Research on Cement-Free Grouting Material for Shield Tunneling in Water-Rich Karst Regions

Abstract

1. Introduction

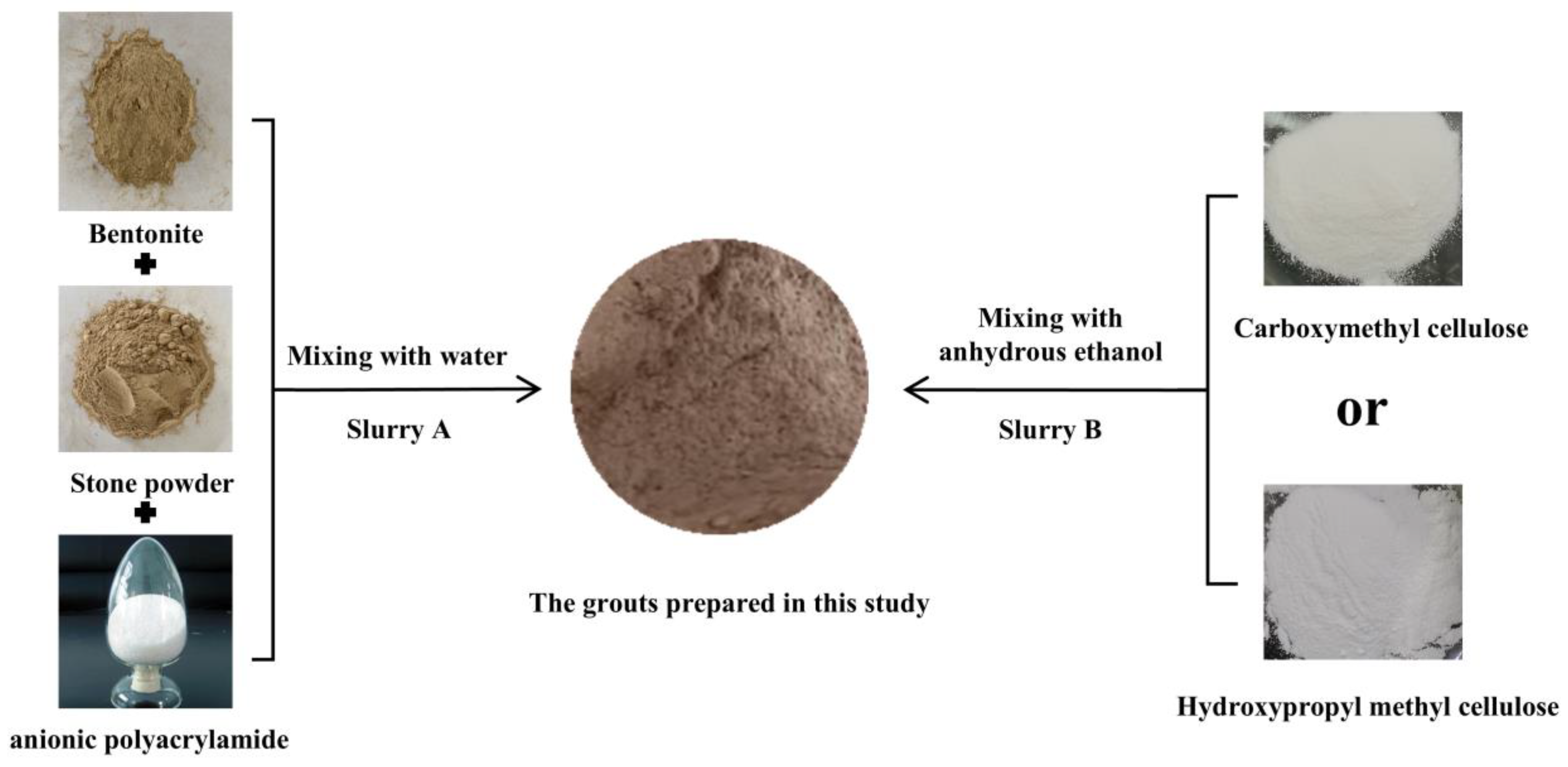

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

3. Results and Discussion

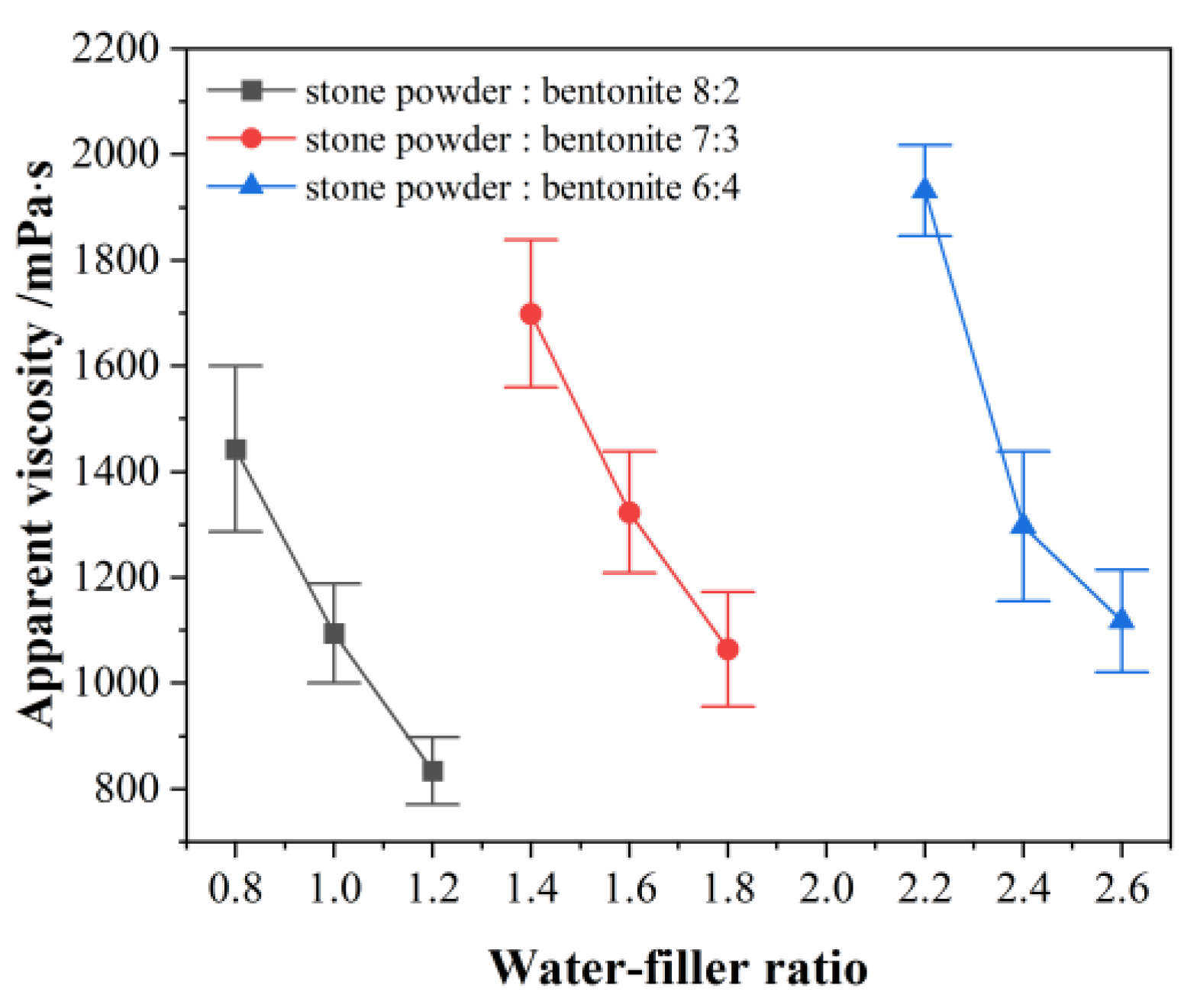

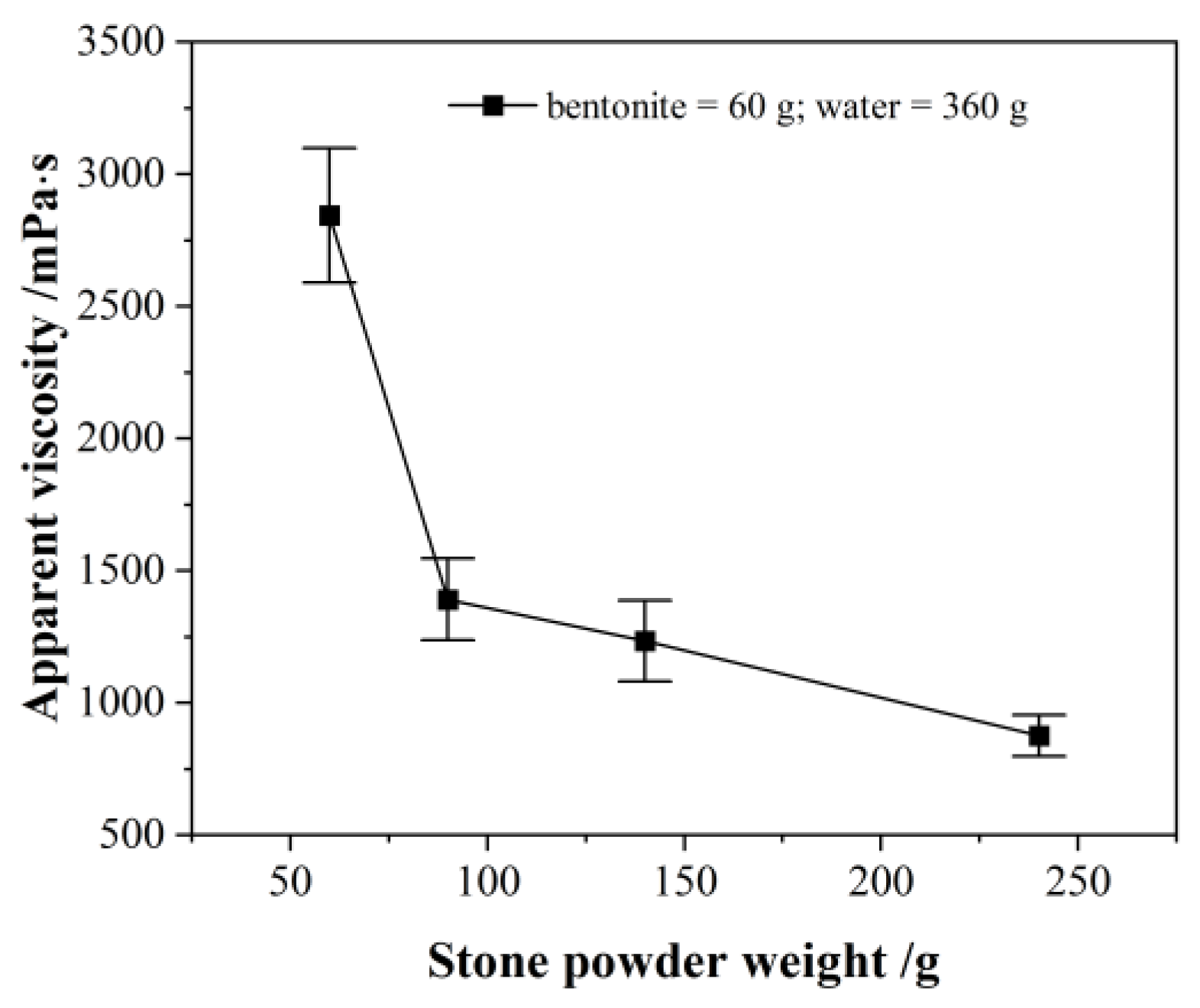

3.1. Slurry A and Its Performance

3.2. Slurry B and Its Performance

4. Conclusions

- The optimal mass ratio of stone powder to bentonite in slurry A was 4:1 (with a water–solid ratio of 0.8:1.0), and the ratio of thickening agents (CMC or HPMC) to anhydrous ethanol in slurry B was 1:5. At this ratio, the slurry had good fluidity. Meanwhile, the viscosity increased rapidly by 2–3 orders of magnitude with the addition of 5–10% slurry B. Therefore, the grout could harden rapidly.

- With the increase in bentonite content, the slurry viscosity increased, and the best proportion of bentonite in grouting was found to be 20~30%, to avoid huge losses in fluidity. With increases in stone powder content, the slurry viscosity decreased, and the stone powder could increase the fluidity of the grouts. The stone powder–bentonite-based grouts proposed in this study significantly reduced the carbon emissions of traditional cement-based materials.

- Using anhydrous ethanol as a carrier, more thickening agents could be admixed without entrapping a large amount of water. This helps to thicken the cement-free grouting material quickly, while maintaining a high plastic strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, D.; Li, B.; Cheng, S. The effect of subway development on air pollution: Evidence from China. J. Clean. Prod. 2020, 275, 124149. [Google Scholar] [CrossRef]

- Mao, R.; Bao, Y.; Duan, H.; Liu, G. Global urban subway development, construction material stocks, and embodied carbon emissions. Humanit. Soc. Sci. Commun. 2021, 8, 1–11. [Google Scholar] [CrossRef]

- Cheng, Y.; Liu, X. Research on the Pressure Distribution Law of Synchronous Grouting in Shield Tunnels and the Force on Segments. Buildings 2024, 14, 1099. [Google Scholar] [CrossRef]

- Ding, Z.; Zhang, M.-B.; Zhang, X.; Wei, X.-J. Theoretical analysis on the deformation of existing tunnel caused by under-crossing of large-diameter slurry shield considering construction factors. Tunn. Undergr. Space Technol. 2023, 133, 104913. [Google Scholar] [CrossRef]

- Fang, Z.; Ding, N.; Yang, W.; Dai, Z.; Wang, J.; He, J.; Ding, R.; Ba, X.; Zhou, Z. The Influence of Different Karst Cave Filling Material Strengths on Stratum Stability During Shield Tunneling. Geotech. Geol. Eng. 2023, 41, 1309–1323. [Google Scholar] [CrossRef]

- Zhang, W.; Tang, X.; Yang, W.; Jiang, J.; Zhang, H.; Li, P. Review of tunnels and tunnelling under unfavourable geological conditions. Geol. J. 2024, 59, 2668–2689. [Google Scholar] [CrossRef]

- Jiang, X.; Zhu, H.; Yan, Z.; Zhang, F.; Ye, F.; Li, P.; Zhang, X.; Dai, Z.; Bai, Y.; Huang, B. A state-of-art review on development and progress of backfill grouting materials for shield tunneling. Dev. Built Environ. 2023, 16, 100250. [Google Scholar] [CrossRef]

- Guo, Q.; Pang, Y.; Liu, R.; Liu, B.; Liu, Z. Integrated Investigation for Geological Detection and Grouting Assessment: A Case Study in Qingdao Subway Tunnel, China. J. Environ. Eng. Geophys. 2019, 24, 629–639. [Google Scholar] [CrossRef]

- Zhou, C.-Y.; Fang, Y.; Fu, Y.-P.; Cui, G. The Grouting Technology of Large -section Highway Tunnel in Water-rich Karst Formations. In Proceedings of the 2nd Global Conference on Civil, Structural and Environmental Engineering (GCCSEE 2013), Shenzhen, China, 28–29 September 2013; pp. 1441–1446. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, L.; Sun, D.; Zhang, Q.; Wang, D.; Wang, L. Quantitative Design Method for Grouting in Sand Layers: Practice in Qingdao Metro Line 2. Processes 2022, 10, 840. [Google Scholar] [CrossRef]

- Yang, Q.; Geng, P.; Wang, J.; Chen, P.; He, C. Research of asphalt-cement materials used for shield tunnel backfill grouting and effect on anti-seismic performance of tunnels. Constr. Build. Mater. 2022, 318, 125866. [Google Scholar] [CrossRef]

- Jiang, B.; Wu, M.; Wu, S.; Zheng, A.; He, S. A Review on Development of Industrial Solid Waste in Tunnel Grouting Materials: Feasibility, Performance, and Prospects. Materials 2023, 16, 6848. [Google Scholar] [CrossRef] [PubMed]

- Mei, Y.; Zhou, D.; Wang, R.; Zhang, M.; Xu, W.; Zhang, Y.; Ke, X. Experimental Study on the Mix Proportion and Mechanical Properties of New Underwater Cementitious Filling Materials. Materials 2022, 15, 2938. [Google Scholar] [CrossRef]

- He, S.; Lai, J.; Wang, L.; Wang, K. A literature review on properties and applications of grouts for shield tunnel. Constr. Build. Mater. 2020, 239, 117782. [Google Scholar] [CrossRef]

- Cui, Q.-L.; Wu, H.-N.; Shen, S.-L.; Xu, Y.-S.; Ye, G.-L. Chinese karst geology and measures to prevent geohazards during shield tunnelling in karst region with caves. Nat. Hazards 2015, 77, 129–152. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, C.; Fu, J.; Wang, S.; Ou, X.; Xie, Y. Pre-grouting reinforcement of underwater karst area for shield tunneling passing through Xiangjiang River in Changsha, China. Tunn. Undergr. Space Technol. 2020, 100, 103380. [Google Scholar] [CrossRef]

- Wang, S.; Wang, J.-F.; Yuan, C.-P.; Chen, L.-Y.; Xu, S.-T.; Guo, K.-B. Development of the nano-composite cement: Application in regulating grouting in complex ground conditions. J. Mt. Sci. 2018, 15, 1572–1584. [Google Scholar] [CrossRef]

- Jin, Q.; Qi, Y.; Li, Z.; Li, H.; Chen, J. Research and Application of Modified Cement Grouting Materials for Gushing Water Disaster in Karst Conduit. Geotech. Geol. Eng. 2022, 40, 5855–5868. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Li, L.; Han, J.; Zhang, B.; Hou, D.; Wang, J.; Lin, C. A preliminary study of the properties of potassium phosphate magnesium cement-based grouts admixed with metakaolin, sodium silicate and bentonite. Constr. Build. Mater. 2020, 262, 119893. [Google Scholar] [CrossRef]

- Feng, X.; Xia, C.; Zhang, S.; Li, C.; Zhao, H.; Wu, J.; Chen, M.; Yan, J. Properties and Engineering Applications of a New Goaf Grouting Filling Material. Geofluids 2022, 2022, 1–14. [Google Scholar] [CrossRef]

- Wu, L.; Wu, Z.; Weng, L.; Liu, Y.; Chu, Z.; Chen, J. Comparative analysis of polyacrylate latex modified cement grout for water blocking and rock reinforcement with six alternative materials. Constr. Build. Mater. 2024, 429, 136377. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, J.; Li, Y.; Liang, J. A pasty clay-cement grouting material for soft and loose ground under groundwater conditions. Adv. Cem. Res. 2017, 29, 54–62. [Google Scholar] [CrossRef]

- Zhu, J.; Hui, J.; Luo, H.; Zhang, B.; Wei, X.; Wang, F.; Li, Y. Effects of polycarboxylate superplasticizer on rheological properties and early hydration of natural hydraulic lime. Cem. Concr. Compos. 2021, 122, 104052. [Google Scholar] [CrossRef]

- Shen, Q.; Jiang, R.; Cong, B.; Guo, B.; Shang, H.; Ji, X. Study on the effect of mineral admixtures on working and mechanical properties of the grouting material. Front. Mater. 2023, 10, 1197997. [Google Scholar] [CrossRef]

- Zhang, C.; Fu, J.; Yang, J.; Ou, X.; Ye, X.; Zhang, Y. Formulation and performance of grouting materials for underwater shield tunnel construction in karst ground. Constr. Build. Mater. 2018, 187, 327–338. [Google Scholar] [CrossRef]

- Xia, J.; Wang, T.; Yang, Y.; Yu, L. Iop, Multi-factor Comprehensive Evaluation on Durability of Various Grouting Materials. In Proceedings of the 5th International Conference on Advances in Energy, Environment and Chemical Engineering (AEECE), Shanghai, China, 16–18 August 2019. [Google Scholar] [CrossRef]

- Kazemian, S.; Prasad, A.; Huat, B.B.K.; Bazaz, J.B.; Aziz, F.N.A.A.; Ali, T.A.M. Influence of cement sodium silicate grout admixed with calcium chloride and kaolinite on sapric peat. J. Civ. Eng. Manag. 2011, 17, 309–318. [Google Scholar] [CrossRef]

- Zou, J.; Zuo, S. Similarity Solution for the Synchronous Grouting of Shield Tunnel Under the Vertical Non-Axisymmetric Displacement Boundary Condition. Adv. Appl. Math. Mech. 2017, 9, 205–232. [Google Scholar] [CrossRef]

- Liang, X.; Ying, K.; Ye, F.; Su, E.; Xia, T.; Han, X. Selection of backfill grouting materials and ratios for shield tunnel considering stratum suitability. Constr. Build. Mater. 2022, 314, 125431. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, J.; Fu, J.; Ou, X.; Xie, Y.; Liang, X. Performance Evaluation of Modified Cement-Sodium Silicate Grouting Material for Prereinforcing Loose Deposit Tunnels. J. Mater. Civ. Eng. 2019, 31, 2747. [Google Scholar] [CrossRef]

- Asada, M.; Horiuchi, S. High-density bentonite slurry for seepage barriers. J. Mater. Civ. Eng. 2005, 17, 178–187. [Google Scholar] [CrossRef]

- Todaro, C.; Zanti, D.; Carigi, A.; Peila, D. The role of bentonite in two-component grout: A comparative study. Tunn. Undergr. Space Technol. 2023, 142, 105412. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, G.H.; Chang, Y.H. Comparison of the effect of lithium bentonite and sodium bentonite on the engineering properties of bentonite-cement-sodium silicate grout. Adv. Concr. Constr. 2020, 9, 279–287. [Google Scholar] [CrossRef]

- Bernal, S.A.; Nicolas, R.S.; van Deventer, J.S.J.; Provis, J.L. Alkali-activated slag cements produced with a blended sodium carbonate/sodium silicate activator. Adv. Cem. Res. 2016, 28, 262–273. [Google Scholar] [CrossRef]

- Toniolo, N.; Rincon, A.; Roether, J.A.; Ercole, P.; Bernardo, E.; Boccaccini, A.R. Extensive reuse of soda-lime waste glass in fly ash-based geopolymers. Constr. Build. Mater. 2018, 188, 1077–1084. [Google Scholar] [CrossRef]

- GB/T 43876-2024; Test Method for Viscosity of Cement Paste. Standardization Administration of China: Beijing, China, 2024.

- Stefanidou, M.; Kamperidou, V.; Konstantinidis, A.; Koltsou, P.; Papadopoulos, S. Use of Posidonia oceanica fibres in lime mortars. Constr. Build. Mater. 2021, 298, 123881. [Google Scholar] [CrossRef]

| Particle Size (μm) | 0–1 | 1–5 | 5–10 | 10–20 | 20–45 | 45–75 | 75–100 |

|---|---|---|---|---|---|---|---|

| Content (%) | 5.51 | 36.97 | 12.54 | 13.03 | 13.28 | 10.00 | 4.93 |

| Particle Size (μm) | 0–5 | 5–10 | 10–20 | 20–45 | 45–75 | 75–100 | 100–300 |

|---|---|---|---|---|---|---|---|

| Content (%) | 10.10 | 10.08 | 19.60 | 15.06 | 13.55 | 6.77 | 13.97 |

| Type | Measuring Range/mPa·s | Rotor Diameter/mm | Rotor Speed/rpm |

|---|---|---|---|

| NDJ-99 | 20~2 × 106 | 18, 15, 10, 3 | 0.3, 0.6, 1.5, 3, 6, 12, 30, 60 |

| Test ID | Stone Powder/%(w/w) | Bentonite/%(w/w) | Water–Filler Ratio | Anti-Dispersant Content /% |

|---|---|---|---|---|

| 1 | 80 | 20 | 0.8 | 0.8 |

| 2 | 80 | 20 | 1.0 | 0.8 |

| 3 | 80 | 20 | 1.2 | 0.8 |

| 4 | 70 | 30 | 1.4 | 0.7 |

| 5 | 70 | 30 | 1.6 | 0.7 |

| 6 | 70 | 30 | 1.8 | 0.7 |

| 7 | 60 | 40 | 2.2 | 0.6 |

| 8 | 60 | 40 | 2.4 | 0.6 |

| 9 | 60 | 40 | 2.6 | 0.6 |

| Variance | Sum of Squares (SS) | Degree of Freedom | Mean Square (MS) | F | p |

|---|---|---|---|---|---|

| Water–filler ratio | 679,744.044 | 2 | 339,872.022 | 3.314 | <0.05 |

| Stone powder–bentonite ratio | 3,707,598.376 | 8 | 463,449.797 | 35.103 | <0.05 |

| Stone powder weight | 6,752,774.789 | 3 | 2,250,924.93 | 76.127 | <0.05 |

| The mass percentage of slurry B in A | 4,900,327,163,786.12 | 3 | 1,633,442,387,928.7 | 19.956 | <0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Che, Z.; Wang, T.-L.; Zhou, Z.-G.; Wang, S.; Ma, X.-W. Research on Cement-Free Grouting Material for Shield Tunneling in Water-Rich Karst Regions. Materials 2025, 18, 1192. https://doi.org/10.3390/ma18061192

Che Z, Wang T-L, Zhou Z-G, Wang S, Ma X-W. Research on Cement-Free Grouting Material for Shield Tunneling in Water-Rich Karst Regions. Materials. 2025; 18(6):1192. https://doi.org/10.3390/ma18061192

Chicago/Turabian StyleChe, Zheng, Tian-Liang Wang, Zheng-Guo Zhou, Shuo Wang, and Xin-Wei Ma. 2025. "Research on Cement-Free Grouting Material for Shield Tunneling in Water-Rich Karst Regions" Materials 18, no. 6: 1192. https://doi.org/10.3390/ma18061192

APA StyleChe, Z., Wang, T.-L., Zhou, Z.-G., Wang, S., & Ma, X.-W. (2025). Research on Cement-Free Grouting Material for Shield Tunneling in Water-Rich Karst Regions. Materials, 18(6), 1192. https://doi.org/10.3390/ma18061192