Assessment of Mechanical and Ecotoxicological Properties of Mortar with Wood Waste Biochar as Partial Cement Replacement

Abstract

1. Introduction

2. Materials and Methods

2.1. Cement, Natural Aggregate, and Biochar

2.2. Fresh Mortar Properties

2.3. Hardened Mortar Properties

2.4. Ecotoxicological Assessment

2.4.1. Preparation and Characterization of Leachates

2.4.2. Phytotoxicity Tests

3. Results and Discussion

3.1. Flowability and Fresh Density

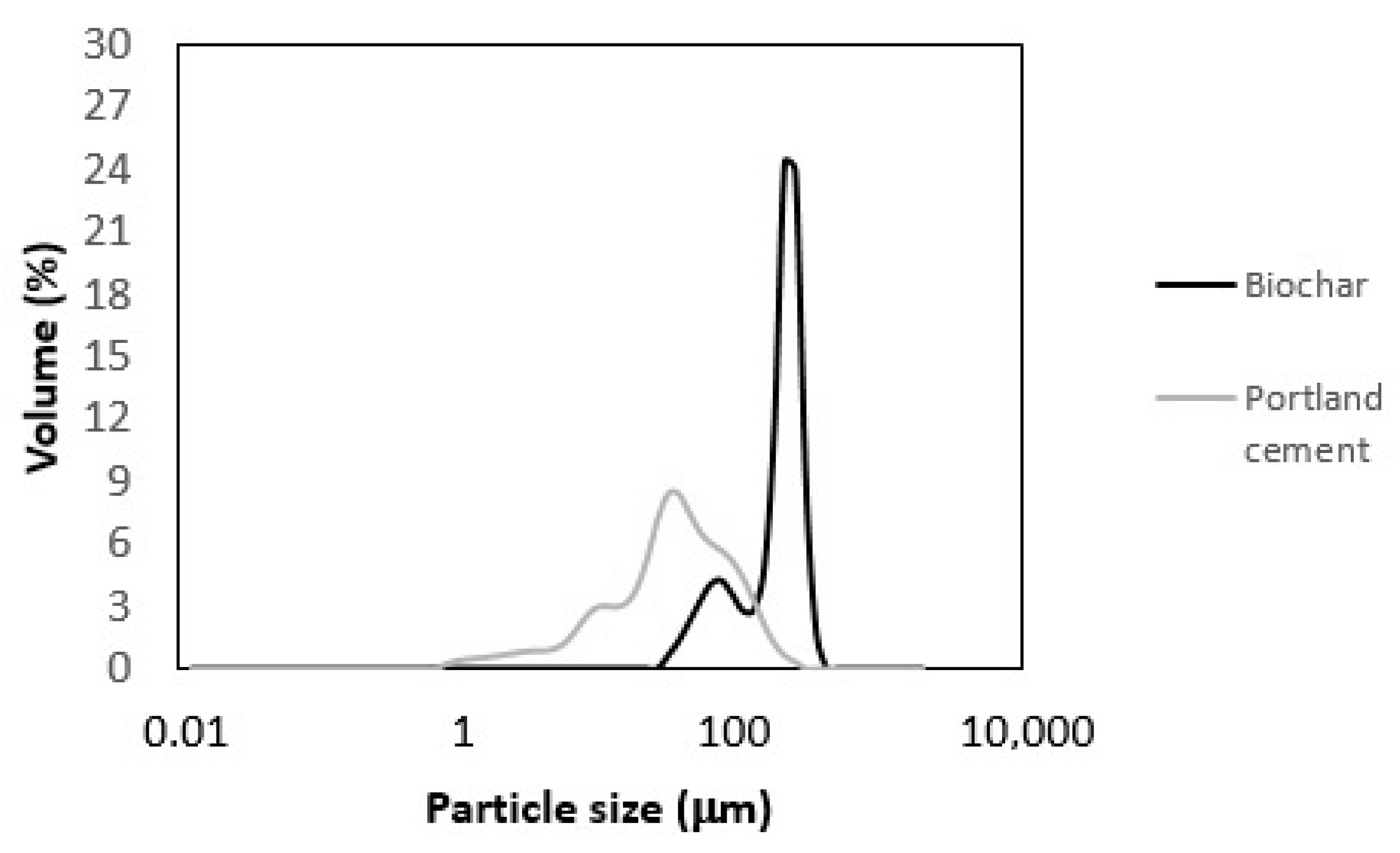

3.2. Particle Size Distribution of Biochar and Cement

3.3. Flexural Strength

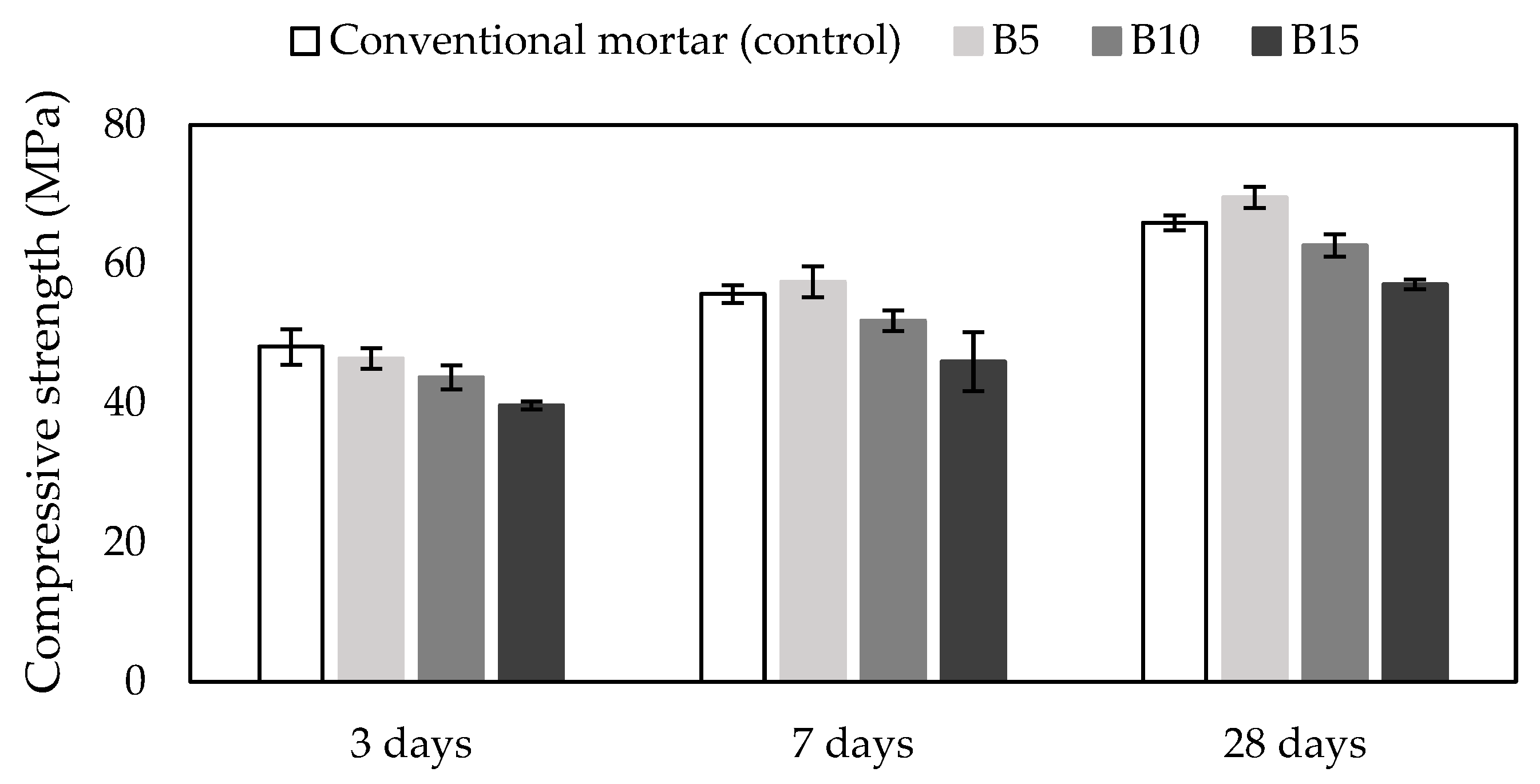

3.4. Compressive Strength

3.5. XRD of Mortar Samples

3.6. SEM

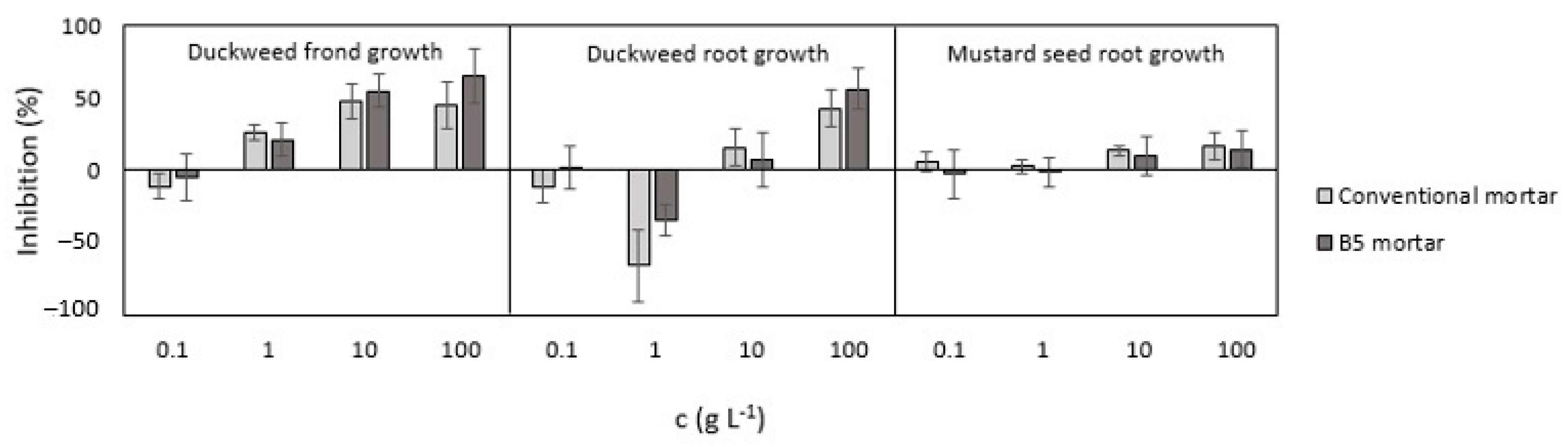

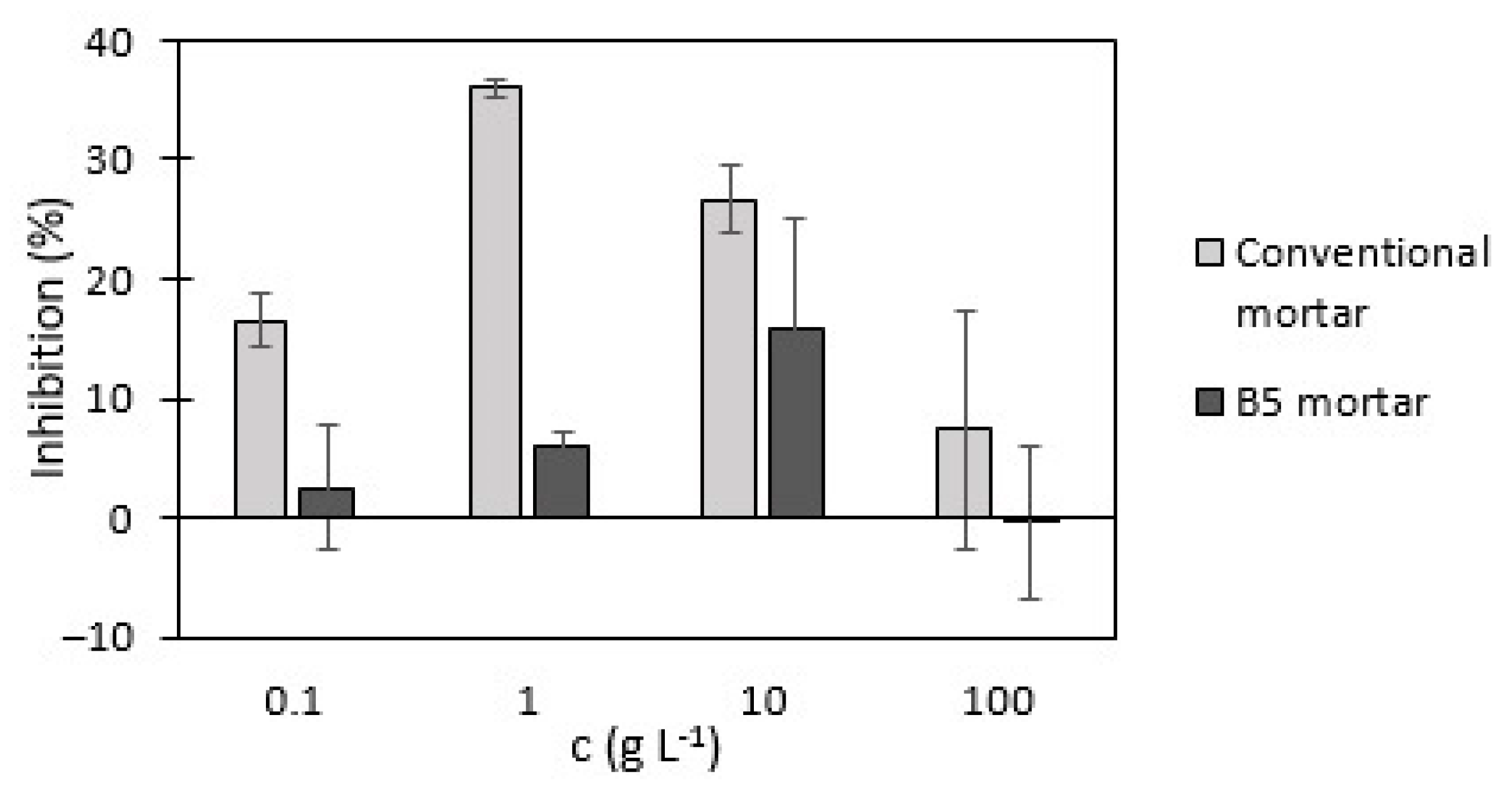

3.7. Phytotoxicity Tests with Duckweed and Mustard Seeds

3.8. Characterization of Mortar Leachates

3.9. Potential of Carbon Footprint Reduction

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adesina, A. Recent advances in the concrete industry to reduce its carbon dioxide emissions. Environ. Chall. 2020, 1, 100004. [Google Scholar] [CrossRef]

- Favier, A.; De Wolf, C.; Scrivener, K.; Habert, G. A Sustainable Future for the European Cement and Concrete Industry: Technology Assessment for Full Decarbonisation of the Industry by 2050; ETH Zurich: Zürich, Switzerland, 2018. [Google Scholar] [CrossRef]

- Pöllmann, H.; Snellings, R.; Valentini, L. Cement and Concrete—Past, Present, and Future. Elem. Int. Mag. Mineral. Geochem. Petrol. 2022, 18, 295–299. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Habert, G.; Bouzidi, Y.; Chen, C.; Jullien, A. Development of a depletion indicator for natural resources used in concrete. Resour. Conserv. Recycl. 2010, 54, 364–376. [Google Scholar] [CrossRef]

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O. Carbon dioxide emissions from the global cement industry. Annu. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- Shah, I.H.; Miller, S.A.; Jiang, D.; Myers, R.J. Cement substitution with secondary materials can reduce annual global CO2 emissions by up to 1.3 gigatons. Nat. Commun. 2022, 13, 5758. [Google Scholar] [CrossRef]

- Cheah, C.B.; Ramli, M. The implementation of wood waste ash as a partial cement replacement material in the production of structural grade concrete and mortar: An overview. Resour. Conserv. Recycl. 2011, 55, 669–685. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Waste glass powder as cement replacement in concrete. J. Adv. Concr. Technol. 2014, 12, 468–477. [Google Scholar] [CrossRef]

- El-Dieb, A.S.; Kanaan, D.M. Ceramic waste powder an alternative cement replacement–Characterization and evaluation. Sustain. Mater. Technol. 2018, 17, e00063. [Google Scholar] [CrossRef]

- Lehmann, J.; Cowie, A.; Masiello, C.A.; Kammann, C.; Woolf, D.; Amonette, J.E.; Cayuela, M.L.; Camps-Arbestain, M.; Whitman, T. Biochar in climate change mitigation. Nat. Geosci. 2021, 14, 883–892. [Google Scholar] [CrossRef]

- Naqi, A.; Jang, J.G. Recent progress in green cement technology utilizing low-carbon emission fuels and raw materials: A review. Sustainability 2019, 11, 537. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A.; Salim, M.U.; Ahmad, N.; Ahmad, F.; Ahmad, A. Reusing biochar as a filler or cement replacement material in cementitious composites: A review. Constr. Build. Mater. 2021, 300, 124295. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Factors determining the potential of biochar as a carbon capturing and sequestering construction material: Critical review. J. Mater. Civ. Eng. 2017, 29, 04017086. [Google Scholar] [CrossRef]

- Ippolito, J.A.; Cui, L.; Kammann, C.; Wrage-Mönnig, N.; Estavillo, J.M.; Fuertes-Mendizabal, T.; Cayuela, M.L.; Sigua, G.; Novak, J.; Spokas, K.; et al. Feedstock choice, pyrolysis temperature and type influence biochar characteristics: A comprehensive meta-data analysis review. Biochar 2020, 2, 421–438. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Bio/Technol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Joseph, S.; Lehmann, J. Biochar for Environmental Management: Science and Technology; No. 631.422 B615bi; Earthscan: London, UK, 2009. [Google Scholar]

- Palanivelu, K.; Ramachandran, A.; Raghavan, V. Biochar from biomass waste as a renewable carbon material for climate change mitigation in reducing greenhouse gas emissions—A review. Biomass Convers. Biorefin. 2021, 11, 2247–2267. [Google Scholar] [CrossRef]

- Kamali, M.; Sweygers, N.; Al-Salem, S.; Appels, L.; Aminabhavi, T.M.; Dewil, R. Biochar for soil applications-sustainability aspects, challenges and future prospects. Chem. Eng. J. 2022, 428, 131189. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S. Preparation, modification and environmental application of biochar: A review. J. Clean. Prod. 2019, 227, 1002–1022. [Google Scholar] [CrossRef]

- Kalus, K.; Koziel, J.A.; Opaliński, S. A review of biochar properties and their utilization in crop agriculture and livestock production. Appl. Sci. 2019, 9, 3494. [Google Scholar] [CrossRef]

- Toth, J.D.; Dou, Z. Use and impact of biochar and charcoal in animal production systems. Agric. Environ. Appl. Biochar Adv. Barriers 2016, 63, 199–224. [Google Scholar] [CrossRef]

- Legan, M.; Gotvajn, A.Ž.; Zupan, K. Potential of biochar use in building materials. J. Environ. Manag. 2022, 309, 114704. [Google Scholar] [CrossRef] [PubMed]

- Woolf, D.; Amonette, J.E.; Street-Perrott, F.A.; Lehmann, J.; Joseph, S. Sustainable biochar to mitigate global climate change. Nat. Commun. 2010, 1, 56. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Xiao, H.; Guan, S.; Zhang, J.; Yao, D. Technology and method for applying biochar in building materials to evidently improve the carbon capture ability. J. Clean. Prod. 2020, 273, 123154. [Google Scholar] [CrossRef]

- Kobetičová, K.; Černý, R. Ecotoxicology of building materials: A critical review of recent studies. J. Clean. Prod. 2017, 165, 500–508. [Google Scholar] [CrossRef]

- Rodrigues, P.; Silvestre, J.D.; Flores-Colen, I.; Viegas, C.A.; De Brito, J.; Kurad, R.; Demertzi, M. Methodology for the assessment of the ecotoxicological potential of construction materials. Materials 2017, 10, 649. [Google Scholar] [CrossRef]

- Kim, J.Y.; Oh, S.; Park, Y.K. Overview of biochar production from preservative-treated wood with detailed analysis of biochar characteristics, heavy metals behaviors, and their ecotoxicity. J. Hazard. Mater. 2020, 384, 121356. [Google Scholar] [CrossRef]

- Teng, T.J.; Arip, M.N.M.; Sudesh, K.; Nemoikina, A.; Jalaludin, Z.; Ng, E.P.; Lee, H.L. Conventional technology and nanotechnology in wood preservation: A review. BioResources 2018, 13, 9220–9252. [Google Scholar] [CrossRef]

- SIST EN 197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2011.

- SIST EN 1015-3:2001; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). Slovenian Institute for Standardization: Ljubljana, Slovenia, 2001.

- SIST EN 1015-6:1999; Methods of Test for Mortar for Masonry—Part 6: Determination of Bulk Density of Fresh Mortar. Slovenian Institute for Standardization: Ljubljana, Slovenia, 1999.

- SIST EN 1015-11:2020; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2020.

- ISO 20079:2005; Water Quality—Determination of the Toxic Effect of Water Constituents and Waste Water on Duckweed (Lemna minor)—Duckweed Growth Inhibition Test. International Organization for Standardization: Geneva, Switzerland, 2005.

- Fargasova, A. Toxicity comparison of some possible toxic metals (Cd, Cu, Pb, Se, Zn) on young seedlings of Sinapis alba L. Plant Soil Environ. 2004, 50, 33–38. [Google Scholar] [CrossRef]

- Mallouhi, J.; Hornyák-Mester, E.; Varga, M.; Viskolcz, B.; Fiser, B.; Szőri-Dorogházi, E. Development of toxicity tests for Polyurethane foams. Heliyon 2024, 10, e38440. [Google Scholar] [CrossRef]

- SIST EN 12457-2:2004; Characterisation of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 2: One Stage Batch Test at a Liquid to Solid Ratio of 10 L/kg for Materials with Particle Size Below 4 mm (Without or With Size Reduction). Slovenian Institute for Standardization: Ljubljana, Slovenia, 2004.

- Lichtenthaler, H.K. Chlorophylls and carotenoids: Pigments of photosynthetic biomembranes. Methods Enzymol. 1987, 148, 350–382. [Google Scholar] [CrossRef]

- Maljaee, H.; Paiva, H.; Madadi, R.; Tarelho, L.A.; Morais, M.; Ferreira, V.M. Effect of cement partial substitution by waste-based biochar in mortars properties. Constr. Build. Mater. 2021, 301, 124074. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Low, C.Y. Use of biochar as carbon sequestering additive in cement mortar. Cem. Concr. Compos. 2018, 87, 110–129. [Google Scholar] [CrossRef]

- Qin, Y.; Pang, X.; Tan, K.; Bao, T. Evaluation of pervious concrete performance with pulverized biochar as cement replacement. Cem. Concr. Compos. 2021, 119, 104022. [Google Scholar] [CrossRef]

- Tan, K.H.; Wang, T.Y.; Zhou, Z.H.; Qin, Y.H. Biochar as a partial cement replacement material for developing sustainable concrete: An overview. J. Mater. Civ. Eng. 2021, 33, 03121001. [Google Scholar] [CrossRef]

- Ahmad, S.; Tulliani, J.M.; Ferro, G.A.; Khushnood, R.A.; Restuccia, L.; Jagdale, P. Crack path and fracture surface modifications in cement composites. Frat. Ed Integrità Strutt. 2015, 9, 524–533. [Google Scholar] [CrossRef]

- Roychand, R.; Patel, S.; Halder, P.; Kundu, S.; Hampton, J.; Bergmann, D.; Surapaneni, A.; Shah, K.; Pramanik, B.K. Recycling biosolids as cement composites in raw, pyrolyzed and ashed forms: A waste utilisation approach to support circular economy. J. Build. Eng. 2021, 38, 102199. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Koh, H.J. Application of biochar from food and wood waste as green admixture for cement mortar. Sci. Total Environ. 2018, 619, 419–435. [Google Scholar] [CrossRef]

- Choi, W.C.; Yun, H.D.; Lee, J.Y. Mechanical properties of mortar containing bio-char from pyrolysis. J. Korea Inst. Struct. Maint. Insp. 2012, 16, 67–74. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Effect of water entrainment by pre-soaked biochar particles on strength and permeability of cement mortar. Constr. Build. Mater. 2018, 159, 107–125. [Google Scholar] [CrossRef]

- Senadheera, S.S.; Gupta, S.; Kua, H.W.; Hou, D.; Kim, S.; Tsang, D.C.; Ok, Y.S. Application of biochar in concrete—A review. Cem. Concr. Compos. 2023, 143, 105204. [Google Scholar] [CrossRef]

- Gupta, S.; Kashani, A. Utilization of biochar from unwashed peanut shell in cementitious building materials–Effect on early age properties and environmental benefits. Fuel Process. Technol. 2021, 218, 106841. [Google Scholar] [CrossRef]

- Zhang, Y.; Maierdan, Y.; Guo, T.; Chen, B.; Fang, S.; Zhao, L. Biochar as carbon sequestration material combines with sewage sludge incineration ash to prepare lightweight concrete. Constr. Build. Mater. 2022, 343, 128116. [Google Scholar] [CrossRef]

- Praneeth, S.; Saavedra, L.; Zeng, M.; Dubey, B.K.; Sarmah, A.K. Biochar admixtured lightweight, porous and tougher cement mortars: Mechanical, durability and micro computed tomography analysis. Sci. Total Environ. 2021, 750, 142327. [Google Scholar] [CrossRef] [PubMed]

- Mocová, K.A.; Sackey, L.N.A.; Renkerová, P. Environmental impact of concrete and concrete-based construction waste leachates. IOP Conf. Ser. Earth Environ. Sci. 2019, 290, 012023. [Google Scholar] [CrossRef]

- Oleszczuk, P.; Jośko, I.; Kuśmierz, M. Biochar properties regarding to contaminants content and ecotoxicological assessment. J. Hazard. Mater. 2013, 260, 375–382. [Google Scholar] [CrossRef]

- Stefaniuk, M.; Oleszczuk, P.; Bartmiński, P. Chemical and ecotoxicological evaluation of biochar produced from residues of biogas production. J. Hazard. Mater. 2016, 318, 417–424. [Google Scholar] [CrossRef]

- Liu, B.; Liu, L.; Li, W. Effective removal of phosphorus from eutrophic water by using cement. Environ. Res. 2020, 183, 109218. [Google Scholar] [CrossRef]

- Walsh, É.; Paolacci, S.; Burnell, G.; Jansen, M.A. The importance of the calcium-to-magnesium ratio for phytoremediation of dairy industry wastewater using the aquatic plant Lemna minor L. Int. J. Phytoremediat. 2020, 22, 694–702. [Google Scholar] [CrossRef]

- Wang, W. Site-specific barium toxicity to common duckweed, Lemna minor. Aquat. Toxicol. 1988, 12, 203–212. [Google Scholar] [CrossRef]

- Reale, L.; Ferranti, F.; Mantilacci, S.; Corboli, M.; Aversa, S.; Landucci, F.; Baldisserotto, C.; Ferroni, L.; Pancaldi, S.; Venanzoni, R. Cyto-histological and morpho-physiological responses of common duckweed (Lemna minor L.) to chromium. Chemosphere 2016, 145, 98–105. [Google Scholar] [CrossRef]

- Aslanzadeh, M.; Saboora, A.; Moradlou, O. Phytoremediation potential of duckweed (Lemna minor L.) for hexavalent chromium removal in synthetic wastewater: Unveiling physiological response and defense mechanisms against excessive heavy metal uptake. Int. J. Environ. Sci. Technol. 2024, 21, 10155–10174. [Google Scholar] [CrossRef]

- Wystalska, K.; Kwarciak-Kozłowska, A. The effect of biodegradable waste pyrolysis temperatures on selected biochar properties. Materials 2021, 14, 1644. [Google Scholar] [CrossRef] [PubMed]

- Ibarrola, R.; Shackley, S.; Hammond, J. Pyrolysis biochar systems for recovering biodegradable materials: A life cycle carbon assessment. Waste Manag. 2012, 32, 859–868. [Google Scholar] [CrossRef] [PubMed]

- Grant, T. Life Cycle Inventory of Cement & Concrete Produced in Australia; Life Cycle Strategies Pty Ltd.: Melbourne, Australia, 2015. [Google Scholar]

- Roh, S.; Kim, R.; Park, W.J.; Ban, H. Environmental evaluation of concrete containing recycled and by-product aggregates based on life cycle assessment. Appl. Sci. 2020, 10, 7503. [Google Scholar] [CrossRef]

- Mackechnie, J.R.; Alexander, M.G. Using durability to enhance concrete sustainability. J. Green Build. 2009, 4, 52–60. [Google Scholar] [CrossRef]

- Kua, H.W.; Ng, M.S.; Ong, K. Innovative uses of biochar as carbon sequestering building materials in wall plaster and pellets. Acad. J. Civ. Eng. 2017, 35, 575–580. [Google Scholar] [CrossRef]

| Oxide | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | K2O | Na2O | Cl | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 63.49 | 19.68 | 4.82 | 2.88 | 2.74 | 1.54 | 0.72 | 0.34 | 0.06 | 0.23 |

| Element | C | H | N | S | O |

|---|---|---|---|---|---|

| Content (%) | 87.29 | 0.43 | 0.57 | 0.01 | 11.70 * |

| Component | Content (kg m−3 of Cement Mortar) | |||

|---|---|---|---|---|

| Conventional Mortar | B5 | B10 | B15 | |

| Cement | 450.00 | 427.50 | 405.00 | 382.50 |

| Water | 209.19 | 209.19 | 209.19 | 209.19 |

| Sand | 1673.62 | 1673.62 | 1673.62 | 1673.62 |

| Biochar | / | 9.29 | 18.58 | 27.87 |

| Superplasticizer | 9.45 | 9.45 | 9.45 | 9.45 |

| Duckweed Phytotoxicity Test | Mustard Seed Phytotoxicity Test | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mortar leachate concentration (g L−1) | 0 | 0.1 | 1 | 10 | 100 | 0 | 0.1 | 1 | 10 | 100 |

| Mortar weight (g) | 0 | 0.1 | 1 | 10 | 100 | 0 | 0.1 | 1 | 10 | 100 |

| Leaching time (h) | 168 | 168 | 168 | 168 | 24 | 168 | 168 | 168 | 168 | 24 |

| Growth medium (composition) | ISO guideline 20079:2005 (Steinberg medium) | 11.76 g L−1 of CaCl2 ▪ 2H2O, 4.93 g L−1 of MgSO4, 2.59 g L−1 of NaHCO3, 0.23 g L−1 of KCl | ||||||||

| Mortar Mix | ||||

|---|---|---|---|---|

| Conventional Mortar | B5 | B10 | B15 | |

| Flow diameter (mm) | 127.0 ± 2.5 | 120.0 ± 1.2 | 126.2 ± 0.8 | 131.0 ± 0.7 |

| Fresh density (kg m−3) | 2342.10 ± 0.30 | 2291.35 ± 7.95 | 2320.50 ± 2.00 | 2337.35 ± 0.75 |

| Mortar Mix | ||||

|---|---|---|---|---|

| Mineral Content (%) | Conventional Mortar | B5 Mortar | B10 Mortar | B15 Mortar |

| Calcite | 85.75 ± 1.73 | 85.06 ± 1.26 | 82.70 ± 0.81 | 81.41 ± 1.02 |

| Dolomite | 6.78 ± 0.71 | 6.42 ± 1.03 | 9.90 ± 0.56 | 11.22 ± 1.61 |

| Portlandite | 5.26 ± 0.48 | 4.41 ± 0.62 | 4.38 ± 0.53 | 3.69 ± 0.57 |

| Ettringite | 1.07 ± 0.23 | 2.43 ± 0.51 | 0.91 ± 0.29 | 0.63 ± 0.28 |

| Kuzelite | 1.14 ± 0.15 | 0.03 ± 0.02 | 0.32 ± 0.09 | 0.51 ± 0.18 |

| Carbon | / | 1.66 ± 0.33 | 1.79 ± 0.25 | 2.53 ± 0.44 |

| Concentrations of Selected Anions in the Leachate (mg L−1) | |||

|---|---|---|---|

| Duckweed Growth Medium | Conventional Mortar | B5 Mortar | |

| Nitrate (NO3−) | 359.43 ± 0.02 | 366.07 ± 0.09 | 411.66 ± 0.07 |

| Nitrite (NO2−) | 0.01 ± 0.00 | 0.02 ± 0.00 | 0.00 ± 0.00 |

| Phosphate (PO43−) | 64.68 ± 0.07 | 0.69 ± 0.05 | 0.41 ± 0.02 |

| Sulfate (SO32−) | 48.00 ± 0.03 | 39.00 ± 0.00 | 34.00 ± 0.01 |

| Chloride (Cl−) | <0.5 | 4.10 ± 0.02 | 7.20 ± 0.03 |

| Concentration of Selected Elements in the Leachate (mg L−1) | |||

|---|---|---|---|

| Duckweed Growth Medium | Conventional Mortar | B5 Mortar | |

| Ca | 49.6 | 205.7 | 200.3 |

| K | 141.1 | 112.7 | 128.5 |

| S | 15.0 | 10.8 | 11.2 |

| Mg | 10.4 | 6.7 × 10−8 | 2.6 × 10−9 |

| Na | 0.67 | 1.3 | 1.6 |

| Sr | 6.9 × 10−3 | 1.8 | 1.8 |

| Si | 3.7 × 10−2 | 0.7 | 0.7 |

| Ba | 0.5 × 10−3 | 272.5 × 10−3 | 277.5 × 10−3 |

| Al | 9.4 × 10−3 | 1.3 × 10−2 | 2.1 × 10−2 |

| B | 1.6 × 10−2 | 4.4 × 10−3 | 5.8 × 10−3 |

| Li | <0.5 × 10−3 | 1.9 × 10−2 | 1.4 × 10−2 |

| Cr | <3.5 × 10−3 | 5.9 × 10−3 | 9.4 × 10−3 |

| Component | CO2-eq | Reference |

|---|---|---|

| Portland cement | 1.002 kg CO2 kg−1 | [62] |

| Natural aggregate (sand) | 2.21 × 10−3 kg CO2 kg−1 | [63] |

| Biochar from wood waste | −1.25 kg CO2 kg−1 | [61] |

| Mortar Mix | Portland Cement (kg) | Sand (kg) | Wood Waste Biochar (kg) | CO2-eq (kg) m−3 of Mortar |

|---|---|---|---|---|

| Conventional mortar | 450.0 | 1673.62 | / | 454.60 |

| B5 | 427.5 | 1673.62 | 9.29 | 420.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Legan, M.; Štukovnik, P.; Zupan, K.; Žgajnar Gotvajn, A. Assessment of Mechanical and Ecotoxicological Properties of Mortar with Wood Waste Biochar as Partial Cement Replacement. Materials 2025, 18, 876. https://doi.org/10.3390/ma18040876

Legan M, Štukovnik P, Zupan K, Žgajnar Gotvajn A. Assessment of Mechanical and Ecotoxicological Properties of Mortar with Wood Waste Biochar as Partial Cement Replacement. Materials. 2025; 18(4):876. https://doi.org/10.3390/ma18040876

Chicago/Turabian StyleLegan, Maša, Petra Štukovnik, Klementina Zupan, and Andreja Žgajnar Gotvajn. 2025. "Assessment of Mechanical and Ecotoxicological Properties of Mortar with Wood Waste Biochar as Partial Cement Replacement" Materials 18, no. 4: 876. https://doi.org/10.3390/ma18040876

APA StyleLegan, M., Štukovnik, P., Zupan, K., & Žgajnar Gotvajn, A. (2025). Assessment of Mechanical and Ecotoxicological Properties of Mortar with Wood Waste Biochar as Partial Cement Replacement. Materials, 18(4), 876. https://doi.org/10.3390/ma18040876