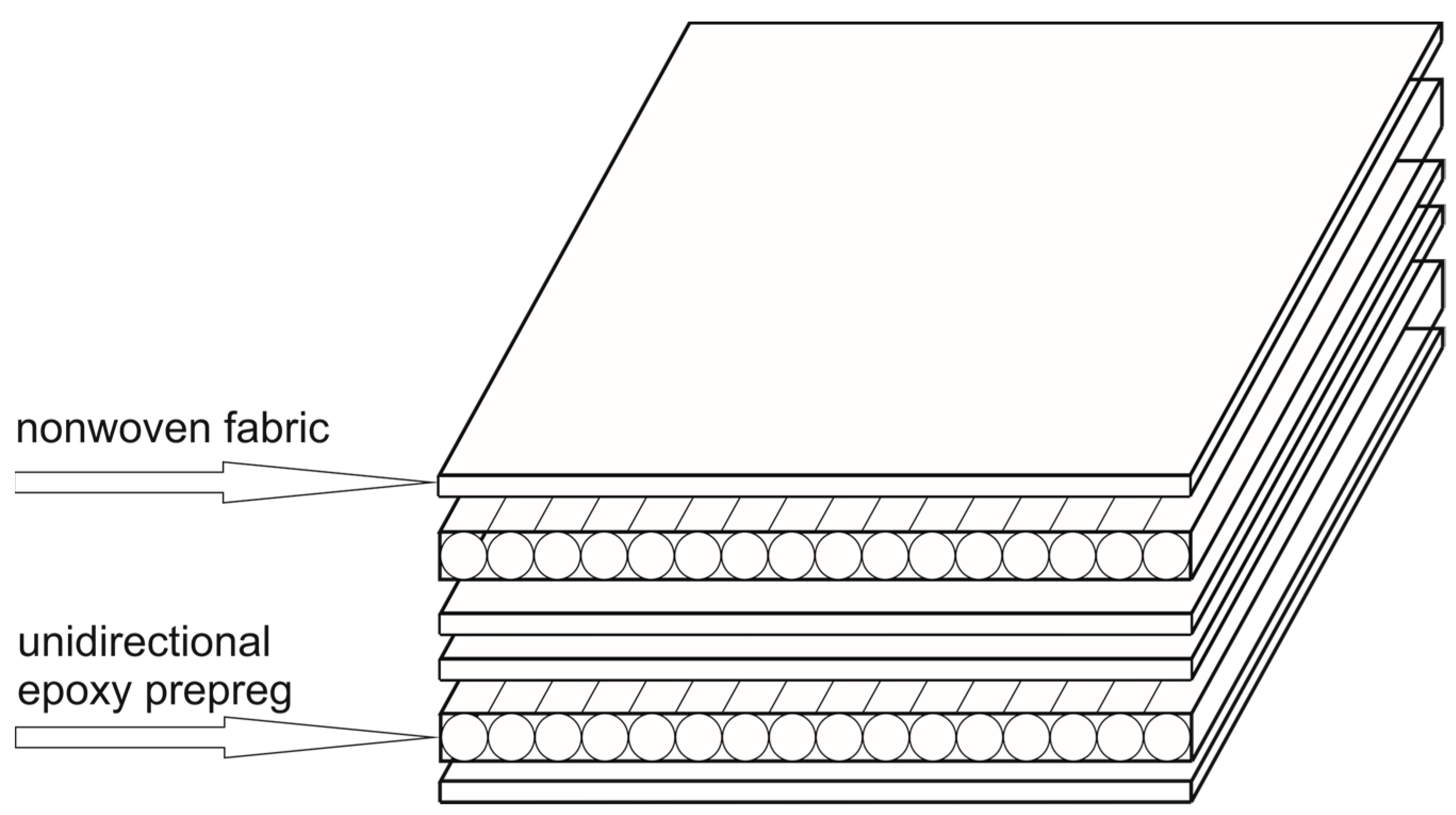

Improvement of the Impact Resistance of Epoxy Prepregs Through the Incorporation of Polyamide Nonwoven Fabric

Abstract

1. Introduction

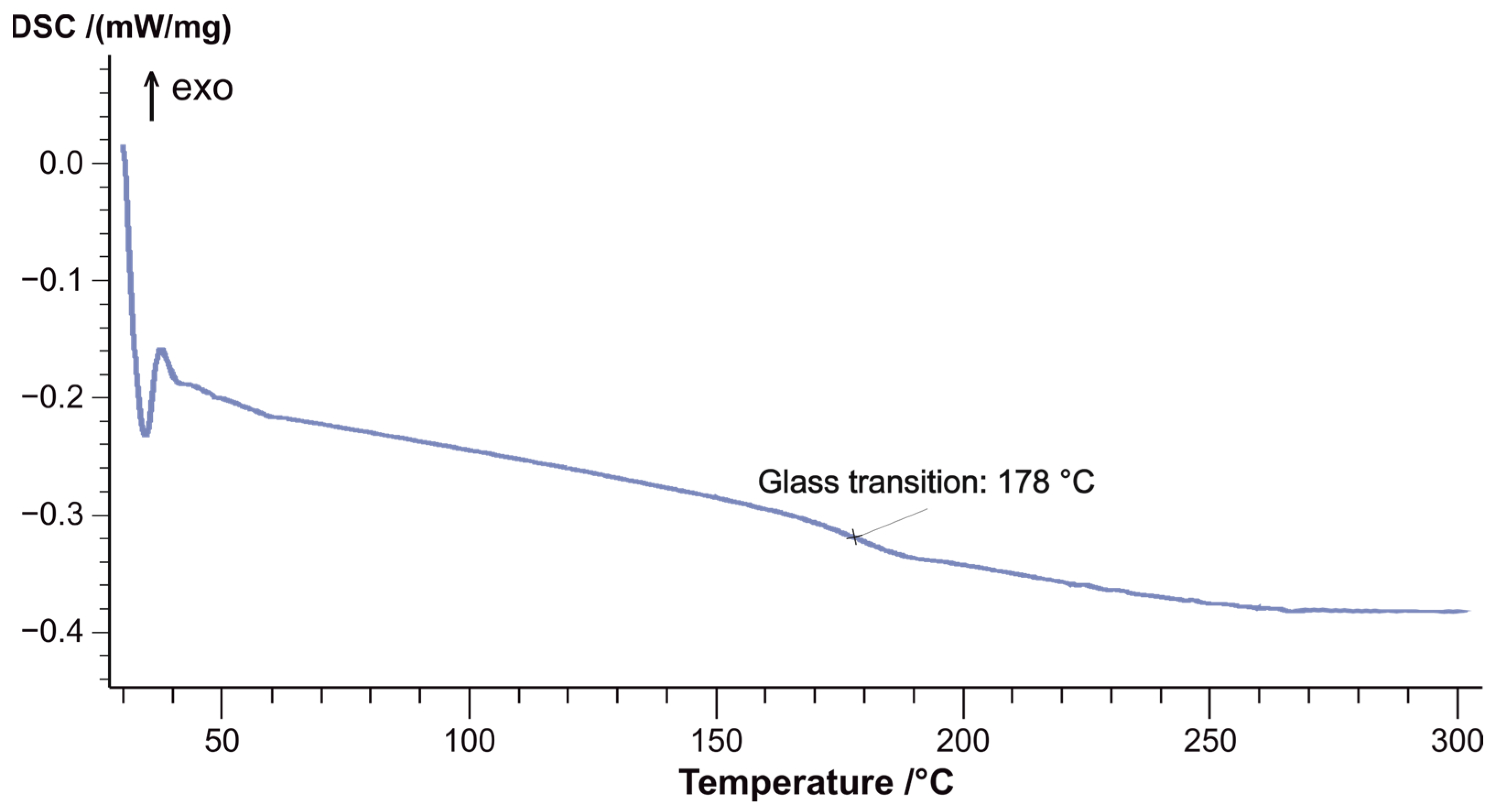

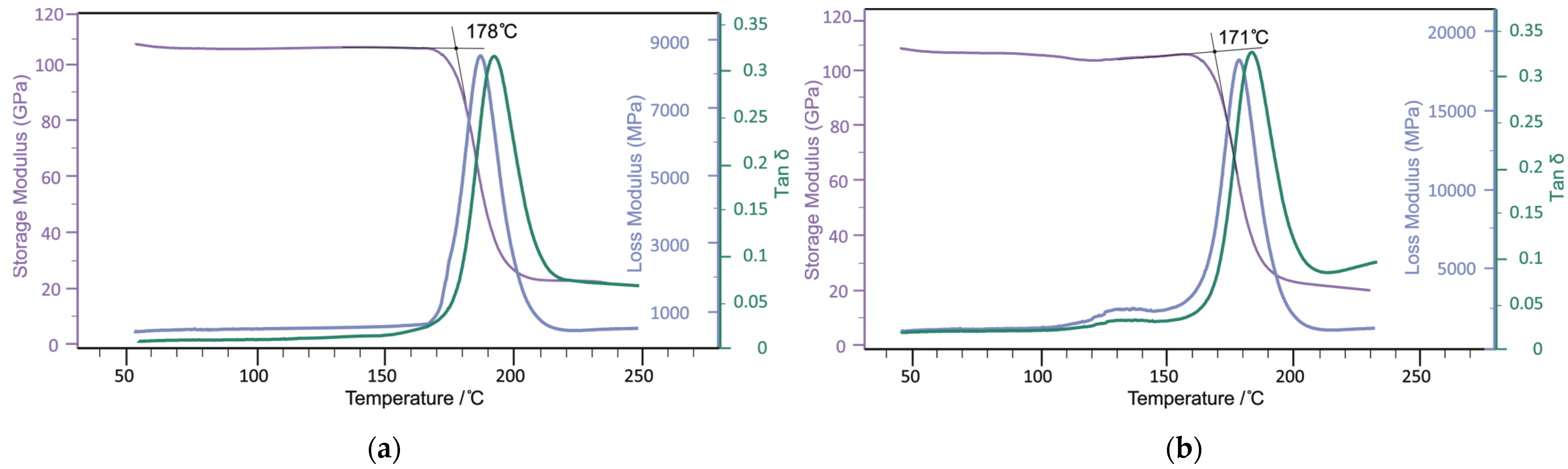

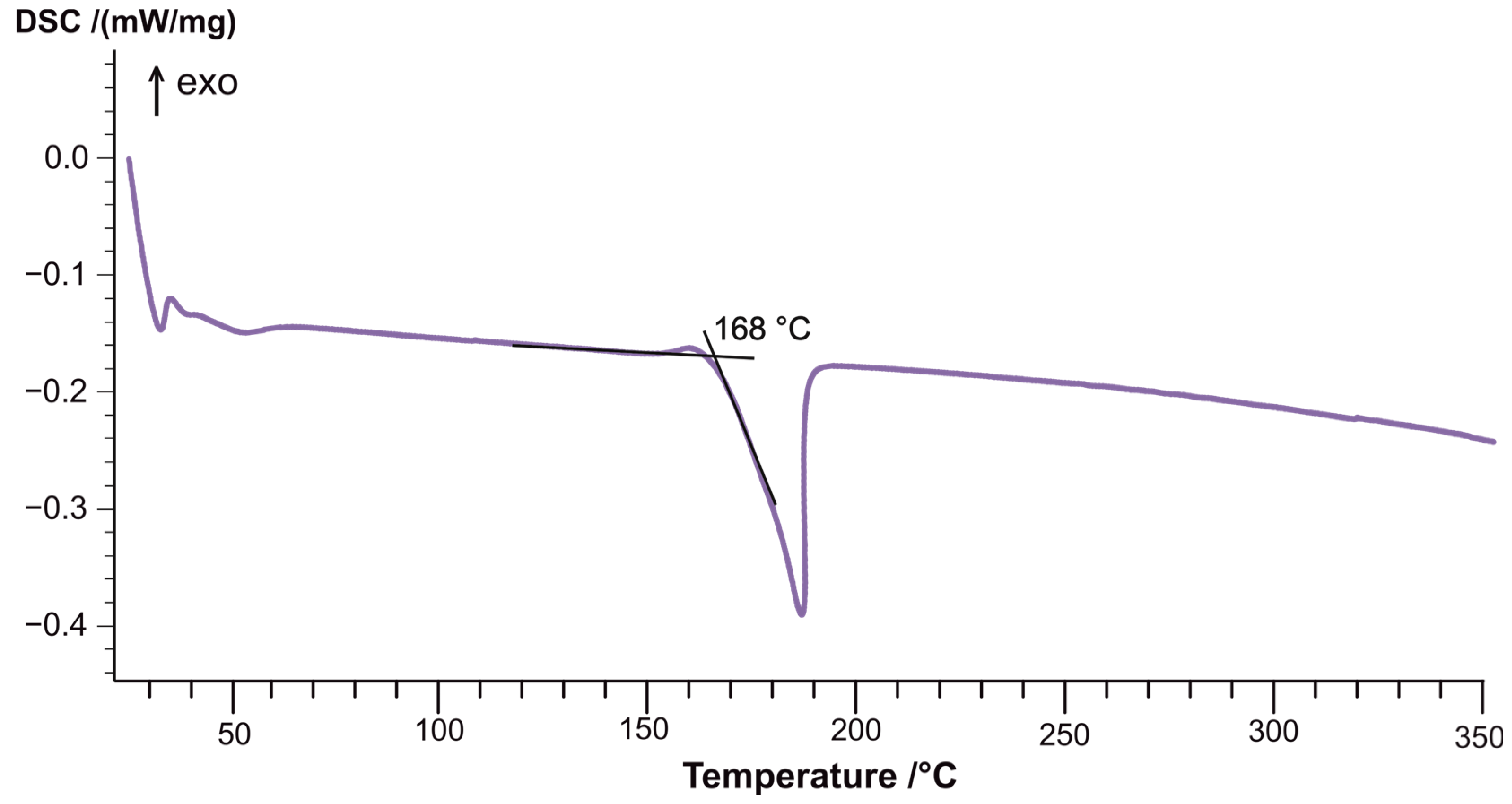

2. Materials and Methods

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hegde, S.; Satish Shenoy, B.; Chethan, K.N. Review on Carbon Fiber Reinforced Polymer (CFRP) and Their Mechanical Performance. Mater. Today Proc. 2019, 19, 658–662. [Google Scholar] [CrossRef]

- Öchsner, A.; Altenbach, H. Engineering Design Applications III; Springer: Berlin/Heidelberg, Germany, 2020; Volume 4, ISBN 9783030390617. [Google Scholar]

- Siddiquee, S.; Hong, M.G.J.; Rahman, M.M. Carbon Fibre Reinforced Polymer (CFRP) Composites: Machining Aspects and Opportunities for Manufacturing Industries; Springer: Berlin/Heidelberg, Germany, 2020; ISBN 9783030454890. [Google Scholar]

- Soutis, C. FAILURE OF NOTCHED CFRP LAMINATES DUE TO FIBRE MICROBUCKLING: A TOPICAL REVIEW. J. Mech. Behav. Mater. 1996, 6, 309–330. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, W.; Li, B.; Zhu, J.; Wang, C.; Song, G.; Wu, G.; Yang, X.; Huang, Y.; Ma, L. Recent Advances of Interphases in Carbon Fiber-Reinforced Polymer Composites: A Review. Compos. Part B Eng. 2022, 233, 109639. [Google Scholar] [CrossRef]

- Jain, S.; Yang, D.C.H. Effects of federate and chisel edge on delamination in composite drilling. Process. Manuf. Compos. Mater. ASME PED 1991, 27, 49. [Google Scholar] [CrossRef]

- Li, Y.; Hori, N.; Arai, M.; Hu, N.; Liu, Y.; Fukunaga, H. Improvement of Interlaminar Mechanical Properties of CFRP Laminates Using VGCF. Compos. Part A Appl. Sci. Manuf. 2009, 40, 2004–2012. [Google Scholar] [CrossRef]

- Li, H.; Chen, W.; Xu, J.; Li, J.; Gan, L.; Chu, X.; Yao, Y.; He, Y.; Li, B.; Kang, F.; et al. Enhanced Thermal Conductivity by Combined Fillers in Polymer Composites. Thermochem. Acta 2019, 676, 198–204. [Google Scholar] [CrossRef]

- Nash, N.H.; Young, T.M.; McGrail, P.T.; Stanley, W.F. Inclusion of a Thermoplastic Phase to Improve Impact and Post-Impact Performances of Carbon Fibre Reinforced Thermosetting Composites—A Review. Mater. Des. 2015, 85, 582–597. [Google Scholar] [CrossRef]

- Basha, M.; Wagih, A.; Melaibari, A.; Lubineau, G.; Eltaher, M.A. On the Impact Damage Resistance and Tolerance Improvement of Hybrid CFRP/Kevlar Sandwich Composites. Microporous Mesoporous Mater. 2022, 333, 111732. [Google Scholar] [CrossRef]

- Cartié, D.D.R.; Irving, P.E. Effect of Resin and Fibre Properties on Impact and Compression after Impact Performance of CFRP. Compos.—Part A Appl. Sci. Manuf. 2002, 33, 483–493. [Google Scholar] [CrossRef]

- Kostopoulos, V.; Baltopoulos, A.; Karapappas, P.; Vavouliotis, A.; Paipetis, A. Impact and After-Impact Properties of Carbon Fibre Reinforced Composites Enhanced with Multi-Wall Carbon Nanotubes. Compos. Sci. Technol. 2010, 70, 553–563. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Wang, X.; Ding, G.; Pan, Y.; Xie, H.; Chen, Q.; Cheng, R. Effects of Amino-Functionalized Carbon Nanotubes on the Properties of Amine-Terminated Butadiene-Acrylonitrile Rubber-Toughened Epoxy Resins. J. Appl. Polym. Sci. 2014, 131, 1–7. [Google Scholar] [CrossRef]

- Mahdi, T.H.; Islam, M.E.; Hosur, M.V.; Jeelani, S. Low-Velocity Impact Performance of Carbon Fiber-Reinforced Plastics Modified with Carbon Nanotube, Nanoclay and Hybrid Nanoparticles. J. Reinf. Plast. Compos. 2017, 36, 696–713. [Google Scholar] [CrossRef]

- Newman, B.; Creighton, C.; Henderson, L.C.; Stojcevski, F. A Review of Milled Carbon Fibres in Composite Materials. Compos. Part A Appl. Sci. Manuf. 2022, 163, 107249. [Google Scholar] [CrossRef]

- Dong, J.; Jia, C.; Wang, M.; Fang, X.; Wei, H.; Xie, H.; Zhang, T.; He, J.; Jiang, Z.; Huang, Y. Improved Mechanical Properties of Carbon Fiber-Reinforced Epoxy Composites by Growing Carbon Black on Carbon Fiber Surface. Compos. Sci. Technol. 2017, 149, 75–80. [Google Scholar] [CrossRef]

- Dong, W.; Liu, H.C.; Park, S.J.; Jin, F.L. Fracture Toughness Improvement of Epoxy Resins with Short Carbon Fibers. J. Ind. Eng. Chem. 2014, 20, 1220–1222. [Google Scholar] [CrossRef]

- Zhang, G.; Karger-Kocsis, J.; Zou, J. Synergetic Effect of Carbon Nanofibers and Short Carbon Fibers on the Mechanical and Fracture Properties of Epoxy Resin. Carbon N. Y. 2010, 48, 4289–4300. [Google Scholar] [CrossRef]

- Pappa, E.J.; Quinn, J.A.; Murray, J.J.; Davidson, J.R.; Ó Brádaigh, C.M.; McCarthy, E.D. Experimental Study on the Interlaminar Fracture Properties of Carbon Fibre Reinforced Polymer Composites with a Single Embedded Toughened Film. Polymers 2021, 13, 4103. [Google Scholar] [CrossRef]

- Xu, X.; Zhou, Z.; Hei, Y.; Zhang, B.; Bao, J.; Chen, X. Improving Compression-after-Impact Performance of Carbon-Fiber Composites by CNTs/Thermoplastic Hybrid Film Interlayer. Compos. Sci. Technol. 2014, 95, 75–81. [Google Scholar] [CrossRef]

- Lee, J.S.; Kim, J.W. Impact Response of Carbon Fibre Fabric/Thermoset-Thermoplastic Combined Polymer Composites. Adv. Compos. Lett. 2017, 26, 82–88. [Google Scholar] [CrossRef]

- Sohn, M.S.; Hu, X.Z. Mode II Delamination Toughness of Carbon-Fibre/Epoxy Composites with Chopped Kevlar Fibre Reinforcement. Compos. Sci. Technol. 1994, 52, 439–448. [Google Scholar] [CrossRef]

- Kutovaya, I.V.; Aleksanova, A.A.; Erdni-Goryaev, E.M.; Lipatov, Y.V.; Afanas’eva, E.S.; Morozov, O.S.; Babkin, A.V.; Kepman, A.V. Enhancement of the Fracture Toughness of Carbon-Reinforced Plastics by Introducing a Thermoplastic Phase into an Epoxy Matrix. Russ. J. Appl. Chem. 2023, 96, 474–483. [Google Scholar] [CrossRef]

- Kutovaya, I.V.; Poliakova, D.I.; Erdni-Goryaev, E.M.; Lipatov, Y.V.; Afanaseva, E.S.; Morozov, O.S.; Babkin, A.V.; Kepman, A.V. Enhancement of Crack Resistance of Phthalonitrile-Based Carbon Fiber Reinforced Plastics by Introducing Polyamide Nonwoven Materials. Polym. Sci.—Ser. B 2023, 65, 672–680. [Google Scholar] [CrossRef]

- Dydek, K.; Latko-Durałek, P.; Boczkowska, A.; Sałaciński, M.; Kozera, R. Carbon Fiber Reinforced Polymers Modified with Thermoplastic Nonwovens Containing Multi-Walled Carbon Nanotubes. Compos. Sci. Technol. 2019, 173, 110–117. [Google Scholar] [CrossRef]

- Tarih, Y.S.; Coskun, T.; Yar, A.; Gundogdu, Ö.; Sahin, Ö.S. The Influences of Low-Velocity Impact Loading on the Vibration Responses of the Carbon/Glass Fiber-Reinforced Epoxy Composites Interleaved with Various Non-Woven Thermoplastic Veils. J. Appl. Polym. Sci. 2023, 140, 1–19. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, X. Influence of Addition of Silica Particles on Reaction-Induced Phase Separation and Properties of Epoxy/PEI Blends. Compos. Part B Eng. 2011, 42, 2163–2169. [Google Scholar] [CrossRef]

- Zhou, S.; Chen, Z.; Tusiime, R.; Cheng, C.; Sun, Z.; Xu, L.; Liu, Y.; Jiang, M.; Zhou, J.; Zhang, H.; et al. Highly Improving the Mechanical and Thermal Properties of Epoxy Resin via Blending with Polyetherketone Cardo. Compos. Commun. 2019, 13, 80–84. [Google Scholar] [CrossRef]

- Palazzetti, R.; Zucchelli, A. Electrospun Nanofibers as Reinforcement for Composite Laminates Materials—A Review. Compos. Struct. 2017, 182, 711–727. [Google Scholar] [CrossRef]

- Ognibene, G.; Latteri, A.; Mannino, S.; Saitta, L.; Recca, G.; Scarpa, F.; Cicala, G. Interlaminar Toughening of Epoxy Carbon Fiber Reinforced Laminates: Soluble versus Non-Soluble Veils. Polymers 2019, 11, 1029. [Google Scholar] [CrossRef]

- Mujika, F.; De Benito, A.; Fernández, B.; Vázquez, A.; Llano-Ponte, R.; Mondragon, I. Mechanical Properties of Carbon Woven Reinforced Epoxy Matrix Composites. A Study on the Influence of Matrix Modification with Polysulfone. Polym. Compos. 2002, 23, 372–382. [Google Scholar] [CrossRef]

- Ramji, A.; Xu, Y.; Yasaee, M.; Grasso, M.; Webb, P. Influence of Veil Interleave Distribution on the Delamination Resistance of Cross-Ply CFRP Laminates under Low Velocity Impact. Int. J. Impact Eng. 2021, 157, 103997. [Google Scholar] [CrossRef]

- Beylergil, B.; Tanoğlu, M.; Aktaş, E. Effect of Polyamide-6,6 (PA 66) Nonwoven Veils on the Mechanical Performance of Carbon Fiber/Epoxy Composites. Compos. Struct. 2018, 194, 21–35. [Google Scholar] [CrossRef]

- Kudrin, A.M.; Karaeva, O.A.; Gabriel`s, K.S.; Solopchenko, A.V. Opredelenie Predela Prochnosti Polimernogo Kompozicionnogo Materiala Na Szhatie Posle Udara v Sootvetstvii so Standartom ASTM D 7137. Vestn. Vor. Gos. texnicheskogo Univ. 2018, 14, 164–169. [Google Scholar]

- Yuan, B.; Tan, B.; Hu, Y.; Shaw, J.; Hu, X. Improving Impact Resistance and Residual Compressive Strength of Carbon Fibre Composites Using Un-Bonded Non-Woven Short Aramid Fibre Veil. Compos. Part A Appl. Sci. Manuf. 2019, 121, 439–448. [Google Scholar] [CrossRef]

- Afanasyeva, E.S.; Apukhtina, T.L.; Avdeev, V.V.; Morozov, O.S.; Kepman, A.V. Non-woven thermoplastic material made of polyamide melt: Formation and properties. Izvestiya Vysshikh Uchebnykh Zavedenii, Seriya Teknologiya Tekstil'noi Promyshlennosti. Available online: https://www.scopus.com/sourceid/57620 (accessed on 25 January 2025).

- Heflin, D.G.; Mansson, J.-A.E. Mechanisms for combining polyamide and epoxy and their effects on mechanical performance—A review. Polym. Polym. Compos. 2022, 30, 1–19. [Google Scholar] [CrossRef]

- Page, I.B. Polyamides as Engineering Thermoplastic Materials; No. 1; iSmithers Rapra Publishing: Akron, OH, USA, 2000; Volume 11. [Google Scholar]

- Razumovskii, L.P.; Markin, V.S.; Zaikov, G.Y. Sorption of water by aliphatic polyamides. Review. Polym. Sci. USSR 1985, 27, 751–768. [Google Scholar] [CrossRef]

- Gilbert, M. Aliphatic polyamides. In Brydson’s Plastics Materials; Butterworth-Heinemann: Oxford, UK, 2017; pp. 487–511. [Google Scholar]

- Favre, J.-P. Improving the fracture energy of carbon fibre-reinforced plastics by delamination promoters. J. Mater. Sci. 1977, 12, 43–50. [Google Scholar] [CrossRef]

- ASTM Standard D7137; Standard Test Method for Compression Residual Strength Properties of Damaged Polymer Matrix Composite Plates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- ASTM Standard D2344; Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2022.

- ISO 9864; Geosynthetics—Test Method for the Determination of Mass per Unit Area of Geotextiles and Geotextile-Related Products. ISO: Geneva, Switzerland, 2014.

- ASTM Standard D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2014.

- ASTM Standard D6641Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture, American Society for Testing and Materials: West Conshohocken, PA, USA, 2014.

- ASTM Standard D5379Standard Test Method for Shear Properties of Composite Materials by the V-Notched Beam Method, American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

| Test Type | Regulatory Documentation | T107 | T107 with One Layer of Nonwoven Material | T107 with Two Layers of Nonwoven Material |

|---|---|---|---|---|

| Compressive strength after impact σ11−, MPa | ASTM D7137 [42] | 260 ± 5.2 | 290 ± 5.6 | 320 ± 6.6 |

| Interlaminar shear strength τ13, MPa | ASTM D2344 [43] | 106 ± 3.7 | 100 ± 1.5 | 97 ± 2.3 |

| Prepreg surface density, g/m2 | ISO 9864 [44] | 308 ± 5.1 | 315 ± 10.3 | 328 ± 13.6 |

| Monolayer thickness, mm | – | 0.2 ± 0.03 | 0.21 ± 0.03 | 0.22 ± 0.04 |

| Test Type | Regulatory Documentation | T107 | T107 with Nonwoven Material |

|---|---|---|---|

| Tensile strength σ11+, MPa | ASTM D3039 [45] | 2136 ± 31.5 | 2300 ± 51.0 |

| Tensile modulus Ε11+, GPa | ASTM D3039 [45] | 139 ± 3.2 | 141 ± 2.9 |

| Compressive strength σ11−, MPa | ASTM D 6641 [46] | 957 ± 21.2 | 1264 ± 25.8 |

| Interlaminar shear strength τ13, MPa | ASTM D2344 [43] | 106 ± 3.7 | 97 ± 2.3 |

| Shear strength τ12, MPa | ASTM D5379 [47] | 147 ± 4.1 | 143 ± 3.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kondrateva, A.; Morozov, O.; Erdni-Goryaev, E.; Afanaseva, E.; Avdeev, V. Improvement of the Impact Resistance of Epoxy Prepregs Through the Incorporation of Polyamide Nonwoven Fabric. Materials 2025, 18, 661. https://doi.org/10.3390/ma18030661

Kondrateva A, Morozov O, Erdni-Goryaev E, Afanaseva E, Avdeev V. Improvement of the Impact Resistance of Epoxy Prepregs Through the Incorporation of Polyamide Nonwoven Fabric. Materials. 2025; 18(3):661. https://doi.org/10.3390/ma18030661

Chicago/Turabian StyleKondrateva, Anastasia, Oleg Morozov, Erdni Erdni-Goryaev, Ekaterina Afanaseva, and Viktor Avdeev. 2025. "Improvement of the Impact Resistance of Epoxy Prepregs Through the Incorporation of Polyamide Nonwoven Fabric" Materials 18, no. 3: 661. https://doi.org/10.3390/ma18030661

APA StyleKondrateva, A., Morozov, O., Erdni-Goryaev, E., Afanaseva, E., & Avdeev, V. (2025). Improvement of the Impact Resistance of Epoxy Prepregs Through the Incorporation of Polyamide Nonwoven Fabric. Materials, 18(3), 661. https://doi.org/10.3390/ma18030661