Activation of Polypropylene (PP) Fiber Surface with 1-Vinyl-1,2,4-triazole and Vinyl Acetate: Synthesis, Characterization, and Application in Cementitious Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Materials Used in the Synthesis of Activation of PP Polymer Surface with 1-Vinyl-1,2,4-Triazole

2.1.2. Materials Used in the Synthesis of PP Polymer Surface Activation with Vinyl Acetate

2.2. Methods

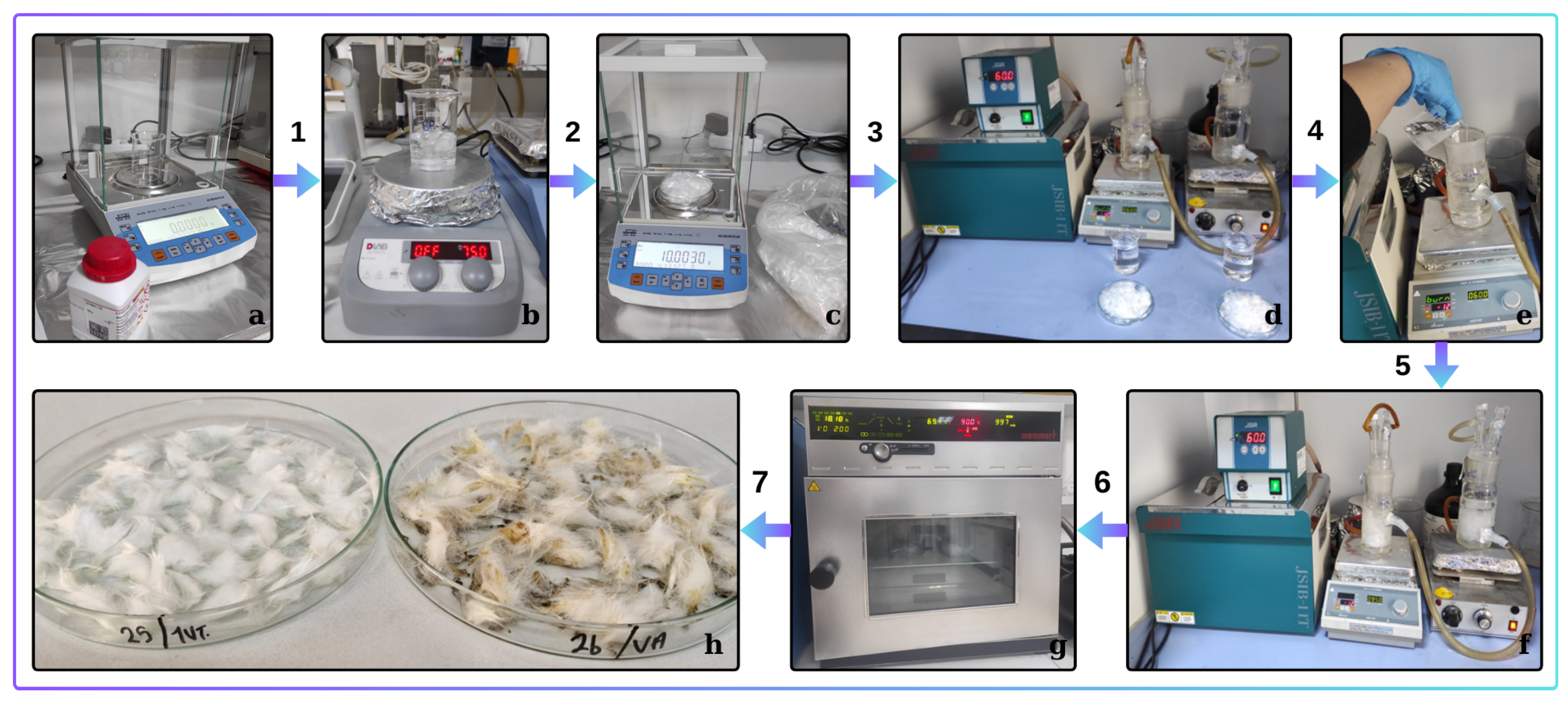

2.2.1. Synthesis of Activation of PP Polymer Surface by 1-Vinyl-1,2,4-Triazole

2.2.2. Synthesis of Activation of PP Polymer Surface with Vinyl Acetate

2.2.3. PP Fiber Surface Modification

2.2.4. Preparation of Mortar Mixtures

2.2.5. Mixture Experiments

2.2.6. Fiber Characterization Processes

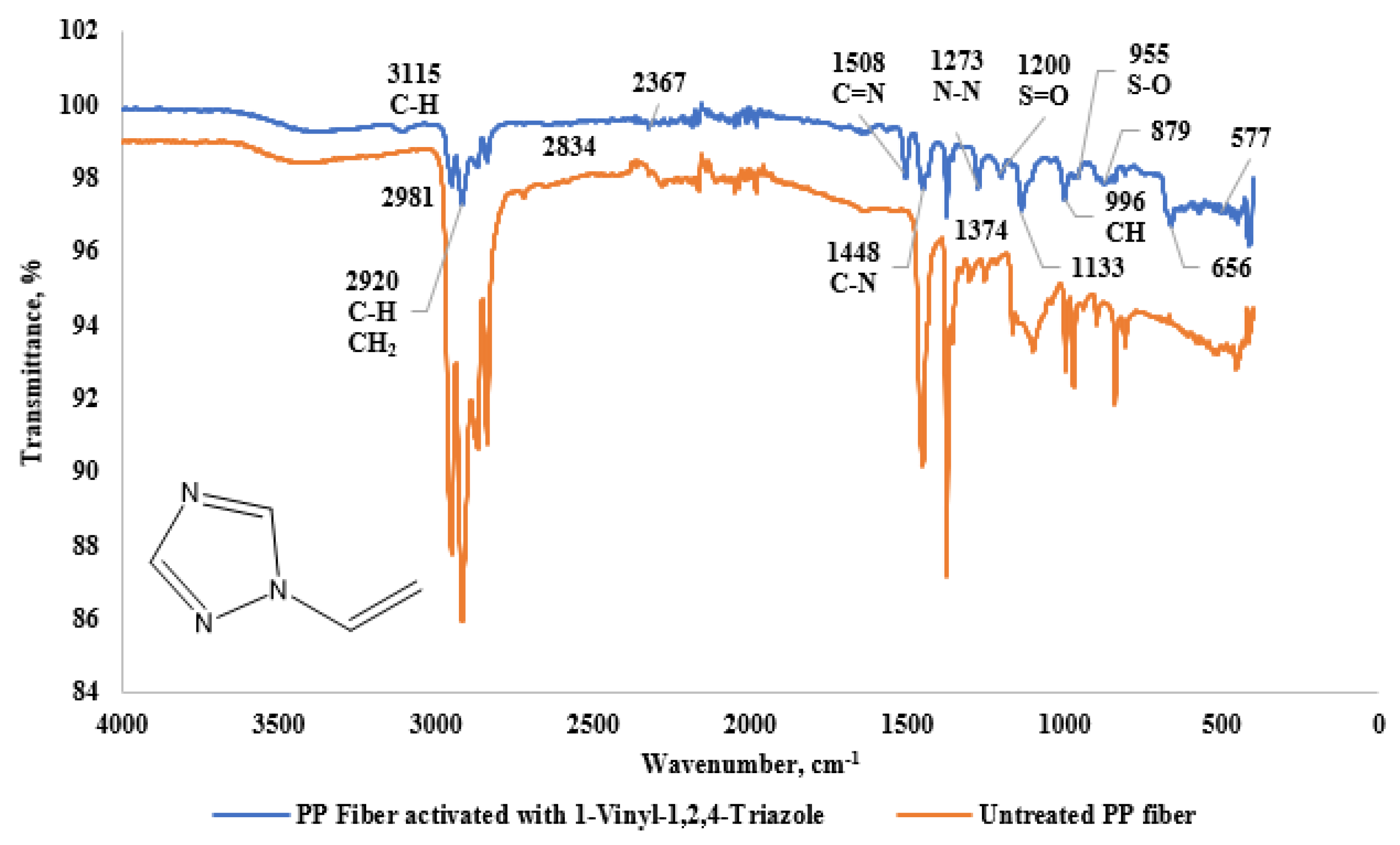

Fourier Transform Infrared Spectroscopy (FTIR) Analysis

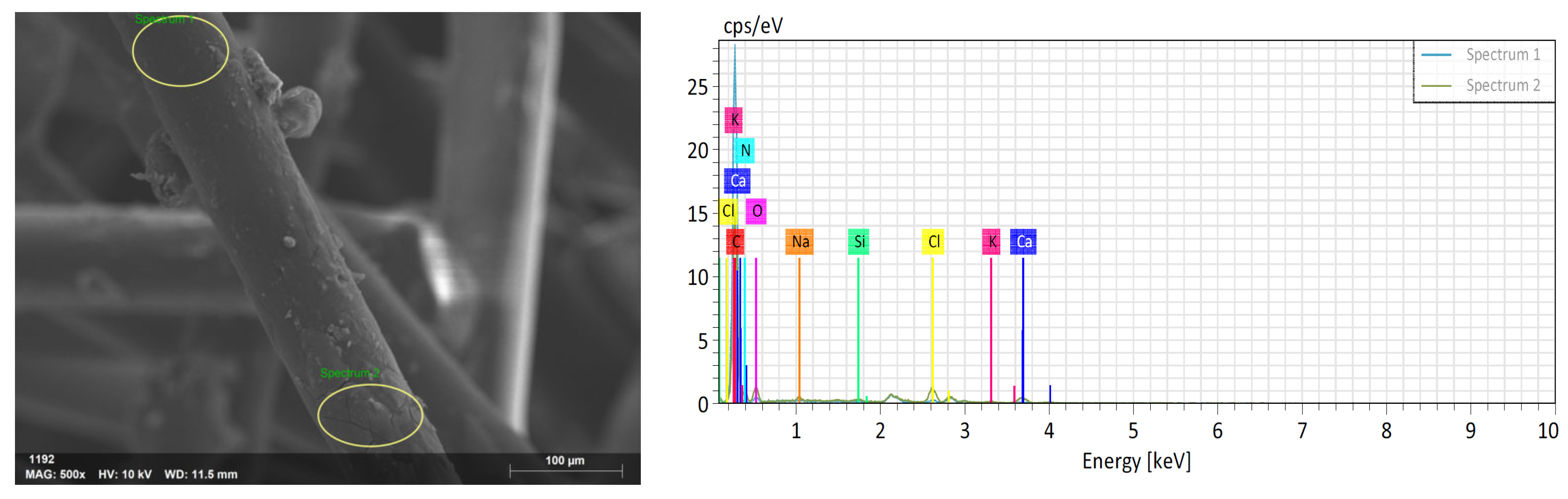

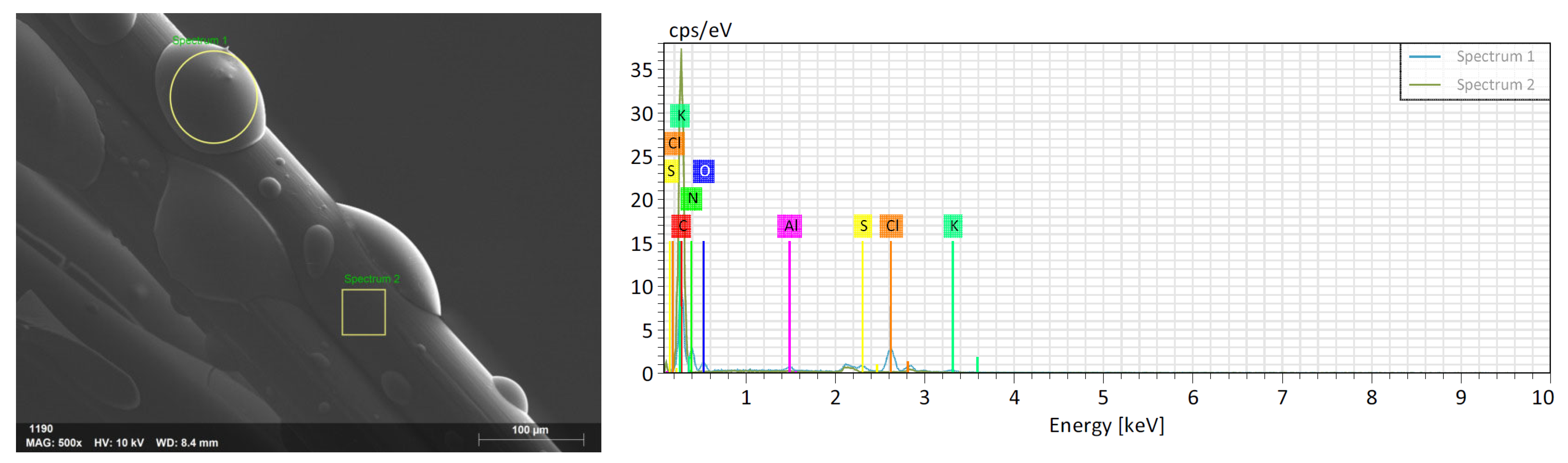

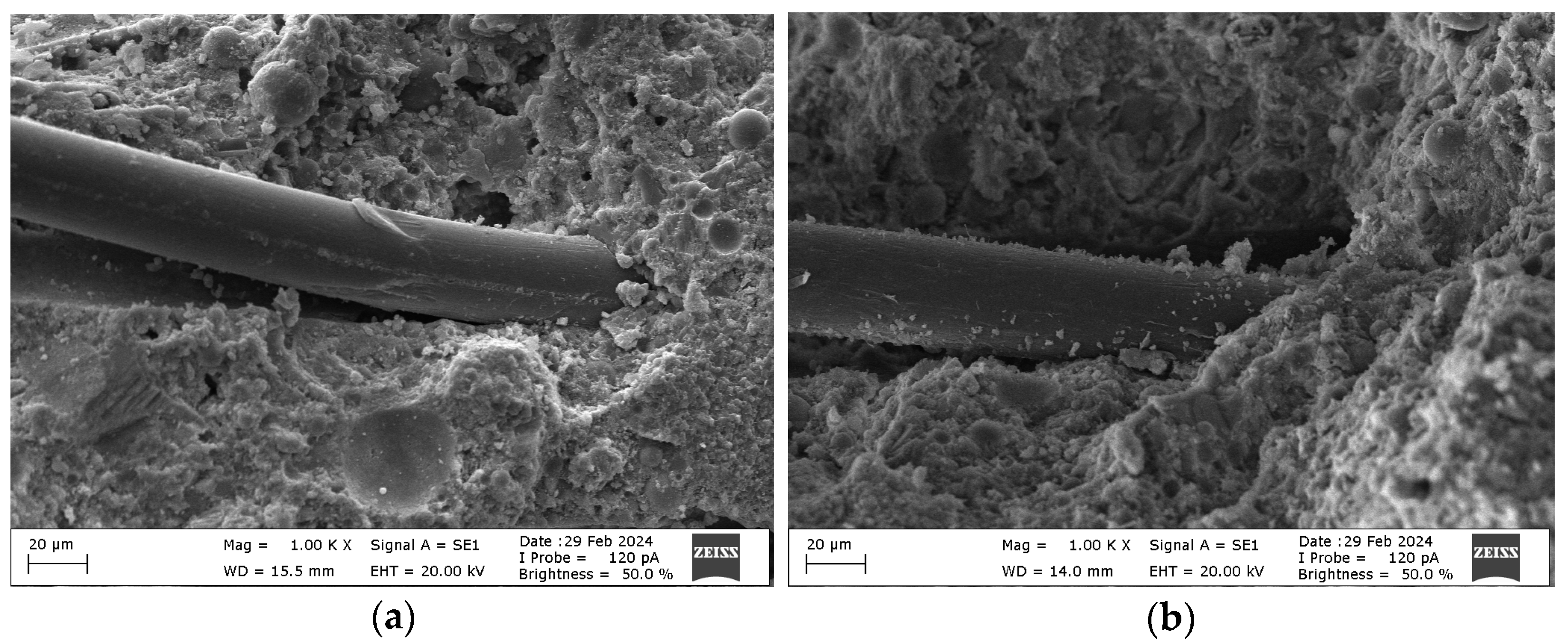

Scanning Electron Microscopy (SEM-EDS) Analysis

3. Results

3.1. Characterization of PP Polymer Surface Activation by 1-Vinyl-1,2,4-Triazole

3.2. Cementitious System Properties

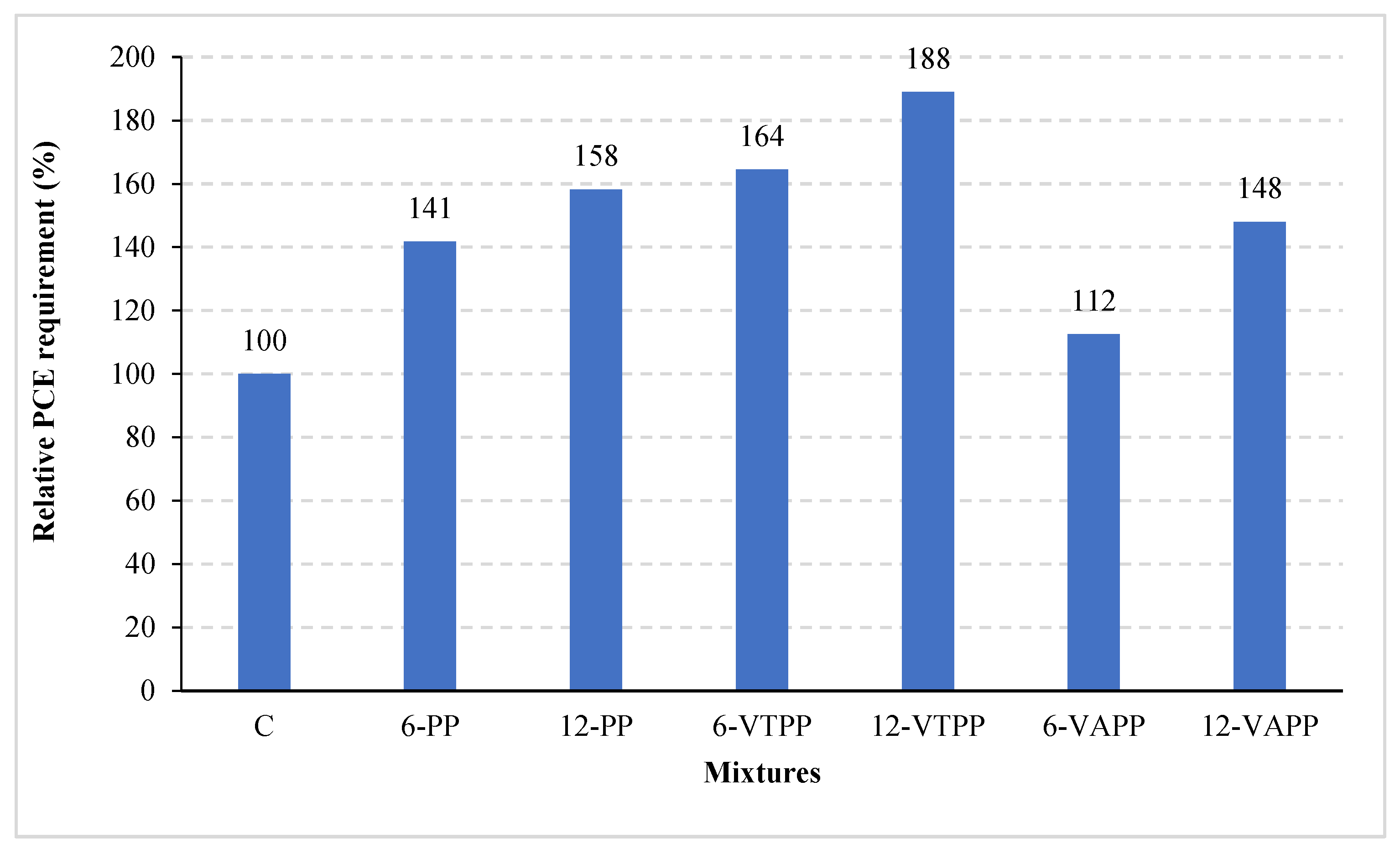

3.2.1. Fresh Properties

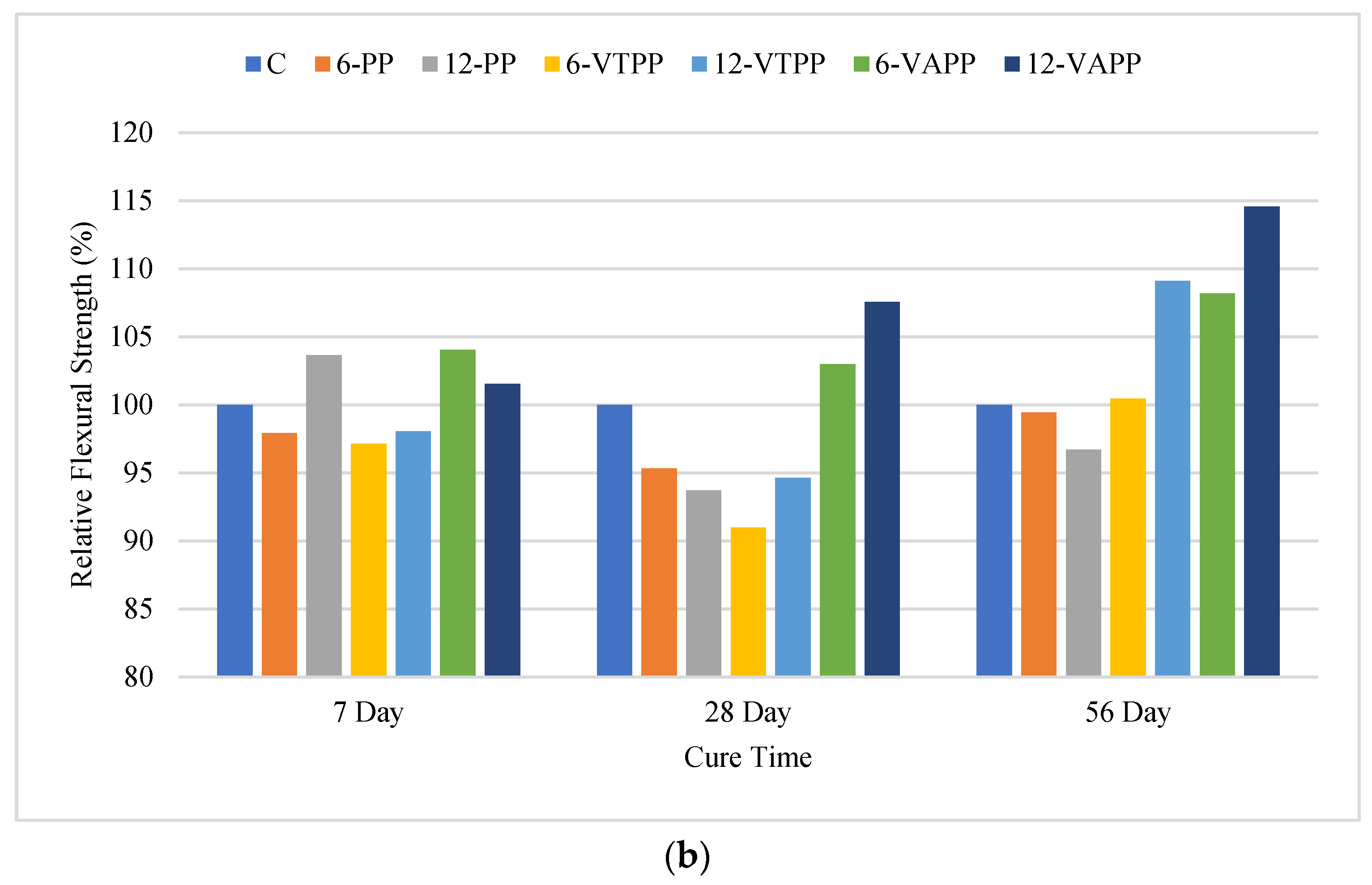

3.2.2. Compressive and Flexural Strength Performance

4. Conclusions

- -

- With the addition of fibers to the mixture, the PCE requirement for the target flow value increased by 12–88% regardless of the fiber type and length.

- -

- Among the modifications applied to recycled waste PP fibers, it was observed that the modification with Vinyl Acetate showed superior performance in terms of flow performance compared to the modification with 1-Vinyl-1,2,4-Triazole.

- -

- Regardless of the fiber type, the compressive strength performance of the mixtures was negatively affected in the range of 4–10% with the increase in fiber length. This situation is thought to be due to the air entrainment of long fibers during mixing.

- -

- Regardless of the modification type, the compressive strength was positively affected in the range of 2–10% by modifying PP fibers.

- -

- It was determined that the modifications were more effective on the flexural strength rather than the compressive strength. This situation shows that the fiber–matrix adhesion was significantly strengthened with the modification.

- -

- As a result, it was observed that fiber–matrix adhesion enhancement can be provided to fibers with poor surface roughness, especially in terms of the flexural strength performance of concrete, with various modifications. Therefore, in future studies, performance increases should be examined by applying different modification methods to different fiber types.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Özen, S.; Altun, M.G.; Mardani-Aghabaglou, A.; Ramyar, K. Effect of main and side chain length change of polycarboxylate-ether-based water-reducing admixtures on the fresh state and mechanical properties of cementitious systems. Struct. Concr. 2021, 22, E607–E618. [Google Scholar] [CrossRef]

- Micelli, F.; Renni, A.; Kandalaft, A.G.; Moro, S. Fiber-reinforced concrete and ultrahigh-performance fiber-reinforced concrete materials. In New Materials in Civil Engineering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 273–314. [Google Scholar]

- Şenol, A.F. Fiber Types in Concrete Technology and Properties of Fiber Reinforced Concretes. In Current Discussions in Engineering Sciences; Duvar Publications: Izmir, Turkey, 2022; pp. 7–22. [Google Scholar]

- Kaya, Y.; Biricik, Ö.; Bayqra, S.H.; Mardani, A. Effect of fiber type and utilization rate on dimensional stability and frost resistance of pavement mortar mixture. Int. J. Pavement Eng. 2023, 24, 2154351. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Karakuzu, K.; Kobya, V.; Hatungimana, D. Durability performance and dimensional stability of road concrete containing dry-shake surface hardener admixture. Constr. Build. Mater. 2021, 274, 121789. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Öztürk, H.T.; Kankal, M.; Ramyar, K. Assessment and prediction of cement paste flow behavior; Marsh funnel flow time and mini slump values. Constr. Build. Mater. 2021, 301, 124072. [Google Scholar] [CrossRef]

- Oltulu, M.; Altun, M.G. Drop Weight Test Method in Determining the Impact Resistance of Concrete and Studies Conducted. Gümüşhane Univ. J. Sci. Inst. 2018, 8, 155–163. [Google Scholar]

- Mengjin, W.U.; Lixia, J.I.A.; Suling, L.U.; Zhigang, Q.I.N.; Sainan, W.E.I.; Ruosi, Y.A.N. Interfacial performance of high-performance fiber-reinforced composites improved by cold plasma treatment: A review. Surf. Interfaces 2021, 24, 101077. [Google Scholar] [CrossRef]

- Lu, Z.; Yao, J.; Leung, C.K.Y. Using graphene oxide to strength the bond between PE fiber and matrix to improve the strain hardening behavior of SHCC. Cem. Concr. Res. 2019, 126, 105899. [Google Scholar] [CrossRef]

- Coppola, B.; DiMaio, L.; Scarfato, P.; Incarnato, L. Use of polypropylene fibers coated with nano-silica particles into a cementitious mortar. AIP Conf. Proc. 2015, 1695, 020056. [Google Scholar] [CrossRef]

- Feng, J.; Yang, F.; Qian, S. Improving the bond between polypropylene fiber and cement matrix by nano calcium carbonate modification. Constr. Build. Mater. 2021, 269, 121249. [Google Scholar] [CrossRef]

- Pozdnyakov, A.S.; Sekretarev, E.A.; Emel’yanov, A.I.; Prozorova, G.F. Hydrophilic functional copolymers of 1-vinyl-1,2,4-triazole with vinylsulfonic acid sodium salt. Russ. Chem. Bull. Int. Ed. 2017, 66, 2293–2297. [Google Scholar] [CrossRef]

- Tuazon, E.C.; Atkinson, R.; Winer, A.M.; Pitts, J.N., Jr. A study of the atmospheric reactions of 1,3-dichloropropene and other selected organochlorine compounds. Arch. Environ. Contam. Toxicol. 1984, 13, 691–700. [Google Scholar] [CrossRef]

- Şahin, H.G.; Mardani, A.; Özen, S.; Emin, A. Utilization of high-range water reducing admixture having air-entraining agents in cementitious systems. J. Build. Eng. 2023, 64, 105565. [Google Scholar] [CrossRef]

- Cherifi, B.I.; Belbachir, M.; Rahmouni, A. Green anionic polymerization of vinyl acetate using Maghnite-Na+ (Algerian MMT): Synthesis, characterization, and reaction all mechanism. Discov. Chem. Eng. 2021, 1, 5. [Google Scholar] [CrossRef]

- Ramírez-Hernández, A.; Aguilar-Flores, C.; Aparicio-Saguilán, A. Finger print analysis of FTIR spectra of polymers containing vinyl acetate. DYNA 2019, 86, 198–205. [Google Scholar] [CrossRef]

- Squillace, O.; Fong, R.; Shepherd, O.; Hind, J.; Tellam, J.; Steinke, N.-J.; Thompson, R.L. Influence of PVAc/PVA Hydrolysis on Additive Surface Activity. Polymers 2020, 12, 205. [Google Scholar] [CrossRef]

- Chen, X.; Huang, L.; Dong, C.; Niu, L.; Zhang, Y.; Chen, Z. Influence of Vinyl Acetate Content on the Surface Hydrophobic Recovery of Ethylene Vinyl Acetate Copolymer after Plasma Modification. Chem. Sel. 2019, 4, 1763–1765. [Google Scholar] [CrossRef]

- Latifi, M.R.; Biricik, Ö.; Mardani Aghabaglou, A. Effect of the addition of polypropylene fiber on concrete properties. J. Adhes. Sci. Technol. 2022, 36, 345–369. [Google Scholar] [CrossRef]

- Laxmi, G.; Patil, S.G. Effect of fiber types, shape, a spect ratio and volume fraction on properties of geopolymer concrete–A review. Mater. Today Proc. 2022, 65, 1086–1094. [Google Scholar] [CrossRef]

- Kaya, Y.; Biricik, Ö.; Bayqra, S.H.; Mardani, A. Rheological properties and thixotropic behavior of cementitious systems containing different fiber types. Arab. J. Sci. Eng. 2024, 49, 5203–5223. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Ramyar, K. Mechanical properties of high-volume fly ash roller compacted concrete designed by maximum density method. Constr. Build. Mater. 2013, 38, 356–364. [Google Scholar] [CrossRef]

- Meltonyan, A.V.; Poghosyan, A.H.; Sargsyan, S.H. Surface coverage and adsorption properties of 1-vinyl-1,2,4-triazole on Au(111) surface: A molecular dynamics study. J. Mol. Model. 2023, 29, 316. [Google Scholar] [CrossRef] [PubMed]

- Prozorova, G.F.; Pozdnyakov, A.S. Synthesis, properties, and biological activity of poly(1-vinyl-1,2,4-triazole) and silver nanocomposites based on it. Polym. Sci. Ser. C 2022, 64, 62–72. [Google Scholar] [CrossRef]

- Galanopoulo, P.; Dugas, P.-Y.; Lansalot, M.; D’Agosto, F. Poly(ethyleneglycol)-b-poly(vinyl acetate) block copolymer particles with various morphologies via RAFT/MADIX aqueous emulsion PISA. Polym. Chem. 2020, 11, 3922–3930. [Google Scholar] [CrossRef]

| Oxide (%) | Cement | Physical Properties | ||

|---|---|---|---|---|

| SiO2 | 18.86 | Spesific gravity C2S (%) C3A (%) C4AF (%) | 3.15 | |

| Al2O3 | 5.71 | Mechanical properties | ||

| Fe2O3 | 3.09 | Compressive strength (MPa) | 1-day | 14.7 |

| CaO | 62.70 | 2-day | 26.80 | |

| MgO | 1.16 | 7-day | 49.80 | |

| SO3 | 2.39 | 28-day | 58.5 | |

| Na2O + 0.658 K2O | 0.92 | Fineness | ||

| Cl− | 0.01 | Specific surface (Blaine, cm2/g) | 3530 | |

| Insoluble residue | 0.32 | Residue on 0.045 mm sieve (%) | 7.6 | |

| Loss of ignition | 3.20 | |||

| Free CaO | 1.26 | |||

| Type | Density (gr/cm3) | Solid Content (%) | pH | Chloride Content (%) | Alkaline Content Na2O (%) |

|---|---|---|---|---|---|

| PCE | 1.097 | 36.35 | 3.82 | <0.1 | <10 |

| Raw Material | Density (gr/cm3) | Length (mm) | Tensile Strength (N/mm2) | Modulus of Elasticity (N/mm2) | Melting Point (°C) |

|---|---|---|---|---|---|

| PP | 0.91 | 6–12 | 450–700 | 3000–3500 | 162 |

| Mixture Code | Cement (g/dm3) | Water (g/dm3) | Sand (g/dm3) | PCE (g/dm3) | Fiber (g/dm3) | Flow (mm) |

|---|---|---|---|---|---|---|

| C | 550 | 266.75 | 1512.50 | 1.27 | - | 182 |

| 6-PP | 550 | 266.75 | 1499.05 | 1.80 | 4.550 | 205 |

| 12-PP | 550 | 266.75 | 1499.05 | 2.01 | 4.550 | 181 |

| 6-VTPP | 550 | 266.75 | 1499.05 | 2.09 | 4.550 | 180 |

| 12-VTPP | 550 | 266.75 | 1499.05 | 2.40 | 4.550 | 202 |

| 6-VAPP | 550 | 266.75 | 1499.05 | 1.43 | 4.550 | 182 |

| 12-VAPP | 550 | 266.75 | 1499.05 | 1.88 | 4.550 | 180 |

| Spektrum | Carbon | Nitrogen | Oxygen | Sodium | Chlorine | Potassium |

|---|---|---|---|---|---|---|

| Spectrum 1 | 92.91 | 0.00 | 4.28 | 0.18 | 1.32 | 0.27 |

| Spectrum 2 | 65.45 | 10.90 | 11.62 | 0.76 | 4.83 | 0.75 |

| Spectrum | Carbon | Nitrogen | Oxygen | Sodium | Chlorine | Potassium |

|---|---|---|---|---|---|---|

| Spectrum 1 | 46.57 | 31.00 | 8.13 | 1.97 | 10.14 | 1.47 |

| Spectrum 2 | 91.71 | 6.99 | 0.54 | 0.21 | 0.42 | 0.00 |

| Compressive Strength (MPa) | Flexural Strength (MPa) | |||||

|---|---|---|---|---|---|---|

| 7 Day | 28 Day | 56 Day | 7 Day | 28 Day | 56 Day | |

| C | 39.6 | 50.54 | 54.09 | 7.72 | 8.76 | 8.79 |

| 6-PP | 42.53 | 51.24 | 55.2 | 7.56 | 8.35 | 8.74 |

| 12-PP | 37.92 | 49.63 | 53.5 | 8.0 | 8.21 | 8.5 |

| 6-VTPP | 43.83 | 55.17 | 56.34 | 7.5 | 7.97 | 8.83 |

| 12-VTPP | 39.89 | 54.99 | 58.76 | 7.57 | 8.29 | 9.59 |

| 6-VAPP | 46.53 | 55.16 | 59.41 | 8.13 | 9.02 | 8.51 |

| 12-VAPP | 39.63 | 51.66 | 56.24 | 7.34 | 8.32 | 10.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaya, Y.; Balcı, P.; Özen, S.; Mardani, A.; Kara, A. Activation of Polypropylene (PP) Fiber Surface with 1-Vinyl-1,2,4-triazole and Vinyl Acetate: Synthesis, Characterization, and Application in Cementitious Systems. Materials 2025, 18, 1071. https://doi.org/10.3390/ma18051071

Kaya Y, Balcı P, Özen S, Mardani A, Kara A. Activation of Polypropylene (PP) Fiber Surface with 1-Vinyl-1,2,4-triazole and Vinyl Acetate: Synthesis, Characterization, and Application in Cementitious Systems. Materials. 2025; 18(5):1071. https://doi.org/10.3390/ma18051071

Chicago/Turabian StyleKaya, Yahya, Petek Balcı, Süleyman Özen, Ali Mardani, and Ali Kara. 2025. "Activation of Polypropylene (PP) Fiber Surface with 1-Vinyl-1,2,4-triazole and Vinyl Acetate: Synthesis, Characterization, and Application in Cementitious Systems" Materials 18, no. 5: 1071. https://doi.org/10.3390/ma18051071

APA StyleKaya, Y., Balcı, P., Özen, S., Mardani, A., & Kara, A. (2025). Activation of Polypropylene (PP) Fiber Surface with 1-Vinyl-1,2,4-triazole and Vinyl Acetate: Synthesis, Characterization, and Application in Cementitious Systems. Materials, 18(5), 1071. https://doi.org/10.3390/ma18051071