An Innovative Approach to Tailor Sandwich Core Structures for Multi-Directional Loading Scenarios

Abstract

1. Introduction

2. Materials and Methods

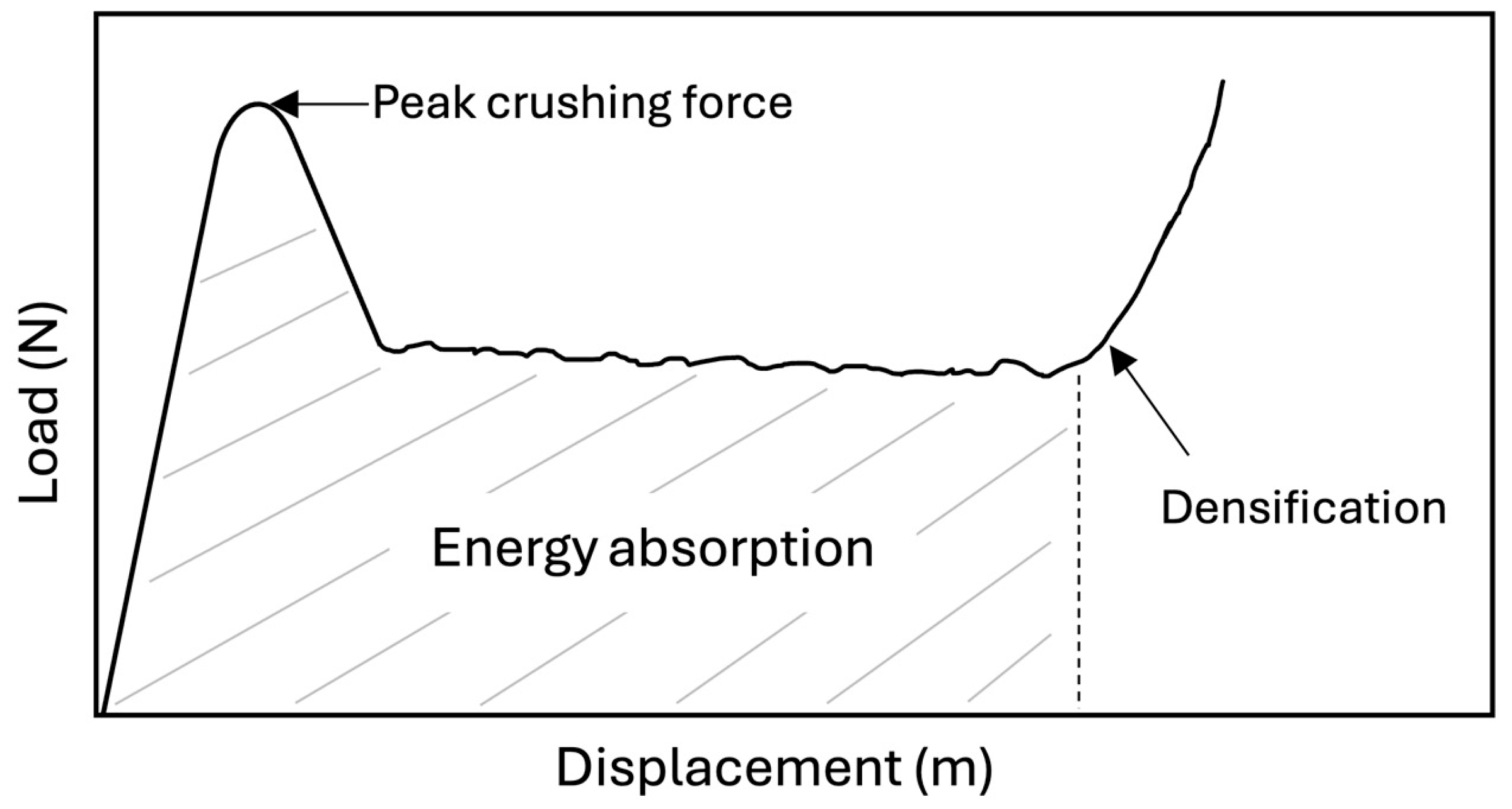

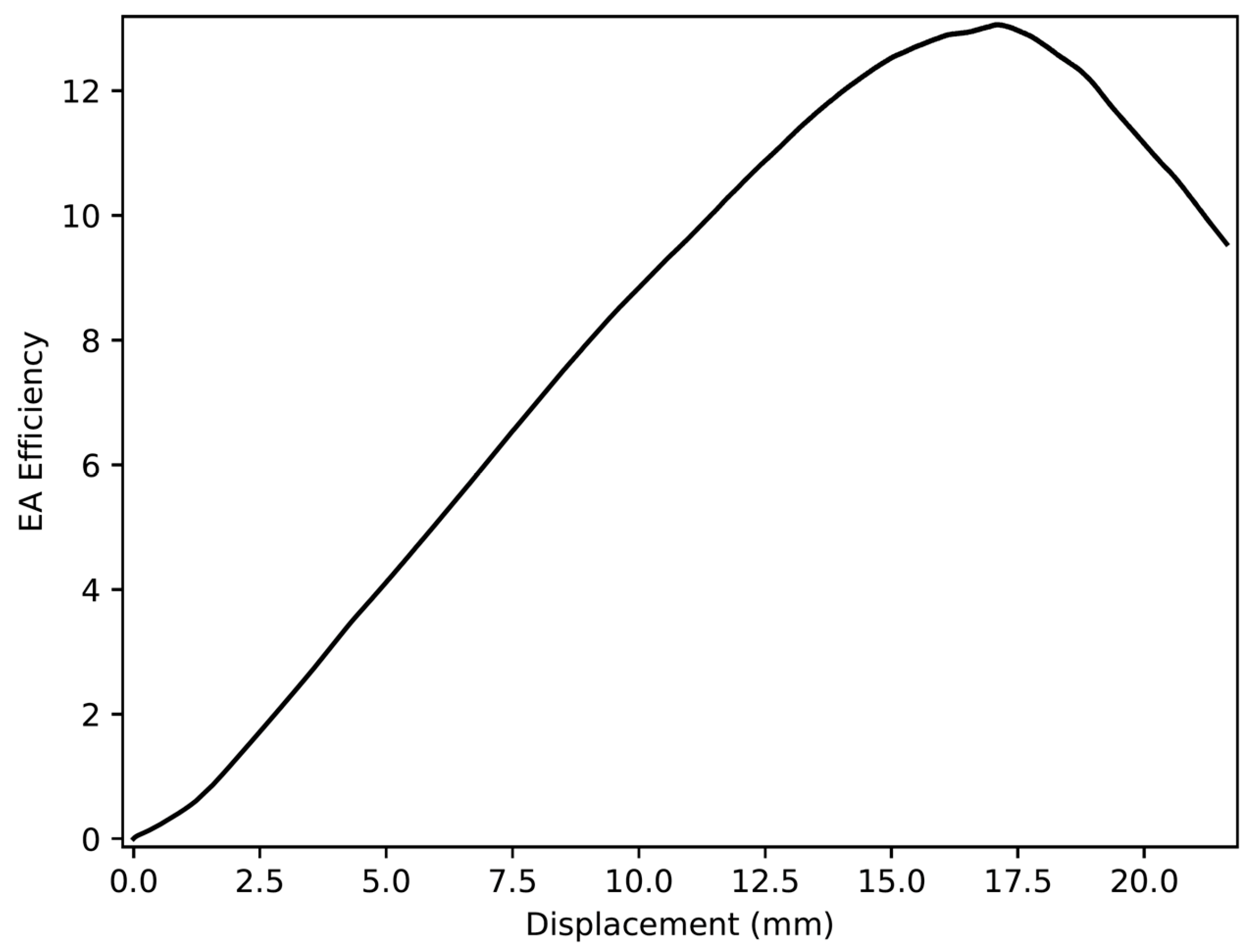

2.1. Performance Parameters

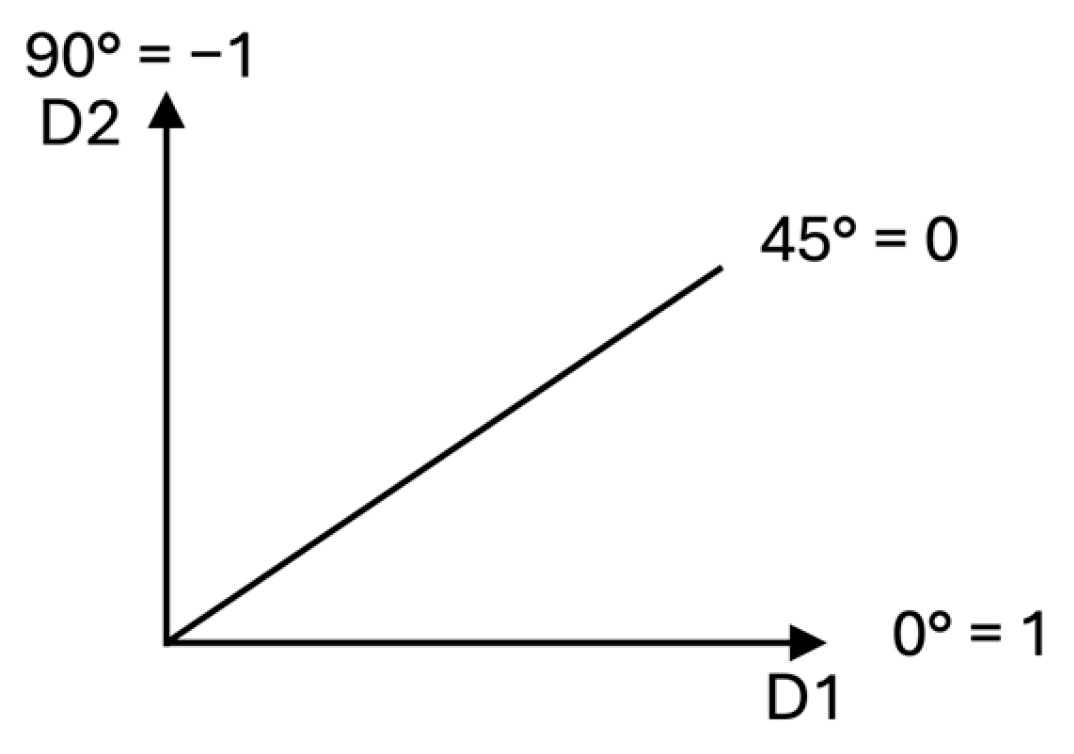

2.2. Multi-Direction Comparison Factor

- A positive result shows how much the SMP of Structure 1 is greater than the SMP of Structure 2.

- A negative result shows how much the SMP of Structure 2 is greater than the SMP of Structure 1.

- A result of 0% shows that neither of the structures has a net advantage over the other.

- A value greater than 0 indicates that the structure with greater SMP surpasses the other structure primarily in Loading Direction 1.

- A value lower than 0 indicates that the structure with greater SMP surpasses the other structure primarily in Loading Direction 2.

- A value of 0 indicates, when the MDCF is ≠0, that both loading directions have the same bearing in the structure, with the greater SMP surpassing the other one, and when the MDCF = 0, the value is 0, because neither of the structures has a net advantage over the other.

- Comparing the different iterations of the optimization of a structure.

- Comparing different designs for a specific application.

- Comparing different structures from the literature. To perform such comparisons, the structures should have been studied under the same type of experiment.

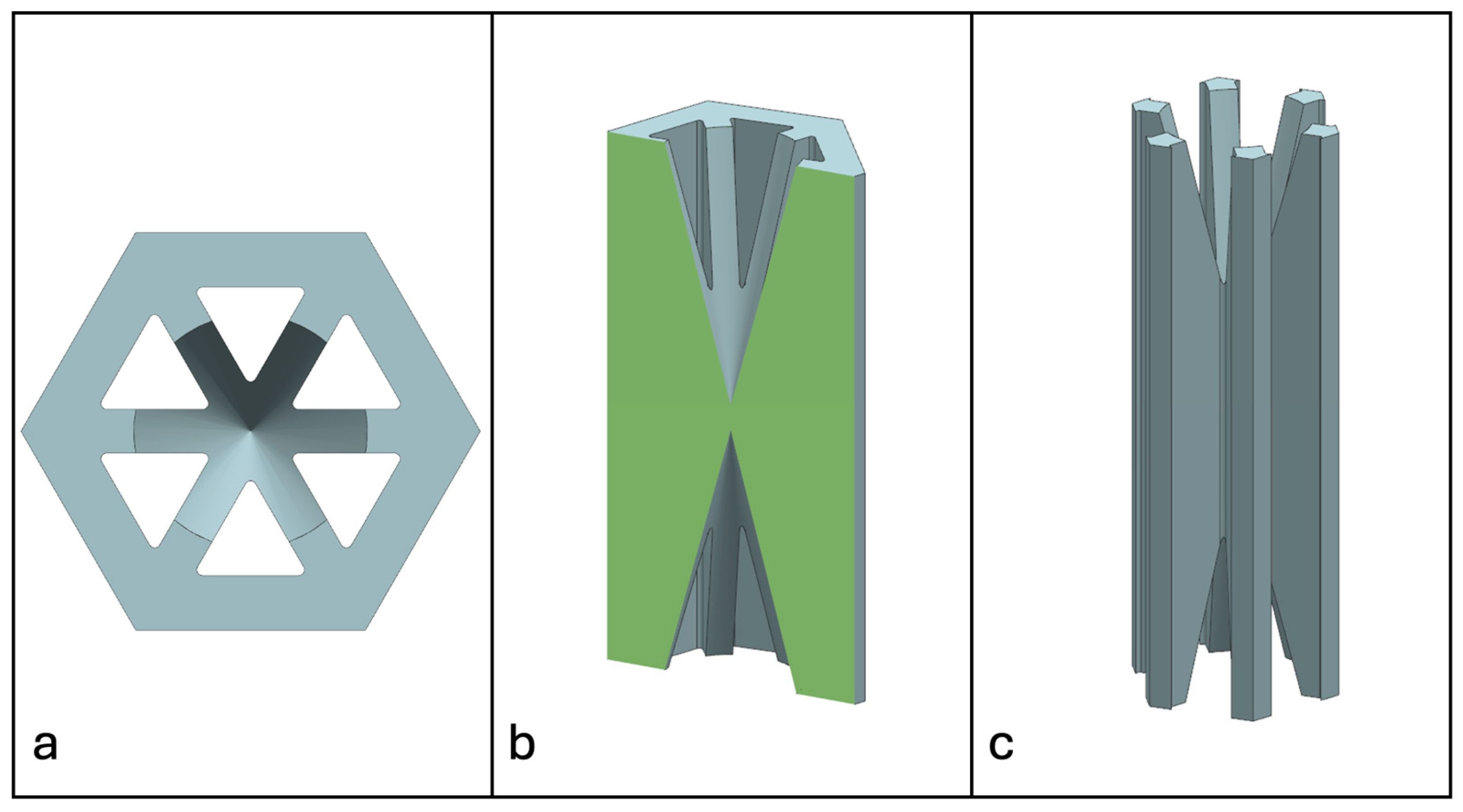

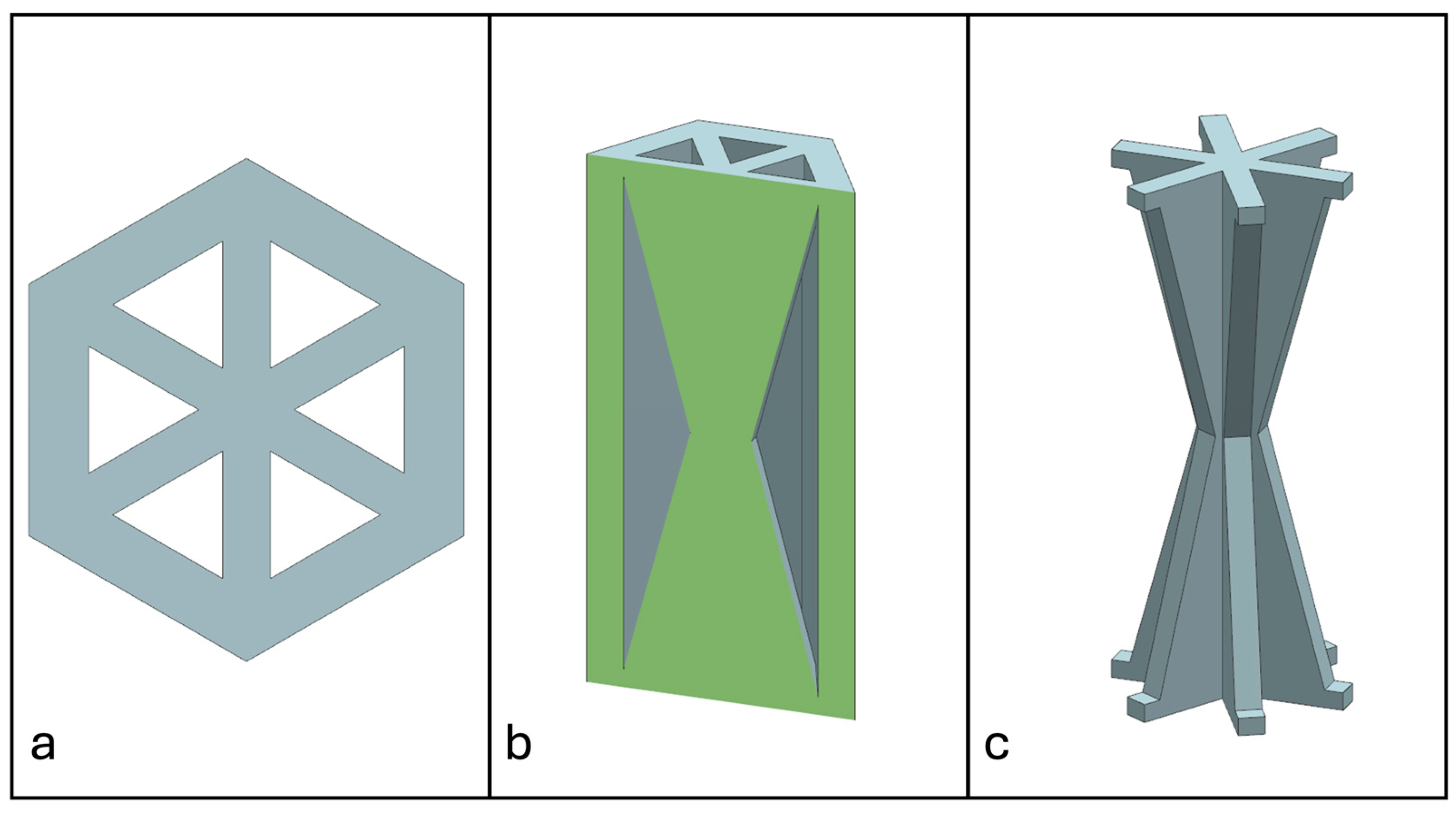

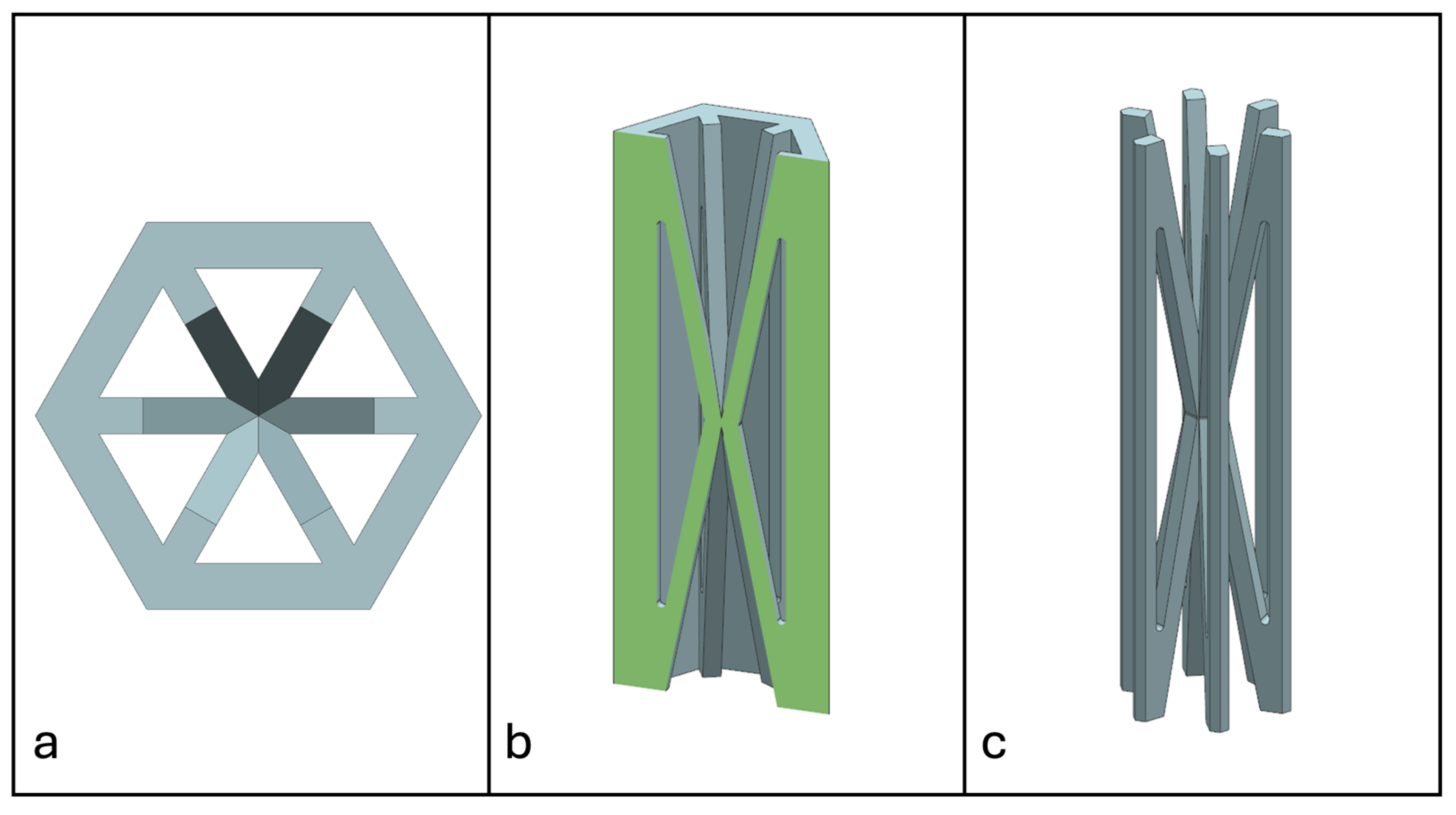

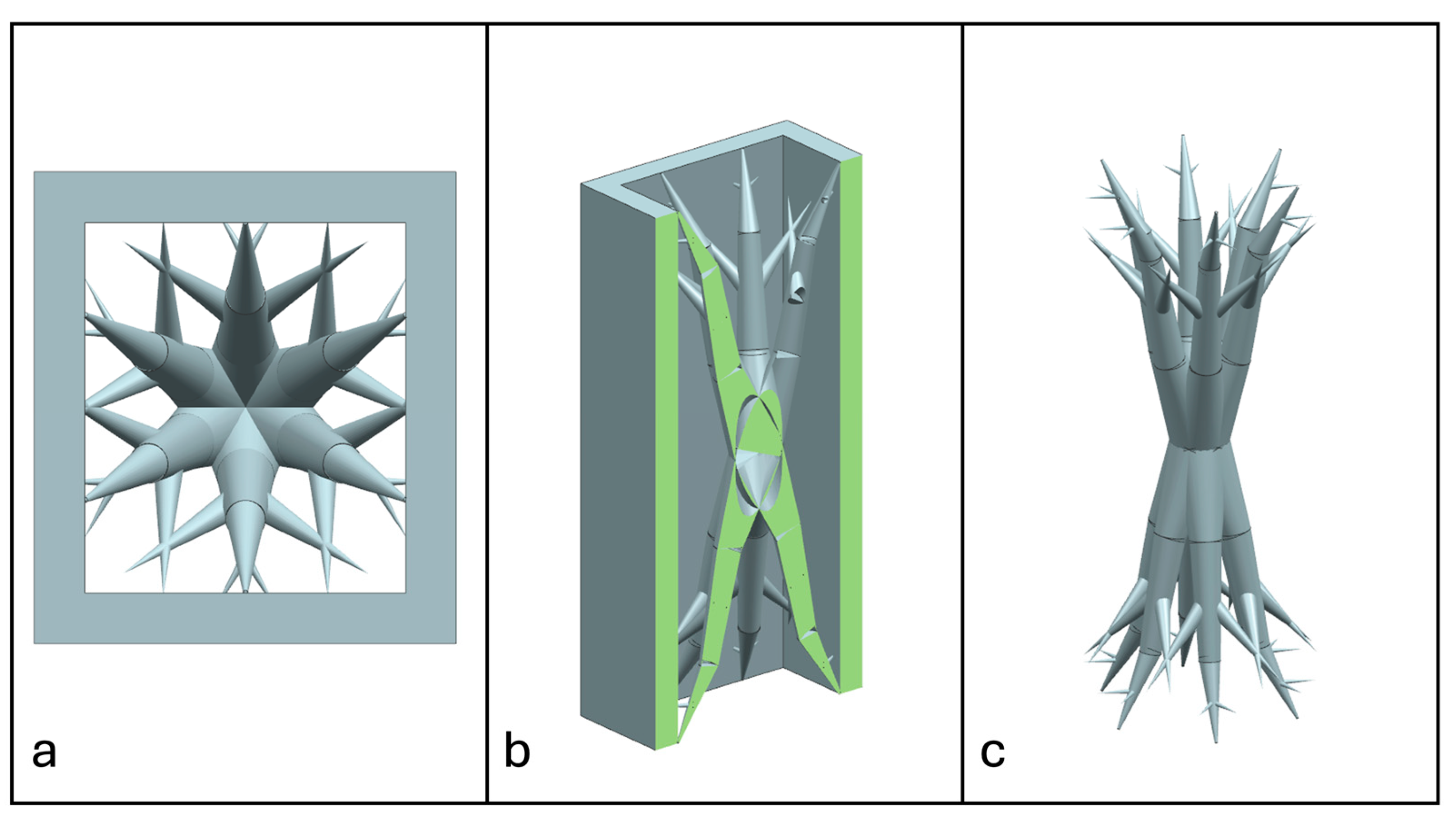

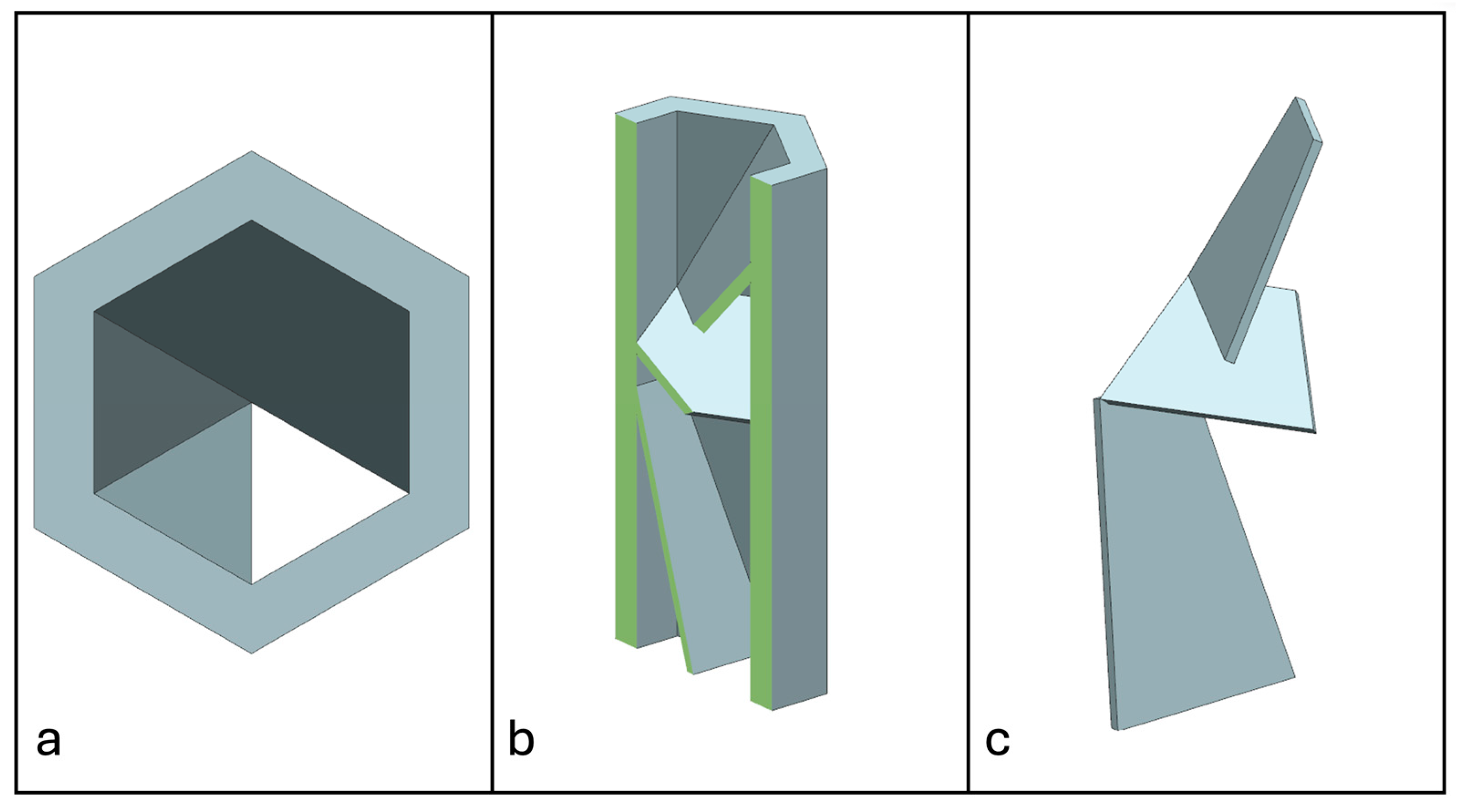

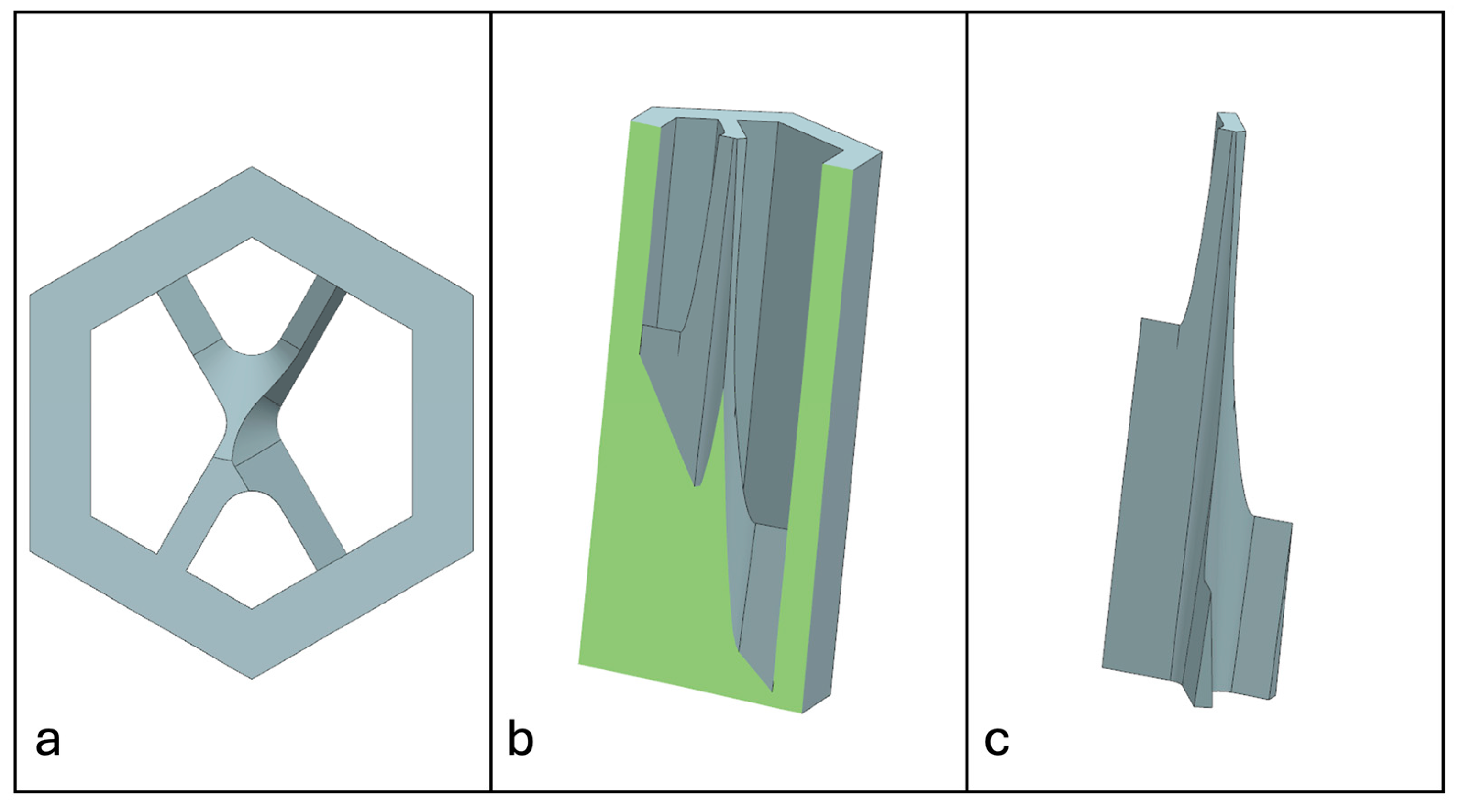

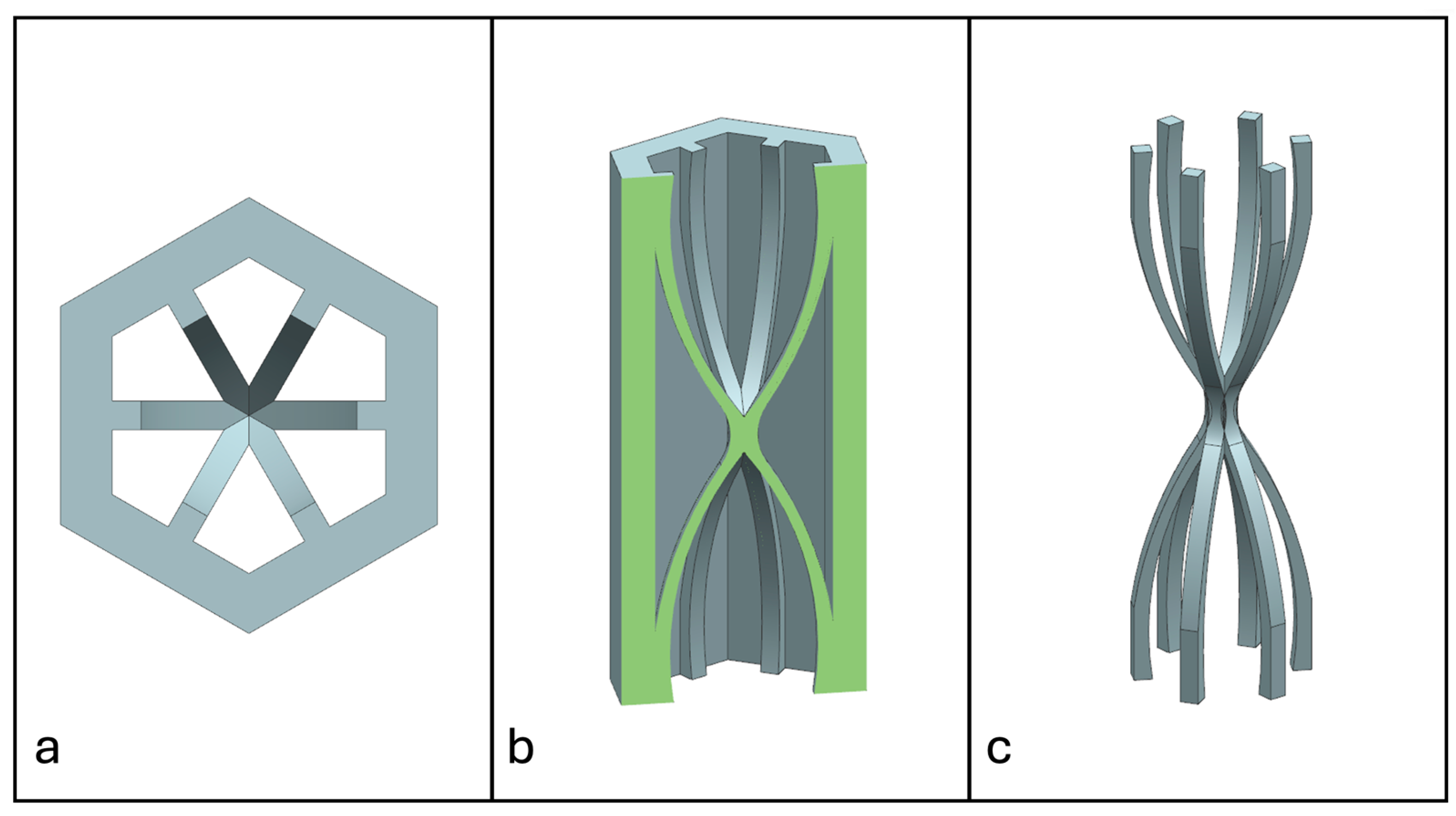

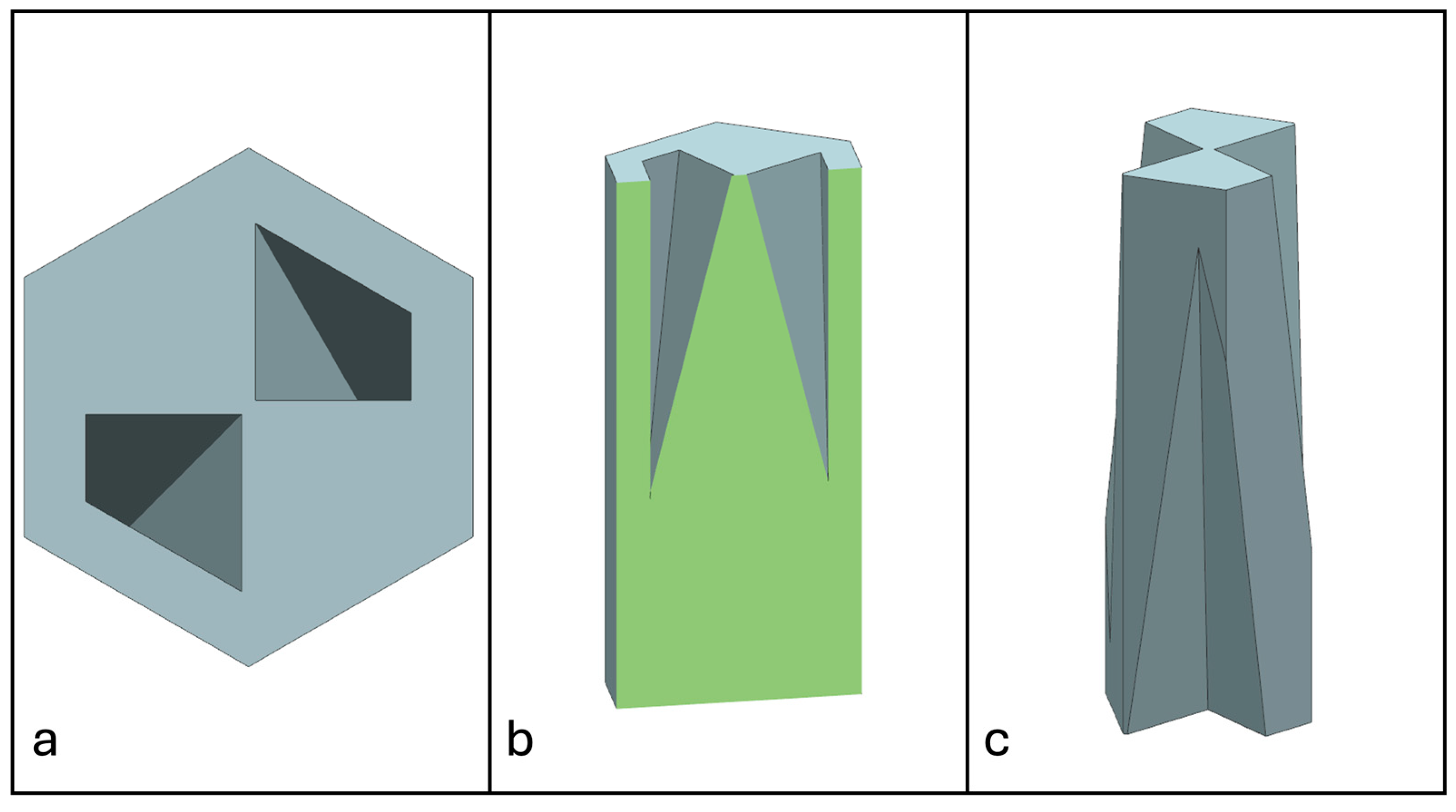

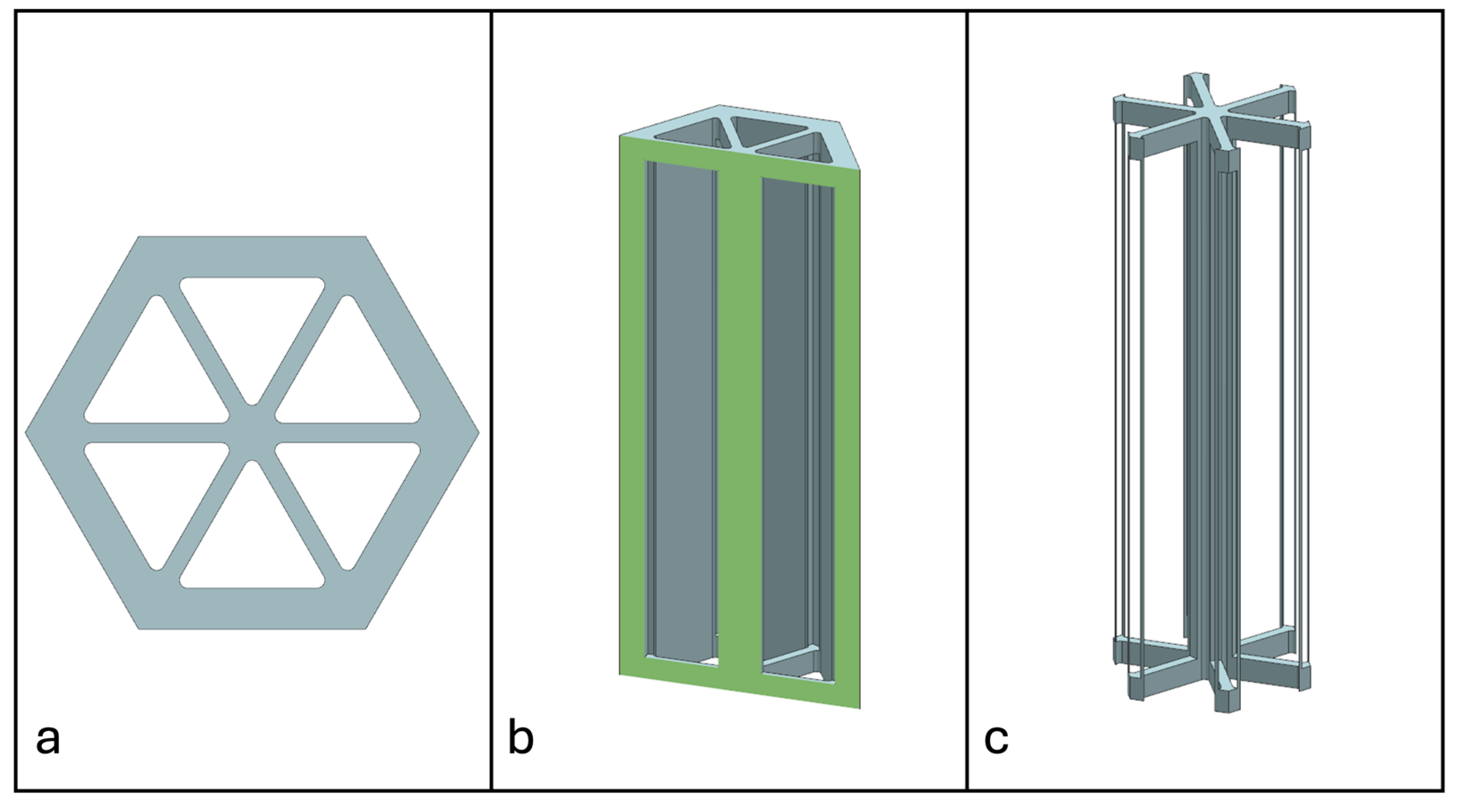

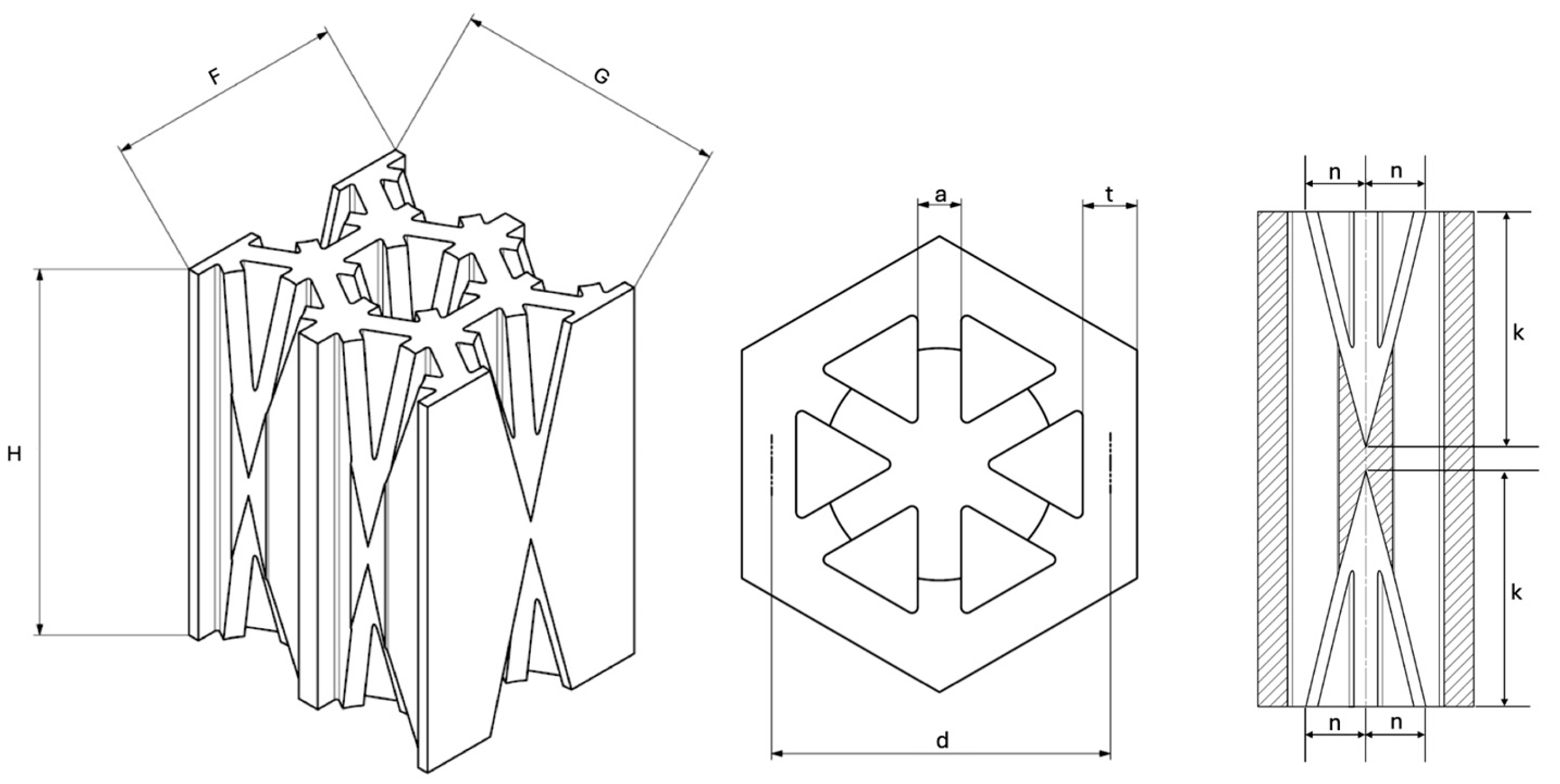

2.3. Non-Prismatic Reinforcements

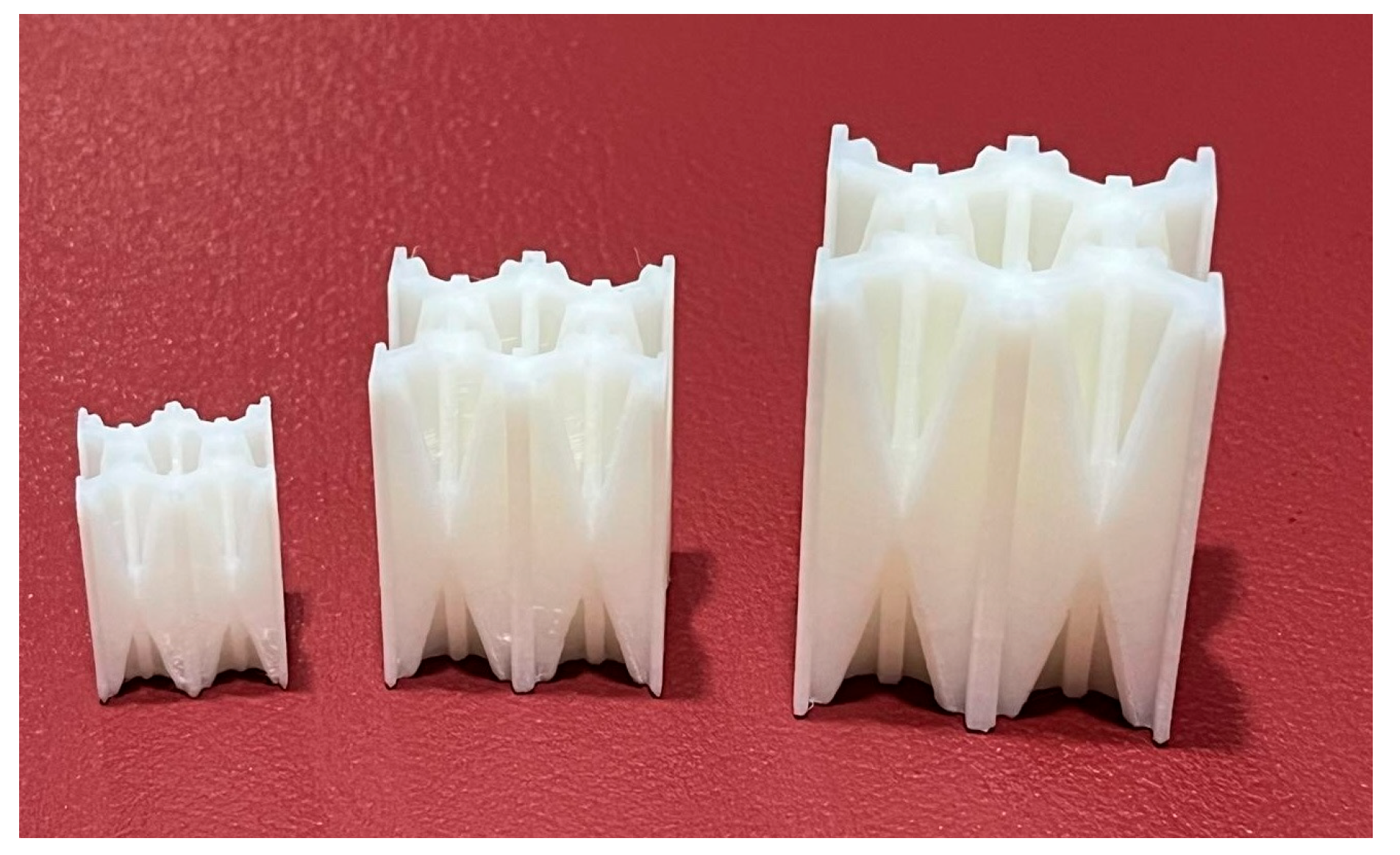

2.4. Manufacturing

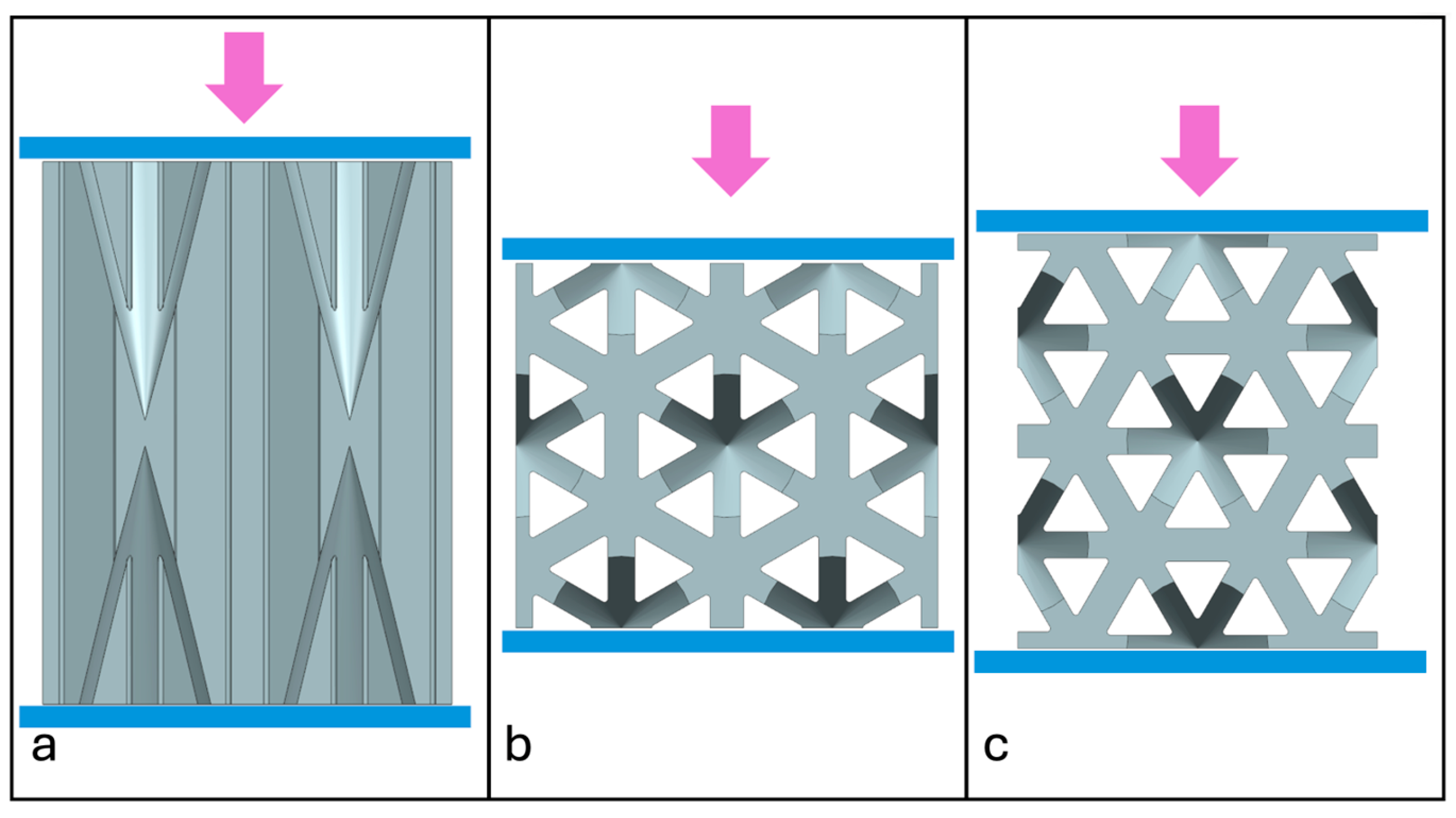

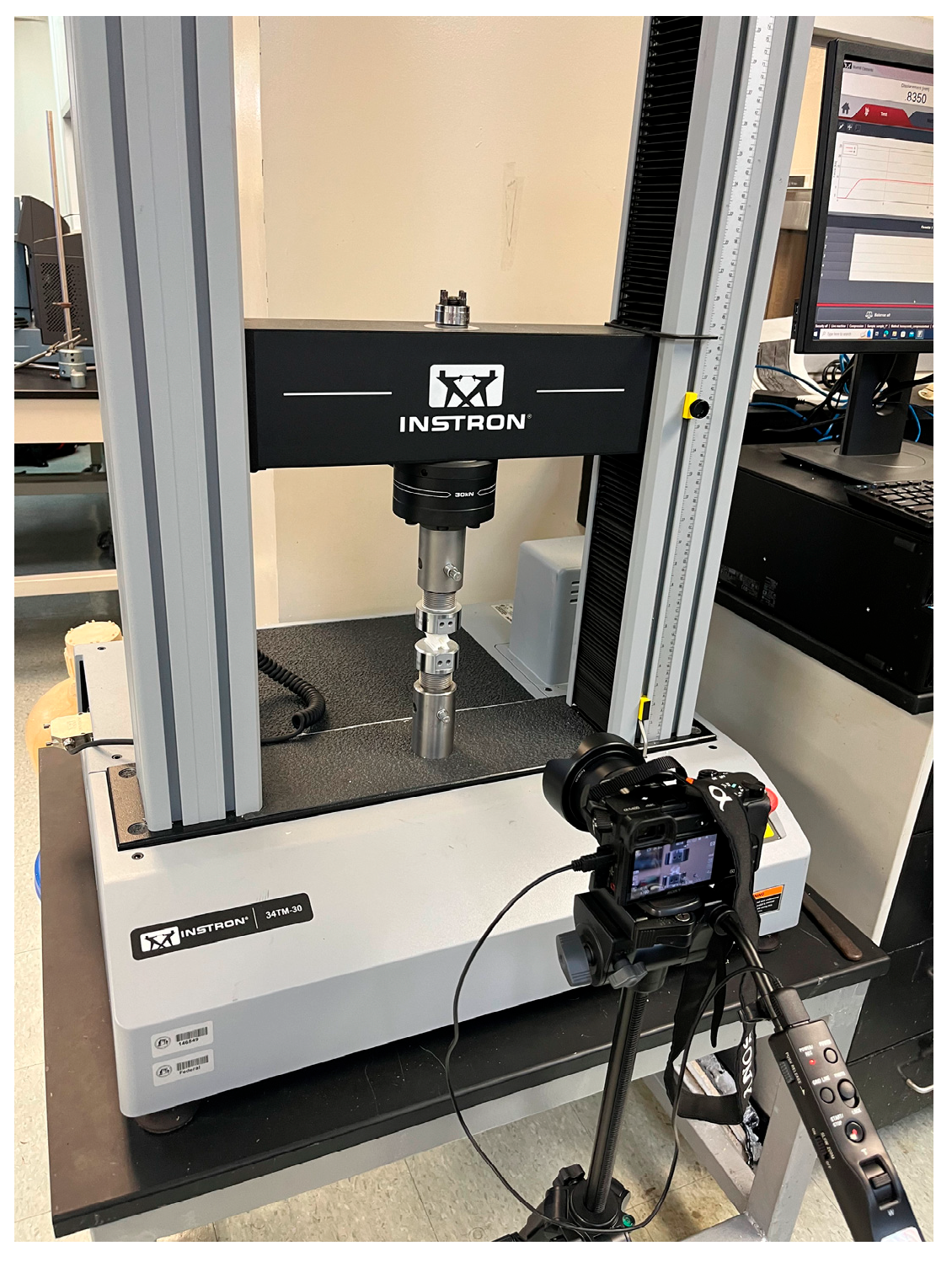

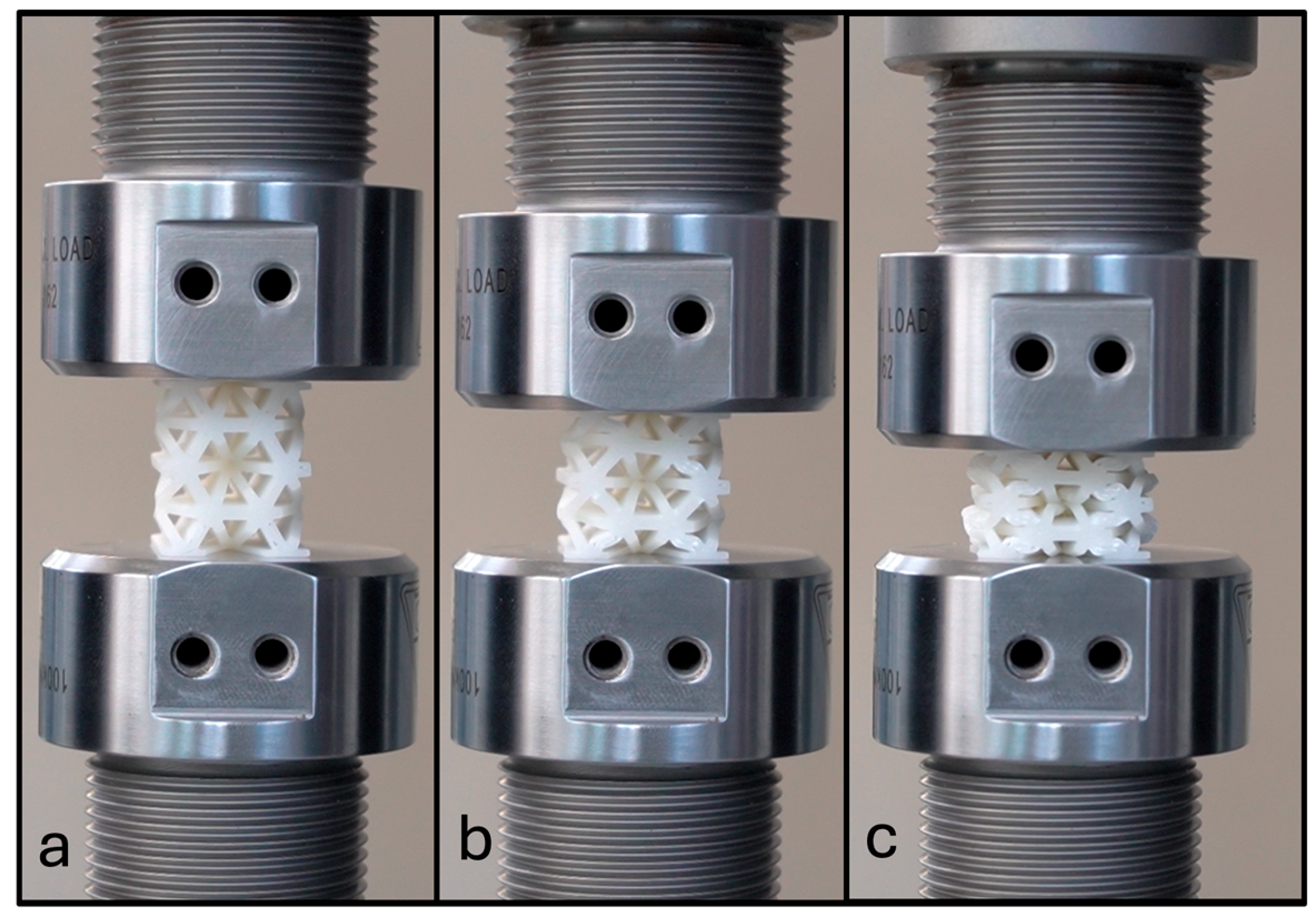

2.5. Experimental Setup

3. Results

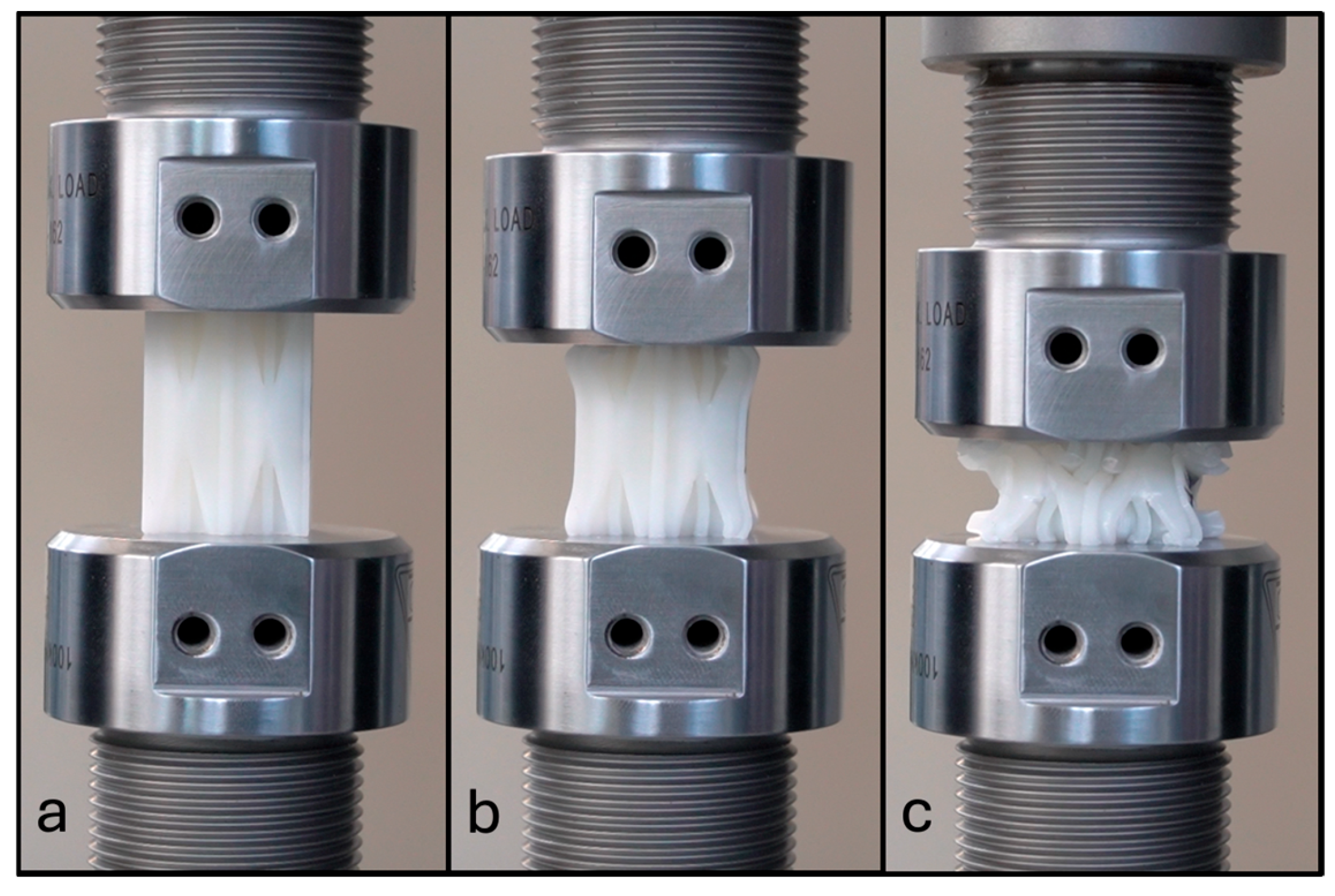

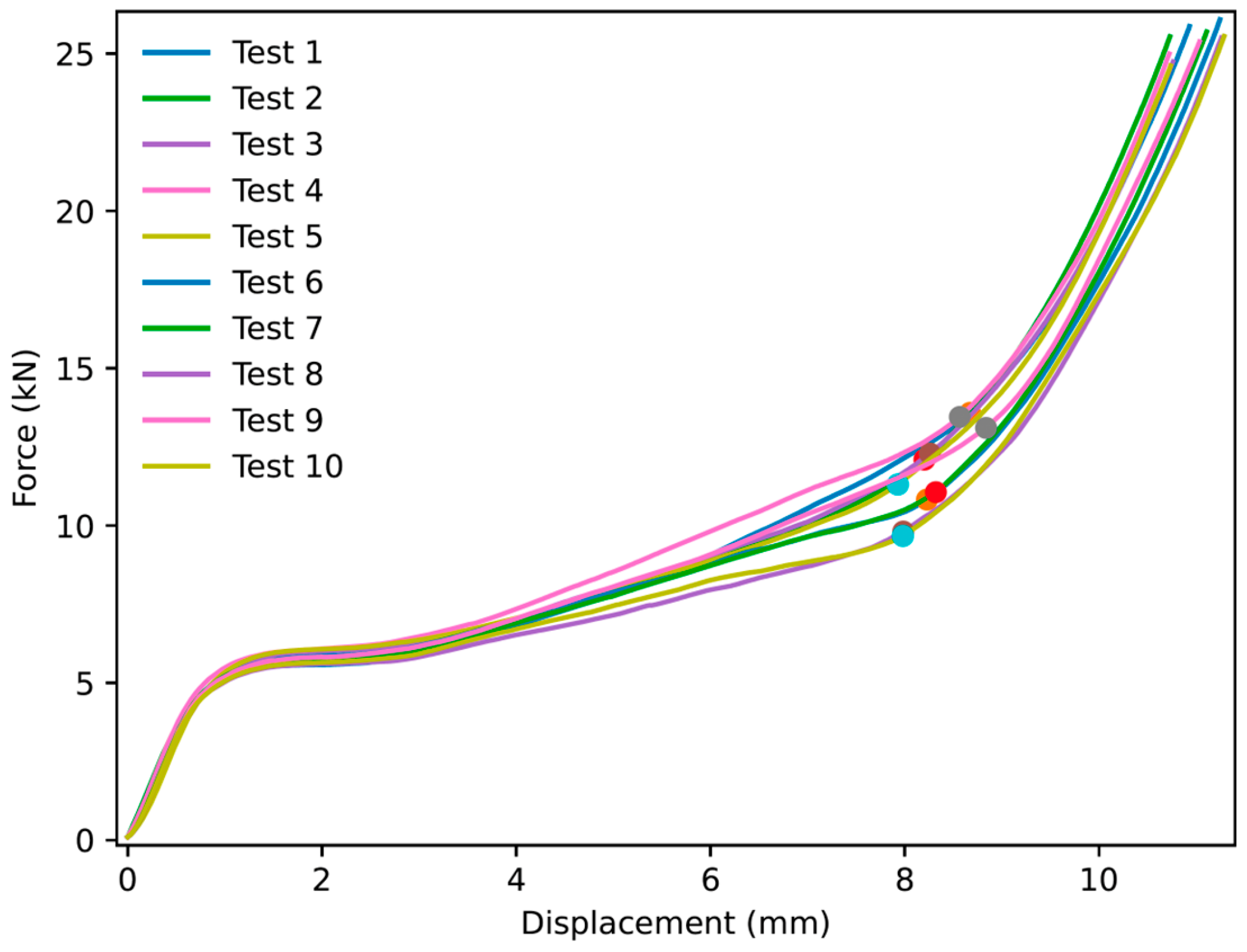

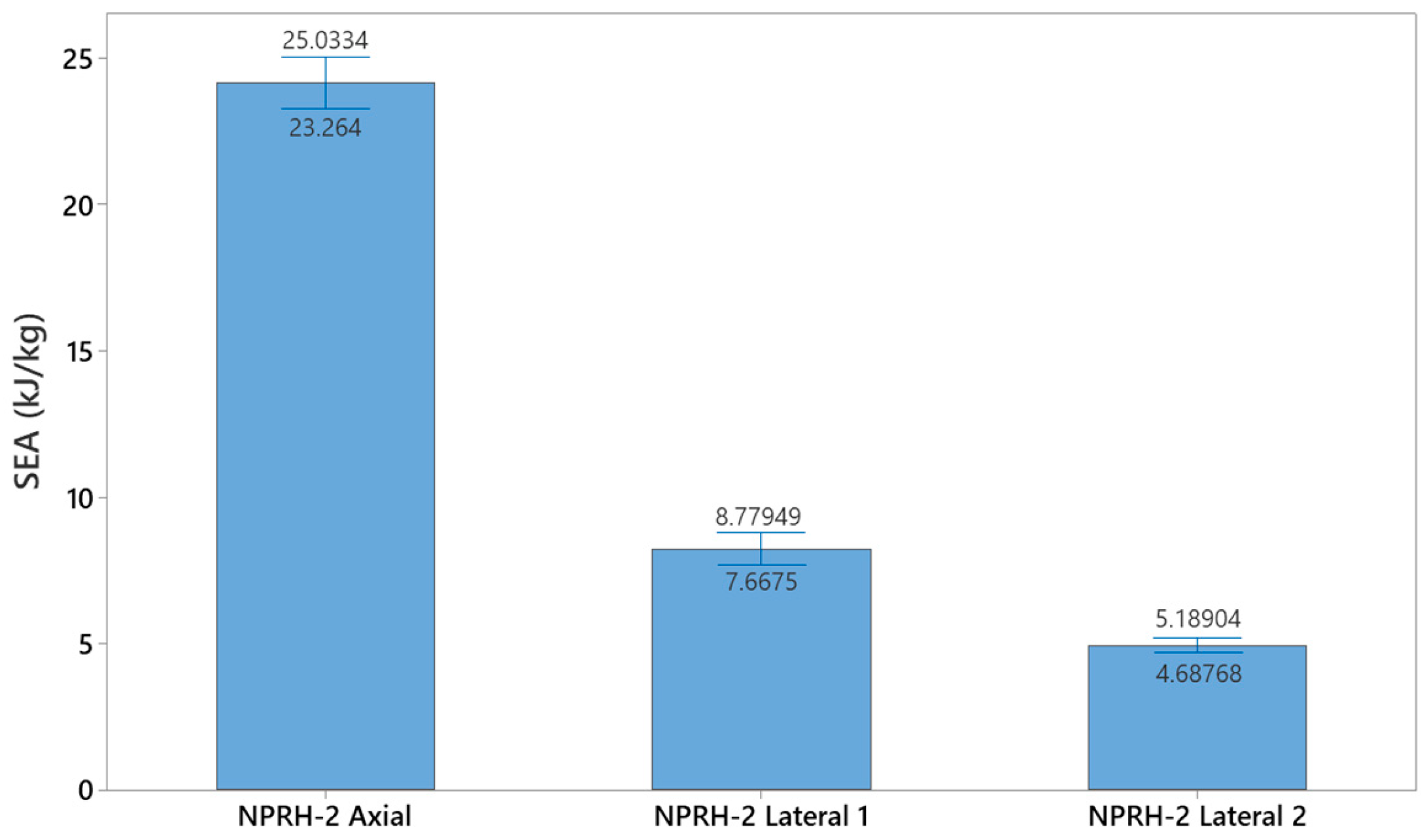

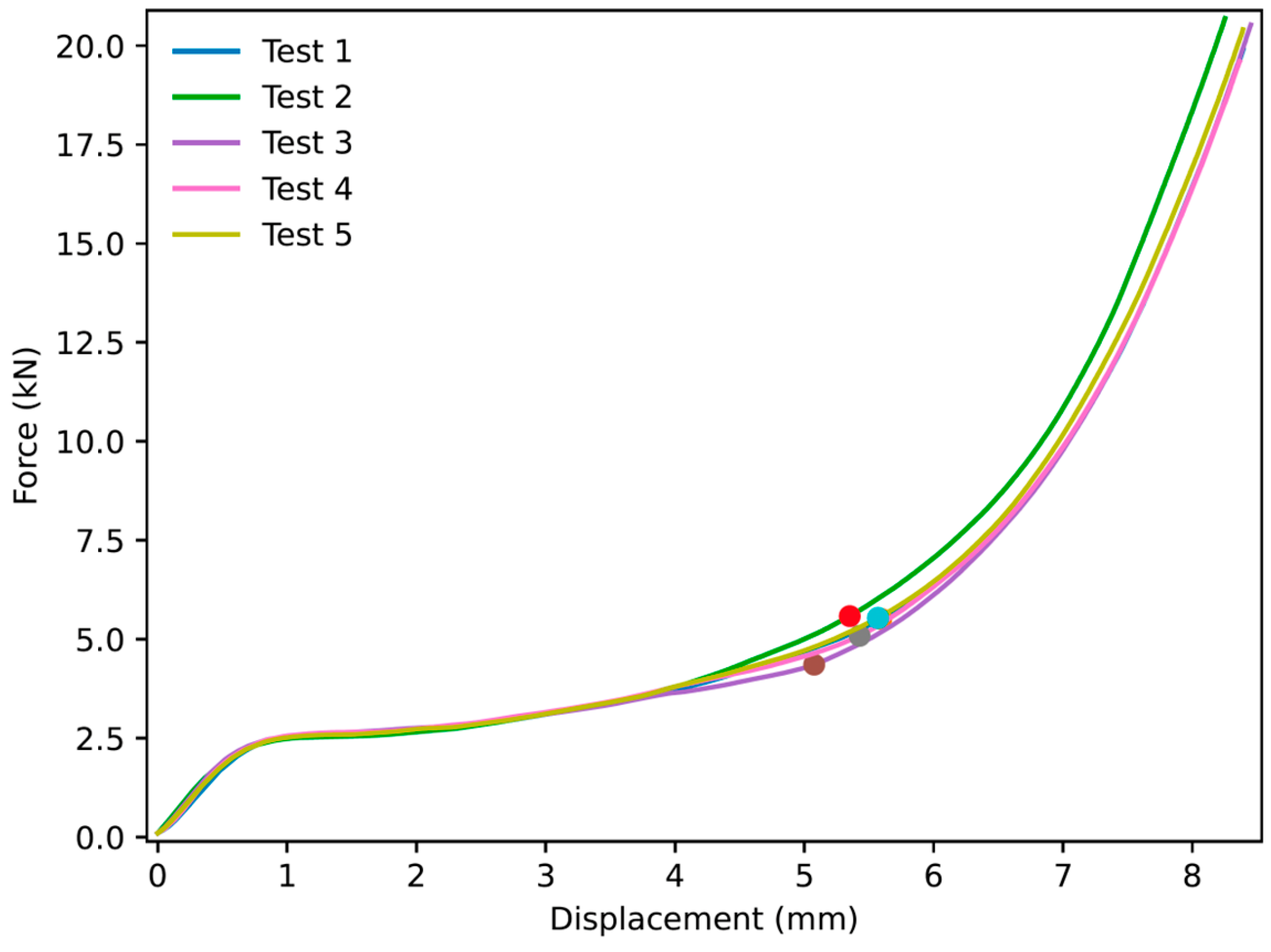

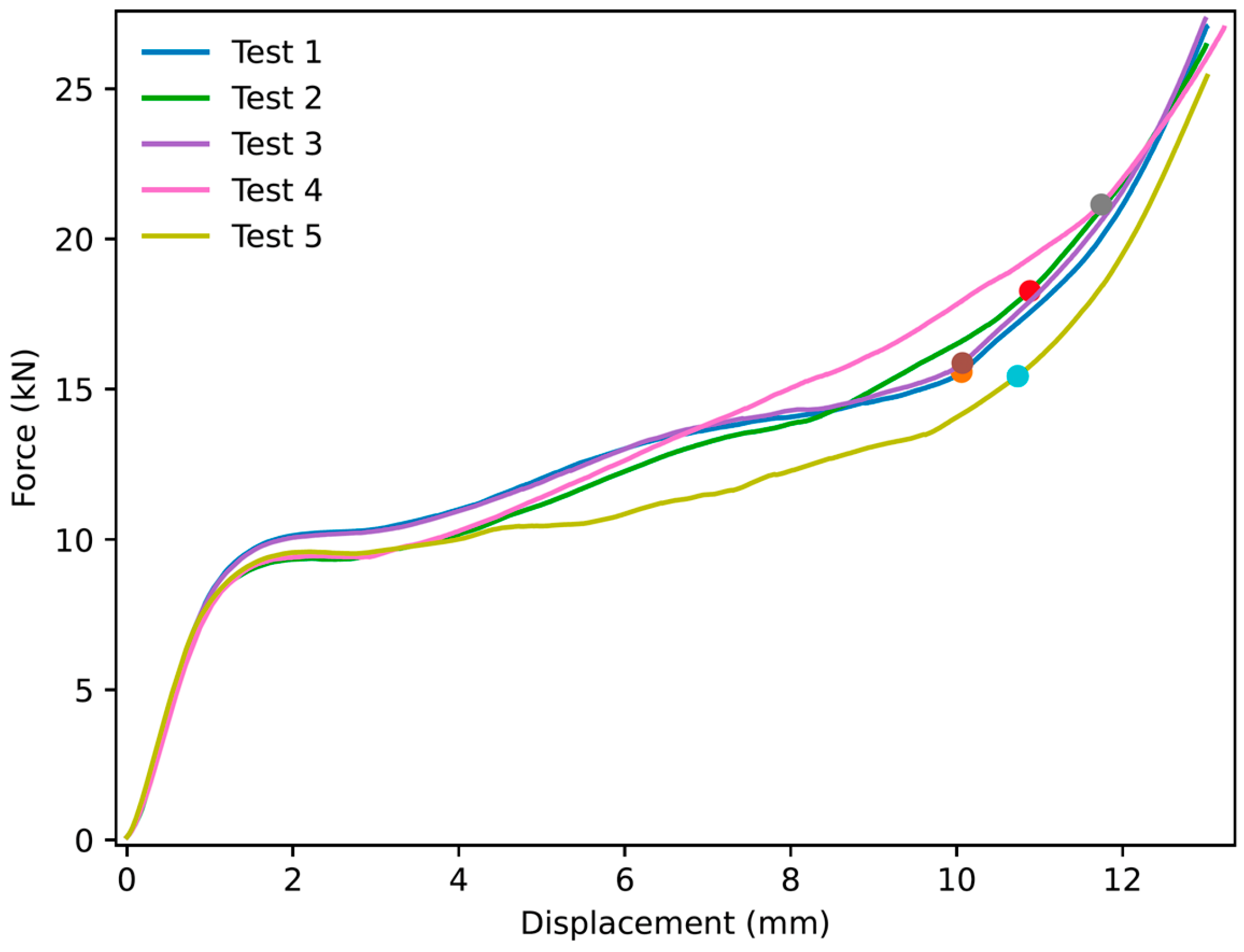

3.1. NPRH-2

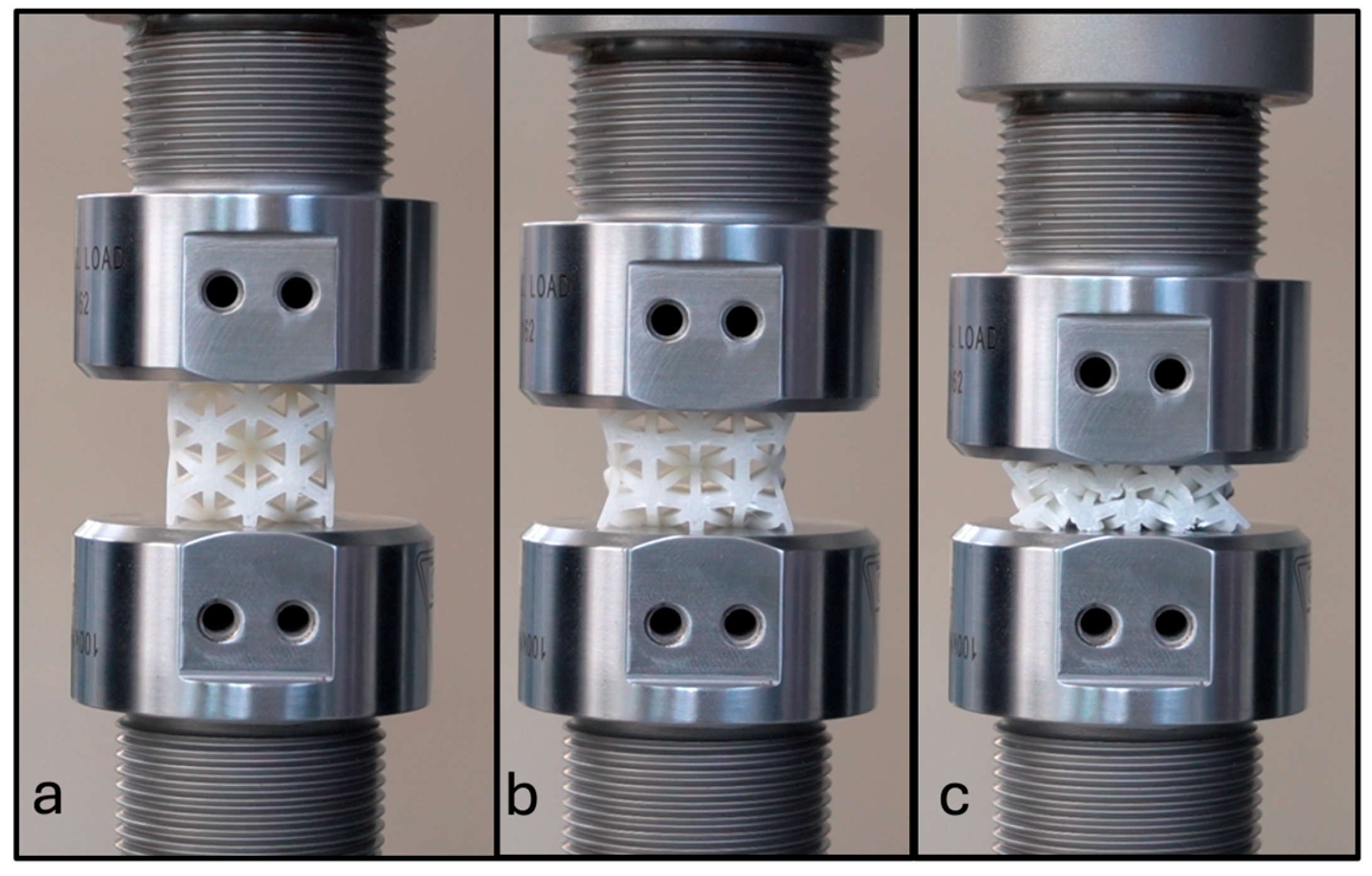

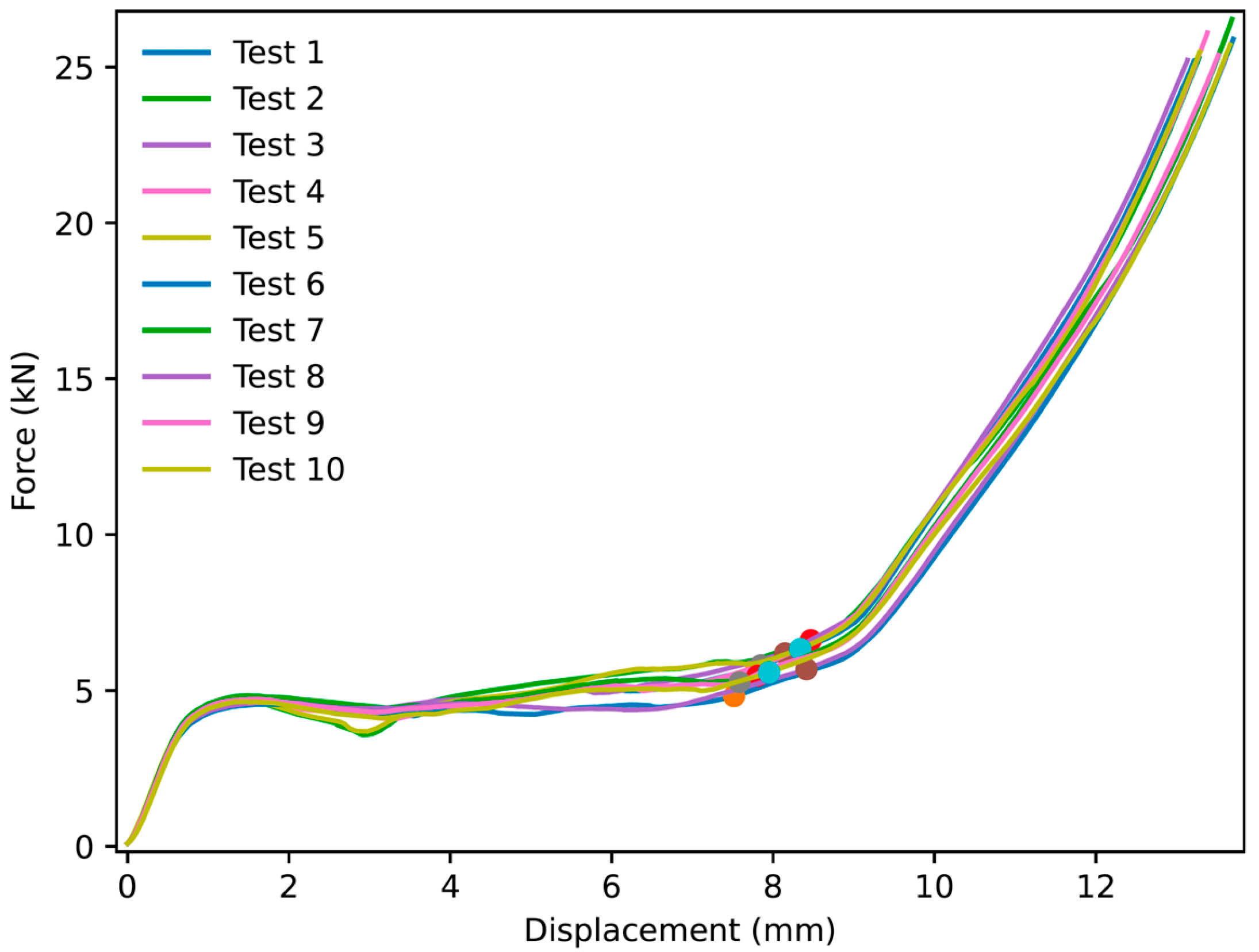

3.2. NPRH-1 and NPRR-3

3.3. MDCF and ACF

4. Discussion

4.1. NPRH-2 Under Multiple Loading Directions

4.2. Multiple Scales of NPRH

4.3. Comparing NPRH-2 with Other Structures

4.4. NPR

5. Conclusions

- In the case of NPRH-2, the Lateral 2 direction had the lowest SEA and earlier densification, possibly due to the NPR’s mass configuration and orientation.

- The peak crushing force (PCF) was not prominent compared to the plateau, with both the PCF and plateau having similar values, in all the curves of the experimental results for three NPRH scales. This suggests that the NPRH potentially does not need pre-crushing, leading to one less step in the manufacturing process, reducing the manufacturing time and costs.

- The three NPRH scales are self-supporting structures that can be manufactured with commercial FFF 3D printers as one part. This improves their manufacturability, reducing the material usage, manufacturing time, and costs. Because external supports are not needed, this enhances the printing repeatability and reduces the standard deviation of the properties of the structures. Designing self-supporting NPR structures can be challenging and less straightforward than designing other simpler structures. Complex geometries may show limitations in printing accuracy at certain scales due to chamfers and small angles.

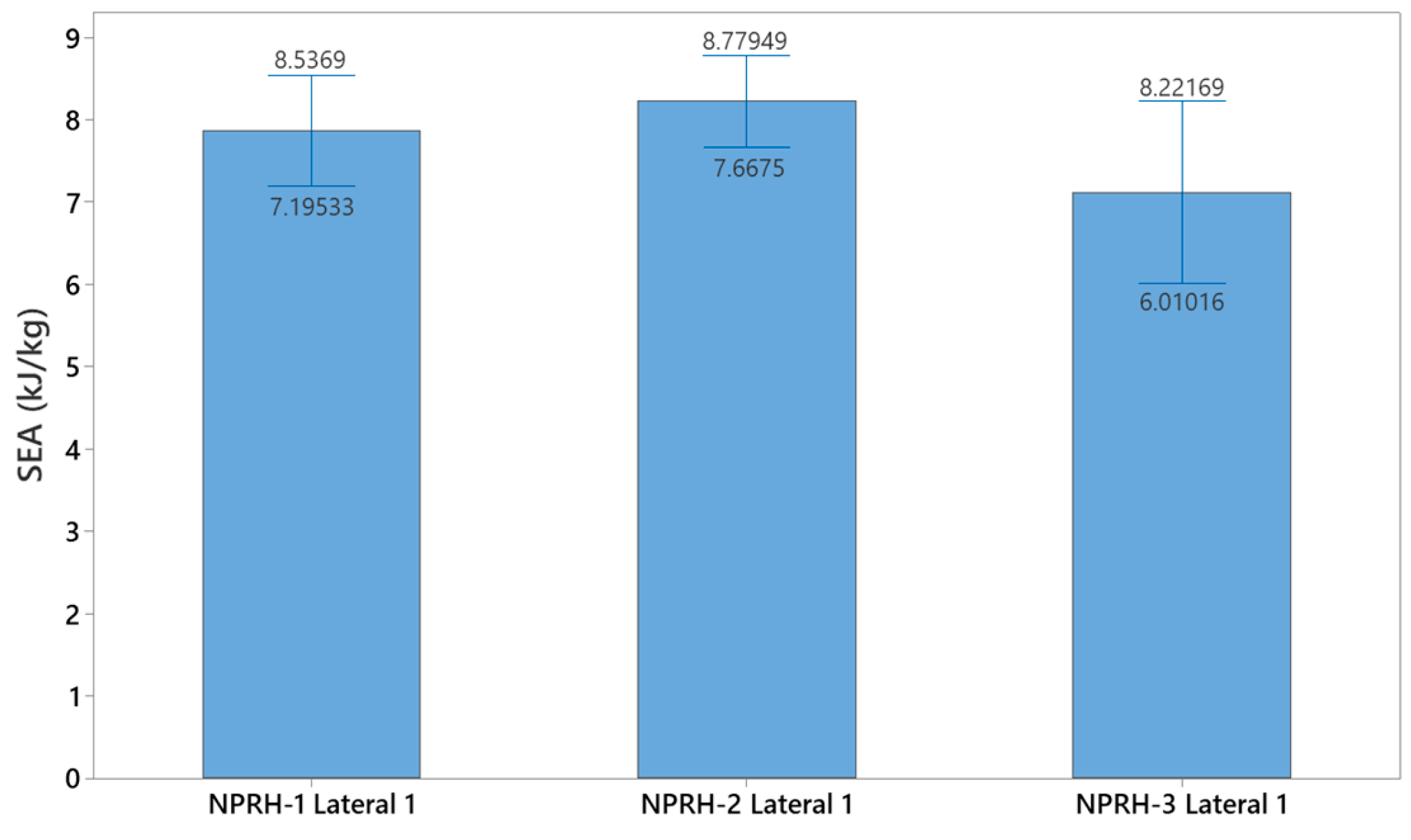

- The average SEAs of the three NPRH scales were not statistically significantly different. This indicates that increasing the scale does not significantly reduce the structures’ mechanical properties.

- In each of the three multi-directional loading scenarios considered, NPRH-2 presented a greater SEA than both the square honeycomb with internal diagonal walls and the hexagonal honeycomb [12]. NPRH-2’s lateral SEA was more than double the SEA of the hexagonal honeycomb, a prismatic cell.

- In order to compare the mechanical behaviors of different cell geometries under axial and lateral loading, two new comparison factors were developed as part of this work, namely, the MDCF and ACF. These factors are dimensionless and are independent of geometries and materials. They facilitated the comparison of the mechanical properties of the different cells under multi-directional loads. The MDCF and ACF were adapted to the three multi-directional loading scenarios.

- The use of NPRs allows for the possibility of increasing the mechanical properties of sandwich core structures, such as honeycombs, allowing them to be tailored for multi-directional loading applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Araújo, H.; Leite, M.; Ribeiro, A.; Deus, A.M.; Vaz, M.F. Investigating the contribution of geometry on the failure of cellular core structures obtained by additive manufacturing. Integrità Strutt. 2019, 13, 478–486. [Google Scholar] [CrossRef]

- Zhai, J.; Zhang, D.; Li, M.; Cui, C.; Cai, J. An Approximately Isotropic Origami Honeycomb Structure and Its Energy Absorption Behaviors. Materials 2023, 16, 1571. [Google Scholar] [CrossRef]

- Cava, K.; Aslan, M.; Alver, Ü.; Gedikli, H.; Gnaniar, K. Compression Properties of 3d Printed Honeycomb and Re-Entrant Sandwich Core Materials. SSRN 2020. [Google Scholar] [CrossRef]

- Baumgart, C.; Halle, T.; Krüger, C.W.L.; Aneziris, C. Effect of honeycomb cell geometry on compressive properties: Finite element analysis and experimental verification. Sci. Technol. Mater. 2018, 30, 35–42. [Google Scholar] [CrossRef]

- Tiwari, G.; Thomas, T.; Khandelwal, R. Influence of reinforcement in the honeycomb structures under axial compressive load. Thin-Walled Struct. 2018, 126, 238–245. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y.; Liu, J. Comparison between five typical reinforced honeycomb structures. In Proceedings of the 2015 International Conference on Advanced Engineering Materials and Technology, Shenzhen, China, 22–23 September 2015. [Google Scholar] [CrossRef][Green Version]

- Thomas, T.; Tiwari, G. Energy absorption and in-plane crushing behavior of aluminium reinforced honeycomb. Vacuum 2019, 166, 364–369. [Google Scholar] [CrossRef]

- Rayhan, S.B.; Chowdhury, M.U.; Pu, X. Ballistic impact response of reinforced honeycomb sandwich panels. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1226, 012079. [Google Scholar] [CrossRef]

- Saufi, S.A.S.A.; Zuhri, M.Y.M.; Dezaki, M.L.; Sapuan, S.M.; Ilyas, R.A.; As’arry, A.; Ariffin, M.K.A.; Bodaghi, M. Compression Behaviour of Bio-Inspired Honeycomb Reinforced Starfish Shape Structures Using 3D Printing Technology. Polymers 2021, 13, 4388. [Google Scholar] [CrossRef]

- He, J.; Kushwaha, S.; Abueidda, D.; Jasiuk, I. Exploring the structure-property relations of thin-walled, 2D extruded lattices using neural networks. Comput. Struct. 2022, 277–278, 106940. [Google Scholar] [CrossRef]

- Menegozzo, M.; Cecchini, A.; Just-Agosto, F.; Acevedo, D.S.; Velez, O.F.; Acevedo-Figueroa, I.; De Jesús Ruiz, J. A 3D-Printed Honeycomb Cell Geometry Design with Enhanced Energy Absorption under Axial and Lateral Quasi-Static Compression Loads. Appl. Mech. 2022, 3, 296–312. [Google Scholar] [CrossRef]

- Menegozzo, M.; Cecchini, A.; Ogle, R.C.; Vaidya, U.K.; Acevedo-Figueroa, I.; Torres-Hernández, J.A. Scale Effect Assessment of Innovative 3D-Printed Honeycomb under Quasi-Static Compression. Aerospace 2023, 10, 242. [Google Scholar] [CrossRef]

- Sun, X.; Huang, Z.; Wang, T.; Hu, L.Y.; Zhao, N. Study on axial compression property of thin walled tube filled with negative Poisson’s ratio lattice. Adv. Mech. Eng. 2023, 15, 16878132231160929. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, Y.; Wang, X.; Wei, K. Compression behavior of strut-reinforced hierarchical lattice—Experiment and simulation. Int. J. Mech. Sci. 2021, 210, 106749. [Google Scholar] [CrossRef]

- Kocabaş, G.B.; Çetin, E.; Yalçınkaya, S.; Şahin, Y. Experimental Comparison of the Energy Absorption Performance of Traditional Lattice and Novel Lattice Filled Tubes. Int. J. Automot. Sci. Technol. 2023, 7, 207–212. [Google Scholar] [CrossRef]

- Tao, C.; Zhou, X.; Liu, Z.; Liang, X.; Zhou, W.; Li, H. Crashworthiness Study of 3D Printed Lattice Reinforced Thin Walled Tube Hybrid Structures. Materials 2023, 16, 1871. [Google Scholar] [CrossRef]

- Tao, C.; Wang, Z.; Liu, Z.; Wang, Y.; Zhou, X.; Liang, X.; Li, H. Crashworthiness of Additively Manufactured Lattice Reinforced Thin-Walled Tube Hybrid Structures. Aerospace 2023, 10, 524. [Google Scholar] [CrossRef]

- Liu, H.; Chng, Z.X.C.; Wang, G.; Ng, B.F. Crashworthiness improvements of multi-cell thin-walled tubes through lattice structure enhancements. Int. J. Mech. Sci. 2021, 210, 106731. [Google Scholar] [CrossRef]

- Lv, J.; Bai, Z.; Du, X.; Zhu, F.; Chou, C.C.; Jiang, B.; Xu, S. Crashworthiness design of 3D lattice-structure filled thin-walled tubes based on data mining. Int. J. Crashworthiness 2022, 28, 435–448. [Google Scholar] [CrossRef]

- Baykasoğlu, A.; Baykasoğlu, C.; Cetin, E. Multi-objective crashworthiness optimization of lattice structure filled thin-walled tubes. Thin-Walled Struct. 2020, 149, 106630. [Google Scholar] [CrossRef]

- Cetina, E.; Baykasoğlua, C.; Baykasoğlu, A. Predicting energy absorption parameters of aluminum lattice structures filled tubes via artificial neural networks. In Proceedings of the International Alumınıum-Themed Engineering and Natural Sciences Conference, Konya, Turkey, 4–6 October 2019. [Google Scholar]

- Zeng, C.; Liu, L.; Bian, W.; Leng, J.; Liu, Y. Compression behavior and energy absorption of 3D printed continuous fiber reinforced composite honeycomb structures with shape memory effects. Addit. Manuf. 2021, 38, 101842. [Google Scholar] [CrossRef]

- Solak, A.; Temiztaş, B.A.; Bolat, B. Estimation of wavy honeycombs’ compression performance via a machine learning algorithm. Lat. Am. J. Solids Struct. 2021, 18, e407. [Google Scholar] [CrossRef]

- Feng, G.; Li, S.; Xiao, L.; Song, W. Energy absorption performance of honeycombs with curved cell walls under quasi-static compression. Int. J. Mech. Sci. 2021, 210, 106746. [Google Scholar] [CrossRef]

- Qin, R.; Zhou, J.; Chen, B. Crashworthiness Design and Multiobjective Optimization for Hexagon Honeycomb Structure with Functionally Graded Thickness. Hindawi. Adv. Mater. Sci. Eng. 2019, 2019, 8938696. [Google Scholar] [CrossRef]

- Sarvestania, H.Y.; Akbarzadeh, A.; Niknama, H.; Hermenean, K. 3D printed architected polymeric sandwich panels: Energy absorption and structural performance. Compos. Struct. 2018, 200, 886–909. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, E.T.; Ng, B.F. In-plane dynamic crushing of a novel honeycomb with functionally graded fractal self-similarity. Compos. Struct. 2021, 270, 114106. [Google Scholar] [CrossRef]

- Sherman, J.; Zhang, W.; Xu, J. Energy Absorption Performance of Bio-inspired Honeycombs: Numerical and Theoretical Analysis. Acta Mech. Solida Sin. 2021, 34, 884–894. [Google Scholar] [CrossRef]

- Chen, G.; Cheng, Y.; Zhang, P.; Liu, J.; Chen, C.; Cai, S. Design and modelling of auxetic double arrowhead honeycomb core sandwich panels for performance improvement under air blast loading. J. Sandw. Struct. Mater. 2020, 23, 3574–3605. [Google Scholar] [CrossRef]

- Rad, M.S.; Hatami, H.; Alipouri, R.; Nejad, A.F.; Omidinasab, F. Determination of energy absorption in different cellular auxetic structures. Mech. Ind. 2019, 20, 302. [Google Scholar] [CrossRef]

- Maharjan, G.K.; Khan, S.Z.; Riza, S.H.; Masood, S. Compressive Behaviour of 3D Printed Polymeric Gyroid Cellular Lattice Structure. IOP Conf. Ser. Mater. Sci. Eng. 2018, 455, 012047. [Google Scholar] [CrossRef]

- Bronder, S.; Adorna, M.; Fíla, T.; Koudelka, P.; Falta, J.; Jiroušek, O.; Jung, A. Hybrid Auxetic Structures: Structural Optimization and Mechanical Characterization. Adv. Eng. Mater. 2021, 23, 2001393. [Google Scholar] [CrossRef]

- Gautam, R.; Sridharan, V.S.; Idapalapati, S. Flatwise Compression and Local Indentation Response of 3D-Printed Strut-Reinforced Kagome with Polyurethane Filling. JOM 2020, 72, 1324–1331. [Google Scholar] [CrossRef]

- Wang, Z. Recent advances in novel metallic honeycomb structure. Compos. Part B 2019, 1, 731–741. [Google Scholar] [CrossRef]

- Birman, V.; Kardomateas, G.A. Review of current trends in research and applications of sandwich structures. Compos. Part B: Eng. 2018, 142, 221–240. [Google Scholar] [CrossRef]

- Wei, X.; Xiong, J.; Wang, J.; Xu, W. New advances in fiber-reinforced composite honeycomb materials. Sci. China Technol. Sci. 2020, 63, 1348–1370. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, G.; You, Z. Large deformation and energy absorption of additively manufactured auxetic materials and structures: A review. Compos. Part B 2020, 201, 108340. [Google Scholar] [CrossRef]

- Ha, N.S.; Lu, G. A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos. Part B Eng. 2020, 181, 107496. [Google Scholar] [CrossRef]

- Wang, J.; Cao, Y. Influence of the Geometric Parameters on the Densification Onset Strain of Double-Walled Honeycomb Aluminum under Out-of-Plane Compression. Adv. Mater. Sci. Eng. 2020, 2020, 7. [Google Scholar] [CrossRef]

- Candelaria, S.; Menegozzo, M.; Serrano, D. Sandwich Core Structures with Internal Non-prismatic Reinforcements. In Proceedings of the 3rd International Conference on Mechanics of Advanced Materials and Structures [Conference presentation], College Station, TX, USA, 9–11 August 2023. [Google Scholar]

- Zortrax. Zortax. 2021. Available online: https://zortrax.com/wp-content/uploads/2018/06/Z-ABS_Technical_Data_Sheet_eng_1.pdf (accessed on 5 June 2024).

- Ambrósio, J.A. Crashworthiness: Energy Management and Occupant Protection; Springer: Vienna, Austria, 2001; p. 19. [Google Scholar]

- Lu, G.; Yu, T. Energy Absorption of Structures and Materials; Woodhead Publishing Limited: Cambridge, UK, 2003; p. 19. [Google Scholar]

- INSTRON. Instron. 2024. Available online: https://www.instron.com/en/products/testing-systems/universal-testing-systems/low-force-universal-testing-systems/-/media/literature-library/products/2019/04/3400-series-universal-testing-systems.pdf?la=en&hash=B1DBFA36CE017B83B416C4515E84CE4A#page=17&sc_ (accessed on 16 September 2024).

| Configuration | Direction 1 Specific Energy Absorption (kJ/kg) | Direction 2 Specific Energy Absorption (kJ/kg) |

|---|---|---|

| Structure 1 | 31.431 | 23.026 |

| Structure 2 | 14.524 | 47.137 |

| Configuration | H | G | F | t | d | a | k | n |

|---|---|---|---|---|---|---|---|---|

| NPRH-1 | 20 | 15.07 | 13.05 | 1.2 | 7.54 | 0.96 | 9.52 | 2.57 |

| NPRH-2 | 30 | 22.61 | 19.58 | 1.8 | 11.30 | 1.44 | 14.29 | 3.85 |

| NPRH-3 | 40 | 30.14 | 26.11 | 2.4 | 15.07 | 1.92 | 19.05 | 5.14 |

| Loading Direction | Energy Absorption (J) | Specific Energy Absorption (kJ/kg) |

|---|---|---|

| Axial | 176.8 (9.19) | 24.15 (1.24) |

| Lateral 1 | 60.34 (5.88) | 8.22 (0.78) |

| Lateral 2 | 36.17 (2.65) | 4.94 (0.35) |

| Configuration | Energy Absorption (J) | Specific Energy Absorption (kJ/kg) | Mass (g) |

|---|---|---|---|

| NPRH-1 | 16.74 (1.14) | 7.87 (0.54) | 2.13 |

| NPRH-2 | 60.34 (5.88) | 8.22 (0.78) | 7.32 |

| NPRH-3 | 124.23 (14.63) | 7.12 (0.89) | 17.47 |

| Configuration | Loading Direction | Specific Energy Absorption (kJ/kg) |

|---|---|---|

| Square | Axial | 17.1 |

| Hexagonal | Axial | 19.5 |

| Square | Lateral | 5.6 |

| Hexagonal | Lateral | 3.8 |

| Scenarios | Structure 1 | Structure 2 | D1 | D2 | MDCF (%) | ACF |

|---|---|---|---|---|---|---|

| A = 0.5 and B = 0.5 | NPRH-1 | Square | Axial | Lateral | 44.0 | −0.08 |

| A = 1 and B = 0 | NPRH-1 | Square | Axial | Lateral | 41.2 | 1.00 |

| A = 0 and B = 1 | NPRH-1 | Square | Axial | Lateral | 46.8 | −1.00 |

| A = 0.5 and B = 0.5 | NPRH-1 | Hexagonal | Axial | Lateral | 70.1 | −0.74 |

| A = 1 and B = 0 | NPRH-1 | Hexagonal | Axial | Lateral | 23.8 | 1.00 |

| A = 0 and B = 1 | NPRH-1 | Hexagonal | Axial | Lateral | 116.4 | −1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Candelaria Caraballo, S.; Menegozzo, M.; Serrano Acevedo, D. An Innovative Approach to Tailor Sandwich Core Structures for Multi-Directional Loading Scenarios. Materials 2025, 18, 599. https://doi.org/10.3390/ma18030599

Candelaria Caraballo S, Menegozzo M, Serrano Acevedo D. An Innovative Approach to Tailor Sandwich Core Structures for Multi-Directional Loading Scenarios. Materials. 2025; 18(3):599. https://doi.org/10.3390/ma18030599

Chicago/Turabian StyleCandelaria Caraballo, Samir, Marco Menegozzo, and David Serrano Acevedo. 2025. "An Innovative Approach to Tailor Sandwich Core Structures for Multi-Directional Loading Scenarios" Materials 18, no. 3: 599. https://doi.org/10.3390/ma18030599

APA StyleCandelaria Caraballo, S., Menegozzo, M., & Serrano Acevedo, D. (2025). An Innovative Approach to Tailor Sandwich Core Structures for Multi-Directional Loading Scenarios. Materials, 18(3), 599. https://doi.org/10.3390/ma18030599