Microstructure Evolution, Tensile/Nanoindentation Response, and Work-Hardening Behaviour of Prestrained and Subsequently Annealed LPBF 316L Stainless Steel

Highlights

- Cold deformation to 0.12 strain enhanced the YTS of LPBF 316L by 25–65%.

- The “melt pool/cellular” structure of LPBF steel is stable until fracture.

- Severely deformed LPBF 316L ruptures via a fully ductile mechanism.

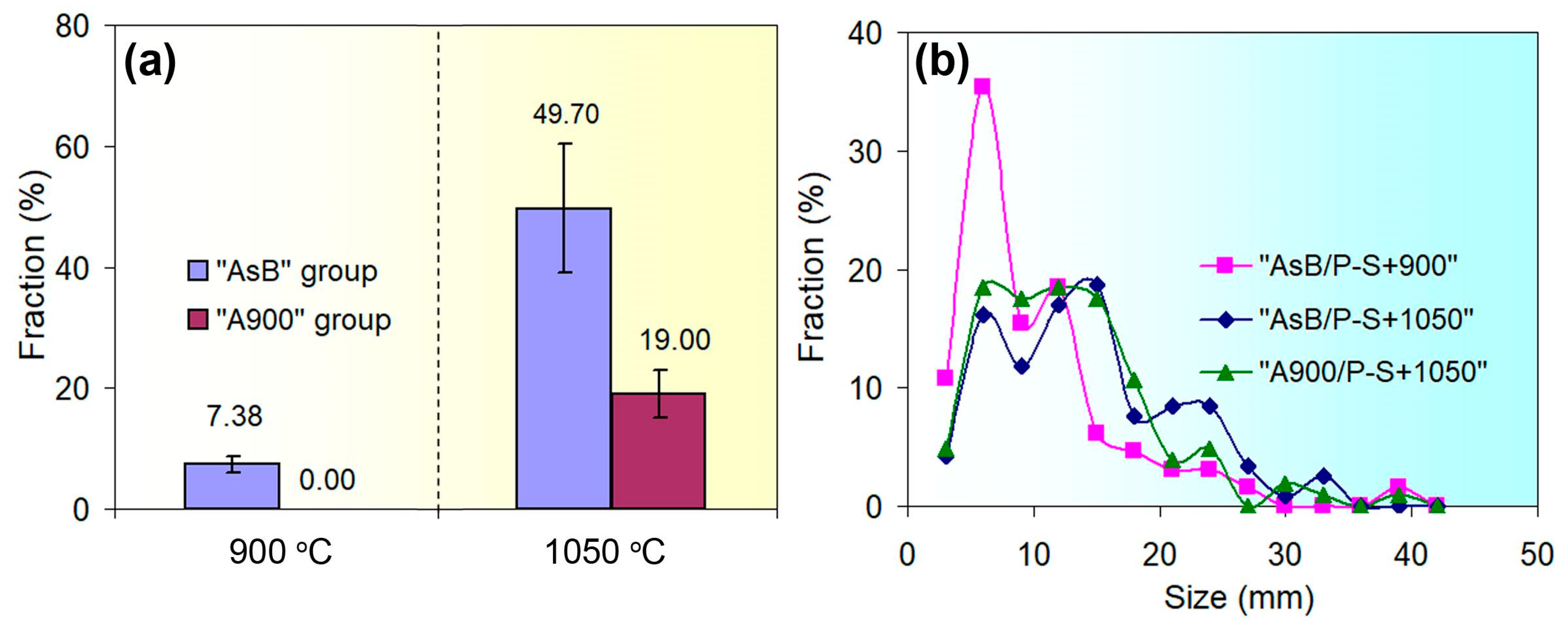

- Prestrained LPBF 316L displays sluggish recrystallization kinetics at 900–1050 °C.

- Prestraining and partial recrystallization increased the PSE of 316L to 40.3 GPa·%.

Abstract

1. Introduction

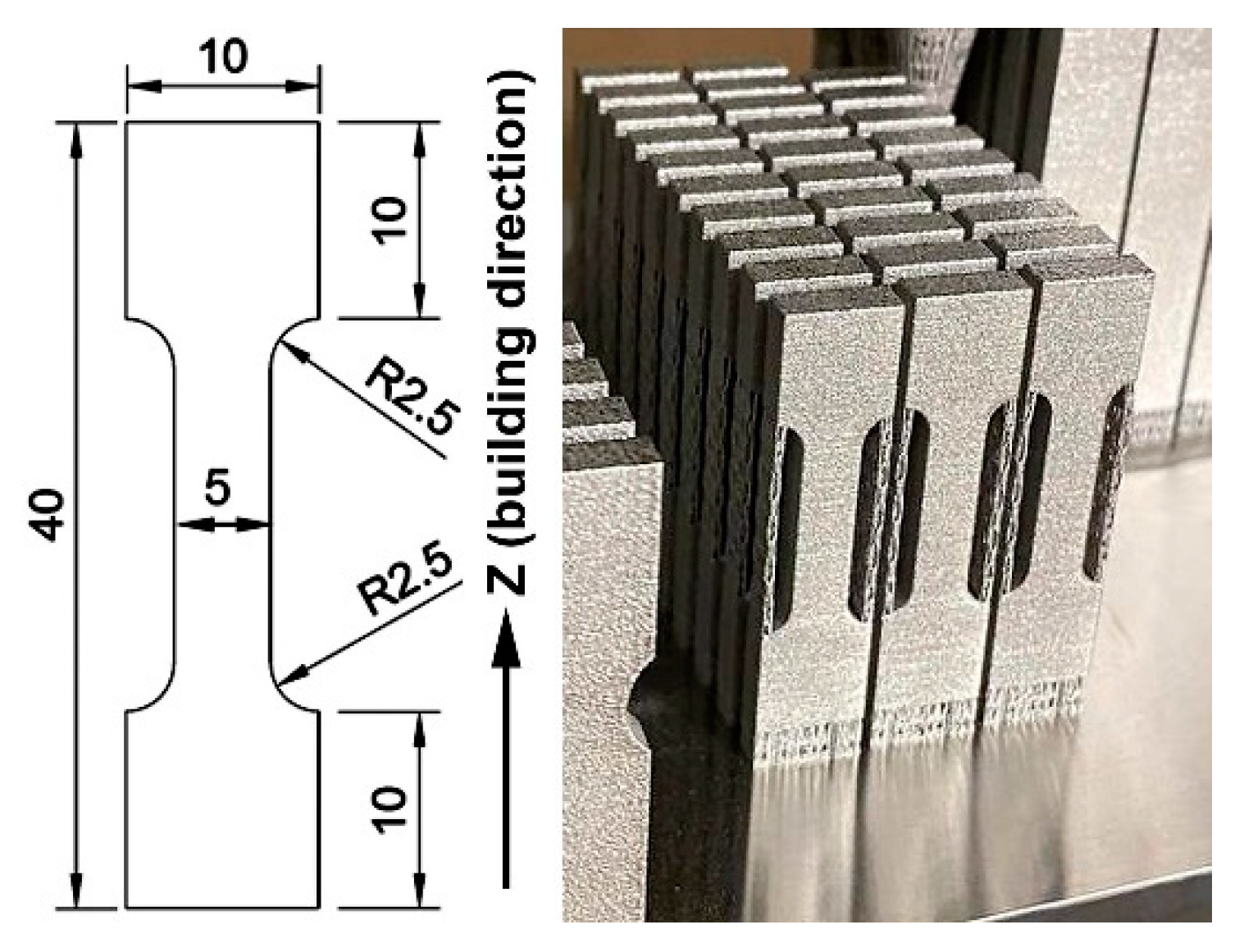

2. Materials and Methods

3. Results

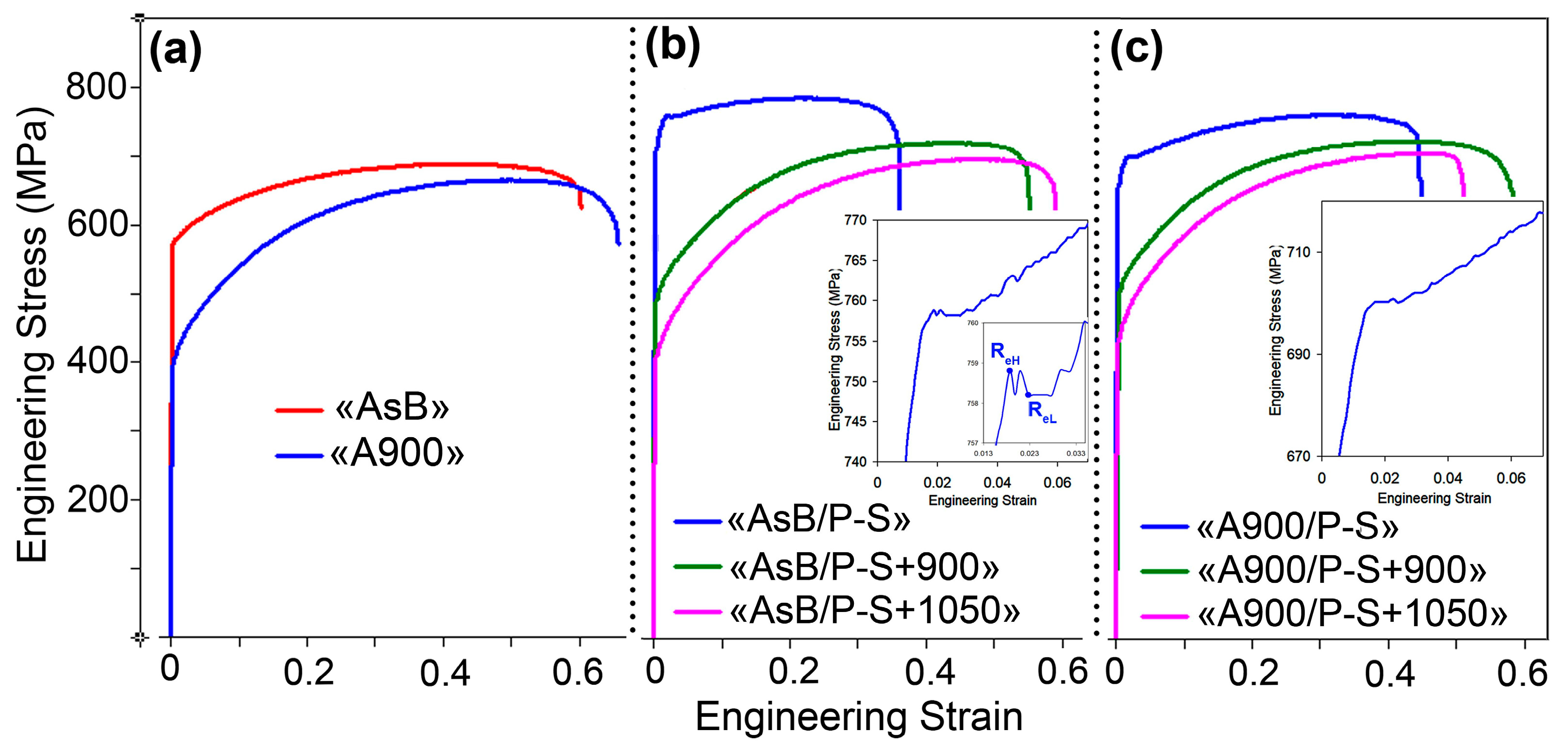

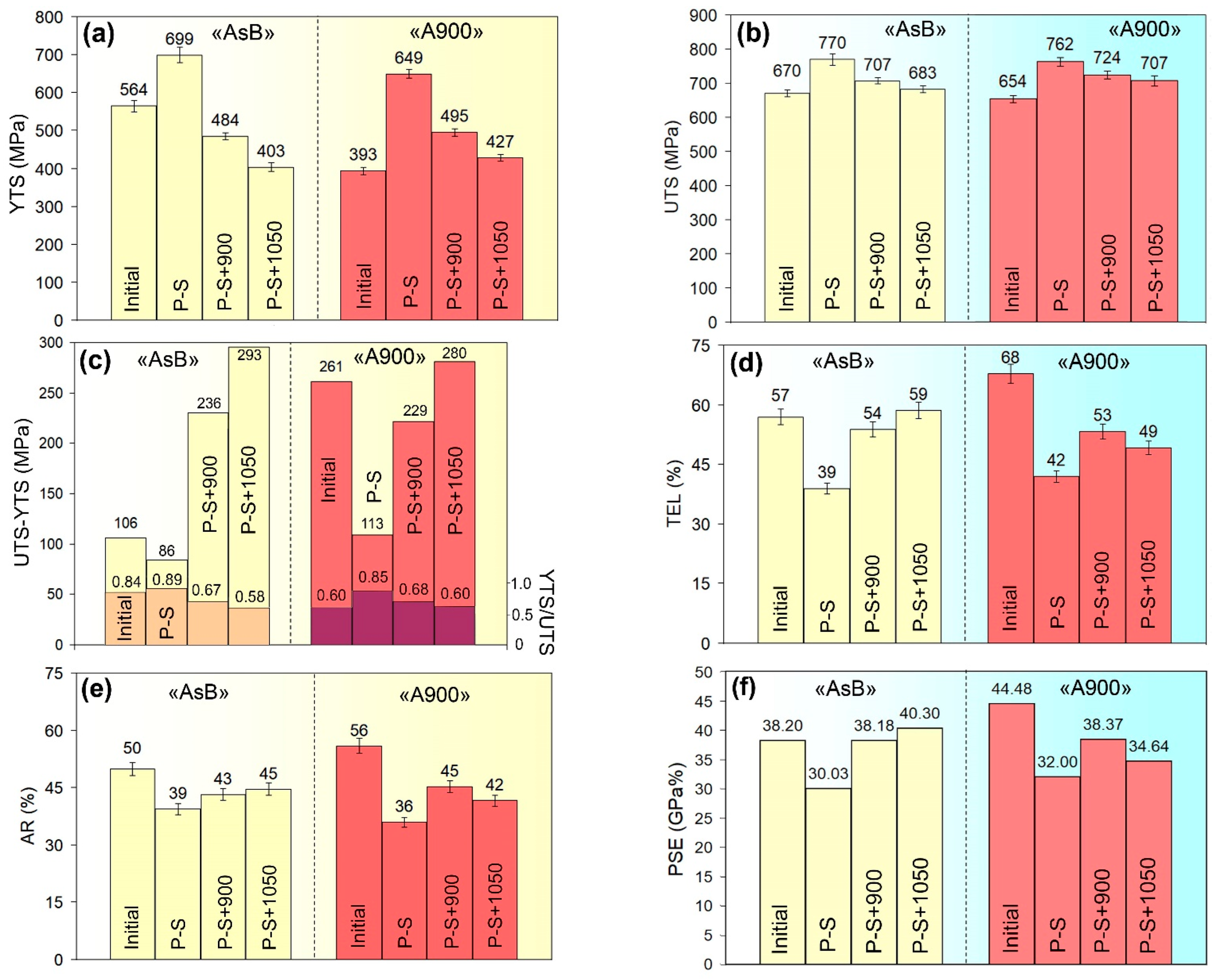

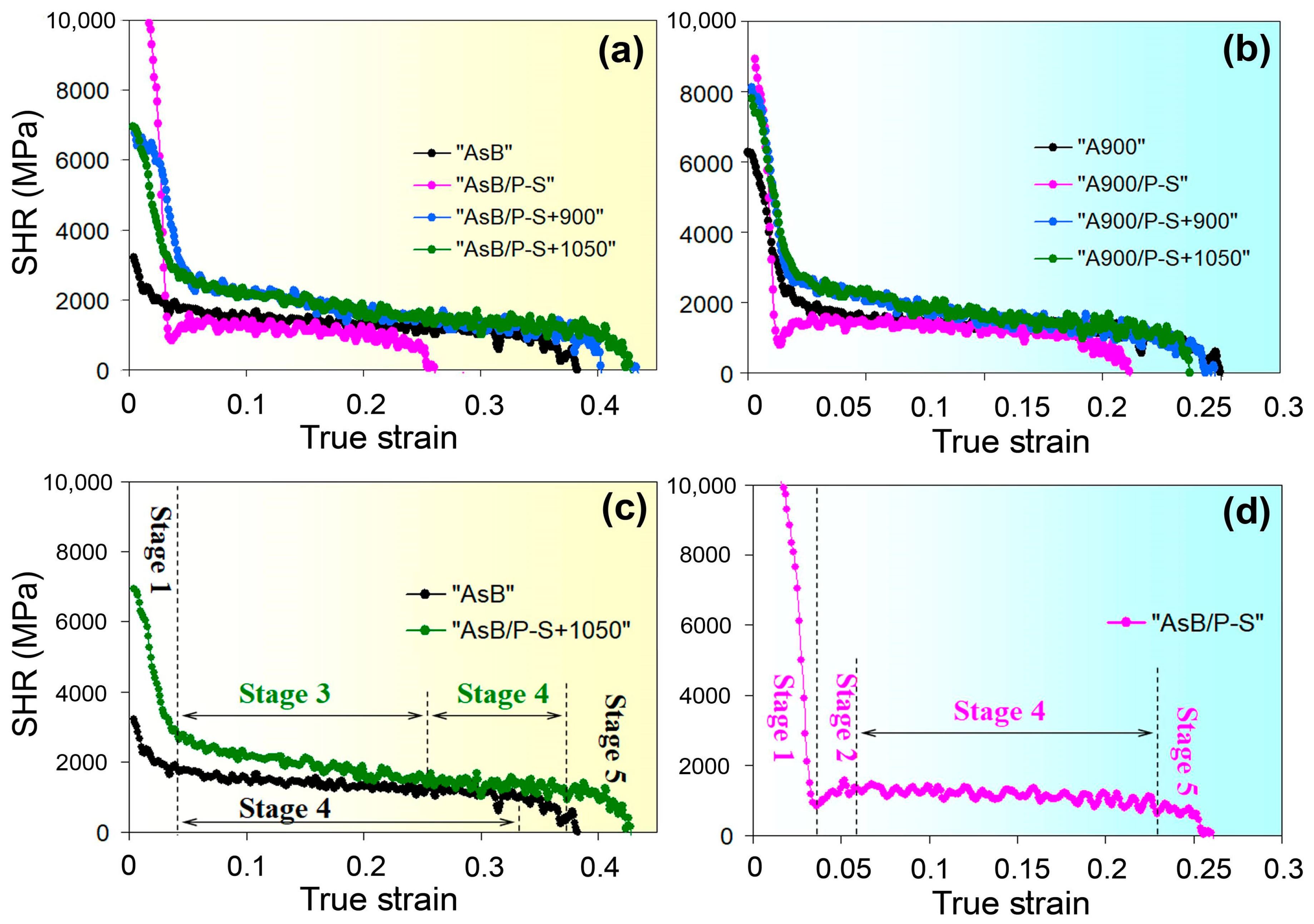

3.1. Mechanical Behaviours Assessment

3.1.1. Tensile Testing

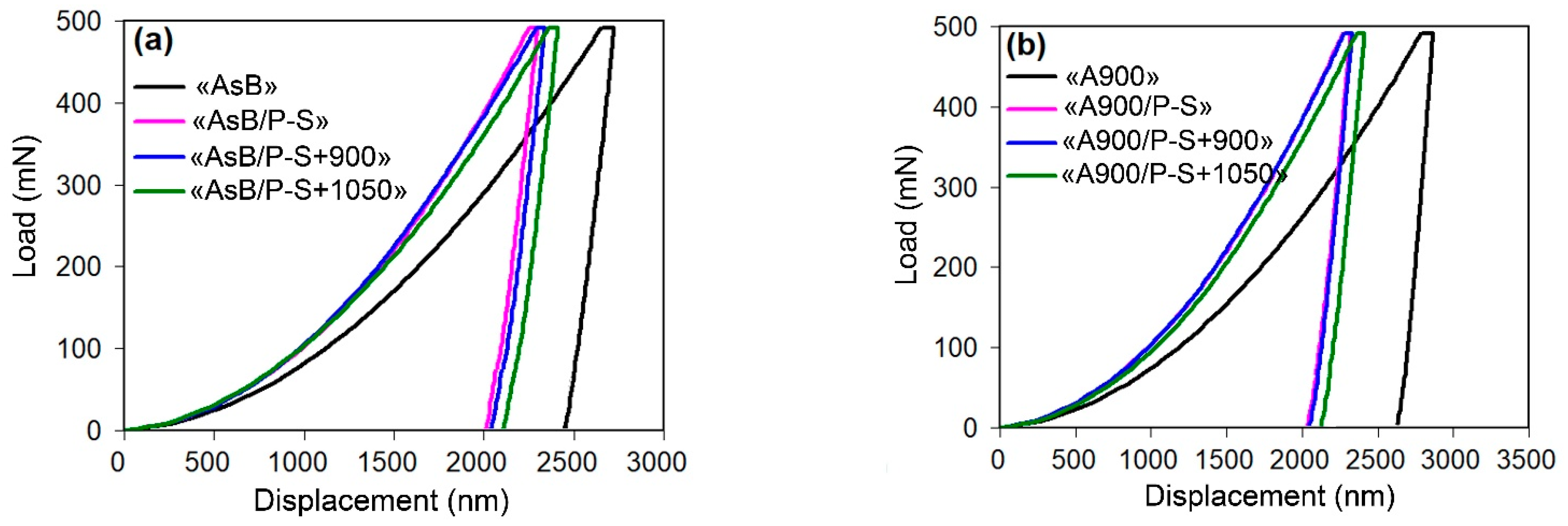

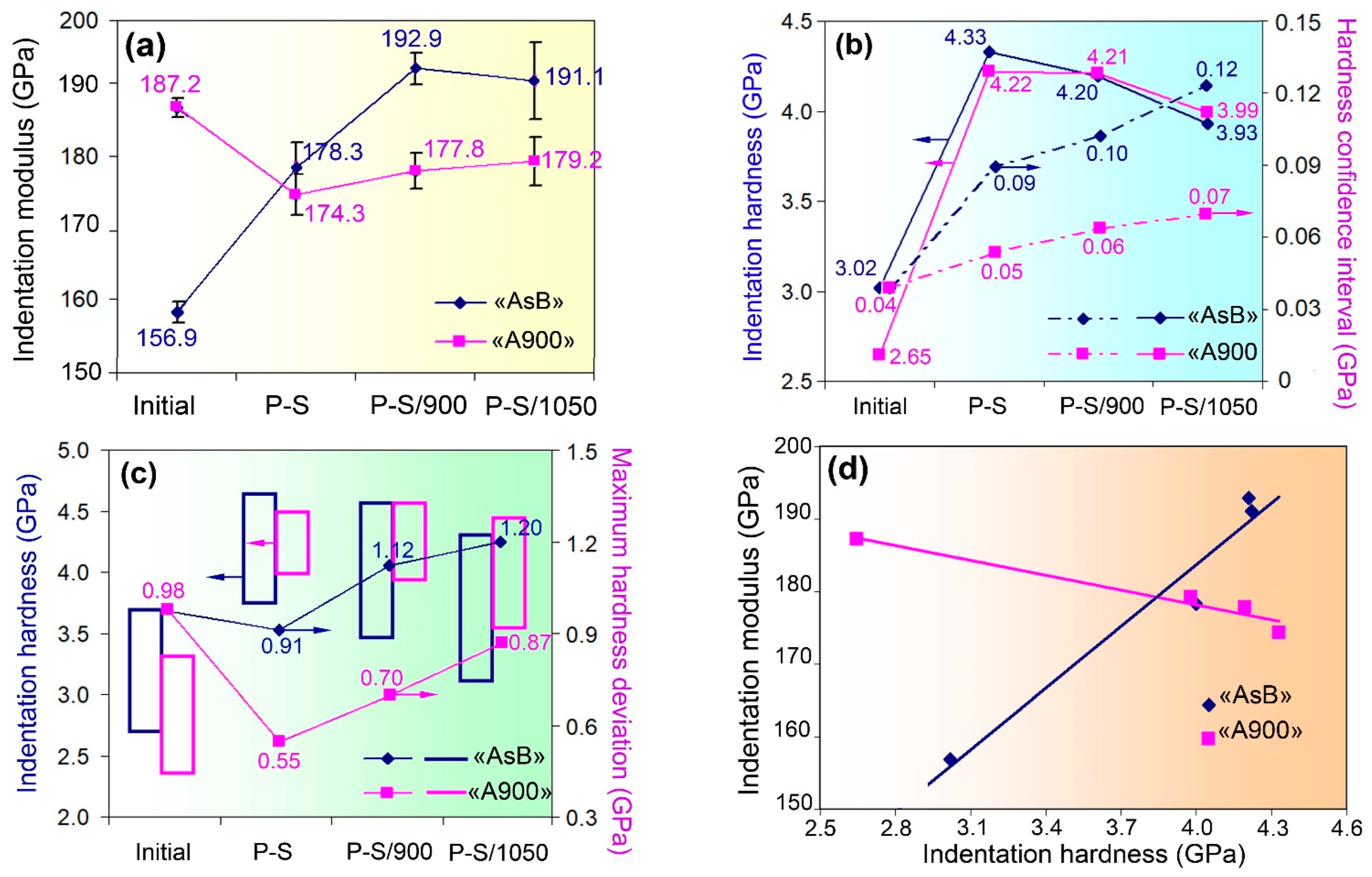

3.1.2. Nanoindentation

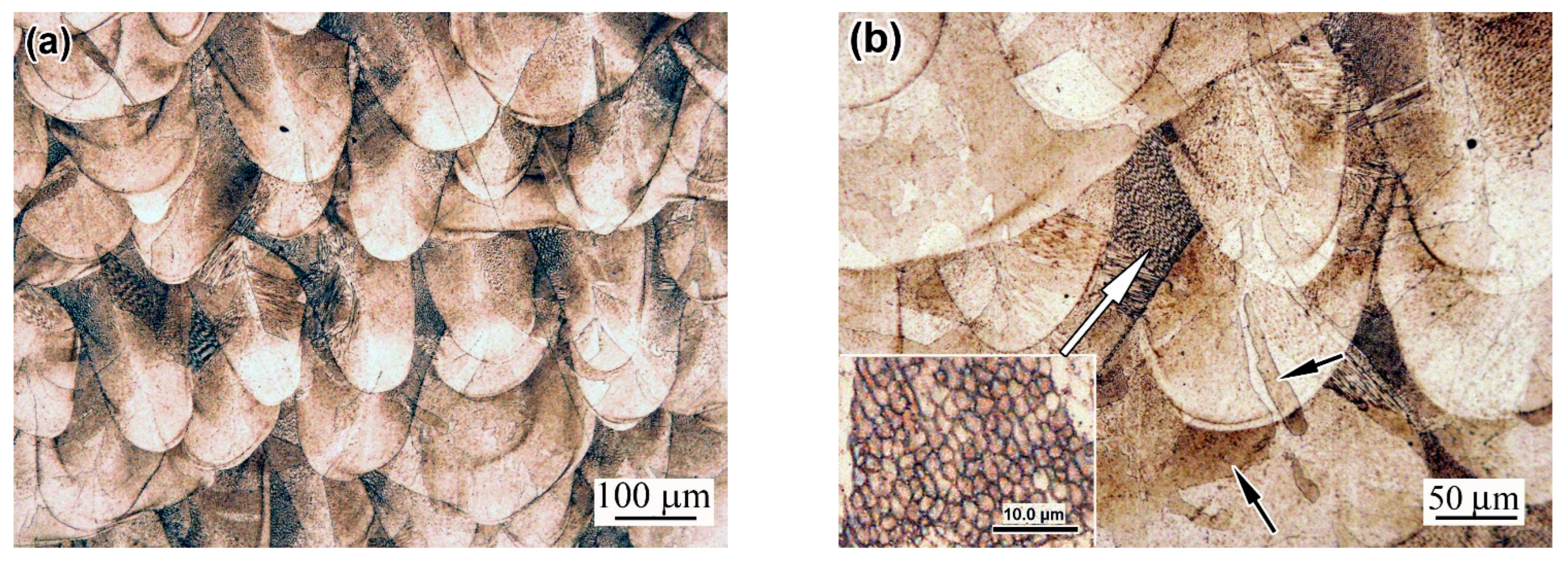

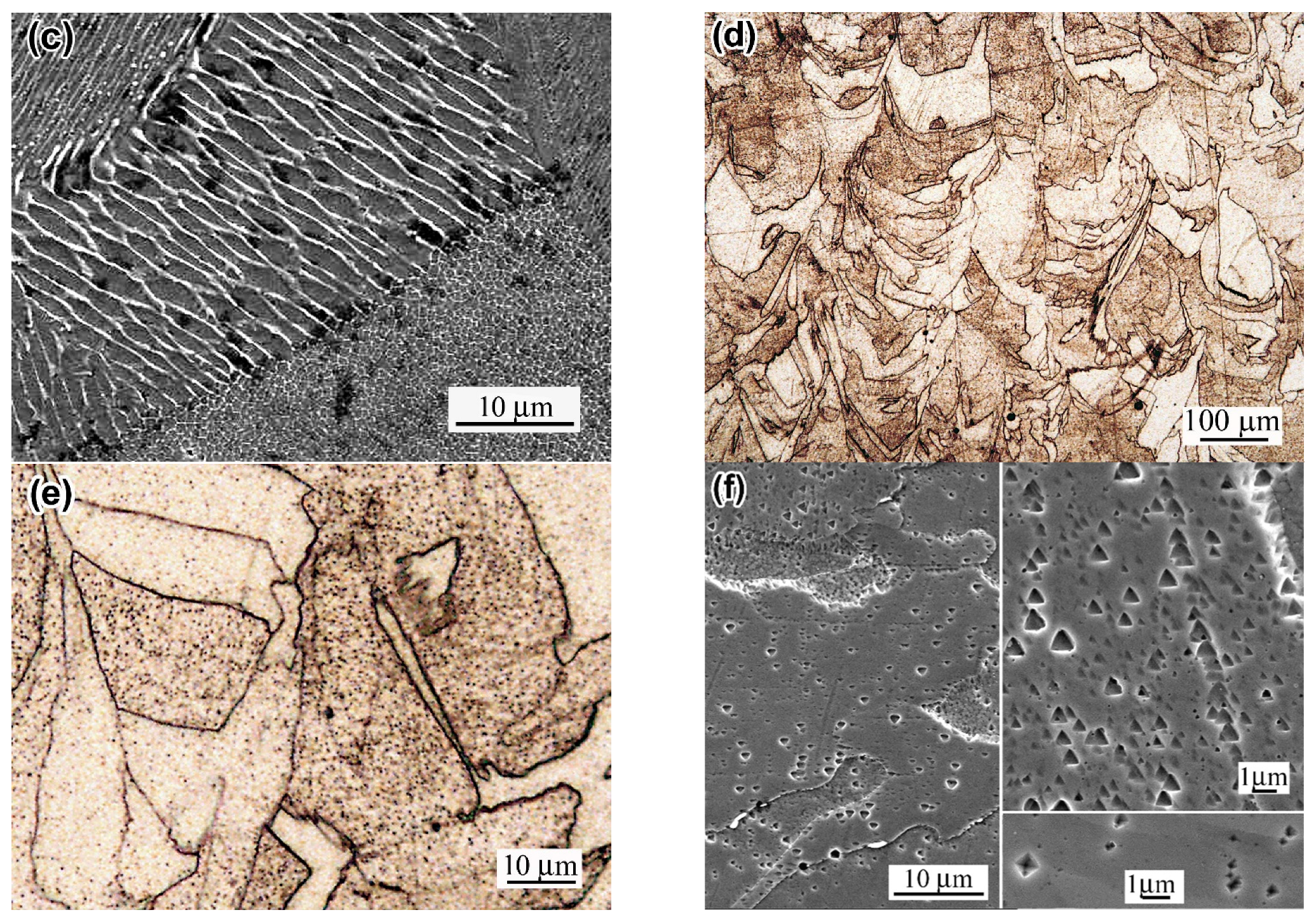

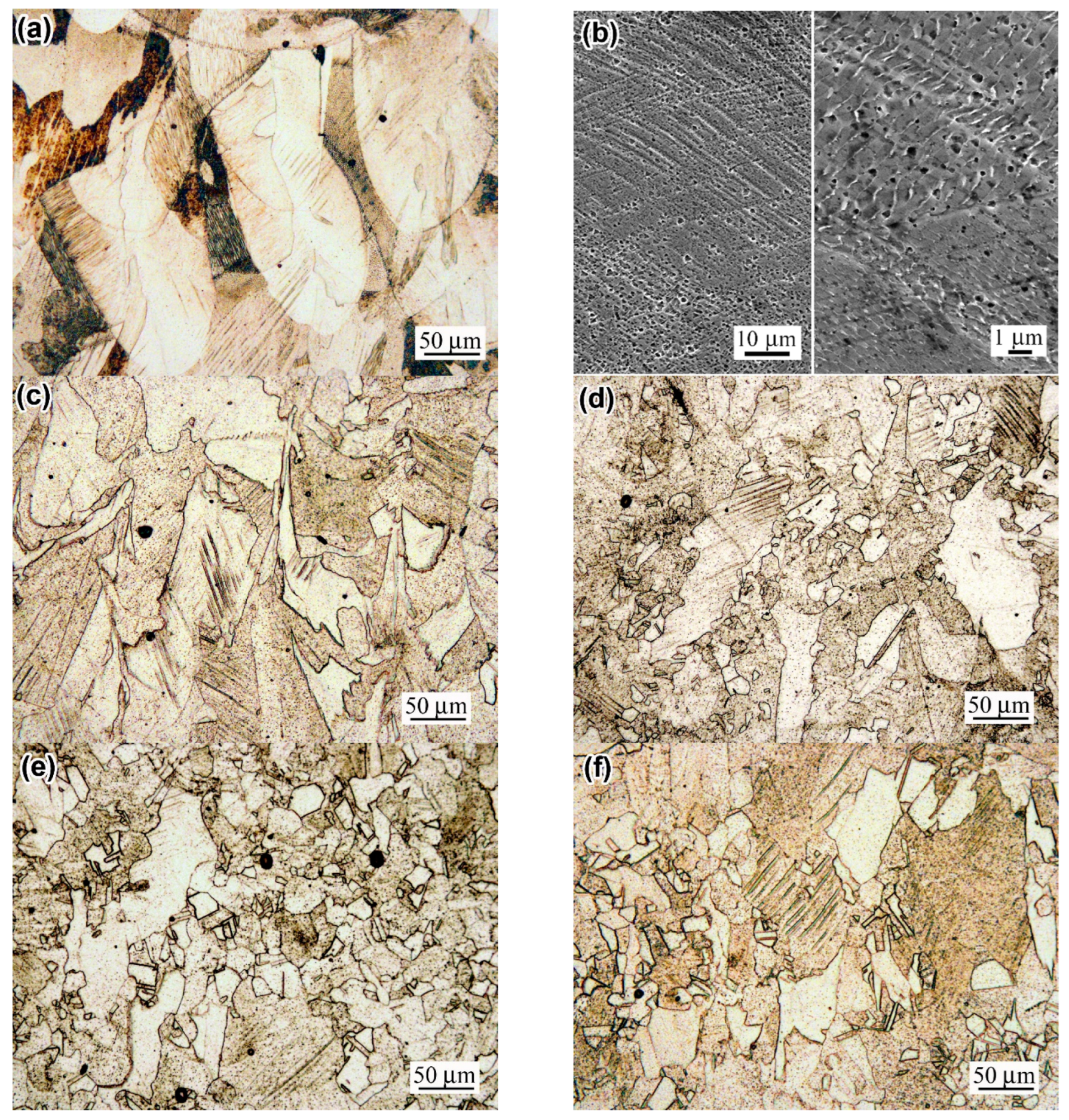

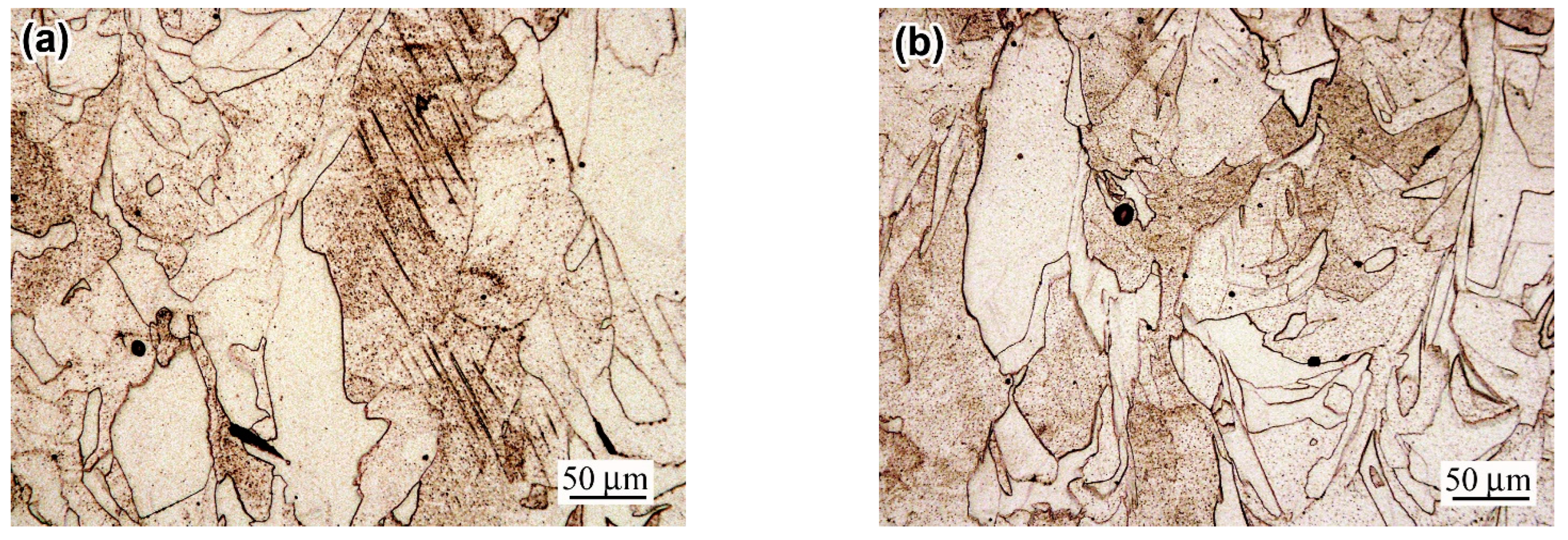

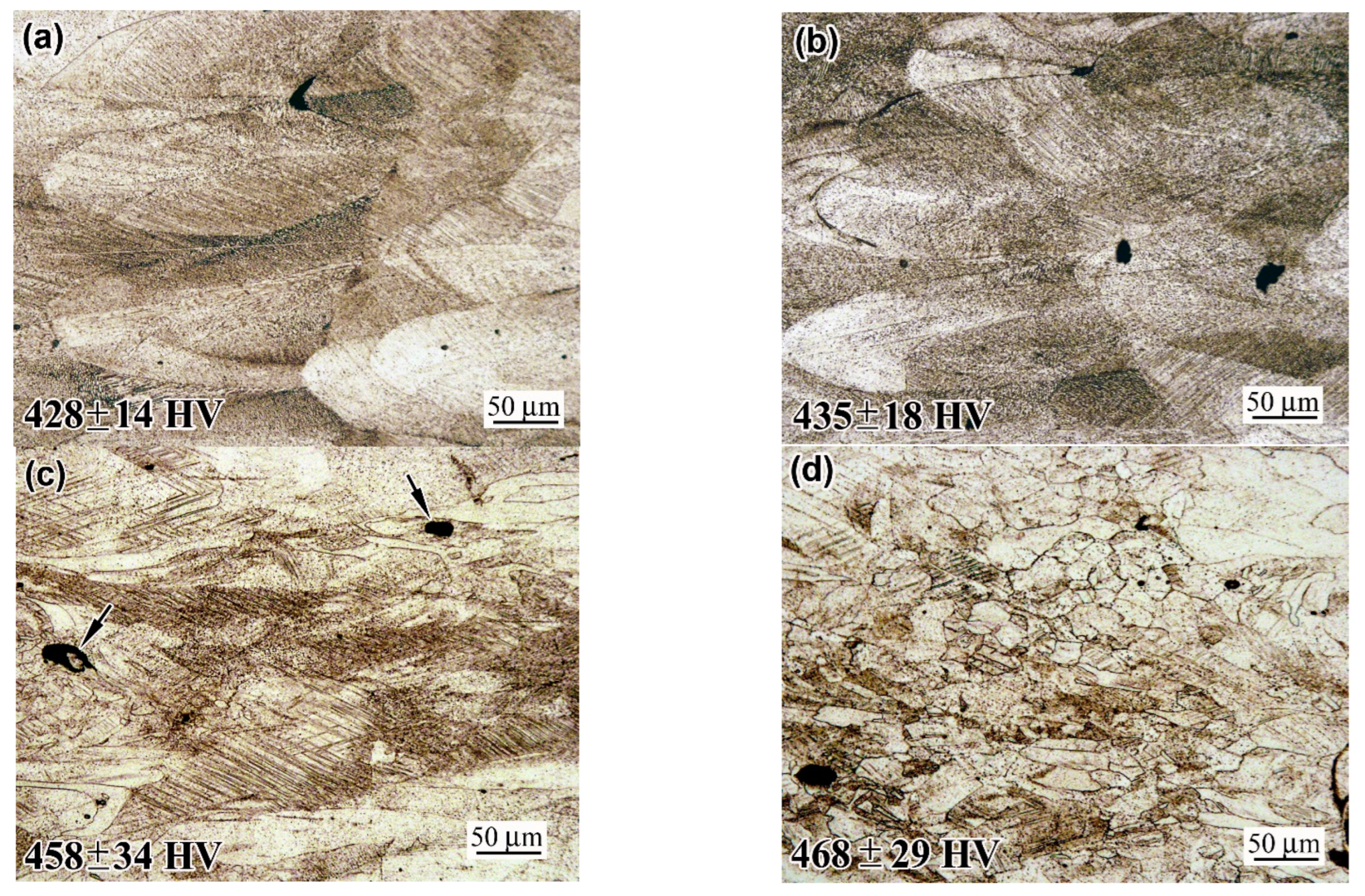

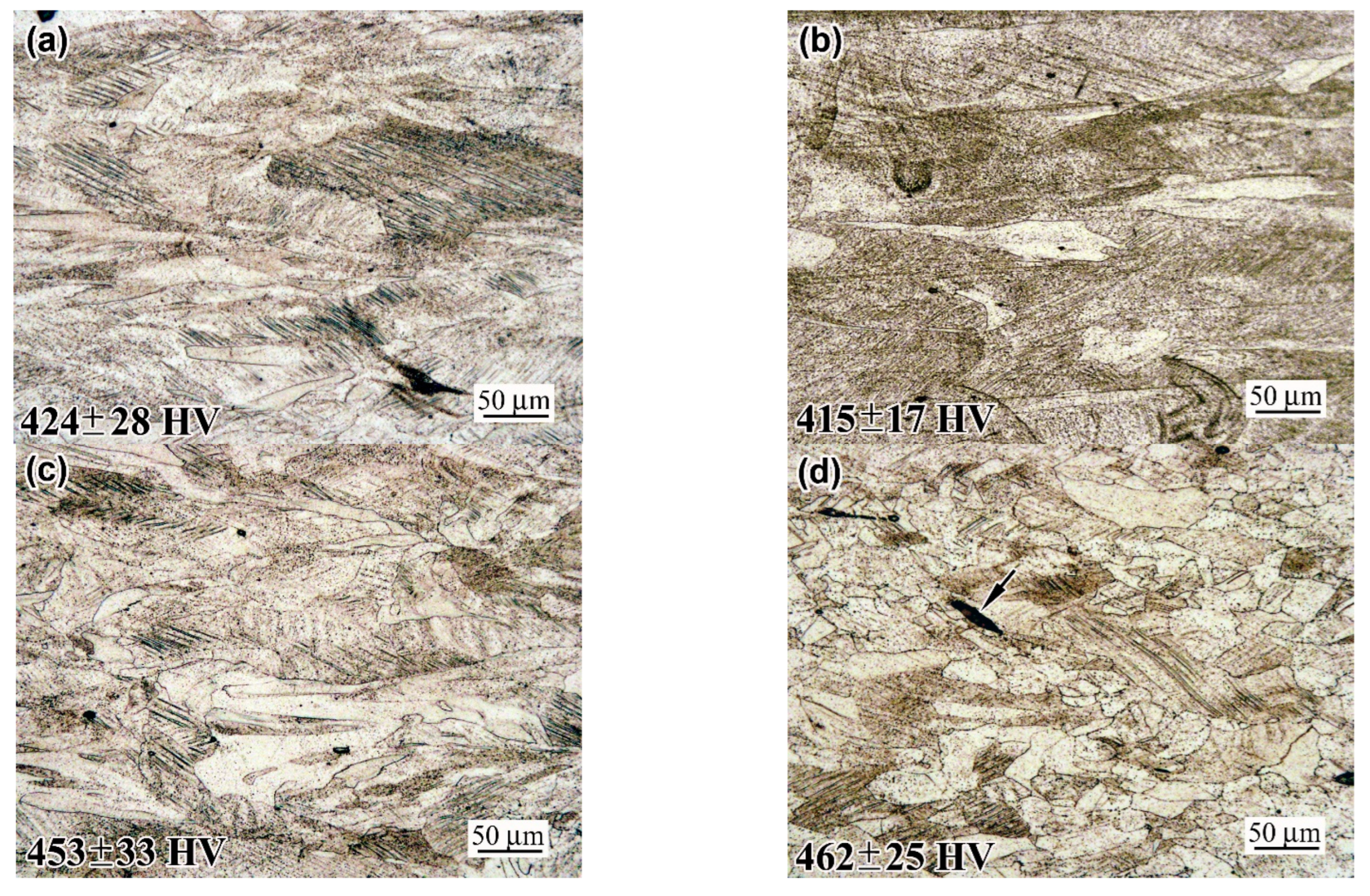

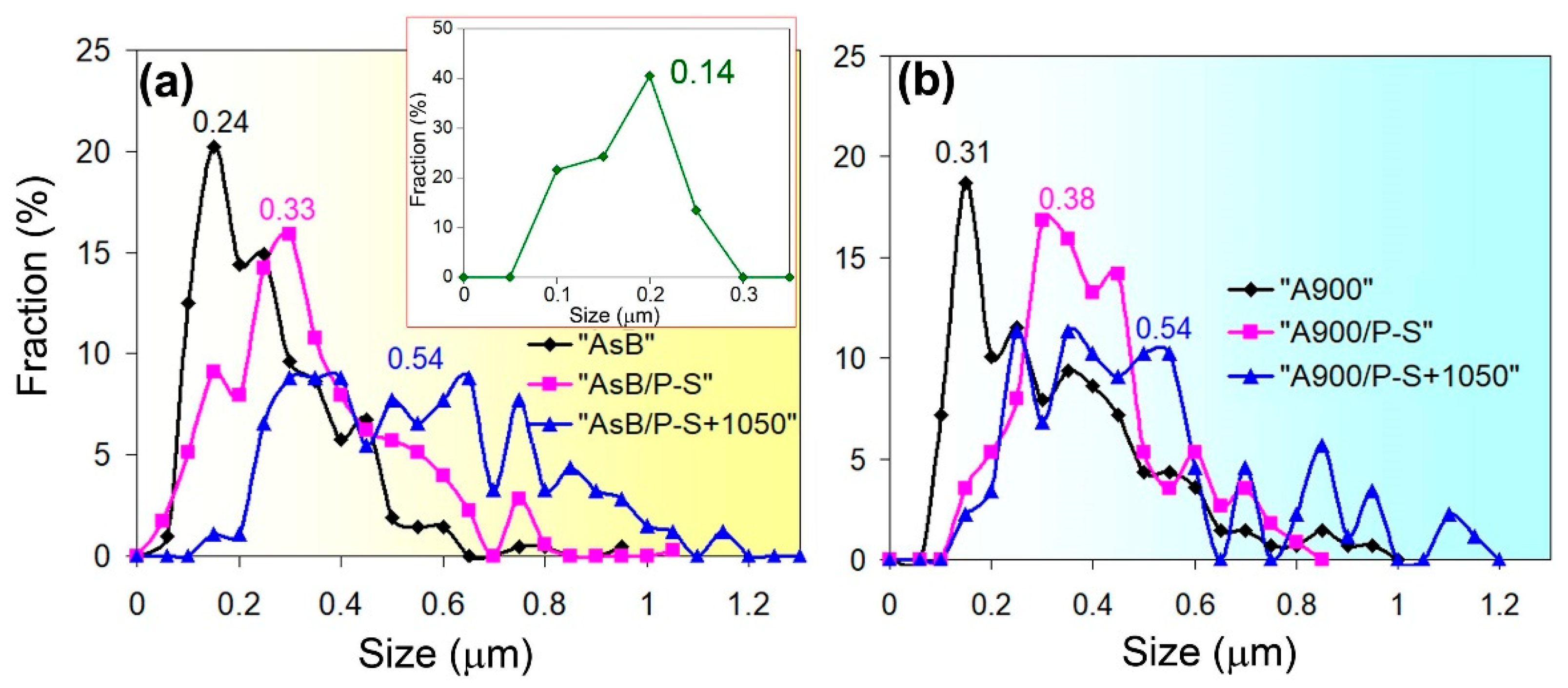

3.2. Microstructure Observation

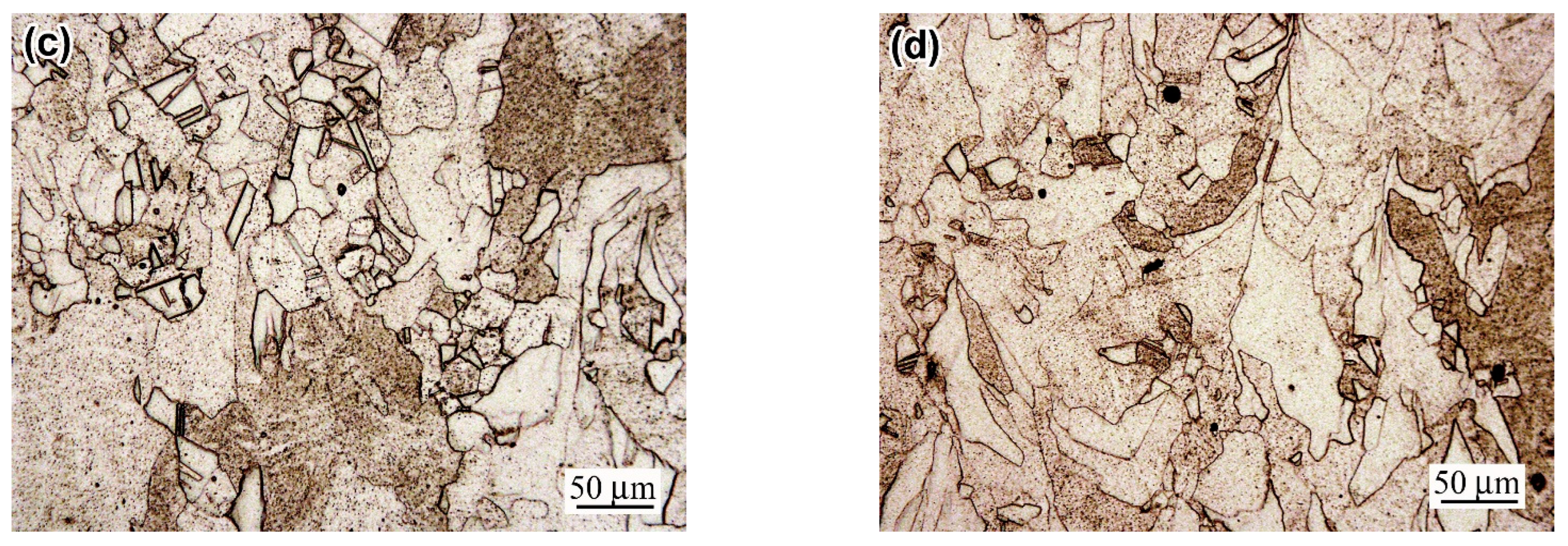

3.3. XRD Analysis

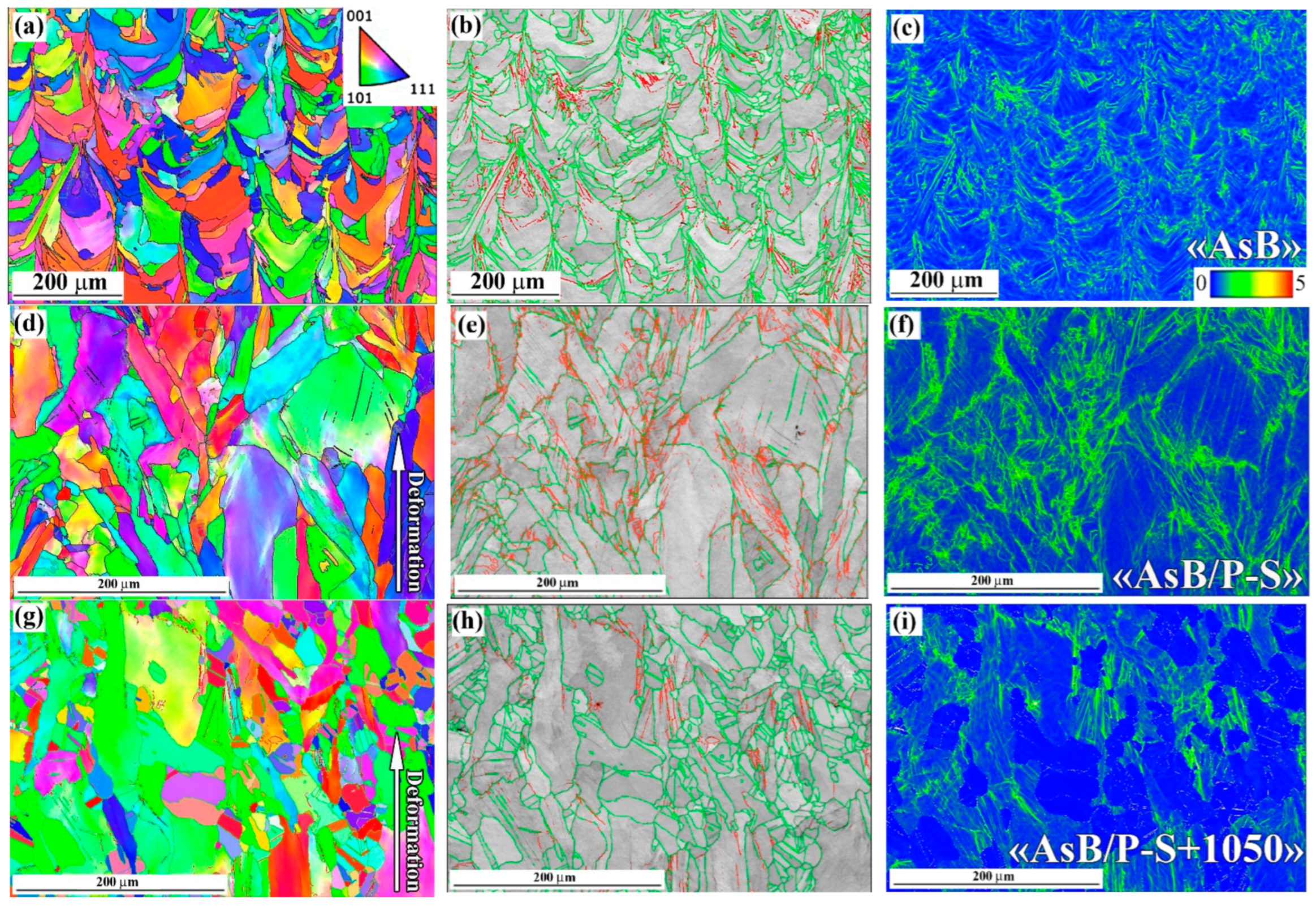

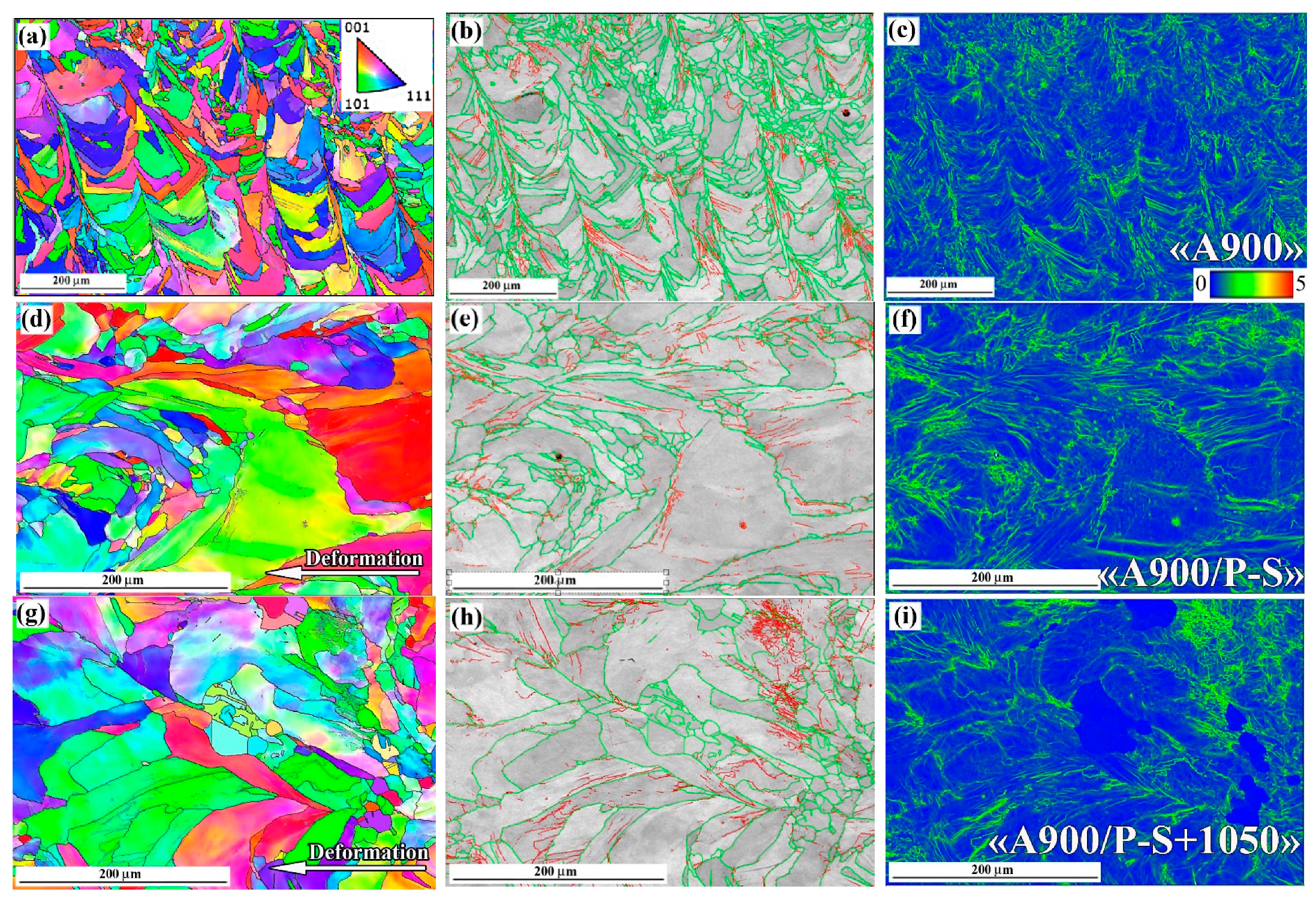

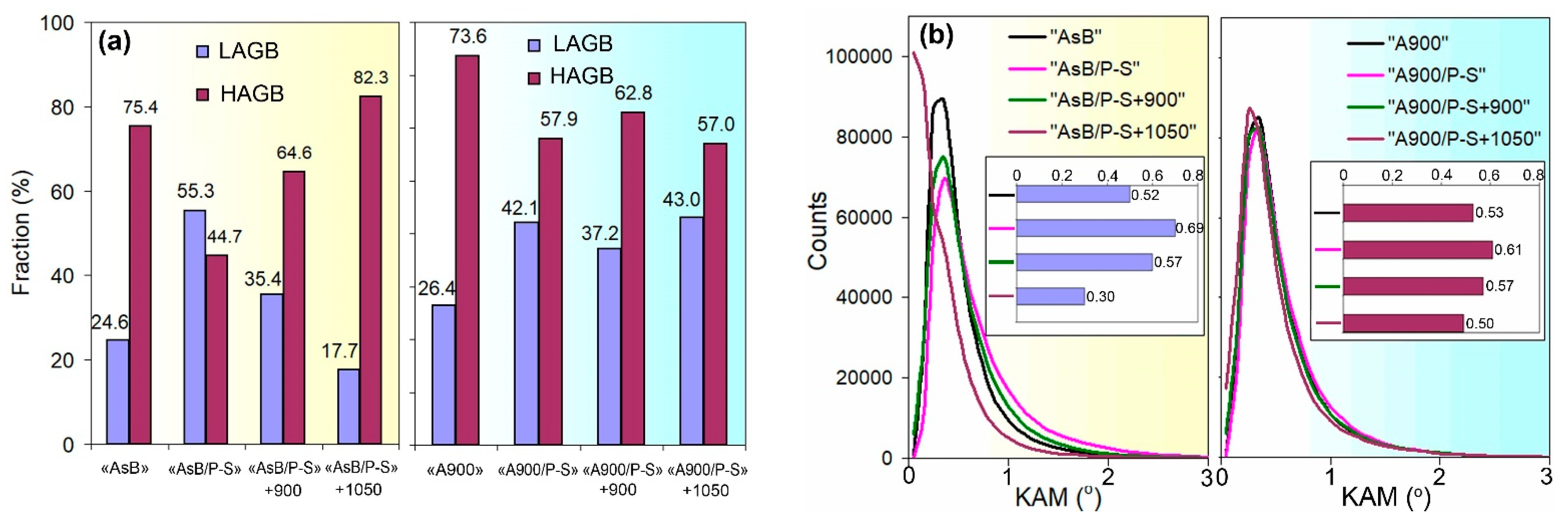

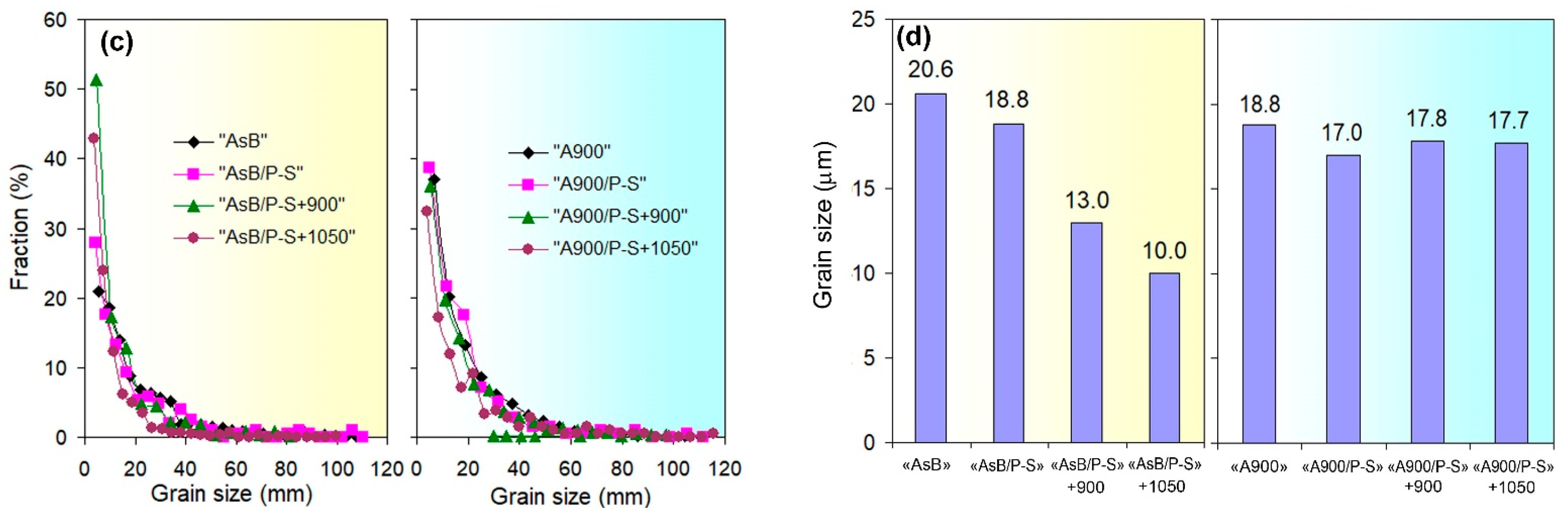

3.4. EBSD Characterisation

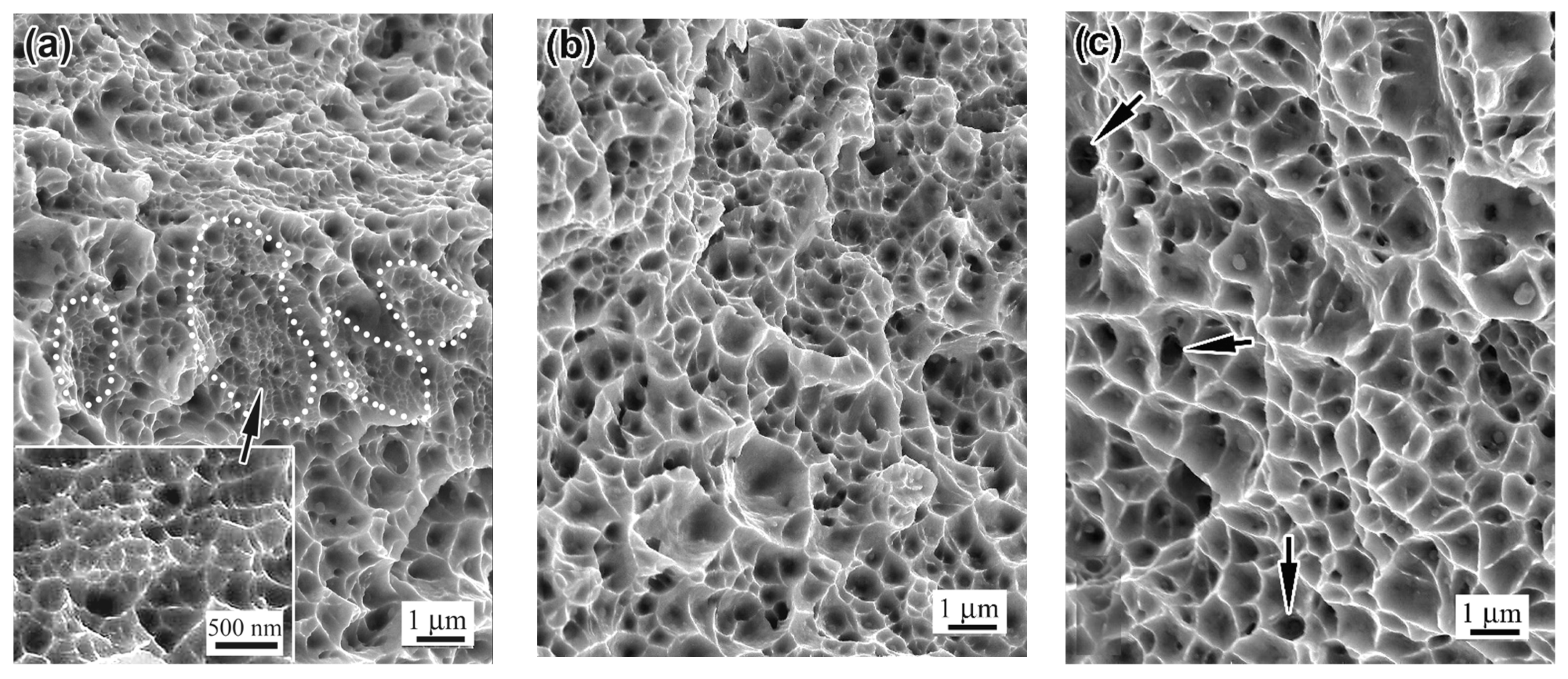

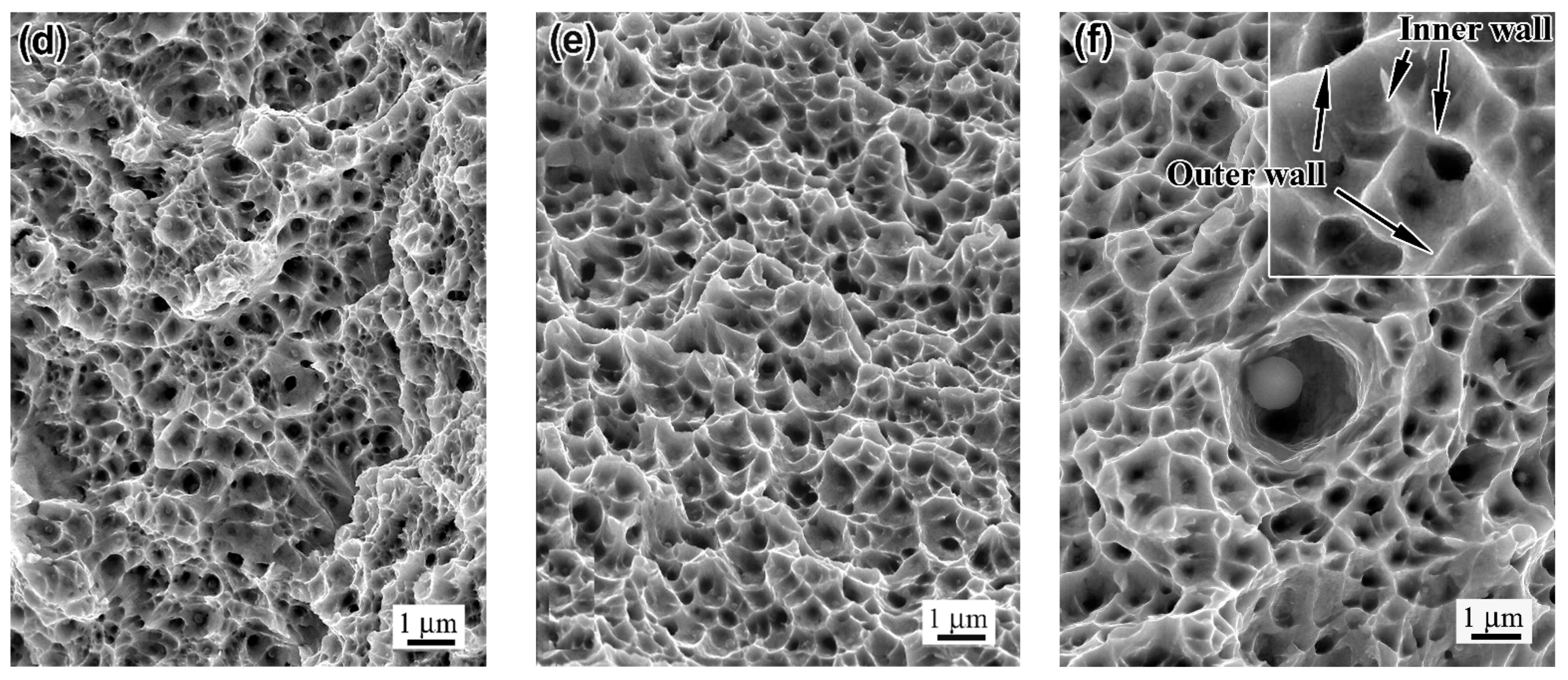

3.5. Structure of the Ultimately Deformed Zone and a Rupture Surface Characterisation

4. Discussion

4.1. Evolution of Microstructure and Crystalline Features Under Applied Processing

4.2. “Mechanical Properties-Microstructure” Correlations

4.3. Work-Hardening Behaviour and Fracture Mechanism

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hanbury, R.D.; Was, G.S. Corrosion of 316L Stainless Steel in High Temperature Water and Steam: Mechanisms of Corrosion. J. Nucl. Mater. 2024, 599, 155180. [Google Scholar] [CrossRef]

- Sukhova, O.V.; Polonskyy, V.A. Structure and Corrosion of Quasicrystalline Cast Al–Co–Ni and Al–Fe–Ni Alloys in Aqueous NaCl Solution. East Eur. J. Phys. 2020, 3, 5–10. [Google Scholar] [CrossRef]

- Xu, K.; Zhu, M.; Zhou, J.; Shen, F.; Zhang, J.; Zhao, B. A Comparative Study on the Corrosion Behavior of 316L and 304 Stainless Steels in a Simulated Alkaline Environment for Lithium Extraction. Int. J. Electrochem. Sci. 2022, 17, 2212111. [Google Scholar] [CrossRef]

- Ladani, L.; Palmieri, M. Review of the Use of Metals in Biomedical Applications: Biocompatibility, Additive Manufacturing Technologies, and Standards and Regulations. Metals 2024, 14, 1039. [Google Scholar] [CrossRef]

- D’Andrea, D. Additive Manufacturing of AISI 316L Stainless Steel: A Review. Metals 2023, 13, 1370. [Google Scholar] [CrossRef]

- Chabak, Y.; Efremenko, B.; Petryshynets, I.; Efremenko, V.; Lekatou, A.G.; Zurnadzhy, V.; Bogomol, I.; Fedun, V.; Kovaľ, K.; Pastukhova, T. Structural and Tribological Assessment of Biomedical 316 Stainless Steel Subjected to Pulsed-Plasma Surface Modification: Comparison of LPBF 3D Printing and Conventional Fabrication. Materials 2021, 14, 7671. [Google Scholar] [CrossRef]

- Lodhi, M.J.K.; Deen, K.M.; Greenlee-Wacker, M.C.; Haider, W. Additively manufactured 316L stainless steel with improved corrosion resistance and biological response for biomedical applications. Addit. Manuf. 2019, 27, 8–19. [Google Scholar] [CrossRef]

- Tepla, T.L.; Izonin, I.V.; Duriagina, Z.A.; Tkachenko, R.O.; Trostianchyn, A.M.; Lemishka, I.A.; Kulyk, V.V.; Kovbasyuk, T.M. Alloys Selection Based on the Supervised Learning Technique for Design of Biocompatible Medical Materials. Arch. Mater. Sci. Eng. 2018, 1, 32–40. [Google Scholar] [CrossRef]

- A276/A276M; Standard Specification for Stainless Steel Bars and Shapes. ASTM International: West Conshohocken, PA, USA, 2023.

- Nguyen, L.T.H.; Hwang, J.-S.; Kim, M.-S.; Kim, J.-H.; Kim, S.-K.; Lee, J.-M. Charpy Impact Properties of Hydrogen-Exposed 316L Stainless Steel at Ambient and Cryogenic Temperatures. Metals 2019, 9, 625. [Google Scholar] [CrossRef]

- ASTM F3184-16; Standard Specification for Additive Manufacturing Stainless Steel Alloy (UNS S31603) with Powder Bed Fusion. ASTM International: West Conshohocken, PA, USA, 2016.

- Chao, Q.; Thomas, S.; Birbilis, N.; Cizek, P.; Hodgson, P.; Fabijanic, D. The Effect of Post-Processing Heat Treatment on the Microstructure, Residual Stress and Mechanical Properties of Selective Laser Melted 316L Stainless Steel. Mater. Sci. Eng. A 2021, 821, 141611. [Google Scholar] [CrossRef]

- Ura-Bińczyk, E.; Dobkowska, A.; Bazarnik, P.; Ciftci, J.; Krawczyńska, A.; Chromiński, W.; Wejrzanowski, T.; Molak, R.; Sitek, R.; Płociński, T.; et al. Effect of Annealing on the Mechanical and Corrosion Properties of 316L Stainless Steel Manufactured by Laser Powder Bed Fusion. Mater. Sci. Eng. A 2022, 860, 144263. [Google Scholar] [CrossRef]

- Wang, W.-Y.; Godfrey, A.; Liu, W. Effect of Heat Treatment on Microstructural Evolution in Additively Manufactured 316L Stainless Steel. Metals 2023, 13, 1062. [Google Scholar] [CrossRef]

- Blinn, B.; Klein, M.; Gläßner, C.; Smaga, M.; Aurich, J.C.; Beck, T. An Investigation of the Microstructure and Fatigue Behavior of Additively Manufactured AISI 316L Stainless Steel with Regard to the Influence of Heat Treatment. Metals 2018, 8, 220. [Google Scholar] [CrossRef]

- Gor, M.; Soni, H.; Wankhede, V.; Sahlot, P.; Grzelak, K.; Szachgluchowicz, I.; Kluczyński, J. A Critical Review on Effect of Process Parameters on Mechanical and Microstructural Properties of Powder-Bed Fusion Additive Manufacturing of SS316L. Materials 2021, 14, 6527. [Google Scholar] [CrossRef]

- Gel’atko, M.; Hatala, M.; Botko, F.; Vandžura, R.; Hajnyš, J.; Šajgalík, M.; Török, J. Stress Relieving Heat Treatment of 316L Stainless Steel Made by Additive Manufacturing Process. Materials 2023, 16, 6461. [Google Scholar] [CrossRef]

- Andreatta, F.; Lanzutti, A.; Revilla, R.I.; Vaglio, E.; Totis, G.; Sortino, M.; de Graeve, I.; Fedrizzi, L. Effect of Thermal Treatment on Corrosion Behavior of AISI 316L Stainless Steel Manufactured by Laser Powder Bed Fusion. Materials 2022, 15, 6768. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.-K.; Shim, S.H.; Kim, Y.K.; Lim, K.R.; Na, Y.-S. Simultaneously Improved Strength and Ductility Yet Strain-Hardenable 316L Stainless Steel by Sigma Phase and Hetero-Structuring. Mater. Des. 2024, 243, 113058. [Google Scholar] [CrossRef]

- Yu, W.; Li, B.; Li, Y.; Yu, J.; Qui, Z.; Chen, X. Effects of Multiaxial Non-Proportional Cyclic Pre-Hardening on Monotonic Tensile and Fatigue Properties of 316L Stainless Steel. Int. J. Fatigue 2024, 182, 108151. [Google Scholar] [CrossRef]

- Jana, S.; Shyamal, S.; Chakraborti, P.C. Unveiling Deformation Microstructure During Cyclic Straining of 316L Stainless Steel at 873 K. Mater. Today Commun. 2024, 41, 110240. [Google Scholar] [CrossRef]

- Vasylyev, M.O.; Mordyuk, B.M.; Sydorenko, S.I.; Voloshko, S.M.; Burmak, A.P.; Franchik, N.V. Evolution of a Structure-Phase State and Microhardness of a Surface of Stainless Steel 12Cr18Ni10Ti in the Conditions of Ultrasonic Impact Treatment in Various Mediums. Metallofiz. Noveishie Tekhnol. 2017, 39, 905–928. [Google Scholar] [CrossRef]

- Li, K.; Peng, J.; Peng, J. Mechanical Behaviour of 316L Stainless Steel After Strain Hardening. MATEC Web Conf. 2017, 114, 02003. [Google Scholar] [CrossRef]

- Wei, Y.; Lu, Q.; Kou, Z.; Feng, T.; Lai, Q. Microstructure and Strain Hardening Behavior of the Transformable 316L Stainless Steel Processed by Cryogenic Pre-Deformation. Mater. Sci. Eng. A 2023, 862, 144424. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Kim, S.-W.; Lim, K.R.; Na, Y.-S. Enhancing Strength-Ductility Synergy in 316L Stainless Steel Through Prestraining at 4.2K. Mater. Sci. Eng. A 2024, 906, 146709. [Google Scholar] [CrossRef]

- Jeong, S.G.; Kim, E.S.; Kwon, H.; Ahn, S.Y.; Choe, J.; Karthik, G.M.; Heo, Y.-U.; Kim, H.S. Tailoring Deformation-Induced Martensitic Transformation Through Cellular Engineering in Laser Powder Bed Fusion Processed 316L Stainless Steel. Mater. Sci. Eng. A 2024, 898, 146383. [Google Scholar] [CrossRef]

- Efremenko, B.V.; Shimizu, K.; Espallargas, N.; Efremenko, V.G.; Kusumoto, K.; Chabak, Y.G.; Belik, A.G.; Chigarev, V.V.; Zurnadzhy, V.I. High-Temperature Solid Particle Erosion of Cr-Ni-Fe-C Arc Cladded Coatings. Wear 2020, 460–461, 203439. [Google Scholar] [CrossRef]

- Man, J.; Blinn, B.; Šulák, I.; Kuběna, I.; Smaga, M.; Chlup, Z.; Kruml, T.; Beck, T.; Polák, J. Formation of Deformation Induced Martensite in Fatigued 316L Steels Manufactured by Selective Laser Melting (SLM). Procedia Struct. Integr. 2023, 43, 203–208. [Google Scholar] [CrossRef]

- Koval, A.D.; Efremenko, V.G.; Brykov, M.N.; Andrushchenko, M.I.; Kulikovskii, R.A.; Efremenko, A.V. Principles for Developing Grinding Media with Increased Wear Resistance. Part Abrasive Wear Resistance of Iron-Based Alloys. J. Frict. Wear 2012, 33, 39–46. [Google Scholar] [CrossRef]

- Ortolland, V.; Martin, F.; Auzoux, Q.; Wolski, K. Experimental Study of the Hydrogen-Microstructure Interactions in a Prestrained 316L Austenitic Stainless Steel. Int. J. Hydrogen Energy 2024, 67, 577–591. [Google Scholar] [CrossRef]

- Enser, S.; Güden, M.; Taşdemirci, A.; Davut, K. The Strain Rate History Effect in a Selective-Laser-Melt 316L Stainless Steel. Mater. Sci. Eng. A 2023, 862, 144439. [Google Scholar] [CrossRef]

- Sabzi, H.E.; Li, X.-H.; Zhang, C.; Fu, H.; Rivera-Díaz-del-Castillo, P.E.J. Strain Hardening in Twinning-Induced Plasticity Stainless Steel Produced by Laser Powder Bed Fusion. Mater. Sci. Eng. A 2022, 855, 143882. [Google Scholar] [CrossRef]

- Wang, Y.; Hou, Q.; Li, X.; Li, Z.; Wu, F.; Chen, S.; Lv, C.; He, Q.; Ye, X.; Yu, Y.; et al. Strain Rate-Dependent Tensile Response and Deformation Mechanism of Laser Powder Bed Fusion 316L Stainless Steel. Mater. Sci. Eng. A 2024, 893, 146124. [Google Scholar] [CrossRef]

- Li, S.-H.; Zhao, Y.; Kumar, P.; Ramamurty, U. Effect of Initial Dislocation Density on the Plastic Deformation Response of 316L Stainless Steel Manufactured by Directed Energy Deposition. Mater. Sci. Eng. A 2022, 851, 143591. [Google Scholar] [CrossRef]

- Taghipour, A.; Mazaheri, Y.; McDavid, J.; Sheikhi, S.; Braun, M.; Junjun, S.; Klusemann, B.; Ehlers, S. Strengthening Mechanisms and Strain Hardening Behavior of 316L Stainless Steel Manufactured by Laser-Based Powder Bed Fusion. Adv. Eng. Mater. 2022, 25, 2201230. [Google Scholar] [CrossRef]

- Efremenko, B.V.; Zurnadzhy, V.I.; Chabak, Y.G.; Efremenko, V.G.; Kudinova, K.V.; Mazur, V.A. A Comparison Study on the Effect of Counter Ball Material on Sliding Wear Response of SLM-Printed Biomedical 316L Steel. Mater. Today: Proc. 2022, 66, 2587–2593. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R. High Strain Rate Induced Shear Banding within Additively Manufactured AISI 316L. Mater. Lett. 2024, 363, 136342. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Fu, C.; Bai, J.; Hou, J.; Lin, J.; Dai, Z. Hardening Behavior of Selective Laser Melted 304L Stainless Steel under Xe Irradiation. Vacuum 2021, 192, 110453. [Google Scholar] [CrossRef]

- Álvarez, G.; Harris, Z.; Wada, K.; Rodríguez, C.; Martínez-Pañeda, E. Hydrogen Embrittlement Susceptibility of Additively Manufactured 316L Stainless Steel: Influence of Post-Processing, Printing Direction, Temperature and Prestraining. Addit. Manuf. 2023, 78, 103834. [Google Scholar] [CrossRef]

- Hukpati, K.; Eliasu, A.; Tetteh, F.; Czekanski, A.; Boakye-Yiadom, S. Effect of Printing Parameters on the Structure and High Strain Rate Deformation Behavior of Additively Manufactured 316L Stainless Steel. Mater. Sci. Eng. A 2022, 853, 143710. [Google Scholar] [CrossRef]

- Kumar, D.; Shankar, G.; Prashanth, K.G.; Suwas, S. Texture Dependent Strain Hardening in Additively Manufactured Stainless Steel 316L. Mater. Sci. Eng. A 2021, 820, 141483. [Google Scholar] [CrossRef]

- Yang, Y.; Bai, Y.; Wang, Y.; Zhang, Y.; Weng, C.; Lu, W.F.; Wang, H. Compressive Mechanical Response and Microstructures in Low Strain Rate Plastic Deformation of Stainless Steel 316L Fabricated by Selective Laser Melting. J. Mater. Res. Technol. 2024, 29, 4327–4344. [Google Scholar] [CrossRef]

- Gao, S.; Hu, Z.; Duchamp, M.; Krishnan, P.S.R.; Tekumalla, S.; Song, X.; Seita, M. Recrystallization-based Grain Boundary Engineering of 316L Stainless Steel Produced via Selective Laser Melting. Acta Mater. 2020, 200, 366–377. [Google Scholar] [CrossRef]

- de Sonis, E.; Dépinoy, S.; Giroux, P.-F.; Maskrot, H.; Lemarquis, L.; Hercher, O.; Villaret, F.; Gourgues-Lorenzon, A.-F. Dependency of Recrystallization Kinetics on the Solidification Microstructure of 316L Stainless Steel Processed by Laser Powder Bed Fusion (LPBF). Mater. Charact. 2022, 194, 112370. [Google Scholar] [CrossRef]

- Aota, L.S.; Bajaj, P.; Zilnyk, K.D.; Jägle, E.A.; Ponge, D.; Zschommler Sandim, H.R.; Raabe, D. Recrystallization Kinetics, Mechanisms, and Topology in Alloys Processed by Laser Powder-Bed Fusion: AISI 316L Stainless Steel as Example. Materialia 2021, 20, 101236. [Google Scholar] [CrossRef]

- Luo, K.; Xu, S.; Xu, L.; Xing, Y.; Zhang, H.; Wang, C.; Lu, J. Wear Behaviors of AISI 316L Stainless Steel with a Gradient Structured Surface Layer Induced by Laser Shock Peening. Surf. Coat. Technol. 2024, 481, 130608. [Google Scholar] [CrossRef]

- Deng, W.W.; Lu, H.F.; Xing, Y.H.; Luo, K.Y.; Lu, J.Z. Effect of Laser Shock Peening on Tensile Properties and Microstructure of Selective Laser Melted 316L Stainless Steel with Different Build Directions. Mater. Sci. Eng. A 2022, 850, 143567. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Doubrava, M.; Pantelejev, L.; Bagherifard, S.; Guagliano, M. Application of Impact-Based and Laser-Based Surface Severe Plastic Deformation Methods on Additively Manufactured 316L: Microstructure, Tensile and Fatigue Behaviors. Mater. Sci. Eng. A 2024, 916, 147360. [Google Scholar] [CrossRef]

- Kim, R.E.; Jeong, S.G.; Ha, H.; Lee, D.W.; Amanov, A.; Kim, H.S. Controlling Defects of Laser-Powder Bed Fusion Processed 316L Stainless Steel via Ultrasonic Nanocrystalline Surface Modification. Mater. Sci. Eng. A 2023, 887, 145726. [Google Scholar] [CrossRef]

- Bae, D.; Park, S.; Seol, J.B.; Lee, D.J.; Amanov, A.; Sung, H.; Kim, J.G. Microstructural Evolution and Mechanical Properties of Laser-Powder Bed Fusion Processed 316L Stainless Steel with an Ultrasonic-Nanocrystalline Surface Modification. Mater. Sci. Eng. A 2023, 862, 144436. [Google Scholar] [CrossRef]

- Amanov, A. Effect of Local Treatment Temperature of Ultrasonic Nanocrystalline Surface Modification on Tribological Behavior and Corrosion Resistance of Stainless Steel 316L Produced by Selective Laser Melting. Surf. Coat. Technol. 2020, 398, 126080. [Google Scholar] [CrossRef]

- ISO/ASTM 52900; Additive Manufacturing—General Principles—Terminology. ASTM International: West Conshohocken, PA, USA, 2015.

- Zhang, H.; Li, C.; Yao, G.; Shi, Y.; Zhang, Y. Effect of annealing treatment on microstructure evolution and deformation behavior of 304 L stainless steel made by laser powder bed fusion. Int. J. Plast. 2022, 155, 103335. [Google Scholar] [CrossRef]

- Morris, J.R.; Bei, H.; Pharr, G.M.; George, E.P. Size Effects and Stochastic Behavior of Nanoindentation Pop in. Phys. Rev. Lett. 2011, 106, 165502. [Google Scholar] [CrossRef] [PubMed]

- Hong, Y.; Zhou, C.; Zheng, Y.; Zhang, L.; Zheng, J. The Cellular Boundary with High Density of Dislocations Governed the Strengthening Mechanism in Selective Laser Melted 316L Stainless Steel. Mater. Sci. Eng. A 2021, 799, 140279. [Google Scholar] [CrossRef]

- Guo, S.; Xu, J.; Gu, J.; Peng, Y.; Zhou, Q.; Wang, K. Effect of cellular structure on the mechanical properties of 316L stainless steel fabricated by EBF3. J. Mater. Res. Technol. 2023, 25, 5469–5482. [Google Scholar] [CrossRef]

- Fu, P.; Chu, R.; Xu, Z.; Ding, G.; Jiang, C. Relation of Hardness with FWHM and Residual Stress of GCr15 Steel After Shot Peening. Appl. Surf. Sci. 2018, 431, 165–169. [Google Scholar] [CrossRef]

- Mote, V.; Purushotham, Y.; Dole, B. Williamson-Hall Analysis in Estimation of Lattice Strain in Nanometer-Sized ZnO Particles. J. Theor. Appl. Phys. 2012, 6, 6. [Google Scholar] [CrossRef]

- Sivagami, M.; Asharani, I.V. Phyto-Mediated Ni/NiO NPs and Their Catalytic Applications—A Short Review. Inorg. Chem. Commun. 2022, 145, 110054. [Google Scholar] [CrossRef]

- Williamson, G.K.; Smallman, R.E. III. Dislocation Densities in Some Annealed and Cold-Worked Metals from Measurements on the X-Ray Debye-Scherrer Spectrum. Philos. Mag. J. Theor. Exp. Appl. Phys. 1956, 1, 34–46. [Google Scholar] [CrossRef]

- Dong, Y.; Sun, Z.; Xia, H.; Feng, J.; Du, J.; Fang, W.; Liu, B.; Wang, G.; Li, L.; Zhang, X.; et al. The Influence of Warm Rolling Reduction on Microstructure Evolution, Tensile Deformation Mechanism and Mechanical Properties of an Fe-30Mn-4Si-2Al TRIP/TWIP Steel. Metals 2018, 8, 742. [Google Scholar] [CrossRef]

- Gubicza, J. Reliability and interpretation of the microstructural parameters determined by X-ray line profile analysis for nanostructured materials. Eur. Phys. J. Spec. Top. 2022, 231, 4153–4165. [Google Scholar] [CrossRef]

- Konijnenberg, P.J.; Zaefferer, S.; Raabe, D. Assessment of Geometrically Necessary Dislocation Levels Derived by 3D EBSD. Acta Mater. 2015, 99, 402–414. [Google Scholar] [CrossRef]

- Moussa, C.; Bernacki, M.; Besnard, R.; Bozzolo, N. Statistical Analysis of Dislocations and Dislocation Boundaries from EBSD Data. Ultramicroscopy 2017, 179, 63–72. [Google Scholar] [CrossRef] [PubMed]

- Guglielmi, P.O.; Ziehmer, M.; Lilleodden, E.T. On a Novel Strain Indicator Based on Uncorrelated Misorientation Angles for Correlating Dislocation Density to Local Strength. Acta Mater. 2018, 150, 195–205. [Google Scholar] [CrossRef]

- Kubin, L.P.; Mortensen, A. Geometrically Necessary Dislocations and Strain-Gradient Plasticity: A Few Critical Issues. Scr. Mater. 2023, 48, 119–125. [Google Scholar] [CrossRef]

- Karnaukh, S.G.; Markov, O.E.; Aliieva, L.I.; Kukhar, V.V. Designing and Researching of the Equipment for Cutting by Breaking of Rolled Stock. Int. J. Adv. Manuf. Technol. 2020, 109, 2457–2464. [Google Scholar] [CrossRef]

- Murray, C.E.; Treger, M.; Noyan, I.C.; Rosenberg, R. Evolution of Strain Energy During Recrystallization of Plated Cu Films. IEEE Trans. Device Mater. Reliab. 2016, 16, 440–445. [Google Scholar] [CrossRef]

- Steinbach, F.; Bons, P.D.; Griera, A.; Jansen, D.; Llorens, M.G.; Roessiger, J.; Weikusat, I. Strain Localization and Dynamic Recrystallization in the Ice–Air Aggregate: A Numerical Study. Cryosphere 2016, 10, 3071–3089. [Google Scholar] [CrossRef]

- Efremenko, V.G.; Lekatou, A.G.; Chabak, Y.G.; Efremenko, B.V.; Petryshynets, I.; Zurnadzhy, V.I.; Emmanouilidou, S.; Vojtko, M. Micromechanical, Corrosion and Wet Sliding Wear Behaviours of Co-28Cr-6Mo Alloy: Wrought vs. LPBF. Mater. Today Commun. 2023, 35, 105936. [Google Scholar] [CrossRef]

- Hama, T.; Oka, M.; Nishi, T.; Matsuno, T.; Hayashi, S.; Takada, K.; Okitsu, Y. Crystal Plasticity Finite-element Simulation of Non-Uniform Deformation Behavior at Grain Level of Ultralow Carbon Steel. ISIJ Int. 2024, 64, 576–586. [Google Scholar] [CrossRef]

- Kheiri, S.; Mirzadeh, H.; Naghizadeh, M. Tailoring the Microstructure and Mechanical Properties of AISI 316L Austenitic Stainless Steel via Cold Rolling and Reversion Annealing. Mater. Sci. Eng. A 2019, 759, 90–96. [Google Scholar] [CrossRef]

- Du, X.; Xi, T.; Yang, C.; Zhao, H.; Yang, K. Cu Addition Retards the Static Recrystallization of Cold-Deformed 316L Biomedical Stainless Steel. J. Mater. Res. Technol. 2022, 19, 1673–1677. [Google Scholar] [CrossRef]

- Pinto, F.C.; Aota, L.S.; Souza Filho, I.R.; Raabe, D.; Sandim, H.R.Z. Recrystallization in non-conventional microstructures of 316L stainless steel produced via laser powder-bed fusion: Effect of particle coarsening kinetics. J. Mater. Sci. 2022, 57, 9576–9598. [Google Scholar] [CrossRef]

- Huang, F.; Chen, Q.; Ding, H.; Wang, Y.; Mou, X.; Chen, J. Automotive Steel with a High Product of Strength and Elongation used for Cold and Hot Forming Simultaneously. Materials 2021, 14, 1121. [Google Scholar] [CrossRef] [PubMed]

- Zurnadzhy, V.I.; Efremenko, V.G.; Wu, K.M.; Petryshynets, I.; Shimizu, K.; Zusin, A.M.; Brykov, M.N.; Andilakhai, V.A. Tailoring Strength/Ductility Combination in 2.5 wt% Si-Alloyed Middle Carbon Steel Produced by the Two-Step Q-P Treatment with a Prolonged Partitioning Stage. Mater. Sci. Eng. A 2020, 791, 139721. [Google Scholar] [CrossRef]

- Butuc, M.C.; Vincze, G.; Santos, R.; Pereira, A.; Santos, A.D.; Amaral, R.L.; Barlat, F. Formability of Third Generation Advanced High Strength Steel: Experimental and Theoretical Approach. Int. J. Mech. Sci. 2024, 281, 109559. [Google Scholar] [CrossRef]

- Efremenko, V.G.; Zotov, D.S.; Zurnadzhy, V.I.; Kussa, R.A.; Savenko, V.I.; Sagirov, R.I.; Bocharova, O.A.; Efremenko, A.V. Computer modelling-based selection of accelerated cooling parameters for advanced high-strength structural steel. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1037, 012030. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and Phenomenology of Strain Hardening: The FCC Case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Zhang, B.; Du, L.X.; Dong, Y.; Han, D.X.; Wu, H.Y.; Lu, F.H.; Misra, R.D.K. Structure-property relationship in novel low carbon hot-rolled TRIP steels via thermo-mechanical controlled processing and coiling. Mater. Sci. Eng. A 2020, 771, 138643. [Google Scholar] [CrossRef]

- Zhang, Q.; Meng, W.; Luo, Y. Hardening Behavior and Model of a 316L Sheet Considering Macro and Micro Size Effects. Metals 2023, 13, 1926. [Google Scholar] [CrossRef]

- Jin, J.-E.; Lee, Y.-K. Strain Hardening Behavior of a Fe–18Mn–0.6C–1.5Al TWIP Steel. Mater. Sci. Eng. A 2009, 527, 157–161. [Google Scholar] [CrossRef]

- Wu, X.L.; Yang, M.X.; Yuan, F.P.; Chen, L.; Zhu, Y.T. Combining Gradient Structure and TRIP Effect to Produce Austenite Stainless Steel with High Strength and Ductility. Acta Mater. 2016, 112, 337–346. [Google Scholar] [CrossRef]

- Vázquez-Fernández, N.I.; Isakov, M.; Hokka, M. Strain Hardening and Adiabatic Heating of Stainless Steels After a Sudden Increase of Strain Rate. J. Dyn. Behav. Mater. 2022, 8, 316–321. [Google Scholar] [CrossRef]

- Karthik, G.M.; Kim, E.S.; Zargaran, A.; Sathiyamoorthi, P.; Jeong, S.G.; Kim, H.S. Role of cellular structure on deformation twinning and hetero-deformation induced strengthening of laser powder-bed fusion processed CuSn alloy. Addit. Manuf. 2022, 54, 102744. [Google Scholar] [CrossRef]

- Mao, Q.; Gao, B.; Li, J.; Huang, Z.; Li, Y. Enhanced Tensile Properties of 316L Steel via Grain Refinement and Low-Strain Rolling. Mater. Sci. Technol. 2019, 35, 1497–1503. [Google Scholar] [CrossRef]

- Liu, J.; Chen, C.; Feng, Q.; Fang, X.; Wang, H.; Liu, F.; Lu, J.; Raabe, D. Dislocation Activities at the Martensite Phase Transformation Interface in Metastable Austenitic Stainless Steel: An In-situ TEM Study. Mater. Sci. Eng. A 2017, 703, 236–243. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | V | Ti | Nb | Co | Al | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.022 | 0.80 | 1.08 | 0.018 | 0.007 | 16.39 | 11.92 | 2.36 | 0.15 | 0.05 | 0.006 | 0.04 | 0.10 | 0.02 | bal. |

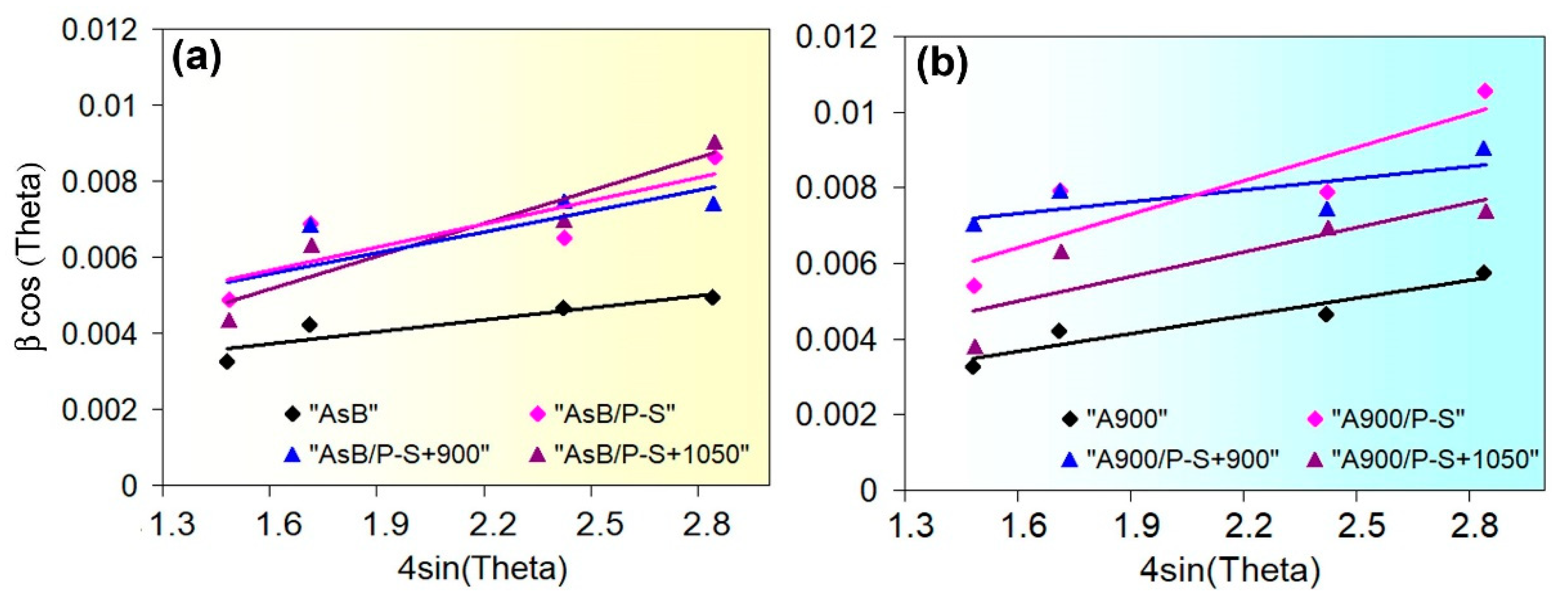

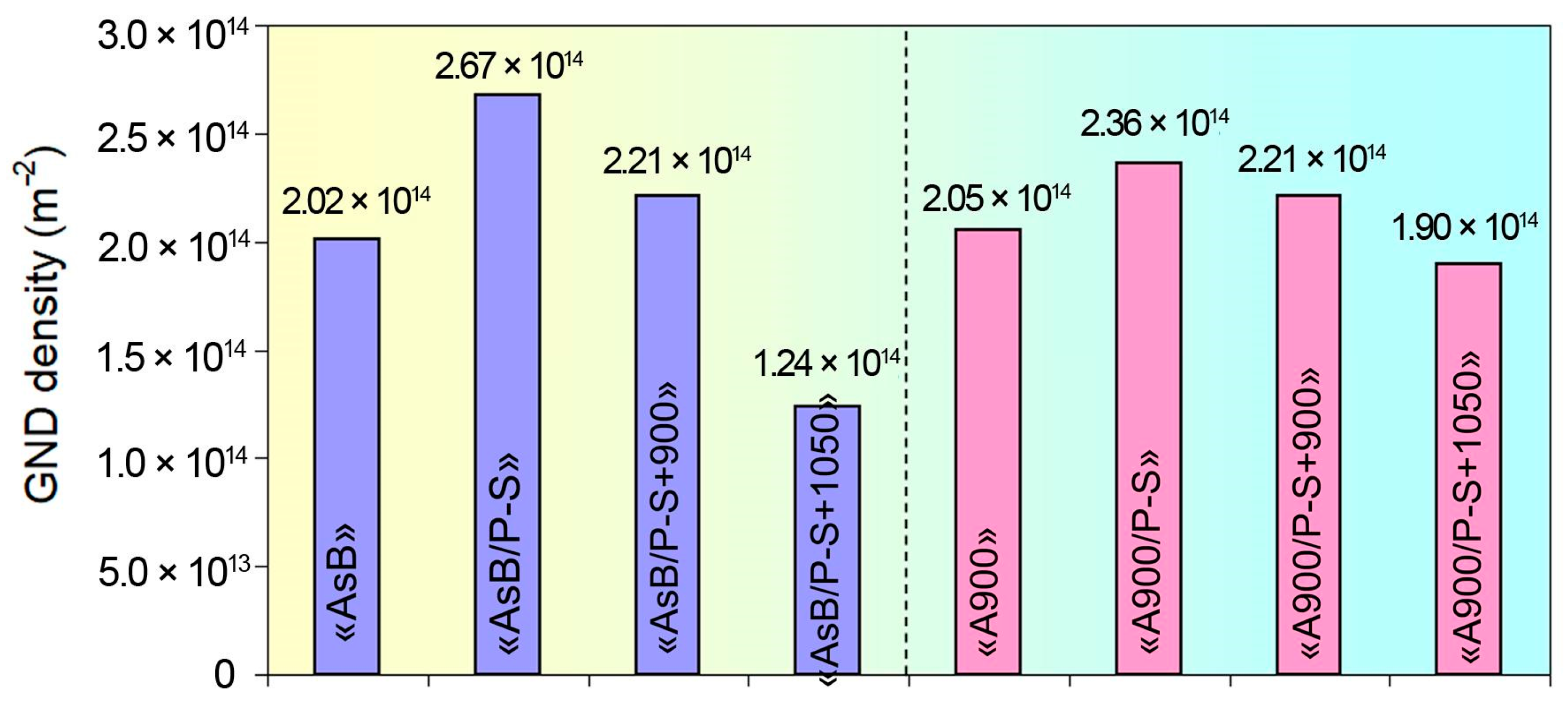

| Specimens | Lattice Parameter (Å) | Microstrain | Crystalline Size (Å) | Dislocation Density (m−2) |

|---|---|---|---|---|

| The specimens of an “AsB” group | ||||

| «AsB» | 3.597 | 11.1 × 10−4 | 860.0 | 9.49 × 1013 |

| «AsB/P-S» | 3.597 | 20.0 × 10−4 | 345.2 | 4.26 × 1014 |

| «AsB/P-S+900» | 3.596 | 5.1 × 10−4 | 557.7 | 6.73 × 1013 |

| «AsB/P-S+1050» | 3.598 | 22.0 × 10−4 | 966.7 | 1.67 × 1014 |

| The specimens of an “A900” group | ||||

| «A900» | 3.598 | 13.0 × 10−4 | 1208.2 | 7.91 × 1013 |

| «A900/P-S» | 3.599 | 21.3 × 10−4 | 433.3 | 3.62 × 1014 |

| «A900/P-S+900» | 3.599 | 8.2 × 10−4 | 651.4 | 9.26 × 1013 |

| «A900/P-S+1050» | 3.599 | 9.0 × 10−4 | 1102.3 | 6.00 × 1013 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Efremenko, B.; Chabak, Y.; Petryshynets, I.; Efremenko, V.; Wu, K.; Arshad, S.; Kromka, F. Microstructure Evolution, Tensile/Nanoindentation Response, and Work-Hardening Behaviour of Prestrained and Subsequently Annealed LPBF 316L Stainless Steel. Materials 2025, 18, 1102. https://doi.org/10.3390/ma18051102

Efremenko B, Chabak Y, Petryshynets I, Efremenko V, Wu K, Arshad S, Kromka F. Microstructure Evolution, Tensile/Nanoindentation Response, and Work-Hardening Behaviour of Prestrained and Subsequently Annealed LPBF 316L Stainless Steel. Materials. 2025; 18(5):1102. https://doi.org/10.3390/ma18051102

Chicago/Turabian StyleEfremenko, Bohdan, Yuliia Chabak, Ivan Petryshynets, Vasily Efremenko, Kaiming Wu, Sundas Arshad, and František Kromka. 2025. "Microstructure Evolution, Tensile/Nanoindentation Response, and Work-Hardening Behaviour of Prestrained and Subsequently Annealed LPBF 316L Stainless Steel" Materials 18, no. 5: 1102. https://doi.org/10.3390/ma18051102

APA StyleEfremenko, B., Chabak, Y., Petryshynets, I., Efremenko, V., Wu, K., Arshad, S., & Kromka, F. (2025). Microstructure Evolution, Tensile/Nanoindentation Response, and Work-Hardening Behaviour of Prestrained and Subsequently Annealed LPBF 316L Stainless Steel. Materials, 18(5), 1102. https://doi.org/10.3390/ma18051102