Effect of Dilution on Microstructure and Phase Transformation of AlCrFeMnNi High-Entropy Alloy by Resonant Ultrasonic Vibration-Assisted Laser Cladding

Abstract

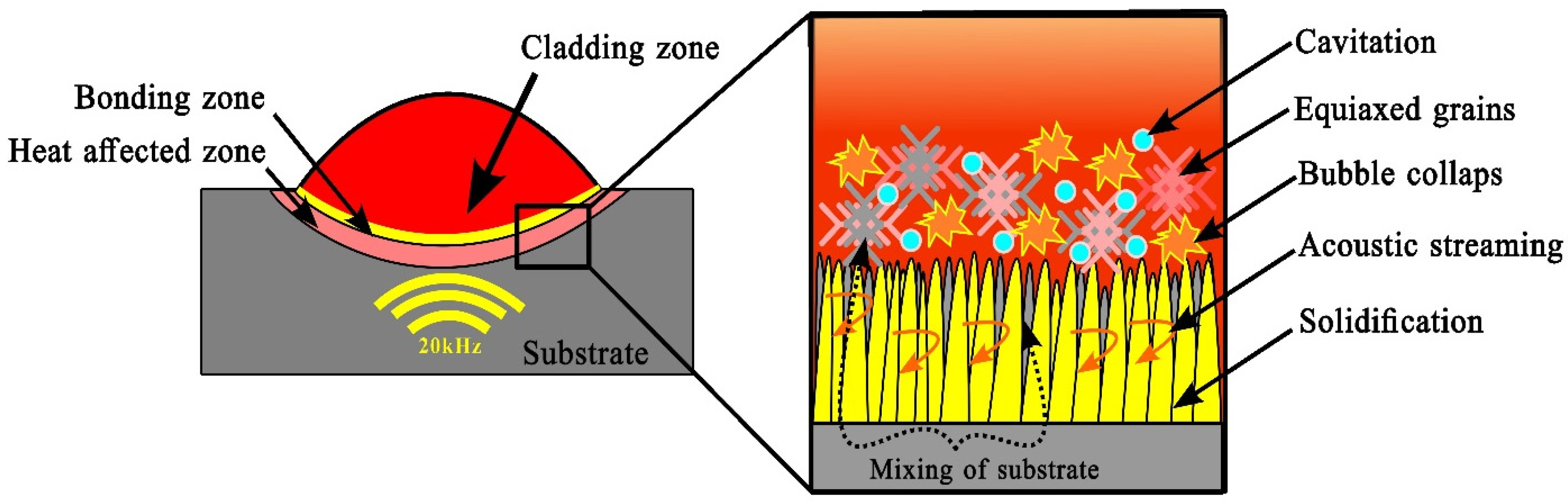

1. Introduction

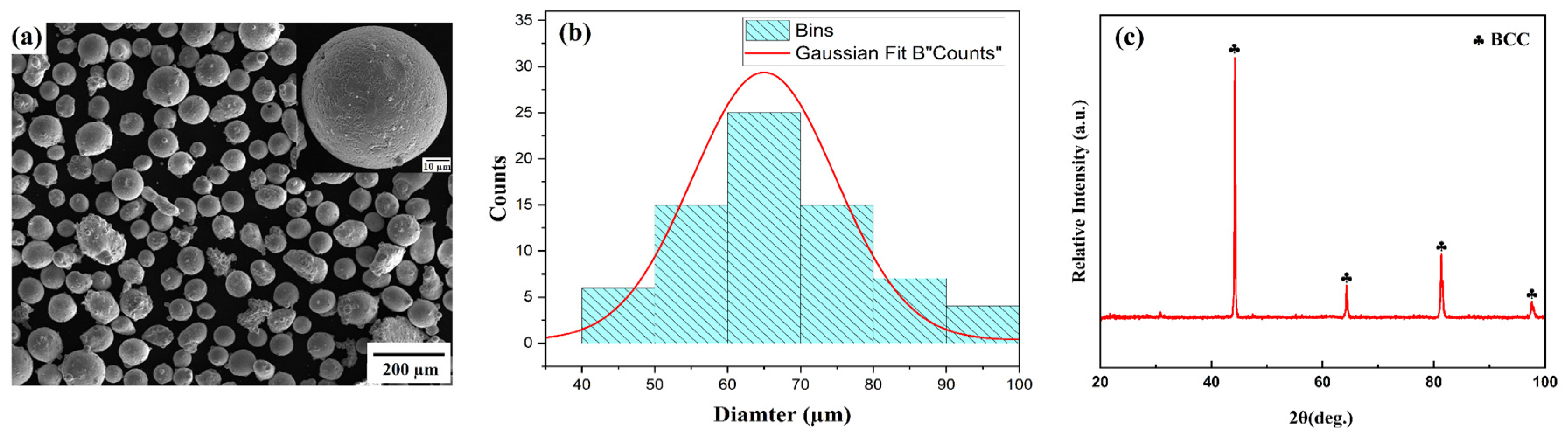

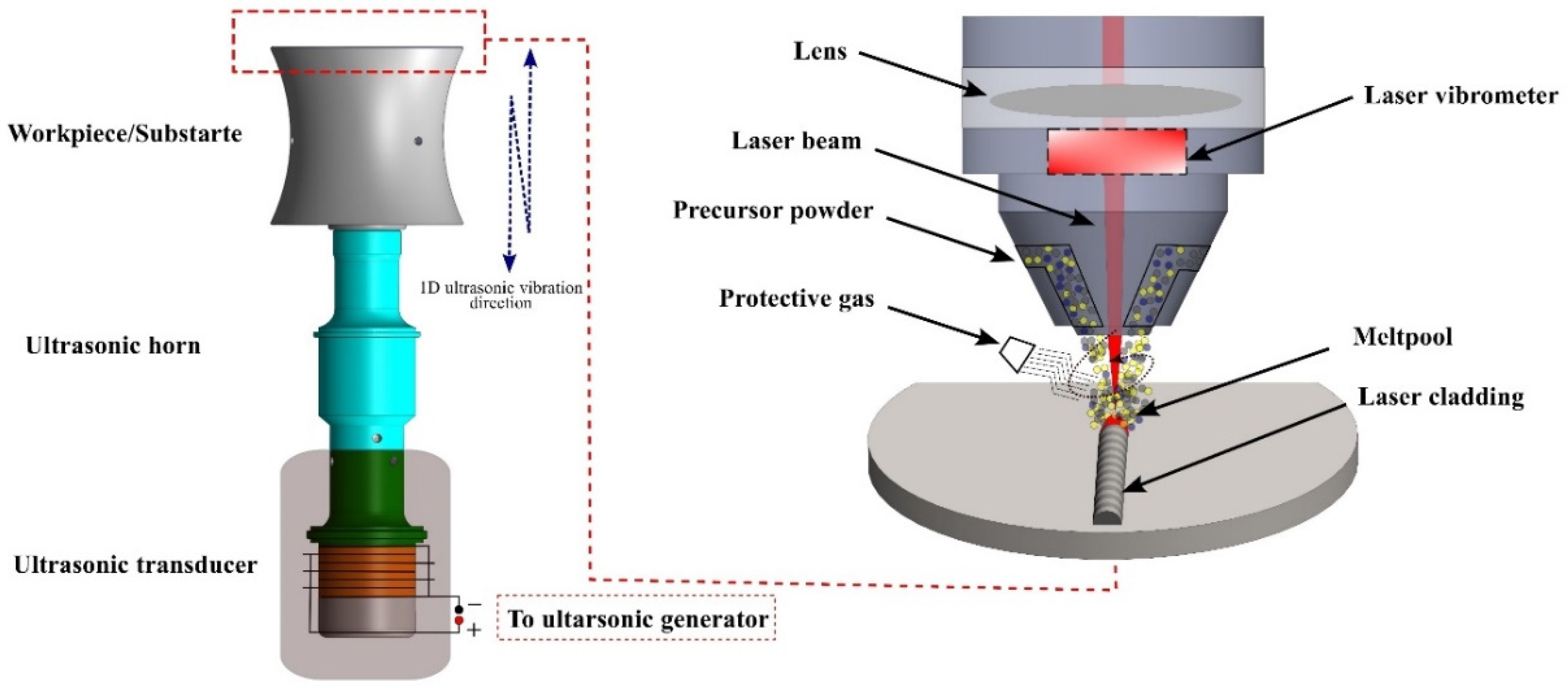

2. Experimental Procedures

3. Results and Discussion

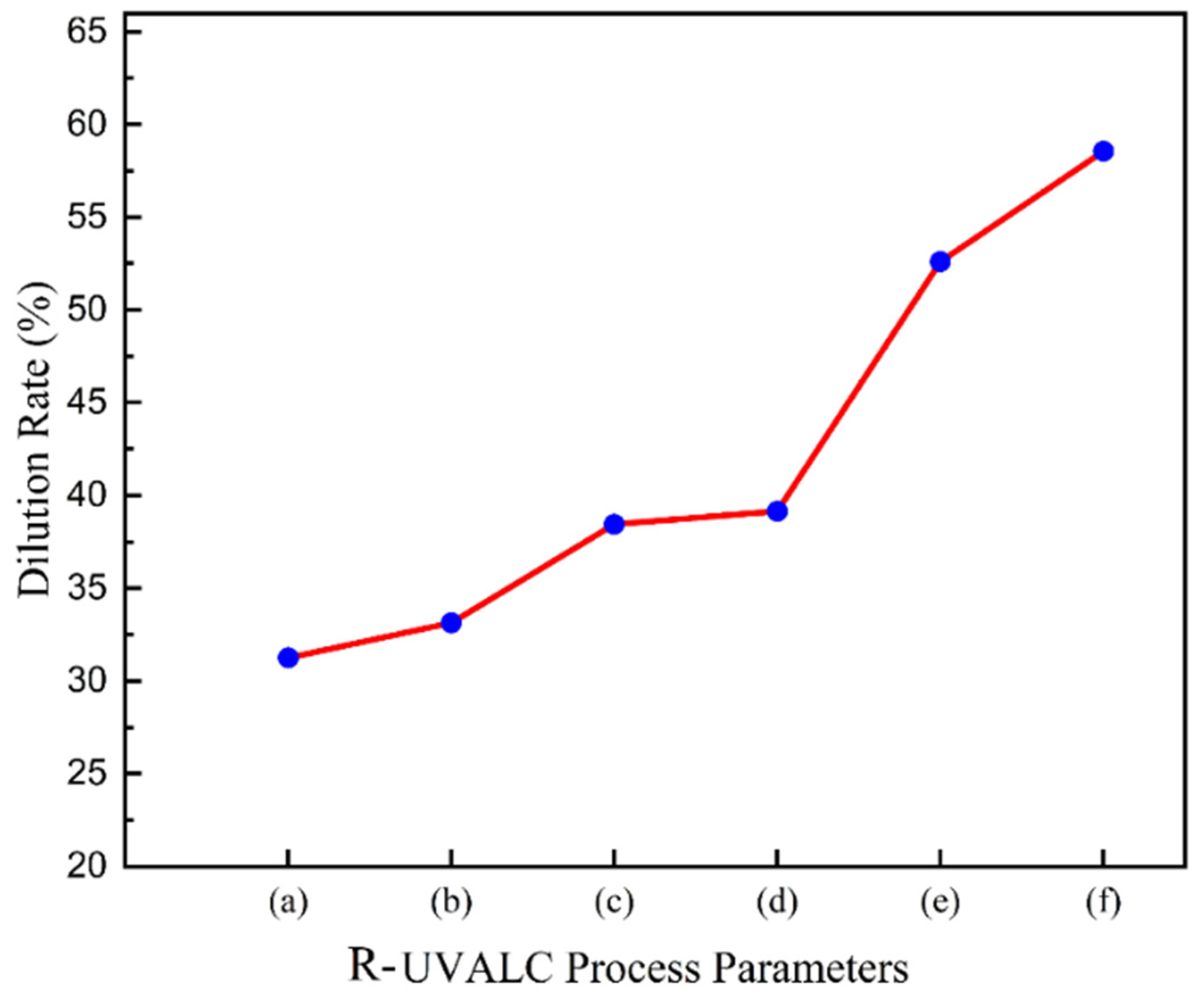

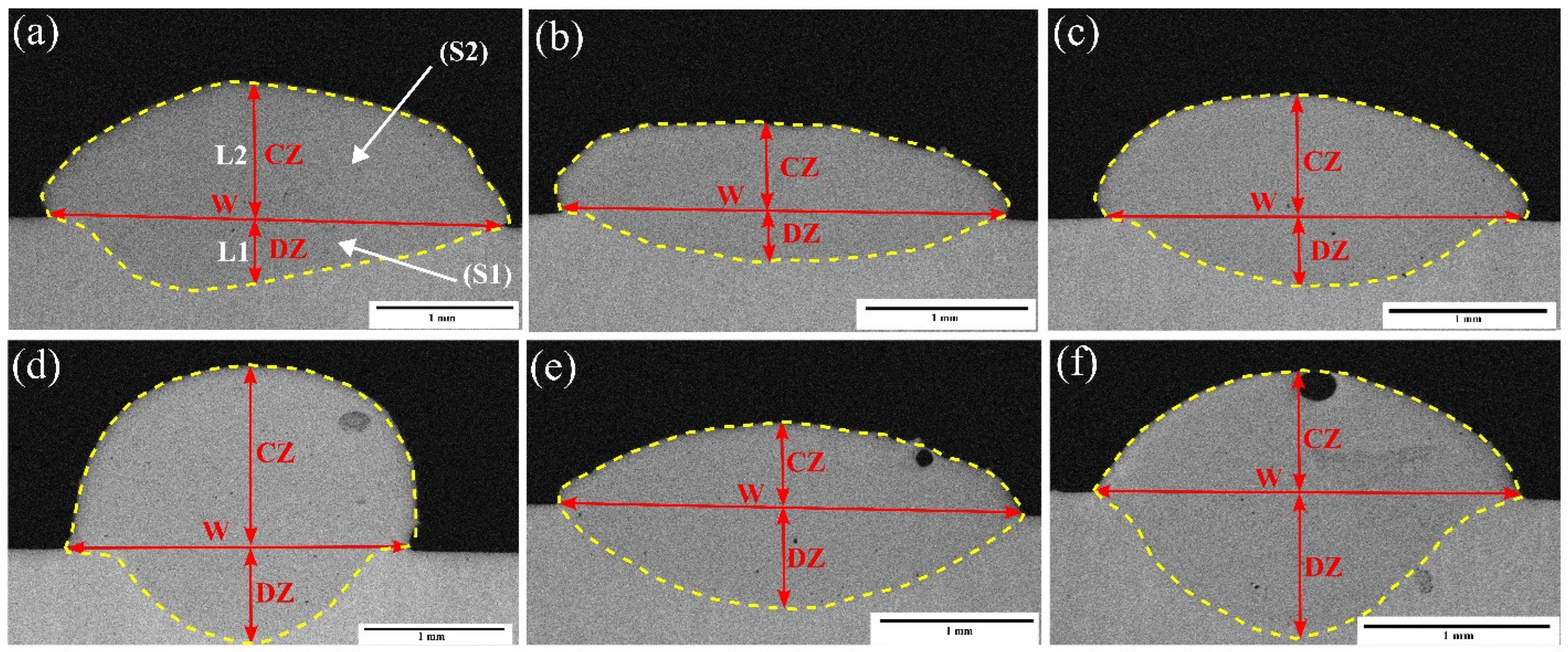

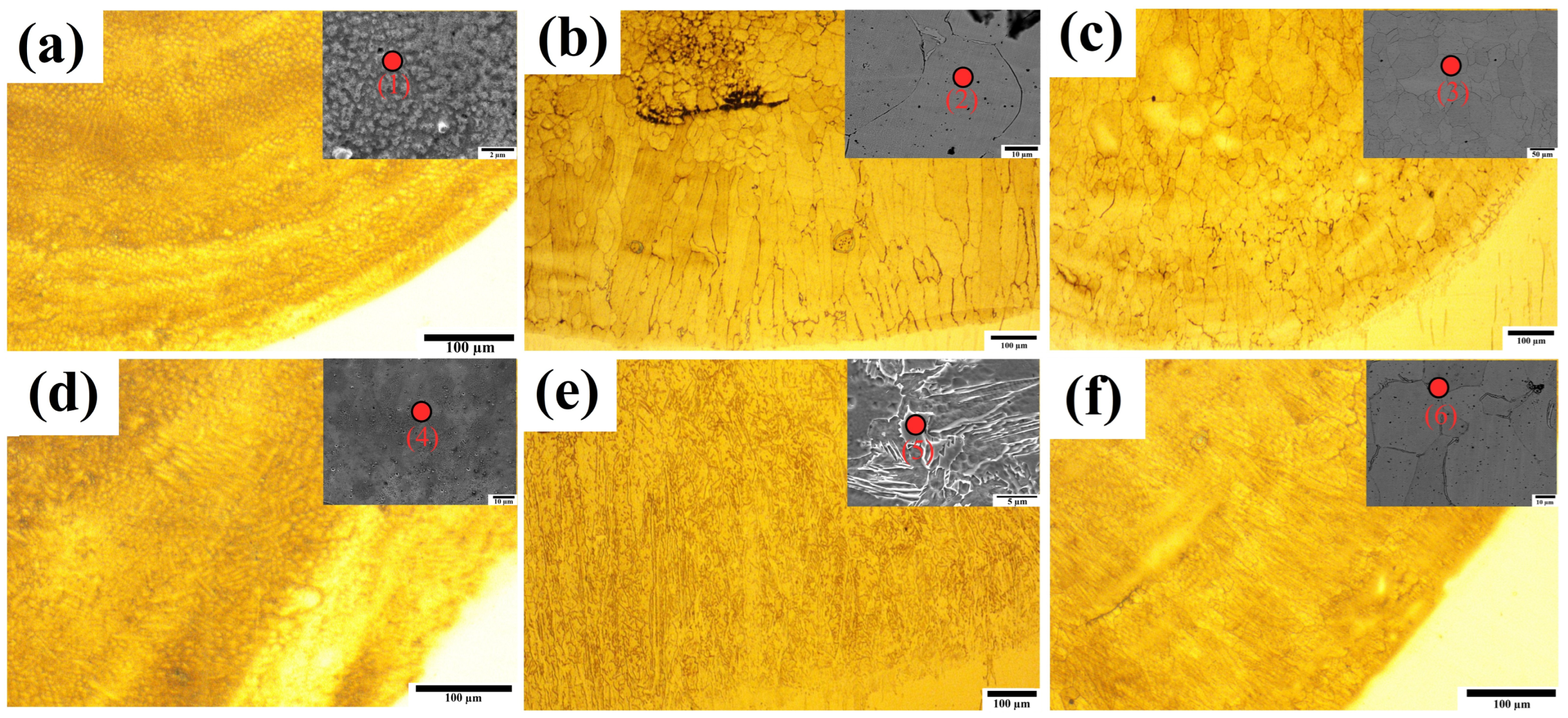

3.1. Dilution Rate

3.2. Phase Transformation

3.3. Microhardness

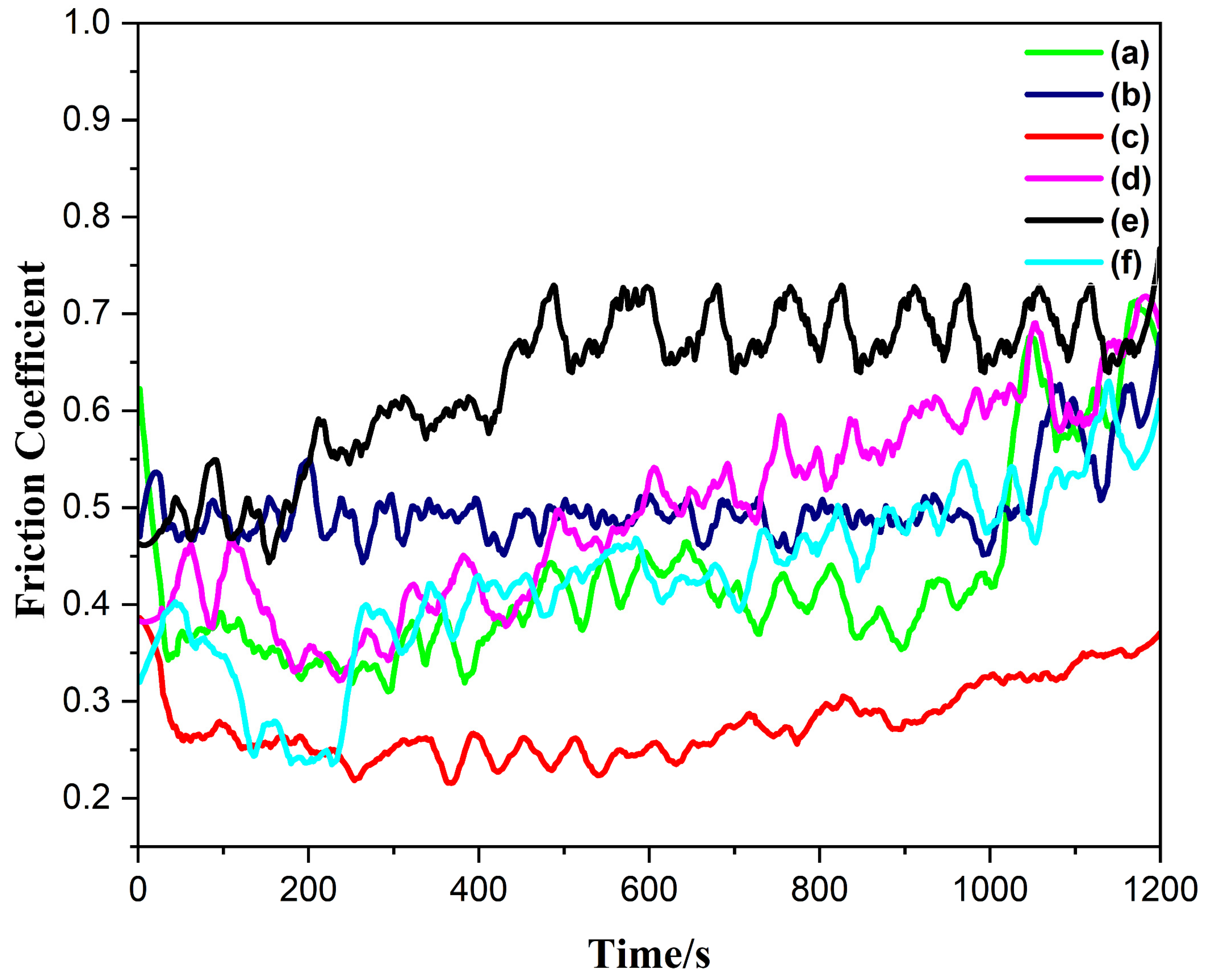

3.4. Friction Coefficient

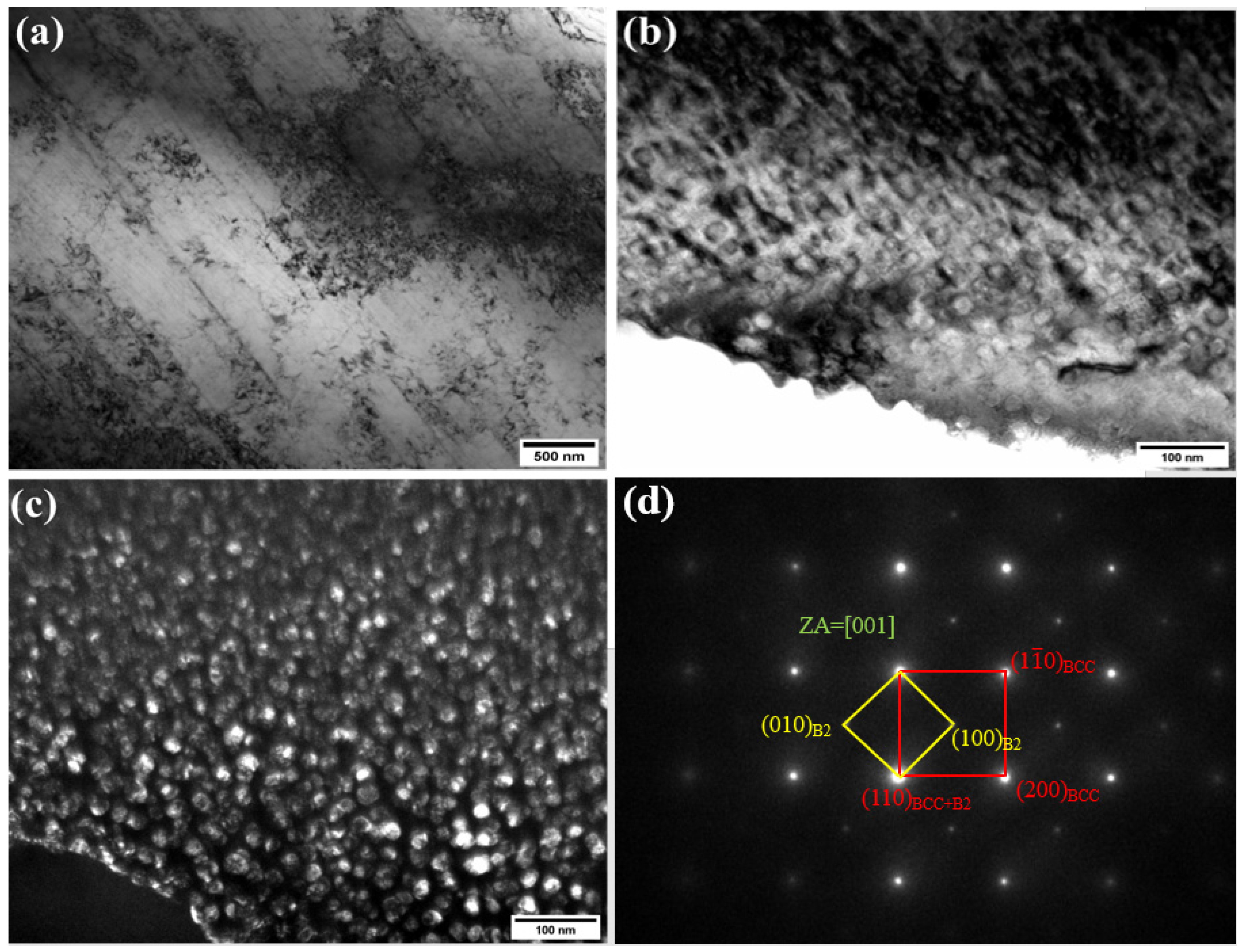

3.5. TEM Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yeh, J.-W.; Chen, S.K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Jiang, H.; Han, K.; Li, D.; Cao, Z. Synthesis and characterization of AlCoCrFeNiNbx high-entropy alloy coatings by laser cladding. Crystals 2019, 9, 56. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, M.; Zhao, G.; Wang, X.; Wang, J. Microstructure and properties of ceramic particle reinforced FeCoNiCrMnTi high entropy alloy laser cladding coating. Intermetallics 2022, 140, 107402. [Google Scholar] [CrossRef]

- Wang, W.R.; Wang, W.L.; Wang, S.C.; Tsai, Y.C.; Lai, C.H.; Yeh, J.W. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 2012, 26, 44–51. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, S.; Wang, H. Effects of the phase content on dynamic damage evolution in Fe50Mn30Co10Cr10 high entropy alloy. J. Alloys Compd. 2021, 851, 156883. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, S.; Wang, Z.Y.; Zhang, C.H.; Zhang, D.X.; Chen, H.T.; Wu, C.L. Phase evolution, microstructure, microhardness and corrosion performance of CoCrFeNiNb x high entropy alloy coatings on 316 stainless steel fabricated by laser cladding. Corros. Eng. Sci. Technol. 2022, 57, 301–310. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, S.; Wang, Z.; Zhang, C.; Chen, H.; Chen, J. New studies on wear and corrosion behavior of laser cladding FeNiCoCrMox high entropy alloy coating: The role of Mo. Int. J. Refract. Met. Hard Mater. 2022, 102, 105721. [Google Scholar] [CrossRef]

- Munitz, A.; Meshi, L.; Kaufman, M. Heat treatments’ effects on the microstructure and mechanical properties of an equiatomic Al-Cr-Fe-Mn-Ni high entropy alloy. Mater. Sci. Eng. A 2017, 689, 384–394. [Google Scholar] [CrossRef]

- Mohsan, A.U.H.; Zhang, M.; Wang, D.; Zhao, S.; Wang, Y.; Chen, C.; Zhang, J. State-of-the-art review on the Ultrasonic Vibration Assisted Laser Cladding (UVALC). J. Manuf. Process. 2023, 107, 422–446. [Google Scholar] [CrossRef]

- Shon, Y.; Joshi, S.S.; Katakam, S.; Rajamure, R.S.; Dahotre, N.B. Laser additive synthesis of high entropy alloy coating on aluminum: Corrosion behavior. Mater. Lett. 2015, 142, 122–125. [Google Scholar] [CrossRef]

- Mohsan, A.U.H.; Zhang, M.; Wang, D.; Wang, Y.; Zhang, J.; Zhou, Y.; Li, Y.; Zhao, S. Design and Effect of Resonant Ultrasonic Vibration-Assisted Laser Cladding (R-UVALC) on AlCrFeMnNi High-Entropy Alloy. Materials 2024, 17, 969. [Google Scholar] [CrossRef]

- Zhu, L.; Yang, Z.; Xin, B.; Wang, S.; Meng, G.; Ning, J.; Xue, P. Microstructure and mechanical properties of parts formed by ultrasonic vibration-assisted laser cladding of Inconel 718. Surf. Coat. Technol. 2021, 410, 126964. [Google Scholar] [CrossRef]

- Zhang, M.; Zhao, G.; Wang, X.; Liu, S.; Ying, W. Microstructure evolution and properties of in-situ ceramic particles reinforced Fe-based composite coating produced by ultrasonic vibration assisted laser cladding processing. Surf. Coatings Technol. 2020, 403, 126445. [Google Scholar] [CrossRef]

- Kim, J.-D.; Peng, Y. Melt pool shape and dilution of laser cladding with wire feeding. J. Mater. Process. Technol. 2000, 104, 284–293. [Google Scholar] [CrossRef]

- Xu, P.; Li, P.; Chen, Y.; Wang, B.; Lu, H.; Xu, C.; Dai, M. Optimization of process parameters for laser cladding Stellite6 cobalt-based alloy. Mater. Today Commun. 2024, 38, 108430. [Google Scholar] [CrossRef]

- Hemmati, I.; Ocelík, V.; De Hosson, J.T.M. Dilution effects in laser cladding of Ni–Cr–B–Si–C hardfacing alloys. Mater. Lett. 2012, 84, 69–72. [Google Scholar] [CrossRef]

- Cui, C.; Wu, M.; Miao, X.; Zhao, Z.; Gong, Y. Microstructure and corrosion behavior of CeO2/FeCoNiCrMo high-entropy alloy coating prepared by laser cladding. J. Alloys Compd. 2022, 890, 161826. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, Y.; Han, J.; Wang, X.; Jiang, W.; Liu, C.T.; Zhang, Z.; Liaw, P.K. Nanoprecipitate-strengthened high-entropy alloys. Adv. Sci. 2021, 8, 2100870. [Google Scholar] [CrossRef]

- Fan, Q.; Chen, C.; Fan, C.; Liu, Z.; Cai, X.; Lin, S.; Yang, C. Ultrasonic induces grain refinement in gas tungsten arc cladding AlCoCrFeNi high-entropy alloy coatings. Mater. Sci. Eng. A 2021, 821, 141607. [Google Scholar] [CrossRef]

- Ma, G.; Yan, S.; Wu, D.; Miao, Q.; Liu, M.; Niu, F. Microstructure evolution and mechanical properties of ultrasonic assisted laser clad yttria stabilized zirconia coating. Ceram. Int. 2017, 43, 9622–9629. [Google Scholar] [CrossRef]

- Chen, Q.; Zhou, K.; Jiang, L.; Lu, Y.; Li, T. Effects of Fe content on microstructures and properties of AlCoCrFe x Ni high-entropy alloys. Arab. J. Sci. Eng. 2015, 40, 3657–3663. [Google Scholar] [CrossRef]

- Yin, K.; Dong, G.; Zhang, G.; Tian, Q.; Wang, Y.; Huang, J. Prediction of phase structures of solid solutions for high entropy alloys. J. Mater. Res. Technol. 2023, 24, 7654–7665. [Google Scholar] [CrossRef]

- Yang, S.; Lu, J.; Xing, F.; Zhang, L.; Zhong, Y. Revisit the VEC rule in high entropy alloys (HEAs) with high-throughput CALPHAD approach and its applications for material design-A case study with Al–Co–Cr–Fe–Ni system. Acta Mater. 2020, 192, 11–19. [Google Scholar] [CrossRef]

- Mishra, R.S.; Haridas, R.S.; Agrawal, P. High entropy alloys—Tunability of deformation mechanisms through integration of compositional and microstructural domains. Mater. Sci. Eng. A 2021, 812, 141085. [Google Scholar] [CrossRef]

- Hassan, M.A.; Ghayad, I.; Mohamed, A.; El-Nikhaily, A.E.; Elkady, O.A. Improvement ductility and corrosion resistance of CoCrFeNi and AlCoCrFeNi HEAs by electroless copper technique. J. Mater. Res. Technol. 2021, 13, 463–485. [Google Scholar] [CrossRef]

- Ng, C.; Guo, S.; Luan, J.; Wang, Q.; Lu, J.; Shi, S.; Liu, C. Phase stability and tensile properties of Co-free Al0.5CrCuFeNi2 high-entropy alloys. J. Alloys Compd. 2014, 584, 530–537. [Google Scholar] [CrossRef]

| Elements | Al | Cr | Fe | Mn | Ni |

|---|---|---|---|---|---|

| At% | 20.89 | 19.25 | 18.02 | 22.26 | 19.58 |

| Wt% | 11.40 | 20.25 | 20.35 | 24.74 | 23.26 |

| Elements (at. %) | Fe | Al | Ni | Mn | Cr | C |

|---|---|---|---|---|---|---|

| Point 1 | 35.40 | 5.66 | 14.42 | 7.96 | 18.77 | 17.79 |

| Point 2 | 37.42 | 5.35 | 14.46 | 7.31 | 17.91 | 17.55 |

| Point 3 | 38.38 | 8.49 | 14.44 | 5.76 | 14.61 | 18.32 |

| Point 4 | 45.33 | 1.96 | 12.34 | 5.33 | 12.41 | 22.63 |

| Point 5 | 48.15 | 3.45 | 11.91 | 4.24 | 11.11 | 21.14 |

| Point 6 | 50.23 | 6.80 | 10.53 | 2.32 | 10.02 | 20.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohsan, A.U.H.; Zhang, M.; Zhai, M.; Wang, Y.; Ullah, M.; Shu, X.; Zhao, S. Effect of Dilution on Microstructure and Phase Transformation of AlCrFeMnNi High-Entropy Alloy by Resonant Ultrasonic Vibration-Assisted Laser Cladding. Materials 2025, 18, 695. https://doi.org/10.3390/ma18030695

Mohsan AUH, Zhang M, Zhai M, Wang Y, Ullah M, Shu X, Zhao S. Effect of Dilution on Microstructure and Phase Transformation of AlCrFeMnNi High-Entropy Alloy by Resonant Ultrasonic Vibration-Assisted Laser Cladding. Materials. 2025; 18(3):695. https://doi.org/10.3390/ma18030695

Chicago/Turabian StyleMohsan, Aziz Ul Hassan, Mina Zhang, Menggang Zhai, Yishen Wang, Mudaser Ullah, Xuedao Shu, and Su Zhao. 2025. "Effect of Dilution on Microstructure and Phase Transformation of AlCrFeMnNi High-Entropy Alloy by Resonant Ultrasonic Vibration-Assisted Laser Cladding" Materials 18, no. 3: 695. https://doi.org/10.3390/ma18030695

APA StyleMohsan, A. U. H., Zhang, M., Zhai, M., Wang, Y., Ullah, M., Shu, X., & Zhao, S. (2025). Effect of Dilution on Microstructure and Phase Transformation of AlCrFeMnNi High-Entropy Alloy by Resonant Ultrasonic Vibration-Assisted Laser Cladding. Materials, 18(3), 695. https://doi.org/10.3390/ma18030695