Microstructure Evolution and Mechanical Properties of Dual-Phase AlCrFe2Ni2 High-Entropy Alloy Under High-Strain-Rate Compression

Highlights

- Showed the excellent dynamic compression properties in AlCrFe2Ni2 alloy.

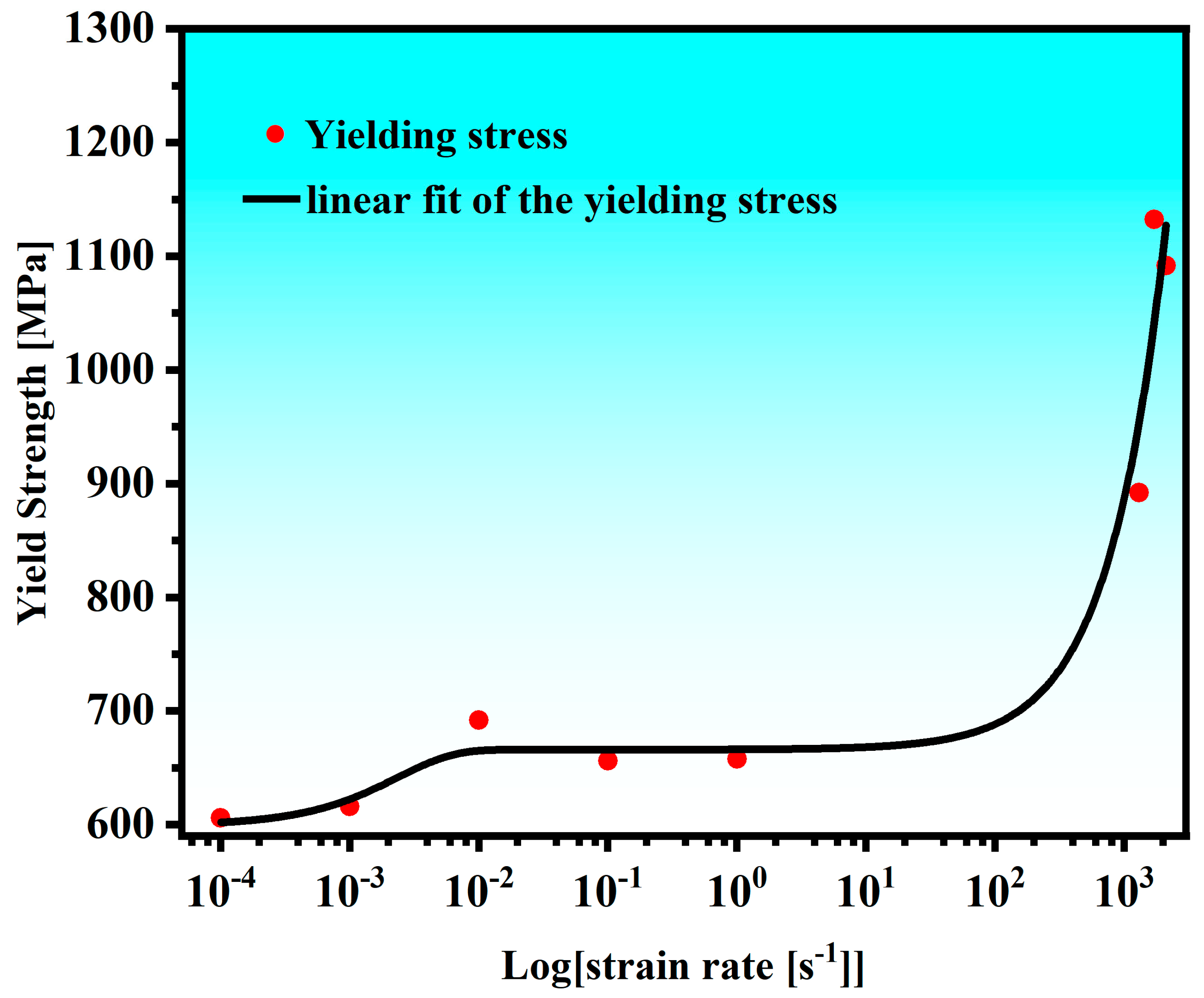

- Observing significant strain rate dependence of yield strength at high strain rates.

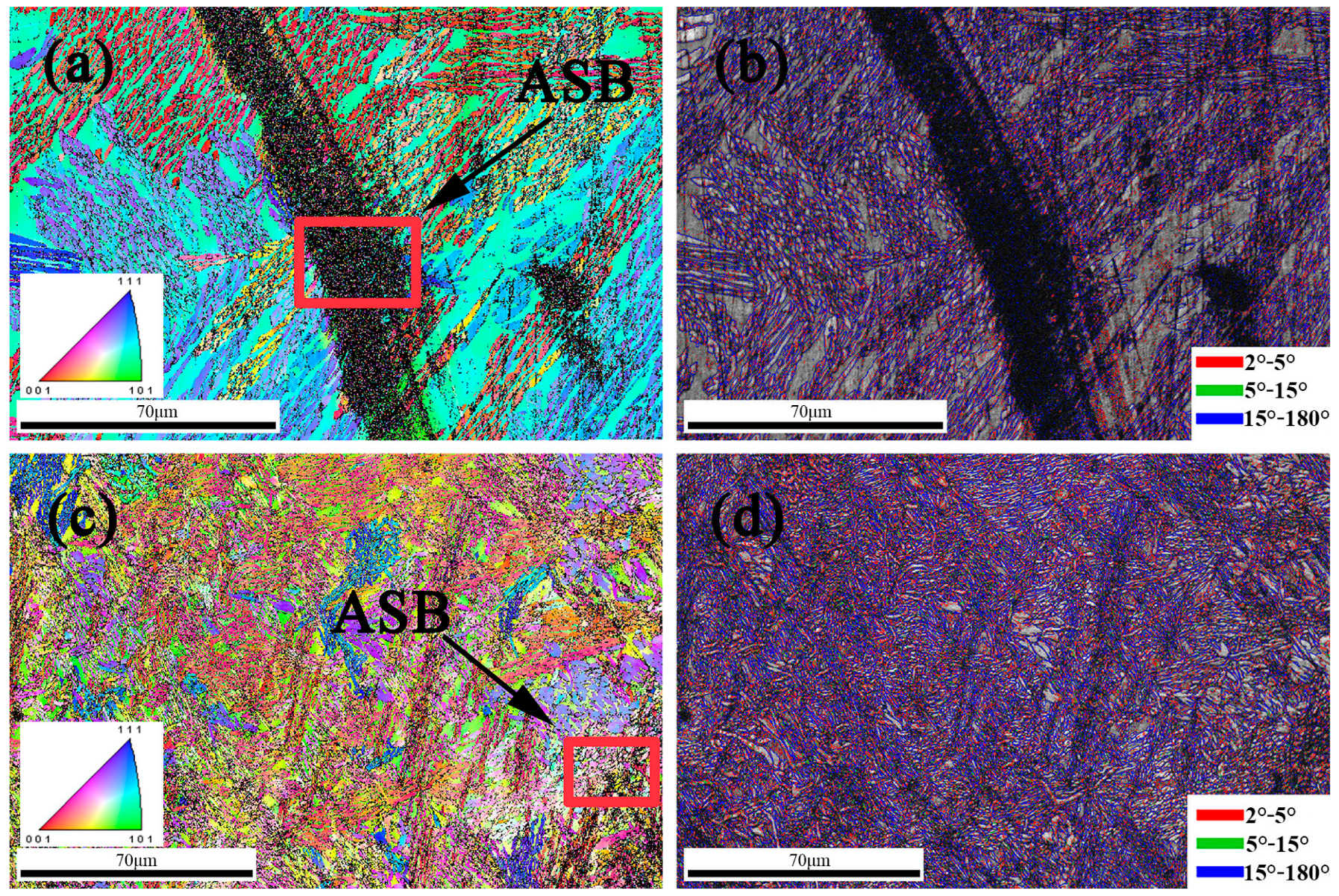

- The adiabatic shear bands elucidate thermal softening effects in AlCrFe2Ni2 alloy.

Abstract

1. Introduction

2. Experimental

2.1. Alloy Fabrication

2.2. Property Testing

2.3. Microstructure Characterization

3. Results and Discussion

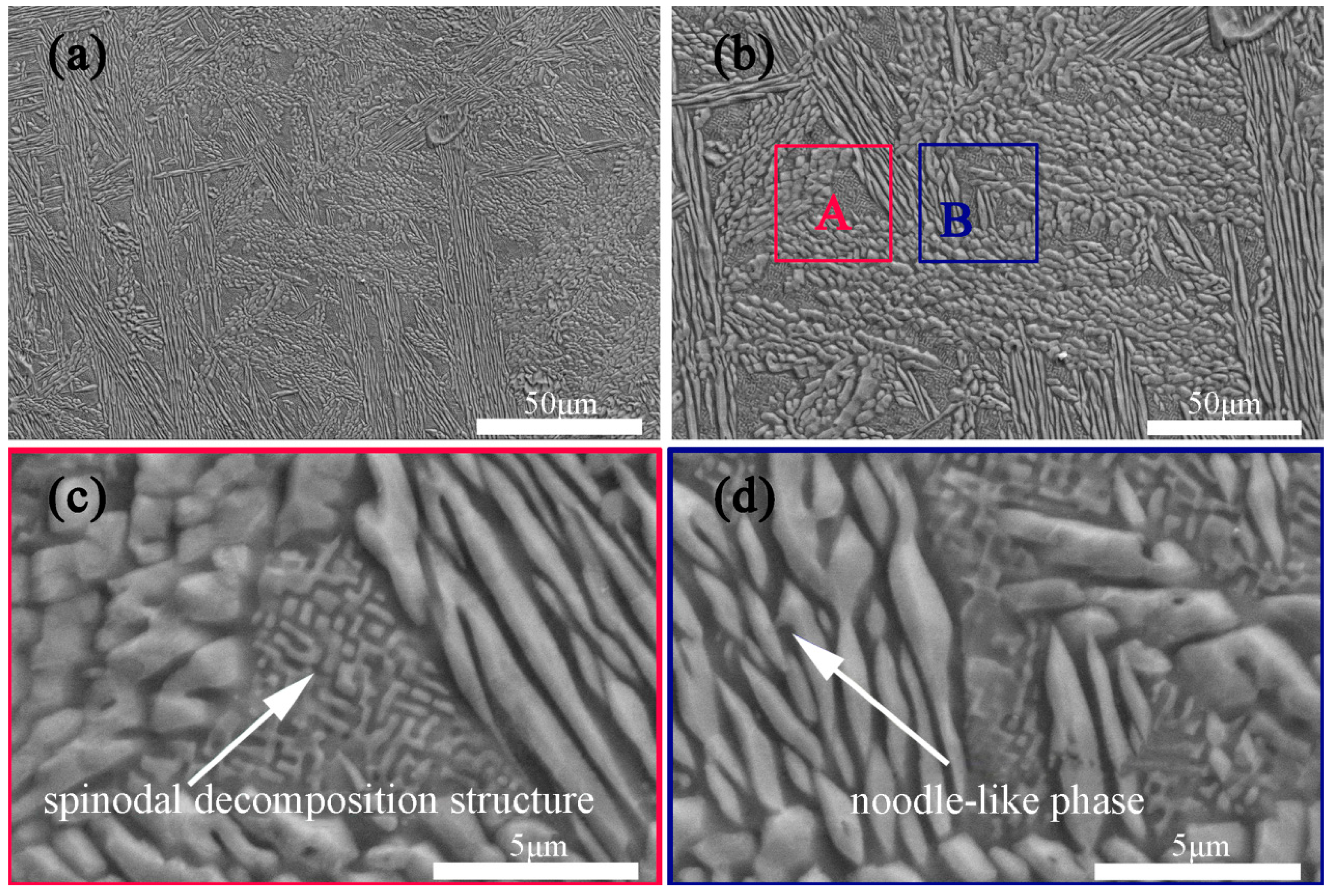

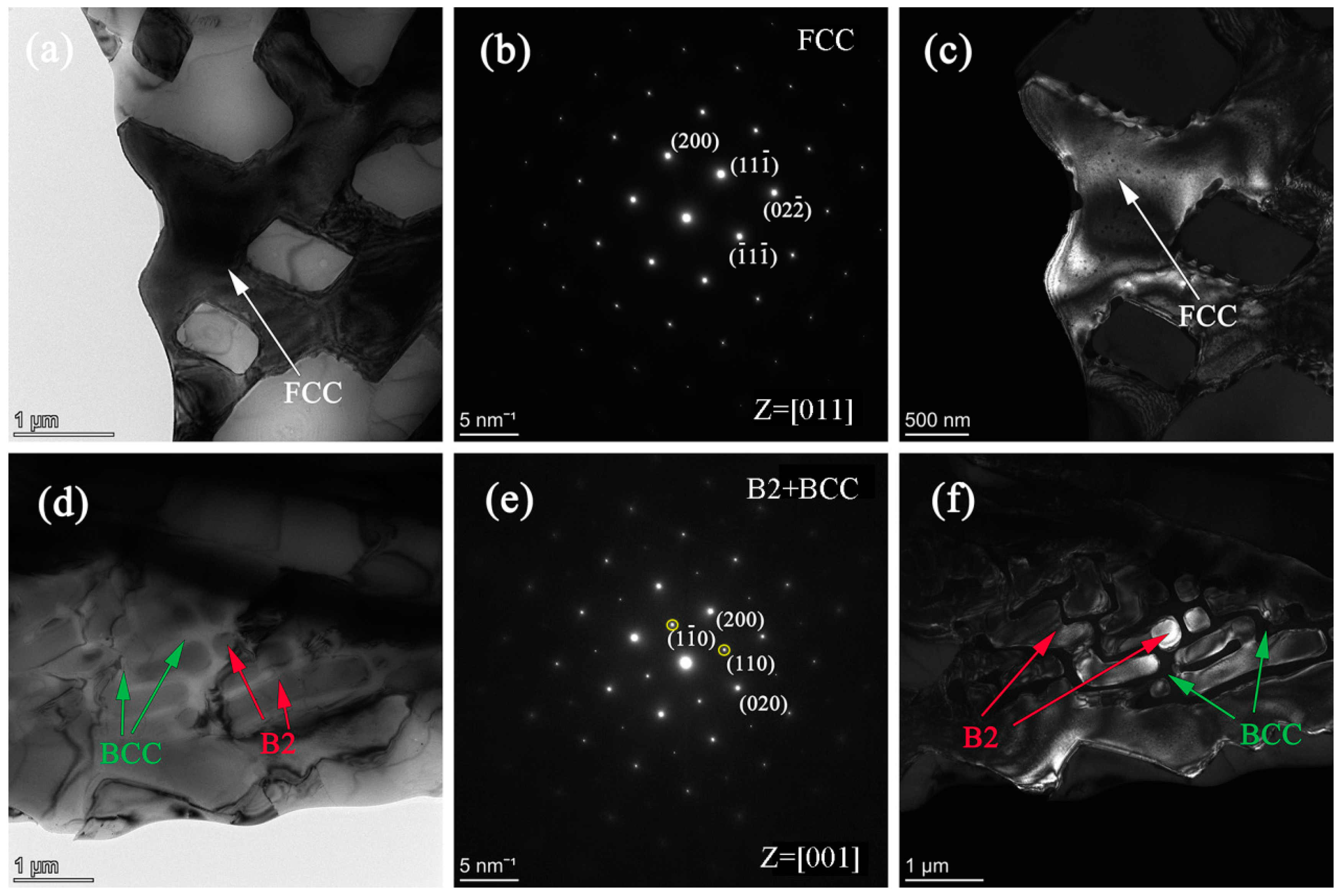

3.1. Microstructural Analysis

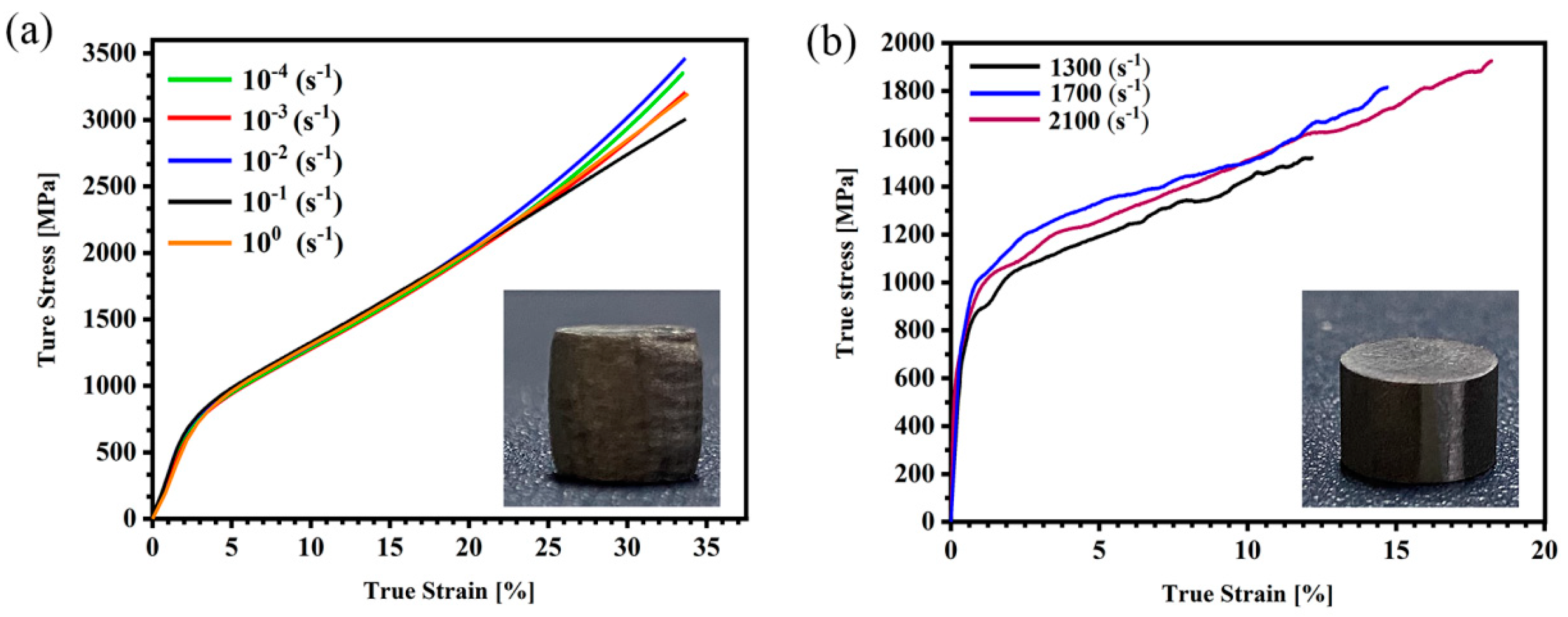

3.2. Mechanical Characteristics Under Compression Testing

3.3. Microstructure Evolution

4. Conclusions

- The as-cast AlCrFe2Ni2 alloy is composed of a mixture of Fe,Ni-enriched FCC phases, disordered Fe,Cr-enriched BCC phases, and ordered Al,Ni-enriched B2 phases.

- The AlCrFe2Ni2 alloy shows excellent compressive properties under quasi-static deformation. The yield strength exceeds 600 MPa while the compressive strength is more than 3000 MPa at the compression rates of 30%.

- The ultimate compression stresses are 1522 MPa, 1816 MPa, and 1925 MPa with compression strains about 12.8%, 14.7%, and 18.2% at strain rates of 1300 s−1, 1700 s−1, and 2100 s−1, respectively. Strain rate sensitivity ranges from 0.0089 at low strain (10−4 s−1–100 s−1) to 0.42 at high strain rates (1300 s−1–2100 s−1), which is due to the phonon drag effect at high strains.

- At high-strain-rate compression, a adiabatic shear phenomenon occurs. The adiabatic shear bands formed by dynamic recrystallization due to the conflicting processes of strain rate hardening and heat softening.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Li, W.D.; Liaw, P.K.; Gao, Y. Fracture resistance of high entropy alloys: A review. Intermetallics 2018, 99, 69–83. [Google Scholar] [CrossRef]

- Liu, W.H.; He, J.Y.; Huang, H.L.; Wang, H.; Lu, Z.P.; Liu, C.T. Effects of Nb additions on the microstructure and mechanical property of CoCrFeNi high-entropy alloys. Intermetallics 2015, 60, 1–8. [Google Scholar] [CrossRef]

- He, J.Y.; Liu, W.H.; Wang, H.; Wu, Y.; Liu, X.J.; Nieh, T.G.; Lu, Z.P. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 2014, 62, 105–113. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of NbMoTaW and VNbMoTaW refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Lu, Y.P.; Dong, Y.; Guo, S.; Jiang, L.; Kang, H.J.; Wang, T.M.; Wen, B.; Wang, Z.J.; Jie, J.C.; Ruan, H.H.; et al. A Promising New Class of High-Temperature Alloys: Eutectic High-Entropy Alloys. Sci. Rep. 2014, 4, 6200. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef]

- Otto, F.; Dlouh, A.; Somsen, C.H.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Chuang, M.H.; Tsai, M.H.; Wang, W.R.; Lin, S.J.; Yeh, J.W. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Hemphill, M.A.; Yuan, T.; Wang, G.Y.; Yeh, J.W.; Tsai, C.W.; Chuang, A.; Liaw, P.K. Fatigue behavior of Al0.5CoCrCuFeNi high entropy alloys. Acta Mater. 2012, 60, 5723–5734. [Google Scholar] [CrossRef]

- Lu, Y.P.; Dong, Y.; Jiang, H.; Wang, Z.J.; Cao, Z.Q.; Guo, S.; Wang, T.M.; Li, T.J.; Liaw, P.K. Promising properties and future trend of eutectic high entropy alloys. Scr. Mater. 2020, 187, 202–209. [Google Scholar] [CrossRef]

- Lu, Y.P.; Gao, X.Z.; Jiang, L.; Chen, Z.N.; Wang, T.M.; Jie, J.C.; Kang, H.J.; Zhang, Y.B.; Guo, S.; Ruan, H.H. Directly cast bulk eutectic and near-eutectic high entropy alloys with balanced strength and ductility in a wide temperature range. Acta Mater. 2017, 124, 143–150. [Google Scholar] [CrossRef]

- Wang, M.L.; Lu, Y.P.; Lan, J.G.; Wang, T.M.; Zhang, C.; Cao, Z.Q.; Li, T.J.; Liaw, P.K. Lightweight, ultrastrong and high thermal-stable eutectic high-entropy alloys for elevated-temperature applications. Acta Mater. 2023, 248, 118806. [Google Scholar] [CrossRef]

- Wang, M.L.; Lu, Y.P.; Lan, J.G.; Wang, T.M.; Zhang, C.A.; Cao, Z.Q.; Li, T.J.; Liaw, P.K. A novel bulk eutectic high-entrogy alloy with outstanding as-cast specific yield strengths at elevated temperatures. Scr. Mater. 2021, 204, 114132. [Google Scholar] [CrossRef]

- Ma, S.G.; Jiao, Z.M.; Qiao, J.W.; Yang, H.J.; Zhang, Y.; Wang, Z.H. Strain rate effects on the dynamic mechanical properties of the AlCrCuFeNi2 high-entropy alloy. Mater. Sci. Eng. A 2016, 649, 35–38. [Google Scholar] [CrossRef]

- Dong, Y.; Gao, X.X.; Lu, Y.P.; Wang, T.M.; Li, T.J. A multi-component AlCrFe2Ni2 alloy with excellent mechanical properties. Mater. Lett. 2016, 169, 62. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Diao, H.; Liaw, P.K.; Meyers, M.A. High-velocity deformation of Al0.3CoCrFeNi high-entropy alloy: Remarkable resistance to shear failure. Sci. Rep. 2017, 7, 42742. [Google Scholar] [CrossRef]

- Meyers, M.A. (Ed.) Dynamic Behavior of Materials; John Wiley and Sons: Hoboken, NJ, USA, 1994. [Google Scholar]

- Cho, K.M.; Lee, S.H.; Nutt, S.R.; Duffy, J. Adiabatic shear band formation during dynamic torsional deformation of an HY-100 steel. Acta Mater. 1993, 41, 923–932. [Google Scholar] [CrossRef]

- Lee, H.S.; Sohn, S.S.; Jeon, C.W.; Jo, I.G.; Lee, S.K.; Lee, S.H. Dynamic compressive deformation behavior of SiC-particulate-reinforced A356 Al alloy matrix composites fabricated by liquid pressing process. Mater. Sci. Eng. A 2017, 680, 368–377. [Google Scholar] [CrossRef]

- Dirras, G.; Couque, H.; Lilensten, L.; Heczel, A.; Tingaud, D.; Couzinié, J.-P.; Perriére, L.; Gubicza, J.; Guillot, I. Mechanical behavior and microstructure of Ti20Hf20Zr20Ta20Nb20 high-entropy alloy loaded under quasi-static and dynamic compression conditions. Mater. Charact. 2016, 111, 106–113. [Google Scholar] [CrossRef]

- Wang, L.; Qiao, J.W.; Ma, S.G.; Jiao, Z.M.; Zhang, T.W.; Chen, G.; Zhao, D.; Zhang, Y.; Wang, Z.H. Mechanical response and deformation behavior of Al0.6CoCrFeNi high-entropy alloys upon dynamic loading. Mater. Sci. Eng. 2018, 727, 208–213. [Google Scholar] [CrossRef]

- Tian, L.; Jiao, Z.M.; Yuan, G.Z.; Ma, S.G.; Wang, Z.H.; Yang, H.J.; Zhang, Y.; Qiao, J.W. Effect of Strain Rate on Deformation Behavior of AlCoCrFeNi High-Entropy Alloy by Nanoindentation. Mater. Eng. Perform. 2016, 25, 2255–2260. [Google Scholar] [CrossRef]

- Cao, T.Q.; Zhang, Q.; Wang, L.; Wang, L.; Xiao, Y.; Yao, J.H.; Liu, H.Y.; Ren, Y.; Liang, J.; Xue, Y.F. Dynamic deformation behaviors and mechanisms of CoCrFeNi high-entropy alloys. Acta Mater. 2023, 260, 119343. [Google Scholar] [CrossRef]

- Yuan, K.B.; Yao, X.H.; Yu, Y.Q.; Wang, R.F.; Chai, Z.S.; Zhou, K.X.; Wang, Z.J. Dynamic thermomechanical response and constitutive modeling of eutectic high-entropy alloy. Int. J. Mech. Sci. 2023, 246, 108148. [Google Scholar] [CrossRef]

- Park, J.M.; Moon, J.; Bea, J.W.; Jang, M.J.; Park, J.; Lee, S.; Kim, H.S. Strain rate effects of dynamic compressive deformation on mechanical properties and microstructure of CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. 2018, 719, 155–163. [Google Scholar] [CrossRef]

- Kumar, N.; Ying, Q.; Nie, X.; Mishra, R.S.; Tang, Z.; Liaw, P.K.; Brenan, R.E.; Doherty, K.J.; Cho, K.C. High strain-rate compressive deformation behavior of the Al0.1CrFeCoNi high entropy alloy. Mater. Des. 2015, 86, 598–602. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Wang, B.F.; Fu, A.; Huang, X.X.; Liu, B.; Liu, Y.; Li, Z.Z.; Zan, X. Mechanical properties and microstructure of the CoCrFeMnNi high entropy alloy under high strain rate compression. Mater. Eng. Perform. 2016, 25, 2985–2992. [Google Scholar] [CrossRef]

- Dong, Y.; Zhou, K.Y.; Lu, Y.P.; Gao, X.X.; Wang, T.M.; Li, T.J. Effect of vanadium addition on the microstructure and properties of AlCoCrFeNi high entropy alloy. Mater. Des. 2014, 57, 67–72. [Google Scholar] [CrossRef]

- Singh, S.; Wanderka, N.; Murty, B.S.; Glatzel, U.; Banhart, J. Decomposition in multi-component AlCoCrCuFeNi high-entropy alloy. Acta Mater. 2011, 59, 182–190. [Google Scholar] [CrossRef]

- Santodonato, L.J.; Zhang, Y.; Feygenson, M.; Parish, C.M.; Gao, M.C.; Weber, R.J.K.; Neuefeind, J.C.; Tang, Z.; Liaw, P.K. Deviation from high-entropy configurations in the atomic distributions of a multi-principal-element alloy. Nat. Commun. 2015, 6, 5964. [Google Scholar] [CrossRef]

- Linden, Y.; Pinkas, M.; Munitz, A.; Meshi, L. Long-period antiphase domains and short-range order in a B2 matrix of the AlCoCrFeNi high-entropy alloy. Scr. Mater. 2017, 139, 49–52. [Google Scholar] [CrossRef]

- Moon, J.; Hong, S.I.; Bae, J.W.; Jang, M.J.; Yim, D.; Kim, H.S. On the strain rate-dependent deformation mechanism of CoCrFeMnNi high-entropy alloy at liquid nitrogen temperature. Mater. Res. Lett. 2017, 5, 472–477. [Google Scholar] [CrossRef]

- Tang, Y.; Wang, R.X.; Xiao, B.; Zhang, Z.R.; Li, S.; Qiao, J.W.; Bai, S.X.; Zhang, Y.; Liaw, P.K. A review on dynamic-mechanical behaviors of high entropy alloys. Prog. Mater. Sci. 2023, 135, 101090. [Google Scholar] [CrossRef]

- Hong, S.I.; Moon, J.; Hong, S.K.; Kim, H.S. Thermally activated deformation and the rate controlling mechanism in CoCrFeMnNi high entropy alloy. Mater. Sci. Eng. A 2017, 682, 569–576. [Google Scholar] [CrossRef]

- Hines, J.A.; Vecchio, K.S. Recrystallization kinetics within adiabatic shear bands. Acta Mater. 1997, 45, 635–649. [Google Scholar] [CrossRef]

- Chen, W.; Song, B. Split Hopkinson (Kolsky) Bar; Springer: New York, NY, USA, 2011. [Google Scholar]

- Conque, H. The use of the direct impact Hopkinson pressure bar technique to describe thermally activated and viscous regimes of metallic materials. Philos. Trans. A Math. Phys. Eng. Sci. 2014, 372, 20130218. [Google Scholar]

- Meyers, M.A.; Nesterenko, V.F.; Lasalvis, J.C.; Xue, Q. Shear localization in dynamic deformation of materials: Microstructural evolution and self-organization. Mater. Sci. Eng. A 2001, 317, 204–225. [Google Scholar] [CrossRef]

- Ahn, D.H.; Lee, D.J.; Kang, M.J.; Park, L.J.; Lee, S.H.; Kim, H.S. Bi-modal structure of copper via room-temperature partial recrystallization after cryogenic dynamic compression. Metall. Mater. Trans. A 2016, 47, 1600–1606. [Google Scholar] [CrossRef]

- Bai, J.; Kou, H.C.; Wang, J.; Li, J.S.; Hu, R. Strain rate response of a Ti-based metallic glass composite at cryogenic temperature. Mater. Lett. 2014, 117, 228–230. [Google Scholar] [CrossRef]

- Jiang, K.; Ren, T.F.; Shan, G.B.; Ye, T.; Chen, L.Y.; Wang, C.X.; Zhao, F.; Li, J.G.; Suo, T. Dynamic mechanical responses of the Al0.1CoCrFeNi high entropy alloy at cryogenic temperature. Mater. Sci. Eng. A 2020, 797, 140125. [Google Scholar] [CrossRef]

| Strain Rate [s−1] | Yield Strength [MPa] | Plastic Strain [%] |

|---|---|---|

| 1 × 10−4 | 606.1 ± 3.0 | >30.0 |

| 1 × 10−3 | 616.3 ± 3.1 | >30.0 |

| 1 × 10−2 | 691.6 ± 3.5 | >30.0 |

| 1 × 10−1 | 655.8 ± 3.3 | >30.0 |

| 1 × 100 | 658.3 ± 3.3 | >30.0 |

| Strain Rate [s−1] | Yield Strength [MPa] | Compressive Stress [MPa] | Plastic Strain [%] |

|---|---|---|---|

| 1300 | 891.9 ± 4.5 | 1521.8 ± 7.6 | 12.8 ± 2.3 |

| 1700 | 1132.4 ± 5.7 | 1815.5 ± 9.1 | 14.7 ± 2.0 |

| 2100 | 1091.7 ± 5.5 | 1925.3 ± 9.6 | 18.2 ± 1.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, H.; Wang, Y.; Gan, X.; Dong, Y.; Liu, S.; Duan, S.; Mao, L. Microstructure Evolution and Mechanical Properties of Dual-Phase AlCrFe2Ni2 High-Entropy Alloy Under High-Strain-Rate Compression. Materials 2025, 18, 1191. https://doi.org/10.3390/ma18061191

Yan H, Wang Y, Gan X, Dong Y, Liu S, Duan S, Mao L. Microstructure Evolution and Mechanical Properties of Dual-Phase AlCrFe2Ni2 High-Entropy Alloy Under High-Strain-Rate Compression. Materials. 2025; 18(6):1191. https://doi.org/10.3390/ma18061191

Chicago/Turabian StyleYan, Hang, Yu Wang, Xilin Gan, Yong Dong, Shichao Liu, Shougang Duan, and Lingbo Mao. 2025. "Microstructure Evolution and Mechanical Properties of Dual-Phase AlCrFe2Ni2 High-Entropy Alloy Under High-Strain-Rate Compression" Materials 18, no. 6: 1191. https://doi.org/10.3390/ma18061191

APA StyleYan, H., Wang, Y., Gan, X., Dong, Y., Liu, S., Duan, S., & Mao, L. (2025). Microstructure Evolution and Mechanical Properties of Dual-Phase AlCrFe2Ni2 High-Entropy Alloy Under High-Strain-Rate Compression. Materials, 18(6), 1191. https://doi.org/10.3390/ma18061191