Effect of Metallurgical Process on Rotational Bending Fatigue Properties of H13 Hot Work Die Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Preparation

2.2. Microstructure, Inclusion, and Phase Analyses Test

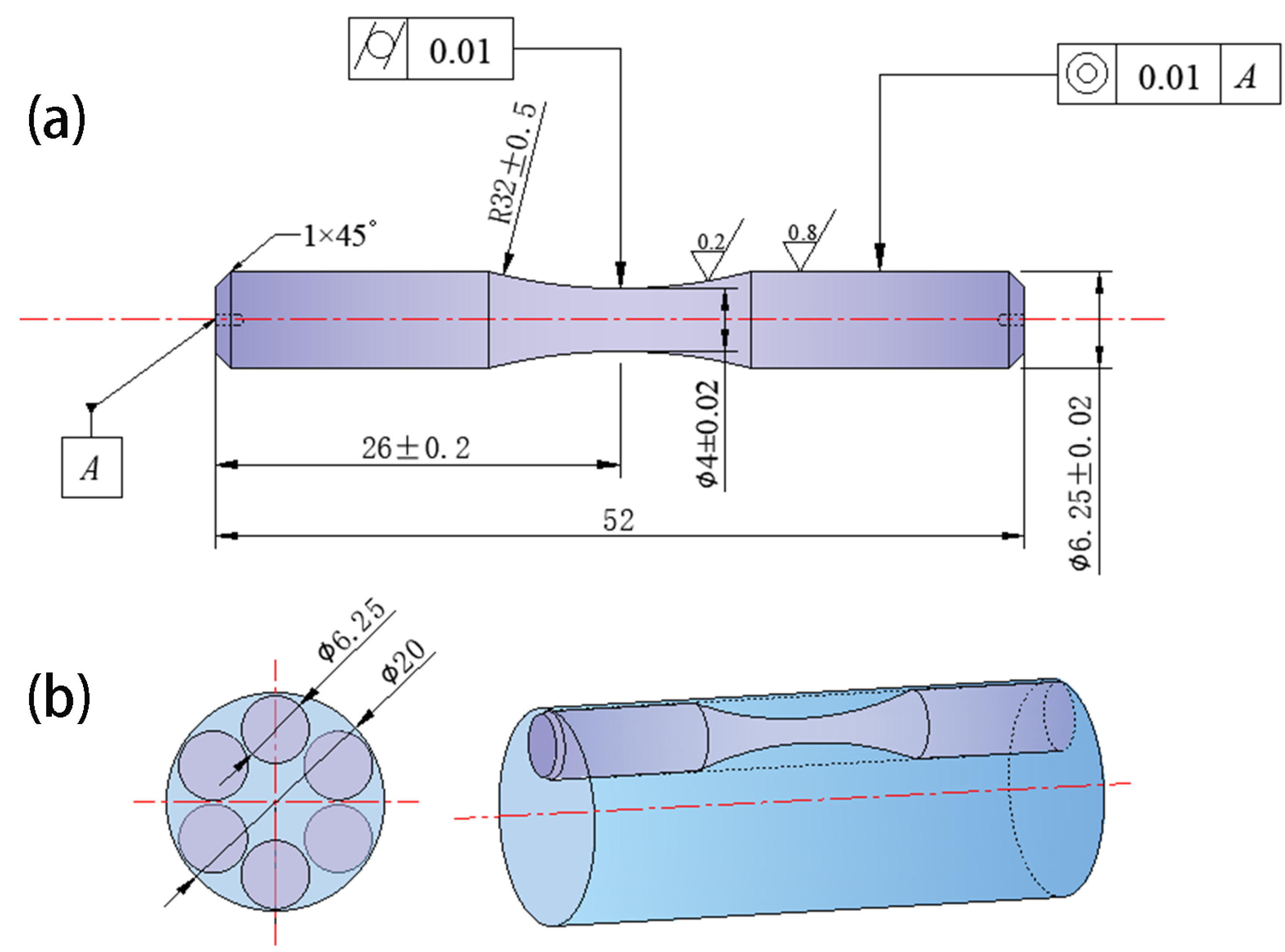

2.3. Mechanical Property Test

3. Results

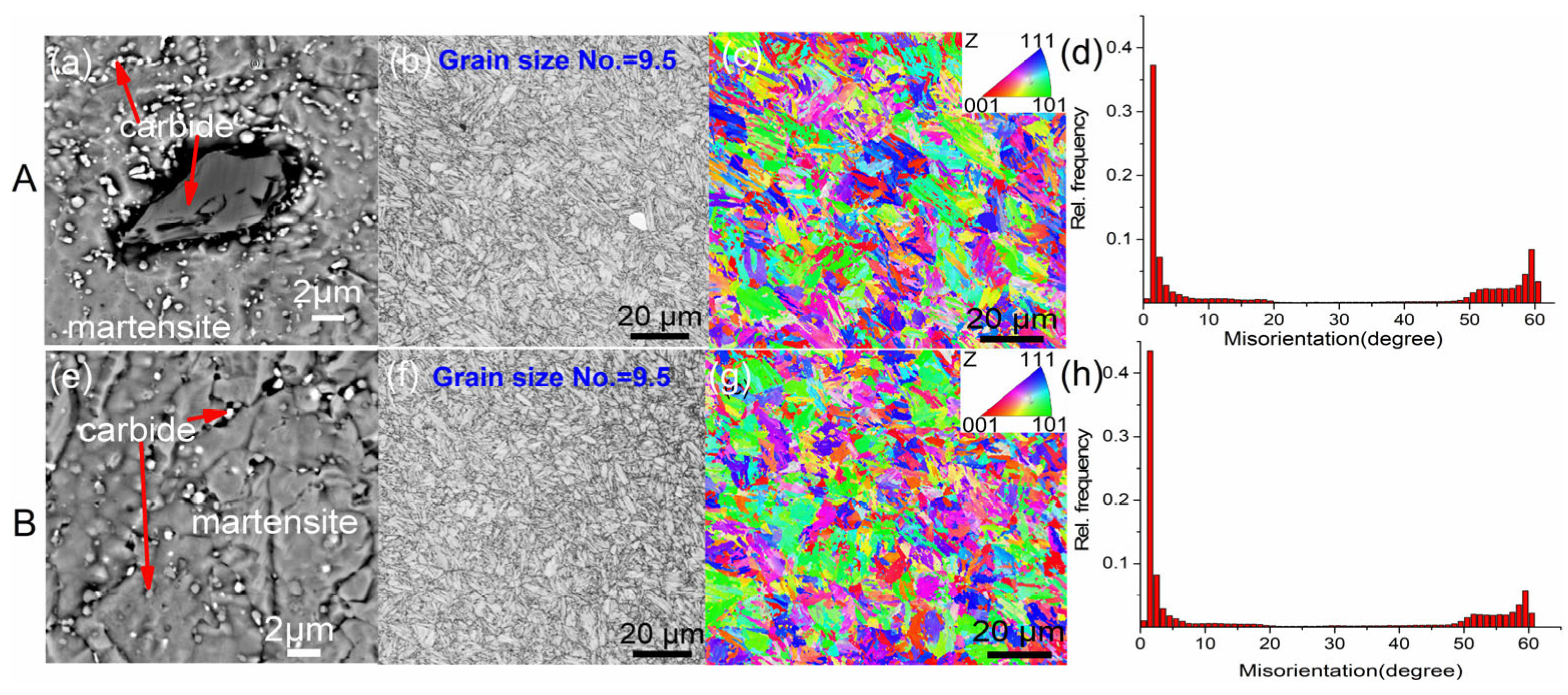

3.1. Microstructure and Grain Size

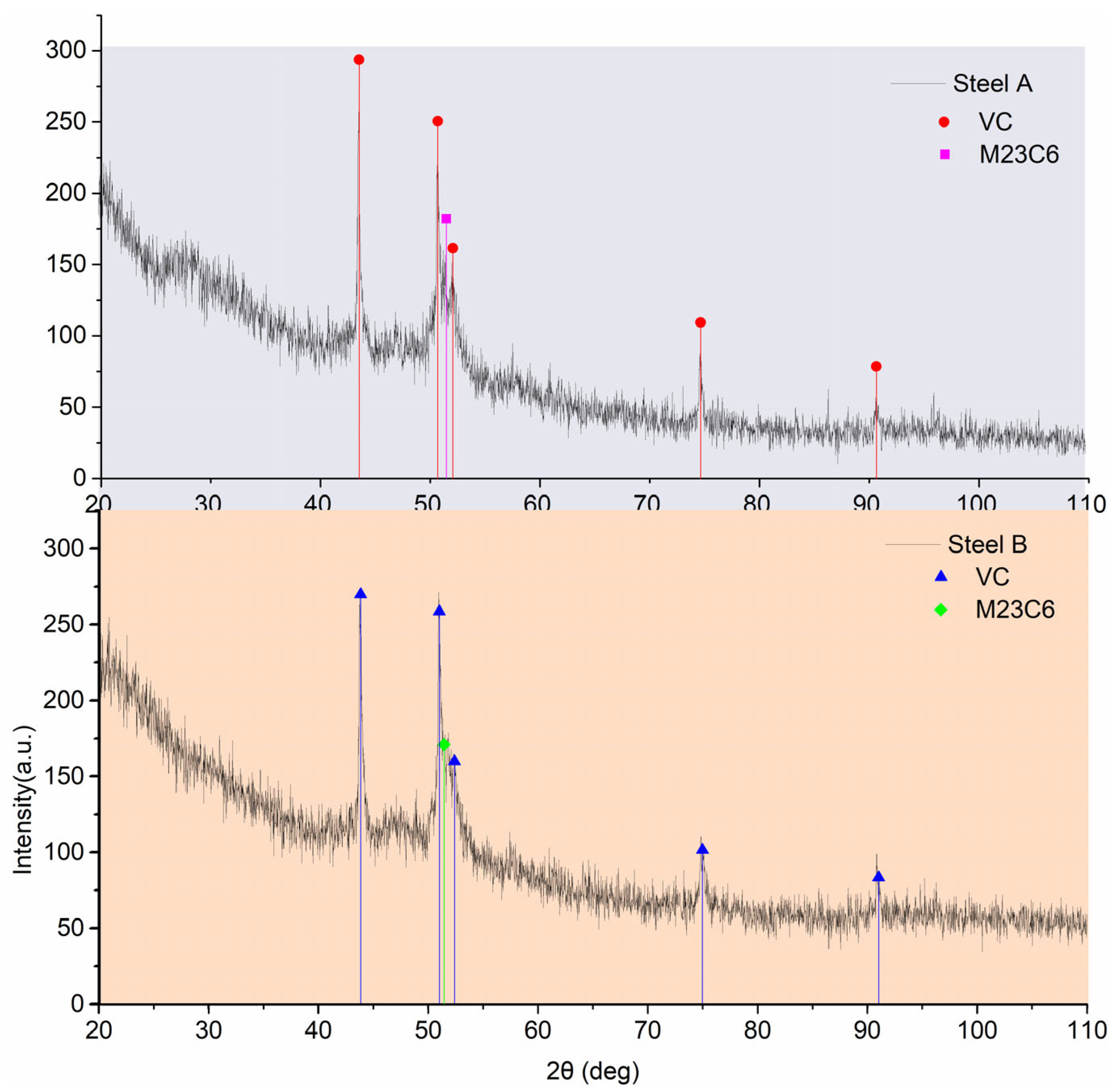

3.2. Carbide

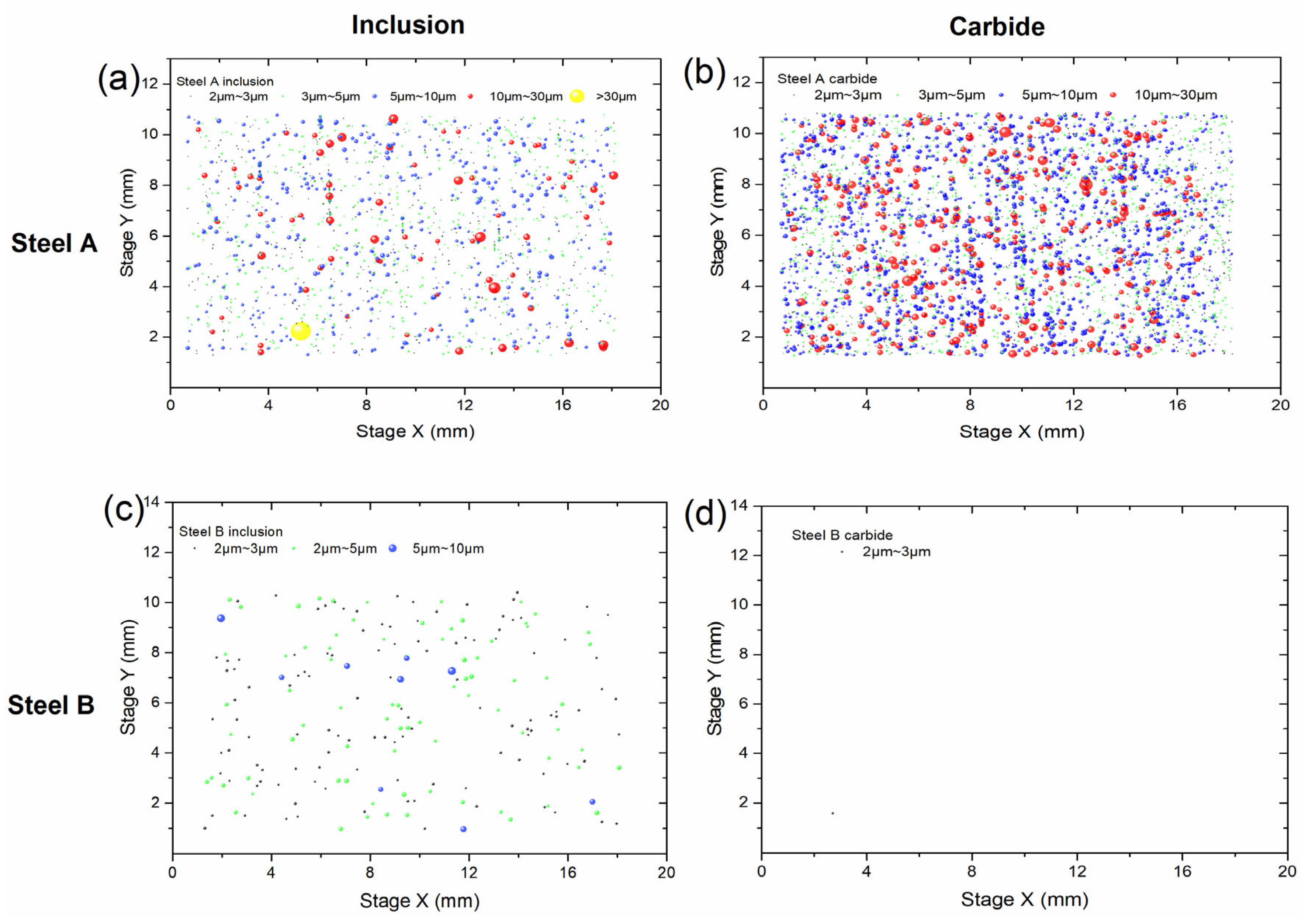

3.3. Characterization of Inclusion and Carbide Size

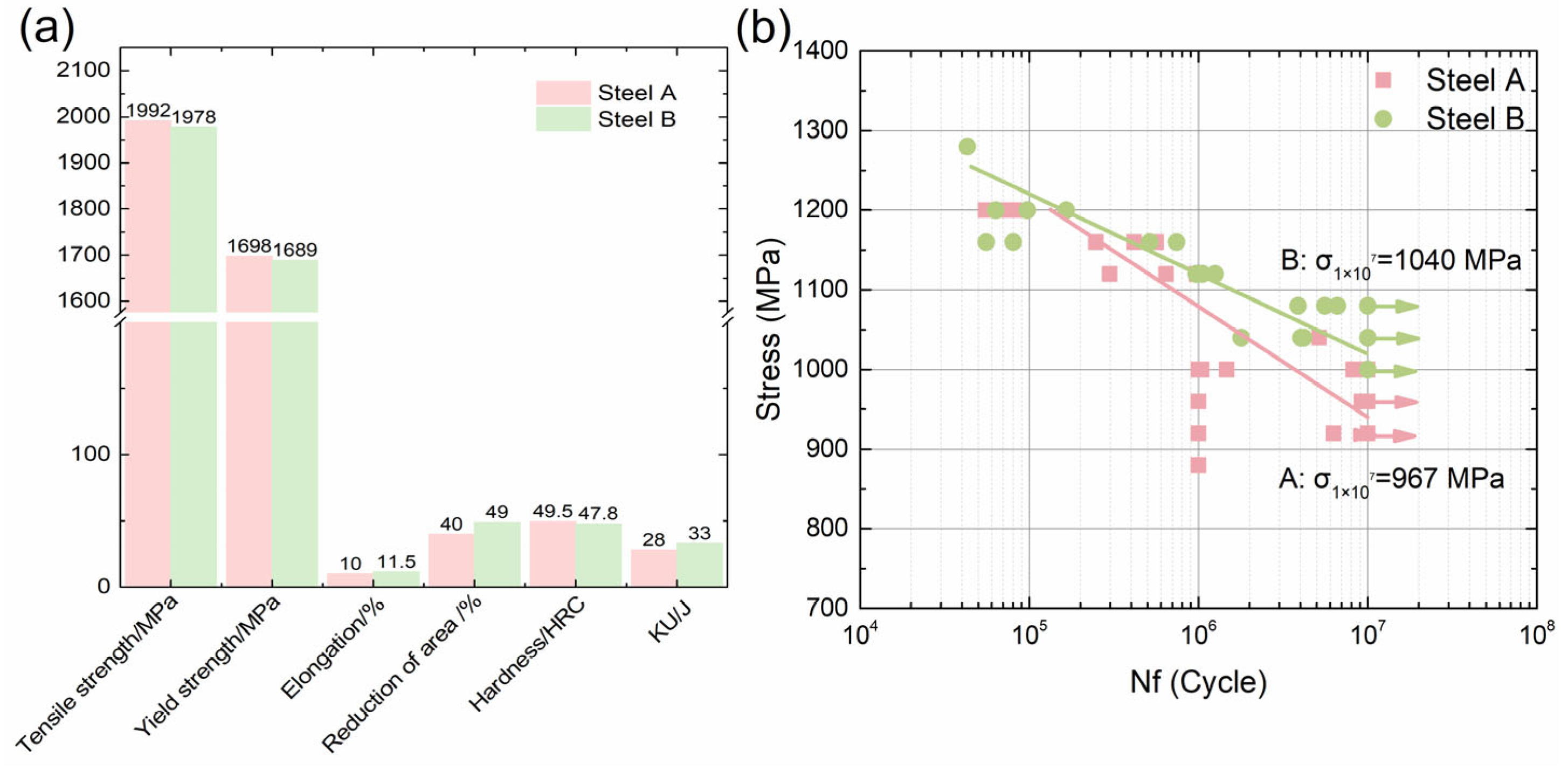

3.4. Mechanical Properties and Rotary Bending Fatigue Performance

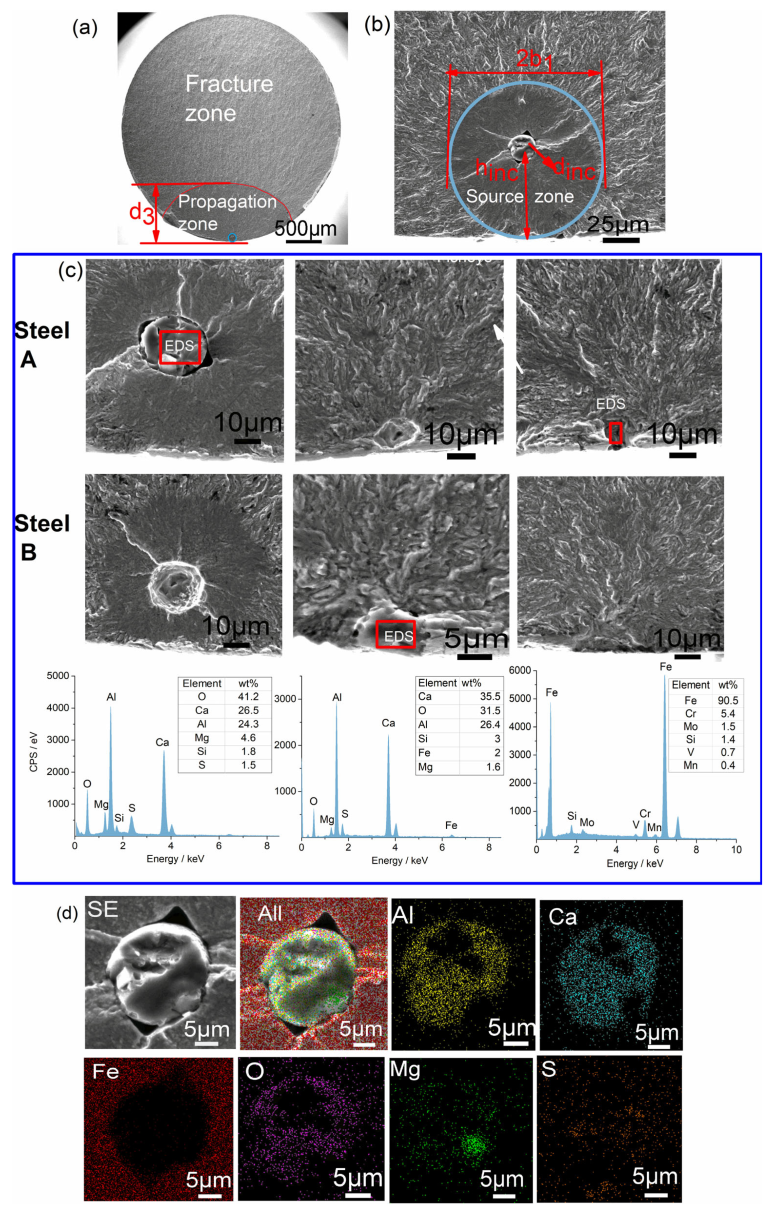

3.5. Characteristics of Rotary Bending Fatigue Fracture

4. Discussion

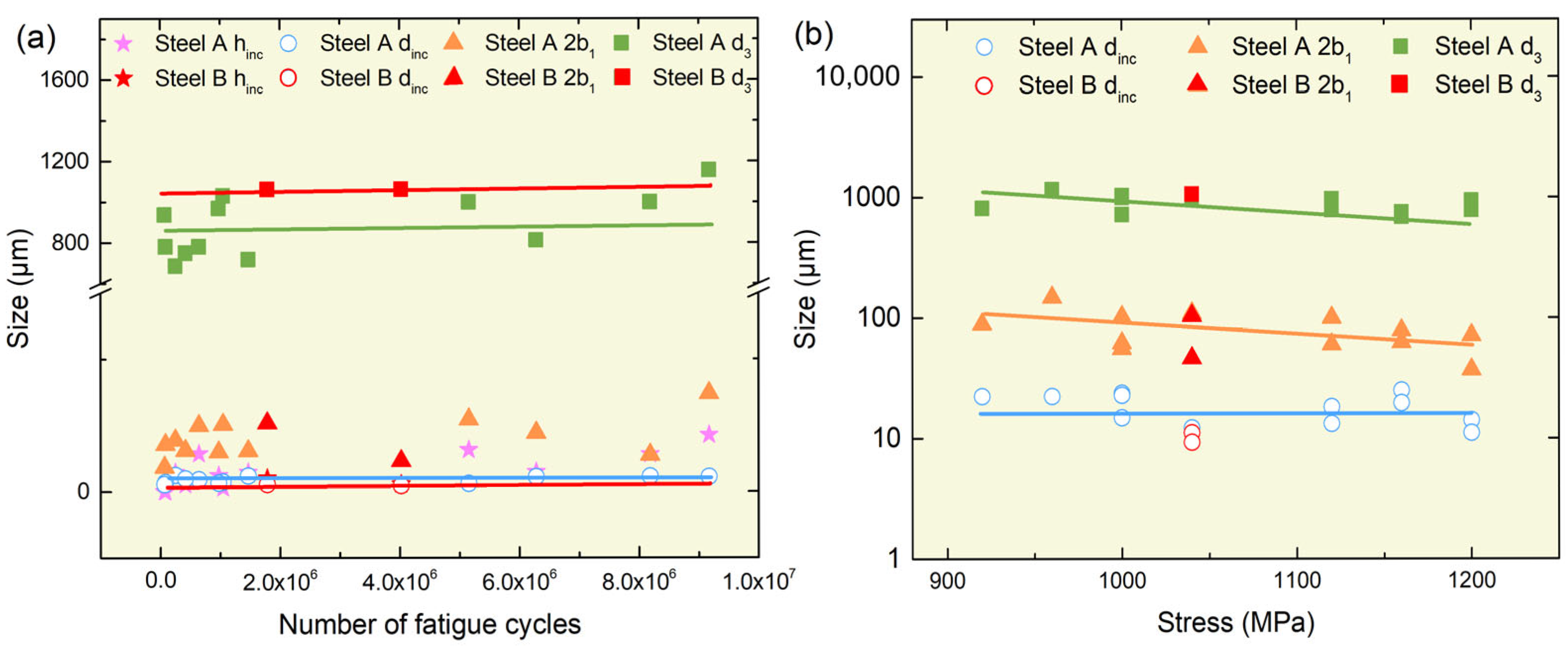

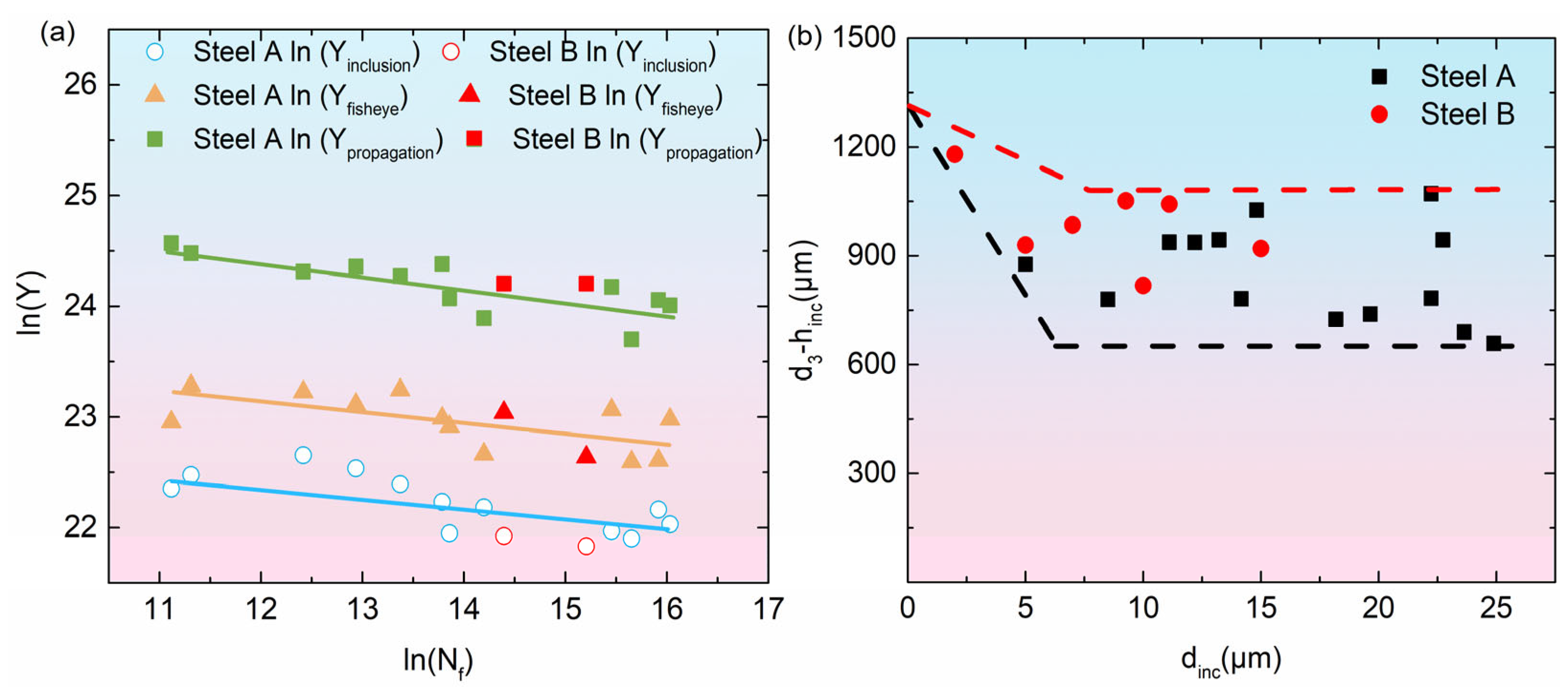

4.1. Relationship Between Fracture Characteristic Parameters, Fatigue Life, and Applied Stress

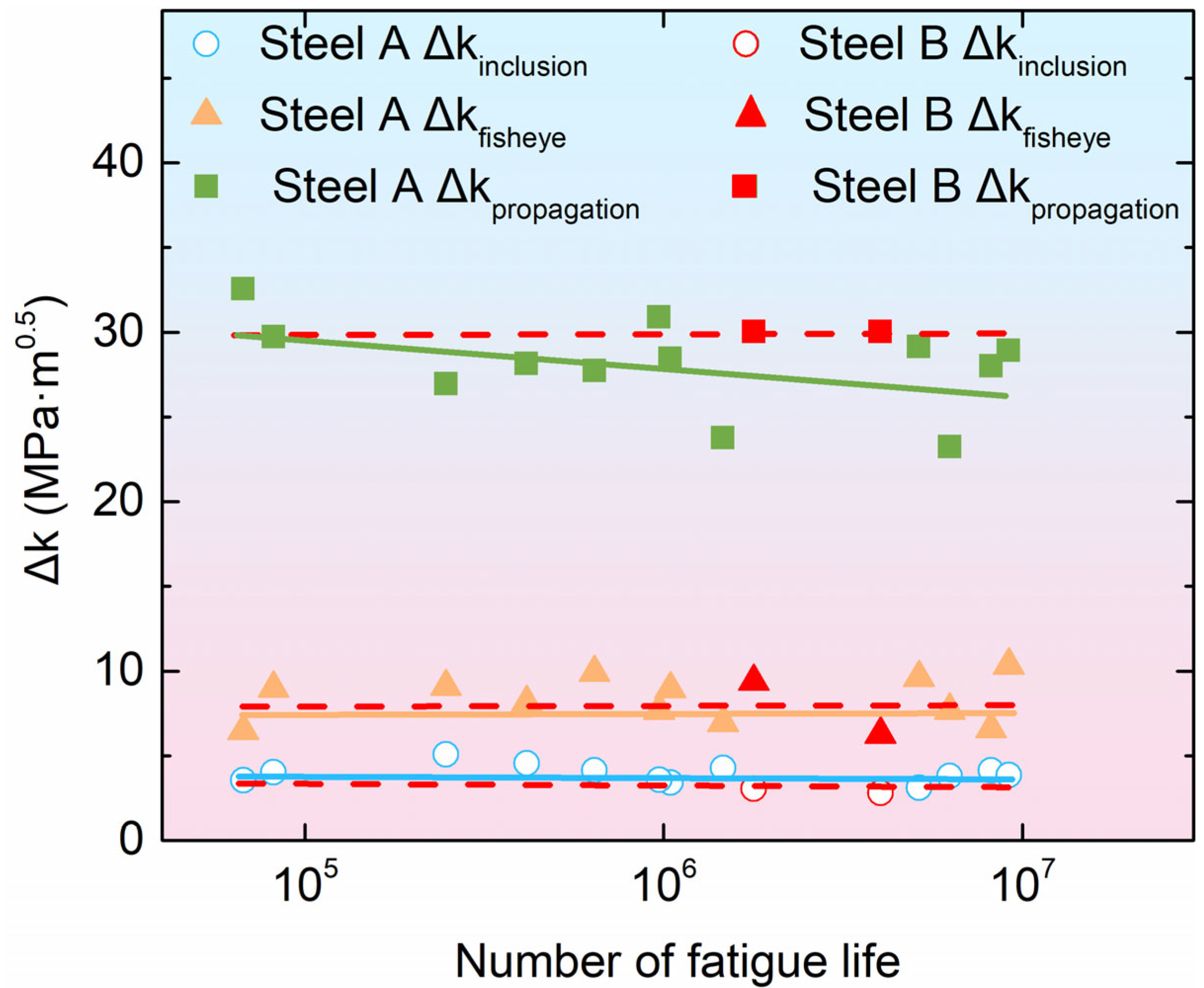

4.2. Fracture Mechanics of Crack Propagation

5. Conclusions

- H13 steels produced by electroslag remelting (ESR) and vacuum induction melting + vacuum arc remelting (VIM+VAR) exhibit similar grain size and microstructure. A comparison of the two samples reveals that they contain the same types of inclusions (composite inclusions of oxides and sulfides) and carbides (VC and M23C6). However, a significant disparity is observed in their distribution and size: ESR steel contains approximately four times more inclusions (>2 μm) and more than 20 times more carbides than VIM+VAR steel. The mean Feret diameter of inclusions/carbides was found to be approximately 4.5 μm in ESR steel and approximately 3 μm in VIM+VAR steel.

- The fatigue fracture surfaces of both steels exhibit four distinct zones: crack origin (inclusion), fisheye, propagation, and final fracture. Oxide sulfide composite inclusions have been observed to function as crack initiators, with fisheye size increasing in proportion to inclusion depth.

- The findings of the rotating bending fatigue tests and fracture parameter analysis suggest that the fatigue life of the material is predominantly influenced by the applied stress and the dimensions of the inclusion. It was observed that as the stress and the inclusion size increased, the life of the material decreased. It is found that ESR steel has numerous and large inclusions, and the crack propagation length is 18 μm~885 μm, while VIM+VAR steel has a few small inclusions, and the crack propagation length is 10 μm~1063 μm. The rotational bending strength and fatigue life of VIM+VAR steel are higher than ESR steel.

- Equations derived from the Paris law have been demonstrated to relate inclusion size to crack-tip stress intensity factor (KIC). The KIC of ESR steel is approximately 28 MPa·m0.5, whereas that of VIM+VAR steel is approximately 30 MPa·m0.5. It can explain the H13 steel fatigue fracture process. Moreover, the relationship between inclusion size, loading stress, and fatigue life is deduced. The formula is . It provides a basis for predicting the rotation bending fatigue life of H13 steel.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guan, C.J.; Han, Y.; Xiu, W.C.; Wang, Q.; Wu, H. Heat Treatment Process of H13 Die Steel for Precision Forged Gear. Heat Treat. Met. 2016, 41, 91–94. [Google Scholar]

- Qiu, C.; Wang, Z.; Gong, D. FEM and Experiment Study on Fatigue Life of H13 Hot-extruded Mandrel. Steel Pipe 2025, 54, 7–11. [Google Scholar] [CrossRef]

- Xiao, Z.; Yang, H.; Xu, R.; Liu, B.; Feng, J.; Ji, P.; Liang, J.; Liang, G. Modification of microstructure and mechanical properties in H13 steel by introducing oxide particles using vacuum casting. J. Mater. Res. Technol. 2024, 30, 3141–3151. [Google Scholar] [CrossRef]

- Du, X.; Liu, X.; Shen, Y.; Liu, R.; Wei, Y. H13 tool steel fabricated by wire arc additive manufacturing: Solidification mode, microstructure evolution mechanism and mechanical properties. Mater. Sci. Eng. A 2023, 883, 145536. [Google Scholar] [CrossRef]

- Çiçek, A.; Kara, F.; Kivak, T.; Ekici, E. Evaluation of machinability of hardened and cryo-treated AISI H13 hot work tool steel with ceramic inserts. Int. J. Refract. Met. Hard Mater. 2013, 41, 461–469. [Google Scholar] [CrossRef]

- Castro, G.; Fernández-Vicente, A.; Cid, J. Influence of the nitriding time in the wear behaviour of an AISI H13 steel during a crankshaft forging process. Wear 2007, 263, 1375–1385. [Google Scholar] [CrossRef]

- Lin, L.; Zeng, J.; Fu, J.; Wu, D.; Cheng, H.; Xia, Y. Experimental study of the wear behavior of tunnel boring machine disc cutter ring under Fe-based coatings. Wear 2024, 548, 205361. [Google Scholar] [CrossRef]

- Ren, J.; Tian, J.; Jiang, Z.; Wang, L.; Jiang, C. Effect of Mg–Ce Treatment on Cleanliness and Primary Carbides of H13 Hot Work Die Steel. Met. Mater. Trans. B 2025, 56, 5100–5115. [Google Scholar] [CrossRef]

- Wang, W.; Cheng, X.; Miao, X.; Ni, C.; Jia, H.; Liu, C.; Jiang, Q.; Ding, H.; Luo, R. Effect of Pre-tempering Process on Microstructure and Properties of H13 Steel. Mater. Mech. Eng. 2024, 48, 47–54. [Google Scholar] [CrossRef]

- Di, Y.; Ma, D.; Zhou, J.; Chi, H.; Gu, J. Effect of cryogenic treatment on microstructure and mechanical properties of H13 steel. Heat Treat. Met. 2024, 49, 38–42. [Google Scholar]

- Di, Y.; Ma, D.; Zhou, J.; Chi, H.; Gu, J. Characteristics of Non-metallic Inclusions in H13 Steel Produced by Different Smelting Processes and Their Effect on Mechanical Properties. Mater. Mech. Eng. 2024, 48, 69–75. [Google Scholar]

- Shi, Z.; Xu, H.; Xu, D.; Yu, F.; Wang, C.; Cao, W. Characterization of inclusions in GCrl5 bearing steel by ASPEX and rotary bending fatigue methods. Iron Steel 2019, 54, 55–62. [Google Scholar]

- Min, Y.-a.; Wu, X.-c.; Xu, L.-p.; Tang, W.-j.; Zhang, S.-k.; Wallner, G.; Liang, D.; Feng, Y.-y. Influence of different surface treatments of H13 hot work die steel on its thermal fatigue behaviors. J. Shanghai Univ. (Engl. Ed.) 2001, 5, 326–330. [Google Scholar] [CrossRef]

- Wang, B.; Zhao, X.; Li, W.; Qin, M.; Gu, J. Effect of nitrided-layer microstructure control on wear behavior of AISI H13 hot work die steel. Appl. Surf. Sci. 2018, 431, 39–43. [Google Scholar] [CrossRef]

- Kolomy, S.; Maly, M.; Doubrava, M.; Sedlak, J.; Zouhar, J.; Cupera, J. Effect of microstructure on machinability of extruded and conventional H13 tool steel. Mater. Des. 2025, 254, 114132. [Google Scholar] [CrossRef]

- Lin, H.; Zhou, H.; Zhu, G.; Fan, K.; Dai, X. Reverse identification and verification of J-C constitutive parameters of H13 steel united with finite element method. Ordnance Mater. Sci. Eng. [CrossRef]

- Dai, S.; Wu, B.; Liu, M.; Zhang, Z.; Li, J. Room Temperature Tensile Test and Simulative Study on Crystal Plasticity for H13 Steel. Shanghai Met. 2025, 47, 42~48+62. [Google Scholar] [CrossRef]

- Silvestri, A.; Squillace, A. Assessment of deposition strategy and overlap in laser-directed energy deposition of H13 tool steel. Prog. Addit. Manuf. 2025, 10, 11595–11610. [Google Scholar] [CrossRef]

- Zhou, H.; Li, R.; Li, N.; Li, T.; Luo, L.; Wang, B. Effect of Y2O3 Addition in Laser Cladding on the Thermal Fatigue of Stellite6 coated H13 Hot Forging Die Substrate Surface. China Surf. Eng. 2025, 38, 130–138. [Google Scholar]

- Shao, Y.; Wang, S.; Fang, L.; Tian, S.; Luo, J.; Zhang, Y.; Li, X.; Hu, Y.; Zhou, Z. Study on Microstructure and Properties of CrAIN/TiAIN Composite Coatings on H13 Steel. Guangzhou Chem. Ind. 2025, 53, 63–66. [Google Scholar]

- Liao, Y.; Shang, Y.; Li, Y.; Liu, Z.; Jiang, M.; Zhou, Z.; Gao, Y. Friction properties of H13 steel nitrocarburizing-modified by hollow cathode plasma source. Heat Treat. Met. 2025, 50, 325–331. [Google Scholar]

- Rao, D.S.; Muraleedharan, K.; Humphreys, C.J. TEM specimen preparation techniques. Microsc. Sci. Technol. Appl. Educ. 2010, 2, 1232–1244. [Google Scholar]

- Zhan, D.; Wang, J.; Qi, M.; Qiu, G.; Wang, D.; Qu, L.; Ma, J.; Li, C.; Zhang, H.; Jiang, Z. A Low-Temperature Electrolysis Extraction Carbide Refrigerator and Its Use Method: China. CN 109254064 B[P], 26 September 2023. [Google Scholar]

- GB/T 228.1-2021; Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature. State Administration for Market Regulation. Standardization Administration of the People’s Republic of China: Beijing, China, 2021.

- GB/T 4337-2025; Metallic Materials-Fatigue Testing-Rotating bar Bending Method. State Administration for Market Regulation. Standardization Administration of the People’s Republic of China: Beijing, China, 2025.

- Wang, J.; Xu, P.; Gao, S. Mechanical Engineering Materials; Tsinghua University Press: Beijing, China, 2016; pp. 50–60. [Google Scholar]

- Ban, J.; Shi, Z.; Yu, F.; Cao, W.; Guo, Y. Effect of double quenching on microstructure and properties of GCr15 bearing steel. Iron Steel 2022, 57, 114–122. [Google Scholar] [CrossRef]

- Yang, P. Electron Backscatter Diffraction Technique and Application; Metallurgical Industry Press: Beijing, China, 2007. [Google Scholar]

- Wang, Y.; Wang, M.; Shi, R.; Yao, L.; Jie, Z.; Wu, C. Effect of Oil Quenching and Tempering Treatment on the Microstructure and Mechanical Properties of H13 Steel. J. Netshape Form. Eng. 2025, 17, 167–179. [Google Scholar] [CrossRef]

- Ouyang, W.; Zhou, J.; Gao, P.; Chi, H.; Xie, G.; Wang, W. Effect of Nb Content on Dendrite Segregation and Carbide Composition and Morphology of H13 Steel. Mater. Mech. Eng. 2022, 46, 43–49. [Google Scholar] [CrossRef]

- Sun, X.; Wang, F.; Mao, M.; Chen, X.; Du, A.; Guo, H. Formation and affecting factors of V-rich carbides in H13 steel. Iron Steel 2018, 53, 68–75. [Google Scholar]

- Cao, Z.; Shi, Z.; Liang, B.; Zhang, X.; Cao, W.; Weng, Y. Melting route effects on the rotatory bending fatigue and rolling contact fatigue properties of high carbon bearing steel SAE52100. Int. J. Fatigue 2020, 140, 105854. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Zhang, Z.; Zhao, X.; Tong, D.; Yan, G.; Han, L.; Gu, J. Tailoring the microstructure and mechanical properties of H13 steel by controlling the pre-precipitation of VC carbides from austenite. J. Mater. Res. Technol. 2024, 33, 9614–9621. [Google Scholar] [CrossRef]

- Shiozawa, K.; Morii, Y.; Nishino, S. Subsurface crack initiation and propagation mechanism under the super-long fatigue regime for high speed tool steel (JIS SKH51) by fracture surface topographic analysis. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 2006, 49, 1–10. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Berard, J.Y.; Rathery, S.; Bathias, C. High cycle fatigue crack initiation and propagation behaviors of high strength spring steel wires. Fatigue Fract. Eng. Mater. Struct. 2003, 22, 673–677. [Google Scholar]

- Uesugi, T. Recent development of bearing steel in Japan. Iron Steel Inst. Jpn. Int. 1988, 28, 893–899. [Google Scholar] [CrossRef]

- Monnot, J.; Heritier, B.; Cogne, J.Y. Relationship of melting practice, inclusion type, and size with fatigue resistance of bearing steels. ASTM Spec. Tech. Publ. Eff. Steel Manuf. Process. Qual. Bear. Steels 1988, 1, 149–165. [Google Scholar]

- Shi, Z.-y.; Xu, H.-f.; Xu, D.; Yu, F.; Cao, W.-q. Effects of metallurgical craftwork on high bending fatigue performance of GCr15 steel during high cycle rotation. Iron Steel 2018, 53, 85–92. [Google Scholar] [CrossRef]

- Shiozawa, K.; Morii, Y.; Nishino, S.; Lu, L. Subsurface crack initiation and propagation mechanism in high cycle fatigue regime. Int. J. Fatigue 2006, 28, 1521. [Google Scholar] [CrossRef]

- Takai, K.; Homma, Y.; Izutsu, K.; Nagumo, M. Identification of trapping sites in high strength steels by secondary ion mass spectrometry for thermally desorbed hydrogen. J. Jpn. Institue Met. 1996, 60, 1155–1162. [Google Scholar] [CrossRef]

- Chapetti, M.D.; Tagawa, T.; Miyata, T. Ultra-long cycle fatigue of high strength carbon steels part II: Estimation of fatigue limit for failure from internal inclusions. Mater. Sci. Eng. A 2003, 356, 236–244. [Google Scholar] [CrossRef]

- Grad, P.; Reuscher, B.; Brodyanski, A.; Kopnarski, M.; Kerscher, E. Mechanism of fatigue crack initiation and propagation in the very high cycle fatigue regime of high-strength steels. Scr. Mater. 2012, 67, 838–841. [Google Scholar] [CrossRef]

- Che, X.; Yang, M.; Tang, H.; Li, J.; Pang, X.; Sun, Y. Inclusion control and fatigue performance in high performance GCr15 bearing steel. Iron Steel 2018, 53, 76–85. [Google Scholar]

- Sakai, T.; Oguma, N.; Morikawa, A. Microscopic and nanoscopic observations of metallurgical structures around inclusions at interior crack initiation site for a bearing steel in very high-cycle fatigue. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1305–1314. [Google Scholar] [CrossRef]

- Spriestersbach, D.; Brodyanski, A.; Lösch, J.; Kopnarski, M.; Kerscher, E. Very high cycle fatigue of bearing steels with artificial defects in vacuum. Mater. Sci. Technol. 2016, 32, 1111. [Google Scholar] [CrossRef]

- Chen, D.; Zhang, X.; Meng, X.; Ma, R.; Li, R.; Wang, Z.; Su, B.; Lang, D.; Yang, T.; Meng, D. Mechanisms of void formation during uniaxial tensile testing in a low-temperature-aged U-Nb alloy. Mater. Sci. Eng. A 2008, 723, 182–193. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, S. Advanced Fracture Mechanics; Science Press: Beijing, China, 2009; p. 24. [Google Scholar]

- Cheng, J.; Zhao, S. Fracture Mechanics; Science Press: Beijing, China, 2006; p. 21. [Google Scholar]

- Wang, P. Investigation on High Cycle Fatigue Damage Mechanism and Fatigue Performance Optimization of GCr15 Bearing Steels. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2023. [Google Scholar]

- Shah, M.; Ali, M.; Sultan, A.; Mujahid, M.; Mehmood, H.; Dar, N.U.; Shuaib, M. An Investigation into the Fatigue Crack Growth Rate of Electron Beam-Welded H13 Tool Steel: Effect of Welding and Post-Weld Heat Treatment. Metallogr. Microstruct. Anal. 2014, 3, 114–125. [Google Scholar] [CrossRef]

- Hou, R. Effect of Plasma Enhanced Diffusion Treatment at Low Temperature on the Microstructure and Property of H13 Steel. Bachelor’s Thesis, South China University of Technology, Guangzhou, China, 2021. [Google Scholar]

- Okorafor, O.E. Fracture toughness of M2 and H13 alloy tool steels. Mater. Sci. Technol. 1987, 3, 118–124. [Google Scholar] [CrossRef]

- Deirmina, F.; Amirabdollahian, S.; Pellizzari, M.; Molinari, A. Effect of Different Post-Processing Thermal Treatments on the Fracture Toughness and Tempering Resistance of Additively Manufactured H13 Hot-Work Tool Steel. Metals 2024, 14, 112. [Google Scholar] [CrossRef]

- Lu, L.; Li, W.; Zhang, J.; Shiozawa, K.; Zhang, W. Analysis of rotary bending gigacycle fatigue properties of bearing steel GCr15. Acta Metall. Sin. 2009, 45, 73–78. [Google Scholar]

- Bathias, C. Fatigue of Materials and Structures; National Defense Industry Press: Beijing, China, 2016. [Google Scholar]

| C | Si | Mn | P | S | Cr | Mo | V | Ti | T.O | N | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Steel A | 0.42 | 1.14 | 0.41 | 0.016 | 0.0009 | 4.96 | 1.36 | 0.98 | 0.0095 | 0.0016 | 0.015 |

| Steel B | 0.38 | 1.09 | 0.38 | 0.005 | 0.0006 | 5.10 | 1.31 | 0.93 | 0.0100 | 0.0008 | 0.001 |

| Steel | Precipitate | Crystal System | Lattice Constant (nm) | Element Content in Different Phases of Steel (Mass Fraction, %) | ||||

|---|---|---|---|---|---|---|---|---|

| Cr | Fe | Mo | V | Σ | ||||

| A | MC | FCC | a0 = 0.417 | 0.193 | 0.049 | 0.135 | 0.799 | 1.176 |

| M23C6 | FCC | a0 = 1.070 | 0.732 | 0.178 | 0.054 | 0.046 | 1.010 | |

| B | MC | FCC | a0 = 0.417 | 0.187 | 0.043 | 0.137 | 0.774 | 1.141 |

| M23C6 | FCC | a0 = 1.070 | 0.729 | 0.196 | 0.047 | 0.043 | 1.015 | |

| Specimen | Average Feret Size (μm) | Aspect (Feret Max/Feret Min) | Density (Features/mm2) | Index * (%) | |

|---|---|---|---|---|---|

| A | Inclusion | 4.5 | 1.4 | 8 | 0.01183 |

| Carbide | 4.6 | 1.7 | 26 | 0.02282 | |

| B | Inclusion | 3.0 | 1.4 | 2 | 0.00080 |

| Carbide | 2.9 | 1.7 | 0 | 0.00003 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Ma, D.; Zhang, S.; Sun, X.; Li, Y.; Zhang, Z.; Zhong, Z. Effect of Metallurgical Process on Rotational Bending Fatigue Properties of H13 Hot Work Die Steel. Materials 2025, 18, 5655. https://doi.org/10.3390/ma18245655

Li Y, Ma D, Zhang S, Sun X, Li Y, Zhang Z, Zhong Z. Effect of Metallurgical Process on Rotational Bending Fatigue Properties of H13 Hot Work Die Steel. Materials. 2025; 18(24):5655. https://doi.org/10.3390/ma18245655

Chicago/Turabian StyleLi, Yunling, Dangshen Ma, Shulan Zhang, Xiaofei Sun, Yuan Li, Zijian Zhang, and Zhenqian Zhong. 2025. "Effect of Metallurgical Process on Rotational Bending Fatigue Properties of H13 Hot Work Die Steel" Materials 18, no. 24: 5655. https://doi.org/10.3390/ma18245655

APA StyleLi, Y., Ma, D., Zhang, S., Sun, X., Li, Y., Zhang, Z., & Zhong, Z. (2025). Effect of Metallurgical Process on Rotational Bending Fatigue Properties of H13 Hot Work Die Steel. Materials, 18(24), 5655. https://doi.org/10.3390/ma18245655