Enhancement of Rheological Performance and Smoke Suppression in Sepiolite-Modified Asphalt

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Asphalt

2.1.2. Sepiolite and Modification Treatment

2.2. Methods

2.2.1. Characterization of Sepiolite Microstructure

2.2.2. Preparation of Sepiolite-Modified Asphalt

2.2.3. Physical and Rheological Property Tests

2.2.4. Analysis of Asphalt Fume Components

2.2.5. Analysis of Microscopic Interaction Mechanisms

3. Results and Discussion

3.1. Characterization of Sepiolite Microstructure

3.2. Selection of Sepiolite Type

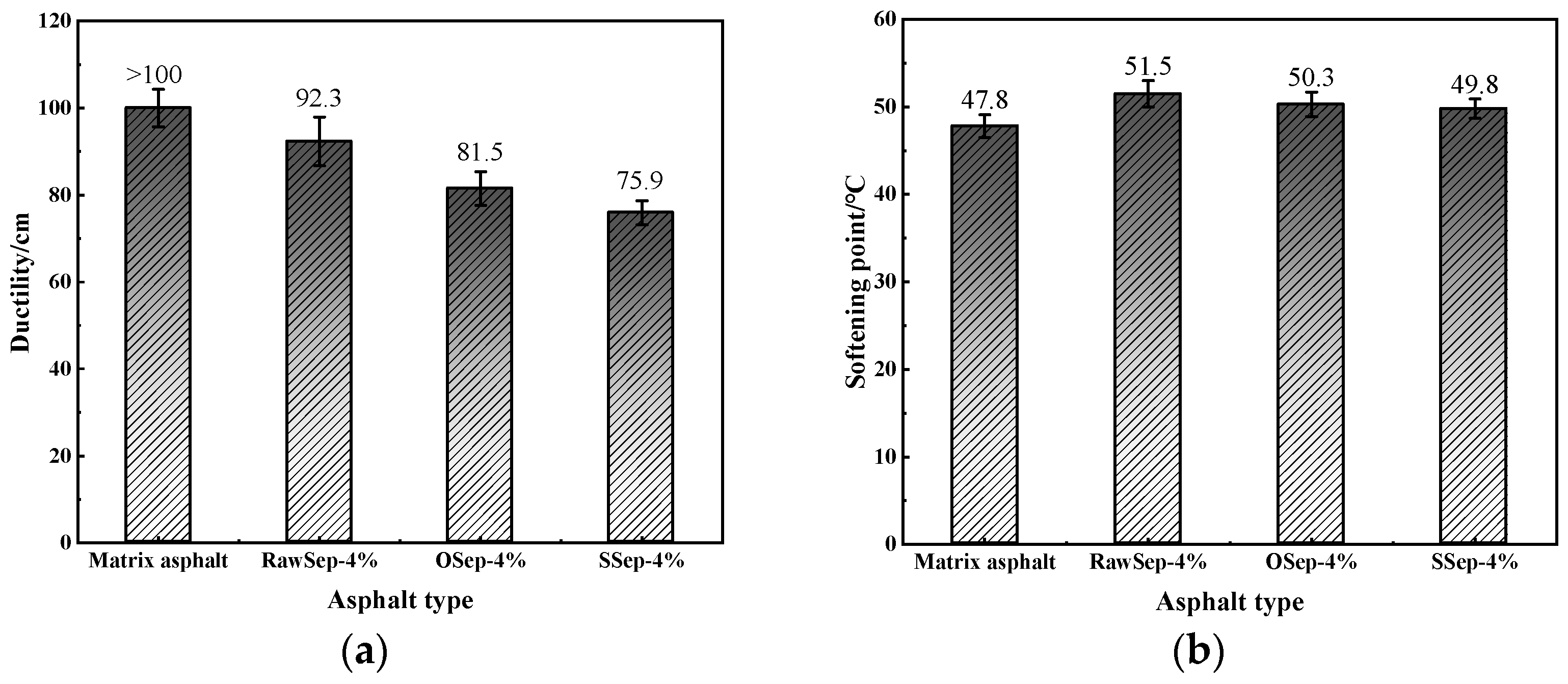

3.2.1. Comparison of Physical Properties

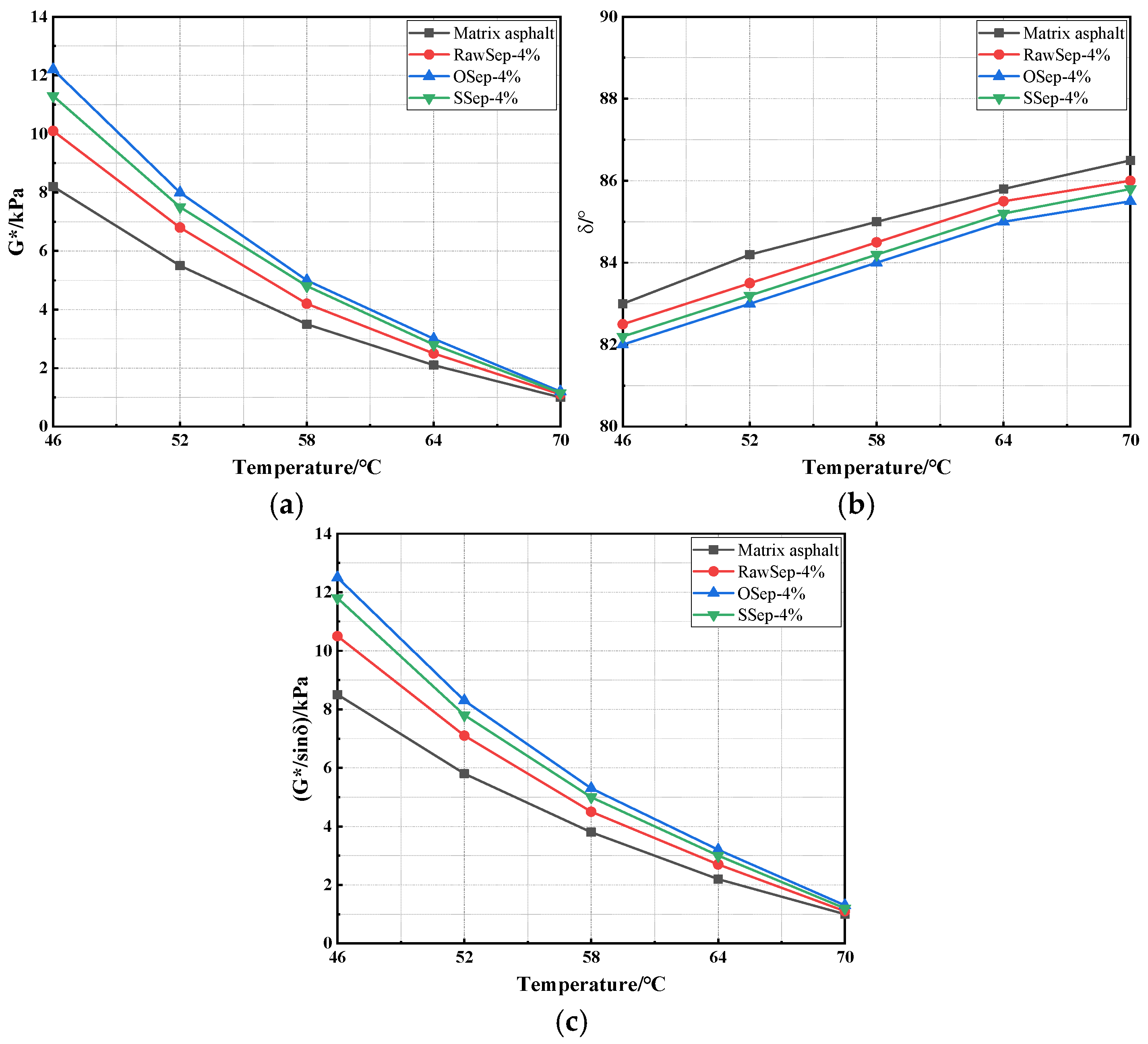

3.2.2. Comparison of Rheological Properties

3.3. Rheological Properties of Sepiolite-Modified Asphalt

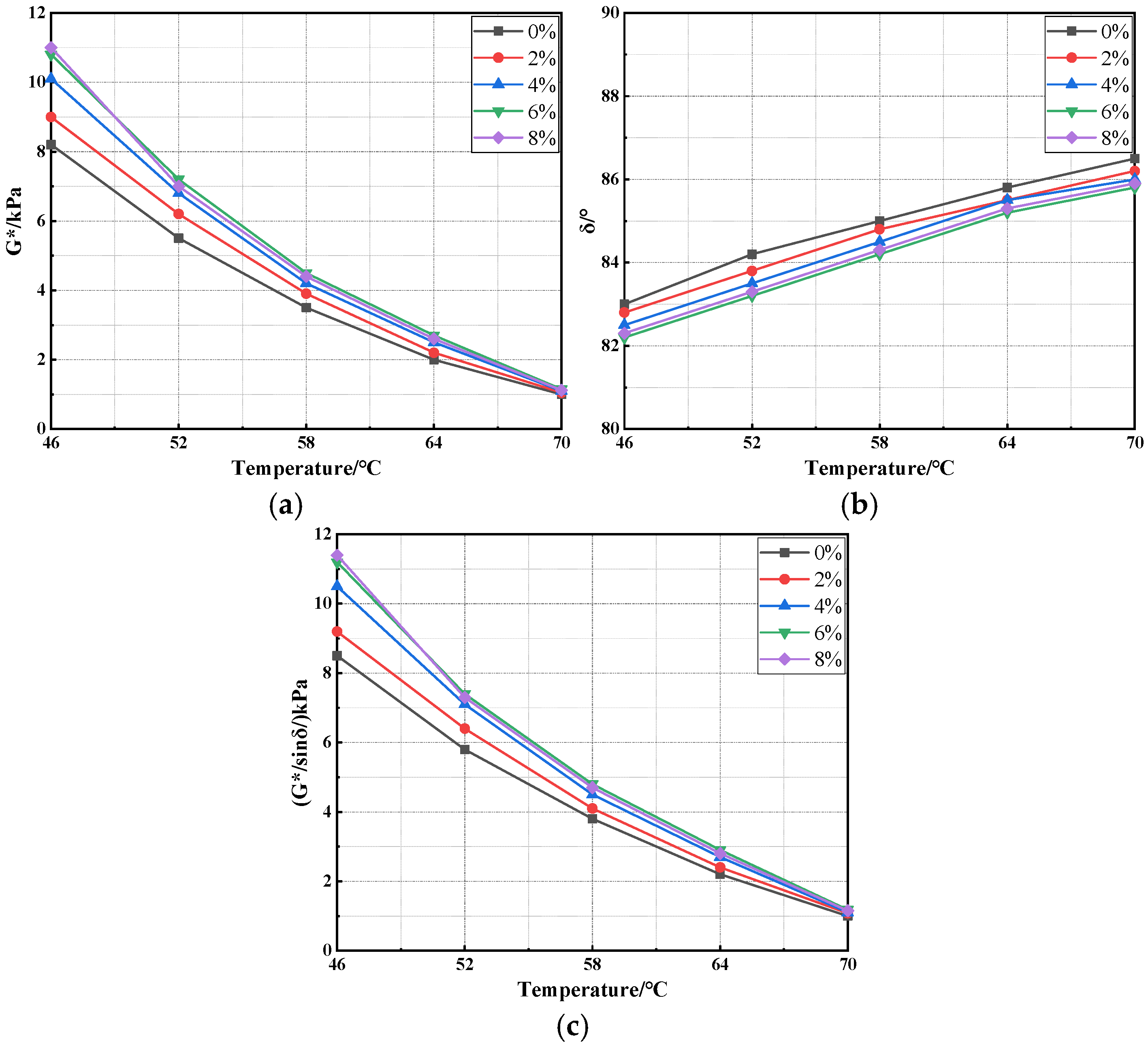

3.3.1. High-Temperature Rutting Resistance

3.3.2. Resistance to Permanent Deformation

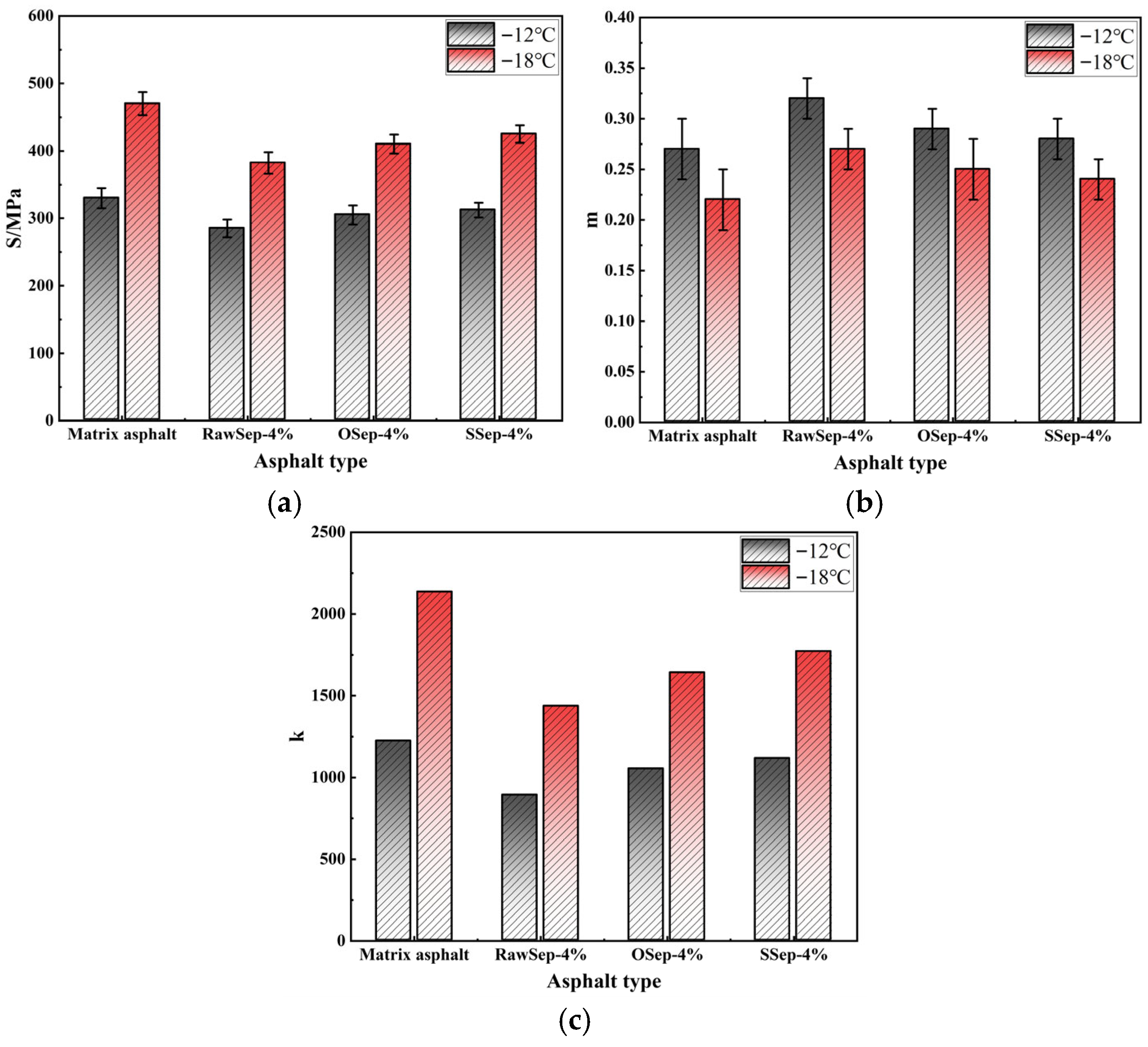

3.3.3. Low-Temperature Cracking Resistance

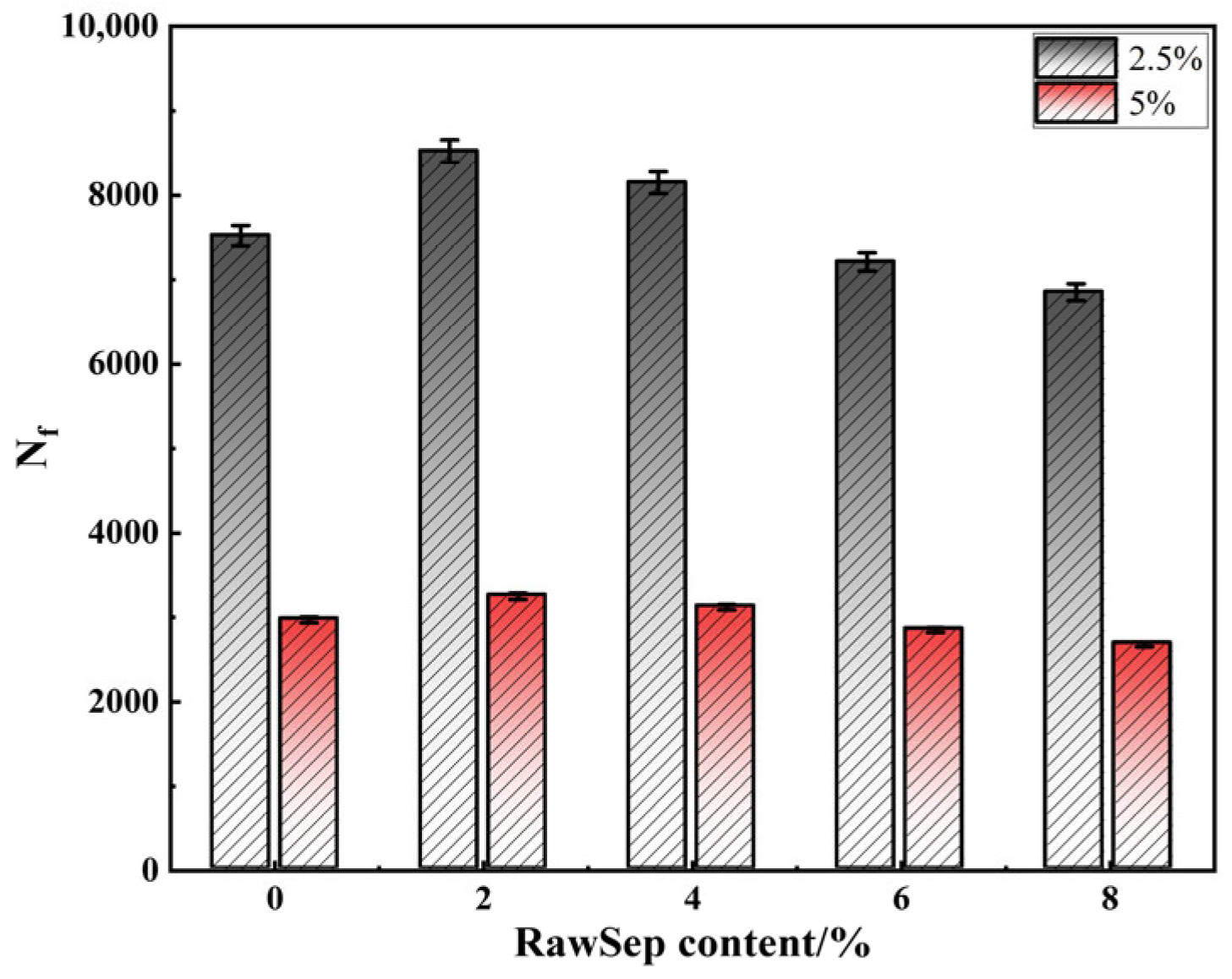

3.3.4. Fatigue Damage Resistance

3.4. Analysis of Fume Components in RawSep-Modified Asphalt

3.5. Microscopic Interaction Mechanism Between RawSep and Asphalt

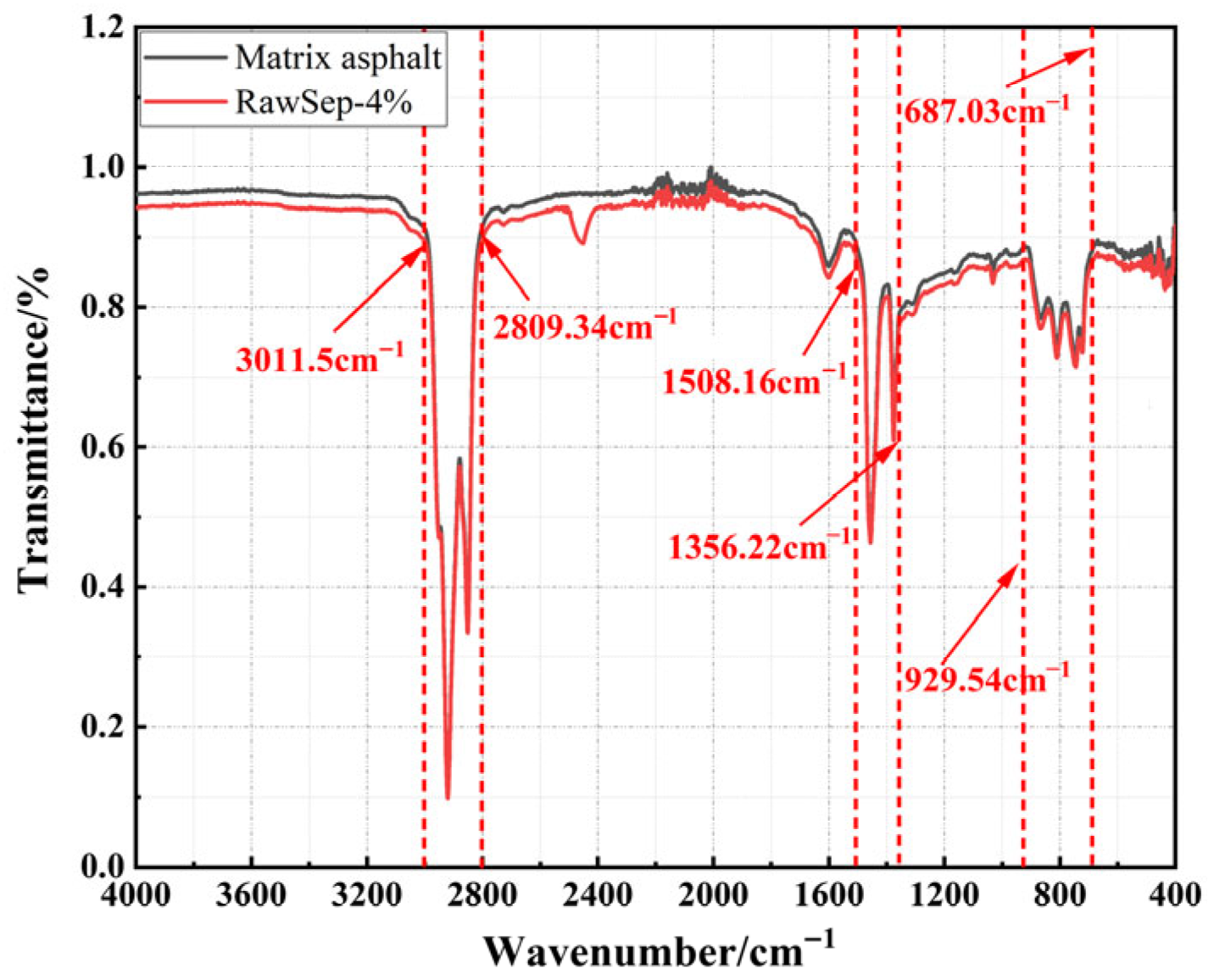

3.5.1. FTIR Analysis

3.5.2. GPC Analysis

4. Conclusions

- (1)

- RawSep exhibited the best compatibility with asphalt. Although the specific surface areas of OSep and SSep increased by 43–45% after modification, the high–low temperature coordination of the modified asphalt decreased by 10–15%, indicating that the optimization of sepiolite microstructure must be coupled with the compatibility of the asphalt matrix.

- (2)

- Sepiolite dosage had a significant impact on the high-temperature rutting and permanent deformation resistance of asphalt. At dosages of 4–6%, the rutting factor increased by 25–30%, resulting in the best high-temperature deformation resistance. Insufficient dispersion at low dosages and particle agglomeration at high dosages both hinder performance improvement.

- (3)

- The 4% RawSep-modified asphalt exhibited the best low-temperature cracking resistance. At this dosage, the creep stiffness decreased by more than 15%. Poor dispersion at low dosages failed to mitigate asphalt brittleness, whereas high dosages caused fiber agglomeration and the formation of rigid particles, which aggravated low-temperature cracking.

- (4)

- Sepiolite at dosages of 2–4% effectively improved the fatigue life of asphalt by 9–13%. The most significant enhancement occurred at 2%, where the stress-dissipation effect of sepiolite delayed damage accumulation. At higher dosages, agglomerated particles acted as stress concentrators, accelerating fatigue failure.

- (5)

- The 4% RawSep-modified asphalt demonstrated the most effective suppression of characteristic pollutants in asphalt fumes. The emissions of aliphatic and aromatic hydrocarbons were significantly reduced, leading to a 12–18% decrease in toxic fume emissions. The porous structure of sepiolite adsorbed 3–5% of light volatile compounds, while its metal oxides inhibited the release of aliphatic and aromatic hydrocarbons.

- (6)

- FTIR and GPC analyses revealed that the interaction between sepiolite and asphalt was dominated by physical adsorption, without chemical functional group recombination. The fibrous network of sepiolite enhanced the structural stability of asphalt, while the adsorption of small- and medium-molecular components optimized the molecular weight distribution. These microstructural effects supported the macroscopic improvements in performance and fume suppression.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, W.; Li, Z.; Zhang, H. Total Quality Management and Evaluation: A Study of the Coastal Highway System. J. Coast. Res. 2019, 98, 407–413. [Google Scholar] [CrossRef]

- Yuan, M.; Mai, J.; Liu, X.; Shen, H.; Wang, J. Current Implementation and Development Countermeasures of Green Energy in China’s Highway Transportation. Sustainability 2023, 15, 3024. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, H.; Li, Q.; Wang, Z.; Jin, D. Influence of different aged RAPs on the long-term performance of emulsified asphalt cold recycled mixture. Constr. Build. Mater. 2025, 458, 139680. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, H.; Guo, H.; Wu, C.; Wei, C. Effect of gradations on the final and long-term performance of asphalt emulsion cold recycled mixture. J. Clean. Prod. 2019, 217, 95–104. [Google Scholar] [CrossRef]

- Hao, Y.; Hu, L.; Cheng, G.; Ma, F.; Jiang, X.; Dai, J.; Xing, Z.; Jia, M. Study on the thermal regulation performance of steel slag ultra-thin wearing courses combined with phase change materials: Towards green and low-carbon applications. Constr. Build. Mater. 2025, 478, 141426. [Google Scholar] [CrossRef]

- Peng, B.; Tong, X.; Cao, S.; Li, W.; Xu, G. Carbon emission calculation method and low-carbon technology for use in expressway construction. Sustainability 2020, 12, 3219. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, C.; Wen, P.; Wang, M.; Zhao, J. Comprehensive performance evaluation of low-carbon modified asphalt based on efficacy coefficient method. J. Clean. Prod. 2018, 203, 633–644. [Google Scholar] [CrossRef]

- Diao, H.; Luo, K.; Kuang, W.; Gao, Y.; Ling, T.; Peng, B.; Yang, Y.; Shi, W. Graphite phase carbon nitride enhances aging resistance of SBS warm mix asphalt and mixtures. Constr. Build. Mater. 2025, 484, 141852. [Google Scholar] [CrossRef]

- Leiva, F.; Yaede, J. Low carbon asphalt pavement alternative for parking lots. Int. J. Pavement Eng. 2024, 25, 2433617. [Google Scholar] [CrossRef]

- Chen, S.; Wang, Y.; He, X.; Su, Y.; Cao, Y.; Yang, C.; Duan, X. Mechanically activated shell powder modified asphalt and its aging resistance enhancement. Case Stud. Constr. Mater. 2024, 21, e04023. [Google Scholar] [CrossRef]

- Li, X.; Wu, S.; Wang, F.; You, L.; Yang, C.; Cui, P.; Zhang, X. Quantitative assessments of GHG and VOCs emissions of asphalt pavement contained steel slag. Constr. Build. Mater. 2023, 369, 130606. [Google Scholar] [CrossRef]

- Cheng, L.; Zhang, L.; Zhang, F.; Zhang, D.; Ma, Y. Evaluation of the effects of asphalt binder aging degree on the curing, compatibility, and mechanical behaviors of epoxy asphalt binders. Constr. Build. Mater. 2023, 377, 131131. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, S.; Liu, Q.; Xie, J.; Yang, C.; Wang, F.; Wan, P. Recycling waste disposable medical masks in improving the performance of asphalt and asphalt mixtures. Constr. Build. Mater. 2022, 337, 127621. [Google Scholar] [CrossRef]

- Autelitano, F.; Giuliani, F. Analytical assessment of asphalt odor patterns in hot mix asphalt production. J. Clean. Prod. 2018, 172, 1212–1223. [Google Scholar] [CrossRef]

- Sun, G.; Ning, W.; Jiang, X.; Qiu, K.; Cao, Z.; Ding, Y. A comprehensive review on asphalt fume suppression and energy saving technologies in asphalt pavement industry. Sci. Total Environ. 2024, 913, 169726. [Google Scholar] [CrossRef]

- Mo, S.; Wang, Y.; Xiong, F.; Ai, C. Effects of asphalt source and mixing temperature on the generated asphalt fumes. J. Hazard. Mater. 2019, 371, 342–351. [Google Scholar] [CrossRef]

- You, Z.; Mills-Beale, J.; Foley, J.M.; Roy, S.; Odegard, G.M.; Dai, Q.; Goh, S.W. Nanoclay-modified asphalt materials: Preparation and characterization. Constr. Build. Mater. 2011, 25, 1072–1078. [Google Scholar] [CrossRef]

- Yu, J.; Zeng, X.; Wu, S.; Wang, L.; Liu, G. Preparation and properties of montmorillonite modified asphalts. Mater. Sci. Eng. A 2007, 447, 233–238. [Google Scholar] [CrossRef]

- Ouyang, C.; Wang, S.; Zhang, Y.; Zhang, Y. Thermo-rheological properties and storage stability of SEBS/kaolinite clay compound modified asphalts. Eur. Polym. J. 2006, 42, 446–457. [Google Scholar] [CrossRef]

- Ouyang, C.; Wang, S.; Zhang, Y.; Zhang, Y. Preparation and properties of styrene–butadiene–styrene copolymer/kaolinite clay compound and asphalt modified with the compound. Polym. Degrad. Stab. 2005, 87, 309–317. [Google Scholar] [CrossRef]

- Huang, G.; Lv, Y.; Qi, T.; Zhou, J.; Zhou, C.; Zhang, X.; Tian, X.; Kang, T.; Du, T. Study on preparation and properties of sepiolite/SBR composite modified emulsified asphalt. Mater. Struct. 2025, 58, 108. [Google Scholar] [CrossRef]

- Li, S.; Liu, Q.; Wang, H.; Wang, J.; He, L.; Wu, S. Effect of kaolin and sepiolite on fume emissions of rubber modified asphalt. Constr. Build. Mater. 2024, 416, 135276. [Google Scholar] [CrossRef]

- Xing, X.; Chen, S.; Li, Y.; Pei, J.; Zhang, J.; Wen, Y.; Li, R.; Cui, S. Effect of different fibers on the properties of asphalt mastics. Constr. Build. Mater. 2020, 262, 120005. [Google Scholar] [CrossRef]

- Yang, H.; Cao, S.; Cui, X.; Xi, Z.; Cai, J.; Yuan, Z.; Zhang, J.; Xie, H. Viscosity, morphology, and thermomechanical performance of attapulgite-reinforced bio-based polyurethane asphalt composites. Polymers 2025, 17, 2045. [Google Scholar] [CrossRef] [PubMed]

- Uncu, D.; Topal, A.; Seydibeyoğlu, Ö. Preparation and Performance Testing of SBS Modified Bitumens Reinforced with Halloysite and Sepiolite Nanoclays. Tek. Dergi 2022, 33, 11661–11680. [Google Scholar] [CrossRef]

- Sun, X.; Qin, X.; Li, S.; Zou, C.; Wang, C.; Wang, X. Characterization of thermal insulating micro-surfacing modified by inorganic insulating material. Constr. Build. Mater. 2018, 175, 296–306. [Google Scholar] [CrossRef]

- Barral, M.; Garmendia, P.; Muñoz, M.E.; Palmillas, Z.; Romera, R.; Santamaria, A.; Villanueva, S. Novel bituminous mastics for pavements with improved fire performance. Constr. Build. Mater. 2012, 30, 650–656. [Google Scholar] [CrossRef]

- Bohn, K.A.; Thives, L.P.; Specht, L.P. Physical, rheological, and permanent deformation behaviors of WMA-RAP asphalt binders. Sustainability 2023, 15, 13737. [Google Scholar] [CrossRef]

- Abualia, A.; Akentuna, M.; Mohammad, L.N.; Cooper, S.B., III; Cooper, S.B., Jr. Improving Asphalt Binder Durability Using Sustainable Materials: A Rheological and Chemical Analysis of Polymer-, Rubber-, and Epoxy-Modified Asphalt Binders. Sustainability 2024, 16, 5379. [Google Scholar] [CrossRef]

- JTG E20–2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. People’s Traffic Press: Beijing, China, 2011.

- Yin, P.; Ong, G.P.; Pan, B.; Li, Z.; Sha, D. Effect of Phosphogypsum Whiskers as a Sustainability Modifier on the Performance of Asphalt and Asphalt Mixtures: Insights from an Organic Coating Method. J. Mater. Civ. Eng. 2025, 37, 04025022. [Google Scholar] [CrossRef]

- Mazalan, N.A.A.; Satar, M.K.I.M.; Mohamed, A.; Warid, M.N.M. Rheological properties of asphaltene-modified asphalt binder and mastic. Phys. Chem. Earth Parts A/B/C 2023, 131, 103422. [Google Scholar] [CrossRef]

- Wang, M.; Xing, C. Evaluation of microstructural features of Buton rock asphalt components and rheological properties of pure natural asphalt modified asphalt. Constr. Build. Mater. 2021, 267, 121132. [Google Scholar] [CrossRef]

- Zhang, H.; Lv, S.; Pang, J.; Chen, J.; Xuan, W.A. Effects of aging on rheological properties and microstructural evolution of SBS modified asphalt and crumb rubber modified asphalt binders. Buildings 2024, 14, 1722. [Google Scholar] [CrossRef]

- AASHTO TP 70; Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). AASHTO: Washington, DC, USA, 2013.

- Meng, Y.; Qin, P.; Yaseen, M.; Chen, J.; Yan, T.; Gan, W.; Lei, J.; Li, J. Effect of tannic acid modified bamboo fiber on the performance of soybean bio-asphalt/styrene-butadiene-styrene modified asphalt. Polym. Compos. 2022, 43, 2288–2302. [Google Scholar] [CrossRef]

- Manfro, A.L.; Melo, J.V.S.; Barra, B.S. Phase Stability Evaluation of Highly Modified Asphalt with High Vinyl Content Copolymer. J. Test. Eval. 2024, 52, 2306–2334. [Google Scholar] [CrossRef]

- AASHTO T 313; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). AASHTO: Washington, DC, USA, 2019.

- Wu, S.; Xu, W.; Zhang, F.; Wu, H. Effect of polyurethane on high-and low-temperature performance of graphene oxide-modified asphalt and analysis of the mechanism based on infrared spectrum. Coatings 2022, 12, 590. [Google Scholar] [CrossRef]

- Li, S.; Xu, W.; Zhang, F.; Wu, H.; Zhao, P. Effect of graphene oxide on the low-temperature crack resistance of polyurethane–SBS-modified asphalt and asphalt mixtures. Polymers 2022, 14, 453. [Google Scholar] [CrossRef]

- Yue, J.; Fu, J.; Wang, Y.; Ming, Y.; Tang, G.; Li, R. Effects of Complex Environmental Conditions on Fatigue Self-Healing Properties of Fast-Melting SBS-Modified Asphalt. Materials 2025, 18, 2157. [Google Scholar] [CrossRef]

- Fatemi, S.; Saadatjoo, S.A.; Babagoli, R.; Bazaz, J.B. Rheological evaluation of asphalt binder modified by amorphous poly alpha olefin (APAO). Constr. Build. Mater. 2022, 314, 125371. [Google Scholar] [CrossRef]

- Kong, L.; Wang, Z.; Su, S.; Yue, J.; Luo, W.; Zhou, S.; Ren, D.; Ai, C. Exploring the interplay between thermo-oxidative degradation and asphalt aging in thermoplastic polyurethane-modified asphalt: Mechanisms, properties, and performance evolution. Constr. Build. Mater. 2024, 412, 134694. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, W.; Han, D.; Guo, H.; Peng, X.; Zhu, W.; Xie, N.; Zuo, X.; Zhang, H.; Pan, Q.; et al. Laboratory investigation of modified asphalt containing buton rock asphalt or ash from buton rock asphalt. Case Stud. Constr. Mater. 2023, 18, e02124. [Google Scholar] [CrossRef]

- Zeng, G.; Shen, A.; Lyu, Z.; Kang, C.; Cui, H.; Ren, G.; Yue, G. Research on anti-aging properties of POE/SBS compound-modified asphalt in high-altitude regions. Constr. Build. Mater. 2023, 376, 131060. [Google Scholar] [CrossRef]

- Ghuzlan, K.A.; Al Assi, M.O. Sasobit-modified asphalt binder rheology. J. Mater. Civ. Eng. 2017, 29, 04017142. [Google Scholar] [CrossRef]

- Fan, G.; Zhang, N.; Lv, S.; Cabrera, M.B.; Yuan, J.; Fan, X.; Liu, H. Correlation analysis of chemical components and rheological properties of asphalt after aging and rejuvenation. J. Mater. Civ. Eng. 2022, 34, 04022303. [Google Scholar] [CrossRef]

- Kumar, A.; Choudhary, R.; Kandhal, P.S.; Julaganti, A.; Behera, O.P.; Singh, A.; Kumar, R. Fatigue characterisation of modified asphalt binders containing warm mix asphalt additives. Road Mater. Pavement Des. 2020, 21, 519–541. [Google Scholar] [CrossRef]

- Aurilio, M.; Tavassoti, P.; Elwardany, M.; Baaj, H. Impact of Styrene-Butadiene-Styrene (SBS) content on asphalt Binder’s fatigue resistance at various aging levels using Viscoelastic Continuum Damage and fracture mechanics. Constr. Build. Mater. 2021, 305, 124627. [Google Scholar] [CrossRef]

- Cong, P.; Luo, W.; Xu, P.; Zhao, H. Investigation on recycling of SBS modified asphalt binders containing fresh asphalt and rejuvenating agents. Constr. Build. Mater. 2015, 91, 225–231. [Google Scholar] [CrossRef]

- Li, J.; Zhang, F.; Liu, Y.; Muhammad, Y.; Su, Z.; Meng, F.; Chen, X. Preparation and properties of soybean bio-asphalt/SBS modified petroleum asphalt. Constr. Build. Mater. 2019, 201, 268–277. [Google Scholar] [CrossRef]

| Index | Unit | Test Value | Requirement |

|---|---|---|---|

| Penetration | 0.1 mm | 64.2 | 60.0~80.0 |

| Ductility | cm/15 °C | >100 | ≥100 |

| Softening point | °C | 47.8 | ≥46.0 |

| Saturates content | % | 12.5 | |

| Aromatics content | % | 30.2 | |

| Resins content | % | 38.8 | |

| Asphaltenes content | % | 18.5 |

| Component | SiO2 | MgO | Al2O3 | Fe2O3 | CaO | K2O | Na2O | TiO2 | Others |

|---|---|---|---|---|---|---|---|---|---|

| Content/% | 58.01 | 24.15 | 1.74 | 0.56 | 0.42 | 0.38 | 0.24 | 0.08 | 14.32 |

| Sepiolite Type | BET Specific Surface Area/(m2·g−1) | Total Pore Volume/(cm3·g−1) | Average Pore Diameter/nm | Mesopore (2~50 nm) Volume Ratio/% | 2~20 nm Pore Volume Ratio/% |

|---|---|---|---|---|---|

| RawSep | 107.95 | 0.32 | 11.8 | 91.2 | 52.5 |

| OSep | 154.83 | 0.45 | 9.2 | 94.5 | 68.9 |

| SSep | 156.53 | 0.48 | 9.5 | 93.8 | 72.3 |

| RawSep Content | Aliphatic Hydrocarbons/% | Aromatic Hydrocarbons/% | Other Components/% | Polycyclic Aromatic Hydrocarbons Detection |

|---|---|---|---|---|

| 0% | 42.5 | 38.2 | 19.3 | Naphthalene, Phenanthrene, Fluoranthene |

| 2% | 37.8 | 33.6 | 28.6 | Naphthalene, Phenanthrene |

| 4% | 31.2 | 25.8 | 43.0 | - |

| 6% | 33.5 | 28.1 | 38.4 | Naphthalene |

| 8% | 35.7 | 30.3 | 34.0 | Naphthalene, Phenanthrene |

| Sample Type | Low-Molecular-Weight Fraction/% | Medium-Molecular-Weight Fraction/% | High-Molecular-Weight Fraction/% | Number-Average Molecular Weight (Mn) | Weight-Average Molecular Weight (Mw) | Polydispersity Index (PDI) |

|---|---|---|---|---|---|---|

| Matrix asphalt | 38.5 | 42.3 | 19.2 | 850 | 2763 | 3.25 |

| RawSep-4% | 31.8 | 46.5 | 21.7 | 920 | 2594 | 2.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Fan, H.; Yang, J.; Yin, P. Enhancement of Rheological Performance and Smoke Suppression in Sepiolite-Modified Asphalt. Materials 2025, 18, 5627. https://doi.org/10.3390/ma18245627

Xu Y, Fan H, Yang J, Yin P. Enhancement of Rheological Performance and Smoke Suppression in Sepiolite-Modified Asphalt. Materials. 2025; 18(24):5627. https://doi.org/10.3390/ma18245627

Chicago/Turabian StyleXu, Yongle, Hongling Fan, Jing Yang, and Peng Yin. 2025. "Enhancement of Rheological Performance and Smoke Suppression in Sepiolite-Modified Asphalt" Materials 18, no. 24: 5627. https://doi.org/10.3390/ma18245627

APA StyleXu, Y., Fan, H., Yang, J., & Yin, P. (2025). Enhancement of Rheological Performance and Smoke Suppression in Sepiolite-Modified Asphalt. Materials, 18(24), 5627. https://doi.org/10.3390/ma18245627