Applicability of Hf-Free 247LC as a Filler Metal for Hot Crack-Free 247LC Superalloy Welds Assisted by Varestraint Testing

Abstract

1. Introduction

2. Materials and Methods

2.1. Hf- and B-Free 247LC Superalloys

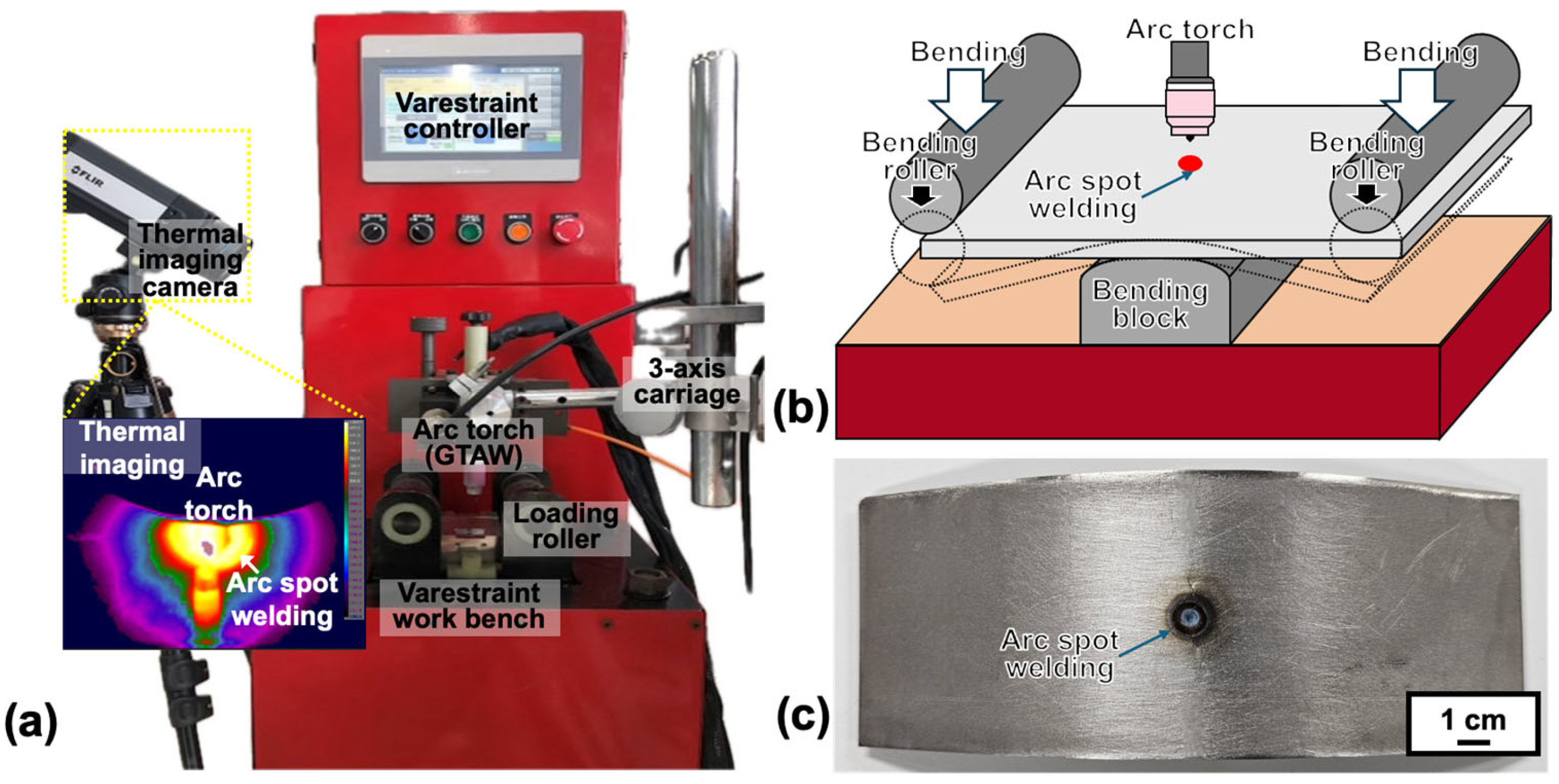

2.2. Spot-Varestraint Weld Cracking Test

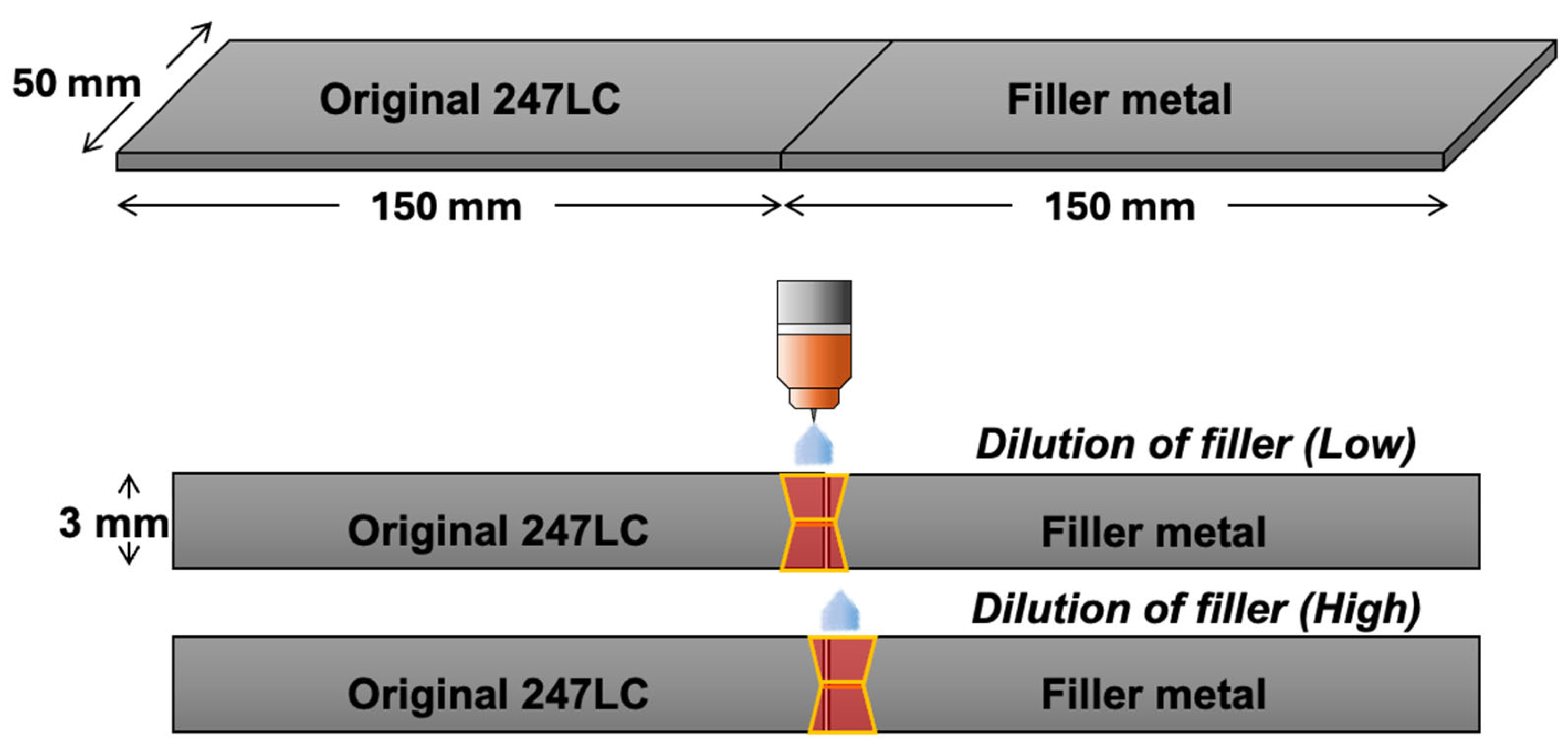

2.3. Double-Square-Groove Welding

2.4. Microstructural Analysis

3. Results and Discussion

3.1. Liquation Cracking Behavior of Hf- and B-Free 247LC Superalloy Welds

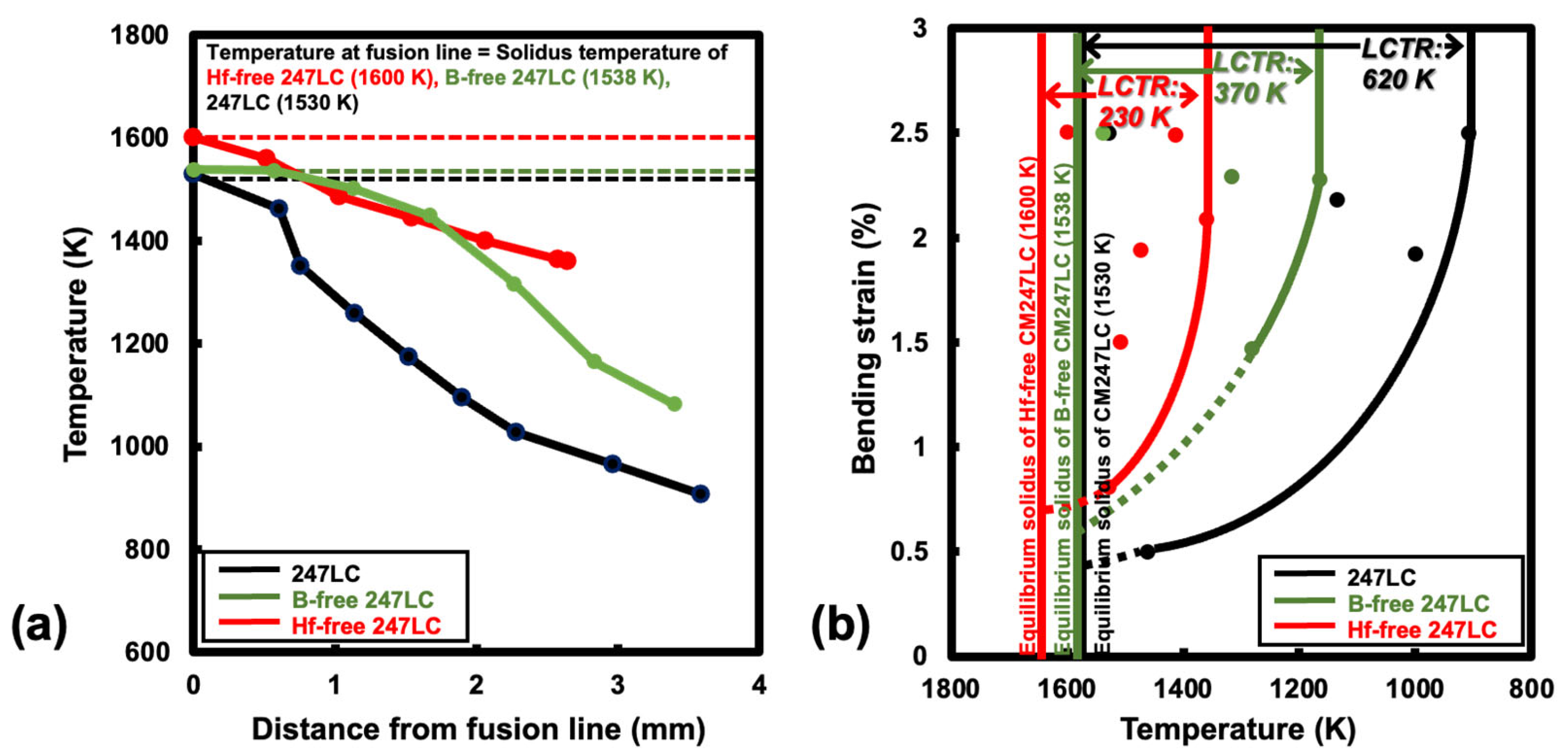

3.2. Effect of Hf and B Removal on LCTR

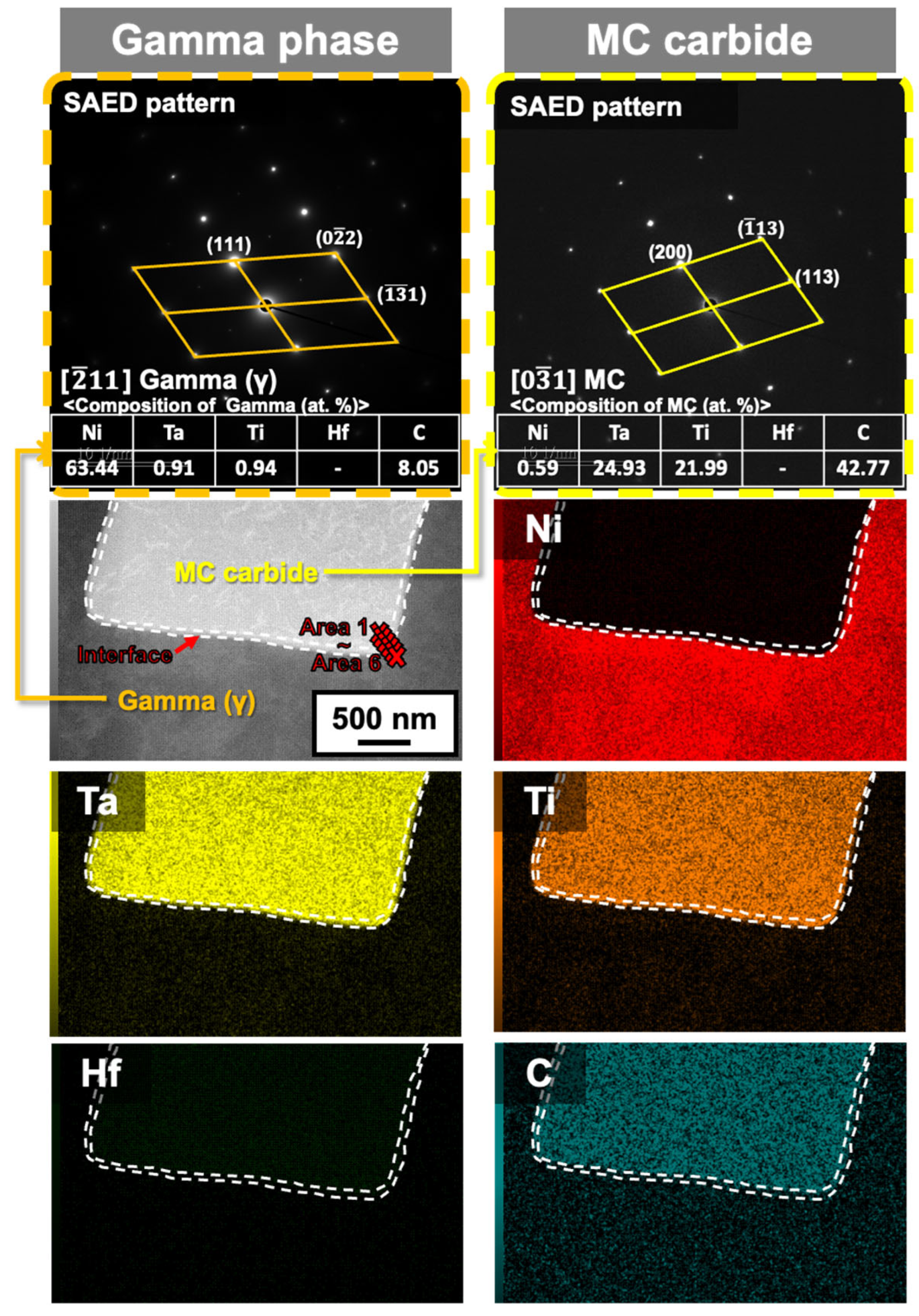

3.3. Welding Metallurgical Mechanism of Reduced LCTR in Hf-Free 247LC Superalloy Welds

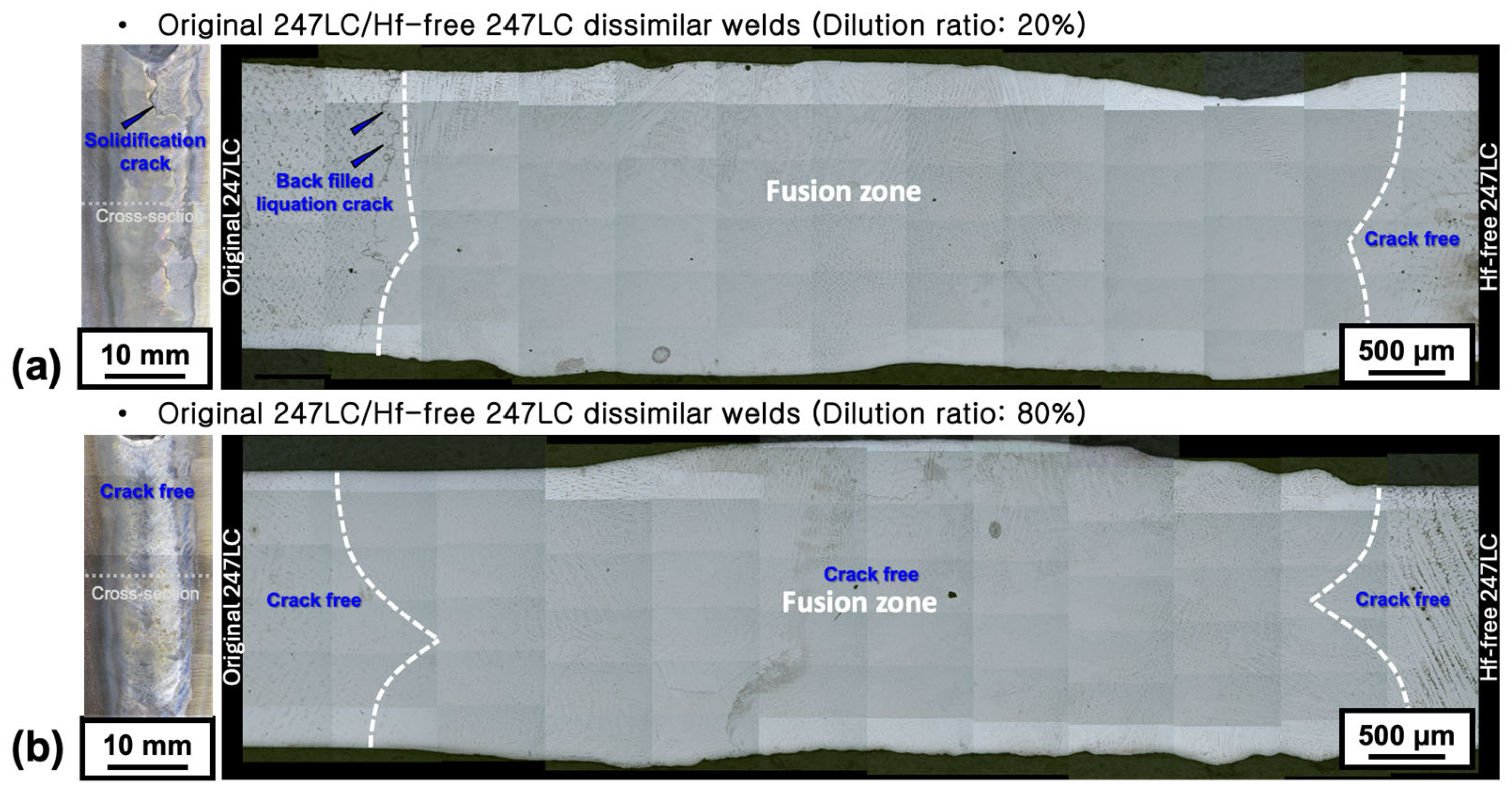

3.4. Weldingvalidation of Hf-Free 247LC Filler Metal Hot Crack-Free 247LC Superalloy Welds

4. Conclusions

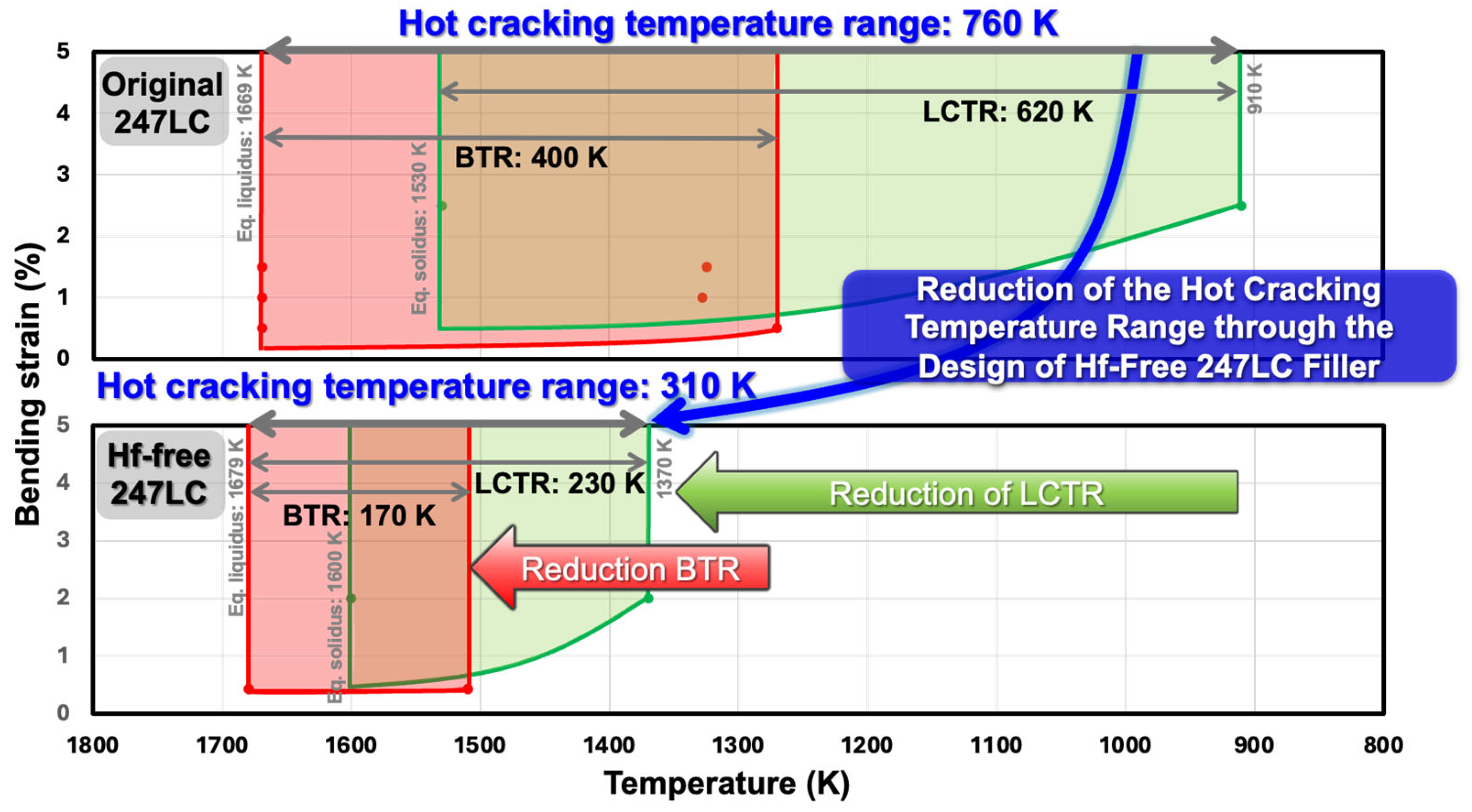

- The as-cast Hf-free 247LC alloy exhibited an LCTR of 230 K, which is approximately 390 K lower than that (620 K) of the original 247LC alloy. This reduction indicates that the Hf-free 247LC alloy has a higher resistance to liquation cracking than the original alloy.

- Microstructural analysis of the crack surfaces indicated that liquation cracking in the Hf-free 247LC alloy primarily occurred at the γ/MC interface. The liquation initiation temperature for the Hf-free alloy was between 1460 and 1600 K, which was significantly higher than the liquation initiation temperature range of 1125–1356 K observed for the original Hf-containing 247LC alloy. The higher liquation initiation temperature of the Hf-free alloy was correlated with its reduced LCTR and contributed to its lower liquation cracking susceptibility.

- Based on these results, the welding validation of Hf-free 247LC filler metal was conducted by performing double square groove welding with the original composition of the 247LC alloy. The Hf-free 247LC filler metal demonstrated excellent weldability in terms of both liquation and solidification cracking susceptibilities, effectively suppressing both types of hot cracking. Namely, these results make it a promising candidate for the manufacturing and repair of gas turbine blades and other critical components.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tan, Q.; Liu, K.; Li, J.; Geng, S.; Sun, L.; Skuratov, V. A review on cracking mechanism and suppression strategy of nickel-based superalloys during laser cladding. J. Alloys Compd. 2024, 1001, 175164. [Google Scholar] [CrossRef]

- Bidron, G.; Doghri, A.; Malot, T.; Fournier-dit-Chabert, F.; Thomas, M.; Peyre, P. Reduction of the hot cracking sensitivity of CM-247LC superalloy processed by laser cladding using induction preheating. J. Mater. Process. Technol. 2020, 277, 116461. [Google Scholar] [CrossRef]

- Kim, I.S.; Choi, B.G.; Seo, S.M.; Kim, D.H.; Jo, C.Y. Influence of heat treatment on microstructure and tensile properties of conventionally cast and directionally solidified superalloy CM247LC. Mater. Lett. 2008, 6–7, 1110–1113. [Google Scholar] [CrossRef]

- Zhang, J.; Singer, R.F. Hot tearing of nickel-based superalloys during directional solidification. Acta Mater. 2002, 7, 1869–1879. [Google Scholar] [CrossRef]

- Senger, A.; Jokisch, T.; Olschok, S.; Reisgen, U.; Fischer, T. Hot-cracks reduction during laser beam welding in vacuum of conventionally cast Alloy-247 LC. Proc. CIRP 2020, 94, 632–637. [Google Scholar] [CrossRef]

- Jokisch, T.; Doynov, N.; Ossenbrink, R.; Michailov, V. Analysis of local strain evolution during electron beam welding of hot crack sensitive nickel base conventionally cast alloy 247 LC CC. J. Mater. Eng. Perform. 2022, 31, 7009–7017. [Google Scholar] [CrossRef]

- Alhuzaim, A.; Imbrogno, S.; Attallah, M.M. Direct laser deposition of crack-free CM247LC thin walls: Mechanical properties and microstructural effects of heat treatment. Mater. Des. 2021, 1, 110123. [Google Scholar] [CrossRef]

- Kim, K.M.; Lee, U.; Lee, H.; Seo, S.M.; Chun, E.J. Quantifying susceptibility to solidification cracking in oscillated CM247LC superalloy welds via Varestraint testing. Met. Mater. Int. 2023, 29, 777–794. [Google Scholar] [CrossRef]

- Chun, E.J. Strategy of suppressing the solidification cracking susceptibility of 247LC superalloy weld metals using commercial Ni-based fillers. J. Weld. Join. 2023, 41, 64–72. [Google Scholar] [CrossRef]

- Lee, S.J.; Seo, S.M.; Chun, E.J. Effects of Hf and carbides formation behavior on the weld solidification cracking susceptibility of 247LC superalloy. Mater. Chem. Phys. 2024, 316, 129147. [Google Scholar] [CrossRef]

- Jeong, H.E.; Seo, S.M.; Chun, E.J. Effect of local carbide formation behavior on repair weld liquation cracking susceptibility for long-term-serviced 247LC superalloy. J. Mater. Res. Technol. 2024, 28, 110–122. [Google Scholar] [CrossRef]

- Osoba, L.O.; Sidhu, R.K.; Ojo, O.A. On preventing HAZ cracking in laser welded DS rene 80 superalloy. Mater. Sci. Tech. 2011, 5, 897–902. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, Y.; Shan, J.; Wu, A.; Sato, Y.; Tokita, S.; Kadoi, K.; Inoue, H.; Gu, H.; Tang, X. The role of shot peening on liquation cracking in laser cladding of K447A nickel superalloy powders over its non-weldable cast structure. Mater. Sci. Eng. A 2021, 17, 141678. [Google Scholar] [CrossRef]

- Zhang, G.; Xiao, C.; Taheri, M. Effect of Nd:YAG pulsed laser welding process on the liquation and strain-age cracking in GTD-111 superalloy. J. Manuf. Process. 2020, 52, 66–78. [Google Scholar] [CrossRef]

- Adegoke, O.; Andersson, J.; Brodin, H.; Pederson, R.; Harlin, P. Influence of laser powder bed fusion process parameters on the microstructure and cracking susceptibility of nickel-based superalloy. Results Mater. 2022, 13, 100256. [Google Scholar] [CrossRef]

- Carter, N.; Martin, C.; Withers, J.; Attallah, M. The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. J. Alloys Compd. 2014, 615, 338–347. [Google Scholar] [CrossRef]

- Gerstgrasser, M.; Cloots, M.; Stirnimann, J.; Wegener, K. Focus shift analysis, to manufacture dense and crack-free SLM-processed CM247LC samples. J. Mater. Process. Technol. 2021, 289, 116948. [Google Scholar] [CrossRef]

- Adegoke, O.; Andersson, J.; Brodin, H.; Pederson, R. Influence of laser powder bed fusion process parameters on voids, cracks, and microhardness of Nickel-based superalloy alloy 247LC. Materials 2020, 13, 3770. [Google Scholar] [CrossRef]

- Griffiths, S.; Tabasi, H.; Ivas, T.; Maeder, X.; Luca, A.; Zweiacker, K.; Wróbel, R.; Jhabvala, J.; Logé, R.; Leinenbach, C. Alloys-by-design: Application to new superalloys for additive manufacturing. Acta Mater. 2021, 202, 417–436. [Google Scholar]

- Griffiths, S.; Tabasi, H.; Ivas, T.; Maeder, X.; Luca, A.; Zweiacker, K.; Wróbel, R.; Jhabvala, J.; Logé, R.; Leinenbach, C. Combining alloy and process modification for micro-crack mitigation in an additively manufactured Ni-base superalloy. Addit. Manuf. 2020, 36, 101443. [Google Scholar] [CrossRef]

- Griffiths, S.; Tabasi, H.G.; Luca, A.D.; Pado, J.; Joglekar, S.; Jhabvala, J.; Logé, R.; Leinenbach, C. Influence of Hf on the heat treatment response of additively manufactured Ni-base superalloy CM247LC. Mater. Charact. 2021, 171, 110815. [Google Scholar] [CrossRef]

- Statharas, D.; Atkinson, H.; Thornton, R.; Marsden, J.; Dong, H.; Wen, S. Getting the strain under control: Trans-Varestraint tests for hot cracking susceptibility. Metall. Mater. Trans. A 2019, 50, 1748–1762. [Google Scholar] [CrossRef]

- Kannengiesser, T.; Boellinghaus, T. Hot cracking tests—An overview of present technologies and applications. Weld. World 2014, 58, 397–421. [Google Scholar] [CrossRef]

- Savage, W.F.; Nippes, E.F.; Goodwin, G.M. Effect of minor elements on hot-cracking tendencies of Inconel 600. Weld. J. 1977, 56, 245s–253s. [Google Scholar]

- Lippold, J.C.; Baeslack, W.A.; Varol, I. Heat-affected zone liquation cracking in austenitic and duplex stainless steels. Weld. J. 1992, 71, 1s–14s. [Google Scholar]

- Lippold, J.C.; Kiser, S.D.; DuPont, J.N. Welding Metallurgy and Weldability of Nickel-Base Alloys; Wiley: Hoboken, NJ, USA, 2009; pp. 157–248. [Google Scholar]

- Li, S.; Mao, Y.; Chen, Z.; Sun, K.; Wang, J.; Guo, C.; Huang, Z.; Wang, D.; Attallah, M.; Wang, C. Investigation of the segregation mechanism and mechanical properties of laser powder bed fusioned CM247LC Ni-superalloy. Scr. Mater. 2025, 257, 116482. [Google Scholar] [CrossRef]

| Materials | Ni | Cr | Co | Mo | W | Ta | Ti | Al | C | B | Zr | Hf | P | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 247LC | Bal. | 8.1 | 9.2 | 0.5 | 9.5 | 3.2 | 0.7 | 5.6 | 0.07 | 0.015 | 0.015 | 1.4 | <0.00006 | <0.00002 |

| B-free 247LC | Bal. | 8.3 | 9.3 | 0.5 | 9.6 | 3.3 | 0.8 | 5.6 | 0.07 | 0 | 0.007 | 1.4 | <0.00006 | <0.00002 |

| Hf-free 247LC | Bal. | 8.3 | 9.3 | 0.5 | 9.6 | 3.3 | 0.8 | 5.6 | 0.07 | 0.015 | 0.007 | 0 | <0.00006 | <0.00002 |

| Parameter | Setting |

|---|---|

| Heat source | GTAW |

| Arc voltage (V) | 18 |

| Arc current (A) | 60 |

| Heat input (J/mm) | 648 |

| Arc length (mm) | 2 |

| Welding time (s) | 10 |

| Shielding gas | Ar |

| Bending rate (mm/s) | 400 |

| Bending strain (%) | 2.5 |

| Analysis Points | Ni | Cr | Co | Mo | W | Ta | Ti | Al | C | B | Zr | Hf |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Area #1 | Bal. | 1.68 | 1.21 | 0.34 | 0.84 | 64.61 | 16.96 | 0.21 | 8.11 | - | 0.46 | - |

| Area #2 | Bal. | 2.08 | 1.98 | 0.15 | 1.52 | 61.59 | 16.93 | 0.17 | 7.06 | - | 0.04 | - |

| Area #3 | Bal. | 2.69 | 2.18 | 0.82 | 0.84 | 58.49 | 16.47 | 0.25 | 7.3 | - | 0.86 | - |

| Area #4 | Bal. | 3.74 | 3.71 | 0.32 | 3.29 | 49.88 | 14.64 | 0.47 | 7.11 | - | 0.29 | - |

| Area #5 | Bal. | 5.32 | 4.71 | 0.89 | 3.98 | 40.08 | 11.98 | 0.9 | 6.43 | - | 0.59 | - |

| Area #6 | Bal. | 6.71 | 5.65 | 1.6 | 6.02 | 30.1 | 10.23 | 2.2 | 4.38 | - | 0.2 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-J.; Chun, E.-J. Applicability of Hf-Free 247LC as a Filler Metal for Hot Crack-Free 247LC Superalloy Welds Assisted by Varestraint Testing. Materials 2025, 18, 1284. https://doi.org/10.3390/ma18061284

Lee S-J, Chun E-J. Applicability of Hf-Free 247LC as a Filler Metal for Hot Crack-Free 247LC Superalloy Welds Assisted by Varestraint Testing. Materials. 2025; 18(6):1284. https://doi.org/10.3390/ma18061284

Chicago/Turabian StyleLee, Seong-Jin, and Eun-Joon Chun. 2025. "Applicability of Hf-Free 247LC as a Filler Metal for Hot Crack-Free 247LC Superalloy Welds Assisted by Varestraint Testing" Materials 18, no. 6: 1284. https://doi.org/10.3390/ma18061284

APA StyleLee, S.-J., & Chun, E.-J. (2025). Applicability of Hf-Free 247LC as a Filler Metal for Hot Crack-Free 247LC Superalloy Welds Assisted by Varestraint Testing. Materials, 18(6), 1284. https://doi.org/10.3390/ma18061284