Effect of Porosity on Tribological Properties of Medical-Grade 316L Stainless Steel Manufactured by Laser-Based Powder Bed Fusion

Highlights

- By varying the laser power and scanning speed in laser powder bed fusion, the porosity level can be controlled.

- Higher porosity allows for a diminishing wear rate.

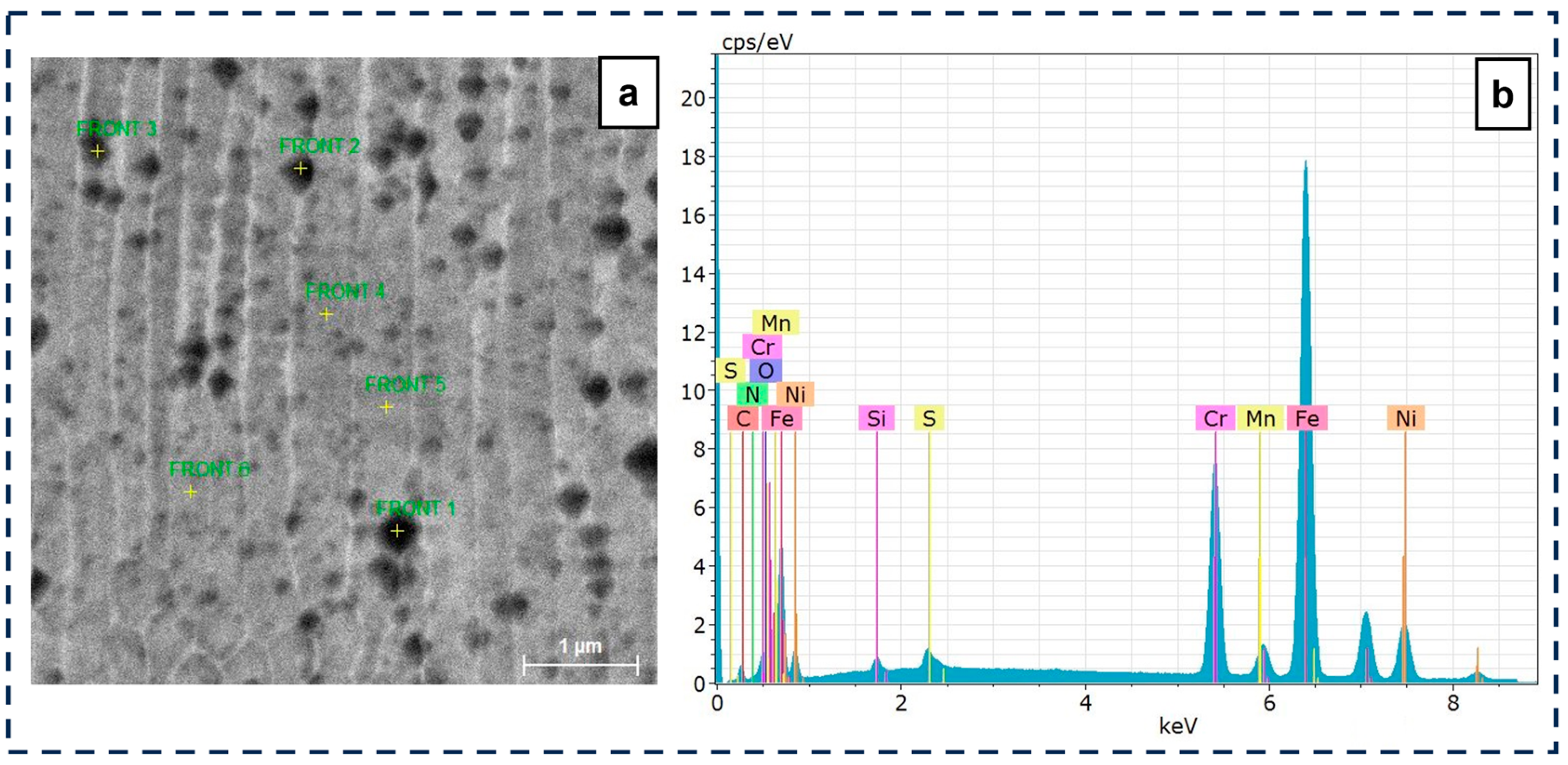

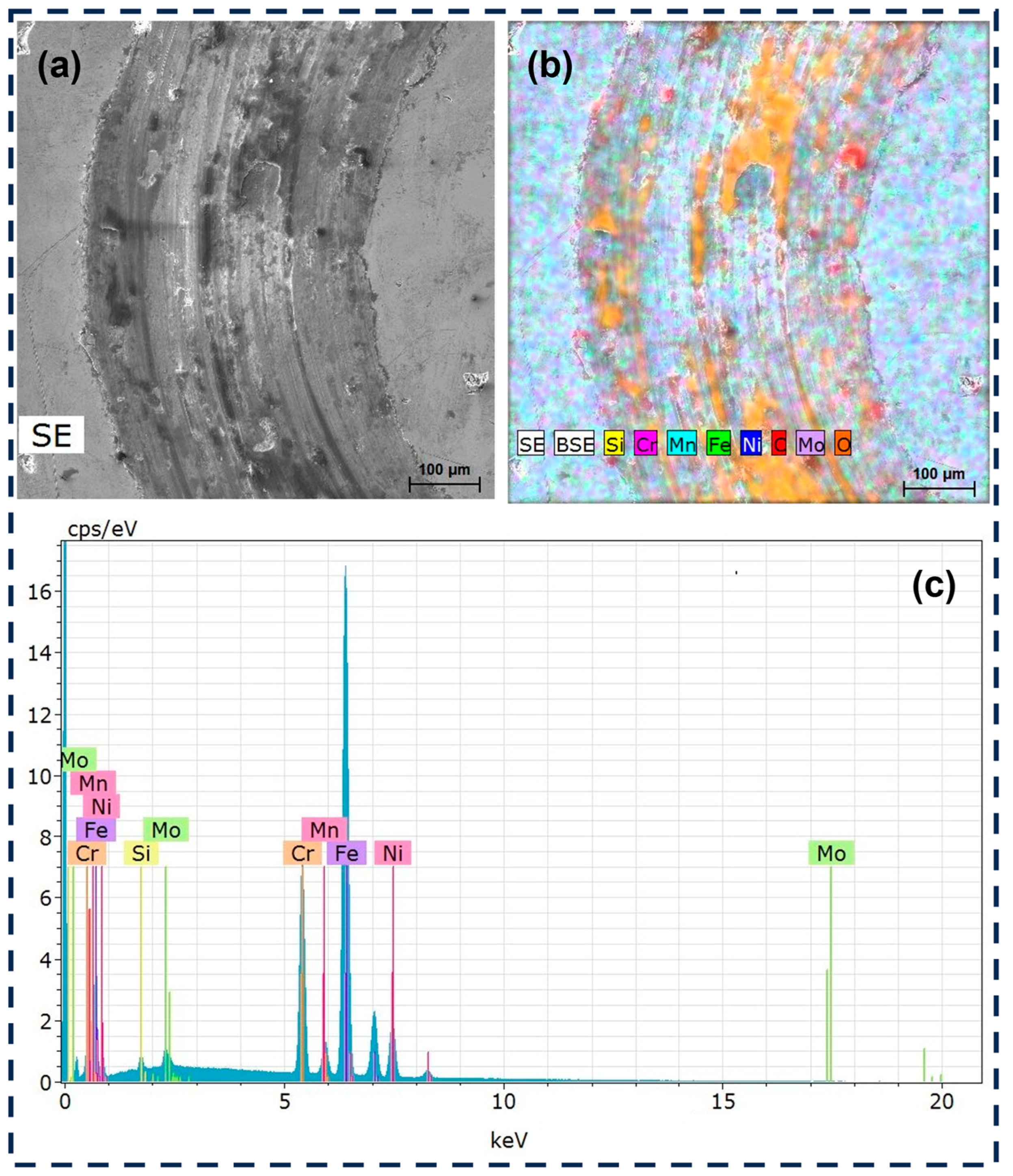

- The primary wear mechanism in dry sliding of 316L stainless steel against a Si3N4 is three-body abrasion.

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation by L-PBF

2.2. Microstructural Characterization

2.3. Tribological Characterization

2.4. Characterization of Nanomechanical Properties

3. Results

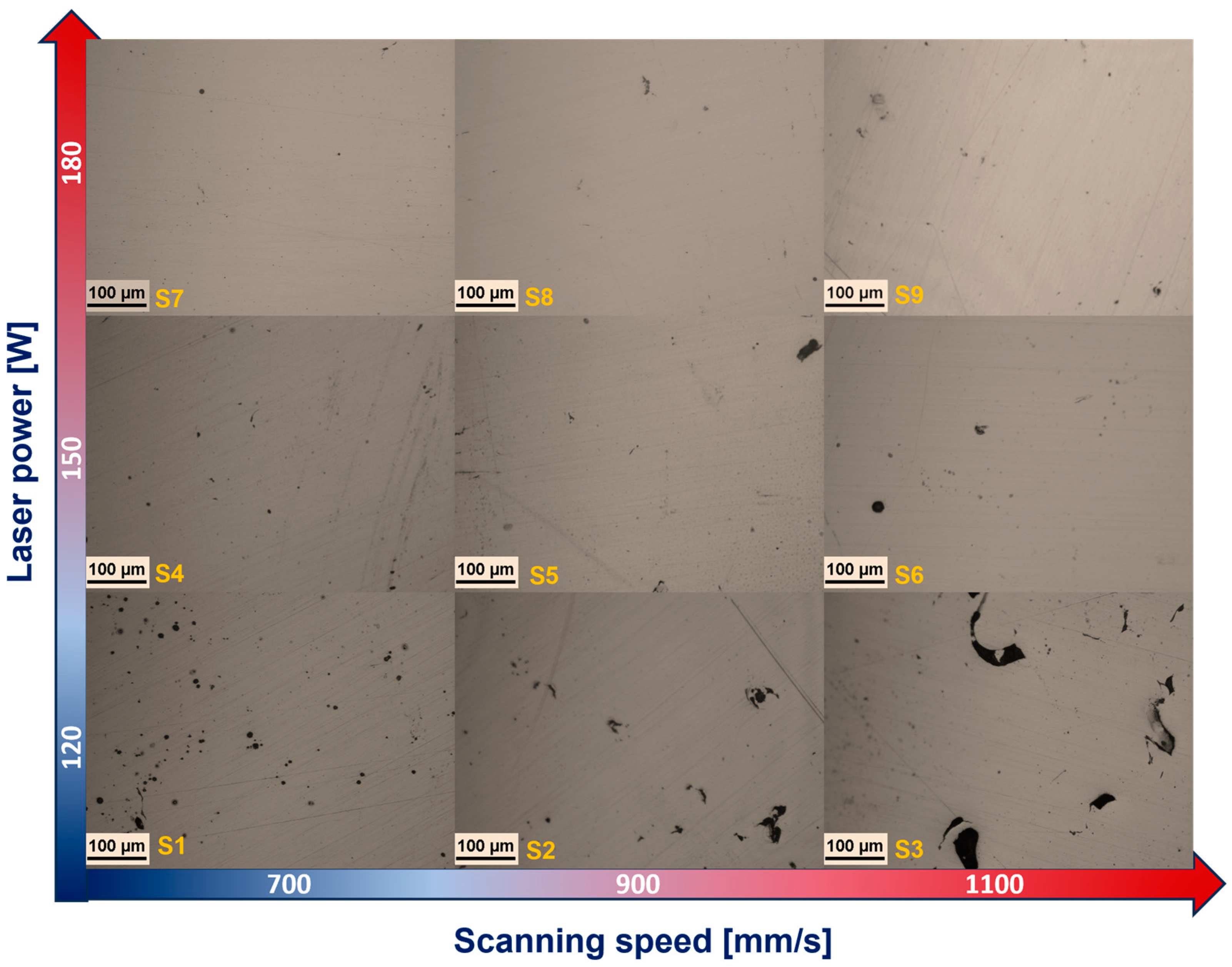

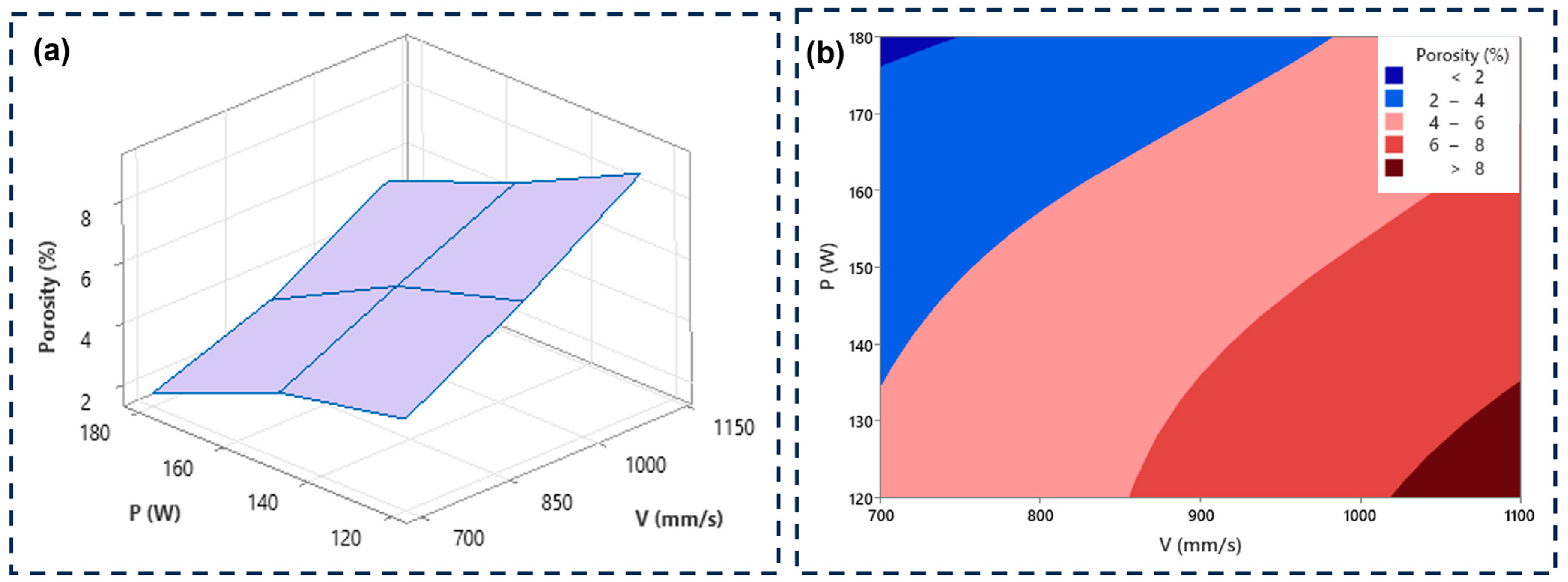

3.1. Porosity

3.2. Tribology Performance

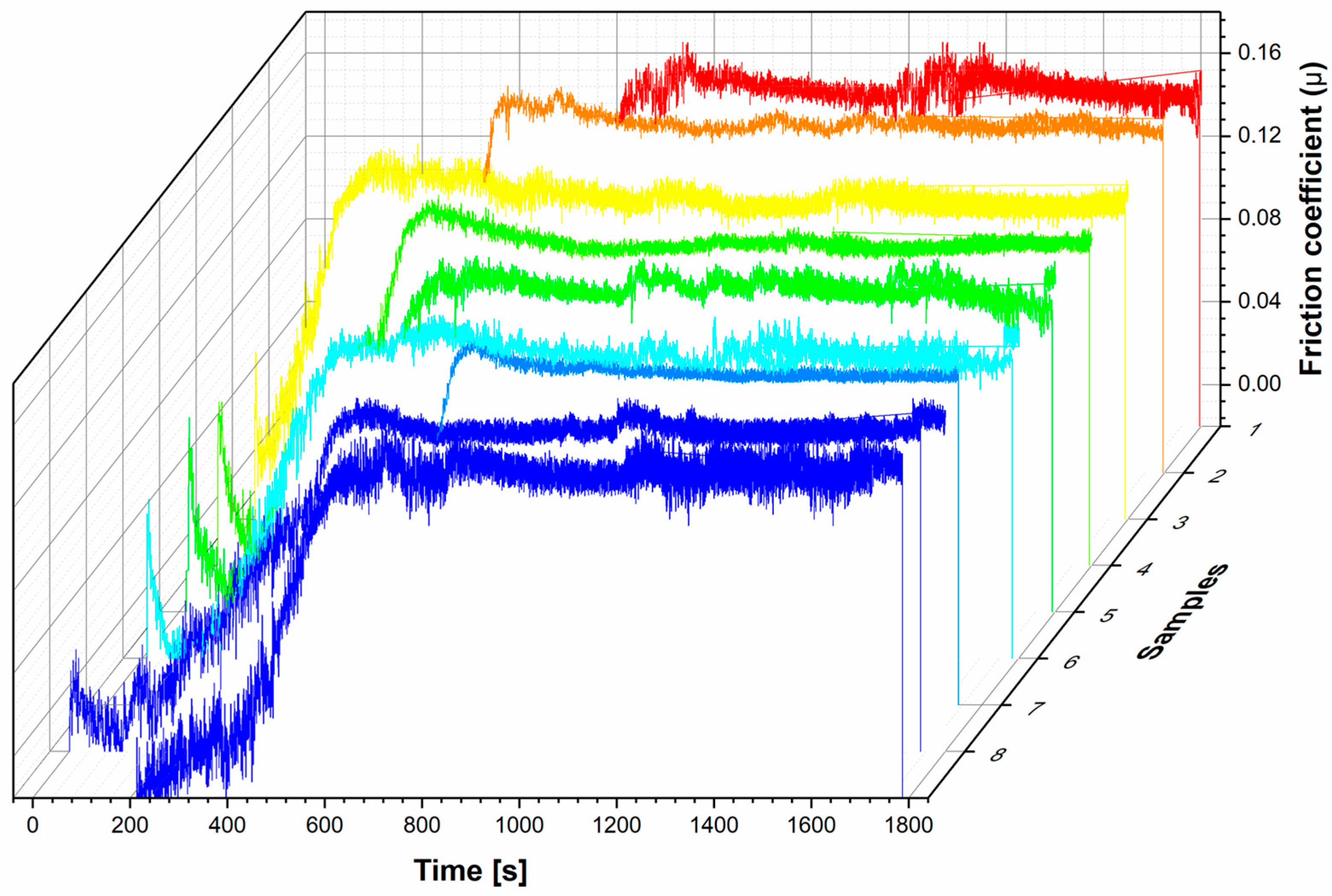

3.2.1. Coefficient of Friction

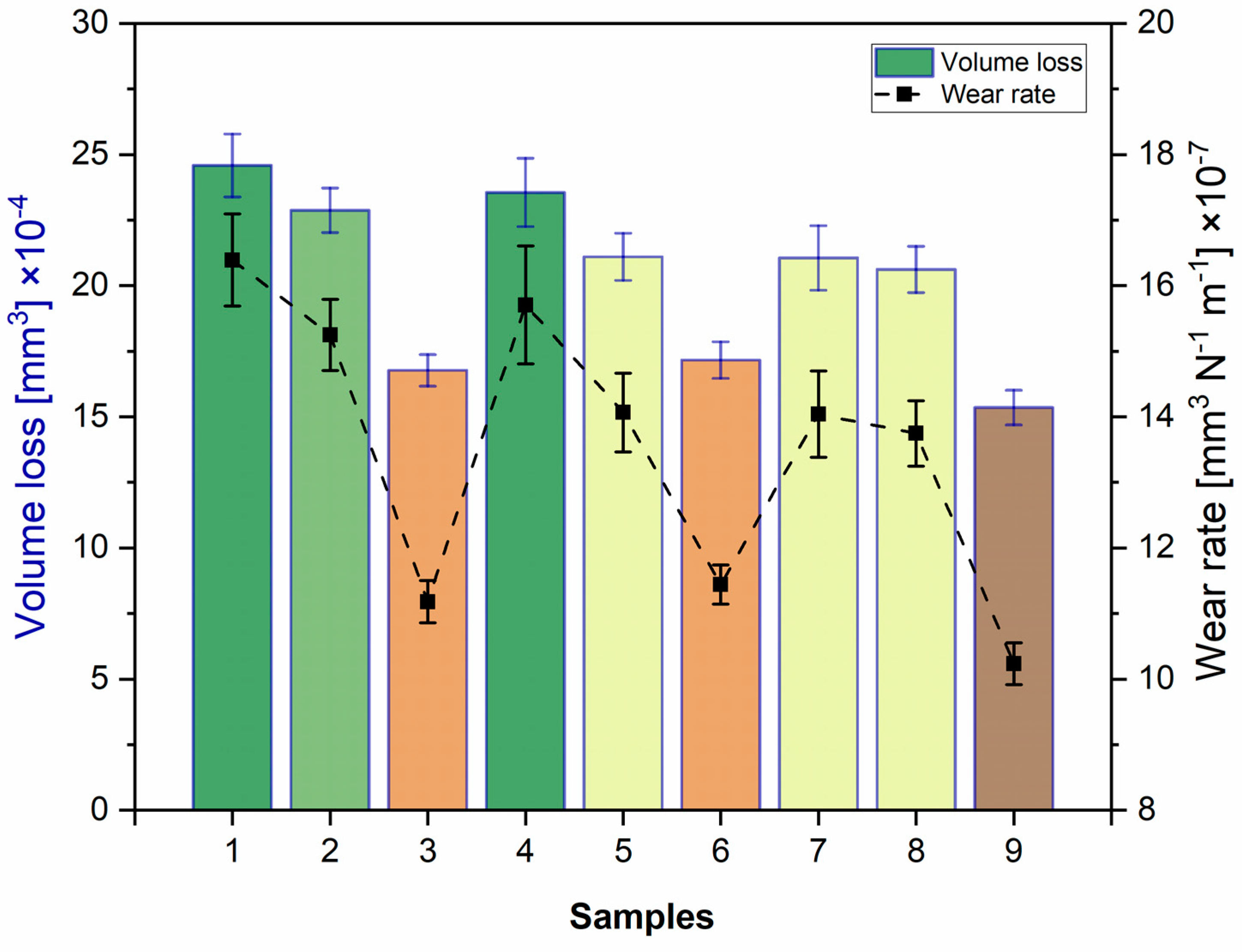

3.2.2. Wear Resistance

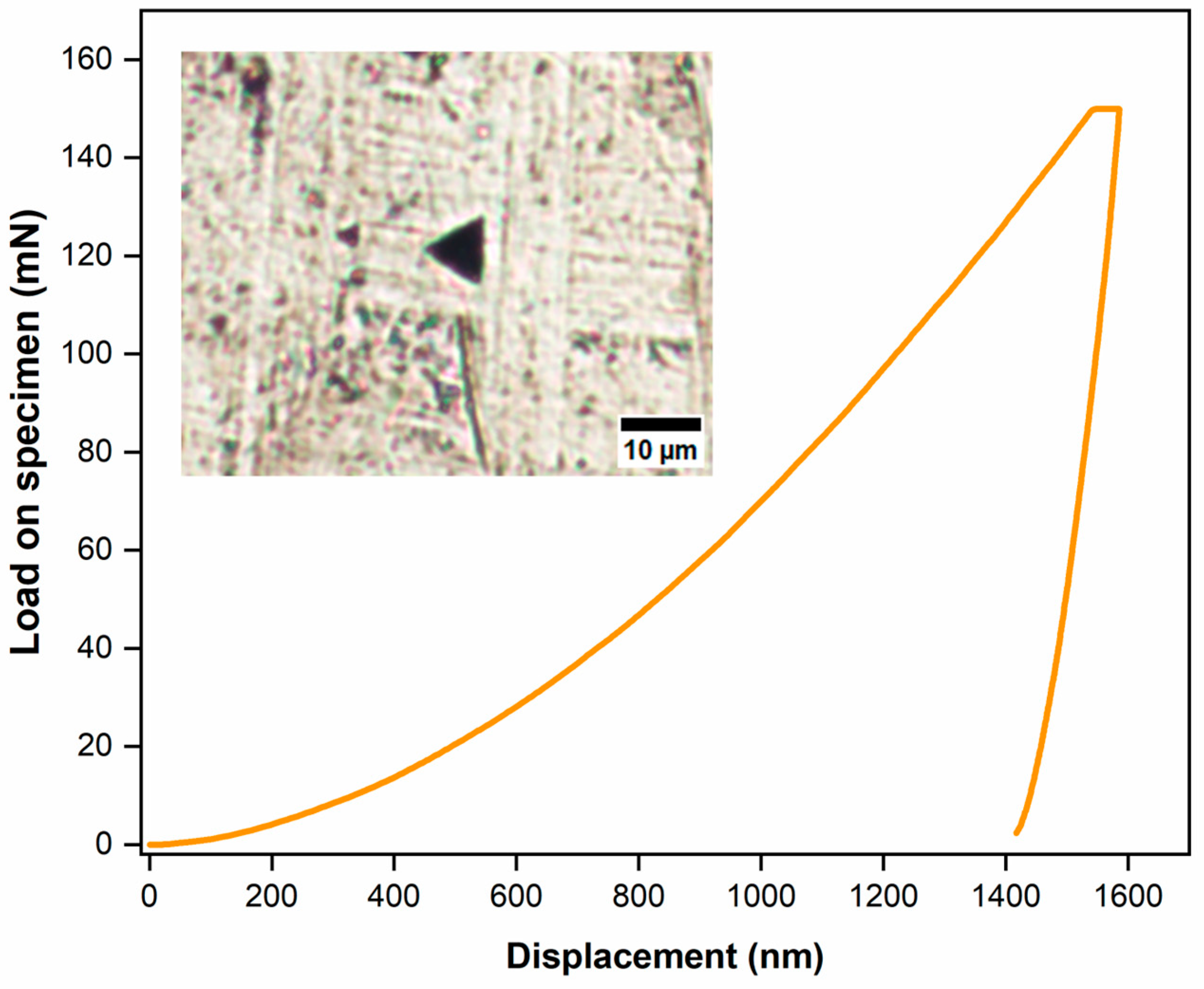

3.2.3. Mechanical Properties from Nanoindentation

4. Discussion

4.1. The L-PBF Process-Induced Porosity

4.2. Porosity Effect on Tribology Properties

5. Conclusions

- A strong correlation exists between the variables of L-PBF processing and porosity, allowing for the tuning of the latter between 1.7 and 9.1% by selecting a suitable laser power and scanning speed. However, in this continuum of porosity, the choice of a working window should consider the possibility of the lack of fusion for combinations of low/high laser power and scanning speed values.

- There is no evident correlation between porosity and the coefficient of friction; however, materials produced at the highest scanning speed (1100 mm/s) and characterized by higher porosity (>5.5%) tend to be more wear resistant in terms of wear rate, which can be attributed to the capacity of the pores to retain wear debris.

- The primary wear mechanism in dry sliding against a harder material (Si3N4) is that of three-body abrasion, involving the physical phenomena of adhesion, delamination, oxidation, and tribochemical reactions. Further study of these phenomena is necessary for exploiting the inherent porosity of L-PBF processing to design wear-resistant 316L SS components.

- This study offered a clear advancement in the comprehension of the porosity effect of tribological properties for biomedical prostheses design. However, verifying this behavior in a lubricated environment is necessary before it can be used in industrial applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haghdadi, N.; Laleh, M.; Moyle, M.; Primig, S. Additive manufacturing of steels: A review of achievements and challenges. J. Mater. Sci. 2021, 56, 64–107. [Google Scholar] [CrossRef]

- Kan, W.H.; Chiu, L.N.S.; Lim, C.V.S.; Zhu, Y.; Tian, Y.; Jiang, D.; Huang, A. A critical review on the effects of process-induced porosity on the mechanical properties of alloys fabricated by laser powder bed fusion. J. Mater. Sci. 2022, 57, 9818–9865. [Google Scholar] [CrossRef]

- Chowdhury, S.; Yadaiah, N.; Prakash, C.; Ramakrishna, S.; Dixit, S.; Gupta, L.R.; Buddhi, D. Laser powder bed fusion: A state-of-the-art review of the technology, materials, properties & defects, and numerical modelling. J. Mater. Res. Technol. 2022, 20, 2109–2172. [Google Scholar] [CrossRef]

- Charmi, A.; Falkenberg, R.; Ávila, L.; Mohr, G.; Sommer, K.; Ulbricht, A.; Sprengel, M.; Saliwan Neumann, R.; Skrotzki, B.; Evans, A. Mechanical anisotropy of additively manufactured stainless steel 316L: An experimental and numerical study. Mater. Sci. Eng. A 2021, 799, 140154. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Ramos-Grez, J.A.; Walczak, M.; Sánchez-Sánchez, X.; Guerra, C.; Debut, A.; Haro, E. Microstructure simulation and experimental evaluation of the anisotropy of 316 L stainless steel manufactured by laser powder bed fusion. Rapid Prototyp. J. 2022, 29, 425–436. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; La Fé-Perdomo, I.; Cáceres-Brito, E.; Navas-Pinto, W. Tensile/Compressive Response of 316L Stainless Steel Fabricated by Additive Manufacturing Respuesta a la tensión / compresión del acero inoxidable 316L fabricado por manufactura aditiva. Ingenius 2024, 9–18. [Google Scholar] [CrossRef]

- AlFaify, A.; Hughes, J.; Ridgway, K. Controlling the porosity of 316L stainless steel parts manufactured via the powder bed fusion process. Rapid Prototyp. J. 2019, 25, 162–175. [Google Scholar] [CrossRef]

- Bartlett, J.L.; Jarama, A.; Jones, J.; Li, X. Prediction of microstructural defects in additive manufacturing from powder bed quality using digital image correlation. Mater. Sci. Eng. A 2020, 794, 140002. [Google Scholar] [CrossRef]

- Mukherjee, T.; DebRoy, T. Mitigation of lack of fusion defects in powder bed fusion additive manufacturing. J. Manuf. Process. 2018, 36, 442–449. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Ramos-Grez, J.A.; Sánchez-Sánchez, X.; Zapata-Hidalgo, D.; Mullo, J.L.; Puma-Araujo, S.D. Influence of the Processing Parameters on the Microstructure and Mechanical Properties of 316L Stainless Steel Fabricated by Laser Powder Bed Fusion. J. Manuf. Mater. Process. 2024, 8, 35. [Google Scholar] [CrossRef]

- Jeyaprakash, N.; Saravana Kumar, M.; Yang, C.H.; Cheng, Y.; Radhika, N.; Sivasankaran, S. Effect of microstructural evolution during melt pool formation on nano-mechanical properties in LPBF based SS316L parts. J. Alloys Compd. 2024, 972, 172745. [Google Scholar] [CrossRef]

- Khorasani, A.M.; Gibson, I.; Ghasemi, A.H.; Ghaderi, A. A comprehensive study on variability of relative density in selective laser melting of Ti-6Al-4V. Virtual Phys. Prototyp. 2019, 14, 349–359. [Google Scholar] [CrossRef]

- Deng, Y.; Mao, Z.; Yang, N.; Niu, X.; Lu, X. Collaborative optimization of density and surface roughness of 316L stainless steel in selective laser melting. Materials 2020, 13, 1601. [Google Scholar] [CrossRef] [PubMed]

- Gatto, M.L.; Cerqueni, G.; Groppo, R.; Santecchia, E.; Tognoli, E.; Defanti, S.; Mattioli-Belmonte, M.; Mengucci, P. Improved biomechanical behavior of 316L graded scaffolds for bone tissue regeneration produced by laser powder bed fusion. J. Mech. Behav. Biomed. Mater. 2023, 144, 105989. [Google Scholar] [CrossRef] [PubMed]

- Rana, M.; Karmakar, S.; Bandyopadhyay, A.; Roychowdhury, A. Design and manufacturing of patient-specific Ti6Al4V implants with inhomogeneous porosity. J. Mech. Behav. Biomed. Mater. 2023, 143, 105925. [Google Scholar] [CrossRef] [PubMed]

- Orgeldinger, C.; Seynstahl, A.; Rosnitschek, T.; Tremmel, S. Surface Properties and Tribological Behavior of Additively Manufactured Components: A Systematic Review. Lubricants 2023, 11, 257. [Google Scholar] [CrossRef]

- Lerebours, A.; Demangel, C.; Dembinski, L.; Bouvier, S.; Rassineux, A.; Egles, C. Effect of the Residual Porosity of CoCrMo Bearing Parts Produced by Additive Manufacturing on Wear of Polyethylene. Biotribology 2020, 23, 1–26. [Google Scholar] [CrossRef]

- Kyun Sung, M.; Schwerin, M.; Badhe, Y.; Porter, D. Influence of topology optimization parameters on the mechanical response of an additively manufactured test structure. J. Mech. Behav. Biomed. Mater. 2023, 142, 105844. [Google Scholar] [CrossRef]

- Zhang, L.; Song, B.; Choi, S.K.; Shi, Y. A topology strategy to reduce stress shielding of additively manufactured porous metallic biomaterials. Int. J. Mech. Sci. 2021, 197, 106331. [Google Scholar] [CrossRef]

- Cortis, G.; Mileti, I.; Nalli, F.; Palermo, E.; Cortese, L. Additive manufacturing structural redesign of hip prostheses for stress-shielding reduction and improved functionality and safety. Mech. Mater. 2022, 165, 104173. [Google Scholar] [CrossRef]

- Liverani, E.; Rogati, G.; Pagani, S.; Brogini, S.; Fortunato, A.; Caravaggi, P. Mechanical interaction between additive-manufactured metal lattice structures and bone in compression: Implications for stress shielding of orthopaedic implants. J. Mech. Behav. Biomed. Mater. 2021, 121, 104608. [Google Scholar] [CrossRef] [PubMed]

- Barrionuevo, G.O.; Walczak, M.; Ramos-grez, J.; Sánchez-sánchez, X. Microhardness and wear resistance in materials manufactured by laser powder bed fusion: Machine learning approach for property prediction. CIRP J. Manuf. Sci. Technol. 2023, 43, 106–114. [Google Scholar] [CrossRef]

- Nudelis, N.; Mayr, P. A novel classification method for pores in laser powder bed fusion. Metals 2021, 11, 1912. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, Y.; Yang, H. Enhancing Wear Resistance of Selective Laser Melted Parts: Influence of Energy Density. J. Tribol. 2020, 142. [Google Scholar] [CrossRef]

- Yarin, A.L. Wetting for self-healing and electrowetting for additive manufacturing. Curr. Opin. Colloid Interface Sci. 2021, 51, 101378. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Patil, S.P.; Markert, B. Effects of porosity on the mechanical properties of additively manufactured components: A critical review. Mater. Res. Express 2020, 7, 122001. [Google Scholar] [CrossRef]

- Peta, K. Multiscale Wettability of Microtextured Irregular Surfaces. Materials 2024, 17, 5716. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, Y.; Khonsari, M.M.; Yang, H. Wear anisotropy of selective laser melted 316L stainless steel. Wear 2019, 428, 376–386. [Google Scholar] [CrossRef]

- Upadhyay, R.K.; Kumar, A. Scratch and wear resistance of additive manufactured 316L stainless steel sample fabricated by laser powder bed fusion technique. Wear 2020, 458, 203437. [Google Scholar] [CrossRef]

- Eliasu, A.; Duntu, S.H.; Hukpati, K.S.; Amegadzie, M.Y.; Agyapong, J.; Tetteh, F.; Czekanski, A.; Boakye-Yiadom, S. Effect of individual printing parameters on residual stress and tribological behaviour of 316L stainless steel fabricated with laser powder bed fusion (L-PBF). Int. J. Adv. Manuf. Technol. 2022, 119, 7041–7061. [Google Scholar] [CrossRef]

- Gençoğlu, U.; Kaya, G.; Ergüder, T.O.; Hacısalihoğlu, İ.; Yıldız, F. Investigation of the Structural and Tribological Properties of 316L Stainless Steel Manufactured Using Variable Production Parameters by Selective Laser Melting. J. Mater. Eng. Perform. 2022, 31, 3688–3703. [Google Scholar] [CrossRef]

- García-León, R.A.; Martínez-Trinidad, J.; Guevara-Morales, A.; Campos-Silva, I.; Figueroa-López, U. Wear Maps and Statistical Approach of AISI 316L Alloy under Dry Sliding Conditions. J. Mater. Eng. Perform. 2021, 30, 6175–6190. [Google Scholar] [CrossRef]

- Kumar, S. Sliding wear behavior of dedicated iron-based SLS materials. Int. J. Adv. Manuf. Technol. 2009, 43, 337–347. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Walczak, M.; Ramos-grez, J.; Mendez, P.; Debut, A. Microstructure effect on sliding wear of 316L stainless steel selectively laser melted. Mater. Sci. Technol. 2024, 40, 466–478. [Google Scholar] [CrossRef]

- Efremenko, B.V.; Zurnadzhy, V.I.; Chabak, Y.G.; Efremenko, V.G.; Kudinova, K.V.; Mazur, V.A. A comparison study on the effect of counter ball material on sliding wear response of SLM-printed biomedical 316L steel. Mater. Today Proc. 2022, 66, 2587–2593. [Google Scholar] [CrossRef]

- Vishnu, V.; Prabhu, T.R.; Imam, M.; Vineesh, K.P. Experimental Investigation into the Dry Reciprocating Wear Behavior of Additively Manufactured Austenitic Stainless Steel (316L) Alloys. JOM 2024, 76, 3081–3098. [Google Scholar] [CrossRef]

- Mandev, Y.Z.; Mandev, E.; Yetim, A.F. Effects of Laser Powder Bed Fusion Process Parameters on Porosity, Liquid Retention, and Thermal and Surface Properties for 316L, CoCrW and Ti6Al4V Alloys. J. Mater. Eng. Perform. 2024. [Google Scholar] [CrossRef]

- Somasundaram, K.; Satheeshkumar, V. Investigations on tribological behavior under lubricated condition of post heat treated additively manufactured SS316L parts. Ind. Lubr. Tribol. 2024, 76, 1003–1014. [Google Scholar] [CrossRef]

- Chen, J.; Liu, H.; Xu, X.; Lu, Z.; Cui, T.; Jia, Y.; Que, Z. Effect of Post-Manufacturing Heat Treatment on Wear Performance of Laser Powder Bed Fusion 316L Stainless Steel Under Various Normal Loads. Met. Mater. Int. 2024. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Calvopiña, H.; Debut, A.; Pérez-Salinas, C. Experimental and numerical investigation of sliding wear of heat-treated 316L stainless steel additively manufactured. J. Mater. Res. Technol. 2024, 33, 2692–2703. [Google Scholar] [CrossRef]

- Cole, M.E.; Stout, S.D.; Dominguez, V.M.; Agnew, A.M. Pore Extractor 2D: An ImageJ toolkit for quantifying cortical pore morphometry on histological bone images, with application to intraskeletal and regional patterning. Am. J. Biol. Anthropol. 2022, 179, 365–385. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Li, J.; Hu, J.; Cao, L.; Wang, S.; Liu, H.; Zhou, Q. Multi-objective process parameters optimization of SLM using the ensemble of metamodels. J. Manuf. Process. 2021, 68, 198–209. [Google Scholar] [CrossRef]

- Yuan, W.; Chen, H.; Cheng, T.; Wei, Q. Effects of laser scanning speeds on different states of the molten pool during selective laser melting: Simulation and experiment. Mater. Des. 2020, 189, 108542. [Google Scholar] [CrossRef]

- La Fé-Perdomo, I.; Ramos-Grez, J.A.; Jeria, I.; Guerra, C.; Barrionuevo, G.O. Comparative analysis and experimental validation of statistical and machine learning-based regressors for modeling the surface roughness and mechanical properties of 316L stainless steel specimens produced by selective laser melting. J. Manuf. Process. 2022, 80, 666–682. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Zhou, L.; Yuan, T.; Li, R.; Li, L. Two ways of evaluating the wear property of Ti-13Nb-13Zr fabricated by selective laser melting. Mater. Lett. 2019, 242, 9–12. [Google Scholar] [CrossRef]

- Shah, R.; Pai, N.; Rosenkranz, A.; Shirvani, K.; Marian, M. Tribological Behavior of Additively Manufactured Metal Components. J. Manuf. Mater. Process. 2022, 6, 138. [Google Scholar] [CrossRef]

- Koutiri, I.; Pessard, E.; Peyre, P.; Amlou, O.; De Terris, T. Influence of SLM process parameters on the surface finish, porosity rate and fatigue behavior of as-built Inconel 625 parts. J. Mater. Process. Technol. 2018, 255, 536–546. [Google Scholar] [CrossRef]

- Marini, D.; Corney, J.R. Concurrent optimization of process parameters and product design variables for near net shape manufacturing processes. J. Intell. Manuf. 2020, 32, 611–631. [Google Scholar] [CrossRef]

- Bahshwan, M.; Gee, M.; Nunn, J.; Myant, C.W.; Reddyhoff, T. In situ observation of anisotropic tribological contact evolution in 316L steel formed by selective laser melting. Wear 2022, 490, 204193. [Google Scholar] [CrossRef]

- Pokorný, P.; Václav, Š.; Petru, J.; Kritikos, M. Porosity analysis of additive manufactured parts using caq technology. Materials 2021, 14, 1142. [Google Scholar] [CrossRef] [PubMed]

- Sola, A.; Nouri, A. Microstructural porosity in additive manufacturing: The formation and detection of pores in metal parts fabricated by powder bed fusion. J. Adv. Manuf. Process. 2019, 1, e10021. [Google Scholar] [CrossRef]

- Fillot, N.; Iordanoff, I.; Berthier, Y. Wear modeling and the third body concept. Wear 2007, 262, 949–957. [Google Scholar] [CrossRef]

- Fischer, A.; Dudzinski, W.; Gleising, B.; Stemmer, P. Analyzing Mild- and Ultra-Mild Sliding Wear of Metallic Materials by Transmission Electron Microscopy. In Proceedings of the Advanced Analytical Methods in Tribology; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 29–59. [Google Scholar]

- Nowell, D.; Nowell, S.C. A comparison of recent models for fatigue crack tip deformation. Theor. Appl. Fract. Mech. 2019, 103, 102299. [Google Scholar] [CrossRef]

- Madhukarϯ, S.; Harshith Reddy, B.R.; Kumar, G.A.; Naikϯ, R.P. A Study on Improvement of Fatigue Life of materials by Surface Coatings. Int. J. Curr. Eng. Technol. 2018, 8, 5–9. [Google Scholar] [CrossRef][Green Version]

| Factors | Levels | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| Laser power [W] | 120 | 150 | 180 |

| Scanning speed [mm/s] | 700 | 900 | 1100 |

| Sample ID | Power [W] | Speed [mm/s] | Archimedes Porosity [%] | Image Analysis Porosity [%] | Average Shape Factor |

|---|---|---|---|---|---|

| S1 | 120 | 700 | 4.3 ± 0.5 | 1.16 | 1.12 |

| S2 | 120 | 900 | 6.5 ± 0.1 | 1.21 | 3.15 |

| S3 | 120 | 1100 | 9.1 ± 1.2 | 3.02 | 2.63 |

| S4 | 150 | 700 | 3.4 ± 0.4 | 1.24 | 1.28 |

| S5 | 150 | 900 | 5.3 ± 0.4 | 1.48 | 1.43 |

| S6 | 150 | 1100 | 7.1 ± 1.4 | 0.32 | 1.13 |

| S7 | 180 | 700 | 1.7 ± 0.1 | 0.21 | 1.18 |

| S8 | 180 | 900 | 3.2 ± 0.5 | 0.25 | 2.09 |

| S9 | 180 | 1100 | 5.4 ± 0.3 | 0.47 | 2.31 |

| Source | Df | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 8 | 121.39 | 15.17 | 21.34 | 0.00 |

| Linear | 4 | 119.86 | 29.97 | 42.15 | 0.00 |

| P (W) | 2 | 46.03 | 23.01 | 32.37 | 0.00 |

| V (mm/s) | 2 | 73.84 | 36.92 | 51.93 | 0.00 |

| Two-Way Interactions | 4 | 1.53 | 0.38 | 0.54 | 0.71 |

| P × V | 4 | 1.53 | 0.38 | 0.54 | 0.71 |

| Error | 18 | 12.79 | 0.71 | ||

| Total | 26 | 134.19 |

| Sample | Friction Coefficient [-] | Wear Rate [mm3 N−1 m−1] × 10−7 |

|---|---|---|

| S1 | 0.137 ± 0.018 | 16.39 ± 0.70 |

| S2 | 0.146 ± 0.011 | 15.25 ± 0.54 |

| S3 | 0.132 ± 0.012 | 11.18 ± 0.32 |

| S4 | 0.137 ± 0.009 | 15.71 ± 0.91 |

| S5 | 0.129 ± 0.022 | 14.06 ± 0.66 |

| S6 | 0.132 ± 0.013 | 11.44 ± 0.32 |

| S7 | 0.133 ± 0.010 | 14.04 ± 0.66 |

| S8 | 0.138 ± 0.011 | 13.75 ± 0.51 |

| S9 | 0.146 ± 0.016 | 10.23 ± 0.32 |

| H (GPa) | Er (GPa) | H3/Er2 | |

|---|---|---|---|

| Low-porosity samples | 2.84 ± 0.039 | 141.18 ± 2.48 | 0.00115 |

| Medium-porosity samples | 2.81 ± 0.031 | 145.22 ± 2.48 | 0.00105 |

| High-porosity samples | 2.76 ± 0.019 | 142.19 ± 6.24 | 0.00104 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barrionuevo, G.O.; Walczak, M.; Mendez, P.; La Fé-Perdomo, I.; Chiluisa-Palomo, E.; Navas-Pinto, W.; Cree, D.E. Effect of Porosity on Tribological Properties of Medical-Grade 316L Stainless Steel Manufactured by Laser-Based Powder Bed Fusion. Materials 2025, 18, 568. https://doi.org/10.3390/ma18030568

Barrionuevo GO, Walczak M, Mendez P, La Fé-Perdomo I, Chiluisa-Palomo E, Navas-Pinto W, Cree DE. Effect of Porosity on Tribological Properties of Medical-Grade 316L Stainless Steel Manufactured by Laser-Based Powder Bed Fusion. Materials. 2025; 18(3):568. https://doi.org/10.3390/ma18030568

Chicago/Turabian StyleBarrionuevo, Germán Omar, Magdalena Walczak, Patricio Mendez, Iván La Fé-Perdomo, Erika Chiluisa-Palomo, Wilson Navas-Pinto, and Duncan E. Cree. 2025. "Effect of Porosity on Tribological Properties of Medical-Grade 316L Stainless Steel Manufactured by Laser-Based Powder Bed Fusion" Materials 18, no. 3: 568. https://doi.org/10.3390/ma18030568

APA StyleBarrionuevo, G. O., Walczak, M., Mendez, P., La Fé-Perdomo, I., Chiluisa-Palomo, E., Navas-Pinto, W., & Cree, D. E. (2025). Effect of Porosity on Tribological Properties of Medical-Grade 316L Stainless Steel Manufactured by Laser-Based Powder Bed Fusion. Materials, 18(3), 568. https://doi.org/10.3390/ma18030568