Performance Analysis of Artificial Neural Network and Its Optimized Models on Compressive Strength Prediction of Recycled Cement Mortar

Abstract

1. Introduction

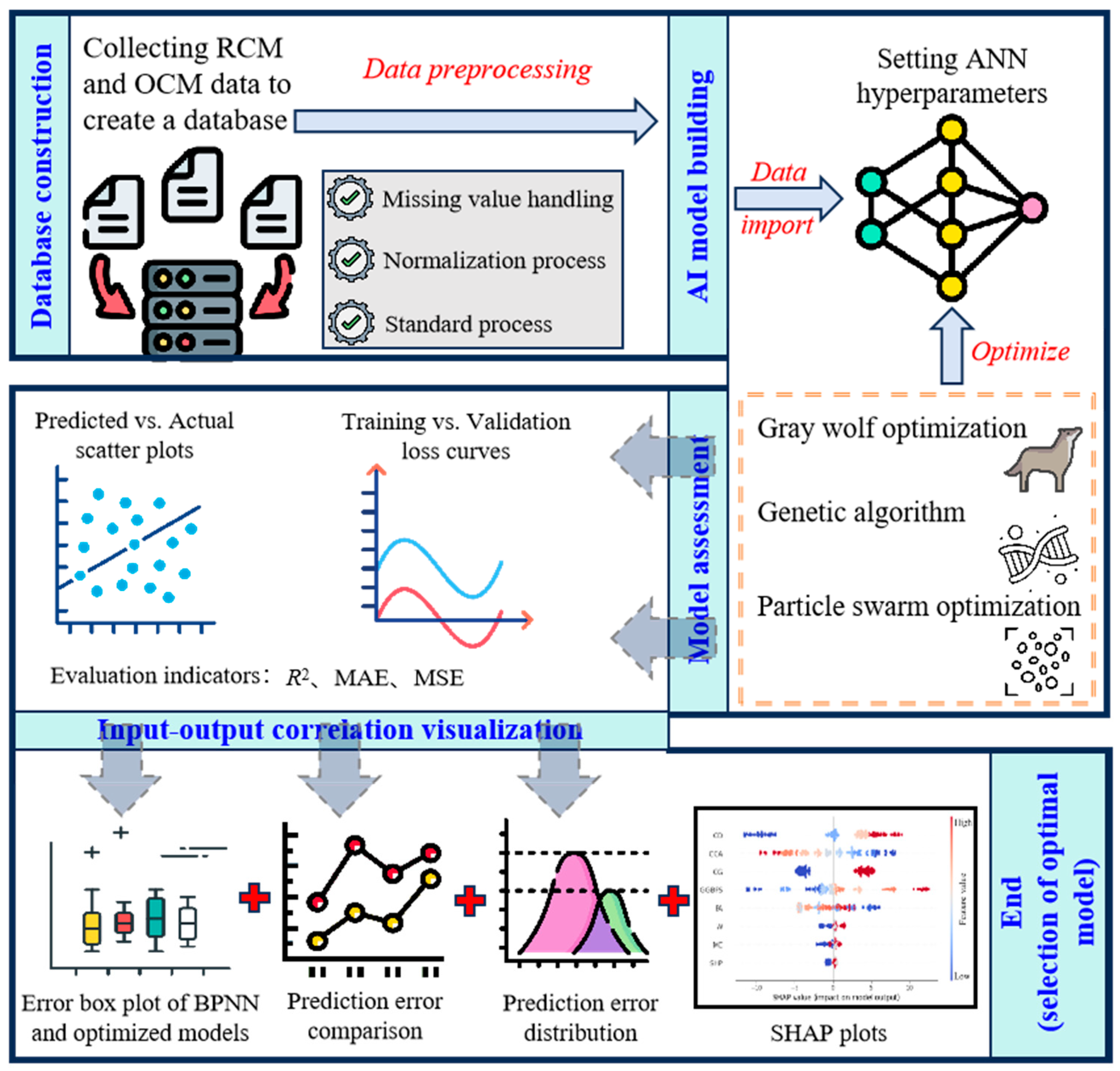

2. Methodology

2.1. Database

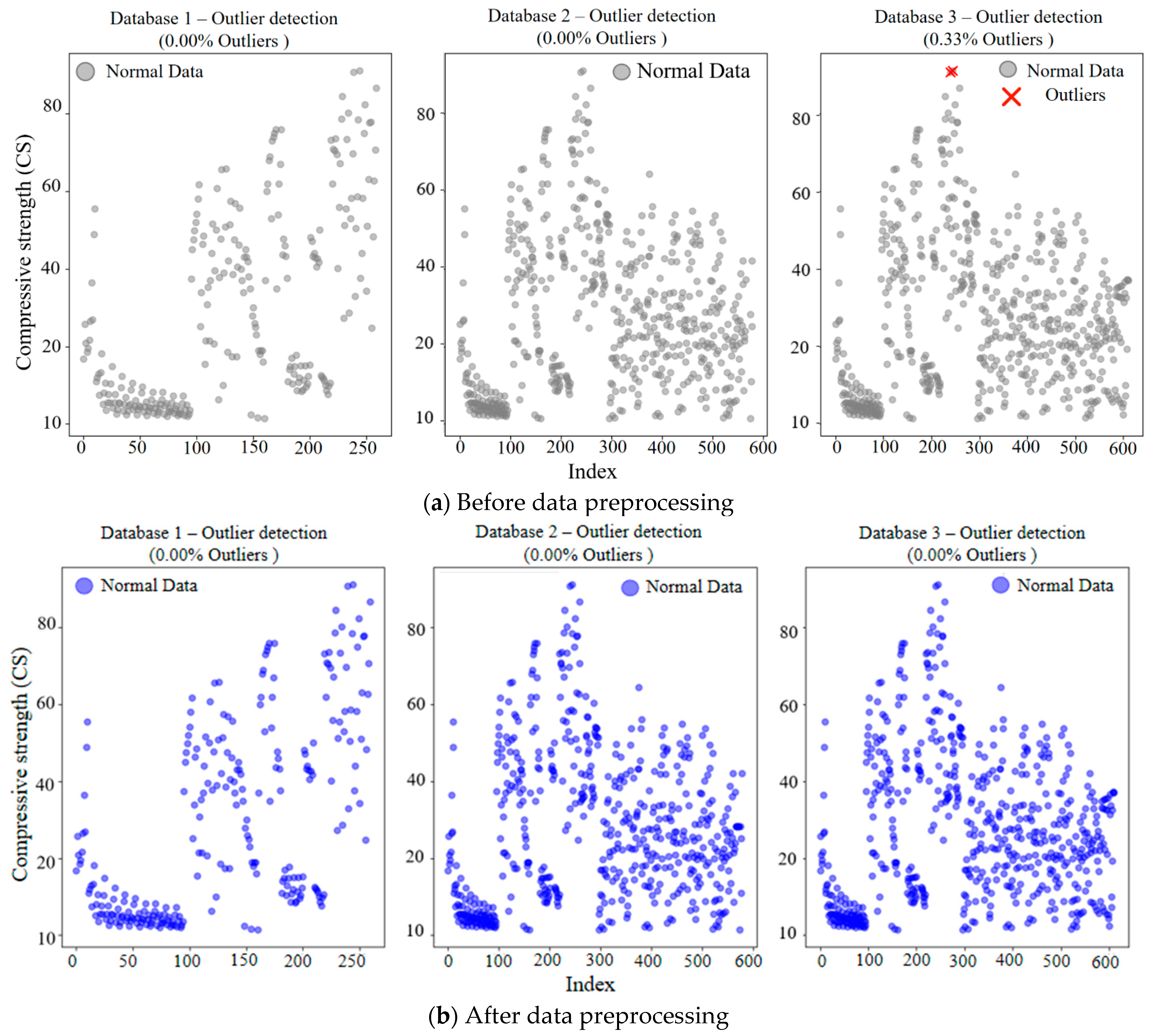

2.2. Data Preprocessing

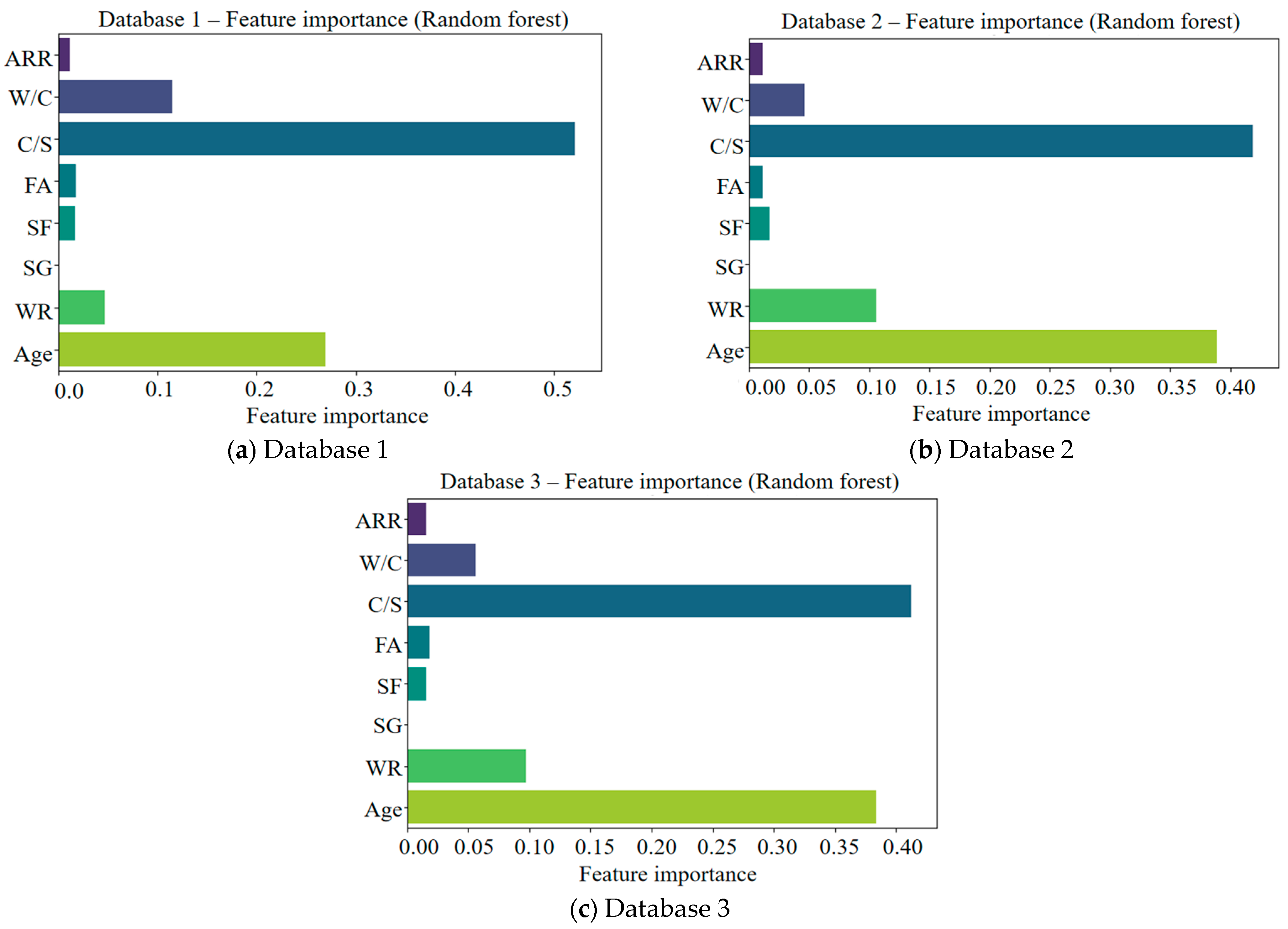

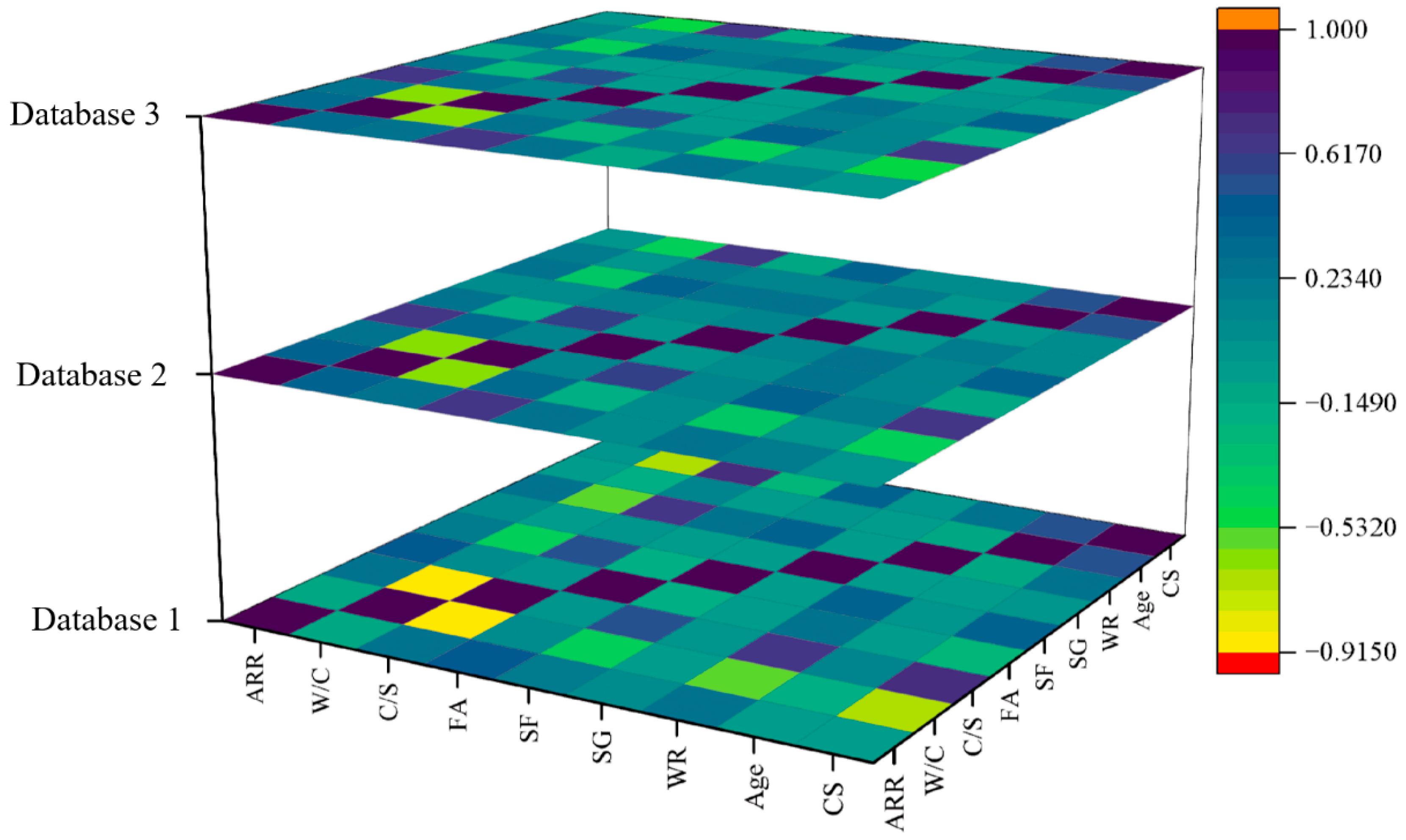

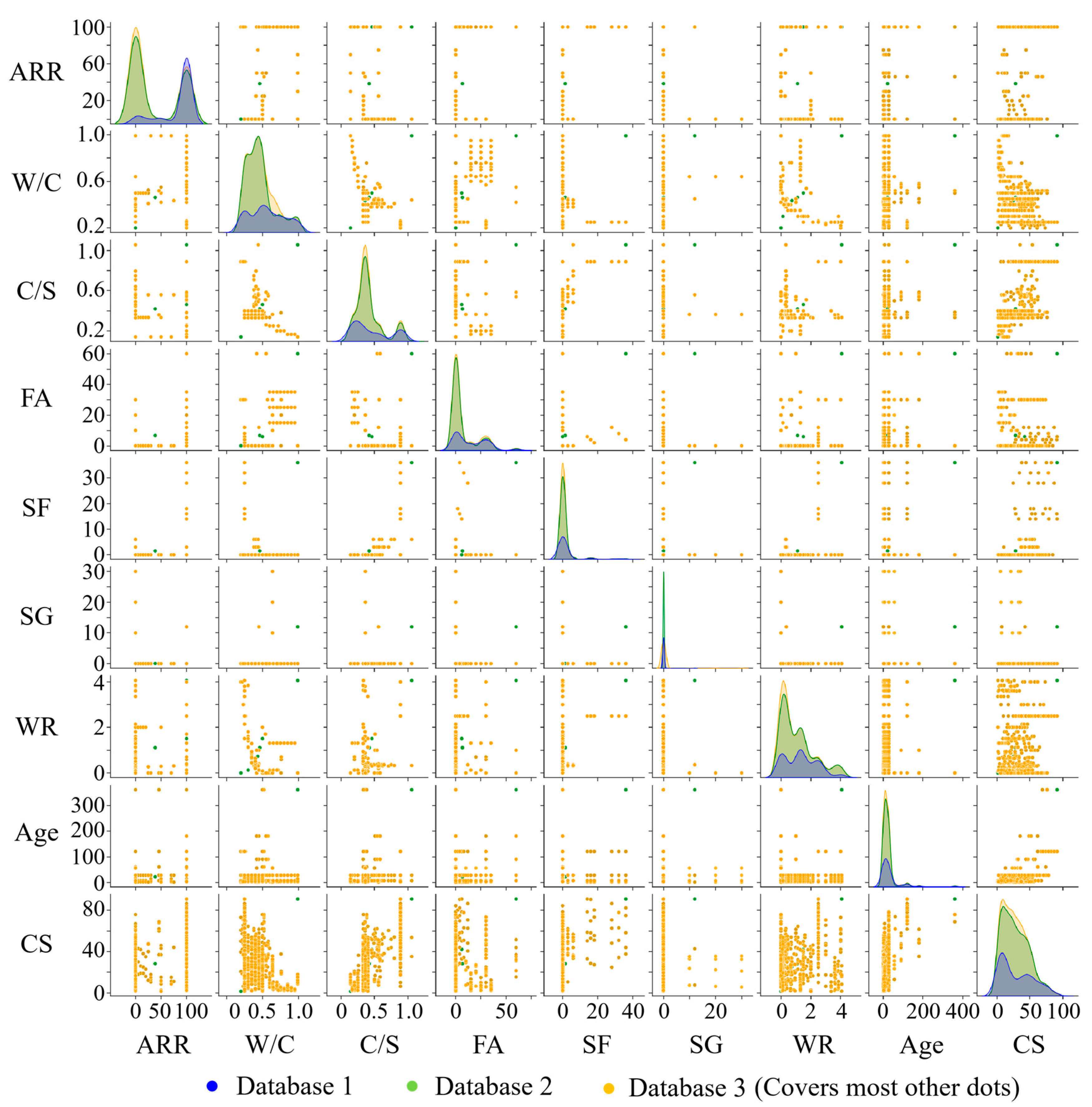

2.3. Data Visualization

2.4. Data Scaling and Partitioning

3. Model and Algorithm

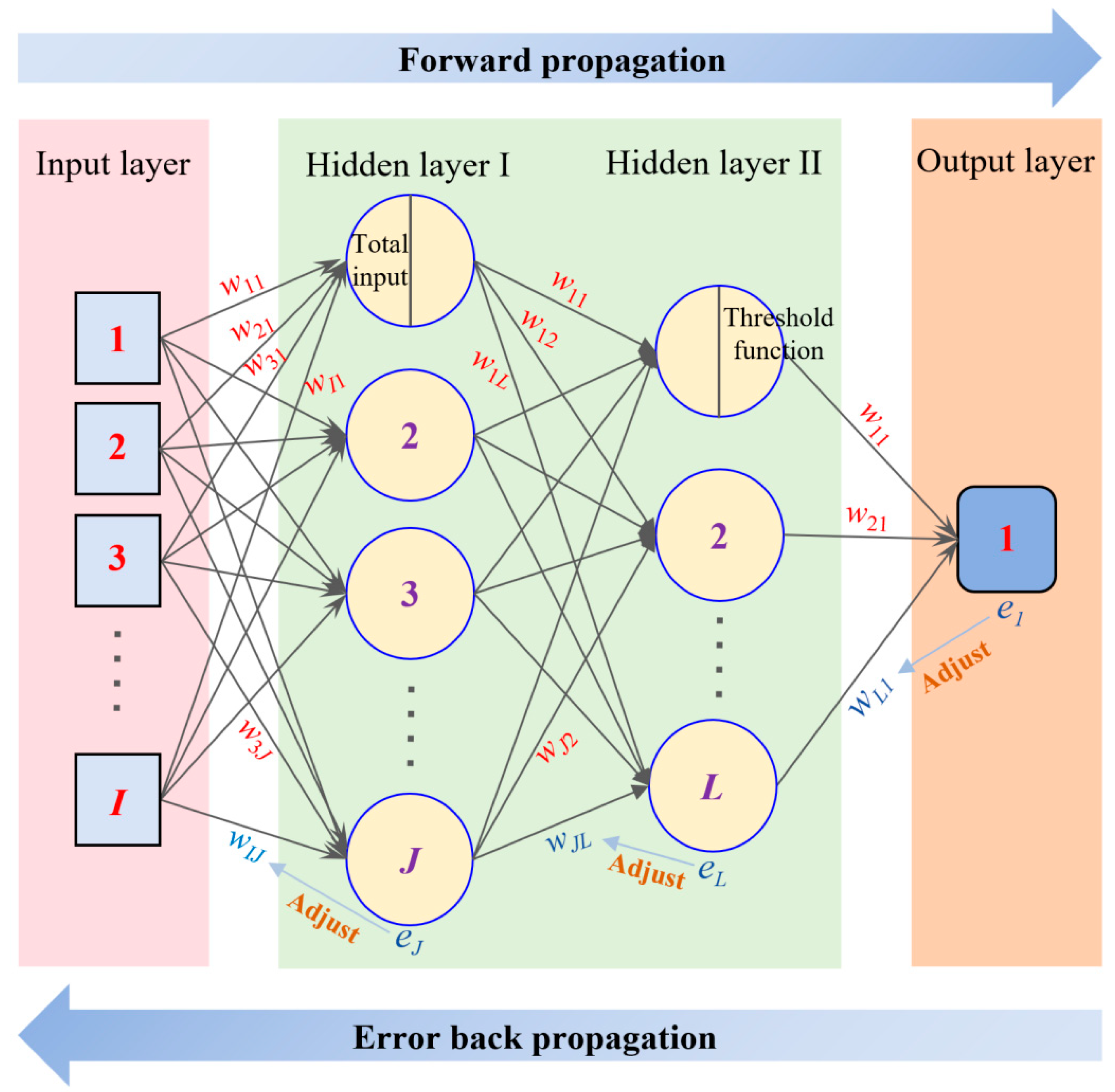

3.1. ANN Model

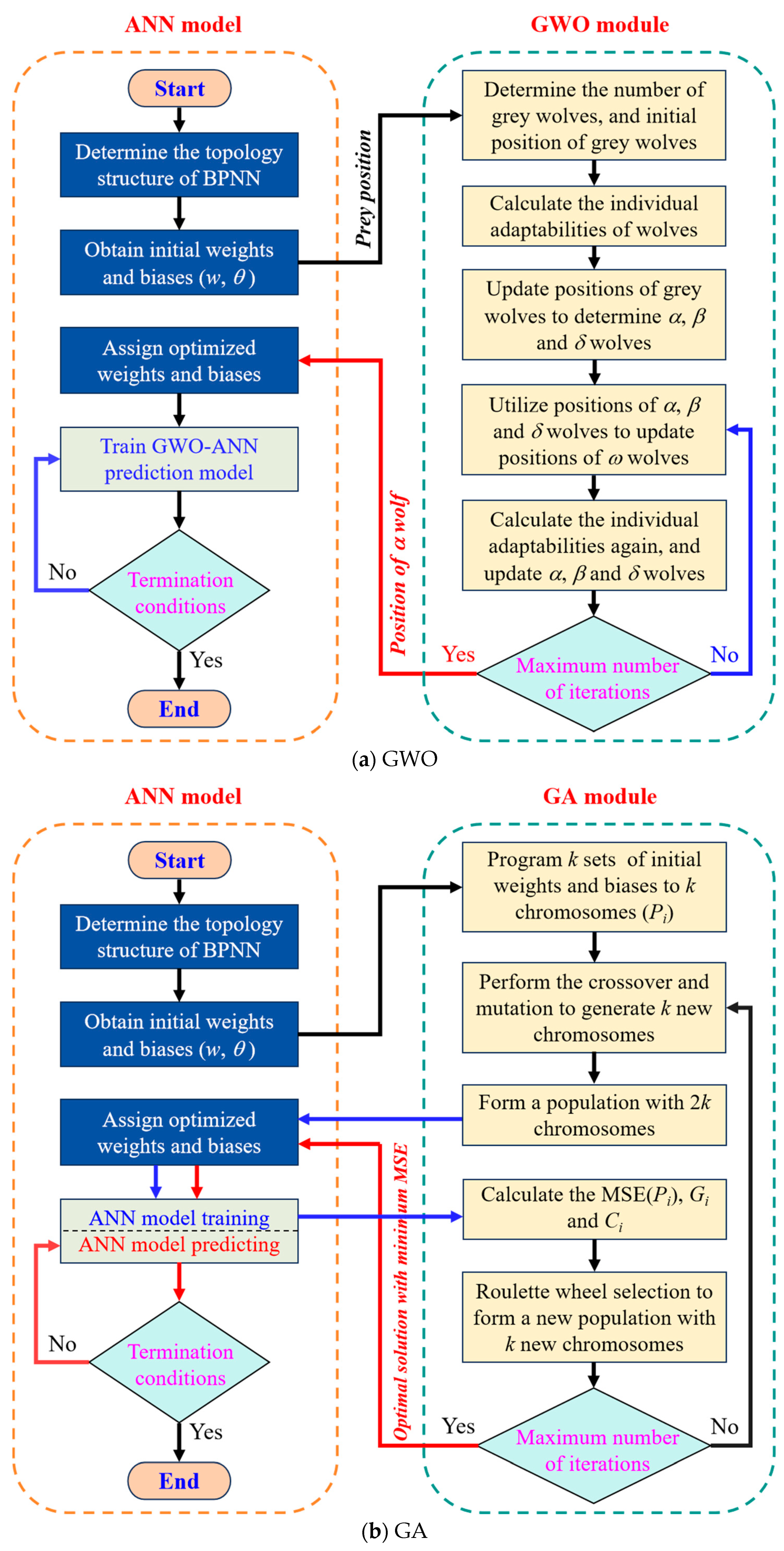

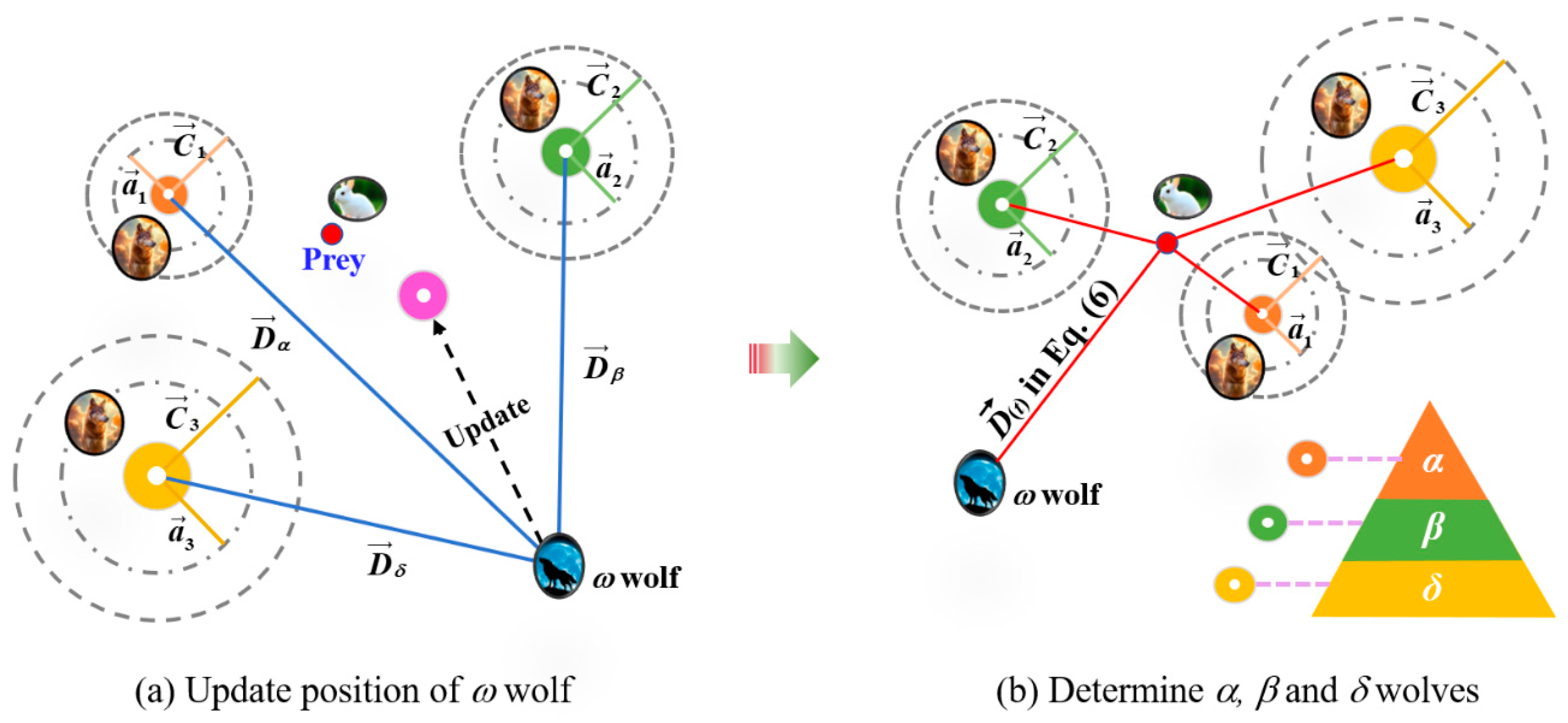

3.2. GWO

3.3. GA

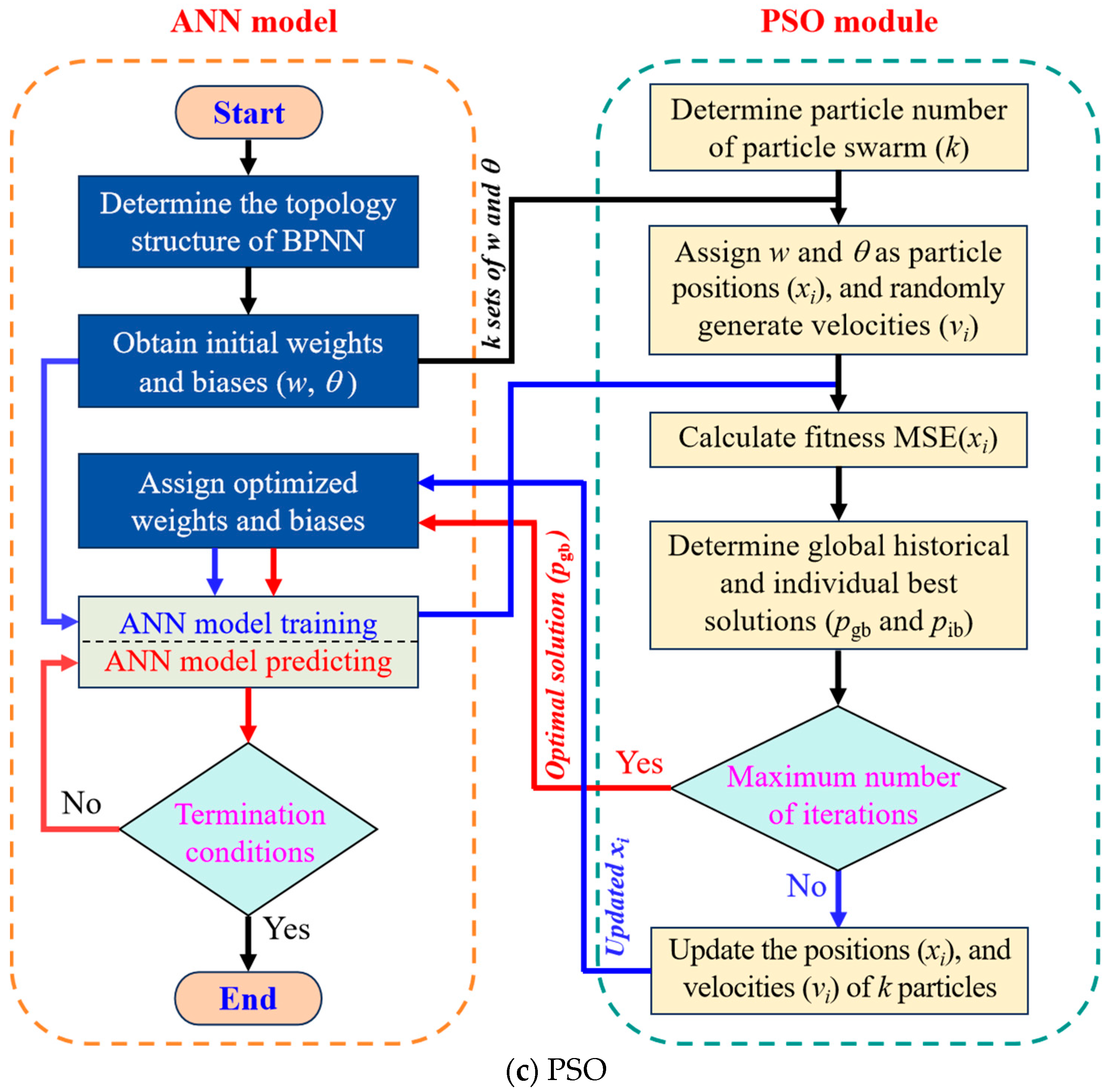

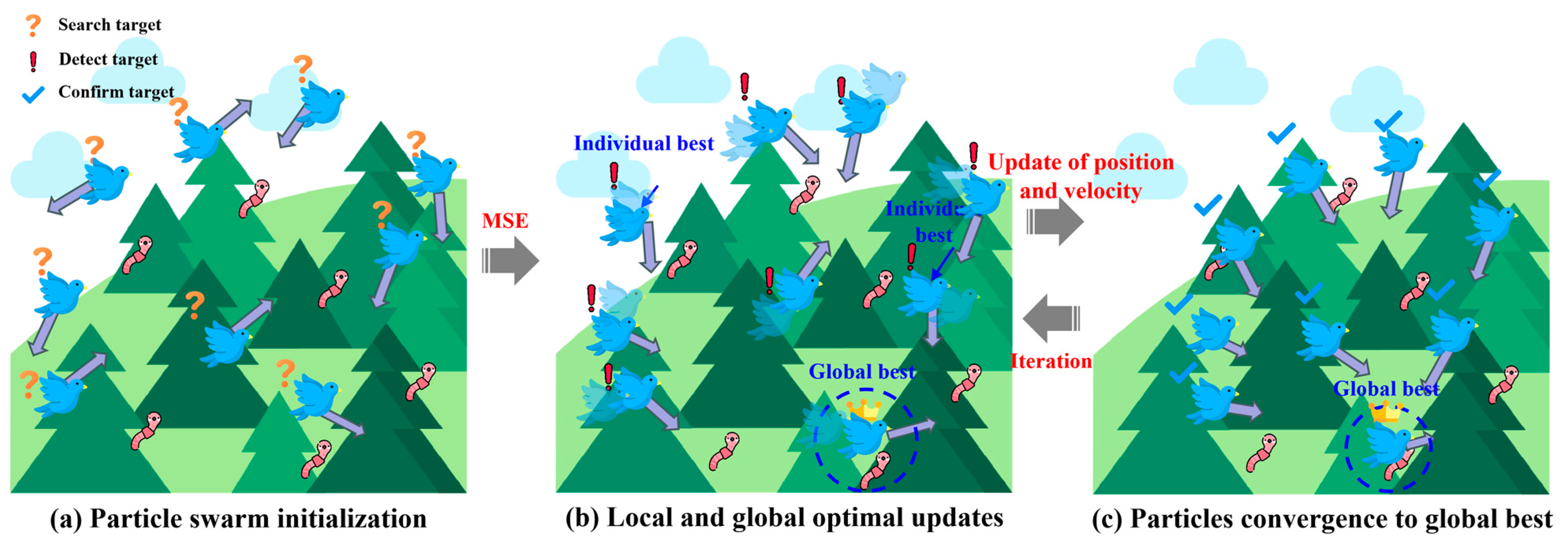

3.4. PSO

3.5. Assessment

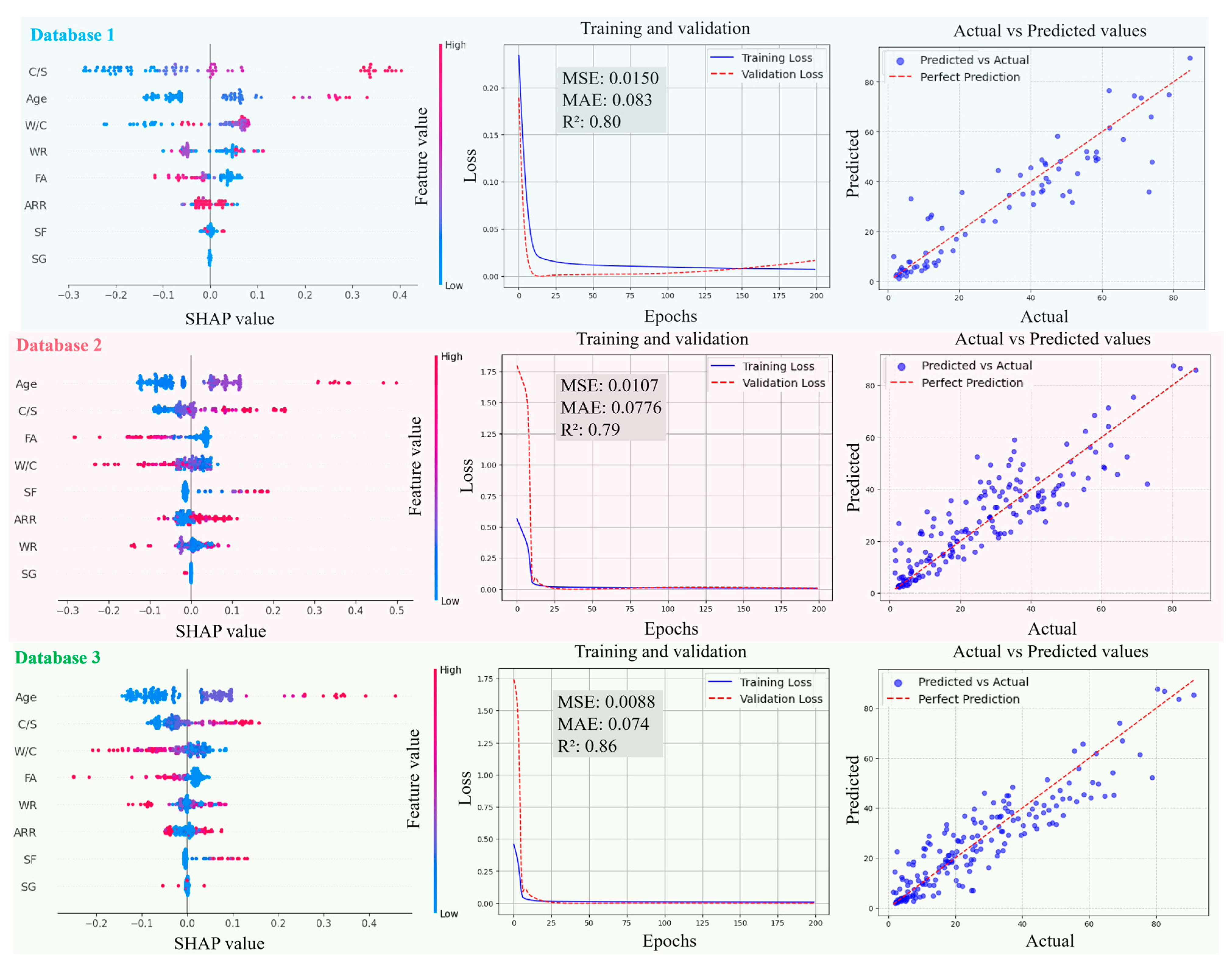

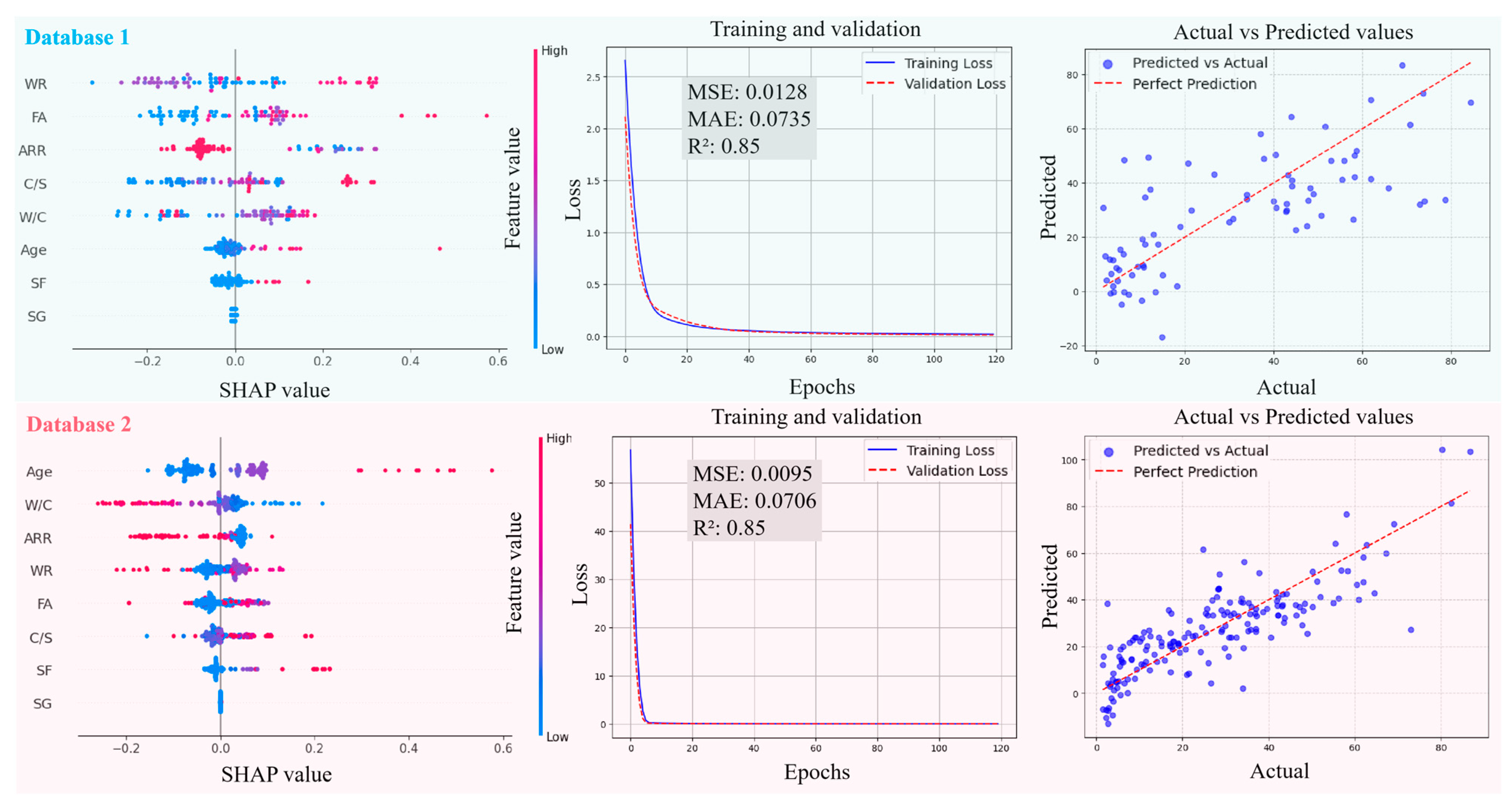

4. Results and Analysis

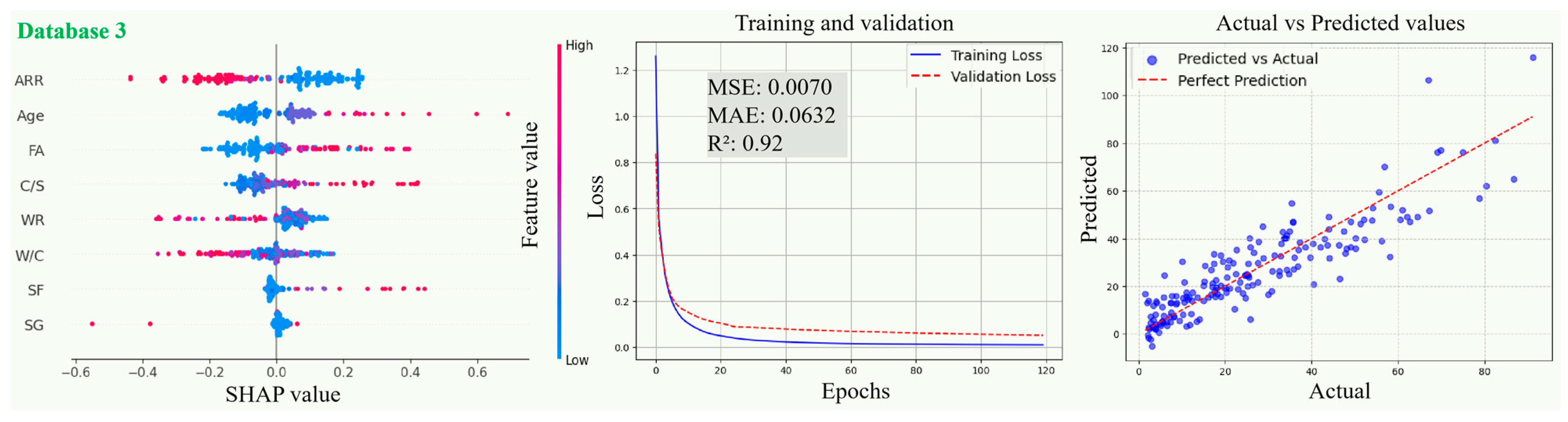

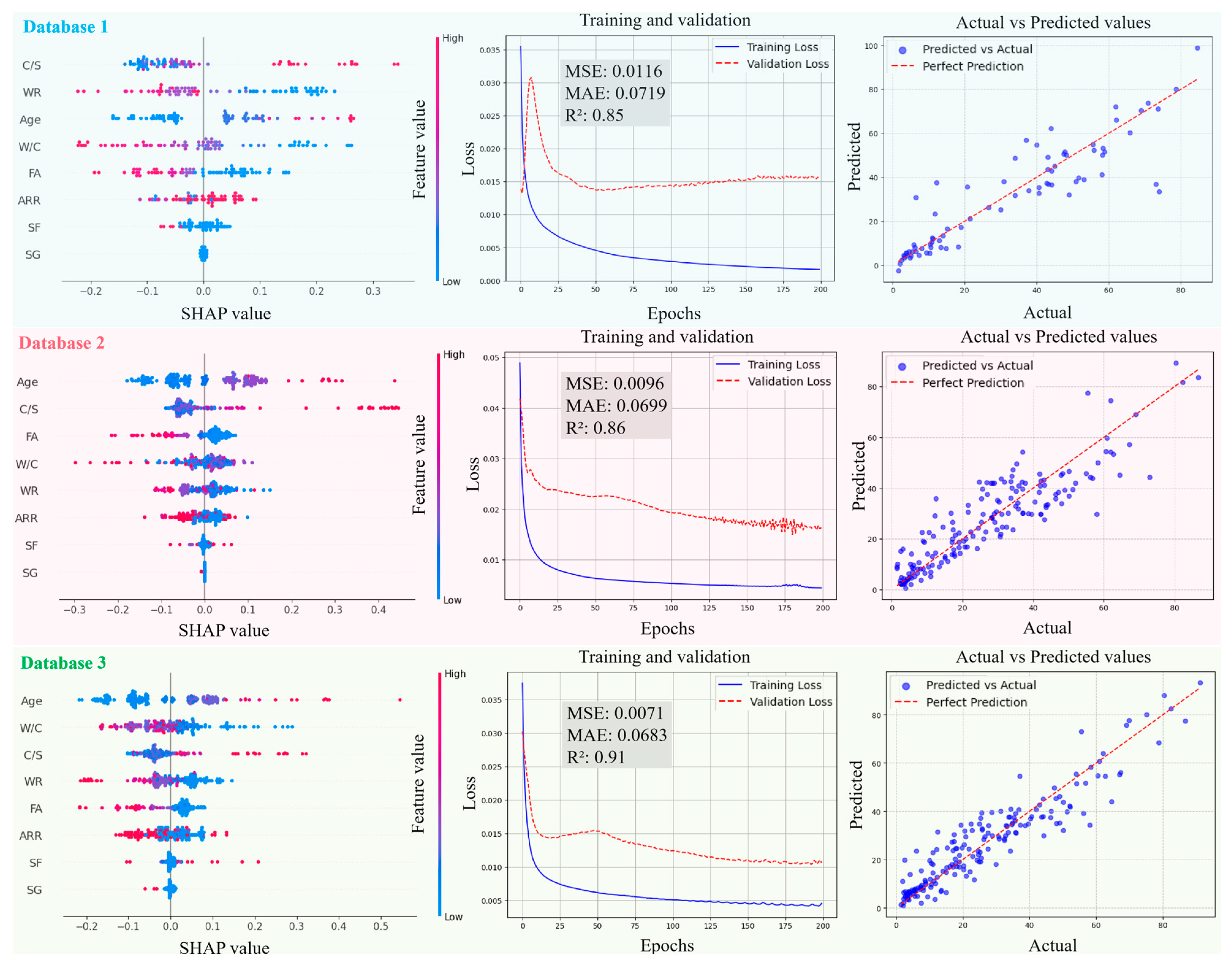

4.1. Prediction Accuracy

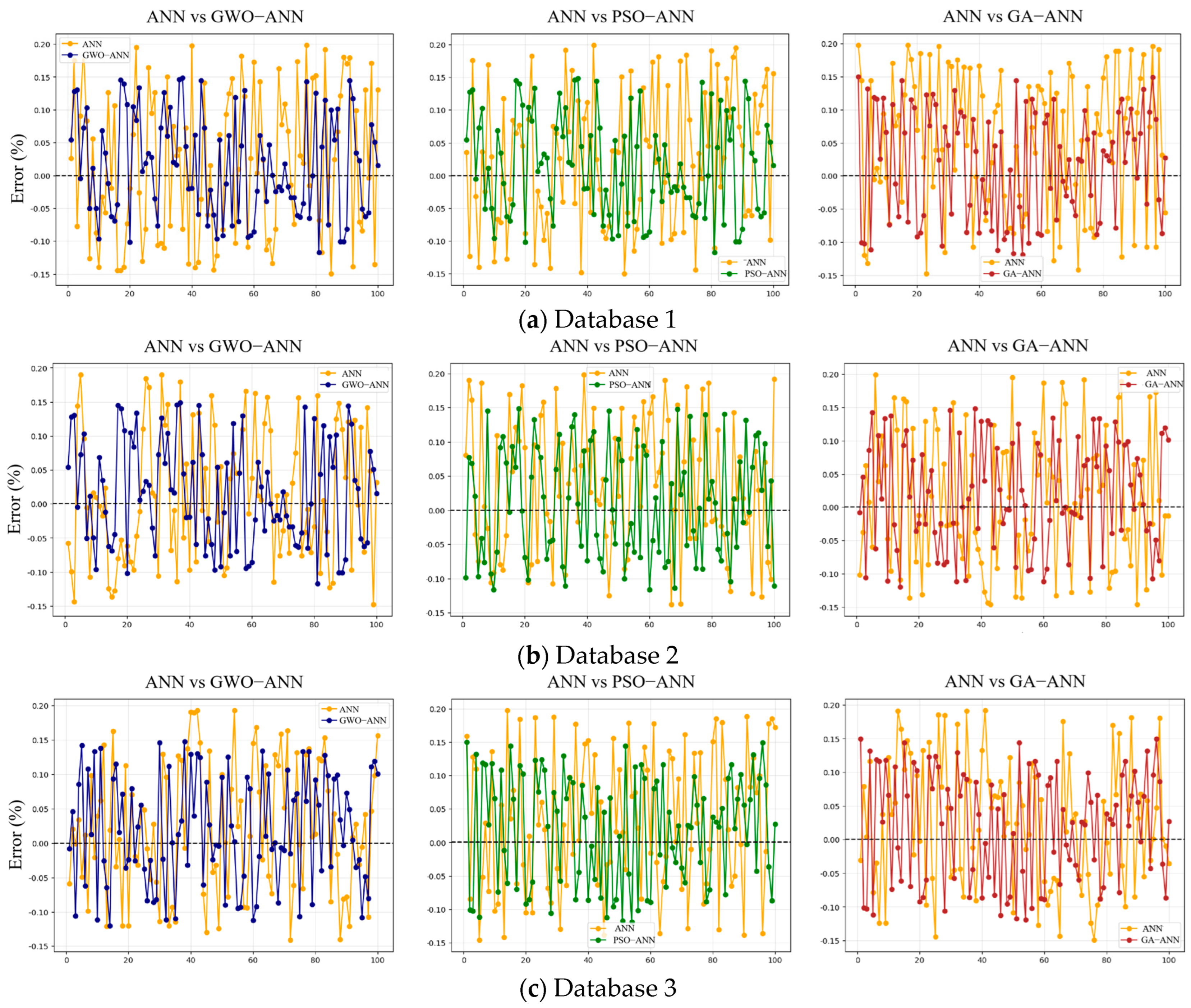

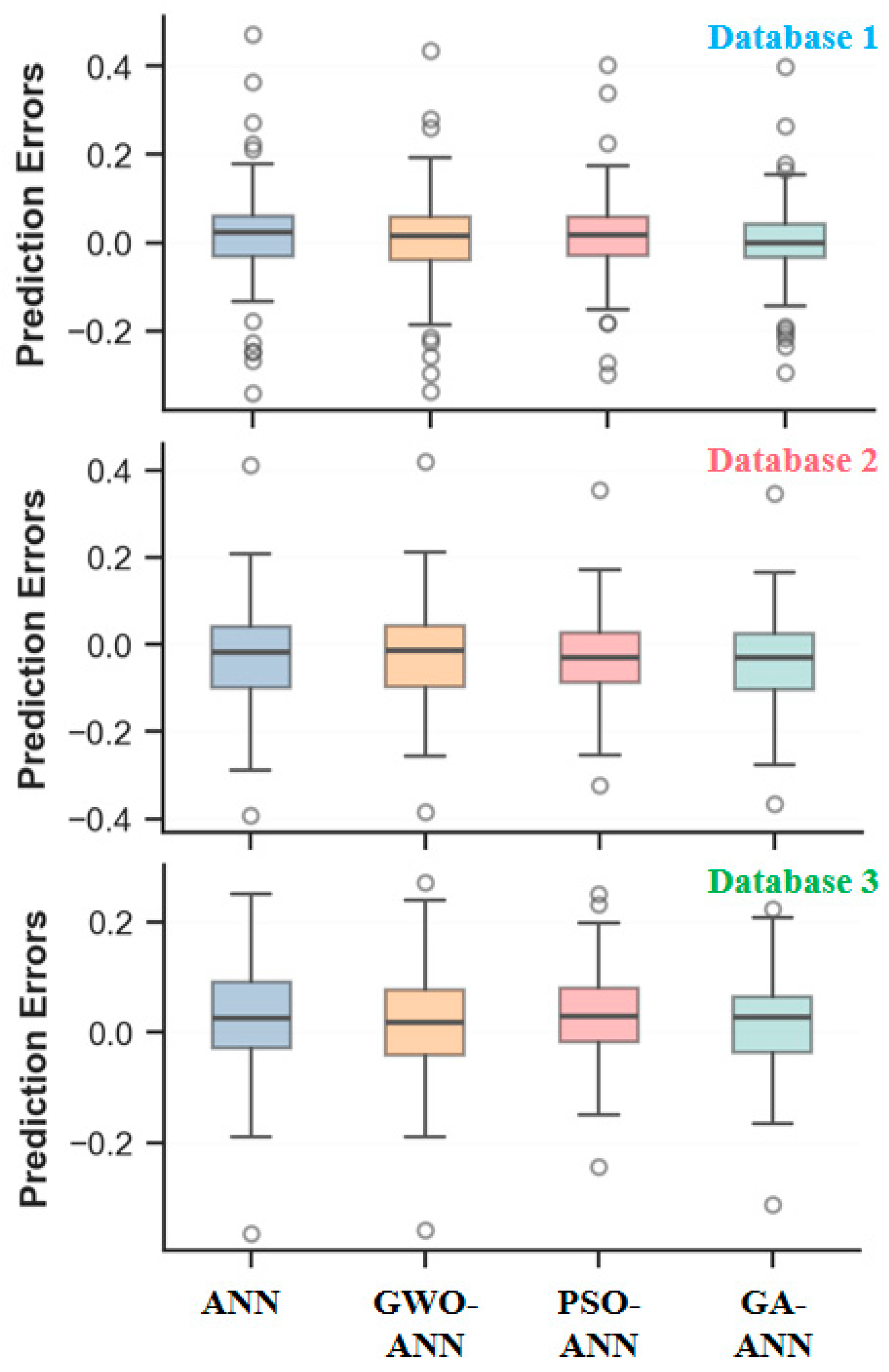

4.2. Prediction Error

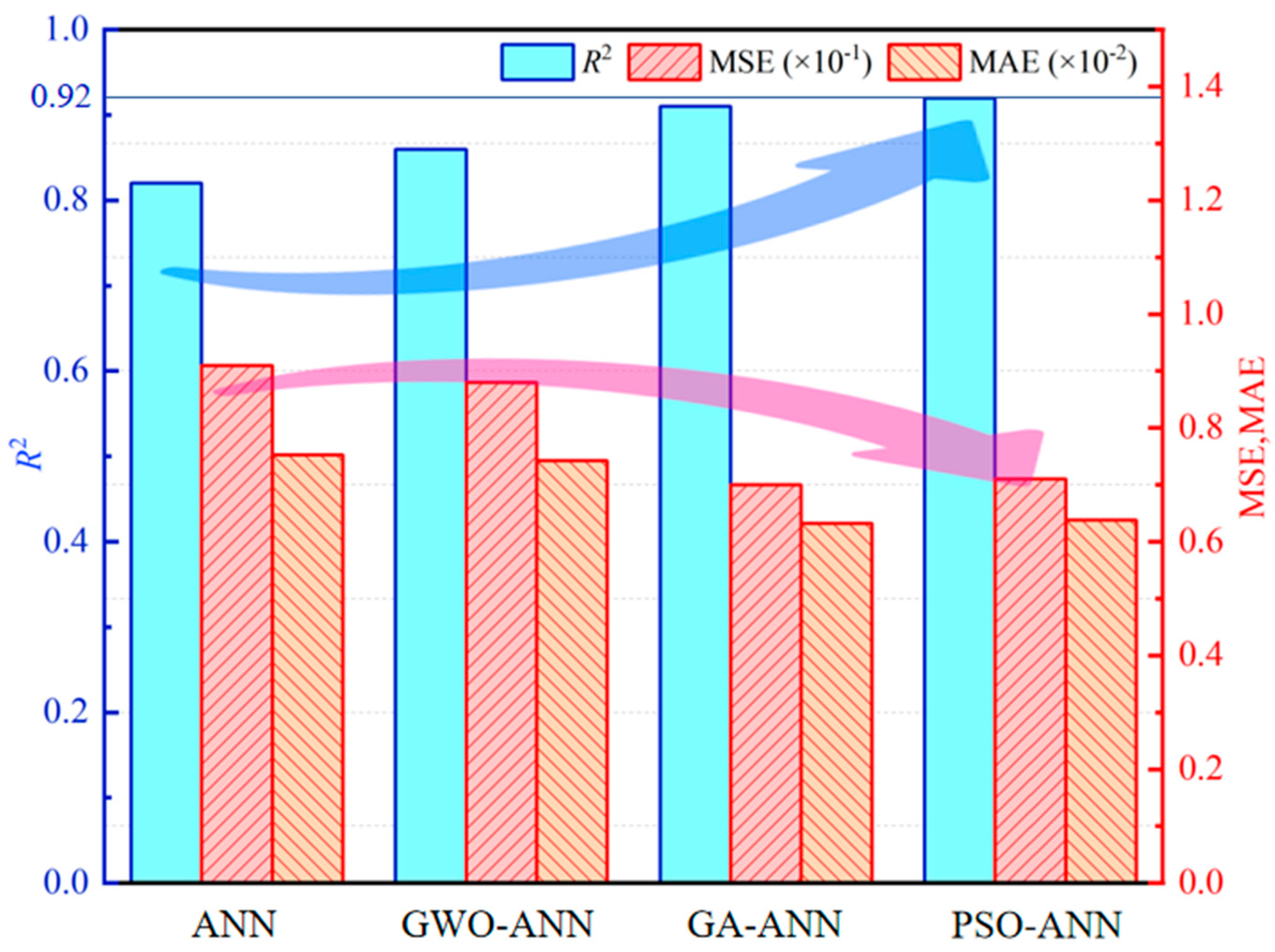

4.3. Optimizer-Based Performance Analysis

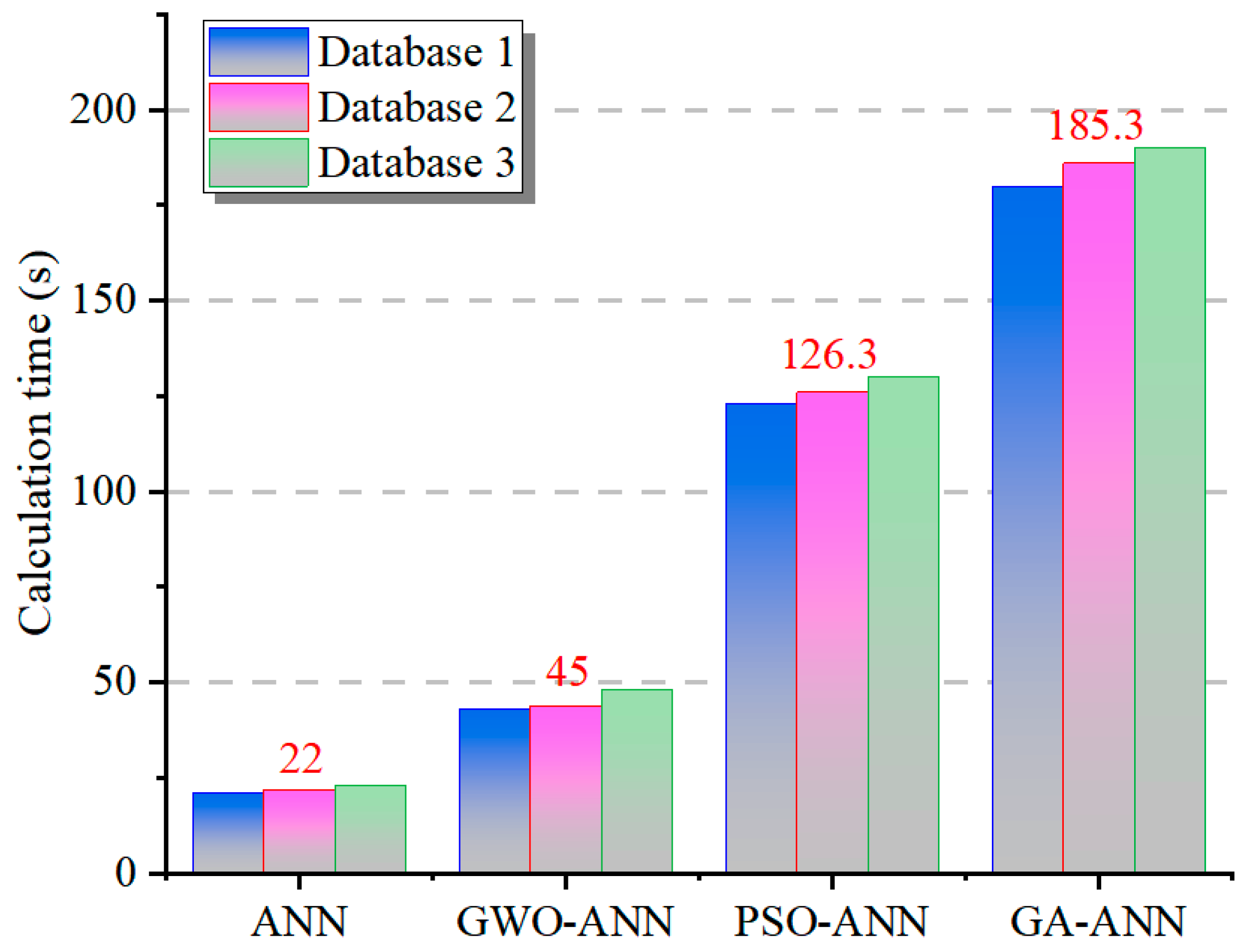

4.4. Calculation Time

5. Conclusions

- (1)

- Optimization algorithms significantly enhance the predictive performance of an ANN. Compared with conventional ANNs, the hybrid models (GWO-ANN, GA-ANN, and PSO-ANN) all demonstrate superior prediction accuracy and faster convergence rates. Notably, PSO-ANN achieves optimal performance in error control (MSE = 0.007; MAE = 0.0632) and fitting capability (R2 = 0.92), followed by GA-ANN. The performance improvement offered by the GWO is relatively modest.

- (2)

- Database scale can influence model performance. Expanding the database scale (from database 1 to databases 2 and 3) significantly improves the prediction accuracy of the models and effectively mitigates outlier issues and overfitting risks inherent in database 1 (small-sample database). This enhancement is particularly pronounced for algorithms with higher complexity (e.g., GA-ANN).

- (3)

- Variables affect the model interpretability. Feature importance analysis and SHAP visualizations reveal scenario-dependent variations in the influence of input variables on output (compression strength). W/C, C/S, and curing age are identified as core governing variables. Optimization via GWO, PSO, and GA effectively enhances the models’ ability to discern the directional effects of input variables, while reducing inter-variable interference and error propagation.

- (4)

- There is a trade-off between computational efficiency and predictive performance. Although intelligent optimization algorithms improve model performance (accuracy and convergence), they concurrently reduce the computational efficiency. PSO achieves a superior balance between accuracy and efficiency, reducing the training time by 33.3% compared with the GA while maintaining high predictive accuracy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Acronyms | |

| AI | Artificial Intelligence |

| ARR | Aggregate Replacement Ratio |

| ANN | Artificial Neural Network |

| CNN | Convolutional Neural Network |

| CS | Compressive Strength |

| C/S | Cement–Sand Ratio |

| FA | Fly Ash |

| GA | Genetic Algorithm |

| GWO | Grey Wolf Optimizer |

| IQR | Interquartile Range |

| MAE | Mean Absolute Error |

| MSE | Mean Squared Error |

| OCM | Ordinary Cement Mortar |

| PSO | Particle Swarm Optimization |

| PSO-BP | PSO-Optimized Backpropagation |

| R2 | Coefficient of Determination |

| RCM | Recycled Cement Mortar |

| RNN | Recurrent Neural Network |

| RMSE | Root Mean Squared Error |

| SF | Silica Fume |

| SG | Slag |

| SHAP | Shapley Additive Explanations |

| WR | Water-Reducing Agent |

| W/C | Water–Cement Ratio |

References

- Ning, W. Effect of recycled fine aggregate on properties of mortar. Ceram. Silik. 2023, 67, 468–476. [Google Scholar]

- Hosseinzadeh, M.; Dehestani, M.; Hosseinzadeh, A. Exploring elastic properties of fly ash recycled aggregate concrete: Insights from multiscale modeling and machine learning. Structures 2024, 59, 105720. [Google Scholar] [CrossRef]

- Gao, S.; Gong, Y.; Li, N.; Ban, S.L.; Liu, A. A Comparative study of the properties of recycled concrete prepared with nano-sio2 and co2 cured recycled coarse aggregates subjected to aggressive ions environment. Materials 2021, 14, 4960. [Google Scholar] [CrossRef]

- Leite, M.B.; Monteiro, P.J.M. Microstructural analysis of recycled concrete using X-ray microtomography. Cem. Concr. Res. 2016, 81, 38–48. [Google Scholar] [CrossRef]

- Yu, J.; Liang, R.; Qin, Y.J. Study on properties of C30 recycled coarse aggregate concrete. Build. Sci. 2015, 31, 59–63. [Google Scholar]

- Zhang, X.B.; Wan, G.Q.; Fang, Z.; Liu, X.H.; Xu, W.; Zhou, L.; Lai, S. Effect of mixing amount of aggregate intensified by RPC on the strength of recycled concrete. J. Build. Mater. 2015, 18, 400–408. [Google Scholar]

- Kisku, N.; Rajhans, P.; Panda, S.K.; Pandey, V.; Nayak, S. Microstructural investigation of recycled aggregate concrete produced by adopting equal mortar volume method along with two stage mixing approach. Structures 2020, 24, 742–753. [Google Scholar] [CrossRef]

- Huang, B. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Rifa, A.; Subhani, S.M.; Bahurudeen, A.; Santhosh, G.K. A systematic comparison of performance of recycled concrete fine aggregates with other alternative fine aggregates: An approach to find a sustainable alternative to river sand. J. Build. Eng. 2023, 78, 107695. [Google Scholar] [CrossRef]

- Ferreira, R.L.S.; Anjos, M.A.S.; Maia, C.; Pinto, L.; Azevedo, A.R.G.; Brito, J. Long-term analysis of the physical properties of the mixed recycled aggregate and their effect on the properties of mortars. Constr. Build. Mater. 2021, 274, 121796. [Google Scholar] [CrossRef]

- Cheng, L.H.; Dong, H.H.; Liang, J.F.; Cheng, L. Experimental study on mechanical properties of recycled sand cement mortar. Concrete 2022, 135–137. [Google Scholar]

- Li, D.; Zhang, Y.L.; Deng, Y.Y.; Charles, F. Influence of recycled fine aggregate on strength and micro-morphology of recycled mortar with recycled fine aggregate. Bull. Chin. Ceram. Soc. 2016, 35, 3876–3880. [Google Scholar]

- Fan, Y.H.; Li, Y.; Kang, X.M. Effect of regenerated powder and fly ash on mechanical properties and microstructure of mortar. Bull. Chin. Ceram. Soc. 2019, 38, 537–542. [Google Scholar]

- Li, C.; Shen, J.; Ma, K.; Chen, J.; Hu, M.; Wang, X. Influence of Recycled Fine Aggregate on the Properties of Self-Leveling Mortars. J. Test. Eval. 2024, 52, 2157–2174. [Google Scholar] [CrossRef]

- Yuan, Z.; Wang, L.N.; Ji, X. Prediction of concrete compressive strength: Research on hybrid models genetic based algorithms and ANFIS. Adv. Eng. Softw. 2014, 67, 156–163. [Google Scholar] [CrossRef]

- Zhou, S.; Jia, Y.; Li, K.; Li, Z.J.; Wu, X.X.; Peng, H.Y.; Zhang, C.M.; Han, K.H.; Wang, C. Mix proportion optimization of ultra high performance concrete based on machine learning. J. Tongji Univ. (Nat. Sci.) 2024, 52, 1018–1023. [Google Scholar]

- Liu, Y.J.; Johar, M.G.M.; Hajamydeen, A.I. Poultry disease early detection methods using deep learning technology. Indones. J. Electr. Eng. Comput. Sci. 2023, 32, 1712. [Google Scholar] [CrossRef]

- Dechun, L. A nonlinear dynamic uniaxial strength criterion that considers the ultimate dynamic strength of concrete. Int. J. Impact Eng. 2017, 103, 124–137. [Google Scholar] [CrossRef]

- Deng, F.; He, Y.; Zhou, S.; Yun, Y.; Cheng, H.; Wu, X. Compressive strength prediction of recycled concrete based on deep learning. Constr. Build. Mater. 2018, 175, 562–569. [Google Scholar] [CrossRef]

- Gros, C.; De Leener, B.; Badji, A.; Maranzano, J.; Eden, D.; Dupont, S.M.; Talbott, J.; Zhuoquiong, R.; Liu, Y.; Granberg, T.; et al. Automatic segmentation of the spinal cord and intramedullary multiple sclerosis lesions with convolutional neural networks. NeuroImage 2019, 184, 901–915. [Google Scholar] [CrossRef] [PubMed]

- Gkountakou, F.I.; Papadopoulos, B.K. The Use of Fuzzy Linear Regression with Trapezoidal Fuzzy Numbers to Predict the Compressive Strength of Lightweight Foamed Concrete. Math. Model. Eng. Probl. 2022, 9, 1–10. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, D.; Cao, K. Prediction of concrete compressive strength using support vector machine regression and non-destructive testing. Case Stud. Constr. Mater. 2024, 21, e03416. [Google Scholar] [CrossRef]

- Chun, P.J.; Ujike, I.; Mishima, K.; Kusumoto, M.; Okazaki, S. Random forest-based evaluation technique for internal damage in reinforced concrete featuring multiple nondestructive testing results. Constr. Build. Mater. 2020, 253, 119238. [Google Scholar] [CrossRef]

- Yu, H.L.; Deng, J.F. Prediction of carbonization depth of recycled concrete based on artificial neural network by Python. Concrete 2020, 52–55. [Google Scholar] [CrossRef]

- Liu, R.G.; Chen, H.; Cui, Z.W.; Chen, Y.Q.; Zhang, S.F.; Yan, Q.X. Mechanical properties of SAP internal curing machine-made sand concrete and bp neural network prediction. J. Jiangsu Univ. (Nat. Sci. Ed.) 2023, 44, 367–372. [Google Scholar]

- Chen, H.G.; Long, W.Y.; Li, X.; Lu, M.J.; Zuo, L.; Pan, C. Prediction of compressive strength of fly ash concrete with BP neural network. Build. Struct. 2021, 51, 1041–1045. [Google Scholar]

- Ma, G.; Liu, K. Prediction of compressive strength of CFRP-confined concrete columns based on BP neural network. J. Hunan Univ. (Nat. Sci.) 2021, 48, 88–97. [Google Scholar]

- Zhong, W.L.; Ding, H.; Zhao, X.; Fan, L.F. Mechanical properties prediction of geopolymer concrete subjected to high temperature by BP neural network. Constr. Build. Mater. 2023, 409, 133780. [Google Scholar] [CrossRef]

- Gao, W. Influencing factors and deep learning prediction model of compression strength of recycled concrete. Concrete 2018, 11, 58–61+70. [Google Scholar]

- Tian, H.Z.; Qiao, H.X.; Zhang, Y.S.; Feng, Q.; Wang, P.H.; Xie, X.Y. Prediction of mechanical properties of manufactured sand polymer-modified mortar based on genetic optimization algorithm backpropagation neural network. Acta Mater. Compos. Sin. 2024, 42, 11–1801. [Google Scholar]

- Li, Y.R.; Xiao, Q.Y.; Liu, H.L. Comparative prediction of fresh performance of self-compacting concrete based on bp neural network and support vector regression. J. Mater. Sci. Eng. 2023, 41, 610–619. [Google Scholar]

- Feng, W.; Wang, Y.; Sun, J.; Tang, Y.; Wu, D.X.; Jiang, Z.W.; Wang, J.Q.; Wang, X.Y. Prediction of thermo-mechanical properties of rubber-modified recycled aggregate concrete. Constr. Build. Mater. 2022, 318, 125970. [Google Scholar] [CrossRef]

- Li, M.; Gao, Y.L. Image compression method of BP neural network based on improved particle swarm optimization. J. Nanjing Univ. Sci. Technol. 2023, 47, 756–766. [Google Scholar]

- Ding, C.; Xia, Y.; Yuan, Z.; Yang, H.; Fu, J.; Chen, Z. Performance prediction for a fuel cell air compressor based on the combination of backpropagation neural network optimized by genetic algorithm (GA-BP) and support vector machine (SVM) algorithms. Therm. Sci. Eng. Prog. 2023, 44, 102070. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, C.; Wu, C.; Kou, X.; Xue, Z. Storage quality prediction of winter jujube based on particle swarm optimization-backpropagation-artificial neural network (PSO-BP-ANN). Sci. Hortic. 2024, 331, 112789. [Google Scholar] [CrossRef]

- Storn, R. Differential evolution—A simple and efficient heuristic for global optimization over continuous spaces. Differ. Evol. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Mirjalili, S.; Saremi, S.; Mirjalili, S.M.; Coelho, L.S. Multi-objective grey wolf optimizer: A novel algorithm for multi-criterion optimization. Expert Syst. Appl. 2016, 47, 106–119. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Wang, D.; Luo, H.; Grunder, O.; Lin, Y.; Guo, H. Multi-step ahead electricity price forecasting using a hybrid model based on two-layer decomposition technique and BP neural network optimized by firefly algorithm. Appl. Energy 2017, 190, 390–407. [Google Scholar] [CrossRef]

- Li, B.L.; Luo, J.L.; Tao, L.Y.; Li, Q.Y.; Gao, S. Effect of low-quality fly ash on the rheology and physical properties of recycled pre-mixed mortar. Concrete 2021, 10, 85–88. [Google Scholar]

- Mou, Y.; Tian, B.P.; Luo, Y.K. Proportioning design and mechanical properties of recycled mixed aggregate concrete. Concrete 2023, 9, 136–140+154. [Google Scholar]

- Fu, Y.; Xue, C.Z.; He, J.H.; Liu, Y.G.; Zhu, X.H. Study on the particle characteristics of recycled concrete powder and the performance of mortar. Mater. Rep. 2022, 36, 98–103. [Google Scholar]

- Liu, X.Y.; Xia, P.Z.; Xu, X.X.; Wang, Y.D.; Ge, Z. Research on mechanical properties of recycled fine aggregate mortar. Concrete 2020, 7, 106–108+113. [Google Scholar]

- Sui, Z.C.; Cui, X.D.; Wang, X.B.; Li, Q.Y.; Tao, L.Y. Experimental study on compressive strength of recycled wet-mixed mortar. Concrete 2019, 9, 97–99+107. [Google Scholar]

- Kurad, R.; Silvestre, J.D.; De Brito, J.; Ahmed, H. Effect of incorporation of high volume of recycled concrete aggregates and fly ash on the strength and global warming potential of concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Verma, S.K.; Ashish, D.K. Mechanical behavior of concrete comprising successively recycled concrete aggregates. Adv. Concr. Constr. 2017, 5, 303–311. [Google Scholar]

- Dapena, E.; Alaejos, P.; Lobet, A.; Pérez, D. Effect of recycled sand content on characteristics of mortars and concretes. J. Mater. Civ. Eng. 2011, 23, 414–422. [Google Scholar] [CrossRef]

- Khelafi, A.; Kaid, N.; Soltani, R.; Elddine, K.D.; Khelafi, H. Elaboration of recycled concrete sand aggregates-based mortars: An alternative recycling process. Constr. Build. Mater. 2023, 398, 132333. [Google Scholar] [CrossRef]

- Wu, H.; Yang, D.; Wang, C.; Ma, Z. Microstructural and macro performance of recycled mortar with high-quality recycled aggregate and powder from high-performance concrete waste. J. Mater. Civ. Eng. 2023, 35, 04022482. [Google Scholar] [CrossRef]

- Bamshad, O.; Mahdikhani, M.; Ramezanianpour, A.M.; Maleki, Z.; Majlesi, A.; Habibi, A.; Delavar, M.A. Prediction and multi-objective optimization of workability and compressive strength of recycled self-consolidating mortar using Taguchi design method. Heliyon 2023, 9, e16381. [Google Scholar] [CrossRef]

- Hamid, N.D.; Ramin, K. ANN prediction of cement mortar compressive strength, influence of cement strength class. Constr. Build. Mater. 2017, 138, 1–11. [Google Scholar] [CrossRef]

- Shao, J.J.; Li, L.B.; Yin, G.J.; Wen, X.D.; Zou, Y.X.; Zuo, X.B.; Gao, X.J.; Cheng, S.S. Prediction of compressive strength of fly ash-recycled mortar based on grey wolf optimizer–backpropagation neural network. Materials 2025, 18, 139. [Google Scholar] [CrossRef]

- Yan, F. Improvement Research on the Grey Wolf Optimizer. Ph.D. thesis, Harbin Engineering University, Harbin, China, 2020. [Google Scholar]

- Ranjbar, I.; Toufigh, V.; Boroushaki, M. A combination of deep learning and genetic algorithm for predicting the compressive strength of high-performance concrete. Struct. Concr. 2022, 23, 2405–2418. [Google Scholar]

- Poli, R.; Kennedy, J.; Blackwell, T. Particle swarm optimization: An overview. Swarm Intell. 2007, 1, 33–57. [Google Scholar] [CrossRef]

- Hosseinzadeh, M.; Dehestani, M.; Hosseinzadeh, A. Prediction of mechanical properties of recycled aggregate fly ash concrete employing machine learning algorithms. J. Build. Eng. 2023, 76, 107006. [Google Scholar] [CrossRef]

- Katz, A.; Kulisch, D. Performance of mortars containing recycled fine aggregate from construction and demolition waste. Mater. Struct. 2017, 50, 199. [Google Scholar] [CrossRef]

- Li, T.; Nogueira, R.; Pereira, M.F.C.; De Brito, J.; Liu, J. Effect of the incorporation ratio of recycled concrete aggregate on the properties of self-compacting mortar. Cem. Concr. Compos. 2024, 147, 105429. [Google Scholar] [CrossRef]

- Ge, Z.; Feng, Y.; Zhang, H.; Xiao, J.; Sun, R.; Liu, X. Use of recycled fine clay brick aggregate as internal curing agent for low water to cement ratio mortar. Constr. Build. Mater. 2020, 264, 120280. [Google Scholar] [CrossRef]

- Jin, D.C.; Li, B.X.; Chen, P.B.; Zeng, B. Study on the effect of recycled sand quality and replacement ratio on additional water consumption and mechanical properties of concrete. Water Resour. Hydropower Eng. 2024, 55, 152–160. [Google Scholar]

- Han, I.J.; Yuan, T.F.; Lee, J.Y.; Yoon, Y.S.; Kim, J.H. Learned prediction of compressive strength of GGBFS concrete using hybrid artificial neural network models. Materials 2019, 12, 3708. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Fan, Z. Evaluation of urban green space landscape planning scheme based on PSO-BP neural network model. Alex. Eng. J. 2022, 61, 7141–7153. [Google Scholar] [CrossRef]

| No. | Reference | Quantity | Proportion |

|---|---|---|---|

| 1 | Gao W. [29] | 3 | 0.5 |

| 2 | Li B.L. et al. [40] | 9 | 1.5 |

| 3 | Mou Y. et al. [41] | 3 | 0.5 |

| 4 | Fu Y. et al. [42] | 4 | 0.6 |

| 5 | Liu X.Y. et al. [43] | 3 | 0.5 |

| 6 | Sui Z.C. et al. [44] | 81 | 13.2 |

| 7 | Kurad R. et al. [45] | 20 | 3.2 |

| 8 | Verma S.K. et al. [46] | 4 | 0.6 |

| 9 | Dapena E. et al. [47] | 18 | 2.9 |

| 10 | Khelafi A. et al. [48] | 15 | 2.5 |

| 11 | Wu H. et al. [49] | 9 | 1.5 |

| 12 | Ning W. [1] | 20 | 3.3 |

| 13 | Li C. et al. [14] | 18 | 3.0 |

| 14 | Bamshad O. et al. [50] | 36 | 5.9 |

| 15 | Hamid, N.D. et al. [51] | 270 | 44.2 |

| 16 | Shao J.J. et al. [52] | 98 | 16.1 |

| Database | Variable | Sample Size | Maximum | Minimum | Average | 25% Quantile | 50% Quantile | 75% Quantile |

|---|---|---|---|---|---|---|---|---|

| 1 | ARR | 260 | 100 | 0 | 83.77 | 100 | 100 | 100 |

| W/C | 260 | 0.99 | 0.2 | 0.56 | 0.365 | 0.52 | 0.75 | |

| C/S | 260 | 0.89 | 0.14 | 0.45 | 0.2 | 0.33 | 0.66 | |

| FA | 260 | 60 | 0 | 14.65 | 0 | 12 | 30 | |

| SF | 260 | 36 | 0 | 2.79 | 0 | 0 | 0 | |

| SG | 260 | 12 | 0 | 0.09 | 0 | 0 | 0 | |

| WR | 260 | 4 | 0 | 1.32 | 0.15 | 1.3 | 2.13 | |

| Age | 260 | 360 | 1 | 29.64 | 3 | 7 | 28 | |

| CS | 260 | 91.1 | 1.5 | 29.34 | 6.7 | 20.1 | 48.26 | |

| 2 | ARR | 566 | 100 | 0 | 38.48 | 0 | 0 | 100 |

| W/C | 566 | 0.99 | 0.2 | 0.46 | 0.3 | 0.44 | 0.5 | |

| C/S | 566 | 1.06 | 0.14 | 0.42 | 0.33 | 0.36 | 0.46 | |

| FA | 566 | 60 | 0 | 6.73 | 0 | 0 | 6 | |

| SF | 566 | 36 | 0 | 1.47 | 0 | 0 | 0 | |

| SG | 566 | 12 | 0 | 0.042 | 0 | 0 | 0 | |

| WR | 566 | 4.07 | 0 | 1.11 | 0.13 | 0.73 | 1.5 | |

| Age | 566 | 360 | 1 | 21.69 | 7 | 14 | 28 | |

| CS | 566 | 91.1 | 1.5 | 28.3 | 11.08 | 25.1 | 42.19 | |

| 3 | ARR | 611 | 100 | 0 | 37.77 | 0 | 0 | 100 |

| W/C | 611 | 0.99 | 0.2 | 0.47 | 0.3 | 0.45 | 0.57 | |

| C/S | 611 | 1.06 | 0.14 | 0.42 | 0.33 | 0.36 | 0.4 | |

| FA | 611 | 60 | 0 | 7.23 | 0 | 0 | 12 | |

| SF | 611 | 36 | 0 | 1.36 | 0 | 0 | 0 | |

| SG | 611 | 30 | 0 | 0.43 | 0 | 0 | 0 | |

| WR | 611 | 4.07 | 0 | 1.04 | 0.11 | 0.64 | 1.5 | |

| Age | 611 | 360 | 1 | 21.76 | 7 | 14 | 28 | |

| CS | 611 | 91.1 | 1.5 | 27.89 | 11.03 | 25.1 | 41.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.-B.; Yin, G.-J.; Shao, J.-J.; Miao, L.; Lang, Y.-J.; Zhu, J.-J.; Cheng, S.-S. Performance Analysis of Artificial Neural Network and Its Optimized Models on Compressive Strength Prediction of Recycled Cement Mortar. Materials 2025, 18, 5694. https://doi.org/10.3390/ma18245694

Li L-B, Yin G-J, Shao J-J, Miao L, Lang Y-J, Zhu J-J, Cheng S-S. Performance Analysis of Artificial Neural Network and Its Optimized Models on Compressive Strength Prediction of Recycled Cement Mortar. Materials. 2025; 18(24):5694. https://doi.org/10.3390/ma18245694

Chicago/Turabian StyleLi, Lin-Bin, Guang-Ji Yin, Jing-Jing Shao, Ling Miao, Yu-Jie Lang, Jia-Jia Zhu, and Shan-Shan Cheng. 2025. "Performance Analysis of Artificial Neural Network and Its Optimized Models on Compressive Strength Prediction of Recycled Cement Mortar" Materials 18, no. 24: 5694. https://doi.org/10.3390/ma18245694

APA StyleLi, L.-B., Yin, G.-J., Shao, J.-J., Miao, L., Lang, Y.-J., Zhu, J.-J., & Cheng, S.-S. (2025). Performance Analysis of Artificial Neural Network and Its Optimized Models on Compressive Strength Prediction of Recycled Cement Mortar. Materials, 18(24), 5694. https://doi.org/10.3390/ma18245694