Influence of PEA on Volume Stability of Cement-Based Grouting Materials and Its Mechanism

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mixture Proportions and Preparation

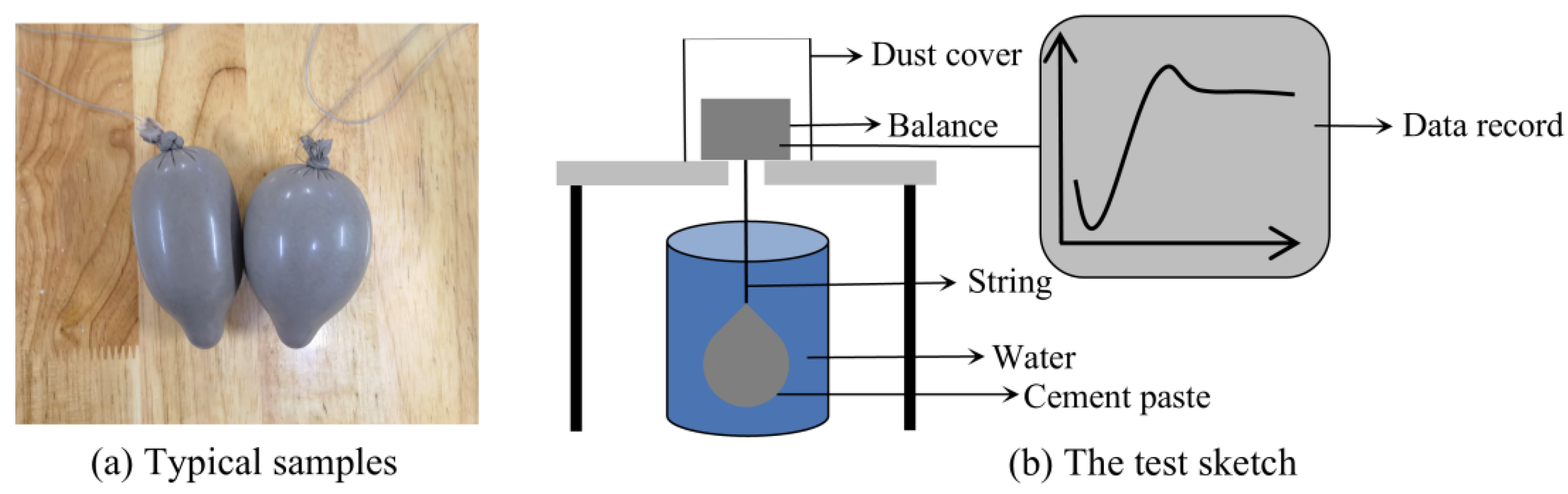

2.3. Test Methods

3. Results

3.1. Volume Expansion/Shrinkage Rate

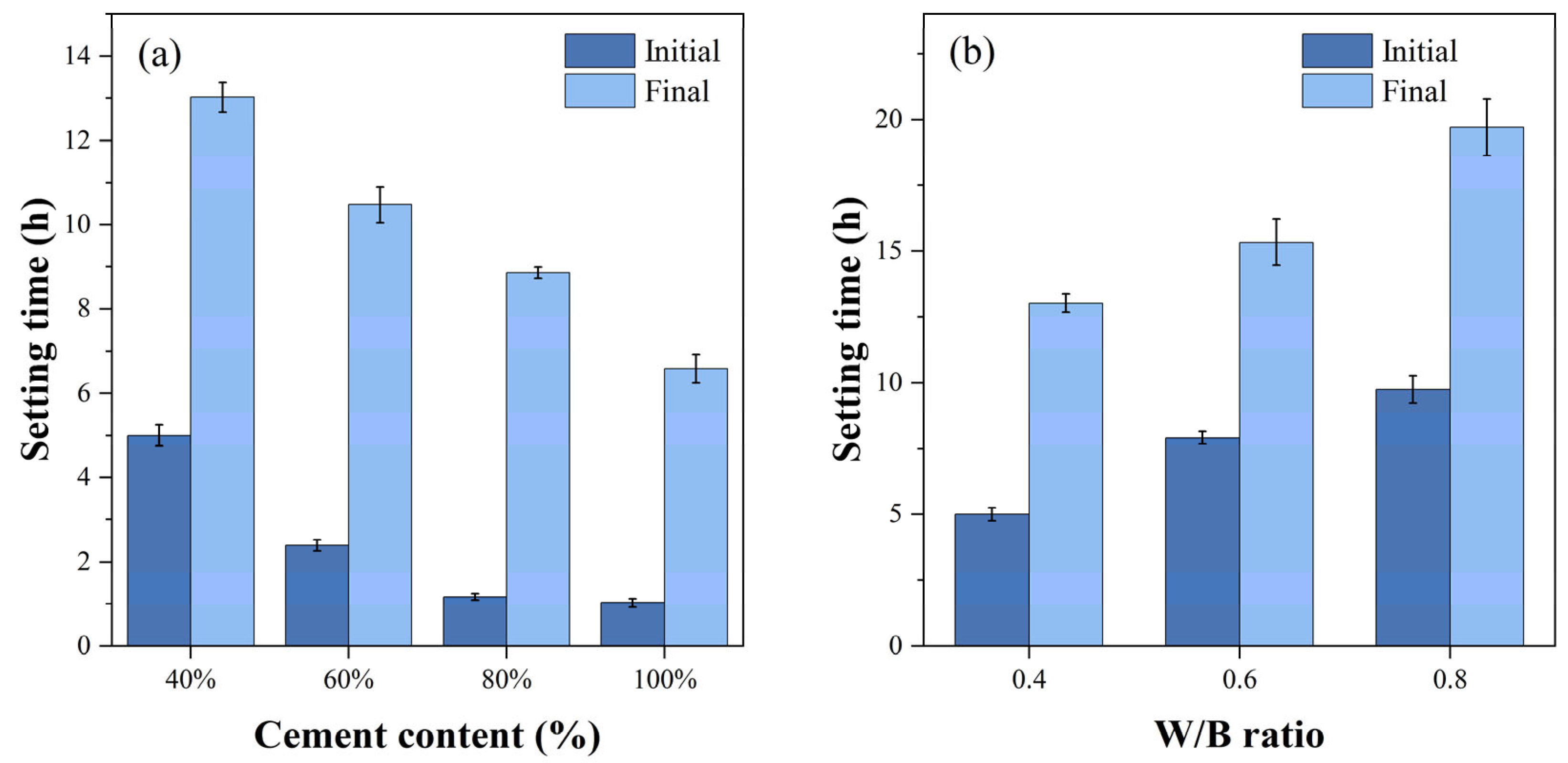

3.2. Setting Time

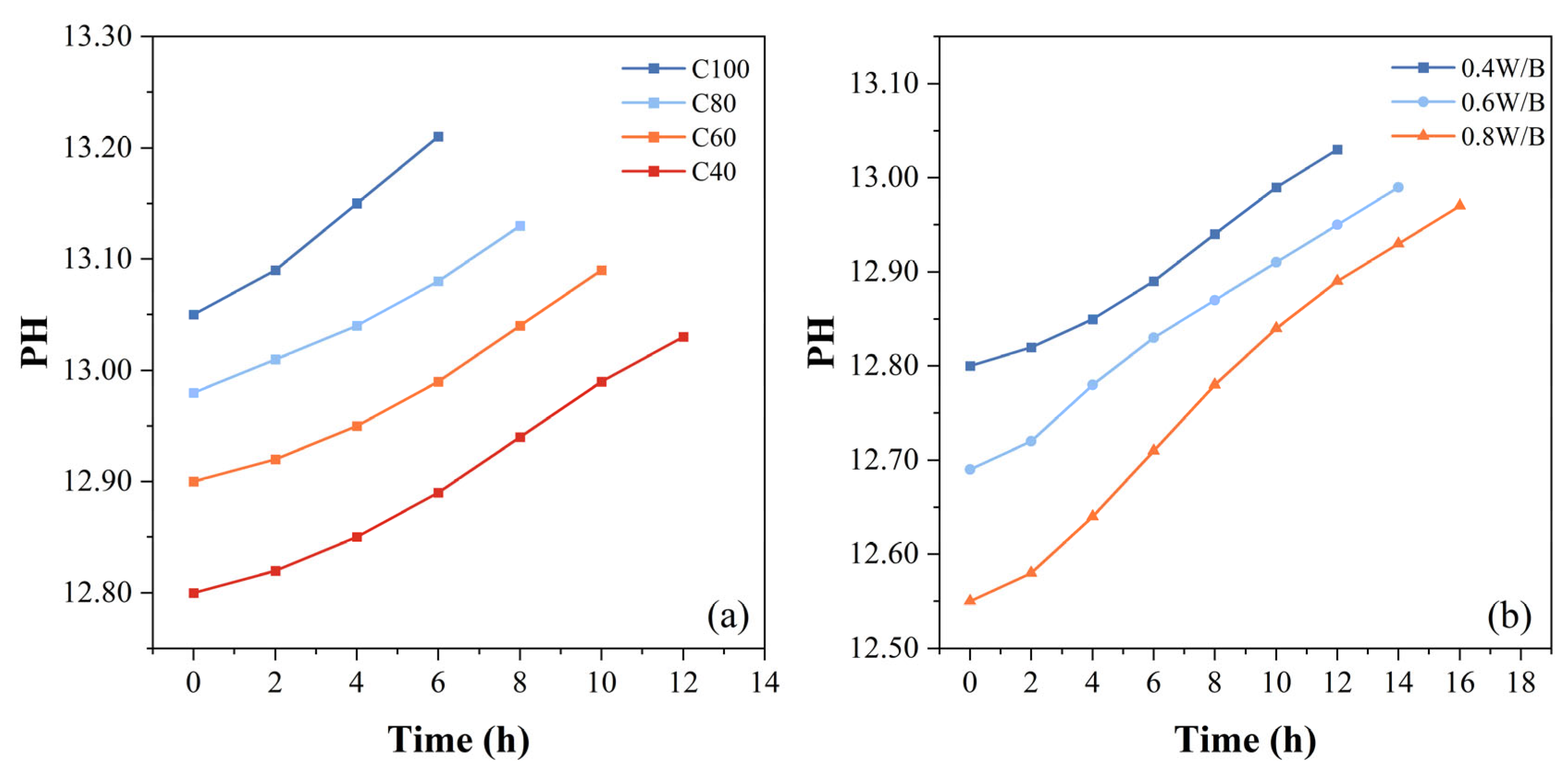

3.3. pH

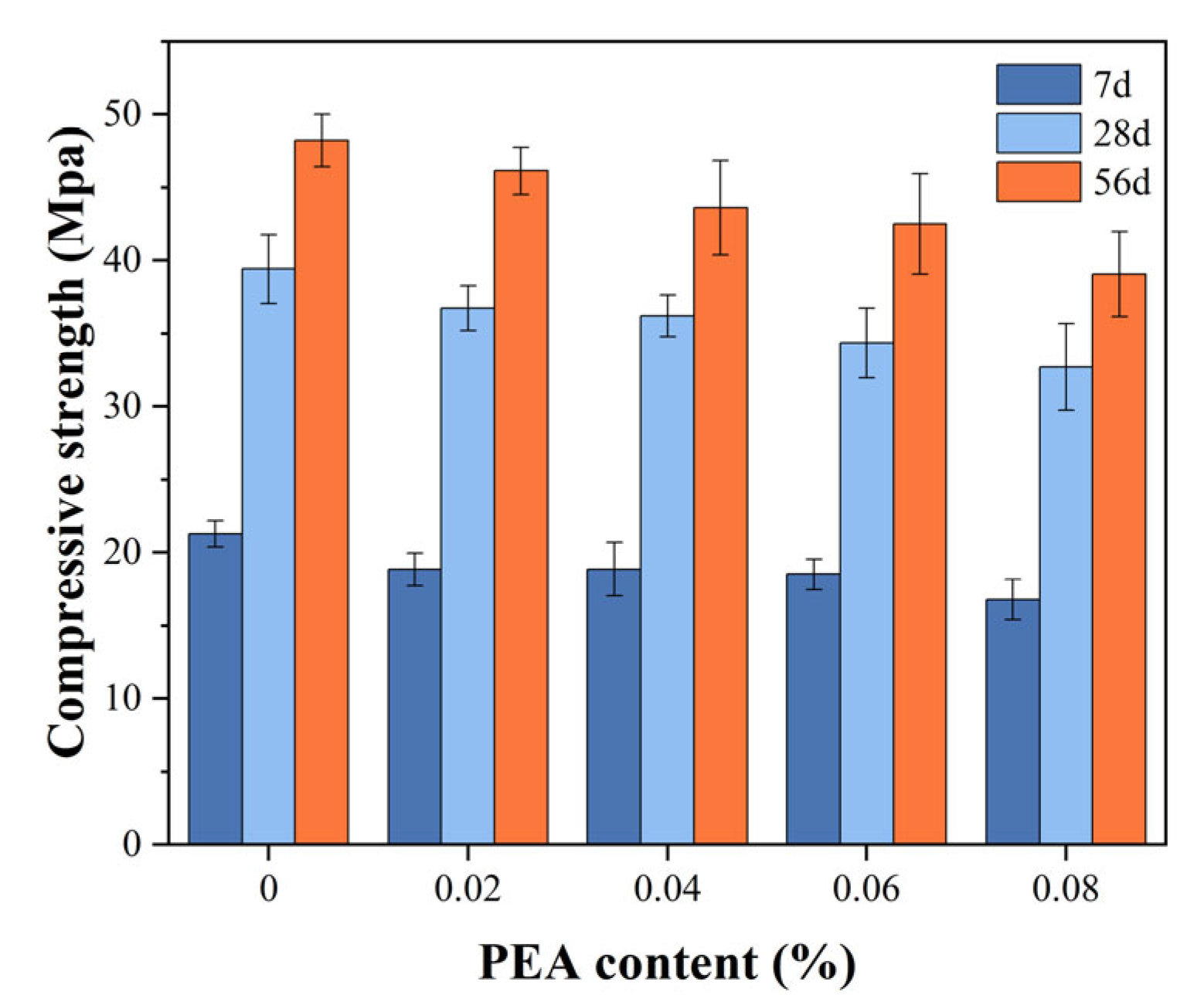

3.4. Compressive Strength

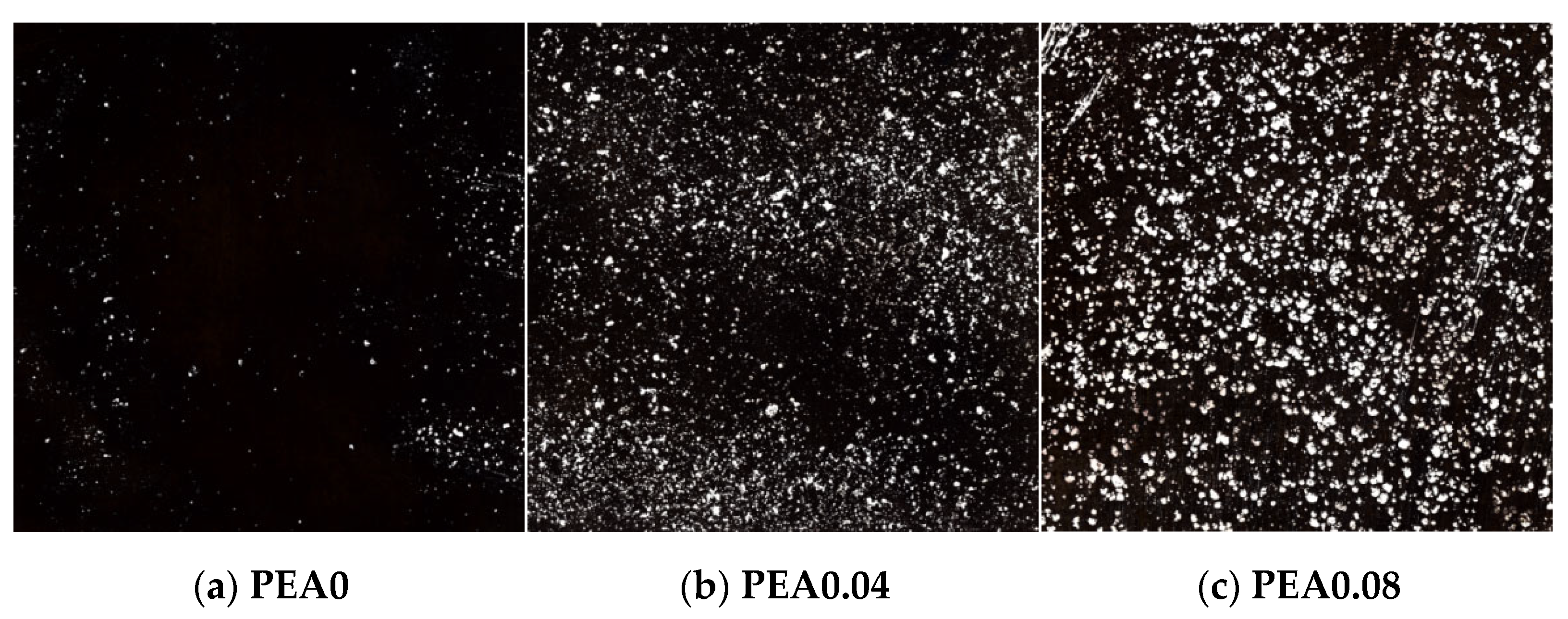

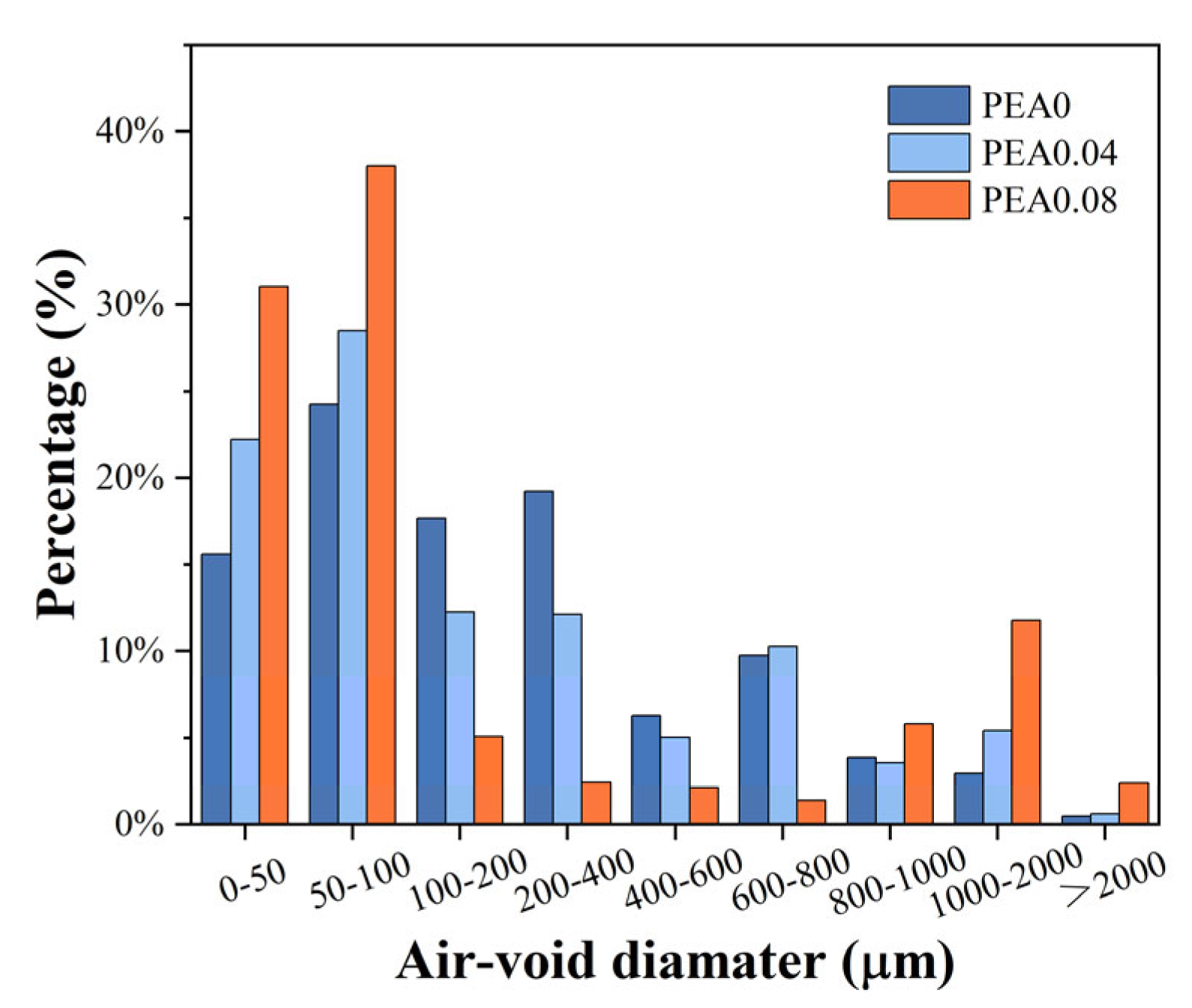

3.5. Air-Void Parameters

4. Discussion

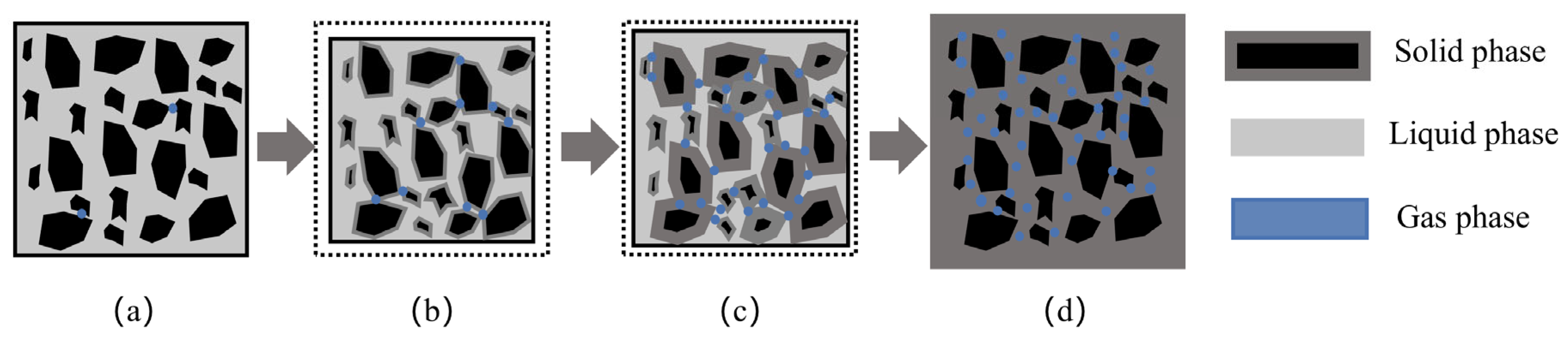

4.1. Mechanisms of Expansion Effect of PEA

4.1.1. Expansion Process of PEA

4.1.2. The Effects of PEA on Cracking Resistance

4.2. The Effects of Mixture Proportions on Expansion Mechanism of PEA

5. Conclusions

- (1).

- The expansion process of PEA could be clearly divided into three stages: the incubation period, the window period, and the stabilization period. The window period was correlated with the setting time of the grout. Once the grout reaches its final setting and attains a certain strength, PEA struggles to produce effective expansion.

- (2).

- As the content of PEA increased, the grout’s resistance to cracking improved. The expansion mechanism involves generating tiny bubbles during the grout’s early shrinkage stage. These air bubbles increase in volume, compensating for the early shrinkage and potentially causing slight expansion.

- (3).

- The bubble spacing coefficient effectively illustrates the impact of PEA on gas production. As the PEA content increased, the bubble spacing coefficient decreased and air contents increased. However, it is not advisable to blindly increase its content. Its higher content can hinder the compaction of the grout structure, leading to a decrease in the compressive strength of the grout. Therefore, there exists an optimal dosage range for the grout containing PEA of approximately between 0.04% and 0.06%.

- (4).

- The mixture proportions play a crucial role in influencing the hydration process of fresh grout. The length of the window period is directly tied to the setting time of the grout, with its peak being influenced by the pH level of the grout. By adjusting the mixture proportions, the window period can be effectively planned, allowing cement-based grouting materials containing PEA to exhibit microexpansion properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, G.; Liu, H.; Luo, J.; Xu, H.; Liu, Q.; Zhou, X.; Hu, Y.; Liu, X. Preparation of a New Borehole Sealing Material of Coal Seam Water Infusion. Adv. Mater. Sci. Eng. 2018, 2018, 5924614. [Google Scholar] [CrossRef]

- Jian, L.M.; Zhao, X.-Y.; Wu, J.; Yan, H.-Y.; Wan, Y.-H.; Wang, S.; Zhang, C.; Long, R.-X. Preparation, properties and grouting process simulation of cement-based grout for loose deposits. Constr. Build. Mater. 2022, 360, 129596. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, Z.; Wang, D.; Tan, Q.; Wu, W.; Zhu, L. Influence of Recycled Cement Paste Powder on Early-Age Plastic Shrinkage and Cracking of Cement-Based Materials. Sustainability 2023, 15, 10661. [Google Scholar] [CrossRef]

- Holt, E.; Leivo, M. Cracking risks associated with early age shrinkage. Cem. Concr. Compos. 2004, 26, 521–530. [Google Scholar] [CrossRef]

- Šmilauer, V.; Dohnalová, L.; Martauz, P. Shrinkage and Creep Properties of Low-Carbon Hybrid Cement. Materials 2024, 17, 4417. [Google Scholar] [CrossRef] [PubMed]

- Hong, M.; Lei, D.; Zhu, F.; Bai, P.; He, J. Experimental research on aggregate restrained shrinkage and cracking of early-age cement paste. Cem. Concr. Res. 2023, 172, 107246. [Google Scholar] [CrossRef]

- Ghourchian, S.; Wyrzykowski, M.; Plamondon, M.; Lura, P. On the mechanism of plastic shrinkage cracking in fresh cementitious materials. Cem. Concr. Res. 2019, 115, 251–263. [Google Scholar] [CrossRef]

- Ozbay, E.; Erdemir, M.; Durmus, H.I. Utilization and efficiency of ground granulated blast furnace slag on concrete properties—A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Du, P.; Yang, J.; Chu, H.; Lu, X.; Cheng, X. Influence of additional components on mechanical and shrinkage properties of high performance cementitious grouting materials. Case Stud. Constr. Mater. 2024, 21, e03425. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, H.; Su, J.; He, H.; Zhao, Y.; Wang, J. Effect of sodium sulfate and gypsum on performances of expansive grouting material with aluminum as expansion agent. Constr. Build. Mater. 2023, 394, 132212. [Google Scholar] [CrossRef]

- Sun, Y.; Meng, X.; Fan, J.; Wang, S. Study on the mechanical properties and hydration synergy of MEA and UEA modified ultrafine cement grouting materials. Constr. Build. Mater. 2024, 423, 135898. [Google Scholar] [CrossRef]

- Shu, X.; Zhao, Y.; Liu, Z.; Zhao, C. A study on the mix proportion of fiber-polymer composite reinforced cement-based grouting material. Constr. Build. Mater. 2022, 328, 127025. [Google Scholar] [CrossRef]

- Chen, Y.; Xian, R.; Wang, J.; Hu, Z.; Wang, W. Synergetic Effect of Superabsorbent Polymer and CaO-Based Expansive Agent on Mitigating Autogenous Shrinkage of UHPC Matrix. Materials 2023, 16, 2814. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Mao, Z.; Huang, X.; Luo, P.; Deng, M.; Tang, M. Effect of Curing Conditions on the Hydration of MgO in Cement Paste Mixed with MgO Expansive Agent. Materials 2023, 16, 4032. [Google Scholar] [CrossRef]

- Mo, L.; Deng, M.; Wang, A. Effects of MgO-based expansive additive on compensating the shrinkage of cement paste under non-wet curing conditions. Cem. Concr. Compos. 2012, 34, 377–383. [Google Scholar] [CrossRef]

- Kabir, H.; Hooton, R.D. Evaluating soundness of concrete containing shrinkage-compensating MgO admixtures. Constr. Build. Mater. 2020, 253, 119141. [Google Scholar] [CrossRef]

- Yin, N.; Chen, S.; Li, Z.; Ouyang, Y.; Hu, W.; Tang, L.; Zhang, W.; Zhou, B.; Yang, J.; Xu, Q.; et al. Porous bacterial cellulose prepared by a facile surfactant-assisted foaming method in azodicarbonamide-NaOH aqueous solution. Mater. Lett. 2012, 81, 131–134. [Google Scholar] [CrossRef]

- Guo, R.-L.; Liu, S.-H.; Lu, Y.-M. Investigation of how pressure influences the thermal decomposition behavior of azodicarbonamide. J. Loss Prev. Process Ind. 2023, 83, 105062. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, Z.; Liu, J. Freeze-thaw resistance of concrete containing azodicarbonamide expansive agent. Constr. Build. Mater. 2023, 367, 130335. [Google Scholar] [CrossRef]

- Mantaranon, N.; Chirachanchai, S. Polyoxymethylene foam: From an investigation of key factors related to porous morphologies and microstructure to the optimization of foam properties. Polymer 2016, 96, 54–62. [Google Scholar] [CrossRef]

- Zhang, G.; Qiu, D.; Wang, S.; Wang, P. Effects of plastic expansive agent on the fluidity, mechanical strength, dimensional stability and hydration of high performance cementitious grouts. Constr. Build. Mater. 2020, 243, 118204. [Google Scholar] [CrossRef]

- Cheng, P.; Song, X.; Li, B.; Hu, S. Effect of plastic expansion agent on the volume deformation and submicroscopic structure of pre-stressed duct grouting materials. Bull. Chin. Ceram. Soc. 2014, 33, 1329–1335. [Google Scholar] [CrossRef]

- Li, T.; Yue, Z.; Li, J.; Li, Q.; Li, Y.; Chen, G. Experimental study of improved cement silicate grouting material for broken surrounding rock. J. Build. Eng. 2023, 74, 106782. [Google Scholar] [CrossRef]

- Li, B.; Sun, Q.; Chen, X.; Xu, Z.; Yang, L. Preparation and microstructure analysis of alkali-activated ground granulated blast furnace slag-steel slag grouting materials. Case Stud. Constr. Mater. 2024, 20, e03235. [Google Scholar] [CrossRef]

- Avci, E. Silica Fume Effect on Engineering Properties of Superfine Cement-Grouted Sands. J. Mater. Civ. Eng. 2019, 31, 04019269. [Google Scholar] [CrossRef]

- Shen, Q.; Jiang, R.; Cong, B.; Guo, B.; Shang, H.; Ji, X. Study on the effect of mineral admixtures on working and mechanical properties of the grouting material. Front. Mater. 2023, 10, 1197997. [Google Scholar] [CrossRef]

- Dong, D.; Huang, Y.; Pei, Y.; Zhang, X.; Cui, N.; Zhao, P.; Hou, P.; Lu, L. Effect of spherical silica fume and fly ash on the rheological property, fluidity, setting time, compressive strength, water resistance and drying shrinkage of magnesium ammonium phosphate cement. J. Build. Eng. 2023, 63, 105484. [Google Scholar] [CrossRef]

- GB/T 51003-2014; Technical Code for Application of Mineral Admixture. Ministry of Housing and Urban-Rural Development: Beijing, China, 2014.

- Charoeythornkhajhornchai, P.; Samthong, C.; Boonkerd, K.; Somwangthanaroj, A. Effect of azodicarbonamide on microstructure, cure kinetics and physical properties of natural rubber foam. J. Cell. Plast. 2017, 53, 287–303. [Google Scholar] [CrossRef]

- Whitmore, M.W.; Cutler, D.P.; Gladwell, J.P. Venting of bottom-initiated decompositions in azodicarbonamide and its formulations. J. Loss Prev. Process Ind. 1994, 7, 49–56. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). Standardization Administration of China: Beijing, China, 2021.

- Lura, P.; Jensen, O.M. Measuring techniques for autogenous strain of cement paste. Mater. Struct. 2007, 40, 431–440. [Google Scholar] [CrossRef]

- GB/T 1346-2011; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Cement. Standardization Administration of China: Beijing, China, 2011.

- Cairong, L.U.; Xueliang, G.E.; Guoxing, M.E.I. Effect of air void parameters on frost resistance of hydraulic concrete. Mater. Res. Innov. 2015, 19, 389–392. [Google Scholar] [CrossRef]

- Lazniewska-Piekarczyk, B. Examining the possibility to estimate the influence of admixtures on pore structure of self-compacting concrete using the air void analyzer. Constr. Build. Mater. 2013, 41, 374–387. [Google Scholar] [CrossRef]

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Ministry of Hous-ing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2009.

- Sant, G.; Lura, P.; Weiss, J. Measurement of volume change in cementitious materials at early ages—Review of testing protocols and interpretation of results. Transp. Res. Rec. J. Transp. Res. Board 2006, 1979, 21–29. [Google Scholar] [CrossRef]

- Lothenbach, B.; Le Saout, G.; Gallucci, E.; Scrivener, K. Influence of limestone on the hydration of Portland cements. Cem. Concr. Res. 2008, 38, 848–860. [Google Scholar] [CrossRef]

- Wu, L.; Farzadnia, N.; Shi, C.; Zhang, Z.; Wang, H. Autogenous shrinkage of high performance concrete: A review. Constr. Build. Mater. 2017, 149, 62–75. [Google Scholar] [CrossRef]

- Stefan, L.; Boulay, C.; Torrenti, J.-M.; Bissonnette, B.; Benboudjema, F. Influential factors in volume change measurements for cementitious materials at early ages and in isothermal conditions. Cem. Concr. Compos. 2018, 85, 105–121. [Google Scholar] [CrossRef]

- Ruan, W.; Zhang, Z.; Cai, M.; She, Y.; Liu, J.; Guo, W.; Ma, X.; Liao, J.; He, X. Comparative study of the effects of magnesium aluminum silicate and bentonite clay on the properties of magnesium phosphate cement-based grouting material. Constr. Build. Mater. 2023, 401, 132852. [Google Scholar] [CrossRef]

- Xu, W.; Mance, D.; de Lacaillerie, J.-B.d.E.; Flatt, R.J. A sweet answer to how sucrose delays tricalcium silicate hydration. Cem. Concr. Res. 2024, 181, 107531. [Google Scholar] [CrossRef]

- Nicoleau, L.; Nonat, A. A new view on the kinetics of tricalcium silicate hydration. Cem. Concr. Res. 2016, 86, 1–11. [Google Scholar] [CrossRef]

- Qiao, M.; Chen, J.; Yu, C.; Wu, S.; Gao, N.; Ran, Q. Gemini surfactants as novel air entraining agents for concrete. Cem. Concr. Res. 2017, 100, 40–46. [Google Scholar] [CrossRef]

- Shah, H.A.; Yuan, Q.; Zuo, S. Air entrainment in fresh concrete and its effects on hardened concrete-a review. Constr. Build. Mater. 2021, 274, 121835. [Google Scholar] [CrossRef]

- Oh, S.; Kim, J.; Song, C.; Choi, S. Effects of fineness and substitution rate of GGBFS on material characteristics of GGBFS-blended cement mortars: Hydration, non-evaporable water, pore structure, mechanical properties, self-desiccation, and autogenous shrinkage. J. Build. Eng. 2024, 92, 109741. [Google Scholar] [CrossRef]

| Composition (%) | CaO | Al2O3 | SiO2 | Fe2O3 | SO3 | MgO | K2O | Na2O |

|---|---|---|---|---|---|---|---|---|

| OPC 1 | 63.19 | 5.68 | 20.45 | 3.73 | 2.59 | 2.99 | 0.92 | - |

| GGBFS 2 | 37.81 | 18.19 | 31.83 | 0.38 | 1.93 | 8.21 | 0.37 | 0.64 |

| Specimen ID | OPC (%) | GGBFS (%) | PCE 1 (%) | PEA 1 (%) | W/B 2 |

|---|---|---|---|---|---|

| C40 (0.4W/B PEA0.04) | 40 | 60 | 0.3 | 0.04 | 0.4 |

| C60 | 60 | 40 | 0.3 | 0.04 | 0.4 |

| C80 | 80 | 20 | 0.3 | 0.04 | 0.4 |

| C100 | 100 | 0 | 0.3 | 0.04 | 0.4 |

| 0.6W/B | 40 | 60 | 0.3 | 0.04 | 0.6 |

| 0.8W/B | 40 | 60 | 0.3 | 0.04 | 0.8 |

| PEA0 | 40 | 60 | 0.3 | 0 | 0.4 |

| PEA0.02 | 40 | 60 | 0.3 | 0.02 | 0.4 |

| PEA0.06 | 40 | 60 | 0.3 | 0.06 | 0.4 |

| PEA0.08 | 40 | 60 | 0.3 | 0.08 | 0.4 |

| Specimen ID | Specific Surface Area (μm2/µm3) | Average Air-Void Diameter (µm) | Air Content (%) | Air-Void Spacing Factor (µm) |

|---|---|---|---|---|

| PEA0 | 0.051 | 48 | 0.48 | 271 |

| PEA0.04 | 0.046 | 51 | 4.97 | 111 |

| PEA0.08 | 0.037 | 50 | 8.35 | 97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Che, Z.; Wang, T.-L.; Zhou, Z.-G.; Wang, S.; Ma, X.-W. Influence of PEA on Volume Stability of Cement-Based Grouting Materials and Its Mechanism. Materials 2025, 18, 749. https://doi.org/10.3390/ma18040749

Che Z, Wang T-L, Zhou Z-G, Wang S, Ma X-W. Influence of PEA on Volume Stability of Cement-Based Grouting Materials and Its Mechanism. Materials. 2025; 18(4):749. https://doi.org/10.3390/ma18040749

Chicago/Turabian StyleChe, Zheng, Tian-Liang Wang, Zheng-Guo Zhou, Shuo Wang, and Xin-Wei Ma. 2025. "Influence of PEA on Volume Stability of Cement-Based Grouting Materials and Its Mechanism" Materials 18, no. 4: 749. https://doi.org/10.3390/ma18040749

APA StyleChe, Z., Wang, T.-L., Zhou, Z.-G., Wang, S., & Ma, X.-W. (2025). Influence of PEA on Volume Stability of Cement-Based Grouting Materials and Its Mechanism. Materials, 18(4), 749. https://doi.org/10.3390/ma18040749