprehensive clinical implementation, workflow, and FMEA of bespoke silicone bolus cast from 3D printed molds using open-source resources. J. Appl. Clin. Med. Phys. 2024, e14498. [Google Scholar] [CrossRef]

- Resende, C.C.D.; Barbosa, T.A.Q.; Moura, G.F.; Rizzante, F.A.P.; Gonzaga, L.H.; Januario, A.L.; Mendonça, G.; das Neves, F.D.; Zancopé, K. Accuracy of Conventional and 3D-Printed Casts for Partial Fixed Prostheses. Int. J. Prosthodont. 2024, 37, 13–17. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.; Ma, Q. The role and impact of 3D printing technologies in casting. China Foundry 2017, 14, 157–168. [Google Scholar] [CrossRef]

- Zmarzły, P.; Gogolewski, D.; Kozior, T. Assessment of surface waviness of casting patterns made using 3D printing technologies. Bull. Pol. Acad. Sci. Tech. Sci. 2023, 71, 144585. [Google Scholar] [CrossRef]

- Royan, M.; Soemowidagdo, A.L.; Sasongko, B.T.; Pradana, D.A. FDM 3D printing application for making plate patterns on sand casting. J. Eng. Appl. Technol. 2023, 4, 67–77. [Google Scholar] [CrossRef]

- Gogolewski, D. Multiscale assessment of additively manufactured free-form surfaces. Metrol. Meas. Syst. 2023, 30, 157–168. [Google Scholar] [CrossRef]

- Pagani, L.; Qi, Q.; Jiang, X.; Scott, P.J. Towards a new definition of areal surface texture parameters on freeform surface. Measurement 2017, 109, 281–291. [Google Scholar] [CrossRef]

- Leach, R.; Thompson, A.; Senin, N.; Maskery, I. A metrology horror story: The additive surface. In Proceedings of the ASPEN/ASPE Spring Topical Meeting on Manufacture and Metrology of Structured and Freeform Surfaces for Functional Applications, Hong Kong, China, 14–17 March 2017. [Google Scholar]

- Gogolewski, D.; Zmarzły, P.; Kozior, T.; Mathia, T.G. Possibilities of a Hybrid Method for a Time-Scale-Frequency Analysis in the Aspect of Identifying Surface Topography Irregularities. Materials 2023, 16, 1228. [Google Scholar] [CrossRef]

- Maleki, I.; Wolski, M.; Woloszynski, T.; Podsiadlo, P.; Stachowiak, G. A comparison of multiscale surface curvature characterization methods for tribological surfaces. Tribol. Online 2019, 14, 8–17. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, M.; Zhang, P.; Geng, G.; Liu, X.; Zhang, H. Skull Sex Estimation Based on Wavelet Transform and Fourier Transform. BioMed Res. Int. 2020, 2020, 8608209. [Google Scholar] [CrossRef]

- Li, G.; Zhang, K.; Gong, J.; Jin, X. Calculation method for fractal characteristics of machining topography surface based on wavelet transform. Procedia CIRP 2019, 79, 500–504. [Google Scholar] [CrossRef]

- Sun, J.; Song, Z.; He, G.; Sang, Y. An improved signal determination method on machined surface topography. Precis. Eng. 2018, 51, 338–347. [Google Scholar] [CrossRef]

- Seid Ahmed, Y.; Arif, A.F.M.; Veldhuis, S.C. Application of the wavelet transform to acoustic emission signals for built-up edge monitoring in stainless steel machining. Measurement 2020, 154, 107478. [Google Scholar] [CrossRef]

- Mahashar Ali, J.; Siddhi Jailani, H.; Murugan, M. Surface roughness evaluation of electrical discharge machined surfaces using wavelet transform of speckle line images. Measurement 2020, 149, 107029. [Google Scholar] [CrossRef]

- Peta, K.; Bartkowiak, T.; Galek, P.; Mendak, M. Contact angle analysis of surface topographies created by electric discharge machining. Tribol. Int. 2021, 163, 107139. [Google Scholar] [CrossRef]

- Yesilli, M.C.; Chen, J.; Khasawneh, F.A.; Guo, Y. Automated surface texture analysis via Discrete Cosine Transform and Discrete Wavelet Transform. Precis. Eng. 2022, 77, 141–152. [Google Scholar] [CrossRef]

- Gogolewski, D. Multiscale Data Treatment in Additive Manufacturing. Materials 2023, 16, 3168. [Google Scholar] [CrossRef]

- Brown, C.A.; Hansen, H.N.; Jiang, X.J.; Blateyron, F.; Berglund, J.; Senin, N.; Bartkowiak, T.; Dixon, B.; Le Goïc, G.; Quinsat, Y.; et al. Multiscale analyses and characterizations of surface topographies. CIRP Ann. 2018, 67, 839–862. [Google Scholar] [CrossRef]

- Xue, H.; Li, G.; Qi, D.; Ni, H. Temporal Evolution, Oscillation and Coherence Characteristics Analysis of Global Solar Radiation Distribution in Major Cities in China’ s Solar-Energy-Available Region Based on Continuous Wavelet Transform. Appl. Sci. 2024, 14, 4794. [Google Scholar] [CrossRef]

- Varanis, M.; Balthazar, J.M.; Tusset, A.M.; Ribeiro, M.A.; Oliveira, C. Signal Analysis in Chaotic Systems: A Comprehensive Assessment through Time-Frequency Analysis. In New Insights on Oscillators and Their Applications to Engineering and Science; Intechopen: London, UK, 2024; pp. 1–22. [Google Scholar]

- Otazu, X.; Ribo, M.; Peracaula, M.; Paredes, J.M.; Nunez, J. Detection of superimposed periodic signals using wavelets. Mon. Not. R. Astron. Soc. 2002, 372, 365–372. [Google Scholar] [CrossRef]

- Adamczak, S.; Makieła, W.; Stepień, K. Investigating advantages and disadvantages of the analysis of a geometrical surface structure with the use of fourier and wavelet transform. Metrol. Meas. Syst. 2010, 17, 233–244. [Google Scholar] [CrossRef]

- ISO/ASTM 52900; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2021.

- Edjeou, W.; Cerezo, V.; Zahouani, H.; Salvatore, F. Multiscale analyses of pavement texture during polishing. Surf. Topogr. Metrol. Prop. 2020, 8, 024008. [Google Scholar] [CrossRef]

- Misiti, M.; Misiti, Y.; Oppenheim, G.; Poggi, J.-M. MathWorks Wavelet Toolbox User’s Guide; MathWorks, Inc.: Natick, MA, USA, 2015. [Google Scholar]

- Gogolewski, D.; Kozior, T.; Zmarzły, P. Multiscale Analysis of Surface Topography in Foundry Aspects. In Proceedings of the Proceedings—ASPE 2023 Annual Meeting, Boston, MA, USA, 12–17 November 2023; pp. 342–345. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gogolewski, D.; Kozior, T.; Zmarzły, P. Multiscale Analysis of Surface Topography for Engineering Applications in the Casting Industry. Materials 2024, 17, 5272. https://doi.org/10.3390/ma17215272

Gogolewski D, Kozior T, Zmarzły P. Multiscale Analysis of Surface Topography for Engineering Applications in the Casting Industry. Materials. 2024; 17(21):5272. https://doi.org/10.3390/ma17215272

Chicago/Turabian StyleGogolewski, Damian, Tomasz Kozior, and Paweł Zmarzły. 2024. "Multiscale Analysis of Surface Topography for Engineering Applications in the Casting Industry" Materials 17, no. 21: 5272. https://doi.org/10.3390/ma17215272

APA StyleGogolewski, D., Kozior, T., & Zmarzły, P. (2024). Multiscale Analysis of Surface Topography for Engineering Applications in the Casting Industry. Materials, 17(21), 5272. https://doi.org/10.3390/ma17215272