Prediction and Experimental Study of Low-Frequency Acoustic and Vibration Responses for an Aircraft Instrument Compartment Based on the Virtual Material Method

Highlights

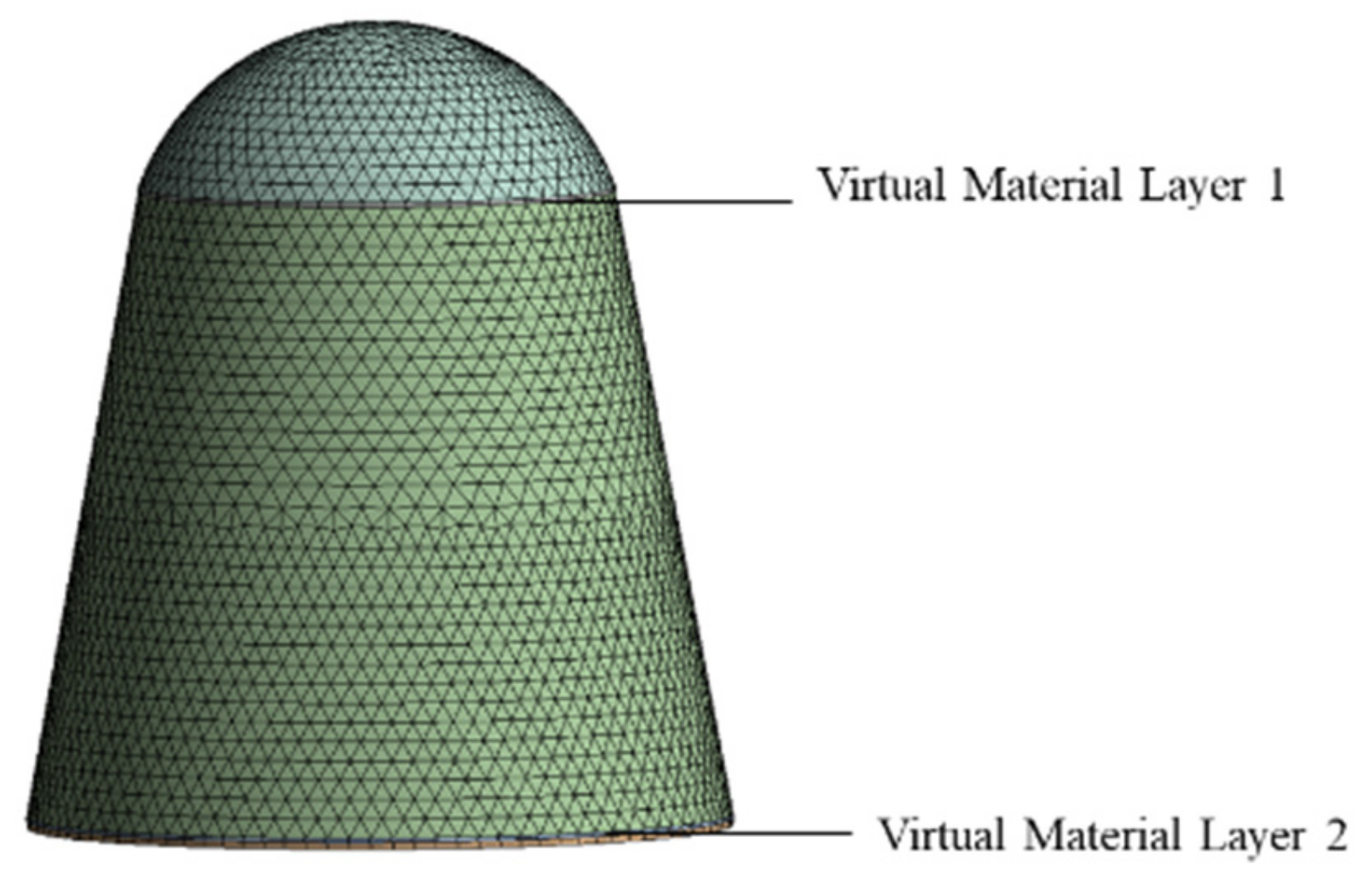

- By adding a layer of virtual material to the joint surface, the finite element model can be closer to the actual structure than the binding constraint method in theory.

- Through a modal experiment, it is found that the modal frequency of the model based on the virtual material method is closer to the experimental value.

- Through the noise excitation experiment, it is found that the model based on the virtual material method has a smaller vibration noise response error, which verifies the superiority of this method.

Abstract

1. Introduction

2. Parametric Modeling of Structural Bolted Joint Virtual Material Layer Dynamics

2.1. Basic Principles of Assumptions in the Virtual Material Method

2.2. Determination of Virtual Material Layer Parameters for Structural Bolted Joints

2.2.1. Determination of Virtual Material Layer Thickness and Density

2.2.2. Parameter Identification for Elastic Modulus and Poisson’s Ratio of the Virtual Material Layer

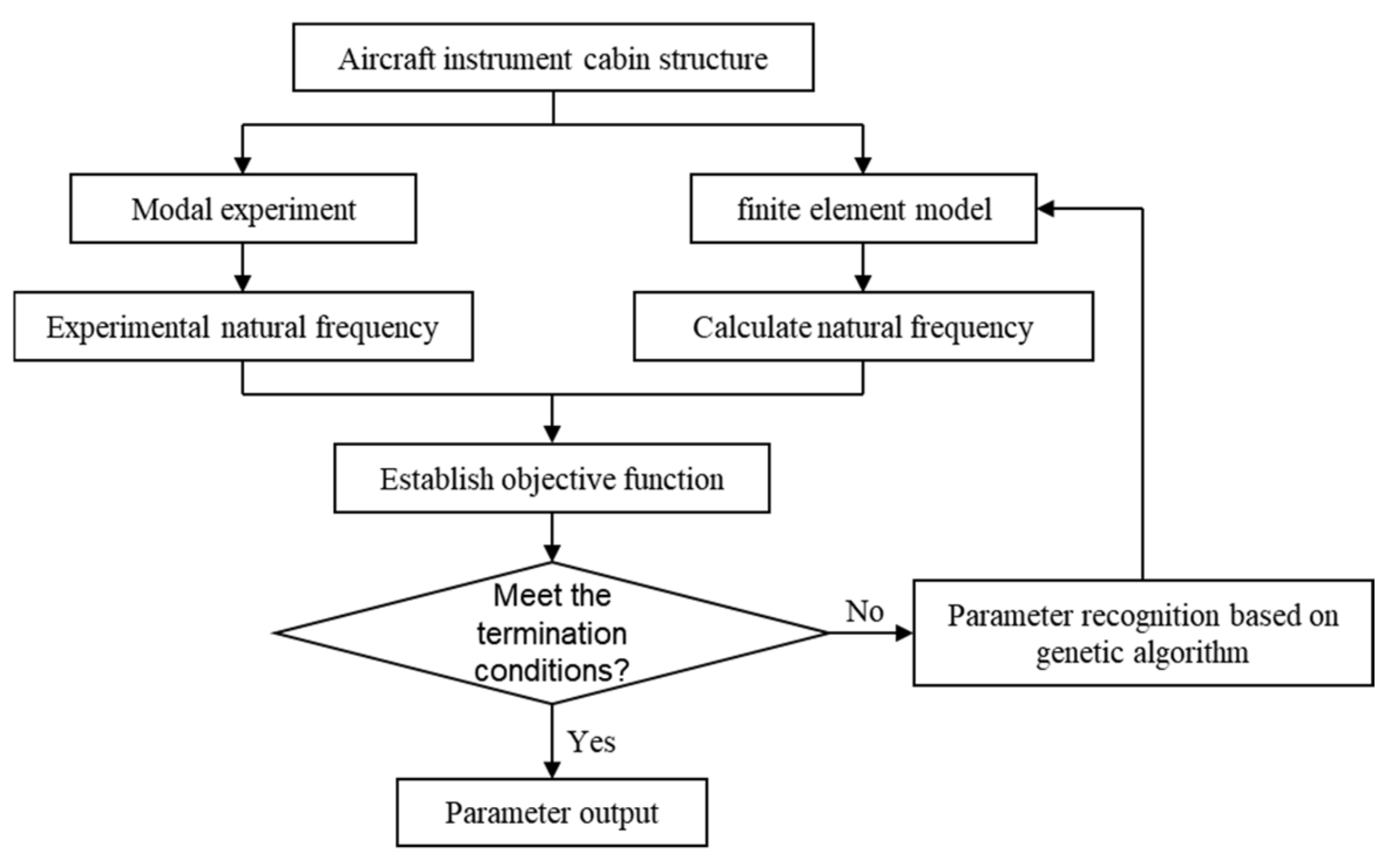

- Establish a finite element model of the aircraft instrument compartment structure in Ansys, incorporating a virtual material layer at the bolted joints, and perform simulation calculations to obtain initial computed frequencies and mode shapes.

- Conduct modal experiments on the aircraft instrument compartment to acquire actual natural frequencies and mode shapes of the structure.

- Formulate an objective function based on the structural computed frequencies and the experimental frequencies obtained from modal testing, with the elastic parameters of the virtual material layer serving as design variables.

- Set constraints and apply genetic algorithms to identify the elastic parameters of the virtual material layer.

- Once the objective function meets the termination criteria, the identified parameters for the virtual material layer model are obtained.

3. Modal Acquisition of Instrument Compartment and Identification of Elastic Parameters of Virtual Material Layer

3.1. Modal Test of Aircraft Instrument Compartment

3.2. Modal Calculation of the Instrument Compartment of the Aircraft

3.3. Identification of Elastic Parameters of Structural Virtual Material Layer Based on Genetic Algorithm

4. Calculation and Test Comparison and Analysis of the Acoustic and Vibrating Response of the Instrument Compartment

4.1. Comparison of the Vibration Response Calculation and Test Results of the Instrument Compartment

4.2. Calculation of Noise Response of Acoustic Cavity Inside the Instrument Compartment and Comparison of Test Results

5. Conclusions

- Accurate Simulation with Virtual Material Method: By adding a layer of virtual material at the bolted interfaces, the virtual material method can accurately simulate the contact characteristics of the joints. While theoretically calculating the elastic parameters (elastic modulus, Poisson’s ratio) of the virtual material is complex, using parameter identification provides a simpler approach to obtaining these parameters with high precision.

- High Precision in Modal Analysis: For structures modeled using the virtual material method, the calculated modal shapes are consistent with experimental modal shapes, and the error between computed frequencies and experimental frequencies is within 3%. Compared to the tied constraint method, this approach offers higher accuracy, indicating that the virtual material method better approximates real-world conditions when simulating bolted connections.

- Superior Vibration and Acoustic Prediction: The structure modeled using virtual material method has a smaller frequency offset of peak vibration response, not exceeding 7 Hz, while the peak frequency offset of the bound constraint model exceeds 20 Hz; The root mean square value of the vibration response acceleration of the virtual material model is also closer to the experimental results. In terms of noise response, the sound pressure level error at each center frequency point is smaller, and the total sound pressure level error does not exceed 2 dB. The above results indicate that the virtual material method is more accurate in describing the dynamic characteristics of structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, R.; Crocombe, A.D.; Richardson, G.; Underwood, C.I. Energy dissipation in spacecraft structures incorporating bolted joints operating in macroslip. J. Aerosp. Eng. 2008, 21, 19–26. [Google Scholar] [CrossRef]

- Crocombe, A.D.; Wang, R.; Richardson, G.; Underwood, C.I. Estimating the energy dissipated in a bolted spacecraft at resonance. Comput. Struct. 2006, 84, 340–350. [Google Scholar] [CrossRef]

- De Benedetti, M.; Garofalo, G.; Zumpano, M.; Barboni, R. On the damping effect due to bolted junctions in space structures subjected to pyro-shock. Acta Astronaut. 2007, 60, 947–956. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Yang, C.; Cai, L.G.; Shi, W.M.; Liu, Z.F. Surface contact stress-based nonlinear virtual material method for dynamic analysis of bolted joint of machine tool. Precis. Eng. J. Int. Soc. Precis. Eng. Nanotechnol. 2016, 43, 230–240. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Wu, P. Equivalence analysis of acoustic excitation and random vibration exerted on spacecraft units. J. Phys. Conf. Ser. 2023, 2569, 012007. [Google Scholar] [CrossRef]

- Forgrave, J.C.; Man, K.F.; Newell, J.M. Spacecraft acoustic and random vibration test optimization. Sound Vib. 1999, 33, 28–31. [Google Scholar]

- Li, Q.; Xing, L.; Bai, J.; Zou, Y. Method Study on Response Prediction of Structural Vibrations in Spacecraft Acoustic Tests. Chin. J. Theor. Appl. Mech. 2019, 51, 569–576. [Google Scholar]

- Rarata, Z.; Dacko, A.; Barcinski, T.; Polak, S.; Musial, J.; Kubacki, S.; Kowalski, T.; Sikorski, A.; Baran, J. Vibro-acoustic response of spacecraft instrument subjected to diffuse sound field: Numerical simulations and experimental verification. Appl. Acoust. 2021, 184, 108338. [Google Scholar] [CrossRef]

- Karpenko, M.; Stosiak, M.; Deptuła, A.; Urbanowicz, K.; Nugaras, J.; Królczyk, G.; Żak, K. Performance evaluation of extruded polystyrene foam for aerospace engineering applications using frequency analyses. Int. J. Adv. Manuf. Technol. 2023, 126, 5515–5526. [Google Scholar] [CrossRef]

- Sestieri, A.; Carcaterra, A. Vibroacoustic: The challenges of a mission impossible? Mech. Syst. Signal Proc. 2013, 34, 1–18. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, Y.M.; Dou, Y.H.; Yuan, Q.Y.; Tang, J.R.; Cao, Y.P. Parameter Identification and Energy Dissipation Analysis of Premium Connections Based on the Iwan Model. Processes 2024, 12, 2382. [Google Scholar] [CrossRef]

- Brake, M.R.W. A reduced Iwan model that includes pinning for bolted joint mechanics. Nonlinear Dyn. 2017, 87, 1335–1349. [Google Scholar] [CrossRef]

- Mignolet, M.P.; Song, P.C.; Wang, X.Q. A stochastic Iwan-type model for joint behavior variability modeling. J. Sound Vib. 2015, 349, 289–298. [Google Scholar] [CrossRef]

- Chu, Y.P.; Wen, H.; Chen, T. Nonlinear Modeling and Identification of an Aluminum Honeycomb Panel with Multiple Bolts. Shock Vib. 2016, 2016, 1276753. [Google Scholar] [CrossRef]

- Alamdari, M.M.; Li, J.C.; Samali, B.; Ahmadian, H.; Naghavi, A. Nonlinear Joint Model Updating in Assembled Structures. J. Eng. Mech. 2014, 140, 04014042. [Google Scholar] [CrossRef]

- Zhan, M.; Guo, Q.T.; Yue, L.; Zhang, B.Q. Modeling and Stochastic Model Updating of Bolt-Jointed Structure. Shock Vib. 2018, 2018, 8354249. [Google Scholar] [CrossRef]

- Tian, H.L.; Li, B.; Liu, H.Q.; Mao, K.M.; Peng, F.Y.; Huang, X.L. A new method of virtual material hypothesis-based dynamic modeling on fixed joint interface in machine tools. Int. J. Mach. Tools Manuf. 2011, 51, 239–249. [Google Scholar] [CrossRef]

- Sun, Y.Y.; Xiao, H.F.; Xu, J.W. Contact stiffness ratio of tribological interface using the equivalent thin layer and the micro-slip model. Proc. Inst. Mech. Eng. Part C J. Eng. Mech. Eng. Sci. 2020, 234, 444–456. [Google Scholar] [CrossRef]

- Sun, Y.Y.; Chuang, H.C.; Xiao, H.F.; Xu, J.W. Prediction of the normal contact stiffness between elastic rough surfaces in lubricated contact via an equivalent thin layer. J. Vib. Control 2020, 26, 2060–2069. [Google Scholar] [CrossRef]

- Yang, Y.; Cheng, H.; Liang, B.A.; Zhao, D.; Hu, J.S.; Zhang, K.F. A novel virtual material layer model for predicting natural frequencies of composite bolted joints. Chin. J. Aeronaut. 2021, 34, 101–111. [Google Scholar] [CrossRef]

- Liu, P.; Guan, T.; Wang, X. Nonlinear connection layer modeling and parametric identification for single bolt connected beam. J. Vib. Shock 2023, 42, 190–197. [Google Scholar]

| Material Parameters | Initial Value | Lower Limit | Upper Limit |

|---|---|---|---|

| Elastic modulus/GPa | 70 | 0.1 | 80 |

| Poisson’s ratio | 0.3 | 0.15 | 0.45 |

| Elastic Modulus/GPa | Poisson’s Ratio | |

|---|---|---|

| Connection Layer 1 | 4.836 | 0.287 |

| Connection Layer 2 | 3.556 | 0.265 |

| Order | Test Modal Frequency/Hz | Virtual Materials Method | Binding Constraint Method | ||

|---|---|---|---|---|---|

| Calculate Modal Frequency/Hz | Error % | Calculate Modal Frequency/Hz | Error % | ||

| 1 | 98.44 | 101.24 | 2.84 | 105.61 | 7.28 |

| 2 | 201.56 | 204.66 | 1.54 | 217.81 | 8.06 |

| 3 | 240.63 | 246.79 | 2.56 | 258.51 | 7.43 |

| 4 | 309.38 | 315.85 | 2.09 | 330.23 | 6.74 |

| Test Peak Frequency/Hz | Virtual Materials Method | Binding Constraint Method | ||||

|---|---|---|---|---|---|---|

| Calculate Peak Frequency/Hz | Frequency Offset/Hz | Error % | Calculate Peak Frequency/Hz | Frequency Offset/Hz | Error % | |

| 97.52 | 102.86 | 5.34 | 5.48 | 105.87 | 8.09 | 8.30 |

| 200.32 | 198.87 | −1.45 | −0.72 | 216.96 | 17.49 | 8.73 |

| 238.45 | 237.01 | −1.44 | −0.60 | 256.43 | 21.5 | 9.02 |

| 307.89 | 314.43 | 6.54 | 2.12 | 328.55 | 15.8 | 5.13 |

| 349.76 | 346.67 | −3.09 | −0.88 | 361.87 | 14.87 | 4.25 |

| Center Frequency/Hz | Sound Pressure Level in the Internal Acoustic Cavity/dB | ||

|---|---|---|---|

| Test Values | Virtual Materials Method | Binding Constraint Method | |

| 50 | 108.4 | 110.4 | 113.2 |

| 63 | 112.2 | 113.7 | 114.9 |

| 80 | 116.7 | 118.4 | 119.7 |

| 100 | 119.3 | 121.3 | 122.5 |

| 125 | 122.5 | 124.8 | 126.9 |

| 160 | 124.2 | 125.4 | 129.1 |

| 200 | 127.5 | 128.2 | 130.7 |

| 250 | 128.7 | 129.9 | 131.1 |

| 315 | 129.9 | 130.7 | 131.9 |

| 400 | 129.5 | 131.1 | 132.6 |

| Total sound pressure level | 135.76 | 136.98 | 138.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, S.; Wang, J.; Liu, C.; Huang, R. Prediction and Experimental Study of Low-Frequency Acoustic and Vibration Responses for an Aircraft Instrument Compartment Based on the Virtual Material Method. Materials 2025, 18, 932. https://doi.org/10.3390/ma18050932

Song S, Wang J, Liu C, Huang R. Prediction and Experimental Study of Low-Frequency Acoustic and Vibration Responses for an Aircraft Instrument Compartment Based on the Virtual Material Method. Materials. 2025; 18(5):932. https://doi.org/10.3390/ma18050932

Chicago/Turabian StyleSong, Shaowei, Jun Wang, Chang Liu, and Rongze Huang. 2025. "Prediction and Experimental Study of Low-Frequency Acoustic and Vibration Responses for an Aircraft Instrument Compartment Based on the Virtual Material Method" Materials 18, no. 5: 932. https://doi.org/10.3390/ma18050932

APA StyleSong, S., Wang, J., Liu, C., & Huang, R. (2025). Prediction and Experimental Study of Low-Frequency Acoustic and Vibration Responses for an Aircraft Instrument Compartment Based on the Virtual Material Method. Materials, 18(5), 932. https://doi.org/10.3390/ma18050932