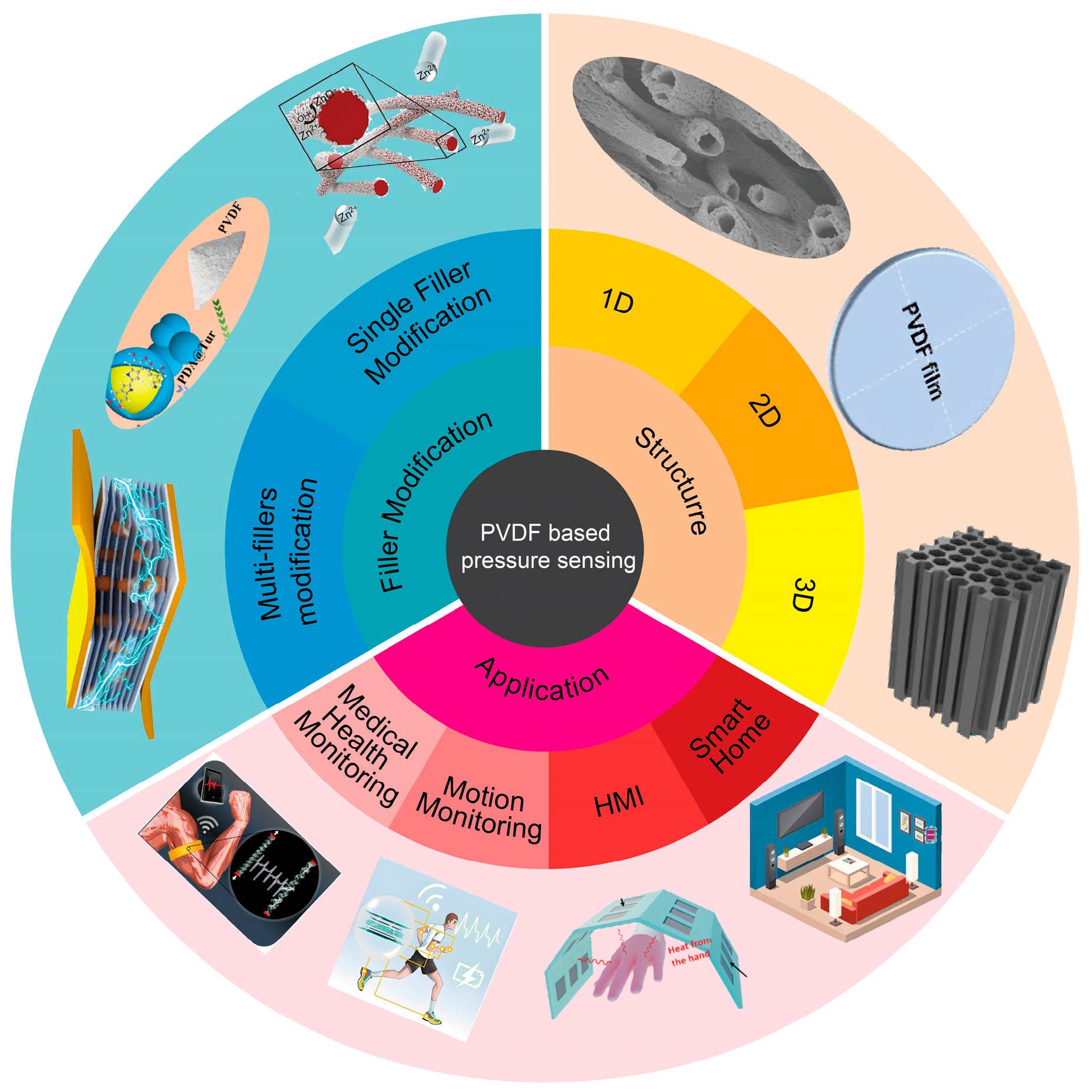

Flexible Pressure Sensors Based on Polyvinylidene Fluoride: A Critical Review

Abstract

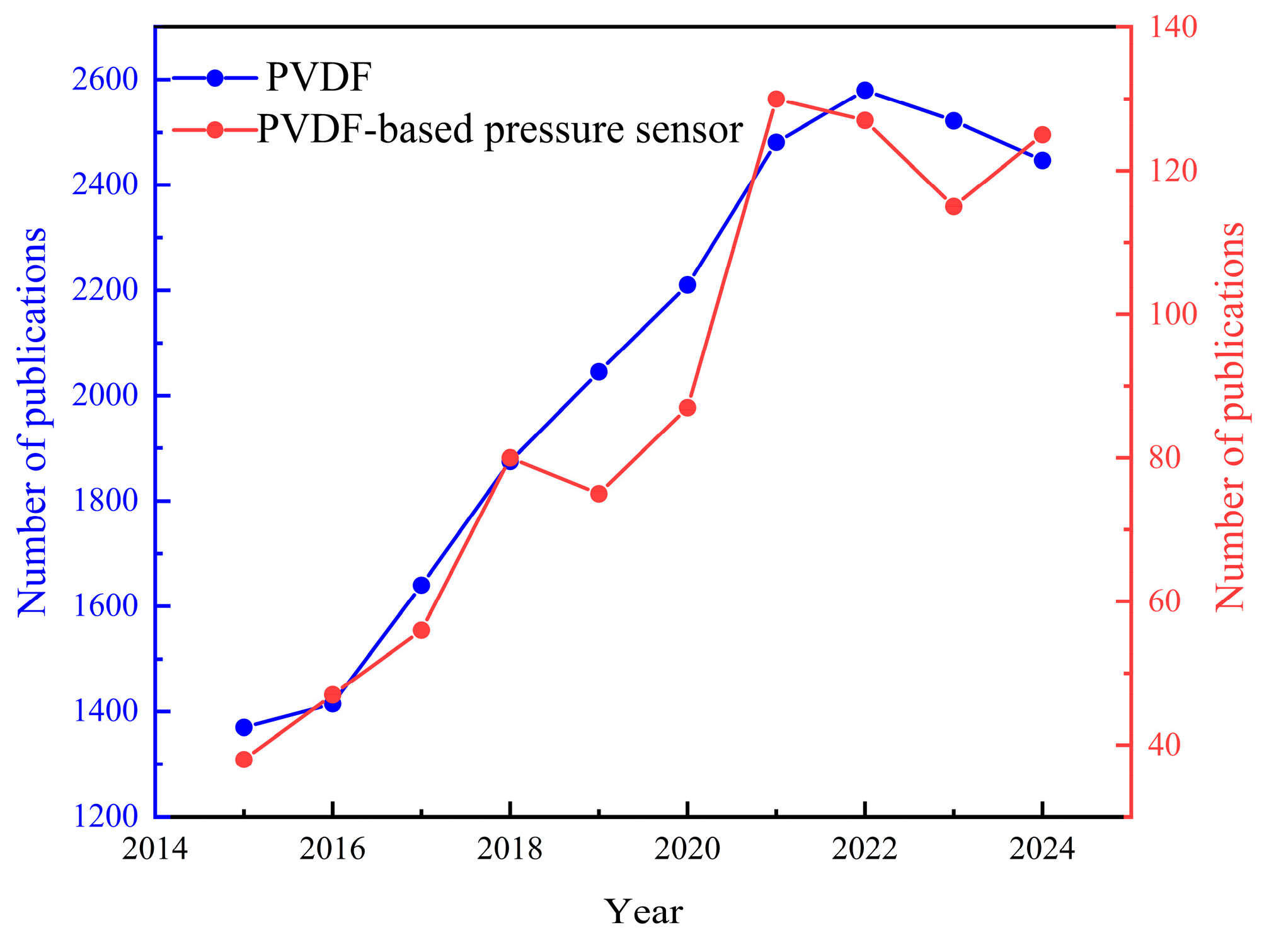

1. Introduction

2. PVDF and PVDF-Based Pressure Sensors

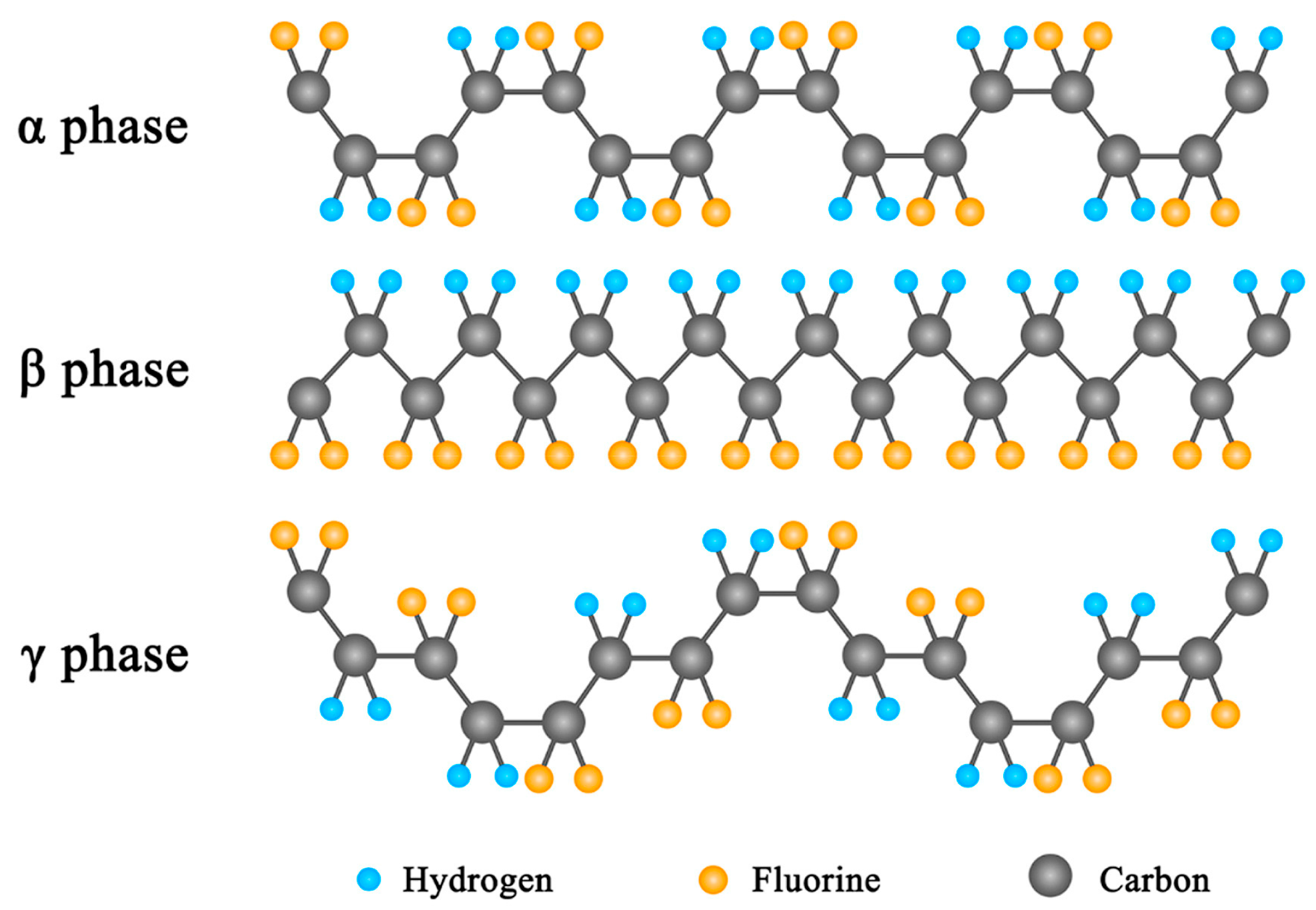

2.1. Piezoelectricity of PVDF

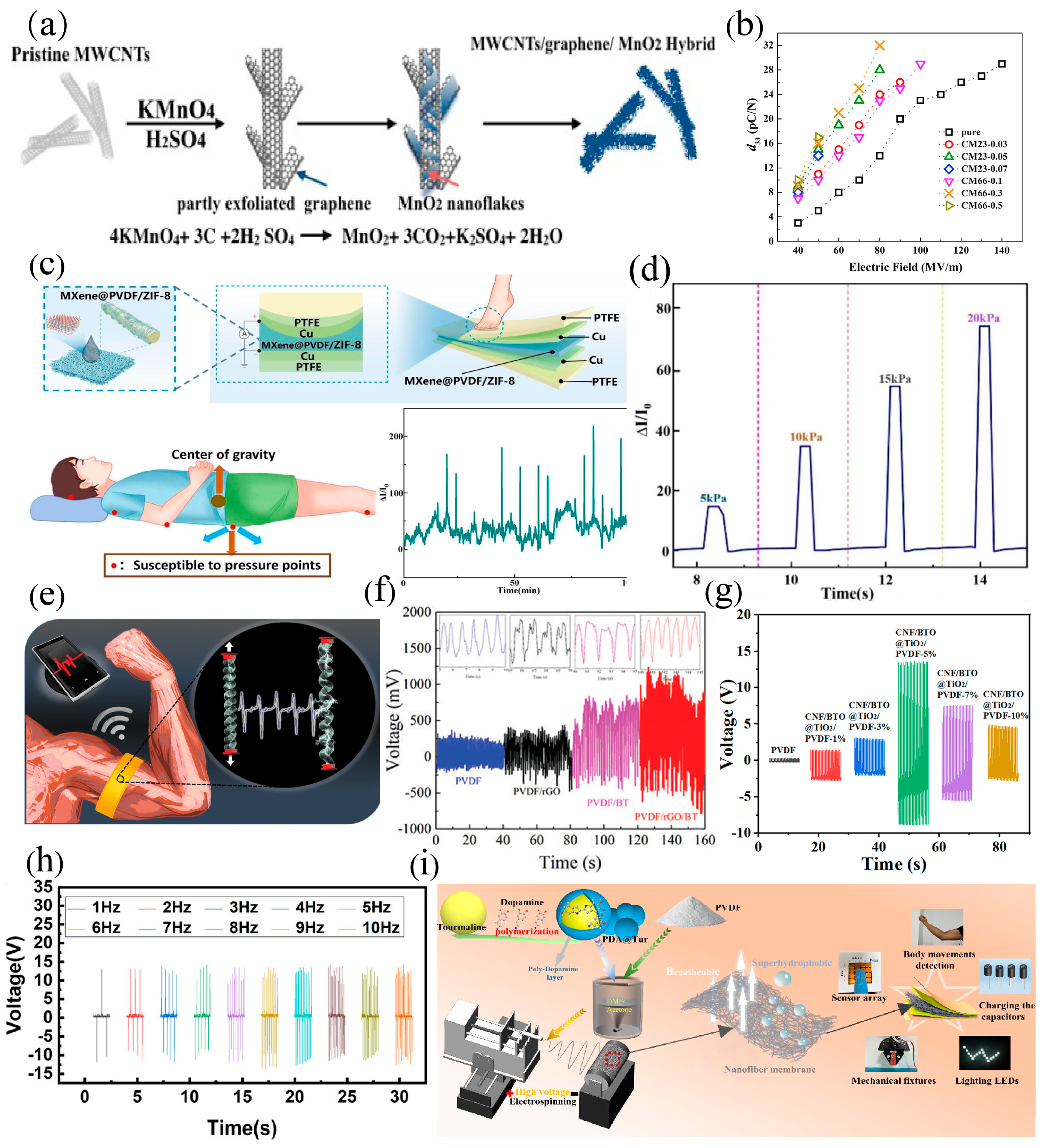

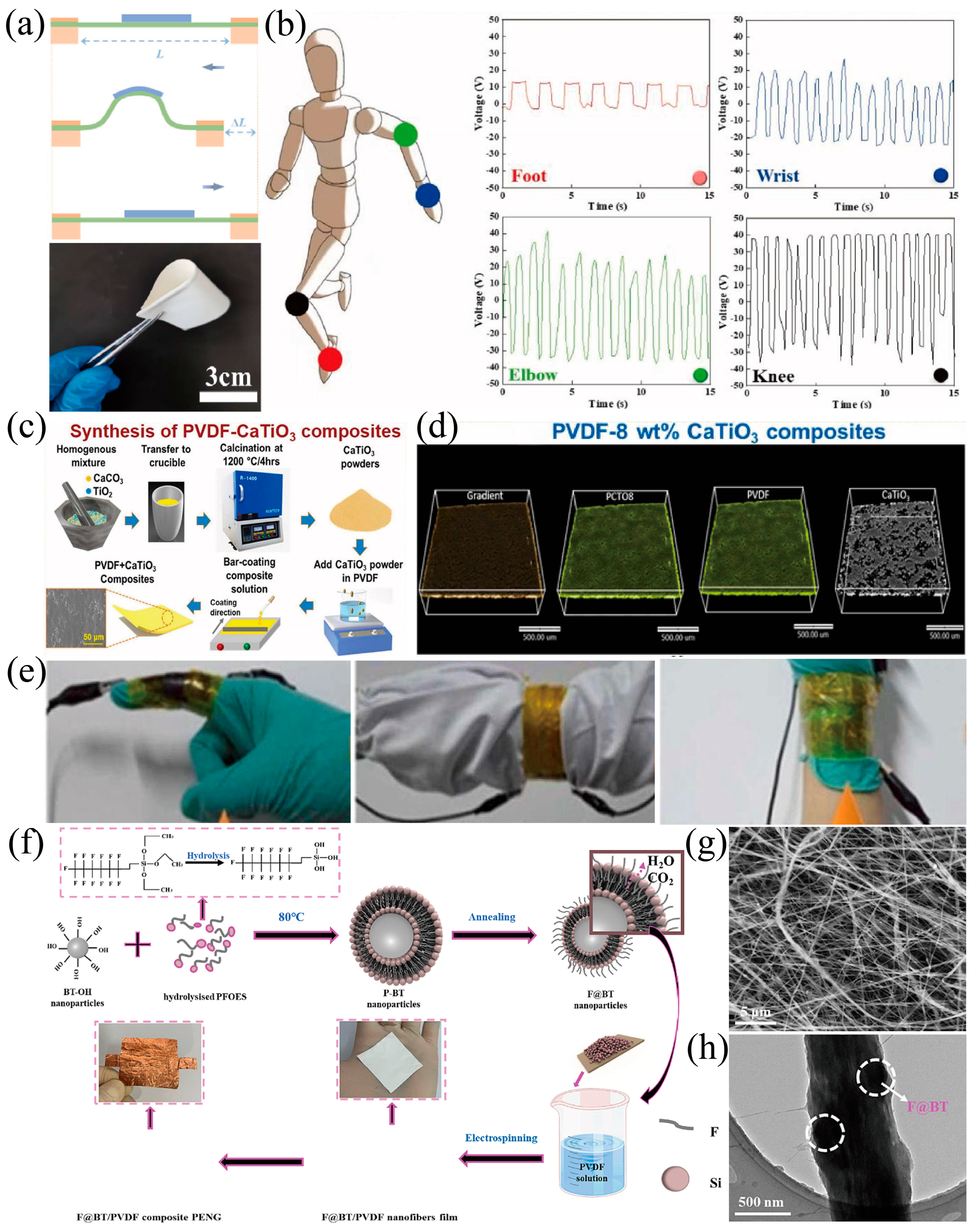

2.2. Modification of PVDF by Adding Filler

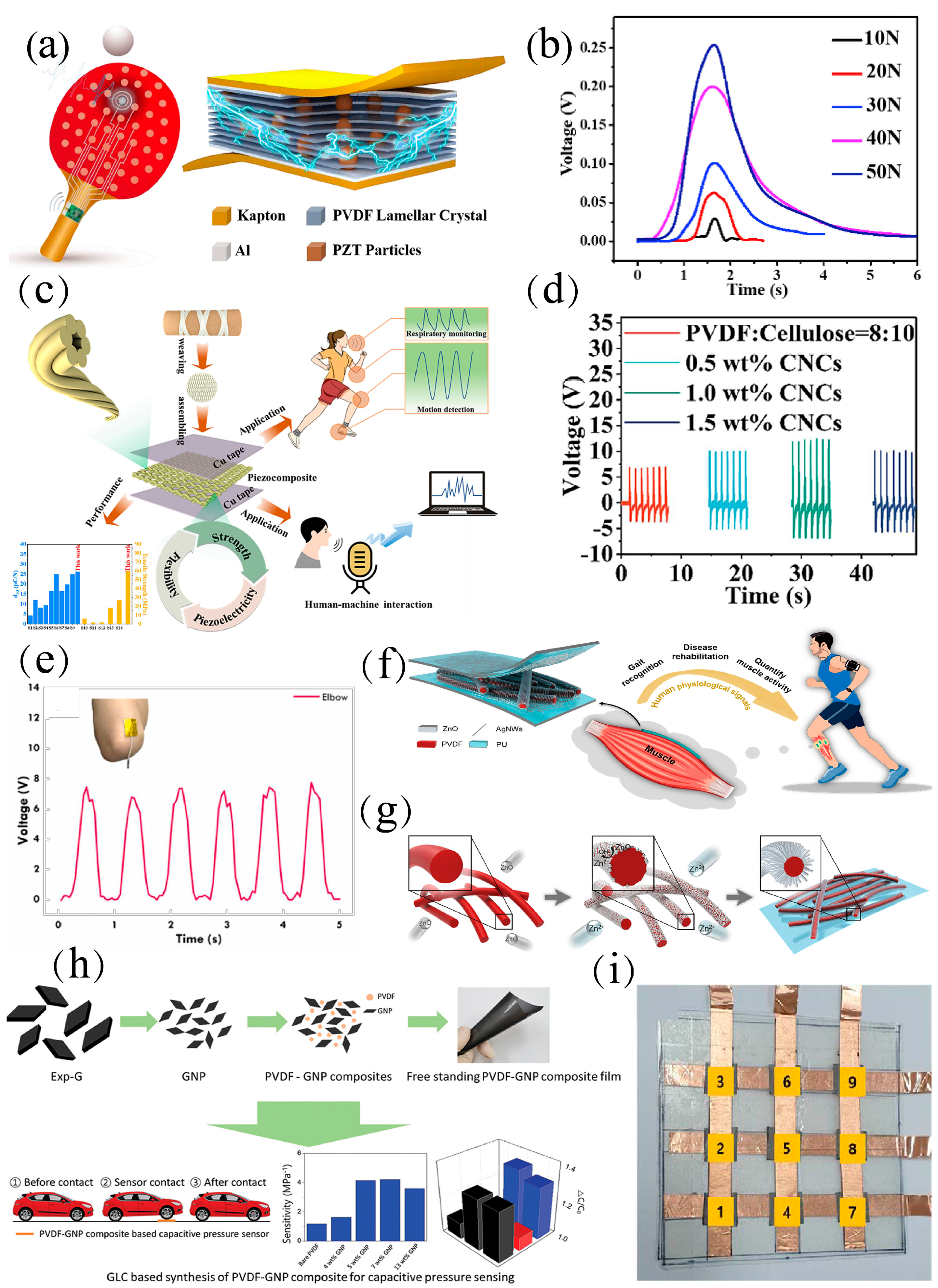

2.2.1. Single Filler Modification

2.2.2. Multi Fillers Modification

2.3. Structural Design

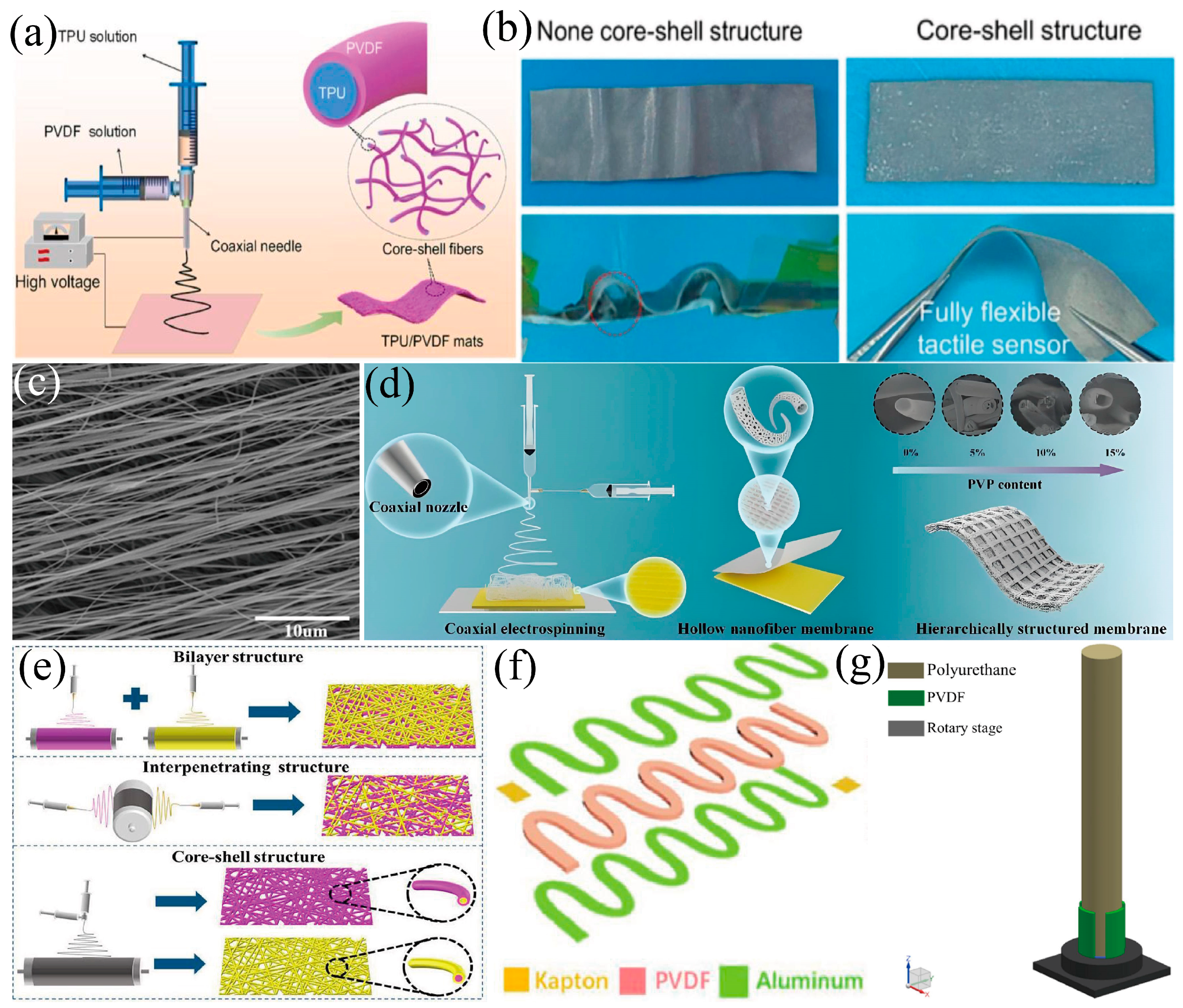

2.3.1. One-Dimensional Structure

2.3.2. Two-Dimensional Structure

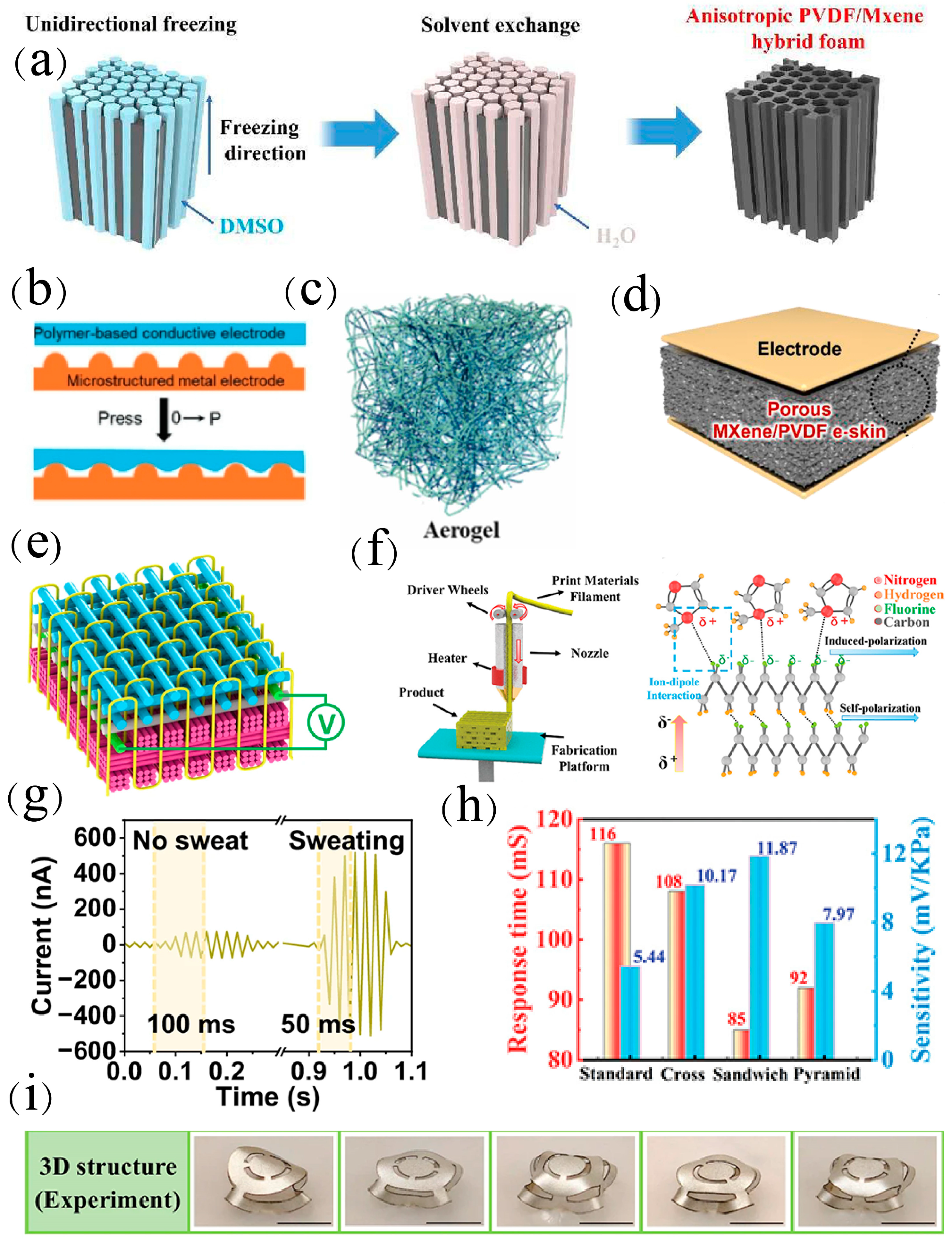

2.3.3. Three-Dimensional Structure

3. Applications

3.1. Medical Health Monitoring

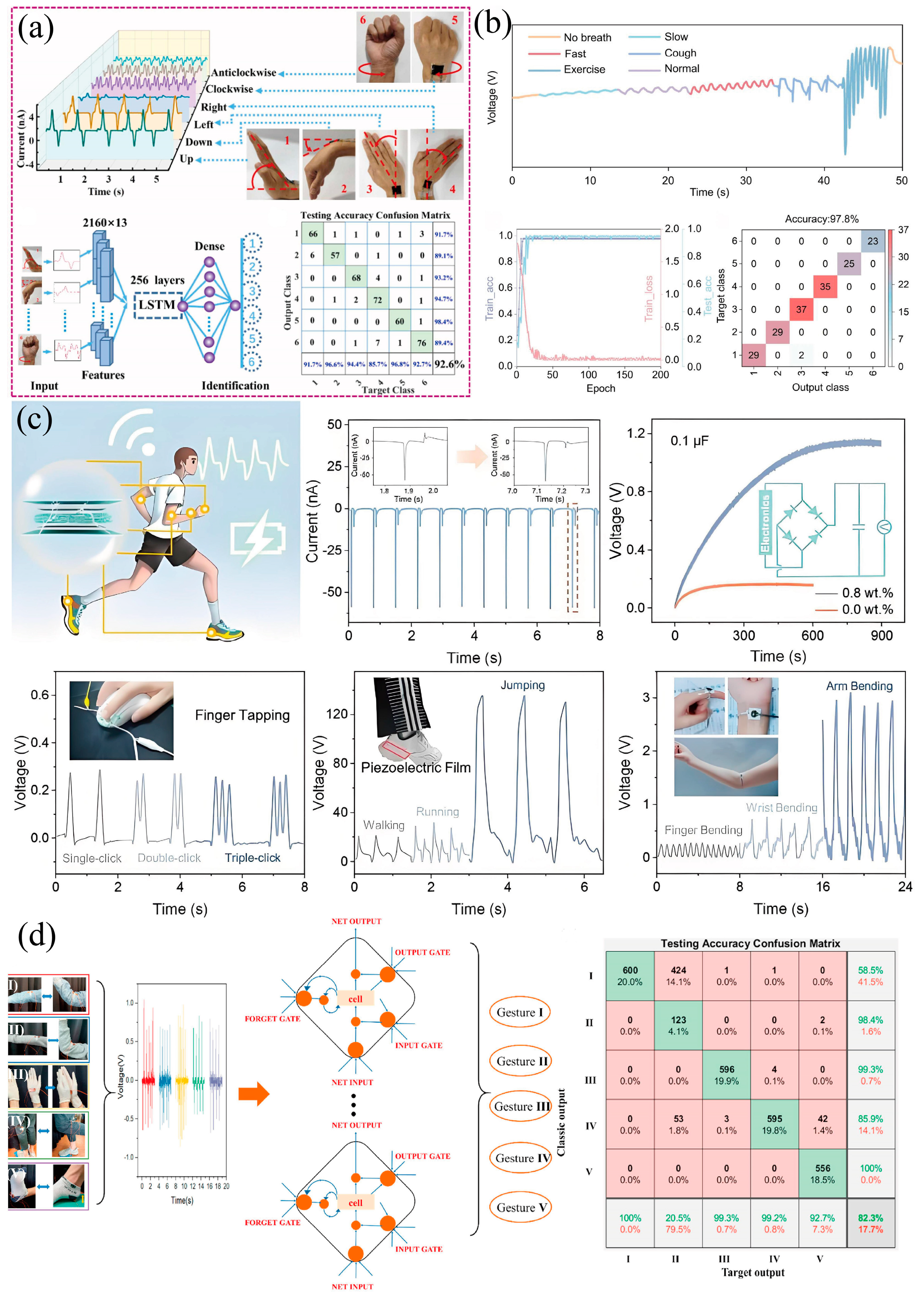

3.2. Motion Monitoring

3.3. Human–Machine Interaction (HMI)

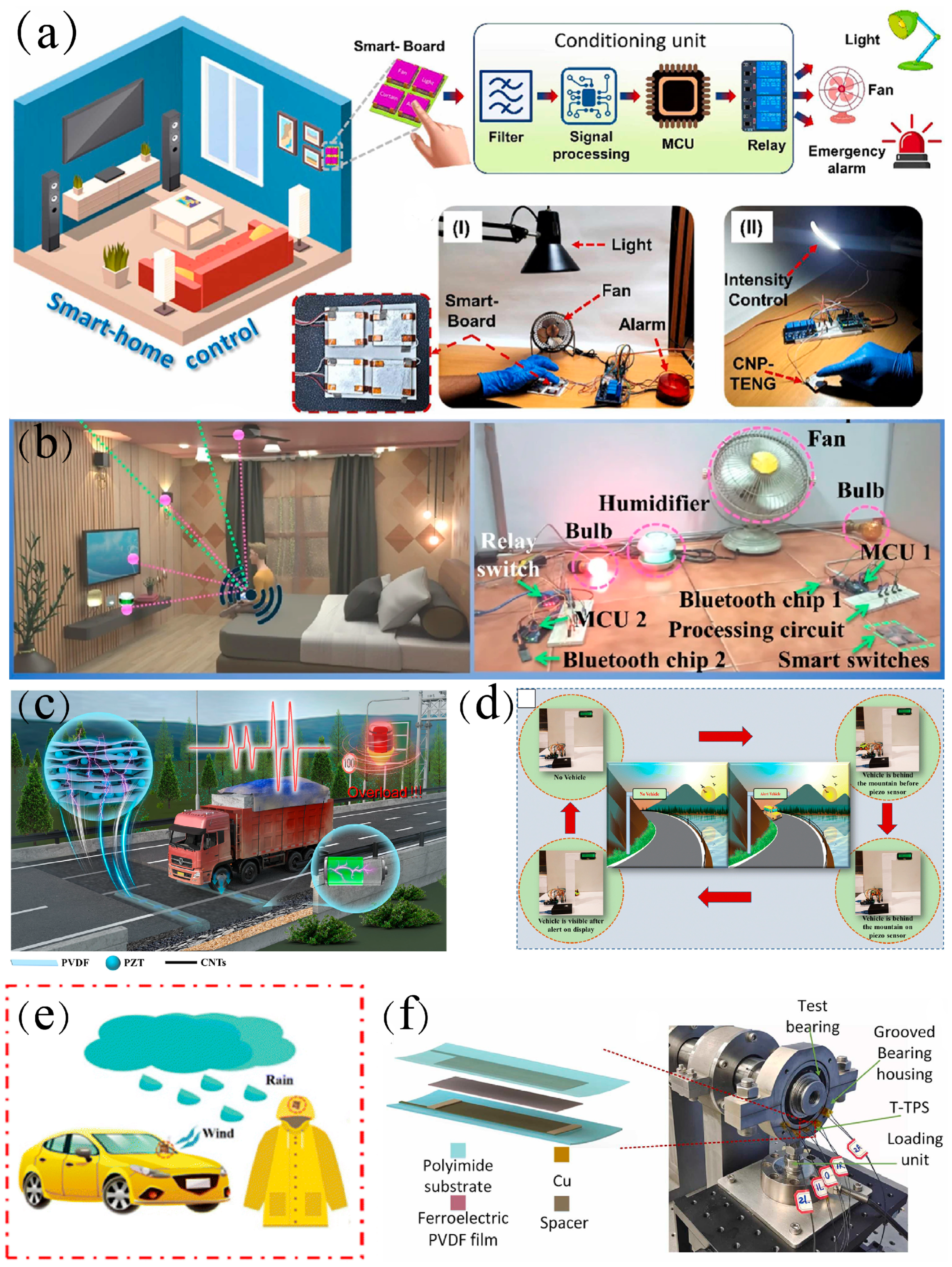

3.4. Smart Home

3.5. Other Applications

4. Conclusions

- (1)

- We generally attribute the intrinsic performance optimization of PVDF-based pressure sensors to the increased β-phase content, but the correlation between performance and the β-phase content needs to be further resolved.

- (2)

- The precise monitoring of minor and low-frequency stress/strain in the human body is mandatory for wearable electronics as human motion is usually located in the low-frequency region.

- (3)

- The rational and effective integration of PVDF pressure sensors with current systems serves as the core and prerequisite for true applications.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Y.; Jeong, C.K.; Wang, J.; Chen, X.; Choi, K.H.; Chen, L.-Q.; Chen, W.; Zhang, Q.M.; Wang, Q. Hydrogel Ionic Diodes toward Harvesting Ultralow-Frequency Mechanical Energy. Adv. Mater. 2021, 33, 2103056. [Google Scholar] [CrossRef] [PubMed]

- Liang, Z.; Cheng, J.; Zhao, Q.; Zhao, X.; Han, Z.; Chen, Y.; Ma, Y.; Feng, X. Tactile sensors: High-performance flexible tactile sensor enabling intelligent haptic perception for a soft prosthetic hand. Adv. Mater. Technol. 2019, 4, 1970041. [Google Scholar] [CrossRef]

- Ryu, C.; Hajra, S.; Sahu, M.; Jung, S.I.; Jang, I.R.; Kim, H.J. PVDF-bismuth titanate based self-powered flexible tactile sensor for biomechanical applications. Mater. Lett. 2022, 309, 131308. [Google Scholar] [CrossRef]

- Li, T.; Luo, H.; Qin, L.; Wang, X.; Xiong, Z.; Ding, H.; Gu, Y.; Liu, Z.; Zhang, T. Flexible Capacitive Tactile Sensor Based on Micropatterned Dielectric Layer. Small 2016, 12, 5042–5048. [Google Scholar] [CrossRef] [PubMed]

- Poddar, S.; Mondal, S.; Bhattacharjee, S.; Pal, P.; Maiti, S.; Banerjee, A.; Chattopadhyay, K.K. Bi-functional Rb4Ag2BiBr9-PVDF composite based piezoelectric mechanical energy harvester and light assisted self-charging power unit. Nano Energy 2024, 123, 109380. [Google Scholar] [CrossRef]

- Du, C.; Zhang, H.; Liu, X.; Zhou, S.; Ma, Y.; Li, S.; Zhang, Y. Flexible and simply degradable MXene–methylcellulose piezoresistive sensor for human motion detection. ACS Appl. Mater. Interfaces 2024, 16, 12996–13005. [Google Scholar] [CrossRef] [PubMed]

- Vera Anaya, D.; He, T.; Lee, C.; Yuce, M.R. Self-powered eye motion sensor based on triboelectric interaction and near-field electrostatic induction for wearable assistive technologies. Nano Energy 2020, 72, 104675. [Google Scholar] [CrossRef]

- Zhang, Y.; Jeong, C.K.; Yang, T.; Sun, H.; Chen, L.-Q.; Zhang, S.; Chen, W.; Wang, Q. Bioinspired elastic piezoelectric composites for high-performance mechanical energy harvesting. J. Mater. Chem. A 2018, 6, 14546–14552. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, H.; Jeong, C.K. Biomimetic porifera skeletal structure of lead-free piezocomposite energy harvesters. ACS Appl. Mater. Interfaces 2018, 10, 35539–35546. [Google Scholar] [CrossRef]

- Zhang, Y.; Jeong, C.K.; Wang, J.; Sun, H.; Li, F.; Zhang, G.; Chen, L.-Q.; Zhang, S.; Chen, W.; Wang, Q. Flexible energy harvesting polymer composites based on biofibril-templated 3-dimensional interconnected piezoceramics. Nano Energy 2018, 50, 35–42. [Google Scholar] [CrossRef]

- Lee, C.; Park, H.; Lee, J.-H. Recent structure development of poly(vinylidene fluoride)-based piezoelectric nanogenerator for self-powered sensor. Actuators 2020, 9, 57. [Google Scholar] [CrossRef]

- Saxena, P.; Shukla, P. A comparative analysis of the basic properties and applications of poly (vinylidene fluoride) (PVDF) and poly (methyl methacrylate) (PMMA). Polym. Bull. 2022, 79, 5635–5665. [Google Scholar] [CrossRef]

- Park, C.; Lim, W.; Joshi, B.; Kim, T.; Samuel, E.; Aldalbahi, A.; Periyasami, G.; Ding, B.; Yoon, S.S. Enhancing the piezoelectric coefficient of SrTiO3 nanocubes and PVDF film deposited by supersonic spraying for energy-harvesting nanogenerators. Chem. Eng. J. 2024, 491, 151945. [Google Scholar] [CrossRef]

- Luo, B.; Wang, X.; Wang, Y.; Li, L. Fabrication, characterization, properties and theoretical analysis of ceramic/PVDF composite flexible films with high dielectric constant and low dielectric loss. J. Mater Chem A 2014, 2, 510–519. [Google Scholar] [CrossRef]

- Yu, C.; Park, J.; Ryoun Youn, J.; Seok Song, Y. Integration of form-stable phase change material into pyroelectric energy harvesting system. Appl. Energy 2022, 307, 118212. [Google Scholar] [CrossRef]

- Alam, M.M.; Mandal, D. Native cellulose microfiber-based hybrid piezoelectric generator for mechanical energy harvesting utility. ACS Appl. Mater. Interfaces 2016, 8, 1555–1558. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.K.; Sinha, T.K.; Mahanty, B.; Mandal, D. Self-poled efficient flexible “ferroelectretic” nanogenerator: A new class of piezoelectric energy harvester. Energy Technol. 2015, 3, 1190–1197. [Google Scholar] [CrossRef]

- Li, L.; Peng, F.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Electrospun core–sheath PVDF piezoelectric fiber for sensing application. ACS Appl. Mater. Interfaces 2023, 15, 15938–15945. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, L.; Pan, X.; Liu, G.; He, Y.; Jin, W.; Li, M.; Hu, Y.; Gu, H. Self-powered viscosity and pressure sensing in microfluidic systems based on the piezoelectric energy harvesting of flowing droplets. ACS Appl. Mater. Interfaces 2017, 9, 28586–28595. [Google Scholar] [CrossRef] [PubMed]

- Shi, K.; Sun, B.; Huang, X.; Jiang, P. Synergistic effect of graphene nanosheet and BaTiO3 nanoparticles on performance enhancement of electrospun PVDF nanofiber mat for flexible piezoelectric nanogenerators. Nano Energy 2018, 52, 153–162. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Mandal, D. Synergistically enhanced piezoelectric output in highly aligned 1D polymer nanofibers integrated all-fiber nanogenerator for wearable nano-tactile sensor. Nano Energy 2018, 53, 245–257. [Google Scholar] [CrossRef]

- Wang, W.; Zheng, Y.; Jin, X.; Sun, Y.; Lu, B.; Wang, H.; Fang, J.; Shao, H.; Lin, T. Unexpectedly high piezoelectricity of electrospun polyacrylonitrile nanofiber membranes. Nano Energy 2019, 56, 588–594. [Google Scholar] [CrossRef]

- Shen, J.; Zeng, Y.; Li, Q.; Zhou, J.; Chen, W. Convenient folding-hot-pressing fabrication and enhanced piezoelectric properties of high β-phase-content poly(vinylidene fluoride) films. Interdiscip. Mater. 2024, 3, 715–725. [Google Scholar] [CrossRef]

- Tian, G.; Deng, W.; Gao, Y.; Xiong, D.; Yan, C.; He, X.; Yang, T.; Jin, L.; Chu, X.; Zhang, H.; et al. Rich lamellar crystal baklava-structured PZT/PVDF piezoelectric sensor toward individual table tennis training. Nano Energy 2019, 59, 574–581. [Google Scholar] [CrossRef]

- Yang, T.; Pan, H.; Tian, G.; Zhang, B.; Xiong, D.; Gao, Y.; Yan, C.; Chu, X.; Chen, N.; Zhong, S.; et al. Hierarchically structured PVDF/ZnO core-shell nanofibers for self-powered physiological monitoring electronics. Nano Energy 2020, 72, 104706. [Google Scholar] [CrossRef]

- Mokhtari, F.; Spinks, G.M.; Sayyar, S.; Cheng, Z.; Ruhparwar, A.; Foroughi, J. Highly stretchable self-powered wearable electrical energy generator and sensors. Adv. Mater. Technol. 2020, 6, 2000841. [Google Scholar] [CrossRef]

- Yang, R.; Ma, Y.; Cui, J.; Liu, M.; Wu, Y.; Zheng, H. Nano PDA@tur-modified piezoelectric sensors for enhanced sensitivity and energy harvesting. ACS Sens. 2024, 9, 3137–3149. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Li, J.; Li, G.; Du, J.; Xie, C.; Li, H.; Jin, Y.; He, Y. Hierarchically structured hollow PVDF nanofibers for flexible piezoelectric sensor. Chem. Eng. J. 2024, 498, 155661. [Google Scholar] [CrossRef]

- Han, C.; Zhang, H.; Chen, Q.; Li, T.; Kong, L.; Zhao, H.; He, L. A directional piezoelectric sensor based on anisotropic PVDF/MXene hybrid foam enabled by unidirectional freezing. Chem. Eng. J. 2022, 450, 138280. [Google Scholar] [CrossRef]

- Wang, X.; Yu, J.; Cui, Y.; Li, W. Research progress of flexible wearable pressure sensors. Sens. Actuators A Phys. 2021, 330, 112838. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, T.; Tian, G.; Lan, B.; Deng, W.; Tang, L.; Ao, Y.; Sun, Y.; Zeng, W.; Ren, X.; et al. Spatially confined MXene/PVDF nanofiber piezoelectric electronics. Adv. Fiber Mater. 2023, 6, 133–144. [Google Scholar] [CrossRef]

- Rahman, M.T.; Rana, S.S.; Zahed, M.A.; Lee, S.; Yoon, E.-S.; Park, J.Y. Metal-organic framework-derived nanoporous carbon incorporated nanofibers for high-performance triboelectric nanogenerators and self-powered sensors. Nano Energy 2022, 94, 106921. [Google Scholar] [CrossRef]

- Lu, L.; Ding, W.; Liu, J.; Yang, B. Flexible PVDF based piezoelectric nanogenerators. Nano Energy 2020, 78, 105251. [Google Scholar] [CrossRef]

- Jin, L.; Ma, S.; Deng, W.; Yan, C.; Yang, T.; Chu, X.; Tian, G.; Xiong, D.; Lu, J.; Yang, W. Polarization-free high-crystallization β-PVDF piezoelectric nanogenerator toward self-powered 3D acceleration sensor. Nano Energy 2018, 50, 632–638. [Google Scholar] [CrossRef]

- Ryu, J.; Kim, J.; Oh, J.; Lim, S.; Sim, J.Y.; Jeon, J.S.; No, K.; Park, S.; Hong, S. Intrinsically stretchable multi-functional fiber with energy harvesting and strain sensing capability. Nano Lett. 2019, 55, 348–353. [Google Scholar] [CrossRef]

- Chang, C.; Tran, V.H.; Wang, J.; Fuh, Y.-K.; Lin, L. Direct-write piezoelectric polymeric nanogenerator with high energy conversion efficiency. Nano Lett. 2010, 10, 726–731. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L.; Zhou, Z.; Li, L.; Xiao, P.; Ma, Y.; Liu, F.; Li, J. PVDF/MOFs mixed matrix ultrafiltration membrane for efficient water treatment. Front. Chem. 2022, 10, 985750. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, Y.; Zhang, W.; Yan, X.; Huang, B. Improved battery performance contributed by the optimized phase ratio of β and α of PVDF. RSC Adv. 2019, 9, 29760–29764. [Google Scholar] [CrossRef]

- Thakur, P.; Kool, A.; Bagchi, B.; Hoque, N.A.; Das, S.; Nandy, P. In situ synthesis of Ni(OH)2 nanobelt modified electroactive poly(vinylidene fluoride) thin films: Remarkable improvement in dielectric properties. Phys. Chem. Chem. Phys. 2015, 17, 13082–13091. [Google Scholar] [CrossRef]

- Mireja, S.; Khakhar, D.V. High β-phase PVDF films formed by uniaxial compression. Polymer 2024, 293, 126665. [Google Scholar] [CrossRef]

- Wang, X.; Qiao, B.; Tan, S.; Zhu, W.; Zhang, Z. Tuning the ferroelectric phase transition of PVDF by uniaxially stretching crosslinked PVDF films with CFCH bonds. J. Mater. Chem. C 2020, 8, 11426–11440. [Google Scholar] [CrossRef]

- Wang, H.; Chen, Q.; Xia, W.; Qiu, X.; Cheng, Q.; Zhu, G. Electroactive PVDF thin films fabricated via cooperative stretching process. J. Appl. Polym. Sci. 2018, 135, 46324. [Google Scholar] [CrossRef]

- Martins, P.; Costa, C.M.; Benelmekki, M.; Botelho, G.; Lanceros-Mendez, S. On the origin of the electroactive poly(vinylidene fluoride) β-phase nucleation by ferrite nanoparticlesvia surface electrostatic interactions. CrystEngComm 2012, 14, 2807–2811. [Google Scholar] [CrossRef]

- Wang, F.; Lack, A.; Xie, Z.; Frübing, P.; Taubert, A.; Gerhard, R. Ionic-liquid-induced ferroelectric polarization in poly(vinylidene fluoride) thin films. Appl. Phys. Lett. 2012, 100, 62903. [Google Scholar] [CrossRef]

- Fu, Y.; He, H.; Zhao, T.; Dai, Y.; Han, W.; Ma, J.; Xing, L.; Zhang, Y.; Xue, X. A self-powered breath analyzer based on PANI/PVDF piezo-gas-sensing arrays for potential diagnostics application. Nano Micro Lett. 2018, 10, 76. [Google Scholar] [CrossRef] [PubMed]

- Rajala, S.; Siponkoski, T.; Sarlin, E.; Mettänen, M.; Vuoriluoto, M.; Pammo, A.; Juuti, J.; Rojas, O.J.; Franssila, S.; Tuukkanen, S. Cellulose nanofibril film as a piezoelectric sensor material. ACS Appl. Mater. Interfaces 2016, 8, 15607–15614. [Google Scholar] [CrossRef] [PubMed]

- Garain, S.; Jana, S.; Sinha, T.K.; Mandal, D. Design of In situ poled Ce3+ -doped electrospun PVDF/graphene composite nanofibers for fabrication of nanopressure sensor and ultrasensitive acoustic nanogenerator. ACS Appl. Mater. Interfaces 2016, 8, 4532–4540. [Google Scholar] [CrossRef] [PubMed]

- Jella, V.; Ippili, S.; Eom, J.-H.; Choi, J.; Yoon, S.-G. Enhanced output performance of a flexible piezoelectric energy harvester based on stable MAPbI3-PVDF composite films. Nano Energy 2018, 53, 46–56. [Google Scholar] [CrossRef]

- Sang, M.; Wang, S.; Liu, M.; Bai, L.; Jiang, W.; Xuan, S.; Gong, X. Fabrication of a piezoelectric polyvinylidene fluoride/carbonyl iron (PVDF/CI) magnetic composite film towards the magnetic field and deformation bi-sensor. Compos. Sci. Technol. 2018, 165, 31–38. [Google Scholar] [CrossRef]

- Singh, H.H.; Khare, N. Flexible ZnO-PVDF/PTFE based piezo-tribo hybrid nanogenerator. Nano Energy 2018, 51, 216–222. [Google Scholar] [CrossRef]

- Shin, K.-Y.; Lee, J.S.; Jang, J. Highly sensitive, wearable and wireless pressure sensor using free-standing ZnO nanoneedle/PVDF hybrid thin film for heart rate monitoring. Nano Energy 2016, 22, 95–104. [Google Scholar] [CrossRef]

- Huang, Y.; Ding, Y.; Bian, J.; Su, Y.; Zhou, J.; Duan, Y.; Yin, Z. Hyper-stretchable self-powered sensors based on electrohydrodynamically printed, self-similar piezoelectric nano/microfibers. Nano Energy 2017, 40, 432–439. [Google Scholar] [CrossRef]

- Huang, T.; Yang, S.; He, P.; Sun, J.; Zhang, S.; Li, D.; Meng, Y.; Zhou, J.; Tang, H.; Liang, J.; et al. Phase-separation-induced PVDF/graphene coating on fabrics toward flexible piezoelectric sensors. ACS Appl. Mater. Interfaces 2018, 10, 30732–30740. [Google Scholar] [CrossRef]

- Park, D.Y.; Joe, D.J.; Kim, D.H.; Park, H.; Han, J.H.; Jeong, C.K.; Park, H.; Park, J.G.; Joung, B.; Lee, K.J. Self-Powered Real-Time Arterial Pulse Monitoring Using Ultrathin Epidermal Piezoelectric Sensors. Adv. Mater. 2017, 29, 1702308. [Google Scholar] [CrossRef]

- Guo, Q.; Xue, Q.; Wu, T.; Pan, X.; Zhang, J.; Li, X.; Zhu, L. Excellent dielectric properties of PVDF-based composites filled with carbonized PAN/PEG copolymer fibers. Compos. Part A 2016, 87, 46–53. [Google Scholar] [CrossRef]

- Panda, P.K. Review: Environmental friendly lead-free piezoelectric materials. J. Mater. Sci. 2009, 44, 5049–5062. [Google Scholar] [CrossRef]

- Matsubara, M.; Yamaguchi, T.; Sakamoto, W.; Kikuta, K.; Yogo, T.; Hirano, S. Processing and piezoelectric properties of lead-free (K,Na) (Nb,Ta) O3 ceramics. J. Am. Ceram. Soc. 2005, 88, 1190–1196. [Google Scholar] [CrossRef]

- Schilling, K.; Bradford, B.; Castelli, D.; Dufour, E.; Nash, J.F.; Pape, W.; Schulte, S.; Tooley, I.; Van Den Bosch, J.; Schellauf, F. Human safety review of “nano” titanium dioxide and zinc oxide. Photochem Photobiol Sci 2010, 9, 495–509. [Google Scholar] [CrossRef] [PubMed]

- Pan, L.; Wang, Y.; Jin, Q.; Hu, Z.; Zhou, Z.; Zhu, M. Self-poled PVDF/recycled cellulose composite fibers utilizing cellulose nanocrystals to induce PVDF β-phase formation through wet-spinning as a flexible fabric piezoelectric sensor. Chem. Eng. J. 2023, 479, 147742. [Google Scholar] [CrossRef]

- Chiu, Y.-S.; Rinawati, M.; Chang, Y.-H.; Aulia, S.; Chang, C.-C.; Chang, L.-Y.; Hung, W.-S.; Mizuguchi, H.; Haw, S.-C.; Yeh, M.-H. Enhancing self-induced polarization of PVDF-based triboelectric film by P-doped g-C3N4 for ultrasensitive triboelectric pressure sensors. Nano Energy 2024, 131, 110207. [Google Scholar] [CrossRef]

- Pusty, M.; Shirage, P.M. Insights and perspectives on graphene-PVDF based nanocomposite materials for harvesting mechanical energy. J. Alloys Compd. 2022, 904, 164060. [Google Scholar] [CrossRef]

- Kim, H.; Lim, M.; Jang, B.; Park, S.; Park, J.Y.; Shen, H.; Koo, K.; Cho, H.-B.; Choa, Y.-H. Enhanced capacitive pressure sensing performance by charge generation from filler movement in thin and flexible PVDF-GNP composite films. Sci. Technol. Adv. Mater. 2023, 24, 2260301. [Google Scholar] [CrossRef]

- Bhavanasi, V.; Kumar, V.; Parida, K.; Wang, J.; Lee, P.S. Enhanced piezoelectric energy harvesting performance of flexible PVDF-TrFE bilayer films with graphene oxide. ACS Appl. Mater. Interfaces 2016, 8, 521–529. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Jiang, P.; Wu, C.; Wang, L.; Wu, X. Graphene nanocomposites based on poly(vinylidene fluoride): Structure and properties. Polym. Compos. 2011, 32, 1483–1491. [Google Scholar] [CrossRef]

- Lee, J.-E.; Eom, Y.; Shin, Y.-E.; Hwang, S.-H.; Ko, H.-H.; Chae, H.G. Effect of Interfacial Interaction on the Conformational Variation of Poly(vinylidene fluoride) (PVDF) Chains in PVDF/Graphene Oxide (GO) Nanocomposite Fibers and Corresponding Mechanical Properties. ACS Appl. Mater. Interfaces 2019, 11, 13665–13675. [Google Scholar] [CrossRef]

- Sharafkhani, S.; Kokabi, M. Ultrathin-shell PVDF/CNT nanocomposite aligned hollow fibers as a sensor/actuator single element. Compos. Sci. Technol. 2020, 200, 108425. [Google Scholar] [CrossRef]

- Xiong, J.; Wang, L.; Liang, F.; Li, M.; Yabuta, Y.; Iqbal, M.A.; Mayakrishnan, G.; Shi, J.; Kim, I.S. Flexible Piezoelectric Sensor Based on Two-Dimensional Topological Network of PVDF/DA Composite Nanofiber Membrane. Adv. Fiber Mater. 2024, 6, 1212–1228. [Google Scholar] [CrossRef]

- Liu, Z.; Li, G.; Qin, Q.; Mi, L.; Li, G.; Zheng, G.; Liu, C.; Li, Q.; Liu, X. Electrospun PVDF/PAN membrane for pressure sensor and sodium-ion battery separator. Adv. Compos. Hybrid Mater. 2021, 4, 1215–1225. [Google Scholar] [CrossRef]

- Krishnaswamy, J.A.; Buroni, F.C.; García-Macías, E.; Melnik, R.; Rodriguez-Tembleque, L.; Saez, A. Design of lead-free PVDF/CNT/BaTiO3 piezocomposites for sensing and energy harvesting: The role of polycrystallinity, nanoadditives, and anisotropy. Smart Mater. Struct. 2019, 29, 15021. [Google Scholar] [CrossRef]

- Chen, J.; Ayranci, C.; Tang, T. Piezoelectric performance of electrospun PVDF and PVDF composite fibers: A review and machine learning-based analysis. Mater. Today Chem. 2023, 30, 101571. [Google Scholar] [CrossRef]

- Yang, L.; Cheng, M.; Lyu, W.; Shen, M.; Qiu, J.; Ji, H.; Zhao, Q. Tunable piezoelectric performance of flexible PVDF based nanocomposites from MWCNTs/graphene/MnO2 three-dimensional architectures under low poling electric fields. Compos. Part A 2018, 107, 536–544. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; Gao, Z.; Gui, H.; Wang, Y.; Tang, J.; Huang, L. Preparation and performance study of high-sensitivity flexible pressure sensors based on MXene/PVDF@ZIF-8 composite membranes. Appl. Surf. Sci. 2025, 681, 161626. [Google Scholar] [CrossRef]

- Zhang, J.; Song, X.; Cao, S.; Zhu, Q.; Chen, X.; Li, D.; Yuan, Q. High output flexible polyvinylidene fluoride based piezoelectric device incorporating cellulose nanofibers/BaTiO3@TiO2 piezoelectric core-shell structure. Int. J. Biol. Macromol. 2024, 275, 133088. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Cheng, T.; Lian, W.; Zhang, M.; Lu, B.; Dong, B.; Tan, K.; Liu, C.; Shen, C. Flexible layered cotton cellulose-based nanofibrous membranes for piezoelectric energy harvesting and self-powered sensing. Carbohydr. Polym. 2022, 275, 118740. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Cai, Y.; Jiang, X.; Wang, J.; Wang, C.; Duan, J. A versatile surface micro structure design strategy for porous-based pressure sensors to enhance electromechanical performance. Chem. Eng. J. 2024, 490, 151529. [Google Scholar] [CrossRef]

- Yang, S.; Ding, K.; Wang, W.; Wang, T.; Gong, H.; Shu, D.; Zhou, Z.; Jiao, L.; Cheng, B.; Ni, Y. Electrospun fiber-based high-performance flexible multi-level micro-structured pressure sensor: Design, development and modelling. Chem. Eng. J. 2022, 431, 133700. [Google Scholar] [CrossRef]

- Bao, H.; Ma, Y.; Sun, J.; Zhao, Q.; Yang, L.; Hou, Y.; He, H.; Huang, H.; Ji, H.; Qiu, J. Flexible and transparent ionic liquids/poly(vinylidene fluoride) composition-gradient piezo-active composites for highly sensitive pressure sensor. Adv. Electron. Mater. 2023, 9, 2201013. [Google Scholar] [CrossRef]

- Yuan, H.; Zhang, Q.; Zhou, T.; Wu, W.; Li, H.; Yin, Z.; Ma, J.; Jiao, T. Progress and challenges in flexible capacitive pressure sensors: Microstructure designs and applications. Chem. Eng. J. 2024, 485, 149926. [Google Scholar] [CrossRef]

- Ni, Y.; Liu, L.; Huang, J.; Li, S.; Chen, Z.; Zhang, W.; Lai, Y. Rational designed microstructure pressure sensors with highly sensitive and wide detection range performance. J. Mater. Sci. Technol. 2022, 130, 184–192. [Google Scholar] [CrossRef]

- Huang, H.; Zhong, J.; Ye, Y.; Wu, R.; Luo, B.; Ning, H.; Qiu, T.; Luo, D.; Yao, R.; Peng, J. Research progresses in microstructure designs of flexible pressure sensors. Polymers 2022, 14, 3670. [Google Scholar] [CrossRef]

- Choi, Y.-Y.; Yun, T.G.; Qaiser, N.; Paik, H.; Roh, H.S.; Hong, J.; Hong, S.; Han, S.M.; No, K. Vertically aligned P(VDF-TrFE) core-shell structures on flexible pillar arrays. Sci. Rep. 2015, 5, 10728. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Jiang, D.; An, Y.; Chen, W.; Huang, Z.; Jiang, B. Wearable flexible pressure sensors: An intriguing design towards microstructural functionalization. J. Mater. Chem. A 2024, 12, 6826–6874. [Google Scholar] [CrossRef]

- Guo, W.; Tan, C.; Shi, K.; Li, J.; Wang, X.-X.; Sun, B.; Huang, X.; Long, Y.-Z.; Jiang, P. Wireless piezoelectric devices based on electrospun PVDF/BaTiO3 NW nanocomposite fibers for human motion monitoring. Nanoscale 2018, 10, 17751–17760. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Zhang, H.; Zhou, S.; Du, C.; Liu, M.; Zhang, Y. Boosting the piezoelectric response and interfacial compatibility in flexible piezoelectric composites via DET-doping BT nanoparticles. Polymers 2024, 16, 743. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Zhang, H.; Du, C.; Liu, M.; Liu, L.; Zhang, Y. Chitosan-doped PVDF film with enhanced electroactive β phase for piezoelectric sensing. ACS Appl. Electron. Mater. 2024, 6, 2575–2583. [Google Scholar] [CrossRef]

- Zhang, H.; Du, C.; Zhang, Y. Constructing the 3D interconnected conductive MXene-cellulose scaffold to boosting the piezoresistive sensing capability. ACS Appl. Electron. Mater. 2024, 6, 6785–6792. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Y.; Jin, W.; Chen, W.; Zhang, Y. Dramatically enhanced energy harvesting capability in sandwich-structure modulated piezoelectric nanocomposites. Mater. Sci. Semicond. Process. 2023, 155, 107260. [Google Scholar] [CrossRef]

- Zhang, H.; Fang, Y.; Lee, J.; Jeong, C.K.; Zhang, Y. Templates-built structural designs for piezoelectrochemical pressure sensors. ACS Appl. Mater. Interfaces 2024, 16, 62617–62626. [Google Scholar] [CrossRef] [PubMed]

- Wei, C.J.; Zhou, H.; Zheng, B.; Zheng, H.; Shu, Q.; Du, H.; Ma, A.; Liu, H. Fully flexible and mechanically robust tactile sensors containing core–shell structured fibrous piezoelectric mat as sensitive layer. Chem. Eng. J. 2023, 476, 146654. [Google Scholar] [CrossRef]

- Zhang, M.; Tan, Z.; Zhang, Q.; Shen, Y.; Mao, X.; Wei, L.; Sun, R.; Zhou, F.; Liu, C. Flexible self-powered friction piezoelectric sensor based on structured PVDF-based composite nanofiber membranes. ACS Appl. Mater. Interfaces 2023, 15, 30849–30858. [Google Scholar] [CrossRef]

- Han, M.; Wang, H.; Yang, Y.; Liang, C.; Bai, W.; Yan, Z.; Li, H.; Xue, Y.; Wang, X.; Akar, B.; et al. Three-dimensional piezoelectric polymer microsystems for vibrational energy harvesting, robotic interfaces and biomedical implants. Nat. Electron. 2019, 2, 26–35. [Google Scholar] [CrossRef]

- Guo, R.; Zhang, H.; Cao, S.; Cui, X.; Yan, Z.; Sang, S. A self-powered stretchable sensor fabricated by serpentine PVDF film for multiple dynamic monitoring. Mater. Des. 2019, 182, 108025. [Google Scholar] [CrossRef]

- Wei, X.; Liu, X.; Zheng, C.; Zhao, H.; Zhong, Y.; Amarasinghe, Y.W.R.; Wang, P. A piezoelectric power generator based on axisymmetrically distributed PVDF array for two-dimension vibration energy harvesting and direction sensing. Sustain. Energy Technol. Assess. 2021, 44, 101001. [Google Scholar] [CrossRef]

- Zhang, H.; Jeong, C.K.; Shen, Z.; Wang, J.; Sun, H.; Jian, Z.; Chen, W.; Zhang, Y. Ultrahigh augmentation of flexible composite-based piezoelectric energy harvesting efficiency via polymer-impregnated nanoparticles network within 3D cellulose scaffold. Compos. Part B 2022, 236, 109813. [Google Scholar] [CrossRef]

- Panda, S.; Hajra, S.; Jeong, H.; Panigrahi, B.K.; Pakawanit, P.; Dubal, D.; Hong, S.; Kim, H.J. Biocompatible CaTiO3-PVDF composite-based piezoelectric nanogenerator for exercise evaluation and energy harvesting. Nano Energy 2022, 102, 107682. [Google Scholar] [CrossRef]

- Cao, S.; Zou, H.; Jiang, B.; Li, M.; Yuan, Q. Incorporation of ZnO encapsulated MoS2 to fabricate flexible piezoelectric nanogenerator and sensor. Nano Energy 2022, 102, 107635. [Google Scholar] [CrossRef]

- Wang, S.; Yu, Z.; Wang, L.; Wang, Y.; Yu, D.; Wu, M. A core-shell structured barium titanate nanoparticles for the enhanced piezoelectric performance of wearable nanogenerator. Appl. Energy 2023, 351, 121835. [Google Scholar] [CrossRef]

- Kim, J.; Jang, M.; Jeong, G.; Yu, S.; Park, J.; Lee, Y.; Cho, S.; Yeom, J.; Lee, Y.; Choe, A.; et al. MXene-enhanced β-phase crystallization in ferroelectric porous composites for highly-sensitive dynamic force sensors. Nano Energy 2021, 89, 106409. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, C.; Jia, B.; Ma, D.; Tian, X.; Cui, Y.; Deng, Y. Kirigami-inspired, three-dimensional piezoelectric pressure sensors assembled by compressive buckling. npj Flex. Electron. 2024, 8, 23. [Google Scholar] [CrossRef]

- Sun, S.; Cheng, Q.; Chen, Z.; Zheng, J.; Liu, R.; Liu, Z.; Wang, Y.; Zheng, L. A shape-adaptable and highly resilient aerogel assembled by poly(vinylidene fluoride) nanofibers for self-powered sensing. Nano Energy 2023, 116, 108820. [Google Scholar] [CrossRef]

- Fan, W.; Lei, R.; Dou, H.; Wu, Z.; Lu, L.; Wang, S.; Liu, X.; Chen, W.; Rezakazemi, M.; Aminabhavi, T.M.; et al. Sweat permeable and ultrahigh strength 3D PVDF piezoelectric nanoyarn fabric strain sensor. Nat. Commun. 2024, 15, 3509. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Liu, J.; He, L.; Shang, Y.; Zhang, C. 3D printed piezoelectric-regulable cells with customized electromechanical response distribution for intelligent sensing. Adv. Funct. Mater. 2022, 32, 2201274. [Google Scholar] [CrossRef]

- Kong, H.; Song, Z.; Xu, J.; Qu, D.; Bao, Y.; Wang, W.; Wang, Z.; Zhang, Y.; Ma, Y.; Han, D.; et al. Untraditional deformation-driven pressure sensor with high sensitivity and ultra-large sensing range up to MPa enables versatile applications. Adv. Mater. Technol. 2020, 5, 2000677. [Google Scholar] [CrossRef]

- Lan, B.; Zhong, C.; Wang, S.; Ao, Y.; Liu, Y.; Sun, Y.; Yang, T.; Tian, G.; Huang, L.; Zhang, J.; et al. A highly sensitive coaxial nanofiber mask for respiratory monitoring assisted with machine learning. Adv. Fiber Mater. 2024, 6, 1402–1412. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, H.; Fang, L.; Wang, Z.; He, W.; Shi, S.; Zhang, R.; Cheng, J.; Wang, P. A self-powered flexible piezoelectric sensor patch for deep learning-assisted motion identification and rehabilitation training system. Nano Energy 2024, 123, 109427. [Google Scholar] [CrossRef]

- Venkatesan, H.M.; Mohammad, S.R.; Ponnan, S.; Kim, K.J.; Gajula, P.; Kim, H.; Arun, A.P. Cobalt ferrite-embedded polyvinylidene fluoride electrospun nanocomposites as flexible triboelectric sensors for healthcare and polysomnographic monitoring applications. Nano Energy 2024, 129, 110003. [Google Scholar] [CrossRef]

- Groo, L.; Inman, D.J.; Sodano, H.A. Dehydrofluorinated PVDF for structural health monitoring in fiber reinforced composites. Compos. Sci. Technol. 2021, 214, 108982. [Google Scholar] [CrossRef]

- Gunasekhar, R.; Reza, M.S.; Kim, K.J.; Prabu, A.A.; Kim, H. Electrospun PVDF/aromatic HBP of 4th gen based flexible and self-powered TENG for wearable energy harvesting and health monitoring. Sci. Rep. 2023, 13, 22645. [Google Scholar] [CrossRef] [PubMed]

- Su, Y.; Chen, C.; Pan, H.; Yang, Y.; Chen, G.; Zhao, X.; Li, W.; Gong, Q.; Xie, G.; Zhou, Y.; et al. Muscle fibers inspired high-performance piezoelectric textiles for wearable physiological monitoring. Adv. Funct. Mater. 2021, 31, 2010962. [Google Scholar] [CrossRef]

- Li, J.; Yin, J.; Wee, M.G.V.; Chinnappan, A.; Ramakrishna, S. A self-powered piezoelectric nanofibrous membrane as wearable tactile sensor for human body motion monitoring and recognition. Adv. Fiber Mater. 2023, 5, 1417–1430. [Google Scholar] [CrossRef]

- Liu, S.; Qing, W.; Zhang, D.; Gan, C.; Zhang, J.; Liao, S.; Wei, K.; Zou, H. Flexible staircase triboelectric nanogenerator for motion monitoring and gesture recognition. Nano Energy 2024, 128, 109849. [Google Scholar] [CrossRef]

- Li, G.Y.; Li, J.; Li, Z.J.; Zhang, Y.P.; Zhang, X.; Wang, Z.J.; Han, W.P.; Sun, B.; Long, Y.Z.; Zhang, H.D. Hierarchical PVDF-HFP/ZnO composite nanofiber–based highly sensitive piezoelectric sensor for wireless workout monitoring. Adv. Compos. Hybrid Mater. 2021, 5, 766–775. [Google Scholar] [CrossRef]

- Lee, D.W.; Jeong, D.G.; Kim, J.H.; Kim, H.S.; Murillo, G.; Lee, G.-H.; Song, H.-C.; Jung, J.H. Polarization-controlled PVDF-based hybrid nanogenerator for an effective vibrational energy harvesting from human foot. Nano Energy 2020, 76, 105066. [Google Scholar] [CrossRef]

- Deng, W.; Yang, T.; Jin, L.; Yan, C.; Huang, H.; Chu, X.; Wang, Z.; Xiong, D.; Tian, G.; Gao, Y.; et al. Cowpea-structured PVDF/ZnO nanofibers based flexible self-powered piezoelectric bending motion sensor towards remote control of gestures. Nano Energy 2019, 55, 516–525. [Google Scholar] [CrossRef]

- Syu, M.H.; Guan, Y.J.; Lo, W.C.; Fuh, Y.K. Biomimetic and porous nanofiber-based hybrid sensor for multifunctional pressure sensing and human gesture identification via deep learning method. Nano Energy 2020, 76, 105029. [Google Scholar] [CrossRef]

- Shen, Z.; Liu, F.; Huang, S.; Wang, H.; Yang, C.; Hang, T.; Tao, J.; Xia, W.; Xie, X. Progress of flexible strain sensors for physiological signal monitoring. Biosens. Bioelectron. 2022, 211, 114298. [Google Scholar] [CrossRef] [PubMed]

- Kim, N.-I.; Lee, J.M.; Moradnia, M.; Chen, J.; Pouladi, S.; Yarali, M.; Kim, J.Y.; Kwon, M.-K.; Lee, T.R.; Ryou, J.-H. Biocompatible composite thin-film wearable piezoelectric pressure sensor for monitoring of physiological and muscle motions. Soft Sci. 2022, 2, 8. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Adhikary, P.; Jana, S.; Biswas, A.; Sencadas, V.; Gupta, S.D.; Tudu, B.; Mandal, D. Electrospun gelatin nanofiber based self-powered bio-e-skin for health care monitoring. Nano Energy 2017, 36, 166–175. [Google Scholar] [CrossRef]

- Gao, C.; Long, Z.; Zhong, T.; Liang, S.; Xing, L. A self-powered intelligent glove for real-time human-machine gesture interaction based on piezoelectric effect of T-ZnO/PVDF film. J. Phys. D Appl. Phys. 2022, 55, 194004. [Google Scholar] [CrossRef]

- Kar, E.; Maity, S.; Kar, A.; Sen, S. Agricultural waste rice husk/poly(vinylidene fluoride) composite: A wearable triboelectric energy harvester for real-time smart IoT applications. Adv. Compos. Hybrid Mater. 2024, 7, 87. [Google Scholar] [CrossRef]

- Wang, D.; Tang, E.; Li, L.; Peng, H.; Han, Y.; Chen, C.; Chang, M.; Guo, K.; He, L. Temperature and pressure propagation characteristics in multi-media interfaces of PVDF pressure sensor near underwater explosion source. Ocean Eng. 2023, 287, 115810. [Google Scholar] [CrossRef]

- Li, F.-C.; Kong, Z.; Wu, J.-H.; Ji, X.-Y.; Liang, J.-J. Advances in flexible piezoresistive pressure sensor. Acta Phys. Sin. 2021, 70, 100703. [Google Scholar] [CrossRef]

- Zhou, Y.; He, J.; Wang, H.; Qi, K.; Nan, N.; You, X.; Shao, W.; Wang, L.; Ding, B.; Cui, S. Highly sensitive, self-powered and wearable electronic skin based on pressure-sensitive nanofiber woven fabric sensor. Sci. Rep. 2017, 7, 12949. [Google Scholar] [CrossRef] [PubMed]

- Liang, M.; Wang, J.; Su, L.; Xin, X.; Chen, Z.; Zhang, Y.; Jiao, Y.; Luan, X.; Chen, L.; Yao, Z. Versatile lamellar wrap-structured PVDF/PZT/CNTs piezoelectric sensor for road traffic information sensing, monitoring, and energy harvesting. Chem. Eng. J. 2024, 497, 154554. [Google Scholar] [CrossRef]

- Verma, A.; Karumuthil, S.C. Vanadium disulfide-incorporated polymer nanocomposites for flexible piezoelectric energy generators and road safety sensors. J. Mater. Chem. A 2024, 12, 12721–12732. [Google Scholar] [CrossRef]

- Li, Y.; Sun, J.; Li, P.; Li, X.; Tan, J.; Zhang, H.; Li, T.; Liang, J.; Zhou, Y.; Hai, Z.; et al. High-performance piezoelectric nanogenerators based on hierarchical ZnO@CF/PVDF composite film for self-powered meteorological sensor. J. Mater. Chem. A 2023, 11, 13708–13719. [Google Scholar] [CrossRef]

- Li, L.; Wang, X.; Hu, Y.; Li, Z.; Zhao, Z.; Zheng, G. The tribo-piezoelectric microscopic coupling mechanism of ferroelectric polymers and the synchronous online monitoring of load distribution/roller speed for intelligent bearings. Nano Energy 2023, 115, 108724. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Zang, H.; Long, J.; Sun, S.; Zhang, Y. Flexible Pressure Sensors Based on Polyvinylidene Fluoride: A Critical Review. Materials 2025, 18, 615. https://doi.org/10.3390/ma18030615

Li M, Zang H, Long J, Sun S, Zhang Y. Flexible Pressure Sensors Based on Polyvinylidene Fluoride: A Critical Review. Materials. 2025; 18(3):615. https://doi.org/10.3390/ma18030615

Chicago/Turabian StyleLi, Ming, Huaikuan Zang, Jiawei Long, Sijia Sun, and Yong Zhang. 2025. "Flexible Pressure Sensors Based on Polyvinylidene Fluoride: A Critical Review" Materials 18, no. 3: 615. https://doi.org/10.3390/ma18030615

APA StyleLi, M., Zang, H., Long, J., Sun, S., & Zhang, Y. (2025). Flexible Pressure Sensors Based on Polyvinylidene Fluoride: A Critical Review. Materials, 18(3), 615. https://doi.org/10.3390/ma18030615