A Comparative Analysis of ProTaper Ultimate and Five Multifile Systems: Design, Metallurgy, and Mechanical Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples Selection

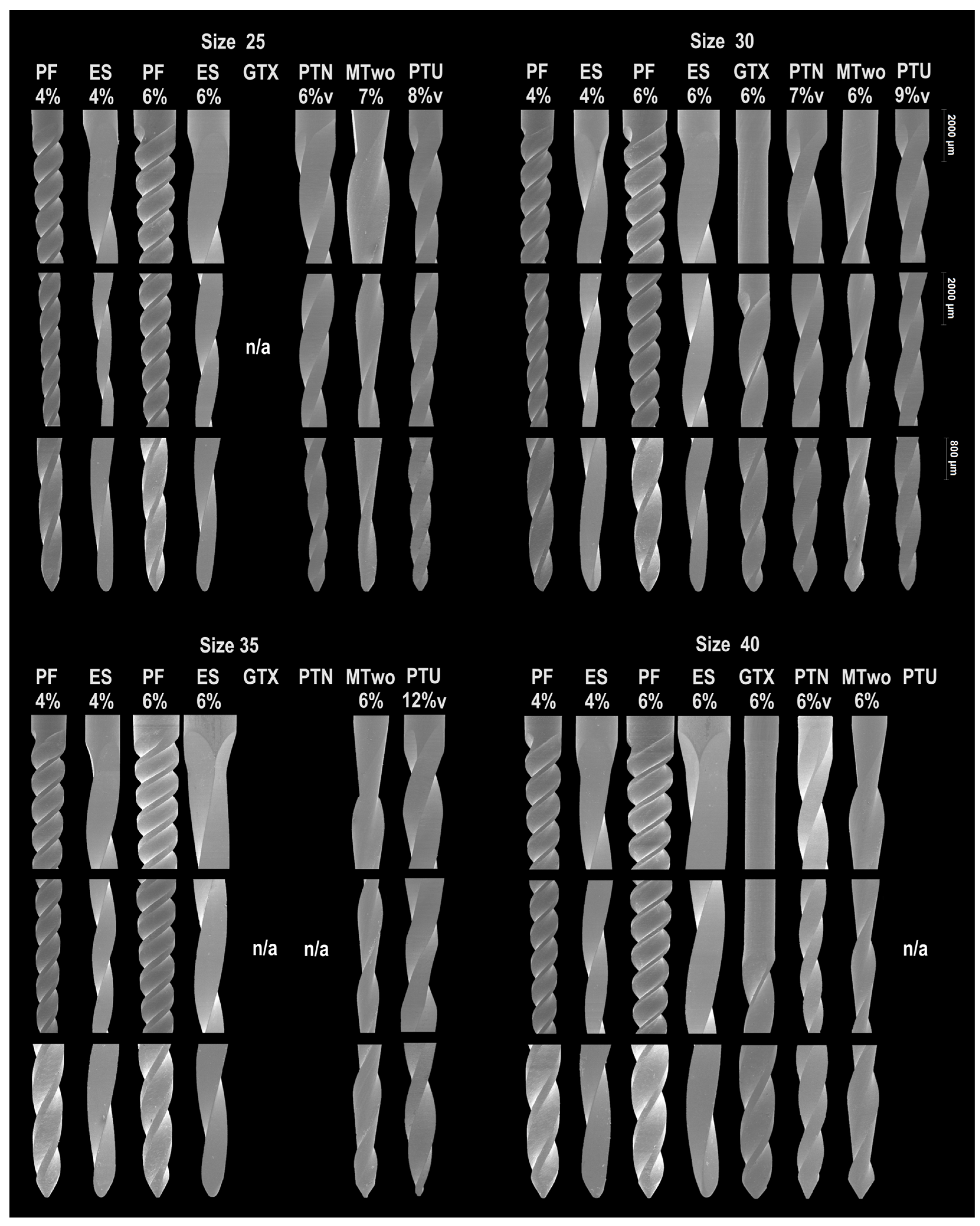

2.2. Design Assessment

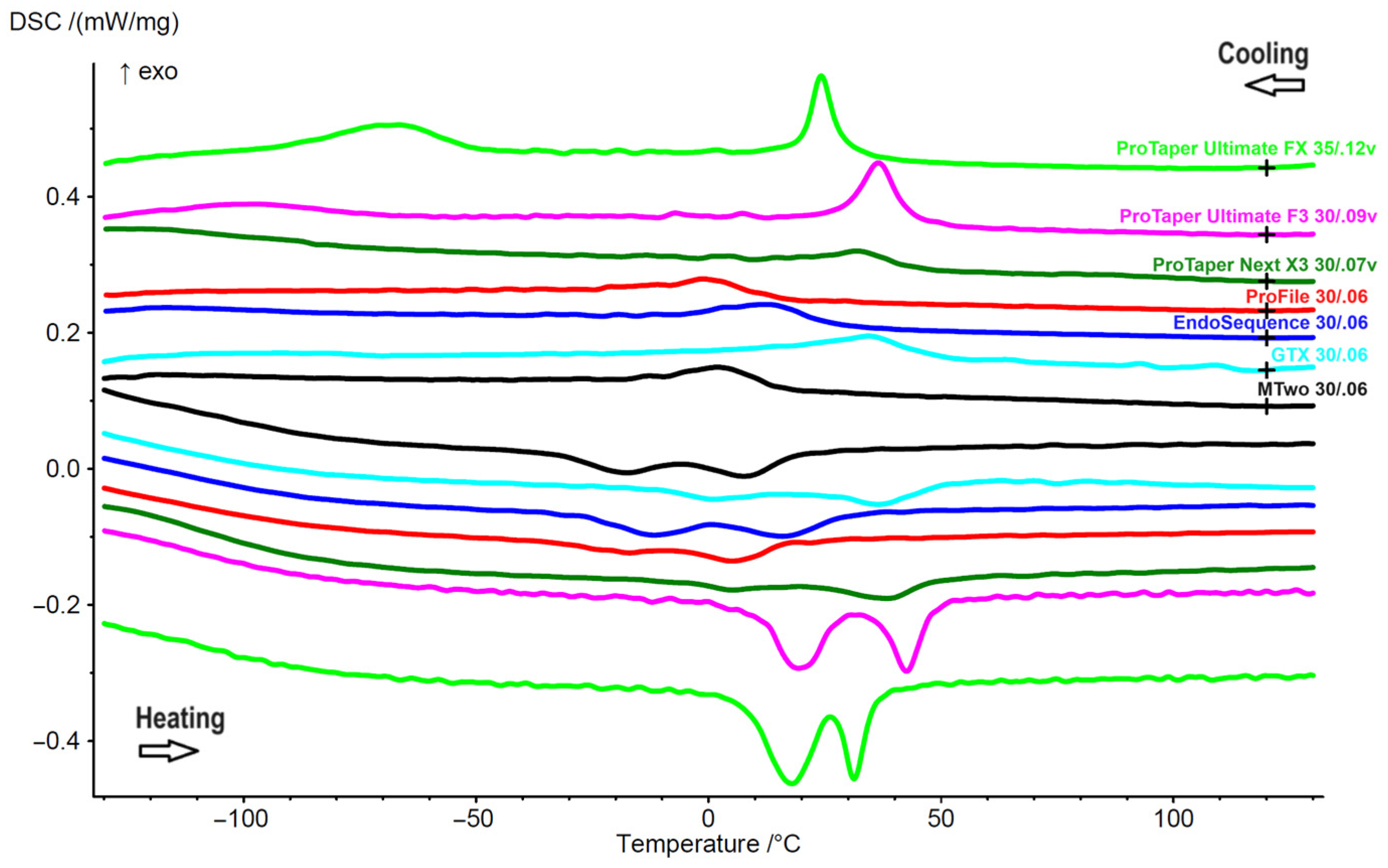

2.3. Metallurgical Characteristics

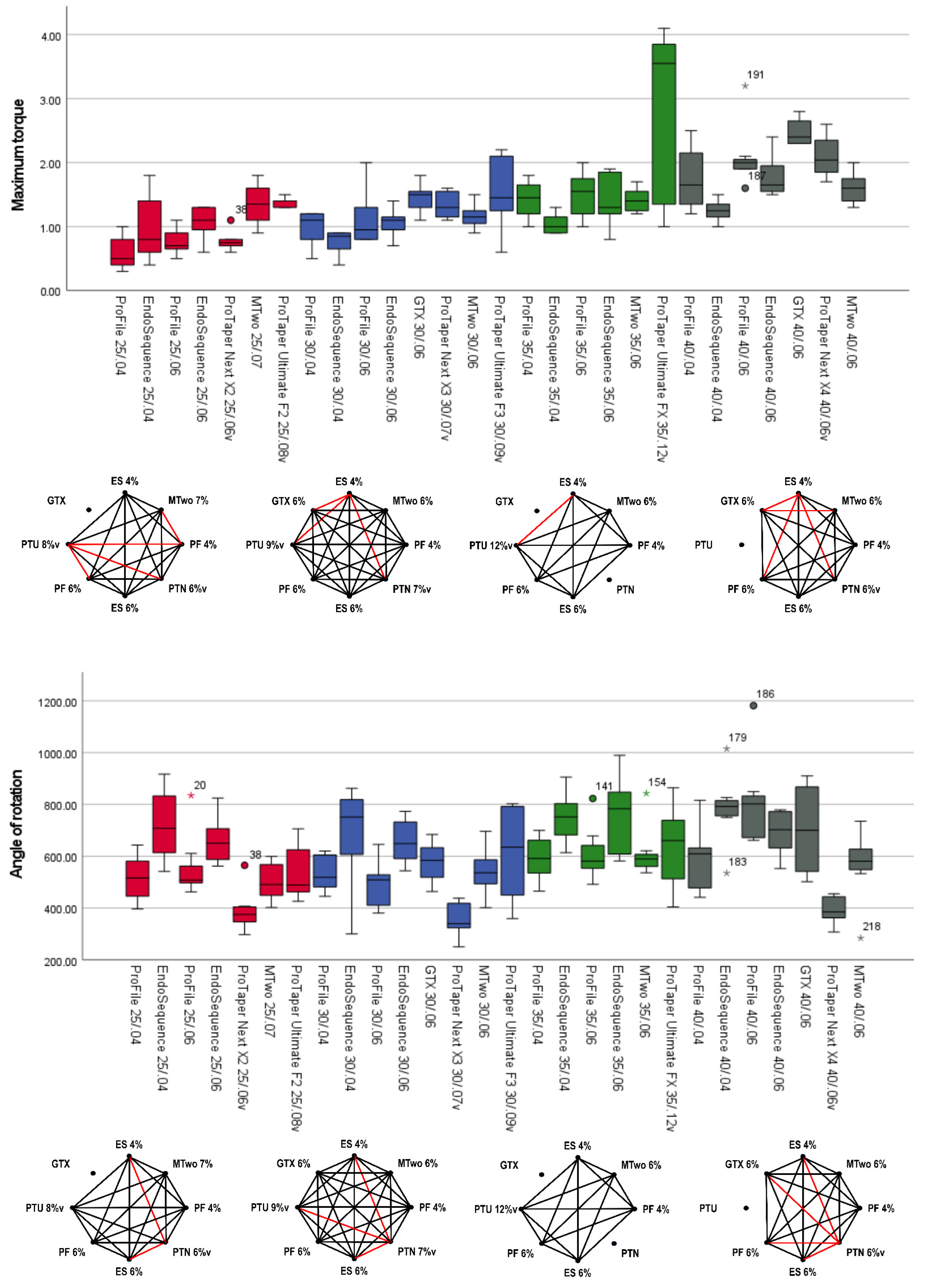

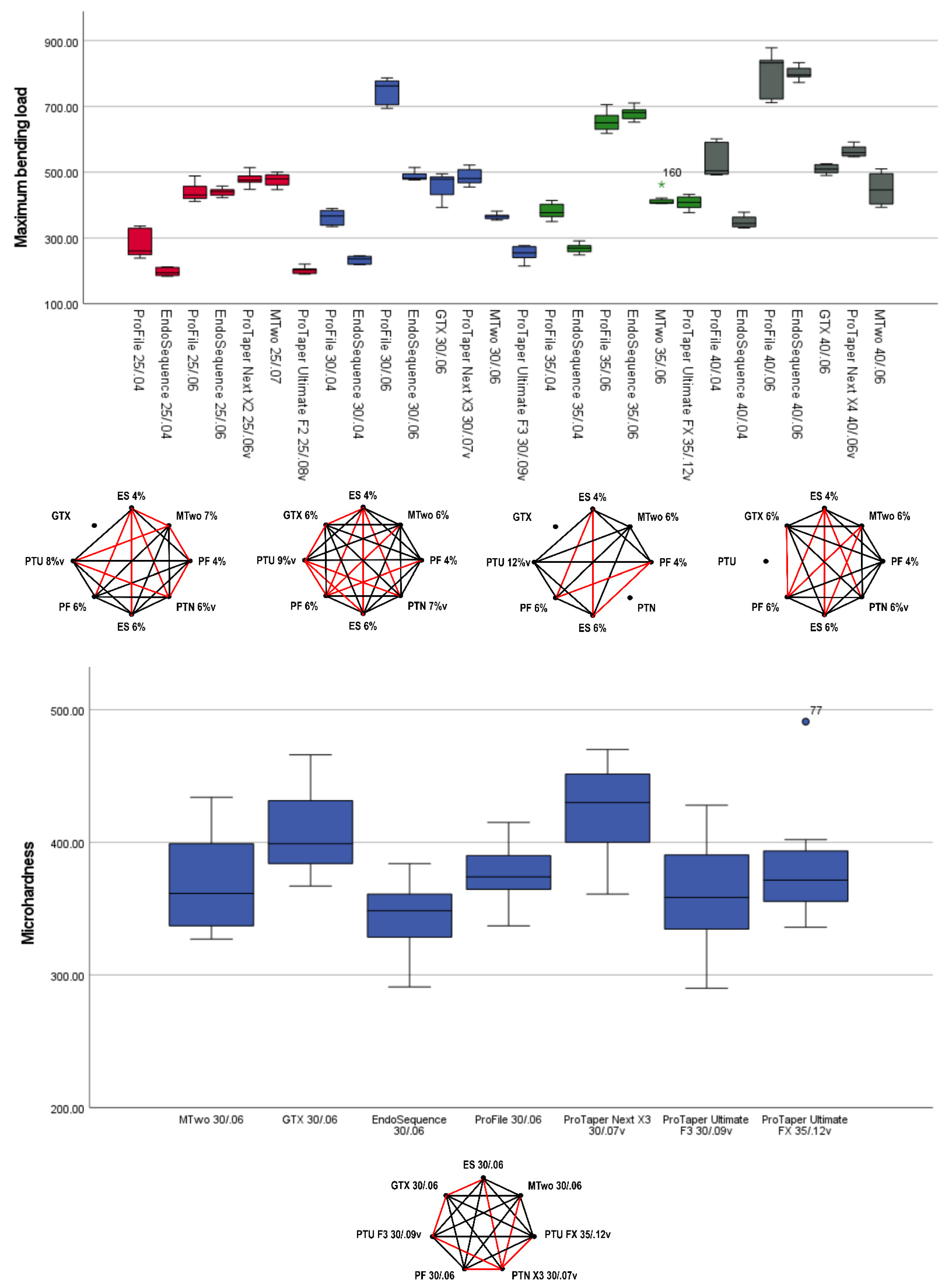

2.4. Mechanical Performance

2.5. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hülsmann, M.; Peters, O.A.; Dummer, P.M. Mechanical preparation of root canals: Shaping goals, techniques, and means. Endod. Top. 2005, 10, 30–76. [Google Scholar] [CrossRef]

- Zhou, H.; Peng, B.; Zheng, Y. An overview of the mechanical properties of nickel–titanium endodontic instruments. Endod. Top. 2013, 29, 42–54. [Google Scholar] [CrossRef]

- Gomes, M.S.; Vieira, R.M.; Bottcher, D.E.; Plotino, G.; Celeste, R.K.; Rossi-Fedele, G. Clinical fracture incidence of rotary and reciprocating NiTi files: A systematic review and meta-regression. Aust. Endod. J. 2021, 47, 372–385. [Google Scholar] [CrossRef]

- Martins, J.N.; Silva, E.J.; Marques, D.; Belladonna, F.G.; Simões-Carvalho, M.; da Costa, R.P.; Ginjeira, A.; Braz Fernandes, F.M.; Versiani, M.A. Comparison of five rotary systems regarding design, metallurgy, mechanical performance, and canal preparation—A multimethod research. Clin. Oral Investig. 2022, 26, 3299–3310. [Google Scholar] [CrossRef]

- McSpadden, J.T. Mastering Instrument Designs. In Mastering Endodontics Instrumentation; McSpadden, J.T., Ed.; Cloudland Institute: Chattanooga, TN, USA, 2007; pp. 37–97. [Google Scholar]

- Hsu, Y.Y.; Kim, S. The ProFile system. Dent. Clin. N. Am. 2004, 48, 69–85. [Google Scholar] [CrossRef]

- Lloyd, A. Root canal instrumentation with ProFile instruments. Endod. Top. 2005, 10, 151–154. [Google Scholar] [CrossRef]

- Buchanan, L. ProSystem GT: Design, technique, and advantages. Endod. Top. 2005, 10, 168–175. [Google Scholar] [CrossRef]

- Yamamura, B.; Cox, T.C.; Heddaya, B.; Flake, N.M.; Johnson, J.D.; Paranjpe, A. Comparing canal transportation and centering ability of EndoSequence and Vortex rotary files by using micro-computed tomography. J. Endod. 2012, 38, 1121–1125. [Google Scholar] [CrossRef]

- Elnaghy, A.M. Cyclic fatigue resistance of ProTaper Next nickel-titanium rotary files. Int. Endod. J. 2014, 47, 1034–1039. [Google Scholar] [CrossRef] [PubMed]

- Elnaghy, A.M.; Elsaka, S.E. Assessment of the mechanical properties of ProTaper Next Nickel-titanium rotary files. J. Endod. 2014, 40, 1830–1834. [Google Scholar] [CrossRef] [PubMed]

- Schäfer, E.; Erler, M.; Dammaschke, T. Comparative study on the shaping ability and cleaning efficiency of rotary Mtwo instruments. Part 1. Shaping ability in simulated curved canals. Int. Endod. J. 2006, 39, 196–202. [Google Scholar] [CrossRef] [PubMed]

- Bürklein, S.; Hiller, C.; Huda, M.; Schäfer, E. Shaping ability and cleaning effectiveness of Mtwo versus coated and uncoated EasyShape instruments in severely curved root canals of extracted teeth. Int. Endod. J. 2011, 44, 447–457. [Google Scholar] [CrossRef] [PubMed]

- Locke, M.; Thomas, M.B.; Dummer, P.M. A survey of adoption of endodontic nickel-titanium rotary instrumentation. Part 1: General dental practitioners in Wales. Br. Dent. J. 2013, 214, E6. [Google Scholar] [CrossRef] [PubMed]

- Sydney, G.B.; Santos, I.M.; Batista, A.; Kowalczuck, A.; Deonizio, M.D. A implementação do uso dos sistemas rotatório em endodontia. Rev. Odontol. Bras. Cent. 2014, 23, 113–120. [Google Scholar]

- Patil, T.N.; Saraf, P.A.; Penukonda, R.; Vanaki, S.S.; Kamatagi, L. A survey on nickel titanium rotary instruments and their usage techniques by endodontists in India. J. Clin. Diagn. Res. 2017, 11, ZC29–ZC35. [Google Scholar] [CrossRef]

- Patturaja, K.; Leelavathi, L.; Jayalakshmi, S. Choice of rotary instrument usage among endodontists—A questionnaire study. Biomed. Pharmacol. J. 2018, 11, 851–856. [Google Scholar] [CrossRef]

- Mustafa, M.; Attur, K.; Bagda, K.; Singh, S.; Oak, A.; Kathiria, N. An appraisal on newer endodontic file systems: A narrative review. J. Contemp. Dent. Pract. 2022, 23, 944–952. [Google Scholar]

- Martins, J.N.R.; Silva, E.J.N.L.; Marques, D.; Ajuz, N.; Rito Pereira, M.; Pereira da Costa, R.; Braz Fernandes, F.M.; Versiani, M.A. Characterization of the file-specific heat-treated ProTaper Ultimate rotary system. Int. Endod. J. 2023, 56, 530–542. [Google Scholar] [CrossRef]

- Ribeiro, G.; Martin, V.; Rodrigues, C.; Gomes, P. Comparative evaluation of the canal shaping ability, pericervical dentin preservation, and smear layer removal of TruNatomy, WaveOne Gold, and ProTaper Ultimate—An ex vivo study in human teeth. J. Endod. 2023, 49, 1733–1738. [Google Scholar] [CrossRef] [PubMed]

- Diaconu, C.T.; Diaconu, A.E.; Tuculina, M.J.; Mihai, L.L.; Gheorghiță, L.M.; Mărășescu, P.; Gliga, A.; Diaconu, O.A. Assessment of the cyclic fatigue performance of the novel Protaper Ultimate file system used in different kinematics: An in vitro study. J. Funct. Biomater. 2024, 15, 85. [Google Scholar] [CrossRef]

- Silva, E.; Martins, J.N.R.; Ajuz, N.; Vieira, V.T.; Pinto, R.; Marques, D.; Fernandes, F.M.B.; Versiani, M.A. Multimethod analysis of a novel multi-coloured heat-treated nickel-titanium rotary system: Design, metallurgy, mechanical properties, and shaping ability. J. Endod. 2024, 50, 1622–1633. [Google Scholar] [CrossRef] [PubMed]

- ASTM F2004-17; Standard Test Method for Transformation Temperature of Nickel-Titanium Alloys by Thermal Analysis. ASTM International: West Conshohocken, PA, USA, 2004; pp. 1–5.

- ISO 3630-3631; Dentistry—Root Canal Instruments—Part 1: General Requirements and Test Methods. ISO: Geneva, Switzerland, 2019.

- ASTM E92–17; Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–27.

- De-Deus, G.; Silva, E.J.; Vieira, V.T.; Belladonna, F.G.; Elias, C.N.; Plotino, G.; Grande, N.M. Blue thermomechanical treatment optimizes fatigue resistance and flexibility of the Reciproc Files. J. Endod. 2017, 43, 462–466. [Google Scholar] [CrossRef] [PubMed]

- Campbell, L.; Shen, Y.; Zhou, H.M.; Haapasalo, M. Effect of fatigue on torsional failure of nickel-titanium controlled memory instruments. J. Endod. 2014, 40, 562–565. [Google Scholar] [CrossRef]

- Elnaghy, A.M.; Elsaka, S.E. Mechanical properties of ProTaper Gold nickel-titanium rotary instruments. Int. Endod. J. 2016, 49, 1073–1078. [Google Scholar] [CrossRef]

- Martins, J.N.R.; Martins, R.F.; Braz Fernandes, F.M.; Silva, E. What meaningful information are the instruments mechanical testing giving us? A comprehensive review. J. Endod. 2022, 48, 985–1004. [Google Scholar] [CrossRef]

- Cheung, G.S.; Darvell, B.W. Fatigue testing of a NiTi rotary instrument. Part 2: Fractographic analysis. Int. Endod. J. 2007, 40, 619–625. [Google Scholar] [CrossRef]

- Pereira, E.S.; Gomes, R.O.; Leroy, A.M.; Singh, R.; Peters, O.A.; Bahia, M.G.; Buono, V.T. Mechanical behavior of M-Wire and conventional NiTi wire used to manufacture rotary endodontic instruments. Dent. Mater. 2013, 29, e318–e324. [Google Scholar] [CrossRef]

- Silva, E.; Martins, J.N.R.; Versiani, M.A. Advancing insights in contemporary endodontics: Proposing a multimethod approach for comprehensive evaluation of NiTi instruments. Int. Endod. J. 2024, 57, 116–118. [Google Scholar] [CrossRef]

- Ozata, M.; Falakaloglu, S.; Keles, A.; Adiguzel, O.; Gundogar, M. Evaluation of shaping ability of different glide path instruments: A micro-computed tomography study. BMC Oral Health 2023, 24, 780. [Google Scholar]

- Shaheen, N.; Elhelbawy, N. Shapping ability and buckling resistance of TruNatomy, WaveOne Gold, and XP-Endo Shaper single-file systems. Contemp. Clin. Dent. 2022, 13, 261–266. [Google Scholar] [CrossRef]

| Instruments | Apical Size/Taper | Active Blade Length (mm) | Number of Spirals | Spirals per Millimetre | Helical Angle (°) | Lot Number |

|---|---|---|---|---|---|---|

| Tip size 25 | ||||||

| ProFile 25/.04 | 25/.04 | 16 | 19 | 1.19 | 40.1 ± 2.4 | 6519600 |

| EndoSequence 25/.04 | 25/.04 | 16 | 8 | 0.50 | 14.7 ± 2.8 | 0198 |

| ProFile 25/.06 | 25/.06 | 16 | 19 | 1.19 | 48.6 ± 1.6 | 1720487 |

| EndoSequence 25/.06 | 25/.06 | 16 | 7 | 0.44 | 13.7 ± 2.8 | 9376 |

| ProTaper Next X2 | 25/.06v | 17 | 8 | 0.47 | 20.8 ± 2.5 | 1515010 |

| MTwo 25/.07 | 25/.07 | 17 | 6 | 0.35 | 18.7 ± 4.5 | 363436 |

| ProTaper Ultimate F2 | 25/.08v | 17 | 16 | 0.94 | 18.9 ± 1.2 | 1854170 |

| Tip size 30 | ||||||

| ProFile 30/.04 | 30/.04 | 16 | 19 | 1.19 | 42.7 ± 2.0 | 2725220 |

| EndoSequence 30/.04 | 30/.04 | 16 | 8 | 0.50 | 14.7 ± 1.8 | 0198 |

| ProFile 30/.06 | 30/.06 | 16 | 19 | 1.19 | 47.3 ± 1.4 | 060308511 |

| EndoSequence 30/.06 | 30/.06 | 16 | 7 | 0.44 | 14.8 ± 1.0 | 9376 |

| GT Series X 30/.06 | 30/.06 | 12 | 8 | 0.67 | 23.0 ± 4.5 | SXRAS25 |

| ProTaper Next X3 | 30/.07v | 17 | 7 | 0.41 | 22.3 ± 2.7 | 1515010 |

| MTwo 30/.06 | 30/.06 | 17 | 7 | 0.41 | 20.9 ± 1.7 | 362601 |

| ProTaper Ultimate F3 | 30/.09v | 17 | 12 | 0.71 | 18.6 ± 1.5 | 1824935 |

| Tip size 35 | ||||||

| ProFile 35/.04 | 35/.04 | 16 | 19 | 1.19 | 42.0 ± 2.1 | 7235110 |

| EndoSequence 35/.04 | 35/.04 | 16 | 7 | 0.44 | 15.8 ± 2.3 | 0198 |

| ProFile 35/.06 | 35/.06 | 16 | 19 | 1.19 | 48.0 ± 2.0 | 1712662 |

| EndoSequence 35/.06 | 35/.06 | 16 | 6 | 0.38 | 13.9 ± 4.0 | 9376 |

| MTwo 35/.06 | 35/.06 | 17 | 8 | 0.47 | 21.2 ± 1.1 | 0903310641 |

| ProTaper Ultimate FX | 35/.12v | 17 | 8 | 0.47 | 19.1 ± 2.0 | 1824935 |

| Tip size 40 | ||||||

| ProFile 40/.04 | 40/.04 | 16 | 19 | 1.19 | 43.7 ± 2.7 | 7051790 |

| EndoSequence 40/.04 | 40/.04 | 17 | 6 | 0.35 | 11.9 ± 1.7 | 0198 |

| ProFile 40/.06 | 40/.06 | 16 | 19 | 1.19 | 50.6 ± 2.6 | 1686802 |

| EndoSequence 40/.06 | 40/.06 | 17 | 5 | 0.29 | 11.9 ± 3.0 | 9376 |

| GT Series X 40/.06 | 40/.06 | 10 | 7 | 0.70 | 22.3 ± 1.5 | SXRAS25 |

| ProTaper Next X4 | 40/.06v | 18 | 7 | 0.39 | 19.1 ± 3.2 | 1529960 |

| MTwo 40/.06 | 40/.06 | 17 | 8 | 0.47 | 24.5 ± 1.6 | 0904310642 |

| Instruments | NiTi Wire | Phase Transformation Temperatures | Elemental Composition | Microhardness | |||||

|---|---|---|---|---|---|---|---|---|---|

| Rs | Rf | As | Af | Nickel | Titanium | Ni/Ti Ratio | |||

| MTwo 30/.06 | Conventional | 15.8 | −12.2 | −32.6 | 19.6 | 51.42 | 48.58 | 1.058 | 370.0 ± 36.9 |

| GT Series X 30/.06 | M-wire | 50.2 | 11.8 | −9.9 | 50.3 | 50.23 | 49.77 | 1.009 | 407.1 ± 30.7 |

| EndoSequence 30/.06 | Conventional | 27.9 | −4.5 | −28.8 | 30.4 | 51.50 | 48.50 | 1.062 | 345.3 ± 26.1 |

| ProFile 30/.06 | Conventional | 15.2 | −26.8 | −33.2 | 17.0 | 51.78 | 48.22 | 1.074 | 376.5 ± 19.9 |

| ProTaper Next X3 | M-wire | 45.3 | 16.3 | −3.1 | 49.6 | 50.32 | 49.68 | 1.013 | 425.0 ± 32.9 |

| ProTaper Ultimate F3 | Gold | 45.1 | 32.7 | 9.1 | 51.1 | 51.08 | 48.92 | 1.044 | 361.7 ± 39.7 |

| ProTaper Ultimate FX | Blue | 32.6 | 21.1 | 5.6 | 34.6 | 50.55 | 49.45 | 1.022 | 380.0 ± 40.7 |

| Instruments | Torsional Test | Bending Test | |

|---|---|---|---|

| Maximum Torque (N.cm) | Angle of Rotation (°) | Maximum Bending Load (gf) | |

| Tip size 25 | |||

| ProFile 25/.04 | 0.50 [0.40–0.80] | 516.7 [430.1–592.8] | 260.9 [246.3–330.5] |

| EndoSequence 25/.04 | 0.80 [0.60–1.50] | 707.4 [601.6–850.6] | 194.3 [186.4–210.9] |

| ProFile 25/.06 | 0.70 [0.63–0.90] | 508.6 [495.7–586.5] | 430.7 [417.3–465.3] |

| EndoSequence 25/.06 | 1.10 [0.93–1.30] | 649.5 [580.5–717.4] | 440.9 [429.6–448.3] |

| ProTaper Next X2 25/.06v | 0.75 [0.70–0.80] | 375.3 [338.2–406.2] | 475.9 [467.7–491.8] |

| MTwo 25/.07 | 1.35 [1.10–1.60] | 490.9 [447.2–570.9] | 479.6 [461.4–495.6] |

| ProTaper Ultimate F2 25/.08v | 1.40 [1.30–1.40] | 489.1 [460.3–630.1] | 202.7 [192.4–206.9] |

| Tip size 30 | |||

| ProFile 30/.04 | 1.10 [0.75–1.20] | 518.7 [474.3–609.3] | 367.0 [338.1–386.5] |

| EndoSequence 30/.04 | 0.85 [0.58–0.90] | 750.8 [606.1–836.8] | 236.8 [220.2–244.6] |

| ProFile 30/.06 | 0.95 [0.80–1.35] | 509.4 [409.9–530.3] | 762.2 [701.2–778.2] |

| EndoSequence 30/.06 | 1.10 [0.93–1.18] | 648.4 [579.5–735.3] | 481.8 [477.7–495.4] |

| GT Series X 30/.06 | 1.50 [1.25–1.58] | 584.7 [495.9–644.1] | 478.6 [414.9–486.9] |

| ProTaper Next X3 30/.07v | 1.30 [1.13–1.58] | 339.9 [321.7–419.6] | 480.9 [465.7–511.2] |

| MTwo 30/.06 | 1.15 [1.03–1.28] | 536.8 [478.4–591.7] | 366.4 [358.2–369.9] |

| ProTaper Ultimate F3 30/.09v | 1.45 [1.23–2.15] | 634.2 [408.3–791.7] | 254.9 [239.2–275.2] |

| Tip size 35 | |||

| ProFile 35/.04 | 1.45 [1.15–1.68] | 591.6 [523.5–673.2] | 376.9 [364.9–403.7] |

| EndoSequence 35/.04 | 1.00 [0.90–1.18] | 751.2 [661.1–811.8] | 269.3 [255.6–278.9] |

| ProFile 35/.06 | 1.55 [1.20–1.78] | 581.9 [551.4–659.4] | 650.3 [624.4–677.7] |

| EndoSequence 35/.06 | 1.30 [1.15–1.88] | 782.9 [597.3–860.1] | 681.3 [661.6–691.6] |

| MTwo 35/.06 | 1.40 [1.23–1.58] | 590.3 [558.2–613.5] | 406.8 [405.4–418.9] |

| ProTaper Ultimate FX 35/.12v | 3.55 [1.33–3.87] | 659.9 [504.5–743.6] | 408.4 [387.9–426.6] |

| Tip size 40 | |||

| ProFile 40/.04 | 1.65 [1.28–2.23] | 608.9 [464.7–633.8] | 504.5 [493.7–591.6] |

| EndoSequence 40/.04 | 1.25 [1.13–1.38] | 791.6 [752.3–820.5] | 344.4 [333.8–367.6] |

| ProFile 40/.06 | 2.00 [1.90–2.08] | 801.9 [666.3–840.7] | 832.4 [720.4–840.7] |

| EndoSequence 40/.06 | 1.65 [1.53–2.08] | 702.0 [629.6–773.4] | 796.0 [789.7–823.5] |

| GT Series X 40/.06 | 2.40 [2.30–2.73] | 699.4 [538.3–873.1] | 509.7 [496.9–523.5] |

| ProTaper Next X4 40/.06v | 2.05 [1.83–2.43] | 385.1 [358.7–445.8] | 559.5 [548.4–580.1] |

| MTwo 40/.06 | 1.60 [1.40–1.78] | 580.9 [541.1–639.5] | 446.2 [402.4–497.8] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martins, J.N.R.; Silva, E.J.N.L.; Vieira, V.T.L.; Pereira da Costa, R.; Baruwa, A.O.; Fernandes, F.M.B.; Versiani, M.A. A Comparative Analysis of ProTaper Ultimate and Five Multifile Systems: Design, Metallurgy, and Mechanical Performance. Materials 2025, 18, 1260. https://doi.org/10.3390/ma18061260

Martins JNR, Silva EJNL, Vieira VTL, Pereira da Costa R, Baruwa AO, Fernandes FMB, Versiani MA. A Comparative Analysis of ProTaper Ultimate and Five Multifile Systems: Design, Metallurgy, and Mechanical Performance. Materials. 2025; 18(6):1260. https://doi.org/10.3390/ma18061260

Chicago/Turabian StyleMartins, Jorge N. R., Emmanuel João Nogueira Leal Silva, Victor Talarico Leal Vieira, Rui Pereira da Costa, Abayomi O. Baruwa, Francisco Manuel Braz Fernandes, and Marco Aurélio Versiani. 2025. "A Comparative Analysis of ProTaper Ultimate and Five Multifile Systems: Design, Metallurgy, and Mechanical Performance" Materials 18, no. 6: 1260. https://doi.org/10.3390/ma18061260

APA StyleMartins, J. N. R., Silva, E. J. N. L., Vieira, V. T. L., Pereira da Costa, R., Baruwa, A. O., Fernandes, F. M. B., & Versiani, M. A. (2025). A Comparative Analysis of ProTaper Ultimate and Five Multifile Systems: Design, Metallurgy, and Mechanical Performance. Materials, 18(6), 1260. https://doi.org/10.3390/ma18061260