Microscopic and Biomechanical Analysis of PEEK Interspinous Spacers for Spinal Fusion Applications

Abstract

1. Introduction

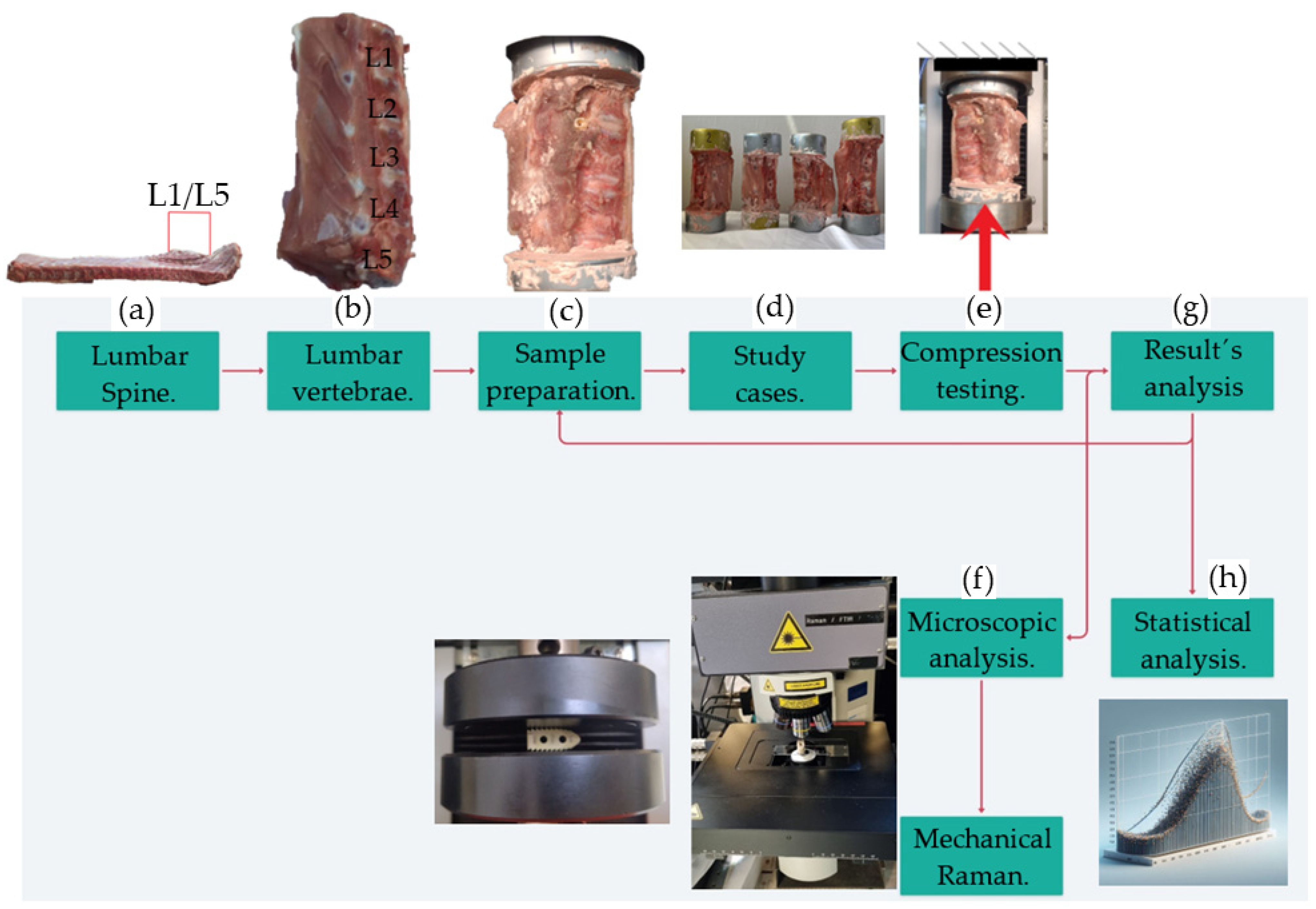

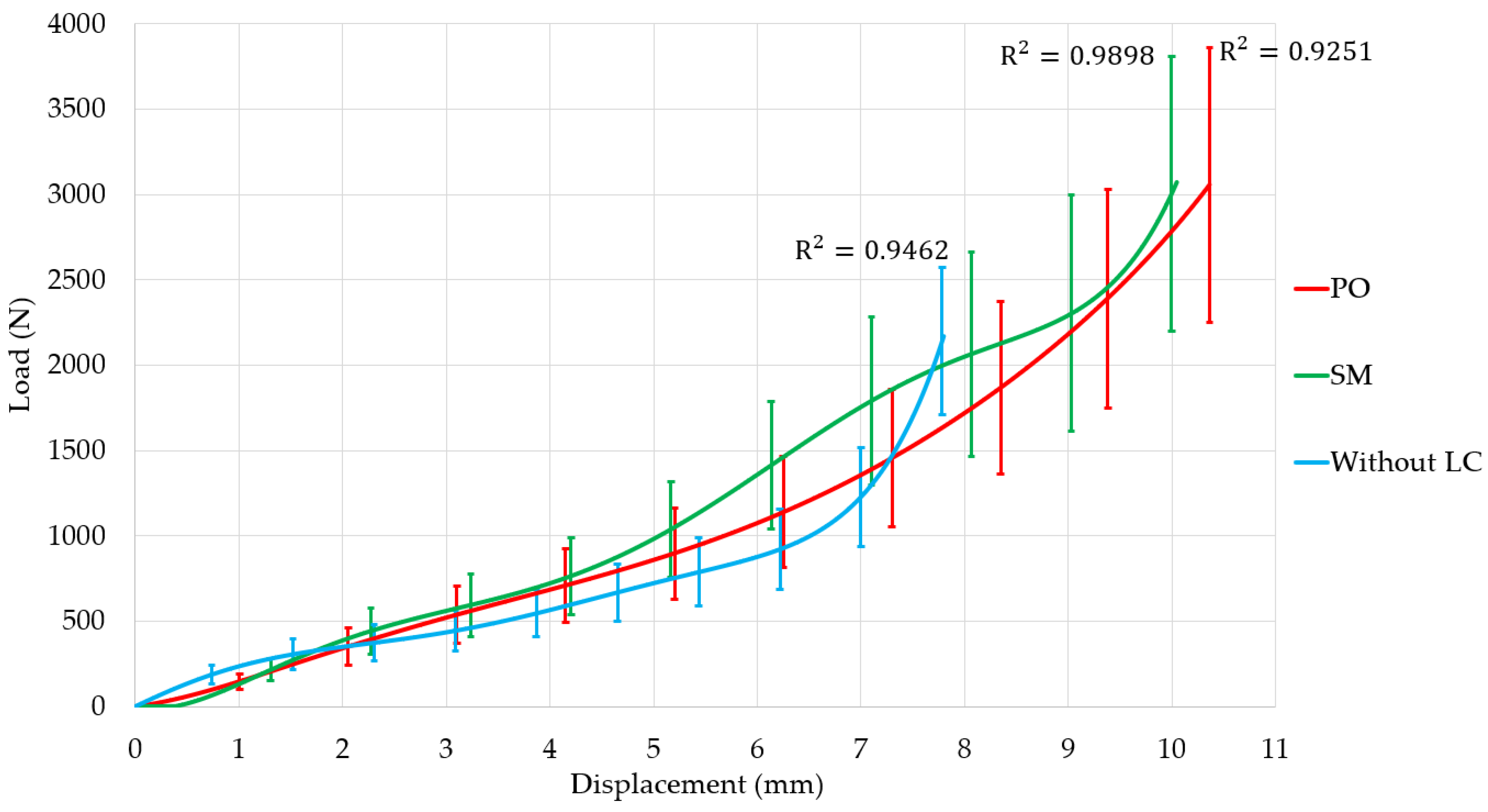

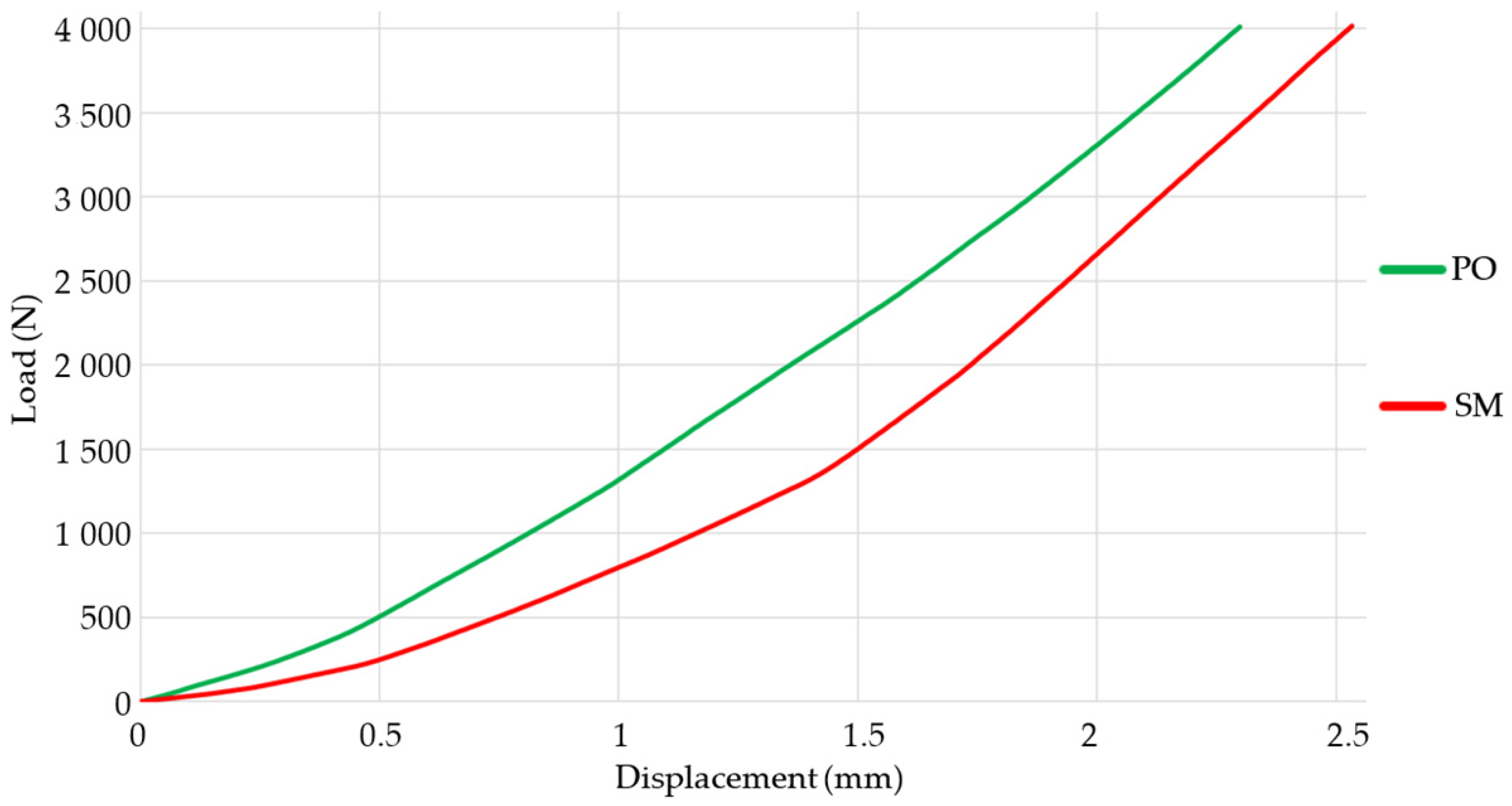

2. Materials and Methods

2.1. Device Description

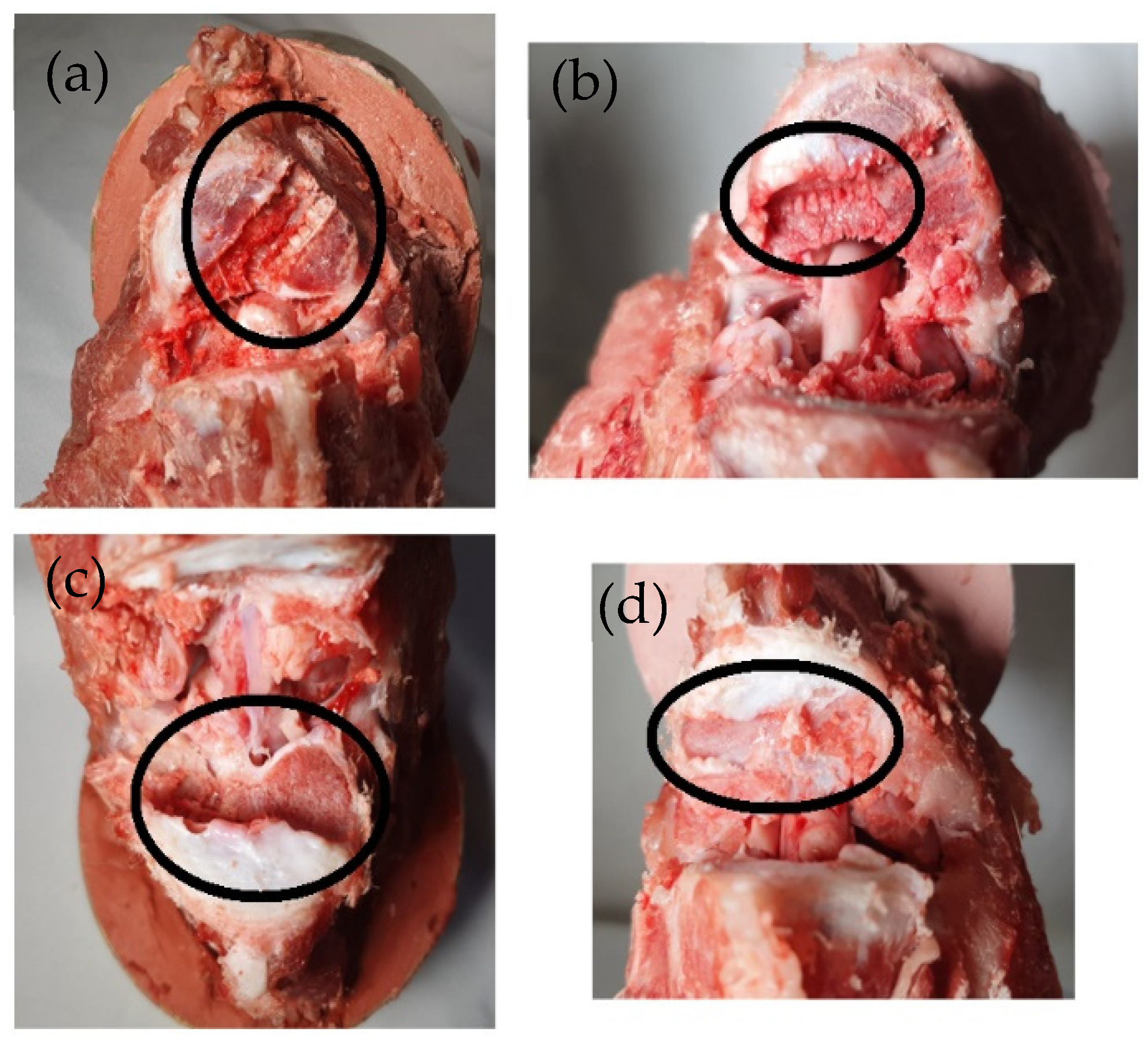

2.2. Sample and LC Testing

2.3. Raman Spectroscopy

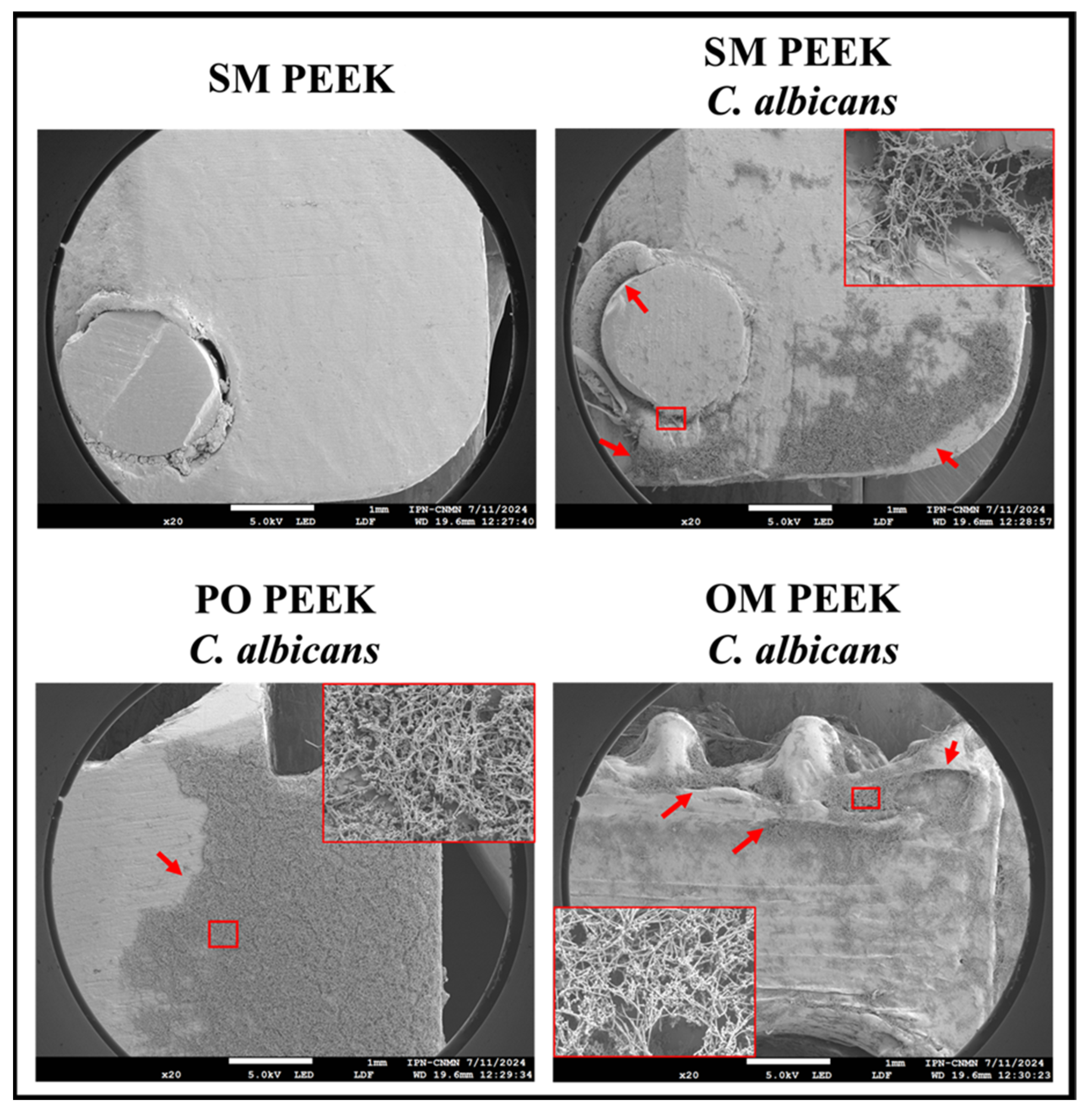

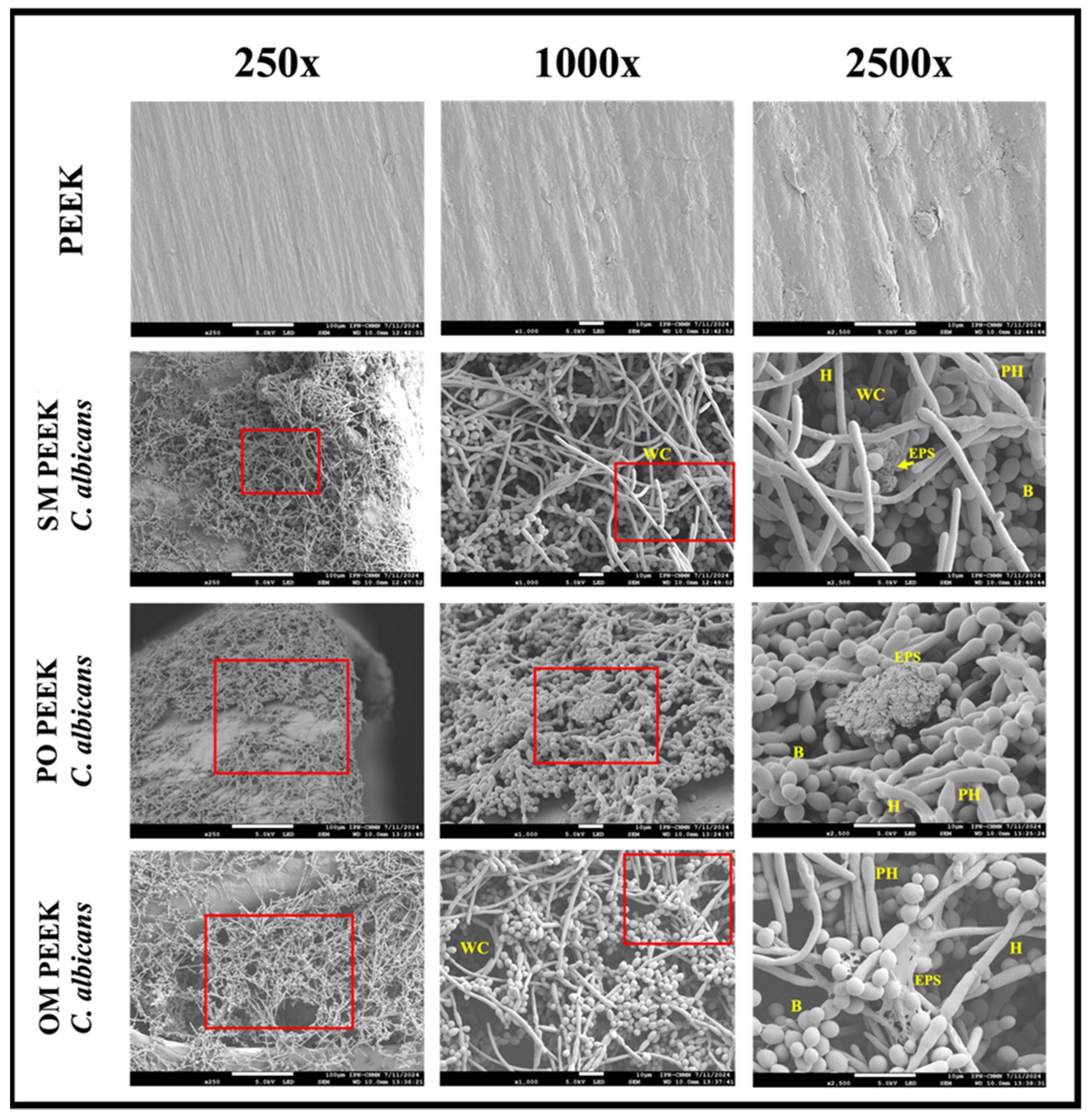

2.4. Fungal Biofilm Formation on Implants

3. Results

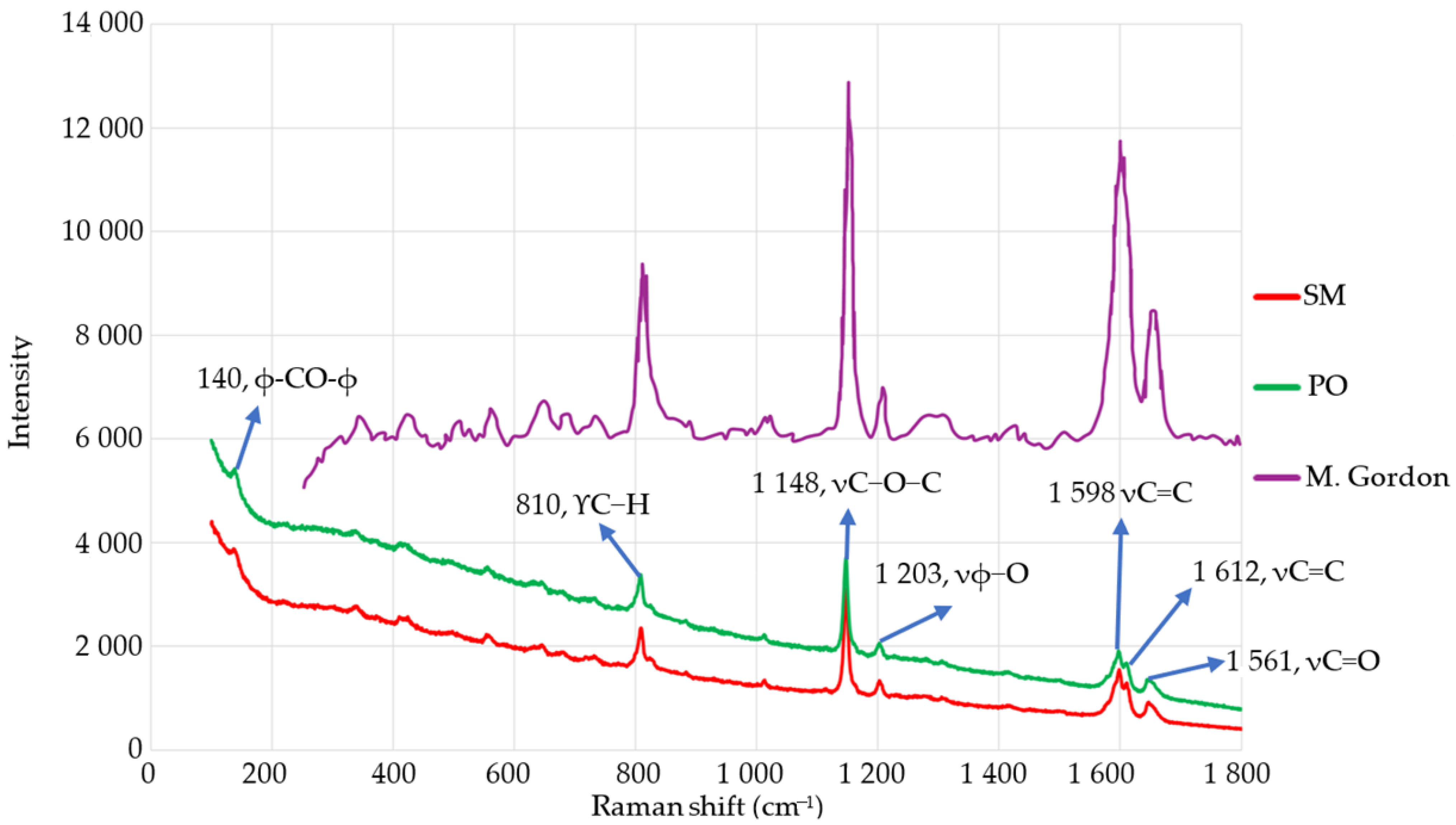

- The frequencies of 200–1020 cm−1 correspond to the out-of-plane C-H deformation of the hydrogen atoms that are bonded to the aromatic rings, known as γC−H. This region exhibits a multitude of modes ranging from strong to extremely weak intensity, which corresponds to deformations of the C-H bond in the phenyl ring that occur out-of-plane.

- The frequencies of 1020 and 1200 cm−1 correspond to the in-plane deformation of the C-H bonds linked to the aromatic rings, as well as the stretching of the C-O-C bonds. In PEEK, the C-O-C stretching mode is utilized for spectral normalization due to its lower sensitivity to microstructural differences compared to other vibration modes.

- Within the range of 1200 to 1540 cm−1, there is a stretching of C-O or C-O-C bonds, specifically vC−O or νC−O−C. In this region, there is a peak at 1203 cm−1 that corresponds to the antisymmetric version of the strong C-O-C stretching found in the prior zone.

- The stretching vibration of the C=C ring, vC=C, occurs within the range of 1540 to 1635 cm−1. Two quite pronounced modes are observed in the spectra at around 1598 and 1612 cm−1. Briscoe et al. [51] attribute the 1595 and the peak at 1607 cm−1 to the vibration of the phenyl ring. The sample’s modes are dependent on the laser’s orientation and polarization [52].

- The stretching of the carbonyl C=O bond in the ketone group, denoted as vC=O, occurs between 1635 and 1700 cm−1.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Levy, H.A.; Karamian, B.A.; Yalla, G.R.; Canseco, J.A.; Vaccaro, A.R.; Kepler, C.K. Impact of surface roughness and bulk porosity on spinal interbody implants. J. Biomed. Mater. Res. B Appl. Biomater. 2023, 111, 478–489. [Google Scholar] [CrossRef]

- Jansson, K.Å.; Németh, G.; Granath, F.; Blomqvist, P. Surgery for herniation of a lumbar disc in Sweden between 1987 and 1999. J. Bone Jt. Surg. Br. 2004, 86, 841–847. [Google Scholar] [CrossRef]

- Sivasubramaniam, V.; Patel, H.C.; Ozdemir, B.A.; Papadopoulos, M.C. Trends in hospital admissions and surgical procedures for degenerative lumbar spine disease in England: A 15-year time-series study. BMJ Open 2015, 5, e009011. [Google Scholar] [CrossRef]

- Grotle, M.; Småstuen, M.C.; Fjeld, O.; Grøvle, L.; Helgeland, J.; Storheim, K.; Solberg, T.K.; Zwart, J.-A. Lumbar spine surgery across 15 years: Trends, complications and reoperations in a longitudinal observational study from Norway. BMJ Open 2019, 9, e028743. [Google Scholar] [CrossRef] [PubMed]

- Drossopoulos, P.N.; Ononogbu-uche, F.C.; Tabarestani, T.Q.; Huang, C.-C.; Paturu, M.; Bardeesi, A.; Ray, W.Z.; Shaffrey, C.I.; Goodwin, C.R.; Erickson, M.; et al. Evolution of the Transforaminal Lumbar Interbody Fusion (TLIF): From Open to Percutaneous to Patient-Specific. J. Clin. Med. 2024, 13, 2271. [Google Scholar] [CrossRef] [PubMed]

- Encarnacion Santos, D.; Nurmukhametov, R.; Donasov, M.; Volovich, A.; Bozkurt, I.; Wellington, J.; Miguel, L.E.; Ismael, P.; Bipin, C. Management of lumbar spondylolisthesis: A retrospective analysis of posterior lumbar interbody fusion versus transforaminal lumbar interbody fusion. J. Craniovertebr. Junction Spine 2024, 15, 99–104. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Wu, H.; Li, F.; Zheng, J.; Cao, P.; Hu, B. Meta-analysis of the efficacy and safety of OLIF and TLIF in the treatment of degenerative lumbar spondylolisthesis. J. Orthop. Surg. Res. 2024, 19, 242. [Google Scholar] [CrossRef]

- Vranceanu, D.M.; Ungureanu, E.; Ionescu, I.C.; Parau, A.C.; Pruna, V.; Titorencu, I.; Badea, M.; Gălbău, C.-Ș.; Idomir, M.; Dinu, M.; et al. In Vitro Characterization of Hydroxyapatite-Based Coatings Doped with Mg or Zn Electrochemically Deposited on Nanostructured Titanium. Biomimetics 2024, 9, 244. [Google Scholar] [CrossRef] [PubMed]

- Nitschke, B.M.; Beltran, F.O.; Hahn, M.S.; Grunlan, M.A. Trends in bioactivity: Inducing and detecting mineralization of regenerative polymeric scaffolds. J. Mater. Chem. B 2024, 12, 2720–2736. [Google Scholar] [CrossRef]

- Lee, J.; Chang, S.-H.; Cho, H.-C.; Song, K.-S. Anterior Bridging Bone in a Newly Designed Cage for Lumbar Interbody Fusion: Radiographic and Finite Element Analysis. World Neurosurg. 2021, 154, e389–e397. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.Y.; Kim, D.-S.; Hwang, G.Y.; Lee, J.-K.; Lee, H.-L.; Jung, J.-W.; Hwang, S.Y.; Baek, S.-W.; Yoon, S.L.; Ha, Y.; et al. Multi-modulation of immune-inflammatory response using bioactive molecule-integrated PLGA composite for spinal fusion. Mater. Today Bio 2023, 19, 100611. [Google Scholar] [CrossRef]

- Fan, W.; Guo, L.-X.; Zhang, M. Biomechanical analysis of lumbar interbody fusion supplemented with various posterior stabilization systems. Eur. Spine J. 2021, 30, 2342–2350. [Google Scholar] [CrossRef]

- Patel, D.V.; Yoo, J.S.; Karmarkar, S.S.; Lamoutte, E.H.; Singh, K. Interbody options in lumbar fusion. J. Spine Surg. 2019, 5, S19–S24. [Google Scholar] [CrossRef]

- Curmi, A.; Rochman, A.; Buhagiar, J. Influence of polyether ether ketone (PEEK) viscosity on interlayer shear strength in screw extrusion additive manufacturing. Addit. Manuf. 2024, 84, 104086. [Google Scholar] [CrossRef]

- Dua, R.; Rashad, Z.; Spears, J.; Dunn, G.; Maxwell, M. Applications of 3D-Printed PEEK via Fused Filament Fabrication: A Systematic Review. Polymers 2021, 13, 4046. [Google Scholar] [CrossRef]

- Ai, J.-R.; Li, S.; Vogt, B.D. Increased strength in carbon-poly(ether ether ketone) composites from material extrusion with rapid microwave post processing. Addit. Manuf. 2022, 60, 103209. [Google Scholar] [CrossRef]

- Chen, P.; Su, J.; Wang, H.; Yang, L.; Cai, H.; Li, M.; Li, Z.; Liu, J.; Wen, S.; Zhou, Y.; et al. Mechanical properties and microstructure characteristics of lattice-surfaced PEEK cage fabricated by high-temperature laser powder bed fusion. J. Mater. Sci. Technol. 2022, 125, 105–117. [Google Scholar] [CrossRef]

- Han, J.; Gao, H.; Liu, X.; Shang, Y.; Zhang, H. Improving the high-temperature performance by constructing restricted amorphous regions in PEEK. Polym. Degrad. Stab. 2024, 220, 110632. [Google Scholar] [CrossRef]

- Doumeng, M.; Makhlouf, L.; Berthet, F.; Marsan, O.; Delbé, K.; Denape, J.; Chabert, F.A. comparative study of the crystallinity of polyetheretherketone by using density, DSC, XRD, and Raman spectroscopy techniques. Polym. Test 2021, 93, 106878. [Google Scholar] [CrossRef]

- Jin, L.; Ball, J.; Bremner, T.; Sue, H.-J. Crystallization behavior and morphological characterization of poly(ether ether ketone). Polymer 2014, 55, 5255–5265. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Kobayasi, S.; Numata, T.; Kamihara, N.; Shimda, T.; Jikei, M.; Muraoka, M.; Barnsley, J.E.; Fraser-Miller, S.J.; Gordon, K.C. Evaluation of crystallinity in carbon fiber-reinforced poly(ether ether ketone) by using infrared low frequency Raman spectroscopy. J. Appl. Polym. Sci. 2022, 139, 51677. [Google Scholar] [CrossRef]

- Jiang, S.; Yuan, C.; Wong, J.S.S. Effectiveness of glycerol-monooleate in high-performance polymer tribo-systems. Tribol. Int. 2021, 155, 106753. [Google Scholar] [CrossRef]

- Yang, X.; Yokokura, S.; Nagahama, T.; Yamaguchi, M.; Shimada, T. Molecular Dynamics Simulation of Poly(Ether Ether Ketone) (PEEK) Polymer to Analyze Intermolecular Ordering by Low Wavenumber Raman Spectroscopy and X-Ray Diffraction. Polymers 2022, 14, 5406. [Google Scholar] [CrossRef]

- Bonmatin, M.; Chabert, F.; Bernhart, G.; Cutard, T.; Djilali, T. Ultrasonic welding of CF/PEEK composites: Influence of welding parameters on interfacial temperature profiles and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2022, 162, 107074. [Google Scholar] [CrossRef]

- Patnaik, L.; Maity, S.R.; Kumar, S. Lubricated sliding of CFRPEEK/AlCrN film tribo-pair and its effect on the mechanical properties and structural integrity of the AlCrN film. Mater. Chem. Phys. 2021, 273, 124980. [Google Scholar] [CrossRef]

- Gaitanelis, D.; Chanteli, A.; Worrall, C.; Weaver, P.M.; Kazilas, M. A multi-technique and multi-scale analysis of the thermal degradation of PEEK in laser heating. Polym. Degrad. Stab. 2023, 211, 110282. [Google Scholar] [CrossRef]

- Al Khatib, A.; Le-Franc, R.; Guin, J.-P.; Coulon, J.-F. Investigating the thermal effects of plasma surface treatment on crystallinity and mechanical behavior of PEEK. Polym. Degrad. Stab. 2023, 216, 110500. [Google Scholar] [CrossRef]

- Delbé, K.; Chabert, F. Raman spectroscopy investigation on amorphous polyetherketoneketone (PEKK). Vib. Spectrosc. 2023, 129, 103620. [Google Scholar] [CrossRef]

- Bobzin, K.; Kalscheuer, C.; Thiex, M.; Sperka, P.; Hartl, M.; Reitschuster, S.; Maier, E.; Lohner, T.; Stahl, K. DLC-Coated Thermoplastics: Tribological Analyses Under Dry and Lubricated Sliding Conditions. Tribol. Lett. 2023, 71, 2. [Google Scholar] [CrossRef]

- Guo, C.; Lu, R.; Wang, X.; Chen, S. Antibacterial activity, bio-compatibility and osteogenic differentiation of graphene oxide coating on 3D-network poly-ether-ether-ketone for orthopaedic implants. J. Mater. Sci. Mater. Med. 2021, 32, 135. [Google Scholar] [CrossRef]

- Kashii, M.; Kitaguchi, K.; Makino, T.; Kaito, T. Comparison in the same intervertebral space between titanium-coated and uncoated PEEK cages in lumbar interbody fusion surgery. J. Orthop. Sci. 2020, 25, 565–570. [Google Scholar] [CrossRef]

- Wu, Y.; Ma, J.; Dai, J.; Wang, Y.; Bai, H.; Lu, B.; Chen, J.; Fan, X.; Ma, X. Design and Biomechanical Evaluation of a Bidirectional Expandable Cage for Oblique Lateral Interbody Fusion. World Neurosurg. 2023, 180, e644–e652. [Google Scholar] [CrossRef]

- Fushimi, K.; Miyagawa, T.; Iwai, C.; Nozawa, S.; Iinuma, N.; Tanaka, R.; Shirai, G.; Tanahashi, H.; Yokoi, T.; Akiyama, H. Transforaminal Lumbar Interbody Fusion with Double Banana Cages: Clinical Evaluations and Finite Element Model Analysis. Glob. Spine J. 2023, 14, 219256822311657. [Google Scholar] [CrossRef]

- Kumar, P.; Bhardwaj, R.; Matharu, A.L.; Meena, V.K. Comparative Analysis of Porous Titanium Spinal Cage with Conventional Spinal Cages: A Finite Element Study. J. Sci. Ind. Res. 2023, 82, 1134–1142. [Google Scholar] [CrossRef]

- Heary, R.F.; Parvathreddy, N.; Sampath, S.; Agarwal, N. Elastic modulus in the selection of interbody implants. J. Spine Surg. 2017, 3, 163–167. [Google Scholar] [CrossRef]

- Deng, X.; Zeng, Z.; Peng, B.; Yan, S.; Ke, W. Mechanical Properties Optimization of Poly-Ether-Ether-Ketone via Fused Deposition Modeling. Materials 2018, 11, 216. [Google Scholar] [CrossRef]

- Wang, Y.; Müller, W.-D.; Rumjahn, A.; Schmidt, F.; Schwitalla, A.D. Mechanical properties of fused filament fabricated PEEK for biomedical applications depending on additive manufacturing parameters. J. Mech. Behav. Biomed. Mater. 2021, 115, 104250. [Google Scholar] [CrossRef]

- Hu, B.; Duan, X.; Xing, Z.; Xu, Z.; Du, C.; Zhou, H.; Chen, R.; Shan, B. Improved design of fused deposition modeling equipment for 3D printing of high-performance PEEK parts. Mech. Mater. 2019, 137, 103139. [Google Scholar] [CrossRef]

- Torstrick, F.B.; Safranski, D.L.; Burkus, J.K.; Chappuis, J.L.; Lee, C.S.D.; Guldberg, R.E.; Gall, K.; Smith, K. Getting PEEK to Stick to Bone: The Development of Porous PEEK for Interbody Fusion Devices. Tech. Orthop. 2017, 32, 158–166. [Google Scholar] [CrossRef]

- Lunney, J.K.; Van Goor, A.; Walker, K.E.; Hailstock, T.; Franklin, J.; Dai, C. Importance of the pig as a human biomedical model. Sci. Transl. Med. 2021, 13, eabd5758. [Google Scholar] [CrossRef]

- Cone, S.G.; Warren, P.B.; Fisher, M.B. Rise of the Pigs: Utilization of the Porcine Model to Study Musculoskeletal Biomechanics and Tissue Engineering During Skeletal Growth. Tissue Eng. Part C Methods 2017, 23, 763–780. [Google Scholar] [CrossRef]

- E9−19; Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature. ASTM International: West Conshohocken, PA, USA, 2021.

- ISO 604; Plastics—Determination of Compressive Properties. International Organization for Standardization: Geneva, Switzerland, 2002.

- Uniyal, P.; Sihota, P.; Kumar, N. Effect of organic matrix alteration on strain rate dependent mechanical behaviour of cortical bone. J. Mech. Behav. Biomed. Mater. 2022, 125, 104910. [Google Scholar] [CrossRef]

- Özkaya, N.; Leger, D.; Goldsheyder, D.; Nordin, M. Fundamentals of Biomechanics; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Hamill, J.; Knutzen, K.M.; Derrick, T.R. Biomechanical Basis of Human Movement, 4th ed.; Wolters Kluwer: Alphen aan den Rijn, The Netherlands, 2015. [Google Scholar]

- Tanguy, A.; Mantisi, B.; Tsamados, M. Vibrational modes as a predictor for plasticity in a model glass. Europhys. Lett. 2010, 90, 16004. [Google Scholar] [CrossRef]

- Kurutzné Kovács, M.; Csákány, T.; Varga, P.; Varga, P.P. Biomechanical evaluation of interbody devices by using mechanical compressive test: PEEK spacers versus PMMA cement spacers. Biomech. Hung. 2013. [Google Scholar] [CrossRef]

- Sastri, V.R. Material Requirements for Plastics used in Medical Devices. In Plastics in Medical Devices; Elsevier: Amsterdam, The Netherlands, 2010; pp. 33–54. [Google Scholar] [CrossRef]

- Gardon, M.; Latorre, A.; Torrell, M.; Dosta, S.; Fernández, J.; Guilemany, J.M. Cold gas spray titanium coatings onto a biocompatible polymer. Mater. Lett. 2013, 106, 97–99. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Stuart, B.H.; Thomas, P.S.; Williams, D.R. A comparison of thermal- and solvent-induced relaxation of poly(ether ether ketone) using Fourier transform Raman spectroscopy. Spectrochim. Acta A 1991, 47, 1299–1303. [Google Scholar] [CrossRef]

- Al Lafi, A.G.; Alzier, A.; Allaf, A.W. Wide angle X-ray diffraction patterns and 2D-correlation spectroscopy of crystallization in proton irradiated poly(ether ether ketone). Heliyon 2021, 7, e07306. [Google Scholar] [CrossRef]

- Knop, C.; Lange, U.; Bastian, L.; Oeser, M.; Blauth, M. Biomechanical compression tests with a new implant for thoracolumbar vertebral body replacement. Eur. Spine J. 2001, 10, 30–37. [Google Scholar] [CrossRef][Green Version]

- Tencer, A.F.; Hampton, D.; Eddy, S. Biomechanical Properties of Threaded Inserts for Lumbar Interbody Spinal Fusion. Spine 1995, 20, 2408–2414. [Google Scholar] [CrossRef]

- Yoder, J.H.; Auerbach, J.D.; Maurer, P.M.; Erbe, E.M.; Entrekin, D.; Balderston, R.A.; Bertagnoli, R.; Elliott, D. Augmentation Improves Human Cadaveric Vertebral Body Compression Mechanics for Lumbar Total Disc Replacement. Spine 2010, 35, E325–E331. [Google Scholar] [CrossRef]

- Xu, D.S.; Walker, C.T.; Godzik, J.; Turner, J.D.; Smith, W.; Uribe, J.S. Minimally invasive anterior, lateral, and oblique lumbar interbody fusion: A literature review. Ann. Transl. Med. 2018, 6, 104. [Google Scholar] [CrossRef]

- Akbary, K.; Quillo-Olvera, J.; Lin, G.-X.; Jo, H.-J.; Kim, J.-S. Outcomes of Minimally Invasive Oblique Lumbar Interbody Fusion in Patients with Lumbar Degenerative Disease with Rheumatoid Arthritis. J. Neurol. Surg. A Cent. Eur. Neurosurg. 2019, 80, 162–168. [Google Scholar] [CrossRef]

- Huang, S.; Min, S.; Wang, S.; Jin, A. Biomechanical effects of an oblique lumbar interbody fusion combined with posterior augmentation: A finite element analysis. BMC Musculoskelet. Disord. 2022, 23, 611. [Google Scholar] [CrossRef] [PubMed]

- Choi, K.-C.; Ryu, K.-S.; Lee, S.-H.; Kim, Y.H.; Lee, S.J.; Park, C.-K. Biomechanical comparison of anterior lumbar interbody fusion: Stand-alone interbody cage versus interbody cage with pedicle screw fixation—A finite element analysis. BMC Musculoskelet. Disord. 2013, 14, 220. [Google Scholar] [CrossRef]

- Lallemant, M.; Kadiakhe, T.; Chambert, J.; Lejeune, A.; Ramanah, R.; Mottet, N.; Jacquet, E. In vitro biomechanical properties of porcine perineal tissues to better understand human perineal tears during delivery. Acta Obs. Gynecol. Scand. 2024, 103, 1386–1395. [Google Scholar] [CrossRef]

- Kong, K.; Davies, R.J.; Young, R.J.; Eichhorn, S.J. Molecular and Crystal Deformation in Poly(aryl ether ether ketone) Fibers. Macromolecules 2008, 41, 7519–7524. [Google Scholar] [CrossRef]

- Najeeb, S.; Zafar, M.S.; Khurshid, Z.; Siddiqui, F. Applications of polyetheretherketone (PEEK) in oral implantology and prosthodontics. J. Prosthodont. Res. 2016, 60, 12–19. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.; Wang, X.; Liu, T.; Dong, L. Biomechanical analysis of a customized lumbar interspinous spacer based on transfacetopedicular screw fixation: A finite element study. Med. Eng. Phys. 2022, 107, 103850. [Google Scholar] [CrossRef]

- Khan, H.A.; Ber, R.; Neifert, S.N.; Kurland, D.B.; Laufer, I.; Kondziolka, D.; Chhabra, A.; Frempong-Boadu, A.K.; Lau, D. Carbon fiber–reinforced PEEK spinal implants for primary and metastatic spine tumors: A systematic review on implant complications and radiotherapy benefits. J. Neurosurg. Spine 2023, 39, 534–547. [Google Scholar] [CrossRef] [PubMed]

- Long, J.; Zhang, J.; Kang, J.; Fan, Y.; Zhang, Z.; Shi, J.; Zhang, Z.; Huang, Y.; Liu, S. Customed 3D-printed Polyetheretherketone (PEEK) Implant for Secondary Salvage Reconstruction of Mandibular Defects: Case Report and Literature Review. J. Craniofacial Surg. 2023, 34, 2460–2463. [Google Scholar] [CrossRef]

- Arciola, C.R.; Campoccia, D.; Montanaro, L. Implant infections: Adhesion, biofilm formation and immune evasion. Nat. Rev. Microbiol. 2018, 16, 397–409. [Google Scholar] [CrossRef]

- Desai, J.V.; Mitchell, A.P.; Andes, D.R. Fungal Biofilms, Drug Resistance, and Recurrent Infection. Cold Spring Harb. Perspect. Med. 2014, 4, a019729. [Google Scholar] [CrossRef] [PubMed]

- Tsui, C.; Kong, E.F.; Jabra-Rizk, M.A. Pathogenesis of Candida albicans biofilm. Pathog. Dis. 2016, 74, ftw018. [Google Scholar] [CrossRef]

- Xin, J.; Guo, Q.-S.; Zhang, H.-Y.; Zhang, Z.-Y.; Talmy, T.; Han, Y.-Z.; Xie, Y.; Zhong, Q.; Zhou, S.R.; Li, Y. Candidal periprosthetic joint infection after primary total knee arthroplasty combined with ipsilateral intertrochanteric fracture: A case report. World J. Clin. Cases 2020, 8, 5401–5408. [Google Scholar] [CrossRef]

- Pereira, R.; Santos Fontenelle, R.O.; Brito, E.H.S.; Morais, S.M. Biofilm of Candida albicans: Formation, regulation and resistance. J. Appl. Microbiol. 2021, 131, 11–22. [Google Scholar] [CrossRef] [PubMed]

- Brum, R.S.; Labes, L.G.; Volpato, C.Â.M.; Benfatti, C.A.M.; Pimenta, A.d.L. Strategies to Reduce Biofilm Formation in PEEK Materials Applied to Implant Dentistry—A Comprehensive Review. Antibiotics 2020, 9, 609. [Google Scholar] [CrossRef]

- Yang, X.; Wang, Q.; Zhang, Y.; He, H.; Xiong, S.; Chen, P.; Li, C.; Wang, L.; Lu, G.; Xu, Y. A dual-functional PEEK implant coating for anti-bacterial and accelerated osseointegration. Colloids Surf. B Biointerfaces 2023, 224, 113196. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Sharma, N.; Xu, Z.; Krajewski, S.; Li, P.; Spintzyk, S.; Lv, L.; Zhou, Y.; Thieringer, F.M.; Rupp, F. A balance of biocompatibility and antibacterial capability of 3D printed PEEK implants with natural totarol coating. Dent. Mater. 2024, 40, 674–688. [Google Scholar] [CrossRef] [PubMed]

- Kranjec, C.; Mathew, J.P.; Ovchinnikov, K.; Fadayomi, I.; Yang, Y.; Kjos, M.; Li, W.W. A bacteriocin-based coating strategy to prevent vancomycin-resistant Enterococcus faecium biofilm formation on materials of interest for indwelling medical devices. Biofilm 2024, 8, 100211. [Google Scholar] [CrossRef]

- Costa-Orlandi, C.; Sardi, J.; Pitangui, N.; De Oliveira, H.; Scorzoni, L.; Galeane, M.; Medina-Alarcón, K.P.; Melo, W.C.M.A.; Marcelino, M.Y.; Braz, J.D.; et al. Fungal Biofilms and Polymicrobial Diseases. J. Fungi 2017, 3, 22. [Google Scholar] [CrossRef]

| Study Case | Velocity Displacement | Prosthesis | Stop Criterion |

|---|---|---|---|

| 1 | 2 mm/min | Without LC | Load of 1500 N |

| 2 | 2 mm/min | Without LC | Load of 2500 N |

| 3 | 2 mm/min | PO | Load of 3000 N |

| 4 | 2 mm/min | SM | Load of 3000 N |

| 5 | 2 mm/min | PO | Load of 3000 N |

| 6 | 2 mm/min | SM | Load of 3000 N |

| 7 | 2 mm/min | Without LC | Until material fail |

| 8 | 2 mm/min | Without LC | Load of 1500 N |

| 9 | 2 mm/min | Without LC | Until material fail |

| 10 | 2 mm/min | Without LC | Load of 2000 N |

| 11 | 2 mm/min | SM | Until material fail |

| 12 | 2 mm/min | SM | Load of 2000 N |

| 13 | 2 mm/min | SM | Until material fail |

| 14 | 2 mm/min | PO | Load of 2000 N |

| 15 | 2 mm/min | PO | Until material fail |

| 16 | 2 mm/min | PO | Load of 2000 N |

| Assignment | ||

|---|---|---|

| 97 | vw | Phonon ϕ-O-ϕ |

| 135 | vw | Phonon ϕ-CO-ϕ |

| 632 | w, sh | γCO |

| 646 | w | γC−H |

| 669 | w | γC−H |

| 680 | vw | γC−H |

| 731 | vw | γC−H |

| 772 | w | γC−H |

| 808 | s | γC−H |

| 825 | w, sh | γC−H |

| 882 | w | γC−H or ring mode |

| 932 | w | γC−H, or symmetric νϕ−CO−ϕ |

| 934 | vw | γC−H |

| 968 | vw | γC−H |

| 1010 | vw | Ring stretching mode, or δC−H |

| 1065 | vw | γC−H |

| 1096 | vw, sh | δϕ |

| 1114 | vw | δC−H or νC−O |

| 1146 | vs | Symmetric νC−O−C |

| 1161 | w, sh | δC−H or ϕ − O and ϕ − CO modes |

| 1173 | w, sh | δC−H |

| 1201 | m | νϕ−O |

| 1288 | w | νϕ−CO−ϕ or ring mode |

| 1307 | w | Ring mode |

| 1414 | vw | ν−CO−, νC−O−C |

| 1499 | vw | Ring stretching mode |

| 1576 | w, sh | νC=C |

| 1595 | vs | νC=C |

| 1607 | s, sh | νC=C |

| 1644 | m | νC=O crystalline |

| 1651 | m, sh | νC=O amorphous |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alcántara-Arreola, E.A.; Rodríguez-Tovas, A.V.; Hernández-Benítez, J.A.; Torres-SanMiguel, C.R. Microscopic and Biomechanical Analysis of PEEK Interspinous Spacers for Spinal Fusion Applications. Materials 2025, 18, 679. https://doi.org/10.3390/ma18030679

Alcántara-Arreola EA, Rodríguez-Tovas AV, Hernández-Benítez JA, Torres-SanMiguel CR. Microscopic and Biomechanical Analysis of PEEK Interspinous Spacers for Spinal Fusion Applications. Materials. 2025; 18(3):679. https://doi.org/10.3390/ma18030679

Chicago/Turabian StyleAlcántara-Arreola, Elliot Alonso, Aida Verónica Rodríguez-Tovas, José Alejandro Hernández-Benítez, and Christopher René Torres-SanMiguel. 2025. "Microscopic and Biomechanical Analysis of PEEK Interspinous Spacers for Spinal Fusion Applications" Materials 18, no. 3: 679. https://doi.org/10.3390/ma18030679

APA StyleAlcántara-Arreola, E. A., Rodríguez-Tovas, A. V., Hernández-Benítez, J. A., & Torres-SanMiguel, C. R. (2025). Microscopic and Biomechanical Analysis of PEEK Interspinous Spacers for Spinal Fusion Applications. Materials, 18(3), 679. https://doi.org/10.3390/ma18030679