Microstructural Engineering of Ferroelectric and Electromechanical Properties in 0.65KBT-0.35BCZT Ceramics

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

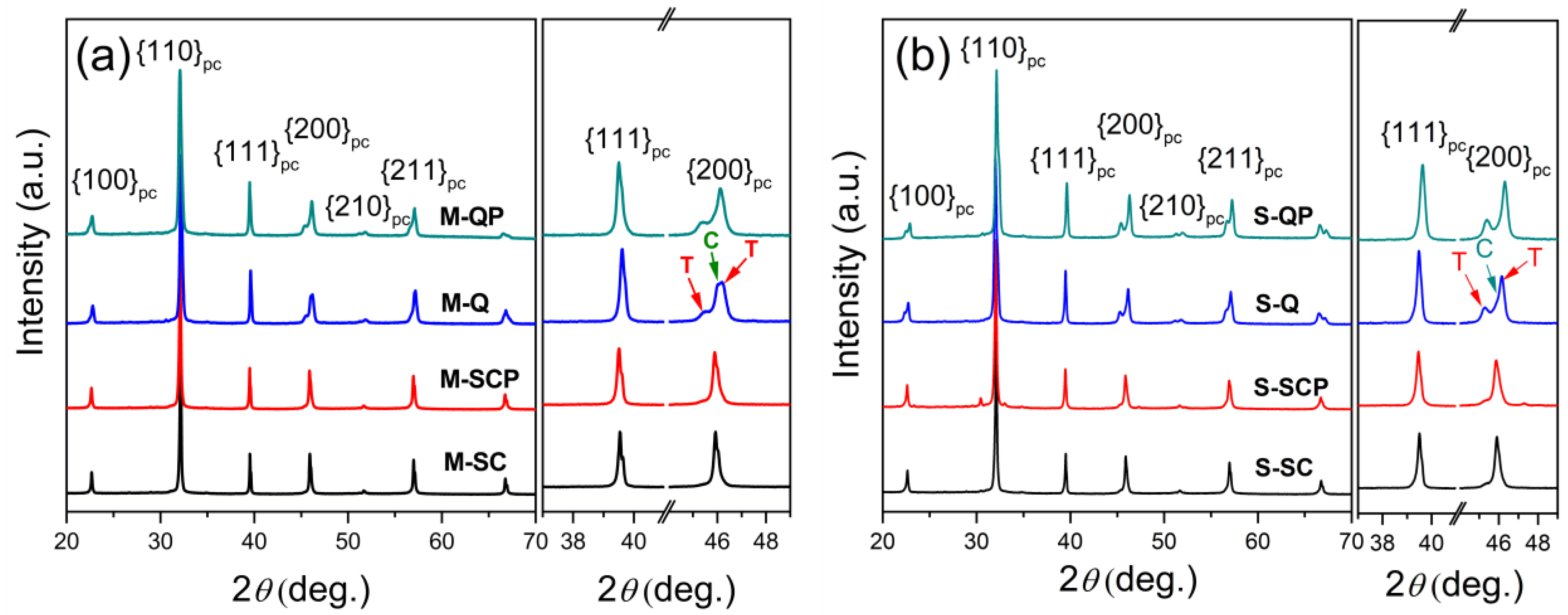

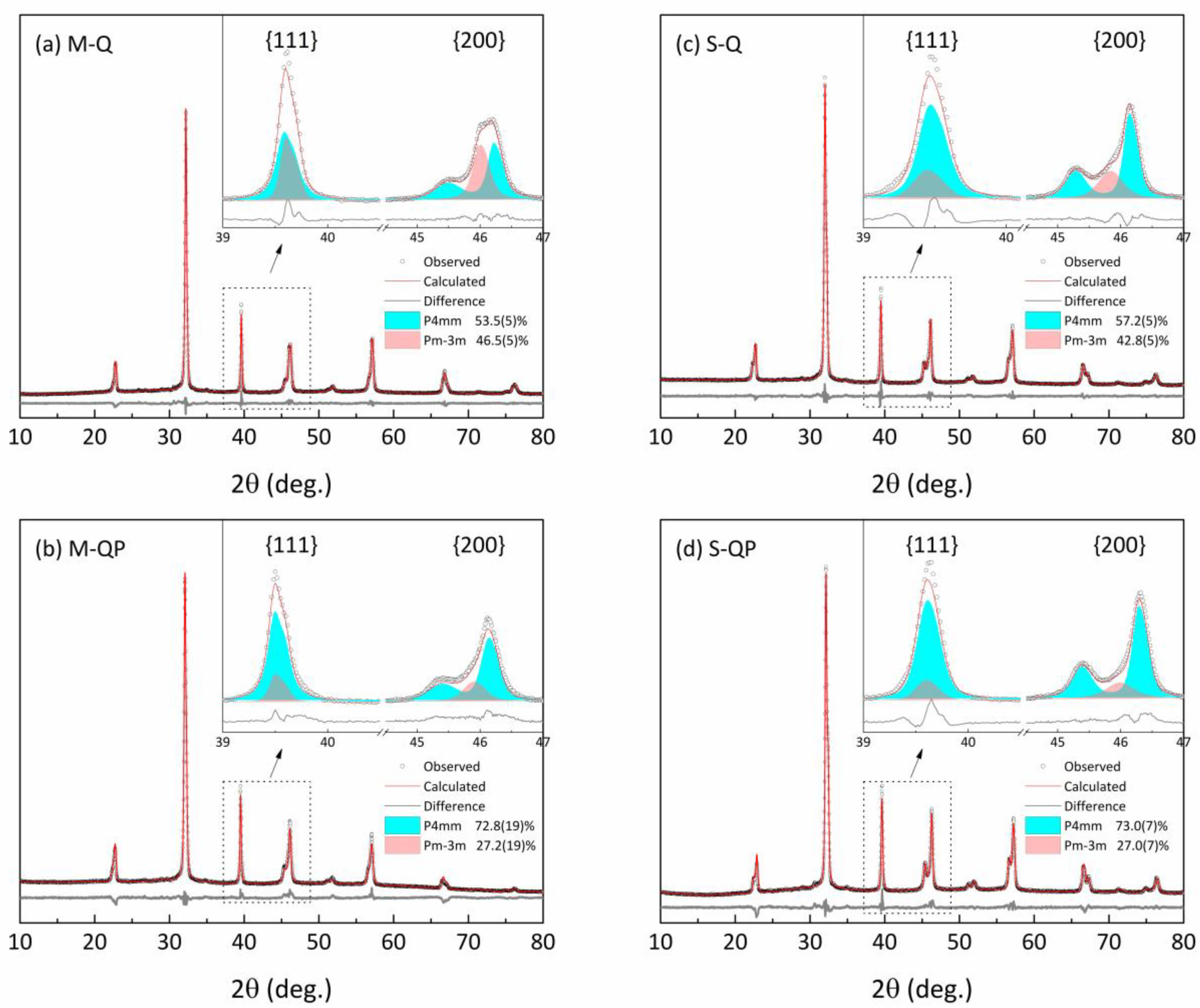

3.1. Structural Characterization

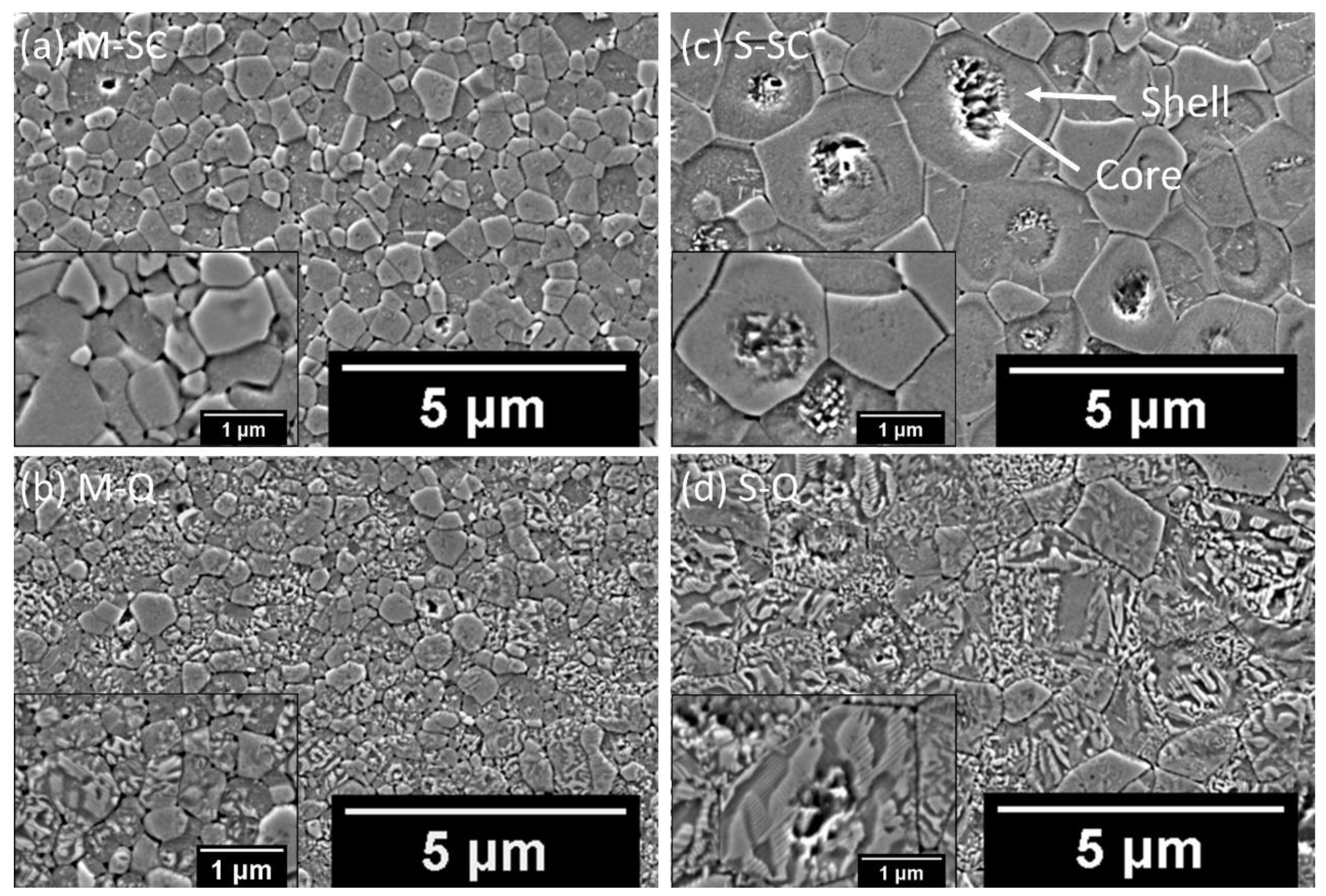

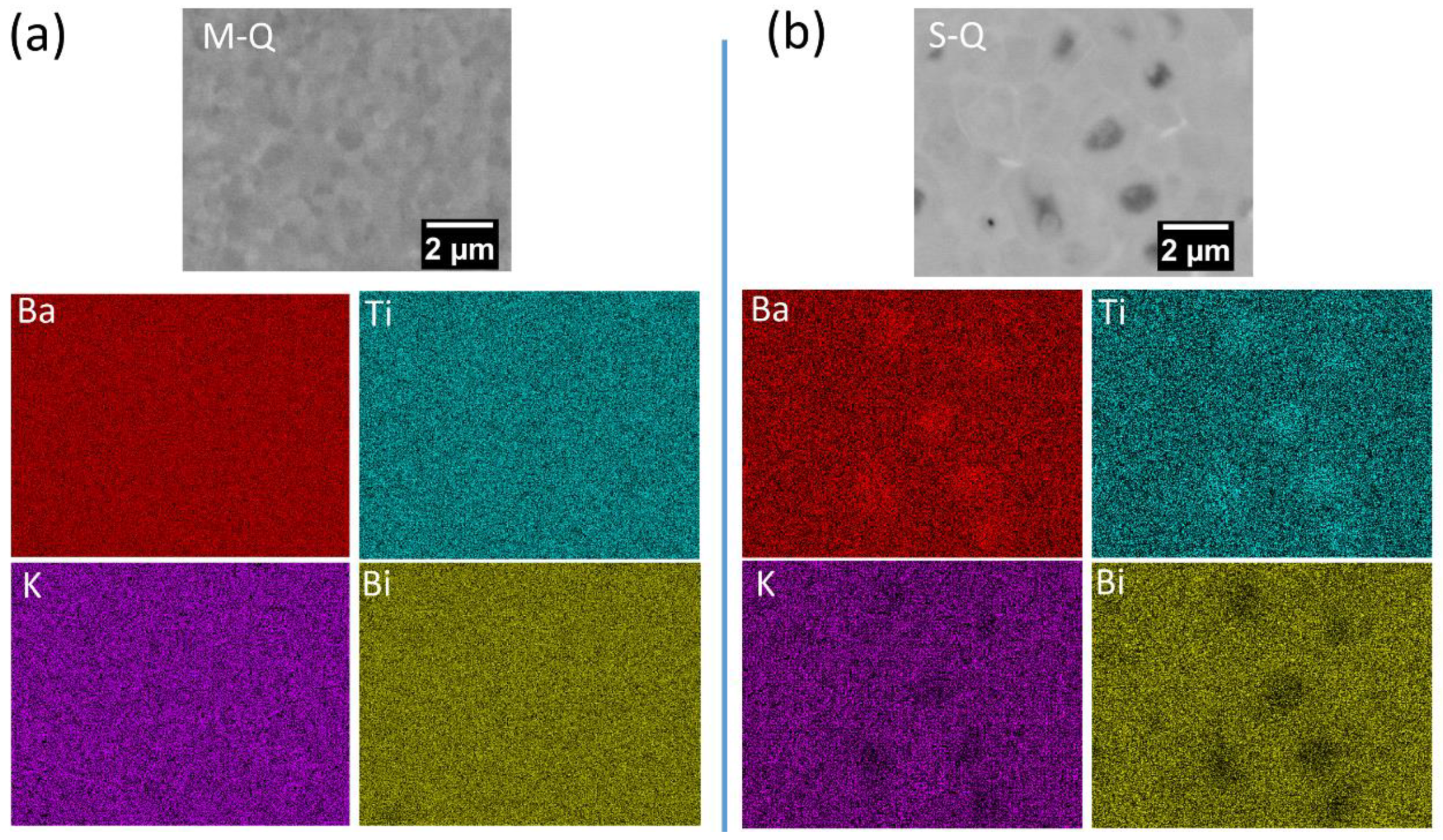

3.2. Microstructure

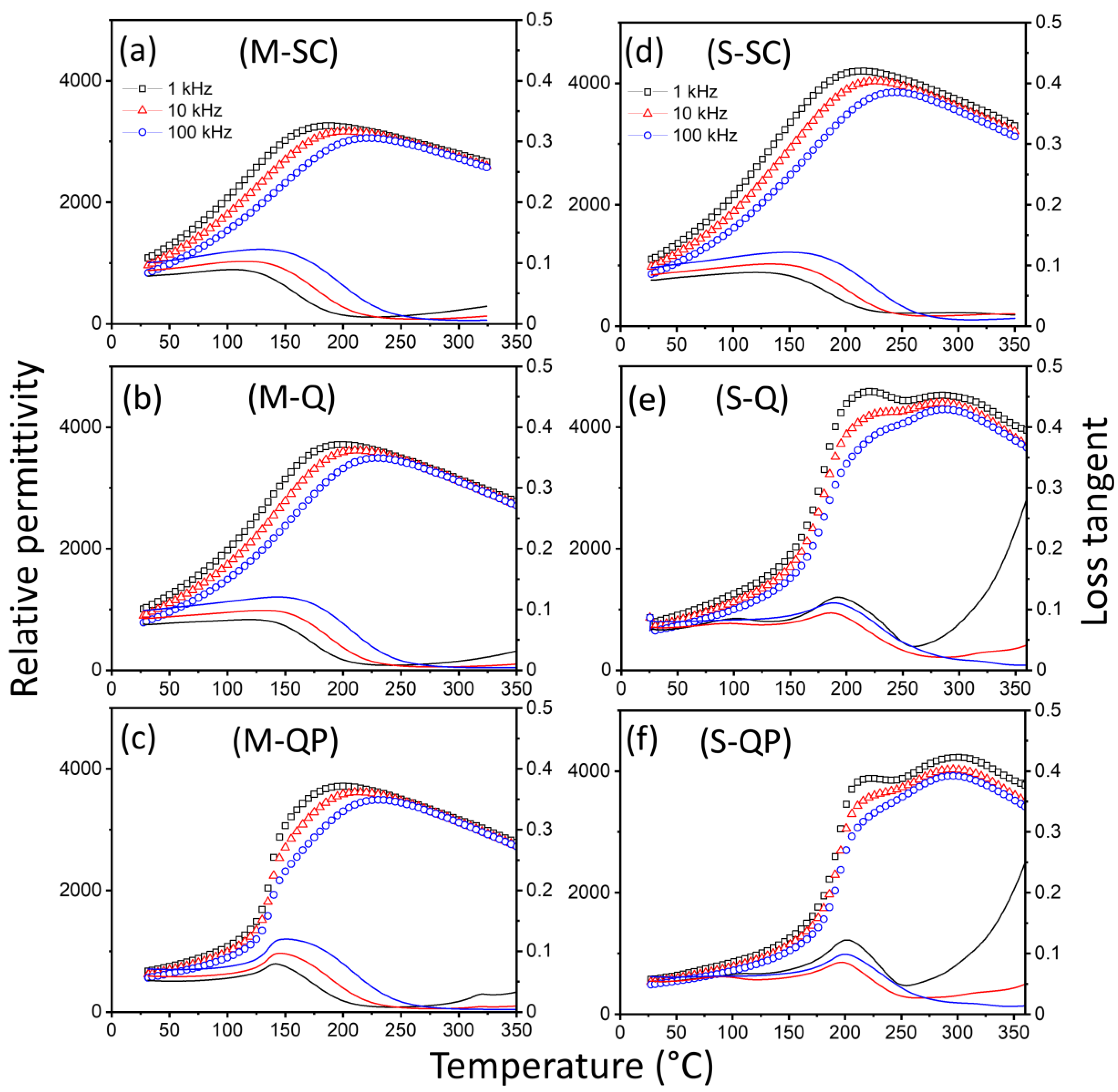

3.3. Dielectric and Ferroelectric Properties

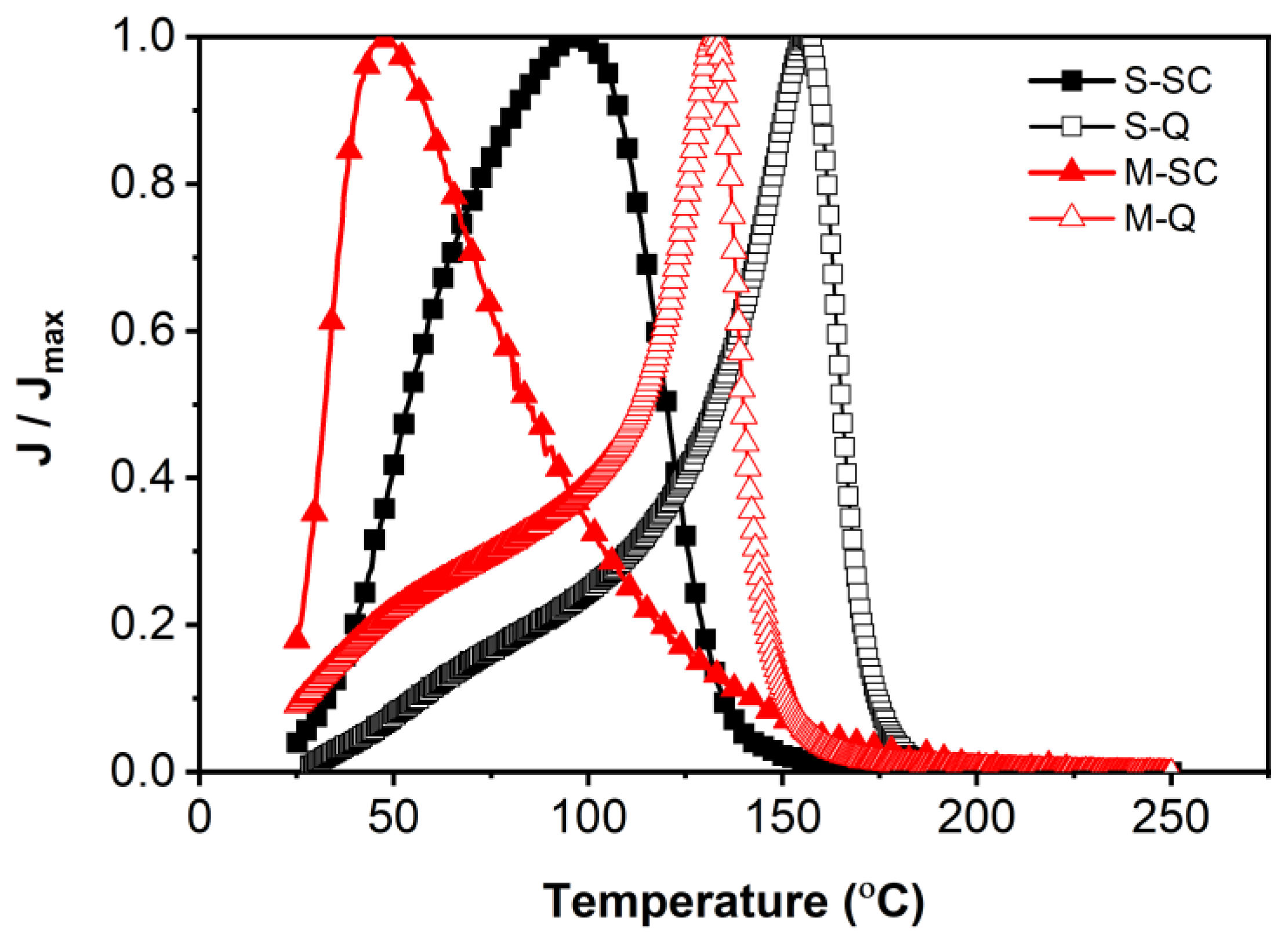

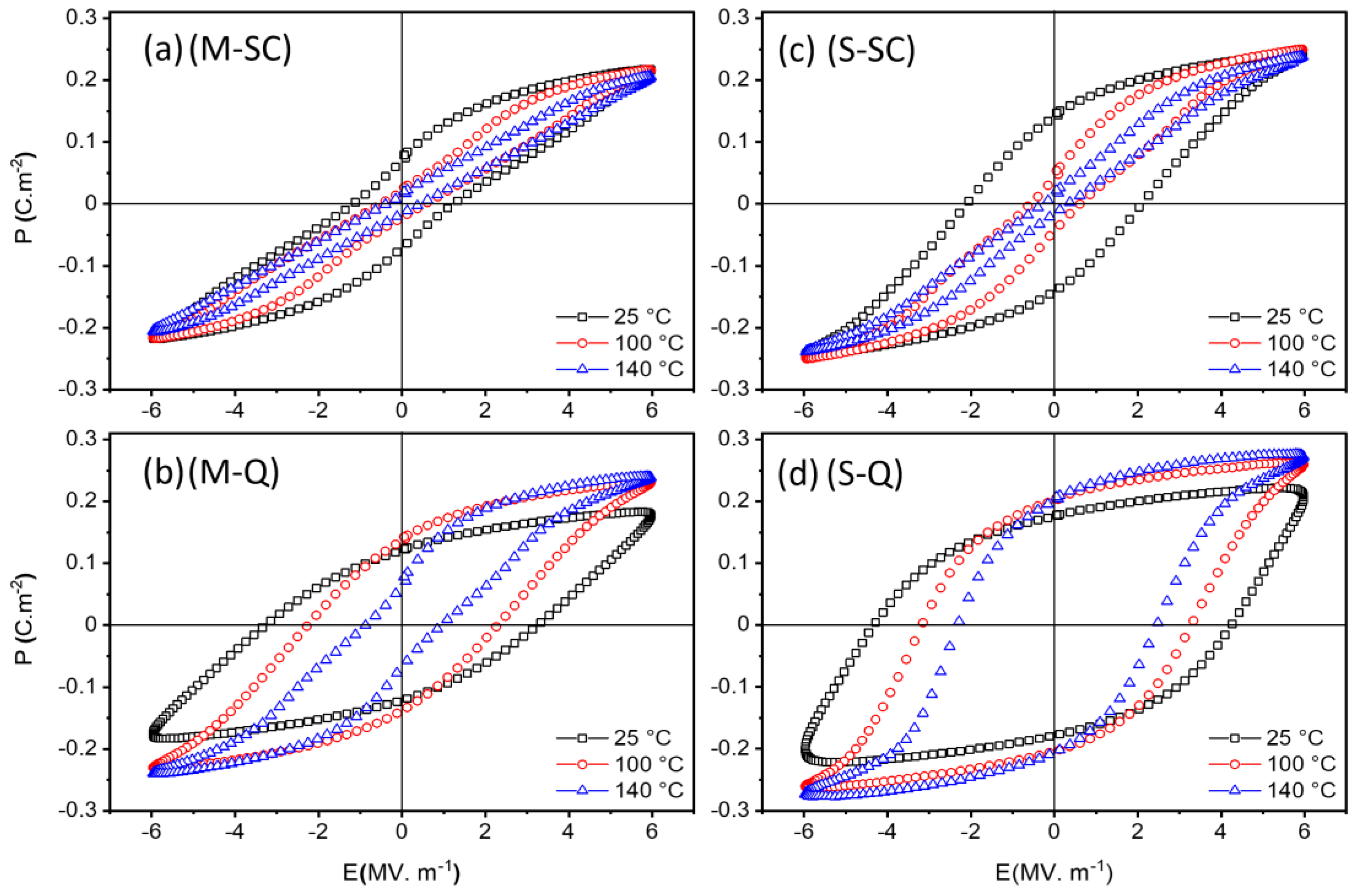

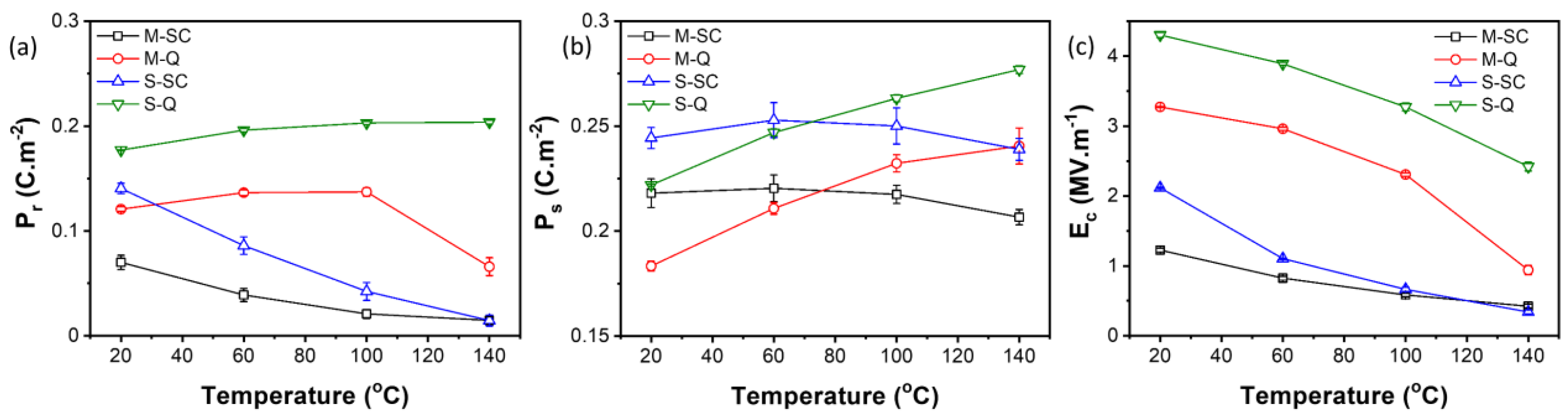

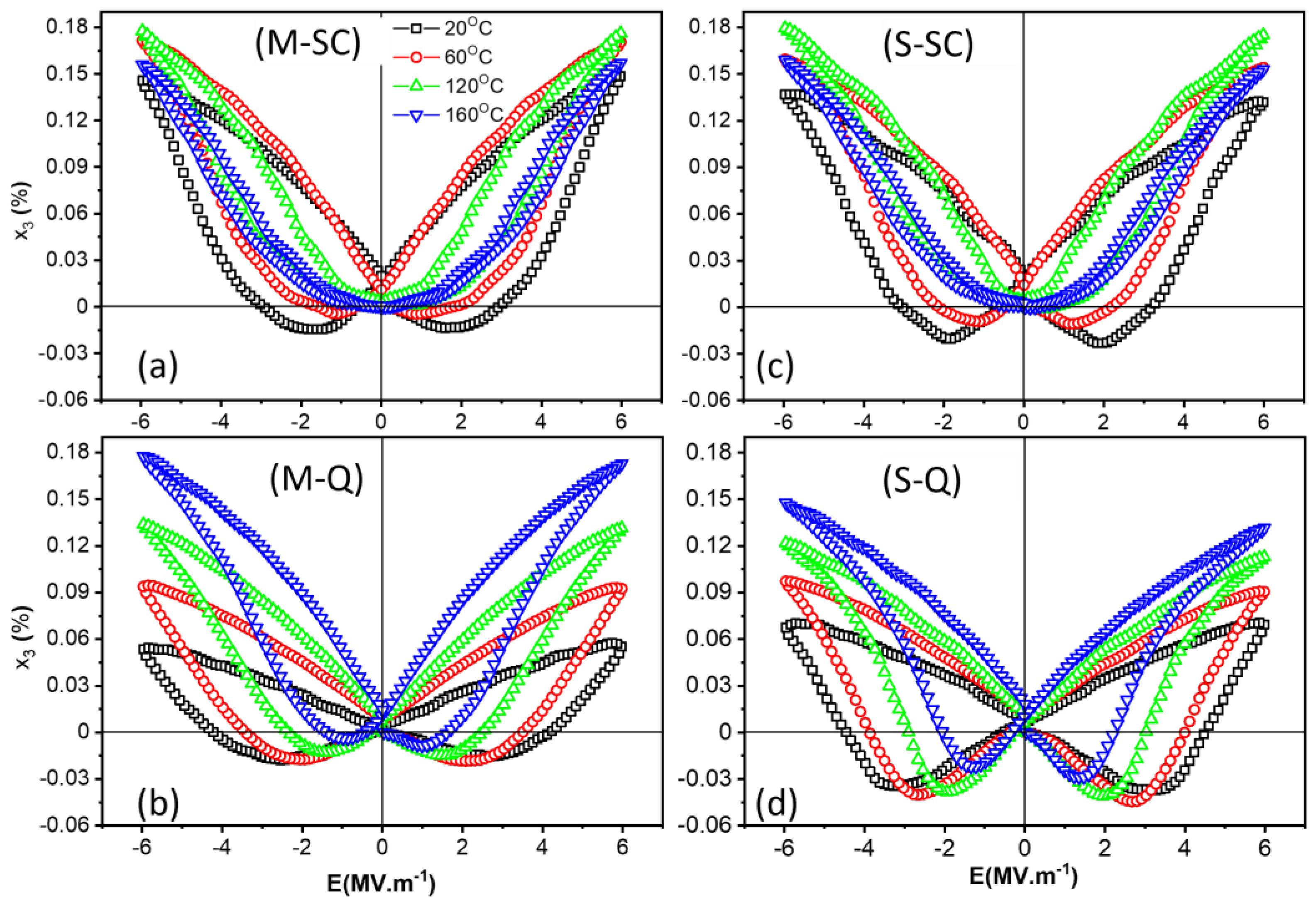

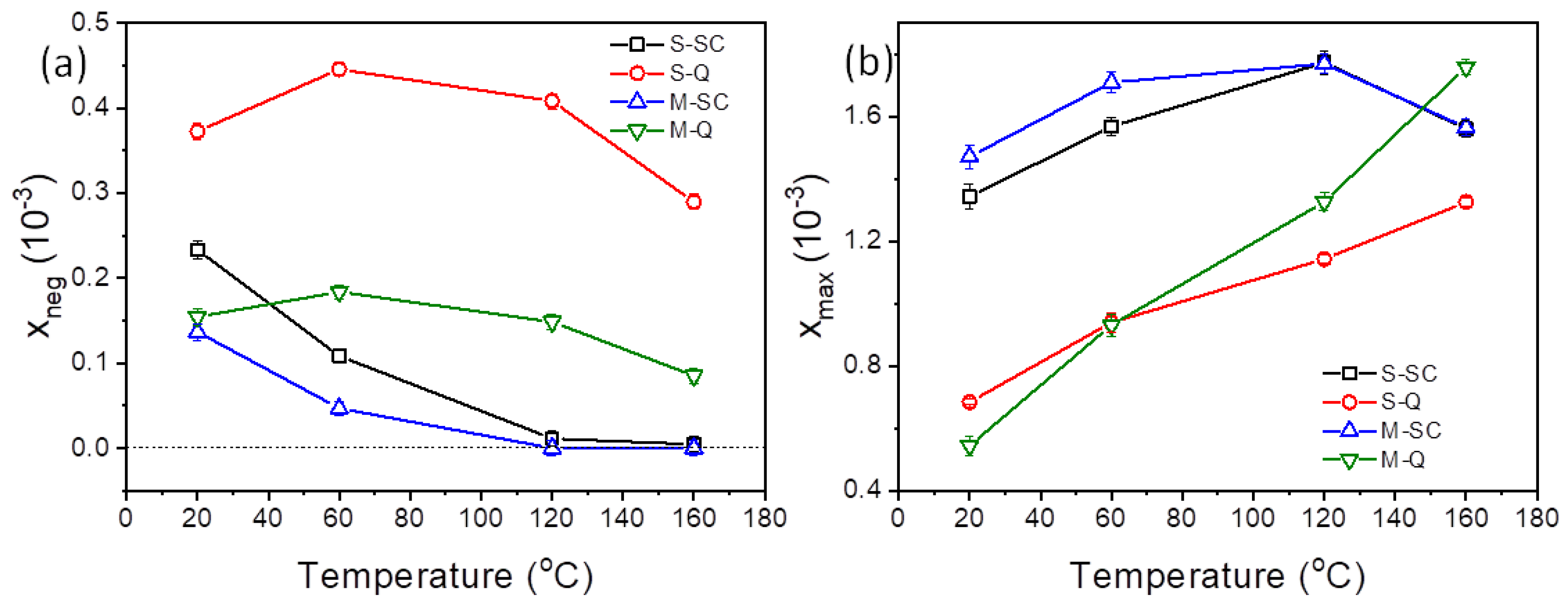

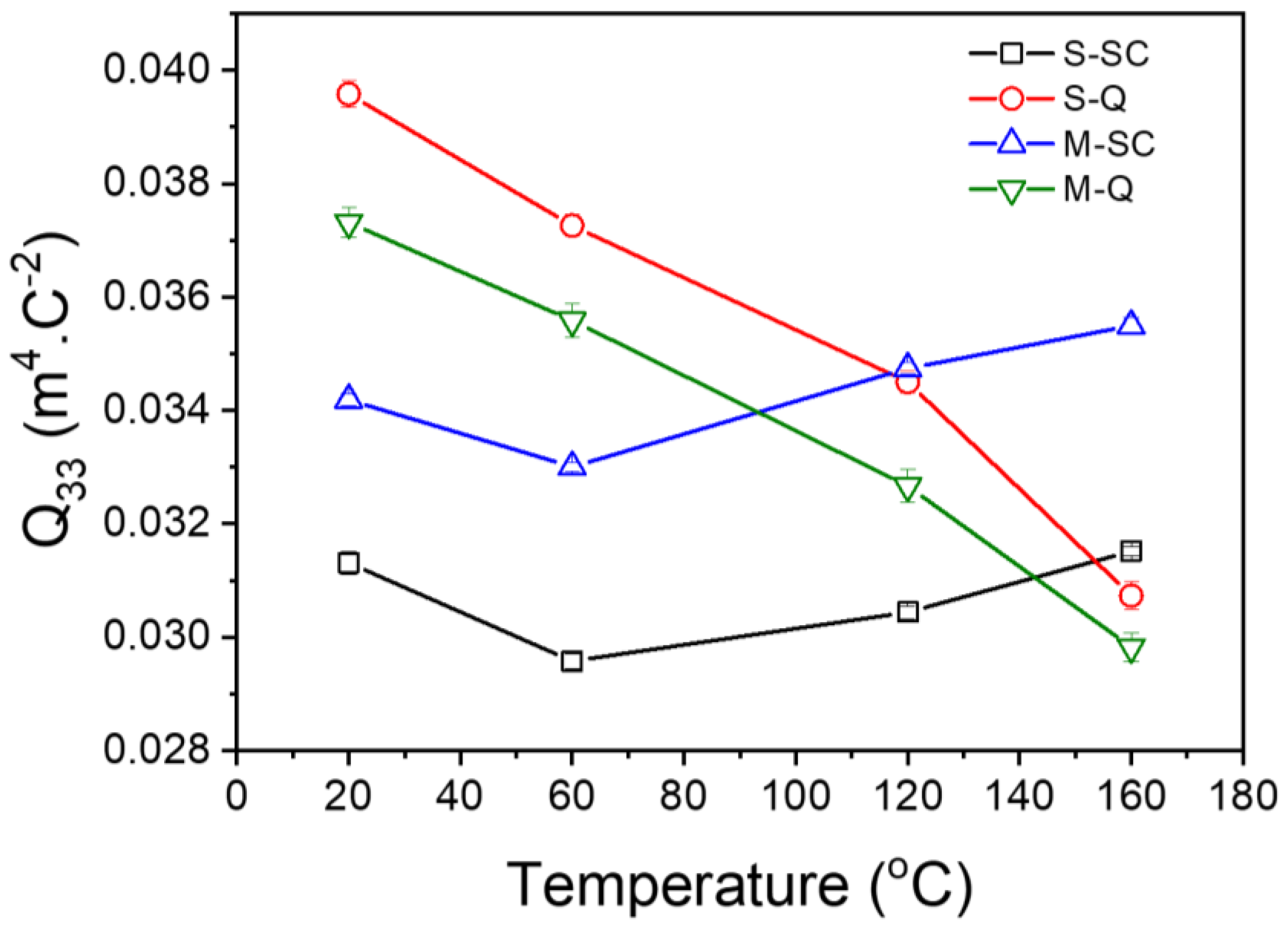

3.4. Thermal Evolution of Ferroelectric and Electromechanical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aksel, E.; Jones, J.L. Advances in lead-free piezoelectric materials for sensors and actuators. Sensors 2010, 10, 1935–1954. [Google Scholar] [CrossRef] [PubMed]

- Rödel, J.; Webber, K.G.; Dittmer, R.; Jo, W.; Kimura, M.; Damjanovic, D. Transferring lead-free piezoelectric ceramics into application. J. Eur. Ceram. Soc. 2015, 35, 1659–1681. [Google Scholar] [CrossRef]

- Hong, C.-H.; Kim, H.-P.; Choi, B.-Y.; Han, H.-S.; Son, J.S.; Ahn, C.W.; Jo, W. Lead-free piezoceramics—Where to move on? J. Mater. 2016, 2, 1–24. [Google Scholar] [CrossRef]

- Jo, W.; Granzow, T.; Aulbach, E.; Rödel, J.; Damjanovic, D. Origin of the large strain response in (K0.5Na0.5)NbO3-modified (Bi0.5Na0.5)TiO3–BaTiO3 lead-free piezoceramics. J. Appl. Phys. 2009, 105, 094102. [Google Scholar] [CrossRef]

- European Parliament and the European Council, On the restriction of the use of certain hazardous substances in electrical and electronic equipment, Directive 2011/65/EU. Off. J. Eur. Union 2011, 174, 88–110.

- Rödel, J.; Jo, W.; Seifert, K.T.P.; Anton, E.-M.; Granzow, T.; Damjanovic, D. Perspective on the Development of Lead-free Piezoceramics. J. Am. Ceram. Soc. 2009, 92, 1153–1177. [Google Scholar] [CrossRef]

- Mane, S.M.; Tirmali, P.M.; Salunkhe, D.J.; Joshi, P.B.; Kolekar, C.B.; Kulkarni, S.B. Synthesis, structural and dielectric characterization of lead free x[(Ba0.7Ca0.3)TiO3]–(1−x)[Ba(Zr0.2Ti0.8)O3] composite. J. Mater. Sci. Mater. Electron. 2016, 27, 7204–7210. [Google Scholar] [CrossRef]

- Mane, S.M.; Tirmali, P.M.; Kadam, S.L.; Salunkhe, D.J.; Kolekar, C.B.; Kulkarni, S.B. Microwave-assisted sintering and improved dielectric, ferroelectric properties of 0.5[(Ba0.7Ca0.3)TiO3]–0.5[Ba(Zr0.2Ti0.8)O3] lead-free ceramics. Adv. Appl. Ceram. 2017, 116, 325–332. [Google Scholar] [CrossRef]

- Acosta, M.; Novak, N.; Rojas, V.; Patel, S.; Vaish, R.; Koruza, J.; Rossetti, G.A.; Rödel, J. BaTiO3-based piezoelectrics: Fundamentals, current status, and perspectives. Appl. Phys. Rev. 2017, 4, 041305. [Google Scholar] [CrossRef]

- Kumari, P.; Rai, R.; Sharma, S.; Shandilya, M.; Tiwari, A. State-of-the-art of lead free ferroelectrics: A critical review. Adv. Mater. Lett. 2015, 6, 453–484. [Google Scholar] [CrossRef]

- Panda, P.K.; Sahoo, B. PZT to lead free piezo ceramics: A review. Ferroelectrics 2015, 474, 128–143. [Google Scholar] [CrossRef]

- Zhang, S.T.; Kounga, A.B.; Aulbach, E.; Ehrenberg, H.; Rödel, J. Giant strain in lead-free piezoceramics Bi0.5Na0.5TiO3–BaTiO3–K0.5Na0.5NbO3 system. Appl. Phys. Lett. 2007, 91, 112906. [Google Scholar] [CrossRef]

- Al-Aaraji, M.N.; Hall, D.A. Influence of K0.5 Bi0.5 TiO3 on the structure, dielectric and ferroelectric properties of (Ba,Ca)(Zr,Ti)O3 ceramics. J. Eur. Ceram. Soc. 2018, 38, 2344–2352. [Google Scholar] [CrossRef]

- Zhao, W.; Zuo, R.; Fu, J.; Shi, M. Large strains accompanying field-induced ergodic phase-polar ordered phase transformations in Bi(Mg0.5Ti0.5)O3–PbTiO3–(Bi0.5Na0.5)TiO3 ternary system. J. Eur. Ceram. Soc. 2014, 34, 2299–2309. [Google Scholar] [CrossRef]

- Al-Aaraji, M.N.; Feteira, A.; Thompson, S.P.; Murray, C.A.; Hall, D.A. Effects of quenching on phase transformations and ferroelectric properties of 0.35BCZT-0.65KBT ceramics. J. Eur. Ceram. Soc. 2019, 39, 4070–4084. [Google Scholar] [CrossRef]

- Müller-Fiedler, R.; Knoblauch, V. Reliability aspects of microsensors and micromechatronic actuators for automotive applications. Microelectron. Reliab. 2003, 43, 1085–1097. [Google Scholar] [CrossRef]

- Acosta, M.; Schmitt, L.A.; Molina-Luna, L.; Scherrer, M.C.; Brilz, M.; Webber, K.G.; Deluca, M.; Kleebe, H.-J.; Rödel, J.; Donner, W. Core-shell lead-free piezoelectric ceramics: Current status and advanced characterization of the Bi1/2Na1/2TiO3-SrTiO3 system. J. Am. Ceram. Soc. 2015, 98, 3405–3422. [Google Scholar] [CrossRef]

- Jo, W.; Dittmer, R.; Acosta, M.; Zang, J.; Groh, C.; Sapper, E.; Wang, K.; Rödel, J. Giant electric-field-induced strains in lead-free ceramics for actuator applications—Status and perspective. J. Electroceramics 2012, 29, 71–93. [Google Scholar] [CrossRef]

- Ahmed Malik, R.; Hussain, A.; Kwon Song, T.; Kim, W.-J.; Ahmed, R.; Sung, Y.S.; Kim, M.-H. Enhanced electromechanical properties of (1-x)BiFeO3–BaTiO3—xLiNbO3 ceramics by quenching process. Ceram. Int. 2017, 43, S198–S203. [Google Scholar] [CrossRef]

- Groh, C.; Franzbach, D.J.; Jo, W.; Webber, K.G.; Kling, J.; Schmitt, L.A.; Kleebe, H.-J.; Jeong, S.-J.; Lee, J.-S.; Rödel, J. Relaxor/Ferroelectric Composites: A Solution in the Quest for Practically Viable Lead-Free Incipient Piezoceramics. Adv. Funct. Mater. 2014, 24, 356–362. [Google Scholar] [CrossRef]

- Ayrikyan, A.; Rojas, V.; Molina-Luna, L.; Acosta, M.; Koruza, J.; Webber, K.G. Enhancing electromechanical properties of lead-free ferroelectrics with bilayer ceramic/ceramic composites. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2015, 62, 997–1006. [Google Scholar] [CrossRef] [PubMed]

- Ogihara, H.; Randall, C.A.; Trolier-McKinstry, S. Weakly coupled relaxor behavior of BaTiO3-BiScO3 ceramics. J. Am. Ceram. Soc. 2009, 92, 110–118. [Google Scholar] [CrossRef]

- Hiruma, Y.; Imai, Y.; Watanabe, Y.; Nagata, H.; Takenaka, T. Large electrostrain near the phase transition temperature of (Bi0.5Na0.5)TiO3–SrTiO3 ferroelectric ceramics. Appl. Phys. Lett. 2008, 92, 262904. [Google Scholar] [CrossRef]

- Acosta, M.; Jo, W.; Rödel, J.; Lupascu, D.C. Temperature- and frequency-dependent properties of the 0.75Bi1/2 Na1/2 TiO3-0.25SrTiO3 lead-free incipient piezoceramic. J. Am. Ceram. Soc. 2014, 97, 1937–1943. [Google Scholar] [CrossRef]

- Rout, D.; Moon, K.-S.; Kang, S.-J.L.; Kim, I.W. Dielectric and Raman scattering studies of phase transitions in the (100−x)Na0.5Bi0.5TiO3–xSrTiO3 system. J. Appl. Phys. 2010, 108, 084102. [Google Scholar] [CrossRef]

- Gomah-Pettry, J. Sodium-bismuth titanate based lead-free ferroelectric materials. J. Eur. Ceram. Soc. 2004, 24, 1165–1169. [Google Scholar] [CrossRef]

- Park, S.E.; Hong, K.S. Variations of structure and dielectric properties on substituting A-site cations for Sr2+ in (Na1/2Bi1/2)TiO3. J. Mater. Res. 1997, 12, 2152–2157. [Google Scholar] [CrossRef]

- Krauss, W.; Schütz, D.; Mautner, F.A.; Feteira, A.; Reichmann, K. Piezoelectric properties and phase transition temperatures of the solid solution of (1−x)(Bi0.5Na0.5)TiO3–xSrTiO3. J. Eur. Ceram. Soc. 2010, 30, 1827–1832. [Google Scholar] [CrossRef]

- Kim, S.; Khanal, G.P.; Ueno, S.; Moriyoshi, C.; Kuroiwa, Y.; Wada, S. Revealing the role of heat treatment in enhancement of electrical properties of lead-free piezoelectric ceramics. J. Appl. Phys. 2017, 122, 014103. [Google Scholar] [CrossRef]

- Miura, T.; Nagata, H.; Takenaka, T. Quenching effects on piezoelectric properties and depolarization temperatures of (Bi0.5Na0.5)TiO3-based solid solution systems. Jpn. J. Appl. Phys. 2017, 56, 10PD05. [Google Scholar] [CrossRef]

- Li, Q.; Wei, J.; Tu, T.; Cheng, J.; Chen, J. Remarkable piezoelectricity and stable high-temperature dielectric properties of quenched BiFeO3 -BaTiO3 ceramics. J. Am. Ceram. Soc. 2017, 100, 5573–5583. [Google Scholar] [CrossRef]

- Muramatsu, H.; Nagata, H.; Takenaka, T. Quenching effects for piezoelectric properties on lead-free (Bi1/2Na1/2)TiO3ceramics. Jpn. J. Appl. Phys. 2016, 55, 10TB07. [Google Scholar] [CrossRef]

- Calisir, I.; Hall, D.A. Chemical heterogeneity and approaches to its control in BiFeO3–BaTiO3 lead-free ferroelectrics. J. Mater. Chem. C 2018, 6, 134–146. [Google Scholar] [CrossRef]

- Koruza, J.; Rojas, V.; Molina-Luna, L.; Kunz, U.; Duerrschnabel, M.; Kleebe, H.-J.; Acosta, M. Formation of the core–shell microstructure in lead-free Bi1/2Na1/2TiO3-SrTiO3 piezoceramics and its influence on the electromechanical properties. J. Eur. Ceram. Soc. 2016, 36, 1009–1016. [Google Scholar] [CrossRef]

- Cheng, S.-Y.; Shieh, J.; Lu, H.-Y.; Shen, C.-Y.; Tang, Y.-C.; Ho, N.-J. Structure analysis of bismuth sodium titanate-based A-site relaxor ferroelectrics by electron diffraction. J. Eur. Ceram. Soc. 2013, 33, 2141–2153. [Google Scholar] [CrossRef]

- Calisir, I.; Amirov, A.A.; Kleppe, A.K.; Hall, D.A. Optimisation of functional properties in lead-free BiFeO3–BaTiO3 ceramics through La3+ substitution strategy. J. Mater. Chem. A 2018, 6, 5378–5397. [Google Scholar] [CrossRef]

- Stewart, M.; Cain, M.G.; Hall, D.A. Ferroelectric Hysteresis Measurement & Analysis; National Physical Laboratory: Teddington, UK, 1999. [Google Scholar]

- Anton, E.-M.; Jo, W.; Damjanovic, D.; Rödel, J. Determination of depolarization temperature of (Bi1/2Na1/2)TiO3-based lead-free piezoceramics. J. Appl. Phys. 2011, 110, 094108. [Google Scholar] [CrossRef]

- Diffrac. Suite TOPAS, version 5.0; BRUKER AXS GmbH: Karlsruhe, Germany, 2014. [Google Scholar]

| Sample Type | Phase Fraction (%) | Lattice Parameter | (c/a)T | GoF | |

|---|---|---|---|---|---|

| a (Å) | c (Å) | ||||

| M-Q | T = 53.5(5) C = 46.5(5) | aT = 3.95331(14) aC = 3.97152(12) | cT = 4.0154(3) | 1.0157 | 1.88 |

| M-QP | T = 72.8(19) C = 27.2(19) | aT = 3.9557(3) aC = 3.9758(3) | cT = 4.0182(5) | 1.0158 | 2.31 |

| S-Q | T = 57.2(5) C = 42.8(5) | aT = 3.94962(12) aC = 3.97613(19) | cT = 4.02212(19) | 1.0185 | 1.96 |

| S-QP | T = 73.0(7) C = 27.0(7) | aT = 3.95016(15) aC = 3.9767(3) | cT = 4.0266(2) | 1.0194 | 2.25 |

| S | M | |||

|---|---|---|---|---|

| SC | Q | SC | Q | |

| d33 (pC N−1) | 40 | 82 | 16 | 71 |

| d33* (pm V−1), xmax/Emax | 240 | 113 | 246 | 91 |

| Q33 (m4 C−2) | 0.031 | 0.04 | 0.034 | 0.037 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Aaraji, M.N.; Wang, B.; Feteira, A.; Hall, D.A. Microstructural Engineering of Ferroelectric and Electromechanical Properties in 0.65KBT-0.35BCZT Ceramics. Materials 2025, 18, 623. https://doi.org/10.3390/ma18030623

Al-Aaraji MN, Wang B, Feteira A, Hall DA. Microstructural Engineering of Ferroelectric and Electromechanical Properties in 0.65KBT-0.35BCZT Ceramics. Materials. 2025; 18(3):623. https://doi.org/10.3390/ma18030623

Chicago/Turabian StyleAl-Aaraji, Mohammed N., Bing Wang, Antonio Feteira, and David A. Hall. 2025. "Microstructural Engineering of Ferroelectric and Electromechanical Properties in 0.65KBT-0.35BCZT Ceramics" Materials 18, no. 3: 623. https://doi.org/10.3390/ma18030623

APA StyleAl-Aaraji, M. N., Wang, B., Feteira, A., & Hall, D. A. (2025). Microstructural Engineering of Ferroelectric and Electromechanical Properties in 0.65KBT-0.35BCZT Ceramics. Materials, 18(3), 623. https://doi.org/10.3390/ma18030623