Turning Waste into Greener Cementitious Building Material: Treatment Methods for Biomass Ashes—A Review

Abstract

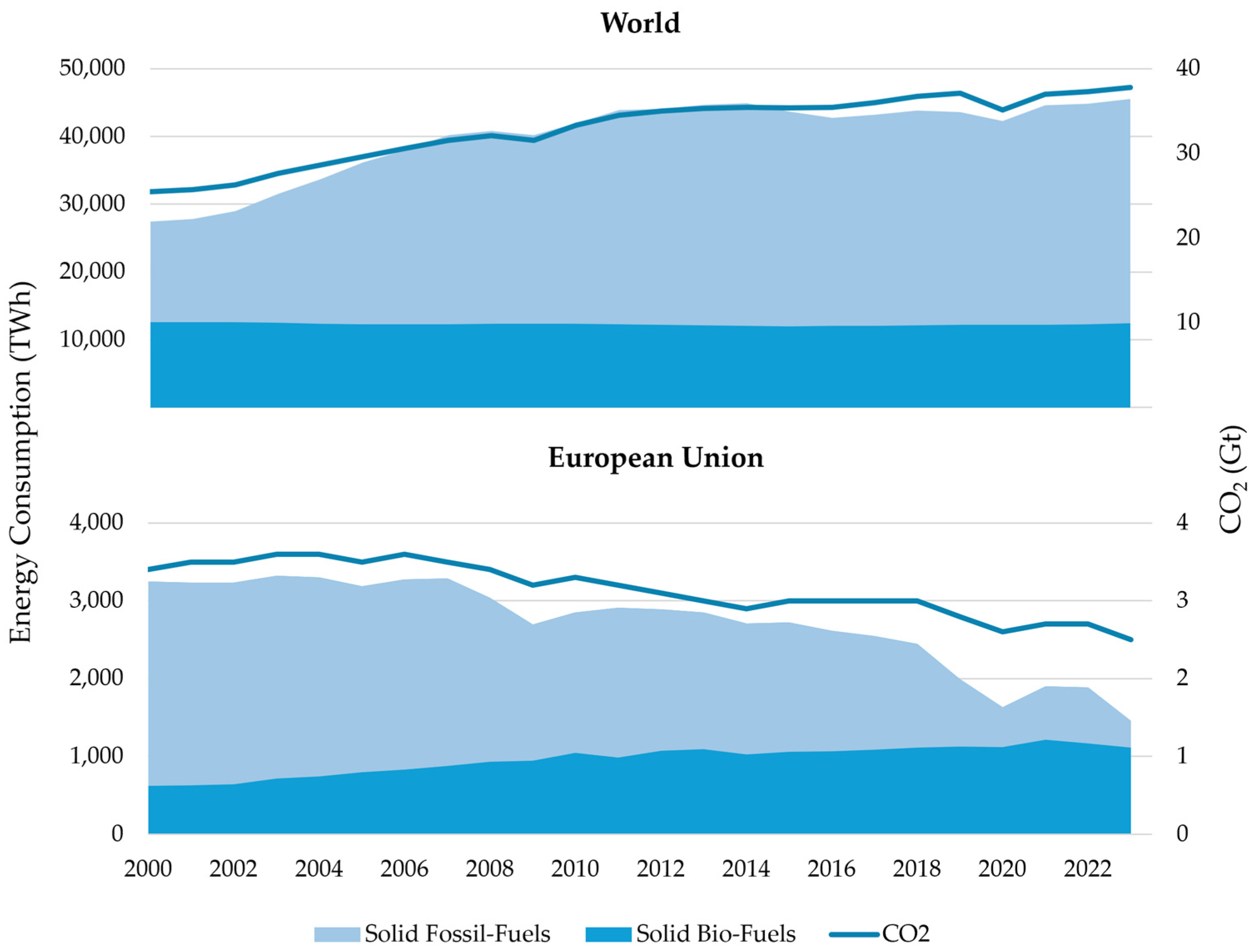

1. Introduction

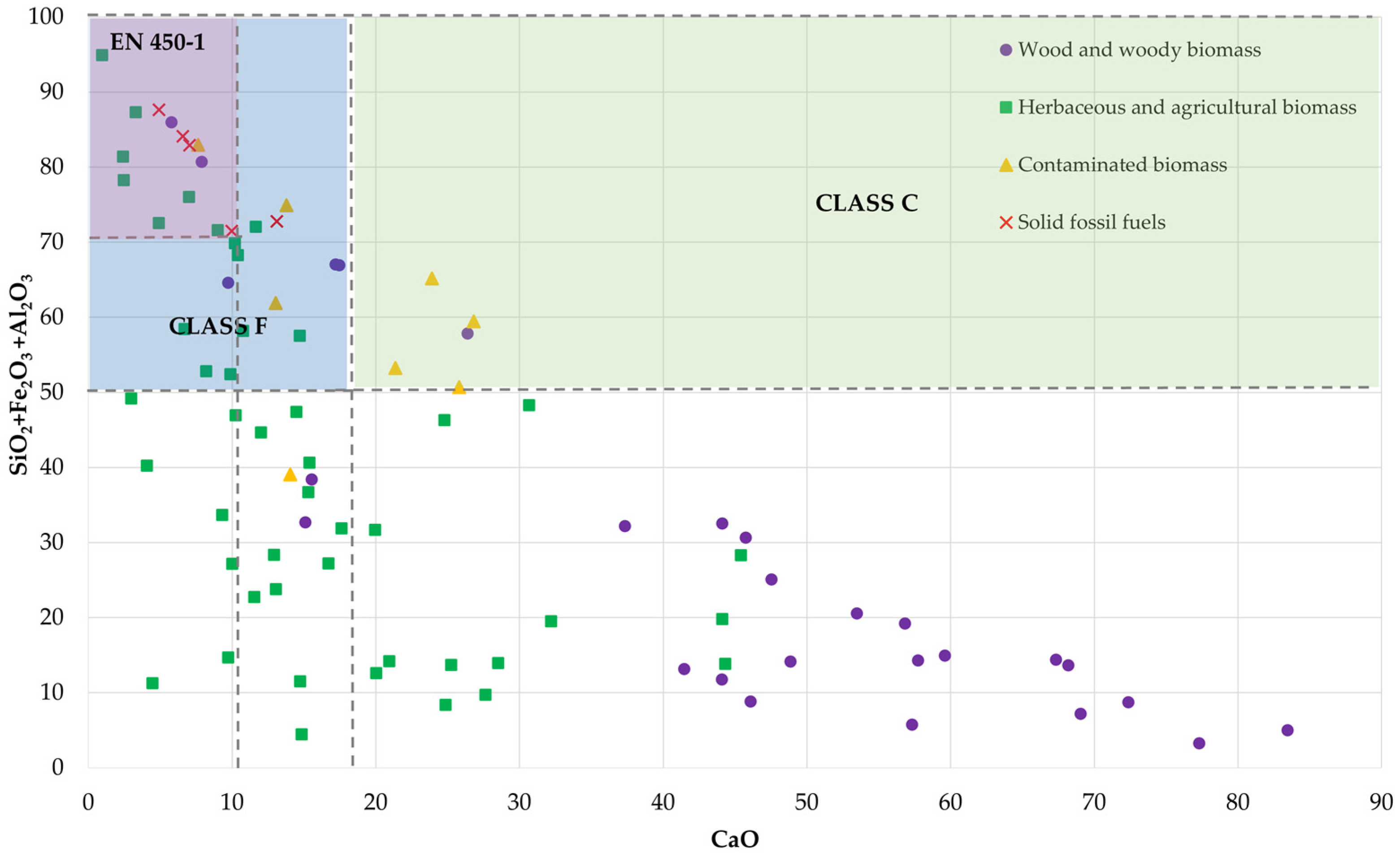

2. Properties of Biomass Ash

| Ash Type | Main Oxides (%wt) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | P2O5 | K2O | MgO | SO3 | MnO | Na2O | Cl | TiO2 | LoI | |

| Woody biomasses (minimum) [53] | 1.86 | 0.12 | 0.37 | 5.79 | 0.66 | 2.19 | 1.10 | 0.36 | - | 0.22 | - | 0.06 | - |

| Woody biomasses (average) [53] | 22.22 | 5.09 | 3.44 | 43.03 | 3.48 | 10.75 | 6.07 | 2.78 | - | 2.85 | - | 0.29 | - |

| Woody biomasses (maximum) [53] | 68.18 | 15.12 | 9.54 | 83.46 | 13.01 | 31.99 | 14.57 | 11.66 | - | 29.82 | - | 1.20 | - |

| Herbaceous and agricultural biomasses (minimum) [53] | 2.01 | 0.10 | 0.22 | 0.97 | 0.54 | 2.29 | 0.19 | 0.01 | - | 0.09 | - | 0.01 | - |

| Herbaceous and agricultural biomasses (average) [53] | 33.39 | 3.66 | 3.26 | 14.86 | 6.48 | 26.65 | 4.02 | 3.61 | - | 2.29 | - | 0.18 | - |

| Herbaceous and agricultural biomasses (maximum) [53] | 94.48 | 14.60 | 36.27 | 44.32 | 31.06 | 63.90 | 16.21 | 14.74 | - | 26.20 | - | 2.02 | - |

| Wood pellets (spruce) [62] | 24.70 | 5.30 | 3.20 | 25.80 | 4.90 | 7.90 | 9.30 | - | 1.00 | 2.30 | - | 0.40 | 9.70 |

| Pine bark [53] | 9.20 | 7.20 | 2.79 | 56.83 | 5.02 | 7.78 | 6.19 | 2.83 | - | 1.97 | - | 0.19 | - |

| Pine chips [53] | 68.18 | 7.04 | 5.45 | 7.89 | 1.56 | 4.51 | 2.43 | 1.19 | - | 1.20 | - | 0.55 | - |

| Pine prunings [53] | 7.76 | 2.75 | 1.25 | 44.10 | 5.73 | 22.32 | 11.33 | 4.18 | - | 0.42 | - | 0.17 | - |

| Pine sawdust [53] | 9.71 | 2.34 | 2.10 | 48.88 | 6.08 | 14.38 | 13.80 | 2.22 | - | 0.35 | - | 0.14 | - |

| Rice straw [53] | 77.20 | 0.55 | 0.50 | 2.46 | 0.98 | 12.59 | 2.71 | 1.18 | - | 1.79 | - | 0.04 | - |

| Rice husk [53] | 94.48 | 0.21 | 0.22 | 0.97 | 0.54 | 2.29 | 0.19 | 0.92 | - | 0.16 | - | 0.02 | - |

| 70% forest r. and 30% peat [63] | 52.20 | 11.00 | 4.80 | 16.00 | 1.70 | 2.90 | 3.50 | 1.70 | - | 2.10 | 0.10 | - | 3.20 |

| 60% forest r., 30% recycling waste, and 10% paper sludge [63] | 39.40 | 12.10 | 4.90 | 23.00 | 1.30 | 2.40 | 3.10 | 6.90 | - | 2.90 | 0.40 | - | 0.70 |

| 50% forest r. 40% peat, and 10% recycled wood waste [63] | 43.80 | 7.40 | 2.60 | 21.10 | 3.00 | 6.50 | 3.40 | 6.30 | - | 2.10 | 0.30 | - | 5.40 |

| 70% forest r. and 30% peat (air-classified) [63] | 53.70 | 11.10 | 4.70 | 15.10 | 1.60 | 2.90 | 3.30 | 1.40 | - | 2.10 | 0.10 | - | 2.90 |

| 60% forest r. 30% recycling waste, and 10% paper sludge (air-classified) [63] | 49.70 | 13.60 | 5.30 | 14.50 | 0.90 | 2.60 | 2.20 | 2.40 | - | 2.90 | 0.10 | - | 3.90 |

| 50% forest r., 40% peat, and 10% recycled wood waste (air-classified) [63] | 56.50 | 8.80 | 2.80 | 13.80 | 1.80 | 5.90 | 2.30 | 2.20 | - | 2.20 | 0.10 | - | 3.30 |

| Pine sawdust and chips (from wood burning) [64] | 9.51 | 2.67 | 2.65 | 5.87 | 0.89 | 1.42 | 1.69 | - | 0.71 | - | - | 0.28 | 74.31 |

| Pine sawdust and chips (from generated ash) [64] | 25.06 | 12.28 | 8.05 | 9.90 | 1.60 | 3.99 | 2.60 | - | 0.69 | 1.33 | - | 3.00 | 31.50 |

| Pine sawdust and chips (from ash disposal) [64] | 21.56 | 10.73 | 7.82 | 4.60 | 0.85 | 3.03 | 1.36 | - | 0.46 | 0.12 | - | 1.61 | 58.59 |

| Wood pellet [65] | 3.22 | 1.07 | 1.31 | 42.38 | 3.23 | 4.57 | 4.87 | 0.59 | 4.73 | 0.11 | 0.07 | 0.07 | - |

| Wood pellet (calcining and milling) [65] | 3.97 | 1.18 | 1.44 | 53.33 | 5.01 | 4.19 | 8.67 | 0.52 | 7.20 | 0.09 | 0.06 | 0.09 | - |

| Wood chips (bottom ash) [66] | 25.10 | 4.51 | 2.28 | 44.60 | 4.96 | 10.20 | 4.73 | - | 0.83 | 0.58 | - | 0.19 | 5.40 |

| Wood chips (electrostatic precipitator) [66] | 13.50 | 3.18 | 1.64 | 30.90 | 4.13 | 18.20 | 3.70 | - | 0.41 | 0.70 | - | 0.17 | 21.1 |

| Wood chips (bottom ash) [66] | 35.80 | 0.98 | 0.79 | 51.10 | 3.51 | 7.31 | 1.48 | - | 0.35 | 0.43 | - | 0.07 | 3.51 |

| Wood chips (cyclone filter) [66] | 17.90 | 1.31 | 8.98 | 55.00 | 1.92 | 1.18 | 1.27 | - | 0.31 | 0.47 | - | 0.10 | 30.20 |

| Woody (grate combustion) [67] | 11.00 | 2.40 | 2.90 | 53.60 | 2.90 | 14.60 | 4.20 | 5.40 | - | 1.00 | 0.80 | - | 15.00 |

| Woody (grate combustion—washed) [67] | 12.70 | 3.00 | 3.20 | 65.00 | 3.80 | 4.40 | 5.80 | 1.30 | - | 1.00 | 0.00 | - | 19.60 |

| Woody (circulating fluidized bed) [67] | 23.80 | 5.60 | 3.10 | 44.70 | 3.80 | 7.60 | 4.10 | 6.10 | - | 0.80 | 0.40 | - | 16.20 |

| Woody (circulating fluidized bed—washed) [67] | 26.50 | 6.30 | 3.30 | 45.00 | 4.20 | 5.70 | 4.40 | 3.70 | - | 0.90 | 0.00 | - | 19.70 |

| Wood and peat [68] | 41.80 | 13.10 | 13.60 | 16.30 | 3.50 | 2.30 | 2.50 | 2.10 | - | 2.10 | 0.10 | 0.50 | 0.30 |

| Wood and peat [68] | 30.80 | 15.10 | 26.70 | 12.00 | 4.90 | 1.60 | 2.50 | 3.50 | 1.10 | 0.10 | 0.40 | 1.50 | |

3. Expectation of Biomass Ash as a Supplementary Cementitious Material

4. Treatments

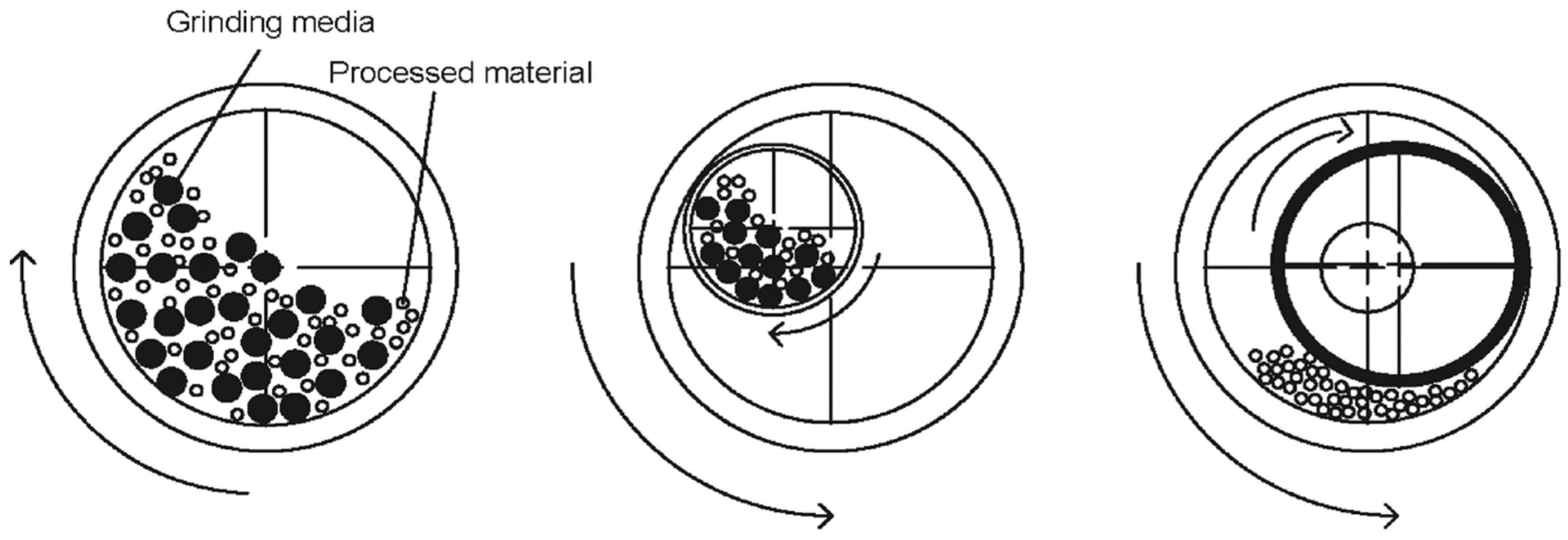

4.1. Grinding

4.2. Mechano-Chemical Activation (MCA)

4.3. High-Temperature Treatment (HTT)

4.4. Hydrothermal Synthesis (HTS)

4.5. Washing Treatment

4.5.1. Water Washing (WW)

4.5.2. Chemical Washing (CW)

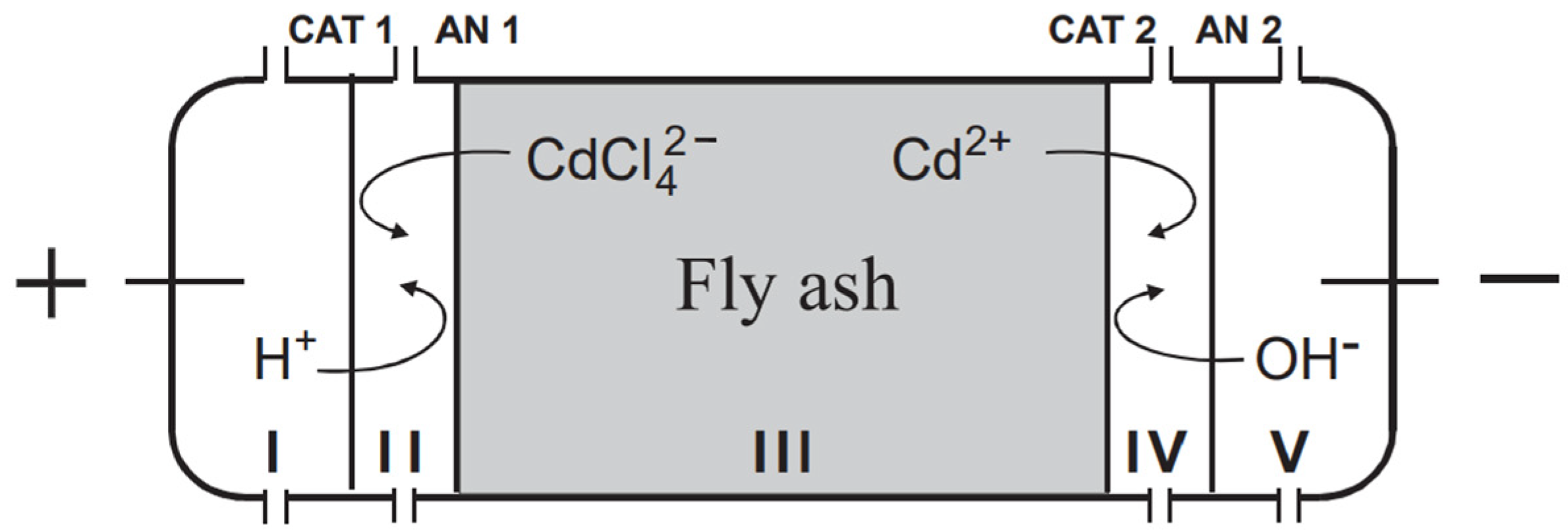

4.6. Electro-Dialytic Remediation (EDR)

4.7. Carbonation—Accelerated Carbonation (AC)

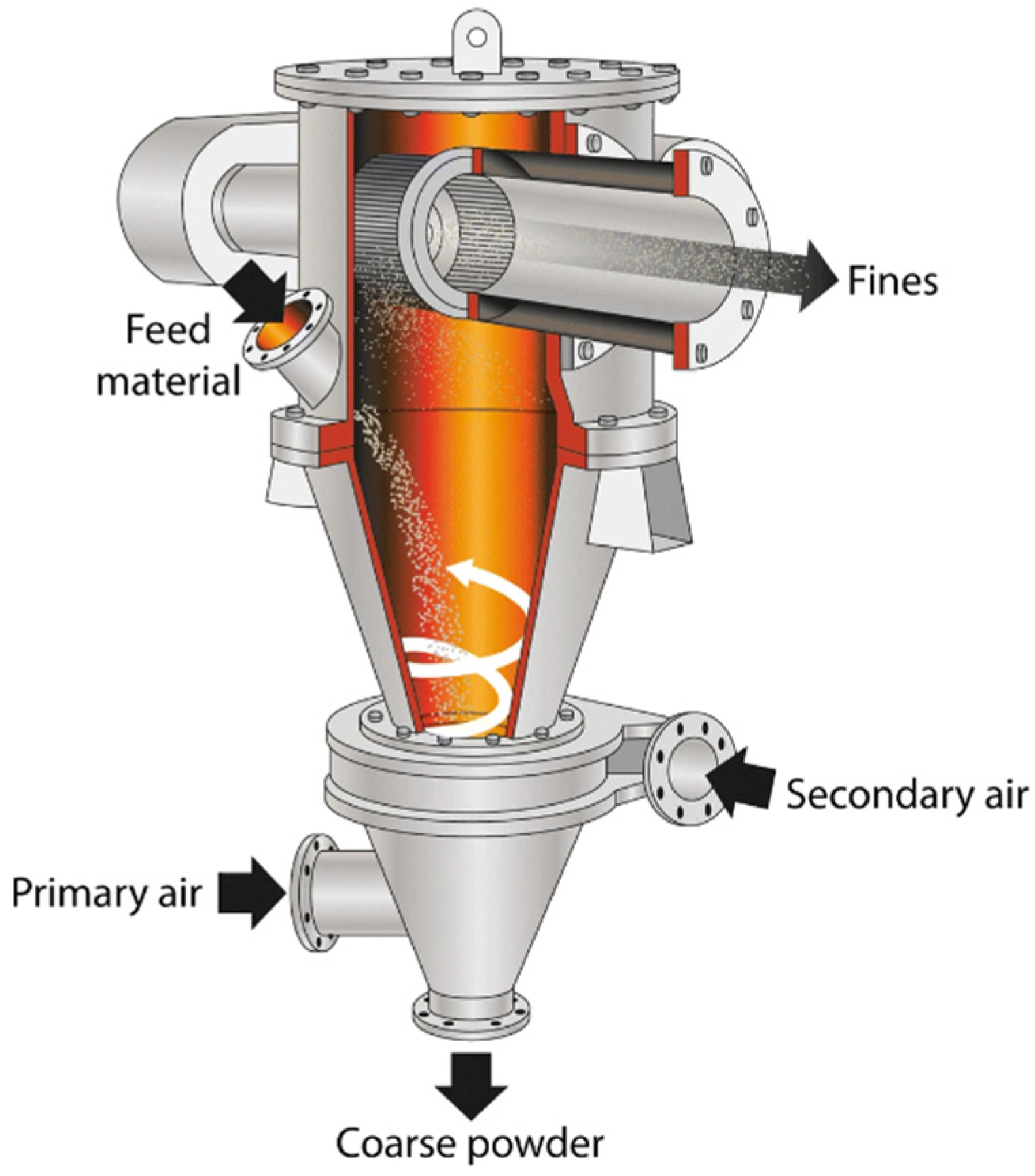

4.8. Air-Classification Treatment (ACT)

4.9. Combined Treatments

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BA | Biomass Ash |

| BFA | Biomass Fly Ash |

| BBA | Biomass Bottom Ash |

| SCM | Supplementary Cementitious Material |

| GHG | Greenhouse Gas |

| PSD | Particle Size Distribution |

| CFA | Coal Fly Ash |

| MCA | Mechano-Chemical Activation |

| C-S-H | Calcium–Silicate–Hydrate |

| C-A-H | Calcium–Aluminate–Hydrate |

| HTS | Hydrothermal Synthesis |

| SSA | Sewage Sludge Ash |

| WW | Water Washing |

| CW | Chemical Washing |

| EDR | Electro-Dialytic Remediation |

| ACT | Air-Classification Treatment |

| AC | Accelerated Carbonation |

| LoI | Loss on Ignition |

| ASTM | American Society for Testing and Materials |

| EN | European Norm |

References

- Andrew, R.M. Global CO2 Emissions from Cement Production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Ritchie, H.; Rosado, P.; Roser, M. CO2 Emissions by Fuel. Our World in Data. 2024. Available online: https://ourworldindata.org/emissions-by-fuel (accessed on 20 September 2024).

- Boden, T.A.; Marland, G.; Andres, R.J. Estimates of Global, Regional, and National Annual CO2 Emissions from Fossil-Fuel Burning, Hydraulic Cement Production, and Gas Flaring: 1950–1992; ORNL/CDIAC–90, NDP–030/R6, 207068; USDOE: Washington, DC, USA, December 1995.

- Ritchie, H.; Roser, M.; Rosado, P. Energy. Our World in Data. 2022. Available online: https://ourworldindata.org/energy (accessed on 20 September 2024).

- International Energy Agency. Energy Technology Perspectives 2023; International Energy Agency: Paris, France; OECD: Paris, France, 2023; ISBN 978-92-64-80416-6.

- Lim, J.S.; Abdul Manan, Z.; Wan Alwi, S.R.; Hashim, H. A Review on Utilisation of Biomass from Rice Industry as a Source of Renewable Energy. Renew. Sustain. Energy Rev. 2012, 16, 3084–3094. [Google Scholar] [CrossRef]

- Ashik, U.P.M.; Wan Daud, W.M.A.; Abbas, H.F. Production of Greenhouse Gas Free Hydrogen by Thermocatalytic Decomposition of Methane–A Review. Renew. Sustain. Energy Rev. 2015, 44, 221–256. [Google Scholar] [CrossRef]

- Munawar, M.A.; Khoja, A.H.; Naqvi, S.R.; Mehran, M.T.; Hassan, M.; Liaquat, R.; Dawood, U.F. Challenges and Opportunities in Biomass Ash Management and Its Utilization in Novel Applications. Renew. Sustain. Energy Rev. 2021, 150, 111451. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G. Water-Soluble Fractions of Biomass and Biomass Ash and Their Significance for Biofuel Application. Energy Fuels 2019, 33, 2763–2777. [Google Scholar] [CrossRef]

- Motghare, K.A.; Rathod, A.P.; Wasewar, K.L.; Labhsetwar, N.K. Comparative Study of Different Waste Biomass for Energy Application. Waste Manag. 2016, 47, 40–45. [Google Scholar] [CrossRef]

- Wang, L.; Hustad, J.E.; Skreiberg, Ø.; Skjevrak, G.; Grønli, M. A Critical Review on Additives to Reduce Ash Related Operation Problems in Biomass Combustion Applications. Energy Procedia 2012, 20, 20–29. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Composition and Application of Biomass Ash. Part 1. Phase–Mineral and Chemical Composition and Classification. Fuel 2013, 105, 40–76. [Google Scholar] [CrossRef]

- Rajamma, R.; Ball, R.J.; Tarelho, L.A.C.; Allen, G.C.; Labrincha, J.A.; Ferreira, V.M. Characterisation and Use of Biomass Fly Ash in Cement-Based Materials. J. Hazard. Mater. 2009, 172, 1049–1060. [Google Scholar] [CrossRef]

- Energy Institute Statistical Review of World Energy; Smil (2017)–with Major Processing by Our World in Data. 2024. Available online: https://ourworldindata.org/grapher/global-energy-substitution?time=2000..latest&facet=none (accessed on 20 September 2024).

- European Commission: Eurostat. Energy, Transport and Environment Statistics: 2020 Edition; Publications Office: Luxemburg, 2020; ISBN 978-92-76-20736-8. [Google Scholar]

- IEA CO2 Total Emissions by Region, 2000-2023–Charts–Data & Statistics. Available online: https://www.iea.org/data-and-statistics/charts/co2-total-emissions-by-region-2000-2023 (accessed on 20 September 2024).

- Agrela, F.; Cabrera, M.; Morales, M.M.; Zamorano, M.; Alshaaer, M. Biomass Fly Ash and Biomass Bottom Ash. In New Trends in Eco-Efficient and Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2019; pp. 23–58. ISBN 978-0-08-102480-5. [Google Scholar]

- Vassilev, S.V.; Baxter, D.; Vassileva, C.G. An Overview of the Behaviour of Biomass during Combustion: Part I. Phase-Mineral Transformations of Organic and Inorganic Matter. Fuel 2013, 112, 391–449. [Google Scholar] [CrossRef]

- Belviso, C. State-of-the-Art Applications of Fly Ash from Coal and Biomass: A Focus on Zeolite Synthesis Processes and Issues. Prog. Energy Combust. Sci. 2018, 65, 109–135. [Google Scholar] [CrossRef]

- Aprianti, E.; Shafigh, P.; Bahri, S.; Farahani, J.N. Supplementary Cementitious Materials Origin from Agricultural Wastes–A Review. Constr. Build. Mater. 2015, 74, 176–187. [Google Scholar] [CrossRef]

- Chen, L.; Liao, Y.; Xia, Y.; Ma, X. Combustion Characteristics of Co-Combusted Municipal Solid Wastes and Sewage Sludge. Energy Sources Part Recovery Util. Environ. Eff. 2020, 46, 5730–5742. [Google Scholar] [CrossRef]

- Tursi, A. A Review on Biomass: Importance, Chemistry, Classification, and Conversion. Biofuel Res. J. 2019, 6, 962–979. [Google Scholar] [CrossRef]

- Tun, M.M.; Juchelkova, D.; Win, M.M.; Thu, A.M.; Puchor, T. Biomass Energy: An Overview of Biomass Sources, Energy Potential, and Management in Southeast Asian Countries. Resources 2019, 8, 81. [Google Scholar] [CrossRef]

- Chinnici, G.; D’Amico, M.; Rizzo, M.; Pecorino, B. Analysis of Biomass Availability for Energy Use in Sicily. Renew. Sustain. Energy Rev. 2015, 52, 1025–1030. [Google Scholar] [CrossRef]

- Kumar, A.; Adamopoulos, S.; Jones, D.; Amiandamhen, S.O. Forest Biomass Availability and Utilization Potential in Sweden: A Review. Waste Biomass Valorization 2021, 12, 65–80. [Google Scholar] [CrossRef]

- Barreiro, S.; Schelhaas, M.-J.; Kändler, G.; Antón-Fernández, C.; Colin, A.; Bontemps, J.-D.; Alberdi, I.; Condés, S.; Dumitru, M.; Ferezliev, A.; et al. Overview of Methods and Tools for Evaluating Future Woody Biomass Availability in European Countries. Ann. For. Sci. 2016, 73, 823–837. [Google Scholar] [CrossRef]

- Ferreira-Leitão, V.; Gottschalk, L.M.F.; Ferrara, M.A.; Nepomuceno, A.L.; Molinari, H.B.C.; Bon, E.P.S. Biomass Residues in Brazil: Availability and Potential Uses. Waste Biomass Valorization 2010, 1, 65–76. [Google Scholar] [CrossRef]

- Lozano-García, D.F.; Santibañez-Aguilar, J.E.; Lozano, F.J.; Flores-Tlacuahuac, A. GIS-Based Modeling of Residual Biomass Availability for Energy and Production in Mexico. Renew. Sustain. Energy Rev. 2020, 120, 109610. [Google Scholar] [CrossRef]

- Balat, M. Use of Biomass Sources for Energy in Turkey and a View to Biomass Potential. Biomass Bioenergy 2005, 29, 32–41. [Google Scholar] [CrossRef]

- Brosowski, A.; Thrän, D.; Mantau, U.; Mahro, B.; Erdmann, G.; Adler, P.; Stinner, W.; Reinhold, G.; Hering, T.; Blanke, C. A Review of Biomass Potential and Current Utilisation–Status Quo for 93 Biogenic Wastes and Residues in Germany. Biomass Bioenergy 2016, 95, 257–272. [Google Scholar] [CrossRef]

- Galik, C.S.; Abt, R.; Wu, Y. Forest Biomass Supply in the Southeastern United States—Implications for Industrial Roundwood and Bioenergy Production. J. For. 2009, 107, 69–77. [Google Scholar] [CrossRef]

- Okafor, C.C.; Nzekwe, C.A.; Ajaero, C.C.; Ibekwe, J.C.; Otunomo, F.A. Biomass Utilization for Energy Production in Nigeria: A Review. Clean. Energy Syst. 2022, 3, 100043. [Google Scholar] [CrossRef]

- Frías, M.; Moreno De Los Reyes, A.M.; Villar-Cociña, E.; García, R.; Vigil De La Villa, R.; Vasić, M.V. New Eco-Cements Made with Marabou Weed Biomass Ash. Materials 2024, 17, 5012. [Google Scholar] [CrossRef]

- Rosales, J.; Cabrera, M.; Beltrán, M.G.; López, M.; Agrela, F. Effects of Treatments on Biomass Bottom Ash Applied to the Manufacture of Cement Mortars. J. Clean. Prod. 2017, 154, 424–435. [Google Scholar] [CrossRef]

- Chang, C.-Y.; Wang, C.-F.; Mui, D.T.; Chiang, H.-L. Application of Methods (Sequential Extraction Procedures and High-Pressure Digestion Method) to Fly Ash Particles to Determine the Element Constituents: A Case Study for BCR 176. J. Hazard. Mater. 2009, 163, 578–587. [Google Scholar] [CrossRef]

- Karps, O.; Aboltins, A.; Palabinskis, J. Biomass Ash Utilization Opportunities in Agriculture. In Proceedings of the International Scientific Conference “RURAL DEVELOPMENT 2017”, Kaunas, Lithuania, 15 February 2018. [Google Scholar]

- James, A.; Thring, R.; Helle, S.; Ghuman, H. Ash Management Review—Applications of Biomass Bottom Ash. Energies 2012, 5, 3856–3873. [Google Scholar] [CrossRef]

- Lu, G.Q.; Do, D.D. Adsorption Properties of Fly Ash Particles for NOx Removal from Flue Gases. Fuel Process. Technol. 1991, 27, 95–107. [Google Scholar] [CrossRef]

- Cho, H.; Oh, D.; Kim, K. A Study on Removal Characteristics of Heavy Metals from Aqueous Solution by Fly Ash. J. Hazard. Mater. 2005, 127, 187–195. [Google Scholar] [CrossRef]

- Polat, H.; Vengosh, A.; Pankratov, I.; Polat, M. A New Methodology for Removal of Boron from Water by Coal and Fly Ash. Desalination 2004, 164, 173–188. [Google Scholar] [CrossRef]

- Izquierdo, M.T.; Rubio, B. Carbon-Enriched Coal Fly Ash as a Precursor of Activated Carbons for SO2 Removal. J. Hazard. Mater. 2008, 155, 199–205. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Guo, Y.; Zhao, C.; Yan, J.; Lu, P. Biomass Derived Wood Ash with Amine Modification for Post-Combustion CO2 Capture. Appl. Energy 2017, 201, 34–44. [Google Scholar] [CrossRef]

- Muñoz, P.; Letelier, V.; Muñoz, L.; Gencel, O.; Sutcu, M.; Vasic, M. Assessing Technological Properties and Environmental Impact of Fired Bricks Made by Partially Adding Bottom Ash from an Industrial Approach. Constr. Build. Mater. 2023, 396, 132338. [Google Scholar] [CrossRef]

- Sarmah, M.; Baruah, B.P.; Khare, P. A Comparison between CO2 Capturing Capacities of Fly Ash Based Composites of MEA/DMA and DEA/DMA. Fuel Process. Technol. 2013, 106, 490–497. [Google Scholar] [CrossRef]

- Wang, S.; Song, X.; Wei, M.; Liu, W.; Wang, X.; Ke, Y.; Tao, T. Strength Characteristics and Microstructure Evolution of Cemented Tailings Backfill with Rice Straw Ash as an Alternative Binder. Constr. Build. Mater. 2021, 297, 123780. [Google Scholar] [CrossRef]

- Qi, T.; Gao, X.; Feng, G.; Bai, J.; Wang, Z.; Chen, Q.; Wang, H.; Du, X. Effect of Biomass Power Plant Ash on Fresh Properties of Cemented Coal Gangue Backfill. Constr. Build. Mater. 2022, 340, 127853. [Google Scholar] [CrossRef]

- Qin, Z.; Jin, J.; Liu, L.; Zhang, Y.; Du, Y.; Yang, Y.; Zuo, S. Reuse of Soil-like Material Solidified by a Biomass Fly Ash-Based Binder as Engineering Backfill Material and Its Performance Evaluation. J. Clean. Prod. 2023, 402, 136824. [Google Scholar] [CrossRef]

- Carrasco, B.; Cruz, N.; Terrados, J.; Corpas, F.A.; Pérez, L. An Evaluation of Bottom Ash from Plant Biomass as a Replacement for Cement in Building Blocks. Fuel 2014, 118, 272–280. [Google Scholar] [CrossRef]

- Olatoyan, O.J.; Kareem, M.A.; Adebanjo, A.U.; Olawale, S.O.A.; Alao, K.T. Potential Use of Biomass Ash as a Sustainable Alternative for Fly Ash in Concrete Production: A Review. Hybrid Adv. 2023, 4, 100076. [Google Scholar] [CrossRef]

- Cabrera, M.; Galvin, A.P.; Agrela, F.; Carvajal, M.D.; Ayuso, J. Characterisation and Technical Feasibility of Using Biomass Bottom Ash for Civil Infrastructures. Constr. Build. Mater. 2014, 58, 234–244. [Google Scholar] [CrossRef]

- Niu, Y.; Tan, H.; Hui, S. Ash-Related Issues during Biomass Combustion: Alkali-Induced Slagging, Silicate Melt-Induced Slagging (Ash Fusion), Agglomeration, Corrosion, Ash Utilization, and Related Countermeasures. Prog. Energy Combust. Sci. 2016, 52, 1–61. [Google Scholar] [CrossRef]

- Pitman, R.M. Wood Ash Use in Forestry-a Review of the Environmental Impacts. Forestry 2006, 79, 563–588. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Chemical Composition of Biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G.; Morgan, T.J. An Overview of the Organic and Inorganic Phase Composition of Biomass. Fuel 2012, 94, 1–33. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Vassilev, V.S. Advantages and Disadvantages of Composition and Properties of Biomass in Comparison with Coal: An Overview. Fuel 2015, 158, 330–350. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Vassileva, C.G. An Overview of the Behaviour of Biomass during Combustion: Part II. Ash Fusion and Ash Formation Mechanisms of Biomass Types. Fuel 2014, 117, 152–183. [Google Scholar] [CrossRef]

- Girón, R.P.; Ruiz, B.; Fuente, E.; Gil, R.R.; Suárez-Ruiz, I. Properties of Fly Ash from Forest Biomass Combustion. Fuel 2013, 114, 71–77. [Google Scholar] [CrossRef]

- Tortosa Masiá, A.A.; Buhre, B.J.P.; Gupta, R.P.; Wall, T.F. Characterising Ash of Biomass and Waste. Fuel Process. Technol. 2007, 88, 1071–1081. [Google Scholar] [CrossRef]

- Suarez-Garcia, F.; Martinez-Alonso, A.; Fernandez-Llorente, M.; Tascon, J. Inorganic Matter Characterization in Vegetable Biomass Feedstocks1. Fuel 2002, 81, 1161–1169. [Google Scholar] [CrossRef]

- Vamvuka, D.; Kakaras, E. Ash Properties and Environmental Impact of Various Biomass and Coal Fuels and Their Blends. Fuel Process. Technol. 2011, 92, 570–581. [Google Scholar] [CrossRef]

- Vassileva, C.G.; Vassilev, S.V. Behaviour of Inorganic Matter during Heating of Bulgarian Coals. Fuel Process. Technol. 2006, 87, 1095–1116. [Google Scholar] [CrossRef]

- Hubert, J.; Grigoletto, S.; Michel, F.; Zhao, Z.; Courard, L. Development and Properties of Recycled Biomass Fly Ashes Modified Mortars. Recycling 2024, 9, 46. [Google Scholar] [CrossRef]

- Ohenoja, K.; Wigren, V.; Österbacka, J.; Illikainen, M. Mechanically Treated Fly Ash from Fluidized Bed Combustion of Peat, Wood, and Wastes in Concrete. Waste Biomass Valorization 2020, 11, 3071–3079. [Google Scholar] [CrossRef]

- Silvestro, L.; Scolaro, T.P.; Ruviaro, A.S.; Santos Lima, G.T.D.; Gleize, P.J.P.; Pelisser, F. Use of Biomass Wood Ash to Produce Sustainable Geopolymeric Pastes. Constr. Build. Mater. 2023, 370, 130641. [Google Scholar] [CrossRef]

- Ates, F.; Park, K.T.; Kim, K.W.; Woo, B.-H.; Kim, H.G. Effects of Treated Biomass Wood Fly Ash as a Partial Substitute for Fly Ash in a Geopolymer Mortar System. Constr. Build. Mater. 2023, 376, 131063. [Google Scholar] [CrossRef]

- Maschowski, C.; Kruspan, P.; Garra, P.; Talib Arif, A.; Trouvé, G.; Gieré, R. Physicochemical and Mineralogical Characterization of Biomass Ash from Different Power Plants in the Upper Rhine Region. Fuel 2019, 258, 116020. [Google Scholar] [CrossRef]

- Sigvardsen, N.M.; Geiker, M.R.; Ottosen, L.M. Phase Development and Mechanical Response of Low-Level Cement Replacements with Wood Ash and Washed Wood Ash. Constr. Build. Mater. 2021, 269, 121234. [Google Scholar] [CrossRef]

- Rissanen, J.; Giosué, C.; Ohenoja, K.; Kinnunen, P.; Marcellini, M.; Letizia Ruello, M.; Tittarelli, F.; Illikainen, M. The Effect of Peat and Wood Fly Ash on the Porosity of Mortar. Constr. Build. Mater. 2019, 223, 421–430. [Google Scholar] [CrossRef]

- Wang, G.; Shen, L.; Sheng, C. Characterization of Biomass Ashes from Power Plants Firing Agricultural Residues. Energy Fuels 2012, 26, 102–111. [Google Scholar] [CrossRef]

- Boström, D.; Skoglund, N.; Grimm, A.; Boman, C.; Öhman, M.; Broström, M.; Backman, R. Ash Transformation Chemistry during Combustion of Biomass. Energy Fuels 2012, 26, 85–93. [Google Scholar] [CrossRef]

- Baxter, L.L.; Miles, T.R.; Miles, T.R.; Jenkins, B.M.; Milne, T.; Dayton, D.; Bryers, R.W.; Oden, L.L. The Behavior of Inorganic Material in Biomass-Fired Power Boilers: Field and Laboratory Experiences. Fuel Process. Technol. 1998, 54, 47–78. [Google Scholar] [CrossRef]

- Lanzerstorfer, C. Cyclone Fly Ash from a Grate-Fired Biomass Combustion Plant: Dependence of the Concentration of Various Components on the Particle Size. Fuel Process. Technol. 2015, 131, 382–388. [Google Scholar] [CrossRef]

- Trivedi, N.S.; Mandavgane, S.A.; Mehetre, S.; Kulkarni, B.D. Characterization and Valorization of Biomass Ashes. Environ. Sci. Pollut. Res. 2016, 23, 20243–20256. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Composition and Application of Biomass Ash. Part 2. Potential Utilisation, Technological and Ecological Advantages and Challenges. Fuel 2013, 105, 19–39. [Google Scholar] [CrossRef]

- Voshell, S.; Mäkelä, M.; Dahl, O. A Review of Biomass Ash Properties towards Treatment and Recycling. Renew. Sustain. Energy Rev. 2018, 96, 479–486. [Google Scholar] [CrossRef]

- van Loo, S.; Koppejan, J. The Handbook of Biomass Combustion and Co-Firing; Earthscan: London, UK, 2008; ISBN 978-1-84407-249-1. [Google Scholar]

- Barbosa, R.; Lapa, N.; Dias, D.; Mendes, B. Concretes Containing Biomass Ashes: Mechanical, Chemical, and Ecotoxic Performances. Constr. Build. Mater. 2013, 48, 457–463. [Google Scholar] [CrossRef]

- Horsakulthai, V.; Phiuvanna, S.; Kaenbud, W. Investigation on the Corrosion Resistance of Bagasse-Rice Husk-Wood Ash Blended Cement Concrete by Impressed Voltage. Constr. Build. Mater. 2011, 25, 54–60. [Google Scholar] [CrossRef]

- Omran, A.; Soliman, N.; Xie, A.; Davidenko, T.; Tagnit-Hamou, A. Field Trials with Concrete Incorporating Biomass-Fly Ash. Constr. Build. Mater. 2018, 186, 660–669. [Google Scholar] [CrossRef]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Influence of Pozzolan from Various By-Product Materials on Mechanical Properties of High-Strength Concrete. Constr. Build. Mater. 2007, 21, 1589–1598. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of Wood Ash in Concrete Manufacturing. Resour. Conserv. Recycl. 2012, 67, 27–33. [Google Scholar] [CrossRef]

- Cheah, C.B.; Ramli, M. The Implementation of Wood Waste Ash as a Partial Cement Replacement Material in the Production of Structural Grade Concrete and Mortar: An Overview. Resour. Conserv. Recycl. 2011, 55, 669–685. [Google Scholar] [CrossRef]

- ASTM C618-23; Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- EN-450-1; Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria. CEN: Brussels, Belgium, 2012.

- Vamvuka, D.; Zografos, D. Predicting the Behaviour of Ash from Agricultural Wastes during Combustion. Fuel 2004, 83, 2051–2057. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G. A New Approach for the Classification of Coal Fly Ashes Based on Their Origin, Composition, Properties, and Behaviour. Fuel 2007, 86, 1490–1512. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G. A New Approach for the Combined Chemical and Mineral Classification of the Inorganic Matter in Coal. 1. Chemical and Mineral Classification Systems. Fuel 2009, 88, 235–245. [Google Scholar] [CrossRef]

- Etiégni, L.; Campbell, A.G. Physical and Chemical Characteristics of Wood Ash. Bioresour. Technol. 1991, 37, 173–178. [Google Scholar] [CrossRef]

- Misra, M.K.; Ragland, K.W.; Baker, A.J. Wood Ash Composition as a Function of Furnace Temperature. Biomass Bioenergy 1993, 4, 103–116. [Google Scholar] [CrossRef]

- Demirbas, A. Potential Applications of Renewable Energy Sources, Biomass Combustion Problems in Boiler Power Systems and Combustion Related Environmental Issues. Prog. Energy Combust. Sci. 2005, 31, 171–192. [Google Scholar] [CrossRef]

- Demirbas, A. Combustion Characteristics of Different Biomass Fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Wigley, F.; Williamson, J.; Malmgren, A.; Riley, G. Ash Deposition at Higher Levels of Coal Replacement by Biomass. Fuel Process. Technol. 2007, 88, 1148–1154. [Google Scholar] [CrossRef]

- Tite, M.S.; Shortland, A.; Maniatis, Y.; Kavoussanaki, D.; Harris, S.A. The Composition of the Soda-Rich and Mixed Alkali Plant Ashes Used in the Production of Glass. J. Archaeol. Sci. 2006, 33, 1284–1292. [Google Scholar] [CrossRef]

- Nutalapati, D.; Gupta, R.; Moghtaderi, B.; Wall, T.F. Assessing Slagging and Fouling during Biomass Combustion: A Thermodynamic Approach Allowing for Alkali/Ash Reactions. Fuel Process. Technol. 2007, 88, 1044–1052. [Google Scholar] [CrossRef]

- Lapuerta, M.; Hernández, J.J.; Pazo, A.; López, J. Gasification and Co-Gasification of Biomass Wastes: Effect of the Biomass Origin and the Gasifier Operating Conditions. Fuel Process. Technol. 2008, 89, 828–837. [Google Scholar] [CrossRef]

- Umamaheswaran, K.; Batra, V.S. Physico-Chemical Characterisation of Indian Biomass Ashes. Fuel 2008, 87, 628–638. [Google Scholar] [CrossRef]

- Madhiyanon, T.; Sathitruangsak, P.; Soponronnarit, S. Co-Combustion of Rice Husk with Coal in a Cyclonic Fluidized-Bed Combustor (ψ-FBC). Fuel 2009, 88, 132–138. [Google Scholar] [CrossRef]

- Miles, T.R.; Miles, T.R.; Baxter, L.L.; Bryers, R.W.; Jenkins, B.M.; Oden, L.L. Boiler Deposits from Firing Biomass Fuels. Biomass Bioenergy 1996, 10, 125–138. [Google Scholar] [CrossRef]

- Bryers, R.W. Fireside Slagging, Fouling, and High-Temperature Corrosion of Heat-Transfer Surface Due to Impurities in Steam-Raising Fuels. Prog. Energy Combust. Sci. 1996, 22, 29–120. [Google Scholar] [CrossRef]

- Tillman, D.A. Biomass Cofiring: The Technology, the Experience, the Combustion Consequences. Biomass Bioenergy 2000, 19, 365–384. [Google Scholar] [CrossRef]

- Werther, J.; Saenger, M.; Hartge, E.-U.; Ogada, T.; Siagi, Z. Combustion of Agricultural Residues. Prog. Energy Combust. Sci. 2000, 26, 1–27. [Google Scholar] [CrossRef]

- Scurlock, J.M.O.; Dayton, D.C.; Hames, B. Bamboo: An Overlooked Biomass Resource? Biomass Bioenergy 2000, 19, 229–244. [Google Scholar] [CrossRef]

- Thy, P.; Lesher, C.E.; Jenkins, B.M. Experimental Determination of High-Temperature Elemental Losses from Biomass Slag. Fuel 2000, 79, 693–700. [Google Scholar] [CrossRef]

- Zevenhoven-Onderwater, M.; Blomquist, J.-P.; Skrifvars, B.-J.; Backman, R.; Hupa, M. The Prediction of Behaviour of Ashes from Five Different Solid Fuels in Fluidised Bed Combustion. Fuel 2000, 79, 1353–1361. [Google Scholar] [CrossRef]

- Risnes, H.; Fjellerup, J.; Henriksen, U.; Moilanen, A.; Norby, P.; Papadakis, K.; Posselt, D.; Sørensen, L.H. Calcium Addition in Straw Gasification. Fuel 2003, 82, 641–651. [Google Scholar] [CrossRef]

- Feng, Q.; Lin, Q.; Gong, F.; Sugita, S.; Shoya, M. Adsorption of Lead and Mercury by Rice Husk Ash. J. Colloid Interface Sci. 2004, 278, 1–8. [Google Scholar] [CrossRef]

- Wei, X.; Schnell, U.; Hein, K. Behaviour of Gaseous Chlorine and Alkali Metals during Biomass Thermal Utilisation. Fuel 2005, 84, 841–848. [Google Scholar] [CrossRef]

- Theis, M.; Skrifvars, B.-J.; Zevenhoven, M.; Hupa, M.; Tran, H. Fouling Tendency of Ash Resulting from Burning Mixtures of Biofuels. Part 2: Deposit Chemistry. Fuel 2006, 85, 1992–2001. [Google Scholar] [CrossRef]

- Ross, A.; Jones, J.; Kubacki, M.; Bridgeman, T. Classification of Macroalgae as Fuel and Its Thermochemical Behaviour. Bioresour. Technol. 2008, 99, 6494–6504. [Google Scholar] [CrossRef]

- Ro, J.W.; Cunningham, P.R.; Miller, S.A.; Kendall, A.; Harvey, J. Technical, Economic, and Environmental Feasibility of Rice Hull Ash from Electricity Generation as a Mineral Additive to Concrete. Sci. Rep. 2024, 14, 9158. [Google Scholar] [CrossRef]

- Udoeyo, F.F.; Inyang, H.; Young, D.T.; Oparadu, E.E. Potential of Wood Waste Ash as an Additive in Concrete. J. Mater. Civ. Eng. 2006, 18, 605–611. [Google Scholar] [CrossRef]

- Skevi, L.; Baki, V.A.; Feng, Y.; Valderrabano, M.; Ke, X. Biomass Bottom Ash as Supplementary Cementitious Material: The Effect of Mechanochemical Pre-Treatment and Mineral Carbonation. Materials 2022, 15, 8357. [Google Scholar] [CrossRef]

- Doudart De La Grée, G.C.H.; Florea, M.V.A.; Keulen, A.; Brouwers, H.J.H. Contaminated Biomass Fly Ashes–Characterization and Treatment Optimization for Reuse as Building Materials. Waste Manag. 2016, 49, 96–109. [Google Scholar] [CrossRef] [PubMed]

- Memon, S.A.; Khan, M.K. Ash Blended Cement Composites: Eco-Friendly and Sustainable Option for Utilization of Corncob Ash. J. Clean. Prod. 2018, 175, 442–455. [Google Scholar] [CrossRef]

- Maschio, S.; Tonello, G.; Piani, L.; Furlani, E. Fly and Bottom Ashes from Biomass Combustion as Cement Replacing Components in Mortars Production: Rheological Behaviour of the Pastes and Materials Compression Strength. Chemosphere 2011, 85, 666–671. [Google Scholar] [CrossRef] [PubMed]

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.M.R. Pozzolanic Activity and Filler Effect of Sugar Cane Bagasse Ash in Portland Cement and Lime Mortars. Cem. Concr. Compos. 2008, 30, 410–418. [Google Scholar] [CrossRef]

- Chusilp, N.; Jaturapitakkul, C.; Kiattikomol, K. Effects of LOI of Ground Bagasse Ash on the Compressive Strength and Sulfate Resistance of Mortars. Constr. Build. Mater. 2009, 23, 3523–3531. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.D.M.R. Ultrafine Grinding of Sugar Cane Bagasse Ash for Application as Pozzolanic Admixture in Concrete. Cem. Concr. Res. 2009, 39, 110–115. [Google Scholar] [CrossRef]

- Zhang, Q.; Saito, F. A Review on Mechanochemical Syntheses of Functional Materials. Adv. Powder Technol. 2012, 23, 523–531. [Google Scholar] [CrossRef]

- Jones, W.; Eddleston, M.D. Introductory Lecture: Mechanochemistry, a Versatile Synthesis Strategy for New Materials. Faraday Discuss 2014, 170, 9–34. [Google Scholar] [CrossRef]

- Szczęśniak, B.; Borysiuk, S.; Choma, J.; Jaroniec, M. Mechanochemical Synthesis of Highly Porous Materials. Mater. Horiz. 2020, 7, 1457–1473. [Google Scholar] [CrossRef]

- Weerdt, K.D.; Sellevold, E.; Kjellsen, K.O.; Justnes, H. Fly Ash–Limestone Ternary Cements: Effect of Component Fineness. Adv. Cem. Res. 2011, 23, 203–214. [Google Scholar] [CrossRef]

- Moghaddam, F.; Sirivivatnanon, V.; Vessalas, K. The Effect of Fly Ash Fineness on Heat of Hydration, Microstructure, Flow and Compressive Strength of Blended Cement Pastes. Case Stud. Constr. Mater. 2019, 10, e00218. [Google Scholar] [CrossRef]

- Li, M.-G.; Sun, C.-J.; Gau, S.-H.; Chuang, C.-J. Effects of Wet Ball Milling on Lead Stabilization and Particle Size Variation in Municipal Solid Waste Incinerator Fly Ash. J. Hazard. Mater. 2010, 174, 586–591. [Google Scholar] [CrossRef]

- Cho, Y.K.; Jung, S.H.; Choi, Y.C. Effects of Chemical Composition of Fly Ash on Compressive Strength of Fly Ash Cement Mortar. Constr. Build. Mater. 2019, 204, 255–264. [Google Scholar] [CrossRef]

- Hsu, S.; Chi, M.; Huang, R. Effect of Fineness and Replacement Ratio of Ground Fly Ash on Properties of Blended Cement Mortar. Constr. Build. Mater. 2018, 176, 250–258. [Google Scholar] [CrossRef]

- Haha, M.B.; De Weerdt, K.; Lothenbach, B. Quantification of the Degree of Reaction of Fly Ash. Cem. Concr. Res. 2010, 40, 1620–1629. [Google Scholar] [CrossRef]

- Wu, F.; Li, H.; Yang, K. Effects of Mechanical Activation on Physical and Chemical Characteristics of Coal-Gasification Slag. Coatings 2021, 11, 902. [Google Scholar] [CrossRef]

- Tole, I.; Habermehl-Cwirzen, K.; Cwirzen, A. Mechanochemical Activation of Natural Clay Minerals: An Alternative to Produce Sustainable Cementitious Binders–Review. Mineral. Petrol. 2019, 113, 449–462. [Google Scholar] [CrossRef]

- Chen, C.-G.; Sun, C.-J.; Gau, S.-H.; Wu, C.-W.; Chen, Y.-L. The Effects of the Mechanical–Chemical Stabilization Process for Municipal Solid Waste Incinerator Fly Ash on the Chemical Reactions in Cement Paste. Waste Manag. 2013, 33, 858–865. [Google Scholar] [CrossRef]

- Nomura, Y.; Fujiwara, K.; Takada, M.; Nakai, S.; Hosomi, M. Lead Immobilization in Mechanochemical Fly Ash Recycling. J. Mater. Cycles Waste Manag. 2008, 10, 14–18. [Google Scholar] [CrossRef]

- Morales, E.V.; Villar-Cociña, E.; Frías, M.; Santos, S.F.; Savastano, H. Effects of Calcining Conditions on the Microstructure of Sugar Cane Waste Ashes (SCWA): Influence in the Pozzolanic Activation. Cem. Concr. Compos. 2009, 31, 22–28. [Google Scholar] [CrossRef]

- Frías, M.; Villar, E.; Savastano, H. Brazilian Sugar Cane Bagasse Ashes from the Cogeneration Industry as Active Pozzolans for Cement Manufacture. Cem. Concr. Compos. 2011, 33, 490–496. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Barroso, T.R.; Toledo Filho, R.D. Enhancement the Properties of Sugar Cane Bagasse Ash with High Carbon Content by a Controlled Re-Calcination Process. KSCE J. Civ. Eng. 2018, 22, 1250–1257. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Santhanam, M. Influence of Different Processing Methods on the Pozzolanic Performance of Sugarcane Bagasse Ash. Cem. Concr. Compos. 2015, 56, 32–45. [Google Scholar] [CrossRef]

- Joshaghani, A.; Moeini, M.A. Evaluating the Effects of Sugar Cane Bagasse Ash (SCBA) and Nanosilica on the Mechanical and Durability Properties of Mortar. Constr. Build. Mater. 2017, 152, 818–831. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Fairbairn, E.M.R. Effect of Calcination Temperature on the Pozzolanic Activity of Sugar Cane Bagasse Ash. Constr. Build. Mater. 2009, 23, 3301–3303. [Google Scholar] [CrossRef]

- Salvo, M.; Rizzo, S.; Caldirola, M.; Novajra, G.; Canonico, F.; Bianchi, M.; Ferraris, M. Biomass Ash as Supplementary Cementitious Material (SCM). Adv. Appl. Ceram. 2015, 114, S3–S10. [Google Scholar] [CrossRef]

- Monteiro, R.C.C.; Alendouro, S.J.G.; Figueiredo, F.M.L.; Ferro, M.C.; Fernandes, M.H.V. Development and Properties of a Glass Made from MSWI Bottom Ash. J. Non-Cryst. Solids 2006, 352, 130–135. [Google Scholar] [CrossRef]

- Ribeiro, A.S.M.; Monteiro, R.C.C.; Davim, E.J.R.; Fernandes, M.H.V. Ash from a Pulp Mill Boiler—Characterisation and Vitrification. J. Hazard. Mater. 2010, 179, 303–308. [Google Scholar] [CrossRef]

- Jiménez, I.; Pérez, G.; Guerrero, A.; Ruiz, B. Mineral Phases Synthesized by Hydrothermal Treatment from Biomass Ashes. Int. J. Miner. Process. 2017, 158, 8–12. [Google Scholar] [CrossRef]

- Byrappa, K.; Yoshimura, M. Handbook of Hydrothermal Technology, 2nd ed.; William Andrew: Oxford, UK; Waltham, MA, USA, 2013; ISBN 978-0-12-375090-7. [Google Scholar]

- Kaminskas, R.; Eisinas, A.; Barauskas, I.; Gaivenis, M. Hydrothermally Treated Biomass Fly Ash as an Additive for Portland Cement. Sustainability 2024, 16, 2754. [Google Scholar] [CrossRef]

- Ríos, C.A.; Williams, C.D.; Roberts, C.L. Removal of Heavy Metals from Acid Mine Drainage (AMD) Using Coal Fly Ash, Natural Clinker and Synthetic Zeolites. J. Hazard. Mater. 2008, 156, 23–35. [Google Scholar] [CrossRef] [PubMed]

- Vadapalli, V.R.K.; Gitari, W.M.; Ellendt, A.; Petrik, L.F.; Balfour, G. Synthesis of Zeolite-P from Coal Fly Ash Derivative and Its Utilisation in Mine-Water Remediation. S. Afr. J. Sci. 2010, 106, 1–7. [Google Scholar] [CrossRef][Green Version]

- Querol, X.; Alastuey, A.; Moreno, N.; Alvarez-Ayuso, E.; García-Sánchez, A.; Cama, J.; Ayora, C.; Simón, M. Immobilization of Heavy Metals in Polluted Soils by the Addition of Zeolitic Material Synthesized from Coal Fly Ash. Chemosphere 2006, 62, 171–180. [Google Scholar] [CrossRef] [PubMed]

- Ríos, R.C.A.; Oviedo, V.J.A.; Henao, M.J.A.; Macías, L.M.A. A NaY Zeolite Synthesized from Colombian Industrial Coal By-Products: Potential Catalytic Applications. Catal. Today 2012, 190, 61–67. [Google Scholar] [CrossRef]

- Pimraksa, K.; Chindaprasirt, P.; Huanjit, T.; Tang, C.; Sato, T. Cement Mortars Hybridized with Zeolite and Zeolite-like Materials Made of Lignite Bottom Ash for Heavy Metal Encapsulation. J. Clean. Prod. 2013, 41, 31–41. [Google Scholar] [CrossRef]

- Girskas, G.; Skripkiūnas, G.; Šahmenko, G.; Korjakins, A. Durability of Concrete Containing Synthetic Zeolite from Aluminum Fluoride Production Waste as a Supplementary Cementitious Material. Constr. Build. Mater. 2016, 117, 99–106. [Google Scholar] [CrossRef]

- Vaitkevičius, V.; Vaičiukynienė, D.; Kantautas, A.; Kartovickis, A.; Rudžionis, Ž. Blended Cements Produced With Synthetic Zeolite Made from Industrial By-Product. Mater. Sci. 2015, 21, 136–142. [Google Scholar] [CrossRef][Green Version]

- Hassan, E.M.; Abdul-Wahab, S.A.; Abdo, J.; Yetilmezsoy, K. Production of Environmentally Friendly Cements Using Synthetic Zeolite Catalyst as the Pozzolanic Material. Clean Technol. Environ. Policy 2019, 21, 1829–1839. [Google Scholar] [CrossRef]

- Fukasawa, T.; Horigome, A.; Tsu, T.; Karisma, A.D.; Maeda, N.; Huang, A.-N.; Fukui, K. Utilization of Incineration Fly Ash from Biomass Power Plants for Zeolite Synthesis from Coal Fly Ash by Hydrothermal Treatment. Fuel Process. Technol. 2017, 167, 92–98. [Google Scholar] [CrossRef]

- Shi, Y.; Wei, L.; Sun, H.; Li, Y.; Cui, J.; Zhang, W. Preparation and Characterization of Biomass-Ash Composites Derived from Incinerated Sewage Sludge Fly Ash after Hydrothermal Treatment. Proc. Inst. Mech. Eng. Part J Mater. Des. Appl. 2024, 238, 1778–1790. [Google Scholar] [CrossRef]

- Lam, C.H.K.; Ip, A.W.M.; Barford, J.P.; McKay, G. Use of Incineration MSW Ash: A Review. Sustainability 2010, 2, 1943–1968. [Google Scholar] [CrossRef]

- Margallo, M.; Taddei, M.B.M.; Hernández-Pellón, A.; Aldaco, R.; Irabien, Á. Environmental Sustainability Assessment of the Management of Municipal Solid Waste Incineration Residues: A Review of the Current Situation. Clean Technol. Environ. Policy 2015, 17, 1333–1353. [Google Scholar] [CrossRef]

- Wang, L.; Li, R.D.; Li, Y.L.; Wei, L.H. Release of Soluble Salts and Heavy Metals during the Short-Time Washing Process of MSWI Fly Ash. Adv. Mater. Res. 2012, 518–523, 3247–3251. [Google Scholar] [CrossRef]

- Phua, Z.; Giannis, A.; Dong, Z.-L.; Lisak, G.; Ng, W.J. Characteristics of Incineration Ash for Sustainable Treatment and Reutilization. Environ. Sci. Pollut. Res. 2019, 26, 16974–16997. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Liao, W.-P.; Wu, P.-H. Basic Characteristics of Leachate Produced by Various Washing Processes for MSWI Ashes in Taiwan. J. Environ. Manag. 2012, 104, 67–76. [Google Scholar] [CrossRef] [PubMed]

- Zhu, F.; Takaoka, M.; Oshita, K.; Kitajima, Y.; Inada, Y.; Morisawa, S.; Tsuno, H. Chlorides Behavior in Raw Fly Ash Washing Experiments. J. Hazard. Mater. 2010, 178, 547–552. [Google Scholar] [CrossRef]

- Weibel, G.; Eggenberger, U.; Kulik, D.A.; Hummel, W.; Schlumberger, S.; Klink, W.; Fisch, M.; Mäder, U.K. Extraction of Heavy Metals from MSWI Fly Ash Using Hydrochloric Acid and Sodium Chloride Solution. Waste Manag. 2018, 76, 457–471. [Google Scholar] [CrossRef]

- Ma, G.X.; Zhang, H.Y. Washing of the Ash from One Shanghai Plant Using Phosphoric Acid. Adv. Mater. Res. 2013, 664, 228–231. [Google Scholar] [CrossRef]

- Pöykiö, R.; Nurmesniemi, H.; Dahl, O.; Mäkelä, M. Chemical Fractionation Method for Characterization of Biomass-Based Bottom and Fly Ash Fractions from Large-Sized Power Plant of an Integrated Pulp and Paper Mill Complex. Trans. Nonferrous Met. Soc. China 2014, 24, 588–596. [Google Scholar] [CrossRef]

- Chen, W.-S.; Chang, F.-C.; Shen, Y.-H.; Tsai, M.-S.; Ko, C.-H. Removal of Chloride from MSWI Fly Ash. J. Hazard. Mater. 2012, 237–238, 116–120. [Google Scholar] [CrossRef]

- Kanhar, A.H.; Chen, S.; Wang, F. Incineration Fly Ash and Its Treatment to Possible Utilization: A Review. Energies 2020, 13, 6681. [Google Scholar] [CrossRef]

- Ottosen, L.M.; Jensen, P.E.; Kirkelund, G.M. Phosphorous Recovery from Sewage Sludge Ash Suspended in Water in a Two-Compartment Electrodialytic Cell. Waste Manag. 2016, 51, 142–148. [Google Scholar] [CrossRef] [PubMed]

- Ebbers, B.; Ottosen, L.M.; Jensen, P.E. Comparison of Two Different Electrodialytic Cells for Separation of Phosphorus and Heavy Metals from Sewage Sludge Ash. Chemosphere 2015, 125, 122–129. [Google Scholar] [CrossRef] [PubMed]

- Ebbers, B.; Ottosen, L.M.; Jensen, P.E. Electrodialytic Treatment of Municipal Wastewater and Sludge for the Removal of Heavy Metals and Recovery of Phosphorus. Electrochim. Acta 2015, 181, 90–99. [Google Scholar] [CrossRef]

- Guedes, P.; Couto, N.; Ottosen, L.M.; Ribeiro, A.B. Phosphorus Recovery from Sewage Sludge Ash through an Electrodialytic Process. Waste Manag. 2014, 34, 886–892. [Google Scholar] [CrossRef]

- Pedersen, A.J. Characterization and Electrodialytic Treatment of Wood Combustion Fly Ash for the Removal of Cadmium. Biomass Bioenergy 2003, 25, 447–458. [Google Scholar] [CrossRef]

- Ferreira, C.D.; Jensen, P.; Ottosen, L.; Ribeiro, A. Preliminary Treatment of MSW Fly Ash as a Way of Improving Electrodialytic Remediation. J. Environ. Sci. Health Part A 2008, 43, 837–843. [Google Scholar] [CrossRef]

- Chen, W.; Jensen, P.E.; Ottosen, L.M.; Kirkelund, G.M. Electrodialytic Remediation of Fly Ash from Co-Combustion of Wood and Straw. Electrochim. Acta 2015, 181, 208–216. [Google Scholar] [CrossRef]

- Chen, W.; Ottosen, L.M.; Jensen, P.; Kirkelund, G.M.; Schmidt, J.W. A Comparative Study on Electrodialytically Treated Bio-Ash and MSWI APC-Residue for Use in Bricks. In Proceedings of the 5th International Conference on Engineering for Waste and Biomass Valorization (WasteEng2014), Rio de Janeiro, Brazil, 25 August 2014; pp. 648–662. [Google Scholar]

- Lima, A.T.; Ottosen, L.M.; Ribeiro, A.B. Assessing Fly Ash Treatment: Remediation and Stabilization of Heavy Metals. J. Environ. Manag. 2010, 95, S110–S115. [Google Scholar] [CrossRef]

- Kirkelund, G.M.; Geiker, M.R.; Jensen, P.E. Electrodialytically Treated MSWI APC Residue as Substitute for Cement in Mortar. Nord. Concr. Res. 2014, 49, 1–16. [Google Scholar]

- Renforth, P. The Negative Emission Potential of Alkaline Materials. Nat. Commun. 2019, 10, 1401. [Google Scholar] [CrossRef] [PubMed]

- Vassilev, S.V.; Vassileva, C.G. Extra CO2 Capture and Storage by Carbonation of Biomass Ashes. Energy Convers. Manag. 2020, 204, 112331. [Google Scholar] [CrossRef]

- Pan, S.-Y.; Chen, Y.-H.; Fan, L.-S.; Kim, H.; Gao, X.; Ling, T.-C.; Chiang, P.-C.; Pei, S.-L.; Gu, G. CO2 Mineralization and Utilization by Alkaline Solid Wastes for Potential Carbon Reduction. Nat. Sustain. 2020, 3, 399–405. [Google Scholar] [CrossRef]

- Liu, W.; Teng, L.; Rohani, S.; Qin, Z.; Zhao, B.; Xu, C.C.; Ren, S.; Liu, Q.; Liang, B. CO2 Mineral Carbonation Using Industrial Solid Wastes: A Review of Recent Developments. Chem. Eng. J. 2021, 416, 129093. [Google Scholar] [CrossRef]

- Kim, J.; Azimi, G. The CO2 Sequestration by Supercritical Carbonation of Electric Arc Furnace Slag. J. CO2 Util. 2021, 52, 101667. [Google Scholar] [CrossRef]

- Carević, I.; Štirmer, N.; Serdar, M.; Ukrainczyk, N. Effect of Wood Biomass Ash Storage on the Properties of Cement Composites. Materials 2021, 14, 1632. [Google Scholar] [CrossRef]

- Chen, T.-L.; Jiang, W.; Shen, A.-L.; Chen, Y.-H.; Pan, S.-Y.; Chiang, P.-C. CO2 Mineralization and Utilization Using Various Calcium-Containing Wastewater and Refining Slag via a High-Gravity Carbonation Process. Ind. Eng. Chem. Res. 2020, 59, 7140–7150. [Google Scholar] [CrossRef]

- Polettini, A.; Pomi, R. The Leaching Behavior of Incinerator Bottom Ash as Affected by Accelerated Ageing. J. Hazard. Mater. 2004, 113, 209–215. [Google Scholar] [CrossRef]

- Ohenoja, K.; Körkkö, M.; Wigren, V.; Österbacka, J.; Illikainen, M. Increasing the Utilization Potential of Fly Ashes from Fluidized Bed Combustion by Mechanical Treatments. Int. J. Environ. Sci. Technol. 2019, 16, 1839–1846. [Google Scholar] [CrossRef]

- Zhang, T.; Yu, Q.; Wei, J.; Zhang, P. Effect of Size Fraction on Composition and Pozzolanic Activity of High Calcium Fly Ash. Adv. Cem. Res. 2011, 23, 299–307. [Google Scholar] [CrossRef]

- Berra, M.; Mangialardi, T.; Paolini, A.E. Reuse of Woody Biomass Fly Ash in Cement-Based Materials. Constr. Build. Mater. 2015, 76, 286–296. [Google Scholar] [CrossRef]

| Characteristics | EN 450-1 (%wt) | ASTM C618-23 (%wt) |

|---|---|---|

| LOI | A ≤ 5–B ≤ 7–C ≤ 9 | ≤6 |

| SiO2 + Al2O3 + Fe2O3 | ≥70 | ≥50 |

| Chloride | ≤0.1 | - |

| Sulfate (SO3) | ≤3 | ≤5 |

| Free CaO | ≤1.5 | - |

| Reactive CaO | ≤10 | F≤18–C>18 |

| Reactive SiO2 | ≥25 | - |

| Moisture Content | - | ≤3 |

| Total Alkalis (Na + K) | ≤5 | - |

| MgO | ≤4 | - |

| P2O5 | ≤5 | - |

| Fineness (45 μm) | S ≤ 12–N ≤ 40 | ≤34 |

| Activity Index (7 day) | - | ≥75 |

| Activity Index (28 day) | ≥75 | ≥75 |

| Activity Index (90 day) | ≥85 | - |

| Ash Type | Source | Treatment | Substitution Ratio (%) | Reference Strength (MPa) | Untreated Strength (MPa) | Treated Strength (MPa) | Effect of Treatment |

|---|---|---|---|---|---|---|---|

| BBA | Wood and timber combustion | Mechano-Chemical Activation | 40% | 36.80 | 6.24 | 23.17 | +271.31% |

| Mineral Carbonation and MCA | 40% | 36.80 | 6.24 | 10.48 | +67.95% | ||

| BBA | Wood (whole tress and primarily pine) | Sieving–Washing | 20% | 69.90 | 51.10 | 59.30 | +16.05% |

| BFA | 70% forest residues and 30% peat | Classification | 20% | 49.40 | 25.80 | 29.00 | +12.40% |

| Classification + Grinding | 20% | 49.40 | 25.80 | 36.60 | +41.86% | ||

| BFA | 60% forest residues, 30% recycling waste, and 10% paper sludge | Classification | 20% | 49.40 | 27.80 | 29.20 | +5.04% |

| Classification + Grinding | 20% | 49.40 | 27.80 | 34.20 | +23.02% | ||

| BFA | 40% peat, 50% forest residues, and 10% recycled wood waste | Classification | 20% | 49.40 | 31.40 | 36.60 | +16.56% |

| Classification + Grinding | 20% | 49.40 | 31.40 | 38.40 | +22.29% | ||

| BBA | Olive tree prunings | Washing | 20% | 58.03 | 25.12 | 27.61 | +9.91% |

| Heat Treatment | 20% | 58.03 | 25.12 | 29.12 | +15.92% | ||

| Grinding | 20% | 58.03 | 25.12 | 36.18 | +44.03% | ||

| Washing + Heat Treatment | 20% | 58.03 | 25.12 | 33.21 | +32.21% | ||

| Washing + Grinding | 20% | 58.03 | 25.12 | 38.92 | +54.94% | ||

| Heat Treatment + Grinding | 20% | 58.03 | 25.12 | 44.17 | +75.84% | ||

| Washing + Heat Treatment + Grinding | 20% | 58.03 | 25.12 | 51.96 | +106.85% | ||

| BFA | Wood chips | Washing | 15% | 46.50 | 40.00 | 38.00 | −5.00% |

| Washing | 30% | 46.50 | 38.20 | 39.00 | +2.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bülbül, F.; Courard, L. Turning Waste into Greener Cementitious Building Material: Treatment Methods for Biomass Ashes—A Review. Materials 2025, 18, 834. https://doi.org/10.3390/ma18040834

Bülbül F, Courard L. Turning Waste into Greener Cementitious Building Material: Treatment Methods for Biomass Ashes—A Review. Materials. 2025; 18(4):834. https://doi.org/10.3390/ma18040834

Chicago/Turabian StyleBülbül, Fatih, and Luc Courard. 2025. "Turning Waste into Greener Cementitious Building Material: Treatment Methods for Biomass Ashes—A Review" Materials 18, no. 4: 834. https://doi.org/10.3390/ma18040834

APA StyleBülbül, F., & Courard, L. (2025). Turning Waste into Greener Cementitious Building Material: Treatment Methods for Biomass Ashes—A Review. Materials, 18(4), 834. https://doi.org/10.3390/ma18040834