Experimental Study of Carbonation and Chloride Resistance of Self-Compacting Concretes with a High Content of Fly Ash and Metakaolin, with and Without Hydrated Lime

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. SCC Proportions and Fresh-State Properties

2.3. Test Programme

3. Results and Discussion

3.1. Compressive Strength

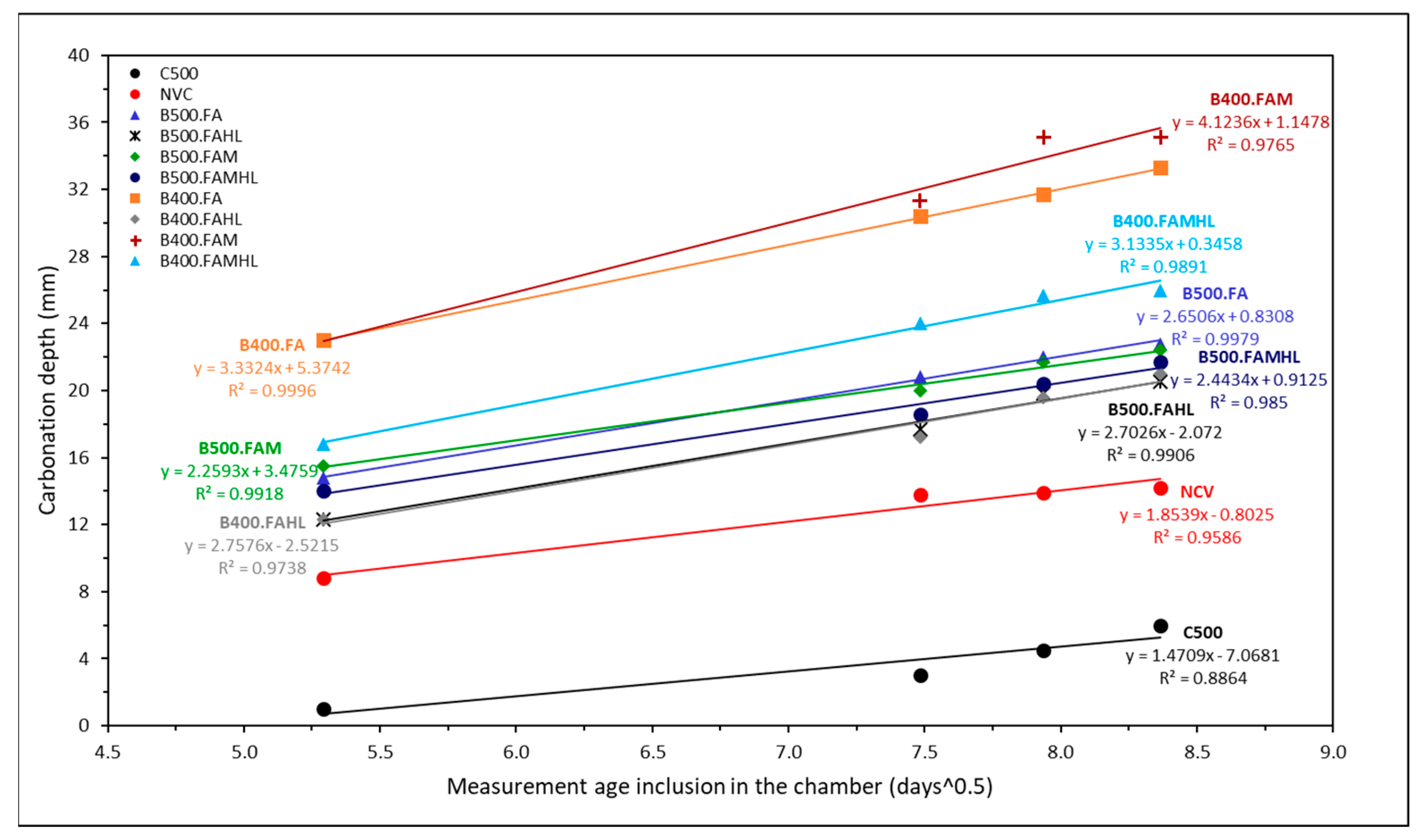

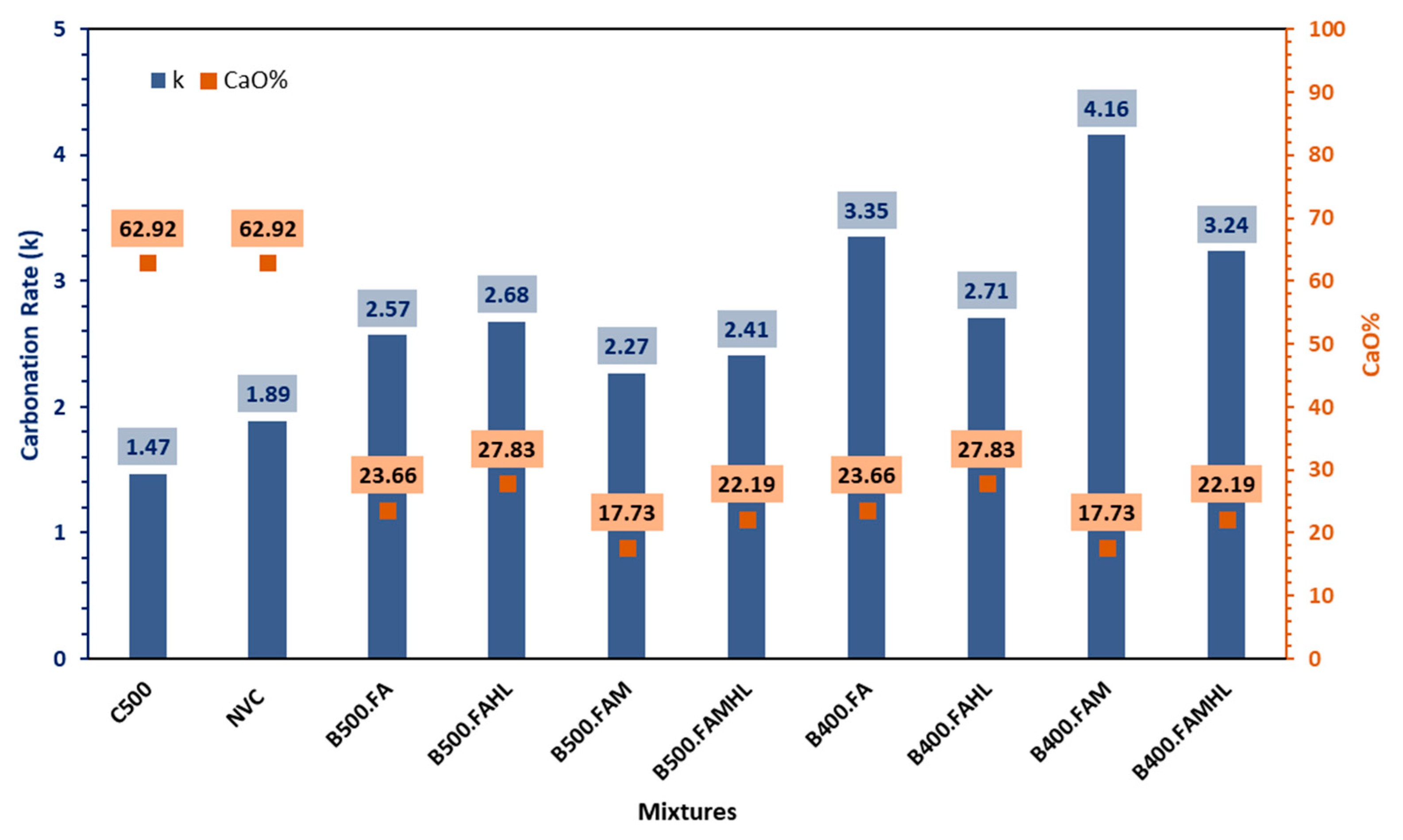

3.2. Accelerated Carbonation Test Results

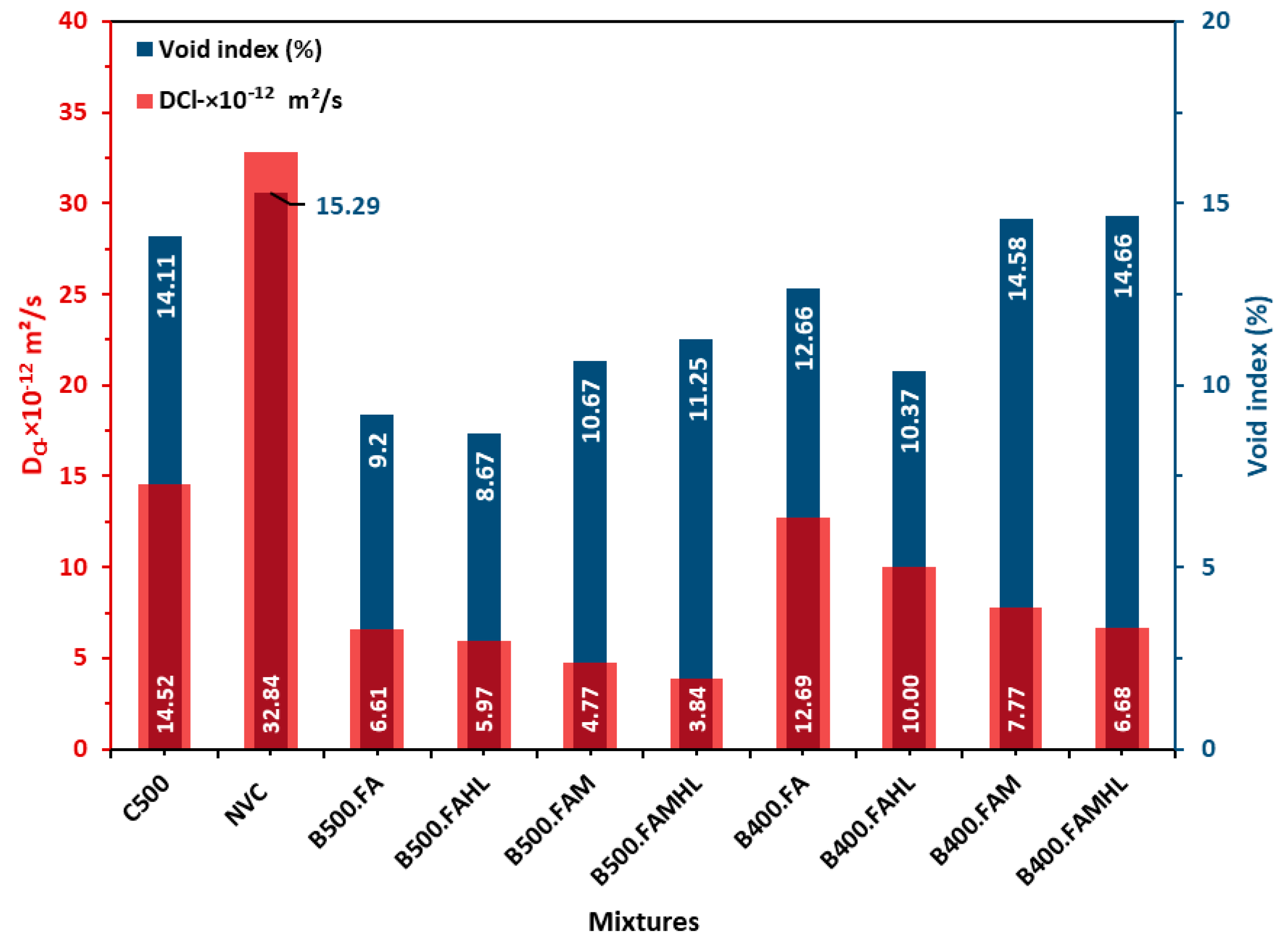

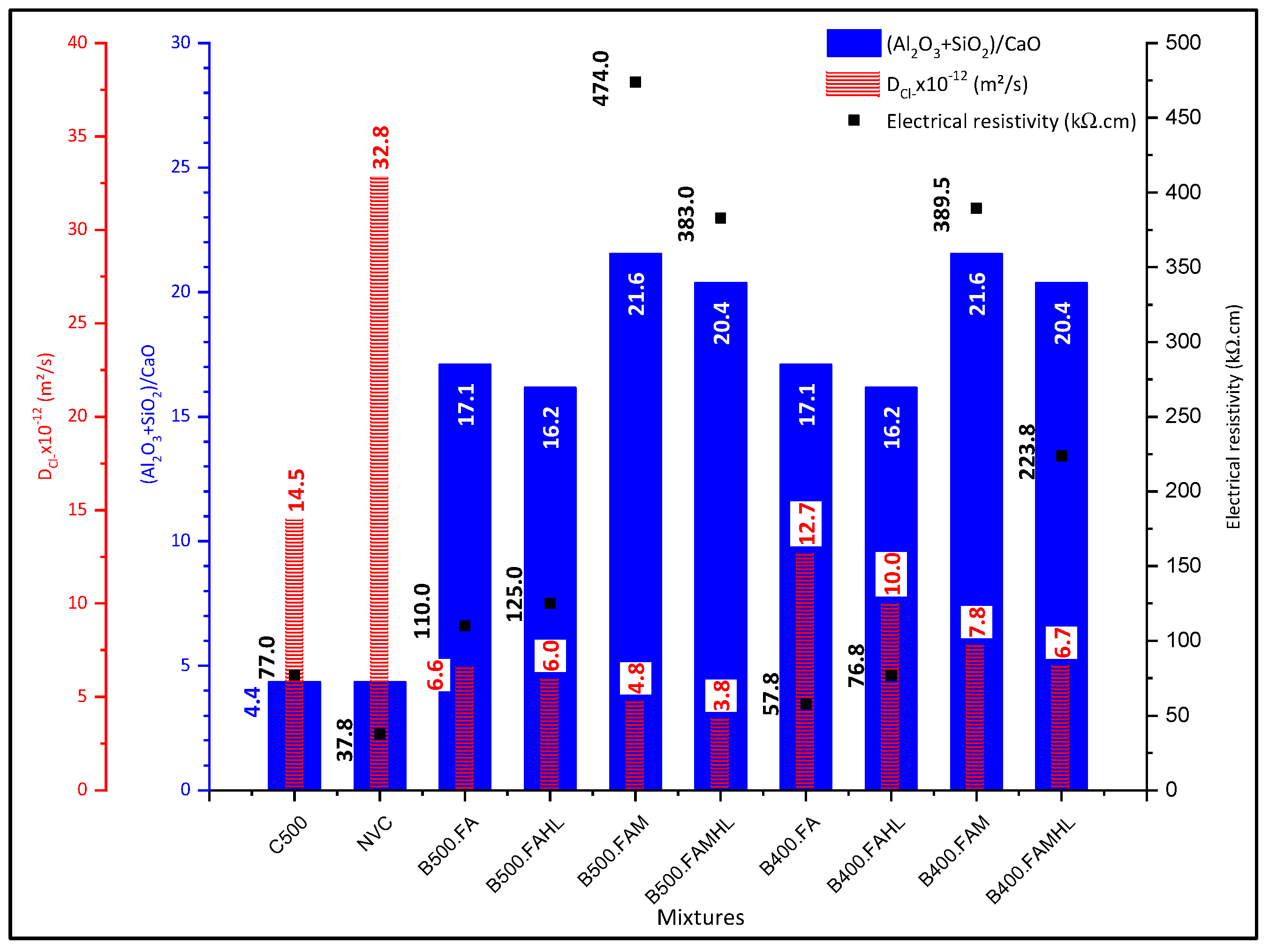

3.3. Chloride Migration Coefficient (Non-Stationary Test) and the Relation with Void Index

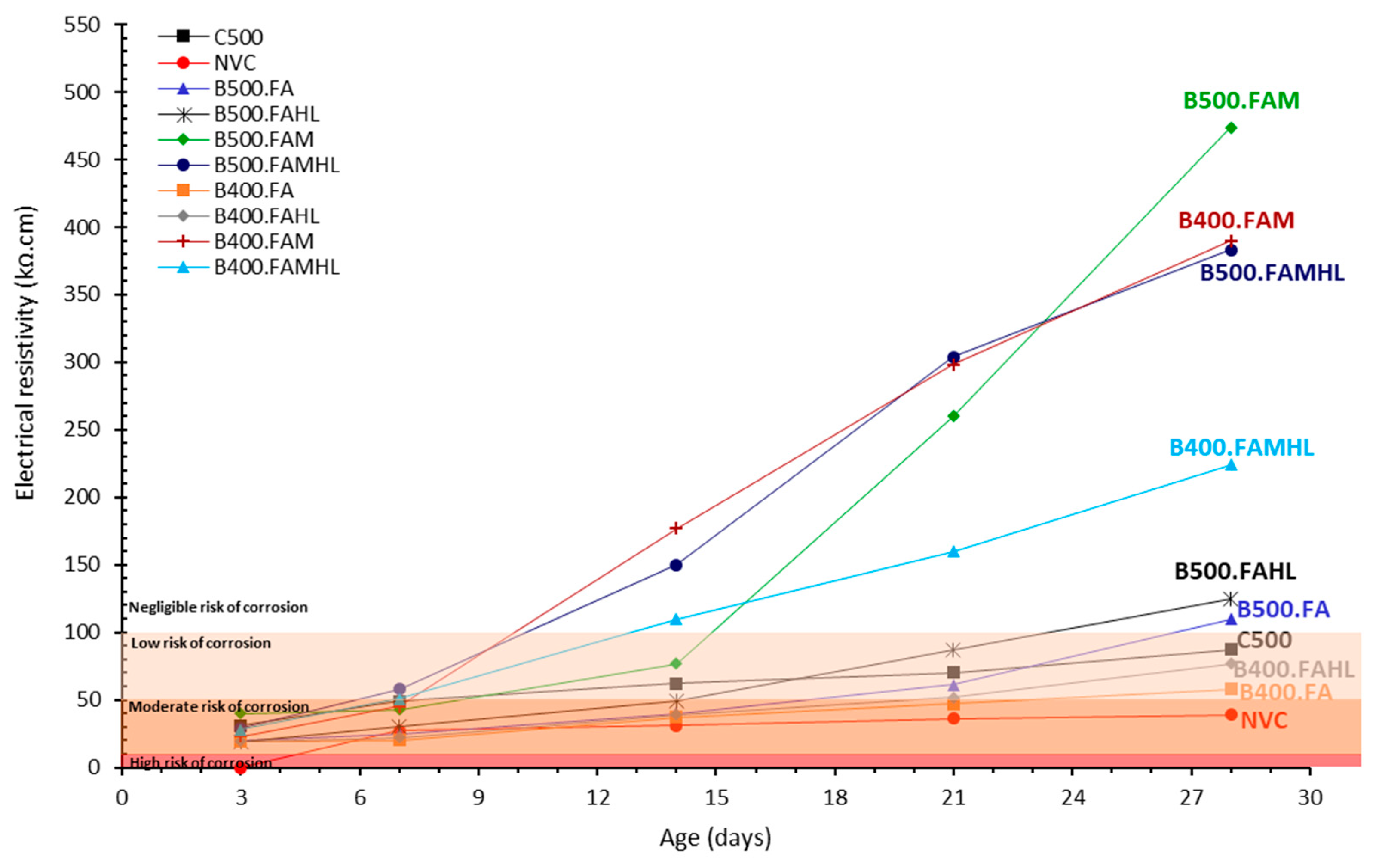

3.4. Electrical Resistivity

4. Conclusions

- The use of high levels of mineral additions strongly reduces the diffusion coefficients of chloride ions in concrete, with greater influence for mixtures with metakaolin at levels of 20% and cement consumption of 150 and 200 kg/m3.

- HL reduced the diffusion coefficients of chloride ions in all mixtures used due to the higher alkalinity of these mixtures compared to mixtures without HL.

- The use of MK and HL was decisive in reducing the diffusion coefficient of chloride ions.

- Accelerated carbonation was negatively affected by the high levels of mineral additions used. This behaviour is more severe when the additions are used together and/or with lower cement contents of the order of 120 to 160 kg/m3.

- The carbonation depth was reduced by up to 33% with the use of 5% hydrated lime in concrete with cement consumption of 120 and 160 kg/m3.

- The risk of corrosion measured through electrical resistivity is low or negligible in B500 and B400 SCCs (cement consumption of 120 to 200 kg/m2).

- There is a direct relationship between the higher Al2O3 content of the B500 and B400 mixtures and the lower chloride-ion diffusion coefficient. The presence of alumina in the mixtures resulted in low corrosion risks for the systems, regardless of the amount of cement present in the mixture.

- The combined use of MK, FA, and HL was relevant to achieve an important reduction in cement consumption, such as 120 and 150 kg/m3, and still presents durability indices compatible with SCC with a consumption of 500 kg/m3.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Okamura, H.; Ouchi, M. Self-Compacting Concrete. J. Adv. Concr. Technol. 2003, 1, 5–15. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M. Properties of Self-Compacting Mortars with Binary and Ternary Cementitious Blends of Fly Ash and Metakaolin. Mater. Struct./Mater. Et. Constr. 2008, 41, 1519–1531. [Google Scholar] [CrossRef]

- Sabet, F.A.; Libre, N.A.; Shekarchi, M. Mechanical and Durability Properties of Self Consolidating High Performance Concrete Incorporating Natural Zeolite, Silica Fume and Fly Ash. Constr. Build. Mater. 2013, 44, 175–184. [Google Scholar] [CrossRef]

- Sharma, R.; Khan, R.A. Sustainable Use of Copper Slag in Self Compacting Concrete Containing Supplementary Cementitious Materials. J. Clean. Prod. 2017, 151, 179–192. [Google Scholar] [CrossRef]

- Alsubari, B.; Shafigh, P.; Jumaat, M.Z. Utilization of High-Volume Treated Palm Oil Fuel Ash to Produce Sustainable Self-Compacting Concrete. J. Clean. Prod. 2016, 137, 982–996. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, W.; Wu, X.; Gao, B. The Properties of the Self-Compacting Concrete with Fly Ash and Ground Granulated Blast Furnace Slag Mineral Admixtures. J. Clean. Prod. 2015, 95, 66–74. [Google Scholar] [CrossRef]

- Khodair, Y.; Raza, M. Sustainable Self-Consolidating Concrete Using Recycled Asphalt Pavement and High Volume of Supplementary Cementitious Materials. Constr. Build. Mater. 2017, 131, 245–253. [Google Scholar] [CrossRef]

- Limbachiya, M.; Bostanci, S.C.; Kew, H. Suitability of BS EN 197-1 CEM II and CEM V Cement for Production of Low Carbon Concrete. Comput. Chem. Eng. 2014, 71, 397–405. [Google Scholar] [CrossRef]

- Da Silva, P.R.; De Brito, J. Experimental Study of the Porosity and Microstructure of Self-Compacting Concrete (SCC) with Binary and Ternary Mixes of Fly Ash and Limestone Filler. Constr. Build. Mater. 2015, 86, 101–112. [Google Scholar] [CrossRef]

- Dinakar, P.; Babu, K.G.; Santhanam, M. Durability Properties of High Volume Fly Ash Self Compacting Concretes. Cem. Concr. Compos. 2008, 30, 880–886. [Google Scholar] [CrossRef]

- Puthipad, N.; Ouchi, M.; Rath, S.; Attachaiyawuth, A. Enhanced Entrainment of Fine Air Bubbles in Self-Compacting Concrete with High Volume of Fly Ash Using Defoaming Agent for Improved Entrained Air Stability and Higher Aggregate Content. Constr. Build. Mater. 2017, 144, 1–12. [Google Scholar] [CrossRef]

- Dadsetan, S.; Bai, J. Mechanical and Microstructural Properties of Self-Compacting Concrete Blended with Metakaolin, Ground Granulated Blast-Furnace Slag and Fly Ash. Constr. Build. Mater. 2017, 146, 658–667. [Google Scholar] [CrossRef]

- Shen, W.; Zhang, Z.; Li, J.; Li, Z.; Wang, Z.; Cao, L.; Rong, G.; Wu, M.; Zhao, D.; Zhao, Z. Experimental Investigation on the High-Volume Fly Ash Ecological Self-Compacting Concrete. J. Build. Eng. 2022, 60, 105163. [Google Scholar] [CrossRef]

- Lorca, P.; Calabuig, R.; Benlloch, J.; Soriano, L.; Payá, J. Microconcrete with Partial Replacement of Portland Cement by Fly Ash and Hydrated Lime Addition. Mater. Des. 2014, 64, 535–541. [Google Scholar] [CrossRef]

- Wongkeo, W.; Thongsanitgarn, P.; Chaipanich, A. Compressive Strength and Drying Shrinkage of Fly Ash-Bottom Ash-Silica Fume Multi-Blended Cement Mortars. Mater. Des. 2012, 36, 655–662. [Google Scholar] [CrossRef]

- Siddique, R. Performance Characteristics of High-Volume Class F Fly Ash Concrete. Cem. Concr. Res. 2004, 34, 487–493. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R.; Rai, B.; Samui, P. Prediction of Compressive Strength of High-Volume Fly Ash Self-Compacting Concrete with Silica Fume Using Machine Learning Techniques. Constr. Build. Mater. 2024, 438, 136933. [Google Scholar] [CrossRef]

- Ponikiewski, T.; Gołaszewski, J. The Influence of High-Calcium Fly Ash on the Properties of Fresh and Hardened Self-Compacting Concrete and High Performance Self-Compacting Concrete. J. Clean. Prod. 2014, 72, 212–221. [Google Scholar] [CrossRef]

- Chousidis, N.; Rakanta, E.; Ioannou, I.; Batis, G. Mechanical Properties and Durability Performance of Reinforced Concrete Containing Fly Ash. Constr. Build. Mater. 2015, 101, 810–817. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W.M. Chloride Induced Corrosion Durability of High Volume Fly Ash Concretes Containing Nano Particles. Constr. Build. Mater. 2015, 99, 208–225. [Google Scholar] [CrossRef]

- Filho, J.H.; Medeiros, M.H.F.; Pereira, E.; Helene, P.; Isaia, G.C. High-Volume Fly Ash Concrete with and without Hydrated Lime: Chloride Diffusion Coefficient from Accelerated Test. J. Mater. Civ. Eng. 2013, 25, 411–418. [Google Scholar] [CrossRef]

- Antiohos, S.K.; Papageorgiou, A.; Papadakis, V.G.; Tsimas, S. Influence of Quicklime Addition on the Mechanical Properties and Hydration Degree of Blended Cements Containing Different Fly Ashes. Constr. Build. Mater. 2008, 22, 1191–1200. [Google Scholar] [CrossRef]

- Larbi, J.A.; Fraay, A.L.A.; Bijen, J.M.J.M. The Chemistry of the Pore Fluid of Silica Fume-Blended Cement Systems Abstract; Elsevier: Amsterdam, The Netherlands, 1990; Volume 20. [Google Scholar]

- Benli, A.; Karataş, M.; Bakir, Y. An Experimental Study of Different Curing Regimes on the Mechanical Properties and Sorptivity of Self-Compacting Mortars with Fly Ash and Silica Fume. Constr. Build. Mater. 2017, 144, 552–562. [Google Scholar] [CrossRef]

- Rashad, A.M. An Exploratory Study on High-Volume Fly Ash Concrete Incorporating Silica Fume Subjected to Thermal Loads. J. Clean. Prod. 2015, 87, 735–744. [Google Scholar] [CrossRef]

- Nazeer, M.; Kumar, R.A. Strength Studies on Metakaolin Blended High-Volume Fly Ash Concrete. Int. J. Eng. Adv. Technol. 2014, 3, 176–179. [Google Scholar]

- Hemalatha, T.; Mapa, M.; Kumar, V. Nano Modified High Volume Flyash Self Compacting Concrete. Int. J. Res. Eng. Technol. 2015, 4, 95–98. [Google Scholar]

- Jayakumar, M.; Salman, A.M. Experimental Study on Sustainable Concrete with the Mixture of Low Calcium Fly Ash and Lime as a Partial Replacement of Cement. In Advanced Materials Research; Trans Tech Publications: New York, NY, USA, 2011; Volume 250–253, pp. 307–312. [Google Scholar]

- Rashad, A.M. An Investigation of High-Volume Fly Ash Concrete Blended with Slag Subjected to Elevated Temperatures. J. Clean. Prod. 2015, 93, 47–55. [Google Scholar] [CrossRef]

- Hoppe Filho, J.; Alba Cincotto, M. Carbonation in Concrete with High Fly Ash Content and Hydrated Lime. In Proceedings of the 11DBMC International Conference on Durability of Building Materials and Components, Istanbul, Turkey, 11–14 May 2008. [Google Scholar]

- Mira, P.; Papadakis, V.G.; Tsimas, S. Effect of Lime Putty Addition on Structural and Durability Properties of Concrete. Cem. Concr. Res. 2002, 32, 683–689. [Google Scholar] [CrossRef]

- Qi, B.; Gao, J.M.; Ma, L.B. Durability of High-Volume Fly Ash Concrete Subjected to Drying-Wetting Cycles and Carbonation Coupling Effects. In Materials Research Innovations; Maney Publishing: Leeds, UK, 2015; Volume 19, pp. S51272–S51275. [Google Scholar]

- Dinakar, P.; Babut, K.G.; Santhanam, M. Corrosion Resistance Performance of High-Volume Fly-Ash Self-Compacting Concretes. Mag. Concr. Res. 2009, 61, 77–85. [Google Scholar] [CrossRef]

- Thiery, M.; Villain, G.; Dangla, P.; Platret, G. Investigation of the Carbonation Front Shape on Cementitious Materials: Effects of the Chemical Kinetics. Cem. Concr. Res. 2007, 37, 1047–1058. [Google Scholar] [CrossRef]

- Kumar, S.; Rai, B.; Biswas, R.; Samui, P.; Kim, D. Prediction of Rapid Chloride Permeability of Self-Compacting Concrete Using Multivariate Adaptive Regression Spline and Minimax Probability Machine Regression. J. Build. Eng. 2020, 32, 101490. [Google Scholar] [CrossRef]

- Nagaratnam, B.H.; Faheem, A.; Rahman, M.E.; Mannan, M.A.; Leblouba, M. Mechanical and Durability Properties of Medium Strength Self-Compacting Concrete with High-Volume Fly Ash and Blended Aggregates. Period. Polytech. Civ. Eng. 2015, 59, 155–164. [Google Scholar] [CrossRef]

- Barbhuiya, S.A.; Gbagbo, J.K.; Russell, M.I.; Basheer, P.A.M. Properties of Fly Ash Concrete Modified with Hydrated Lime and Silica Fume. Constr. Build. Mater. 2009, 23, 3233–3239. [Google Scholar] [CrossRef]

- Menéndez, E.; Sanjuán, M.Á.; Recino, H. Study of Microstructure, Crystallographic Phases and Setting Time Evolution over Time of Portland Cement, Coarse Silica Fume, and Limestone (PC-SF-LS) Ternary Portland Cements. Crystal 2023, 13, 1289. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Menéndez, E.; Recino, H. Carbonation Resistance of Ternary Portland Cements Made with Silica Fume and Limestone. Materials 2024, 17, 2705. [Google Scholar] [CrossRef]

- Myadraboina, H.; Setunge, S.; Patnaikuni, I. Pozzolanic Index and Lime Requirement of Low Calcium Fly Ashes in High Volume Fly Ash Mortar. Constr. Build. Mater. 2017, 131, 690–695. [Google Scholar] [CrossRef]

- Yildirim, G.; Sahmaran, M.; Ahmed, H.U. Influence of Hydrated Lime Addition on the Self-Healing Capability of High-Volume Fly Ash Incorporated Cementitious Composites. J. Mater. Civ. Eng. 2015, 27, 04014187. [Google Scholar] [CrossRef]

- Srinivas, D.; Dey, D.; Panda, B.; Sitharam, T.G. Printability, Thermal and Compressive Strength Properties of Cementitious Materials: A Comparative Study with Silica Fume and Limestone. Materials 2022, 15, 8607. [Google Scholar] [CrossRef]

- Anjos, M.A.S.; Camões, A.; Campos, P.; Azeredo, G.A.; Ferreira, R.L.S. Effect of High Volume Fly Ash and Metakaolin with and without Hydrated Lime on the Properties of Self-Compacting Concrete. J. Build. Eng. 2020, 27, 100985. [Google Scholar] [CrossRef]

- Anjos, M.A.S.; Reis, R.; Camões, A.; Duarte, F.; Jesus, C. Evaluation of Hydration of Cement Pastes Containing High Volume of Mineral Additions. Eur. J. Environ. Civ. Eng. 2019, 23, 987–1002. [Google Scholar] [CrossRef]

- EN 450-1; Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria. European Committee for Standardization: Brussels, Belgium, 2012.

- NP EN 206-9:2010; Regras Adicionais Para. Betão Autocompactável. IPQ: Lisboa, Portugal, 2010.

- BS EN 12390-3: 2019; Testing Hardened Concrete Part 3: Compressive Strength of Test Specimens. British Standard Institution: London, UK, 2019.

- ABNT NBR 9778:2009; Argamassa e Concreto Endurecidos-Determinação Da Absorção de Água. Índice de Vazios e Massa Específica: Rio de Janeiro, Brazil, 2009.

- LNEC E-463; Betão-Determinação Do Coeficiente de Difusão Dos Cloretos Por Migração Em Regime Não Estacionário. Documentação Normativa; Especificação LNEC: Lisbon, Portugal, 2004.

- EN 12390-12; Testing Hardened Concrete—Part. 12: Determination of the Potential. Carbonation Resistance of Concrete: Accelerated Carbonation Method. European Committee for Standardization (CEN): Brussels, Belgium, 2020.

- Pacheco Torgal, F.; Miraldo, S.; Labrincha, J.A.; De Brito, J. An Overview on Concrete Carbonation in the Context of Eco-Efficient Construction: Evaluation, Use of SCMs and/or RAC. Constr. Build. Mater. 2012, 36, 141–150. [Google Scholar] [CrossRef]

- Ashraf, W. Carbonation of Cement-Based Materials: Challenges and Opportunities. Constr. Build. Mater. 2016, 120, 558–570. [Google Scholar] [CrossRef]

- Wang, X.Y.; Lee, H.S. A Model for Predicting the Carbonation Depth of Concrete Containing Low-Calcium Fly Ash. Constr. Build. Mater. 2009, 23, 725–733. [Google Scholar] [CrossRef]

- Houst, Y.F.; Wittmann, F.H. Depth Profiles of Carbonates Formed during Natural Carbonation; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Lye, C.Q.; Dhir, R.K.; Ghataora, G.S. Carbonation Resistance of GGBS Concrete. Mag. Concr. Res. 2016, 68, 936–969. [Google Scholar] [CrossRef]

- EN 1992-1-1; Eurocode 2—Design of Concrete Structures—Part. 1-1: General. Rules and Rules for Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- Mohammed, T.; Torres, A.; Aguayo, F.; Okechi, I.K. Evaluating Carbonation Resistance and Microstructural Behaviors of Calcium Sulfoaluminate Cement Concrete Incorporating Fly Ash and Limestone Powder. Constr. Build. Mater. 2024, 442, 137551. [Google Scholar] [CrossRef]

- Murtaza, M.; Zhang, J.; Yang, C.; Su, C.; Wu, H. Durability of High Strength Self-Compacting Concrete with Fly Ash, Coal Gangue Powder, Cement Kiln Dust, and Recycled Concrete Powder. Constr. Build. Mater. 2024, 449, 138345. [Google Scholar] [CrossRef]

- Zhong, C.; Zhang, L.; Mao, W.; Xing, S.; Chen, J.; Zhou, J. An Investigation on Mechanical Properties and Durability of Metakaolin Reinforced Modified Recycled Concrete. Case Stud. Constr. Mater. 2024, 20, e02978. [Google Scholar] [CrossRef]

- Roberto da Silva, S.; de Brito, J.; Andrade, J.J.d.O. Synergic Effect of Recycled Aggregate, Fly Ash, and Hydrated Lime in Concrete Production. J. Build. Eng. 2023, 70, 106370. [Google Scholar] [CrossRef]

- Diniz, H.A.A.; dos Anjos, M.A.S.; Rocha, A.K.A.; Ferreira, R.L.S. Effects of the Use of Agricultural Ashes, Metakaolin and Hydrated-Lime on the Behavior of Self-Compacting Concretes. Constr. Build. Mater. 2022, 319, 126087. [Google Scholar] [CrossRef]

- Fonseca, T.V.; dos Anjos, M.A.S.; Ferreira, R.L.S.; Branco, F.G.; Pereira, L. Evaluation of Self-Compacting Concretes Produced with Ternary and Quaternary Blends of Different SCM and Hydrated-Lime. Constr. Build. Mater. 2022, 320, 126235. [Google Scholar] [CrossRef]

- Peixoto, L.K.S.; dos Anjos, M.A.S.; de Farias, E.C.; Branco, F.G. Evaluation of Chloride Ion Attack in Self-Compacting Concrete Using Recycled Construction and Demolition Waste Aggregates. Buildings 2024, 14, 319. [Google Scholar] [CrossRef]

- Bouzoubaâ, N.; Zhang, M.H.; Malhotra, V.M. Mechanical Properties and Durability of Concrete Made with High-Volume Fly Ash Blended Cements Using a Coarse Fly Ash; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Chalee, W.; Ausapanit, P.; Jaturapitakkul, C. Utilization of Fly Ash Concrete in Marine Environment for Long Term Design Life Analysis. Mater. Des. 2010, 31, 1242–1249. [Google Scholar] [CrossRef]

- Badogiannis, E.G.; Sfikas, I.P.; Voukia, D.V.; Trezos, K.G.; Tsivilis, S.G. Durability of Metakaolin Self-Compacting Concrete. Constr. Build. Mater. 2015, 82, 133–141. [Google Scholar] [CrossRef]

- Poon, C.S.; Lam, L.; Wong, Y.L. A Study on High Strength Concrete Prepared with Large Volumes of Low Calcium Fly Ash; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Nehdi, M.; Pardhan, M.; Koshowski, S. Durability of Self-Consolidating Concrete Incorporating High-Volume Replacement Composite Cements. Cem. Concr. Res. 2004, 34, 2103–2112. [Google Scholar] [CrossRef]

- Wang, X.; Lan, Q.; Lin, H.; Wang, Y.; Wu, W.; Xu, L.; Fu, L.; Li, C. Effects of Alkali Activator on the Chloride-Ion Permeability of One-Part Alkali-Activated Nickel Slag Concrete. Case Stud. Constr. Mater. 2024, 20, e02970. [Google Scholar] [CrossRef]

- Andradre, C.; Alonso, C. Test Methods for On-Site Corrosion Rate Measurement of Steel Reinforcement in Concrete by Means of the Polarization Resistance Method. Mater. Struct. 2004, 37, 623–643. [Google Scholar] [CrossRef]

- Sang, Y.; Yang, Y.; Zhao, Q. Electrical Resistivity of Plain Cement-Based Materials Based on Ionic Conductivity: A Review of Applications and Conductive Models. J. Build. Eng. 2022, 46, 103642. [Google Scholar] [CrossRef]

- Singh, N.; Singh, S.P. Carbonation and Electrical Resistance of Self Compacting Concrete Made with Recycled Concrete Aggregates and Metakaolin. Constr. Build. Mater. 2016, 121, 400–409. [Google Scholar] [CrossRef]

- Erdoǧdu, Ş.; Kondratova, I.L.; Bremner, T.W. Determination of Chloride Diffusion Coefficient of Concrete Using Open-Circuit Potential Measurements. Cem. Concr. Res. 2004, 34, 603–609. [Google Scholar] [CrossRef]

| Materials | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | K2O | LOI |

|---|---|---|---|---|---|---|---|---|---|

| PC (%) | 19.92 | 4.36 | 3.51 | 62.92 | 1.83 | 2.86 | nd * | nd | 3.12 |

| FA (%) | 48.61 | 23.79 | 7.91 | 3.06 | 2.07 | 0.40 | 0.78 | 3.78 | 2.64 |

| MK (%) | 47.00 | 37.10 | 1.30 | 0.10 | 0.15 | nd | 0.20 | 2.00 | 11.75 |

| Materials (kg) | w/b (L/m3) | Slump Flow (mm) | T500 (s) | V-Test (s) | L-Box (H2/H1) | J-Ring (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Concrete ID | C | FA | MK | HL | S | G | W | SP | ||||||

| C500 | 500 | - | - | - | 870 | 880 | 200 | 13.0 | 1.3 | 625 | 1.67 | 4.6 | 0.75 | |

| NVC | 300 | - | - | - | 1053 | 867 | 180 | 7.8 | 1.8 | 500 | 4.20 | - | - | |

| B500.FA | 200 | 300 | - | - | 870 | 880 | 170 | 9.0 | 0.9 | 700 | 1.85 | 4.8 | 0.86 | 700 |

| B500.FAHL | 200 | 300 | - | 25 | 870 | 880 | 170 | 9.6 | 0.9 | 700 | 2.11 | 12.0 | 1.0 | 700 |

| B500.FAM | 150 | 250 | 100 | - | 870 | 880 | 170 | 9.6 | 0.9 | 670 | 3.15 | 13.9 | 0.92 | 615 |

| B500.FAMHL | 150 | 250 | 100 | 25 | 870 | 880 | 170 | 12.3 | 0.9 | 700 | 2.63 | 12.8 | 0.89 | 695 |

| B400.FA | 160 | 240 | - | - | 1034 | 916 | 140 | 12.4 | 0.9 | 750 | 1.83 | 5.85 | 0.94 | 705 |

| B400.FAHL | 160 | 240 | - | 20 | 1034 | 916 | 140 | 12.4 | 0.9 | 745 | 3.81 | 6.14 | 0.97 | 690 |

| B400.FAM | 120 | 200 | 80 | - | 1034 | 916 | 140 | 13.5 | 0.9 | 740 | 3.30 | 9.09 | 0.95 | 720 |

| B400.FAMHL | 120 | 200 | 80 | 20 | 1034 | 916 | 140 | 13.5 | 0.9 | 665 | 3.61 | 10.4 | 0.88 | 625 |

| Concrete ID | Vf (Volumetric Fraction) | % Binder | ||||

|---|---|---|---|---|---|---|

| C | FA | MK | HL | Al2O3 | CaO | |

| C500 | 1.00 | 0.00 | 0.00 | 0.00 | 4.36 | 62.92 |

| NVC | 1.00 | 0.00 | 0.00 | 0.00 | 4.36 | 62.92 |

| B500.FA | 0.34 | 0.66 | 0.00 | 0.00 | 17.10 | 23.66 |

| B500.FAHL | 0.32 | 0.62 | 0.00 | 0.06 | 16.17 | 27.83 |

| B500.FAM | 0.26 | 0.54 | 0.20 | 0.00 | 21.55 | 17.73 |

| B500.FAMHL | 0.24 | 0.51 | 0.19 | 0.06 | 20.38 | 22.19 |

| B400.FA | 0.34 | 0.66 | 0.00 | 0.00 | 17.10 | 23.66 |

| B400.FAHL | 0.32 | 0.62 | 0.00 | 0.06 | 16.17 | 27.83 |

| B400.FAM | 0.26 | 0.54 | 0.20 | 0.00 | 21.55 | 17.73 |

| B400.FAMHL | 0.24 | 0.51 | 0.19 | 0.06 | 20.38 | 22.19 |

| Tests | Standard/Method | Specimen Dimensions (mm) | Testing Age (Days) | Conditions |

|---|---|---|---|---|

| Compressive strength | EN 12390-3 [47] | Cube—100 × 100 × 100 | 28 and 90 | Test carried out after curing by immersion in water on the dates mentioned. |

| Void index | NBR 9778 [48] | Cube—150 × 150 × 150 | 90 | Test carried out after curing by immersion in water on the date mentioned. |

| Chloride diffusion by migration | LNEC E-463 [49] | Cylinder—H200D100 | 90 | Test pieces measuring H50D100 mm were tested. |

| Electrical resistivity | Wenner probe principle with four equidistant electrodes | Cube—150 × 150 × 150 | 3, 7, 14, 21, and 28 | Measurement in the saturated state. |

| Accelerated carbonation | EN 12390-12 [50] | Cube—100 × 100 × 100 | 42 (entrance to the chamber) | Conditions: 4 ± 0.5% CO2, 20 ± 2 °C, and HR 55 ± 5%. Carbonation measurement: 28, 56, 63, and 70 days. |

| Concrete ID | Compressive Strength (MPa) | Strength Increases from 28 to 90 Days | |

|---|---|---|---|

| 28 Days | 90 Days | ||

| C500 | 60.1 | 63.0 | 4.8% |

| NVC | 32.1 | 34.9 | 8.6% |

| B500.FA | 27.8 | 37.5 | 34.9% |

| B500.FAHL | 40.9 | 58.3 | 42.5% |

| B500.FAM | 32.6 | 38.3 | 17.5% |

| B500.FAMHL | 40.0 | 46.5 | 16.3% |

| B400.FA | 20.0 | 32.1 | 60.1% |

| B400.FAHL | 28.4 | 40.7 | 43.1% |

| B400.FAM | 23.0 | 28.3 | 21.9% |

| B400.FAMHL | 27.5 | 33.5 | 22.0% |

| Mixtures | Cement (kg/m3) | Carbonation Depth (mm) 28 Days | Carbonation Depth (mm) 70 Days | Carbonation Depth Strength Increases from 28 to 70 Days | Increased Depth of Carbonation Compared to NVC (28 Days) | Increased Depth of Carbonation Compared to NVC (70 Days) |

|---|---|---|---|---|---|---|

| C500 | 500 | 1.00 | 6.00 | 500.00% | −88.64% | −57.75% |

| NVC | 300 | 8.80 | 14.20 | 61.36% | - | - |

| B500.FA | 200 | 14.80 | 22.80 | 54.05% | 68.18% | 60.56% |

| B500.FAHL | 200 | 12.30 | 20.50 | 66.67% | 39.77% | 44.37% |

| B500.FAM | 150 | 15.50 | 22.40 | 44.52% | 76.14% | 57.75% |

| B500.FAMHL | 150 | 14.00 | 21.70 | 55.00% | 59.09% | 52.82% |

| B400.FA | 160 | 23.00 | 33.30 | 44.78% | 161.36% | 134.51% |

| B400.FAHL | 160 | 12.30 | 21.00 | 70.73% | 39.77% | 47.89% |

| B400.FAM | 120 | 23.00 | 35.10 | 52.61% | 161.36% | 147.18% |

| B400.FAMHL | 120 | 16.80 | 26.00 | 54.76% | 90.91% | 83.10% |

| Mixtures | Cement (kg/m3) | DCl (10−12 m2/s) | Reduced DCl Compared to NVC |

|---|---|---|---|

| C500 | 500 | 14.52 | −56% |

| NVC | 300 | 32.84 | - |

| B500.FA | 200 | 6.61 | −80% |

| B500.FAHL | 200 | 5.97 | −82% |

| B500.FAM | 150 | 4.77 | −85% |

| B500.FAMHL | 150 | 3.84 | −88% |

| B400.FA | 160 | 12.69 | −61% |

| B400.FAHL | 160 | 10.00 | −70% |

| B400.FAM | 120 | 7.77 | −76% |

| B400.FAMHL | 120 | 6.68 | −80% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anjos, M.A.S.d.; Camões, A.; Malheiro, R.; Maia Pederneiras, C.; Peixoto, L.K.S. Experimental Study of Carbonation and Chloride Resistance of Self-Compacting Concretes with a High Content of Fly Ash and Metakaolin, with and Without Hydrated Lime. Materials 2025, 18, 422. https://doi.org/10.3390/ma18020422

Anjos MASd, Camões A, Malheiro R, Maia Pederneiras C, Peixoto LKS. Experimental Study of Carbonation and Chloride Resistance of Self-Compacting Concretes with a High Content of Fly Ash and Metakaolin, with and Without Hydrated Lime. Materials. 2025; 18(2):422. https://doi.org/10.3390/ma18020422

Chicago/Turabian StyleAnjos, Marcos Alyssandro S. dos, Aires Camões, Raphaele Malheiro, Cinthia Maia Pederneiras, and Lorena K. S. Peixoto. 2025. "Experimental Study of Carbonation and Chloride Resistance of Self-Compacting Concretes with a High Content of Fly Ash and Metakaolin, with and Without Hydrated Lime" Materials 18, no. 2: 422. https://doi.org/10.3390/ma18020422

APA StyleAnjos, M. A. S. d., Camões, A., Malheiro, R., Maia Pederneiras, C., & Peixoto, L. K. S. (2025). Experimental Study of Carbonation and Chloride Resistance of Self-Compacting Concretes with a High Content of Fly Ash and Metakaolin, with and Without Hydrated Lime. Materials, 18(2), 422. https://doi.org/10.3390/ma18020422