Subsea Gate Valve—PDC Material and Sand Slurry Test

Highlights

- PDC coating reduced erosion depth by 77.6% compared with WC.

- Valve lifetime extended by about 4.5 times under slurry flow.

- Erosion concentrated near gate–seat interface areas.

- PDC coating improves durability of subsea gate valves.

- Lower wear reduces maintenance and downtime costs.

- Supports material selection for erosion-critical valve designs.

Abstract

1. Introduction

1.1. Background

1.2. Industrial Challenge

1.3. Research Question

1.4. Material Properties

1.5. Related Work

2. Methodology

2.1. Flow Model

2.2. Turbulence Modeling

2.3. Simulation Input

2.4. Mass Loss Calculations

2.5. Model Validity and Deviation Analysis

3. Results and Discussion

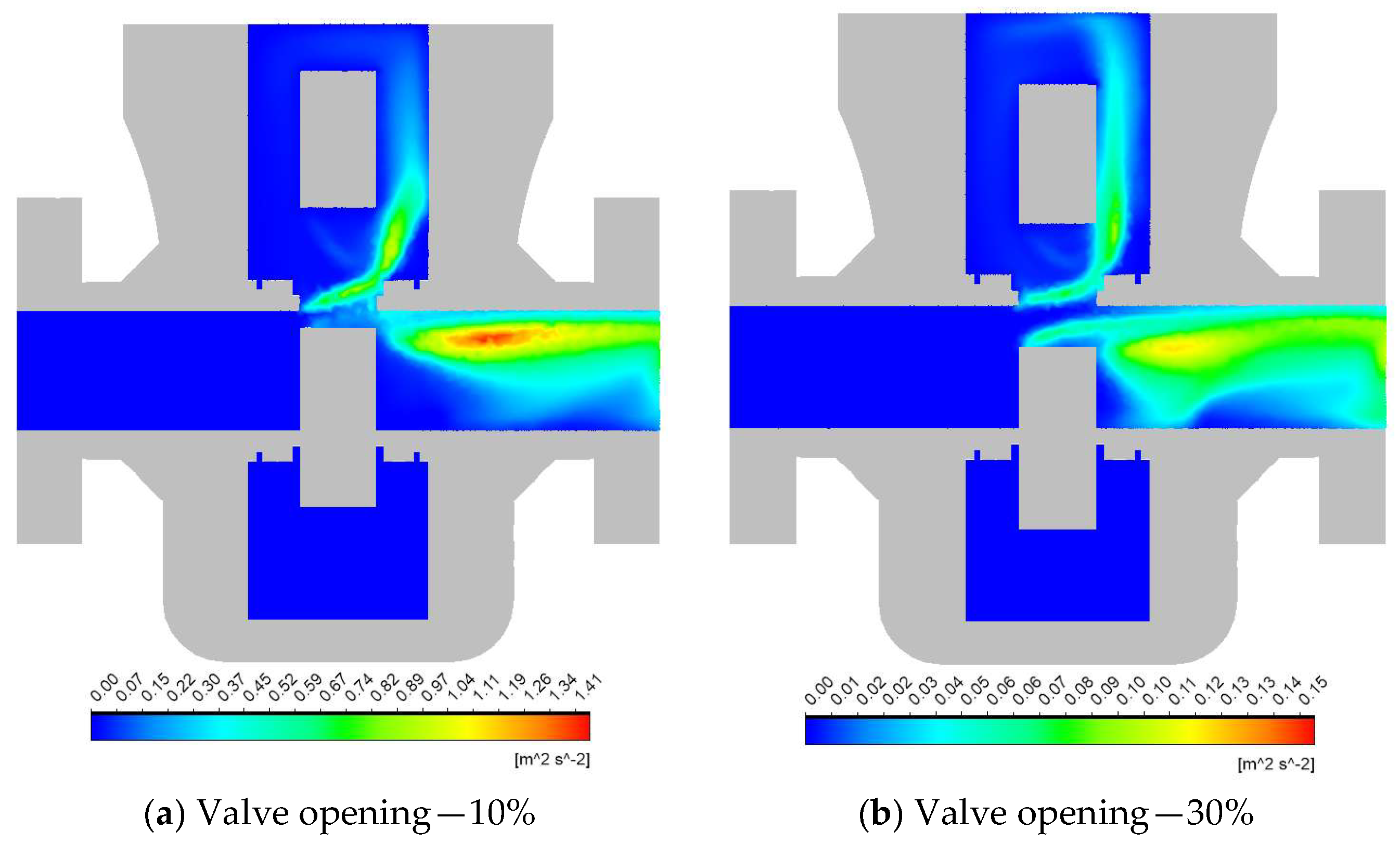

3.1. Velocity Distribution

3.2. Turbulence Analysis

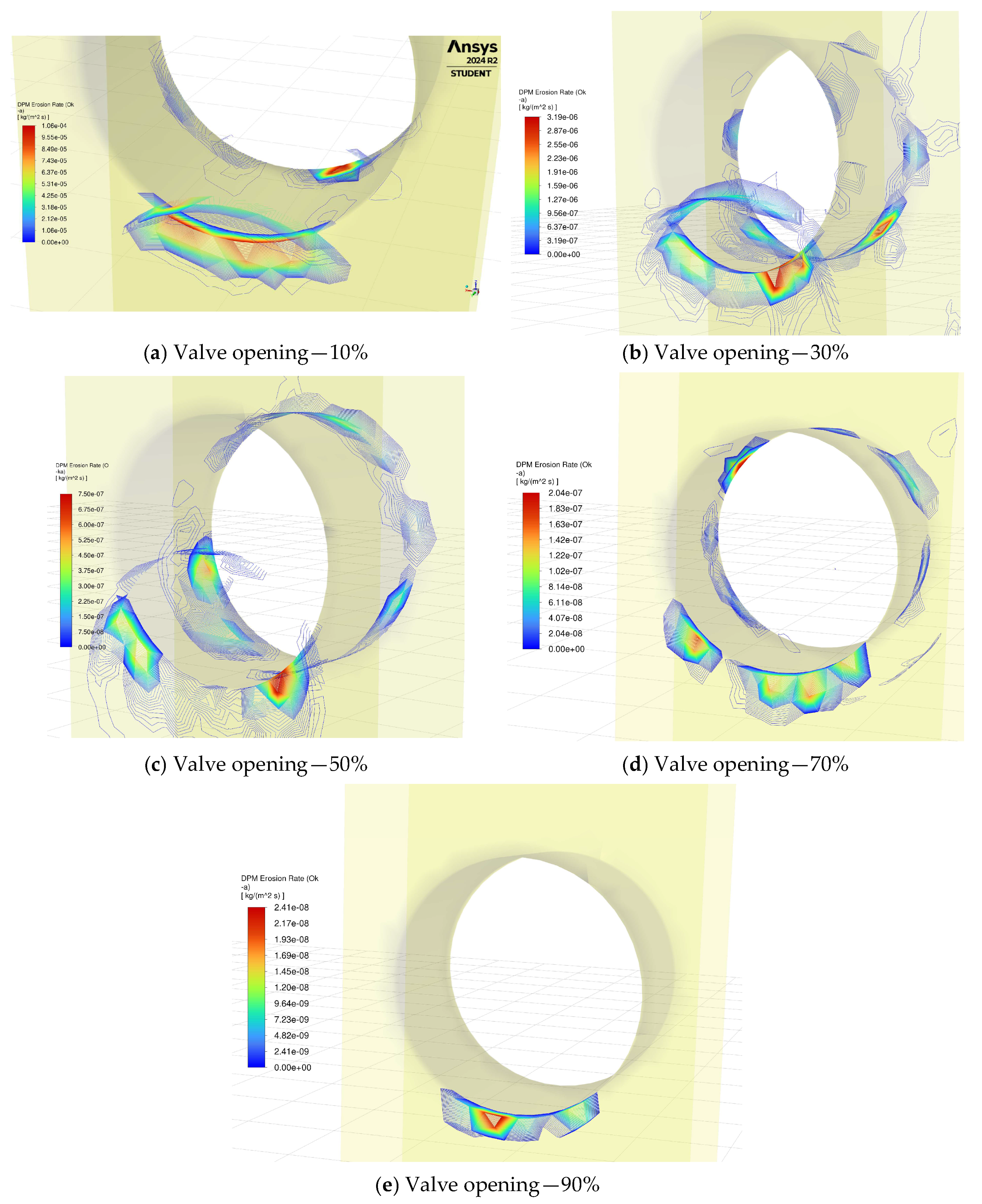

3.3. Erosion Rate Distribution

3.4. Cumulative Erosion and Mass Loss

3.5. Time-Dependence and Repeatability Analysis

3.6. Coating Failure Mechanism and Erosion Trend

3.7. Expected Lifetime of a Subsea Valve

3.8. Limitations

- The erosion predictions for 50 h are extrapolated from a one-hour simulation. Although this approach initially assumes a near-linear wear progression, additional cumulative-exposure analyses at 1 h, 10 h, and 50 h confirm that the variation in erosion remained within 3%. This validates the use of short-term results for long-term estimation.

- To assess numerical repeatability, each step of the slurry test is repeated three times using independent random particle-injection seeds. The relative standard deviation (RSD) remains below 4% for all cases, which confirms stable and reproducible solver performance.

- The Oka erosion model was selected due to its established performance across ductile and brittle materials, including its consideration of impact angles. However, like all empirical models, it has limitations under complex geometries and variable flow conditions.

- The simulation uses the DPM with particle sizes ranging as . Although a size range is considered, broader variations in subsea environments are not fully represented.

- Full dynamic simulation of 500 valve cycles was not feasible. Instead, six representative static positions were selected, including critical stages such as crack-open and crack-close. Interpolation (Simpson’s rule) was applied to estimate cumulative erosion. While this introduces approximation, the method is conservative and consistent with practices in valve erosion studies.

- The current study is part of a pre-prototype design phase. While experimental validation is not included in this study, a physical test is planned further. The numerical results will be validated in future work using gravimetric mass-loss measurements under API 6A slurry test conditions. The test setup will follow the same flow geometry and particle loading as in the simulations. A precision balance (±0.01 mg) will be used to determine cumulative material loss after each test.

- The simulations are based on API 6A Class II slurry test conditions. Broader operating conditions such as different flow rates, particle distributions, and slurry compositions, are not addressed in this work.

- Manufacturing PDC-coated valve components can be challenging due to the HPHT process and residual stresses, but these factors are well managed with current industrial methods and do not pose a major limitation.

- Post-erosion SEM/TEM of valve components is not performed in this simulation stage and is planned in the prototype validation to directly verify the coating damage modes.

4. Conclusions

- This study presents a quantitative comparison of WC and PDC coatings under API slurry test conditions, which enables the prediction of erosion behavior and valve lifetime in realistic subsea environments.

- Severe erosion occurs at narrow valve openings (10–30%). At these openings, the flow velocity reaches up to 7.8 m/s and the turbulence kinetic energy peaks at 1.44 m2/s2, resulting in highly localized erosion, especially on the valve seats.

- Jetting effects at partial openings cause aggressive surface wear. Measured erosion rates are 106 mg/m2 s for tungsten carbide (WC) coatings and 4.24 mg/m2 s for polycrystalline diamond compact (PDC) coatings.

- At near-full opening (90%), flow velocity drops to 0.49 m/s and turbulence kinetic energy decreases to 0.01 m2/s2, resulting in a significantly lower erosion risk.

- PDC coatings demonstrate superior erosion resistance. Simulation-based extrapolation shows that only 1.093 μm of the PDC layer is removed after extended slurry exposure—5.6 times less than the erosion observed in WC coated surfaces.

- Applying erosion trends to coating thickness standards (based on American Petroleum Institute guidelines), PDC coatings reduce the total erosion depth by and increase the valve’s expected lifetime by a factor of 4.5.

- Repeatability analyses confirmed numerical stability, with relative standard deviations below 4%, reinforcing the robustness of the simulation framework.

- The findings elevate the technology readiness level (TRL) of PDC-coated subsea valves, supporting their application in offshore field developments with improved operational reliability.

- Improved erosion resistance and extended service life of PDC-coated valves contribute to reduced offshore project costs, lower intervention frequency, and decreased health, safety, and environmental (HSE) risks.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature and Acronyms

| Nomenclature | |

| Area of valve seat | |

| Area fractions in x, y, z directions | |

| Material constant | |

| Particle diameter | |

| Blending function | |

| Depth of erosion | |

| Depth of erosion per year | |

| Turbulent kinetic energy | |

| Particle size exponent | |

| Number of valve cycles | |

| Pressure | |

| Velocity in x, y, z directions | |

| Particle velocity | |

| Turbulent kinetic viscosity | |

| Erosion rate | |

| Mass loss due to erosion | |

| Model constant | |

| Model constant | |

| Impact angle function | |

| Dynamic viscosity | |

| Turbulent viscosity | |

| Fluid density | |

| Material density | |

| Model constants | |

| Specific dissipation rate | |

| Acronyms | |

| Area of valve seat | |

| Area fractions in x, y, z directions | |

| Material constant | |

| Particle diameter | |

| Blending function | |

| HVOF | High-Velocity Oxy-Fuel (HVOF) |

| PCD | Polycrystalline diamond |

| Depth of erosion | |

| Depth of erosion per year | |

| RSD | Relative standard deviation |

| Turbulent kinetic energy | |

| SD | Standard deviation |

| Particle size exponent | |

| Number of valve cycles | |

Appendix A

| Property | WC | PDC | Typical Test/Standard | |

|---|---|---|---|---|

| Vickers hardness (HV) | 1200–1600 | 7000–9000 | ASTM E384 [43] | [15,22,23] |

| Rockwell hardness (HRC, eq.) | 85–92 | >100 (est.) | ASTM E18 [44] | [14,22] |

| Coefficient of friction (self-paired) | 0.12–0.20 | 0.05–0.08 | ASTM G99 [45] | [13,23] |

| Thermal conductivity (W m−1 K−1) | 84–110 | 600–1200 | ASTM E1461 [46]/ISO 22007-2 [47] | [16,22] |

| Thermal expansion coefficient (×10−6 K−1) | 4.3–6.0 | 1.0–1.2 | ASTM E228 [48] | [17,24] |

| Typical manufacturing process | HVOF/Plasma-sprayed WC–Co | HPHT sintered diamond on WC substrate | - | [19,20,21] |

| Adhesion strength (MPa) | 60–80 (HVOF) | >80 (HPHT bonded) | ASTM C633 [49]/Scratch test ISO 20502 [50] | [18,24] |

| Thermal stability limit (°C) | ≤500–600 (binder softening) | 700–1200 (depends on binder) | - | [22,25] |

| Step 1 (1 h-Based)/(Variation %) | Step 1 (10 h-Based)/(Variation %) | Step 1 (50 h-Based)/(Variation %) | |

|---|---|---|---|

| 5.407 (-) | 5.489 (+1.52%) | 5.533 (+2.33%) | |

| 0.273 (-) | 0.278 (+1.83%) | 0.281 (+2.93%) |

| Material | Step | Mean Erosion Mass Loss (mg) | SD (mg) | RSD (%) | Number of Repetitions |

|---|---|---|---|---|---|

| WC | Step 1 (fully open) | 5.428 | 0.079 | 1.45 | 3 |

| Step 2 (cycling) | 720.4 | 21.8 | 3.03 | 3 | |

| PDC | Step 1 (fully open) | 0.275 | 0.009 | 3.18 | 3 |

| Step 2 (cycling) | 28.763 | 0.846 | 2.94 | 3 |

References

- International Energy Agency (IEA). World Energy Outlook 2024. 2024. Available online: https://www.iea.org/reports/world-energy-outlook-2024 (accessed on 26 October 2025).

- Bai, Y.; Bai, Q. Subsea Engineering Handbook; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Williams, T.; Pappas, J.; Perry, K. Ultra-Deepwater and Unconventional Natural Gas and Other Petroleum Resources Program Administration; Technical Report; Research Partnership to Secure Energy for America: Houston, TX, USA, 2016. [Google Scholar] [CrossRef]

- Bruschi, R.; Marchionni, L.; Mancini, A.; Vitali, L.; Pazzaglia, J. Controlling fatigue damage in deep-water installation. In Proceedings of the 26th International Ocean and Polar Engineering Conference, Rhodes, Greece, 26 June–2 July 2016; p. ISOPE-I-16-493. Available online: https://onepetro.org/ISOPEIOPEC/proceedings-pdf/ISOPE16/All-ISOPE16/ISOPE-I-16-493/1337506/isope-i-16-493.pdf (accessed on 26 October 2025).

- Ragazzoni, S.; Campanelli, G.; Pozzati, R.; Ambrosini, I.; Gjedrem, T. Very large size valves and actuators—Design and testing. In Proceedings of the Twenty-Second International Offshore and Polar Engineering Conference, Rhodes, Greece, 17–22 June 2012; p. ISOPE-I-12-242. Available online: https://onepetro.org/ISOPEIOPEC/proceedings-abstract/ISOPE12/All-ISOPE12/12622 (accessed on 26 October 2025).

- Ri, J.; Ripeanu, R.G.; Dinita, A. Erosion modeling in parallel gate valve. FME Trans. 2020, 48, 808–815. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Y.; Hou, W.; Wang, G.; Zheng, Y. Reliability and availability modeling of subsea xmas tree system using dynamic bayesian network with different maintenance methods. J. Loss Prev. Process Ind. 2020, 64, 104066. [Google Scholar] [CrossRef]

- Sotoodeh, K. Simulation of underwater conditions for subsea valves—A review of hyperbaric tests and validation. Int. J. Press. Vessel. Pip. 2021, 191, 104353. [Google Scholar] [CrossRef]

- Praveen, J.; Pathan, M.; Ansari, K. Hyperbaric pressure testing of a subsea valve to validate deep water condition. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 1011–1022. [Google Scholar] [CrossRef]

- Wang, H.; Liu, G.; Zhou, L.; Jia, P.; Yun, F. Design and test of the electrical system of the all-electric subsea gate valve actuator. Actuators 2024, 13, 263. [Google Scholar] [CrossRef]

- Ahmadli, M.; Gjersvik, T.B.S.; Sangesland, S.; Reynes, C. Enhancing subsea ball valve performance: A material and design approach. In Proceedings of the ASME 2024 43rd International Conference on Ocean, Offshore and Arctic Engineering, Singapore, 9–14 June 2024; Volume 8: Offshore Geotechnics; Petroleum Technology. p. V008T11A044. [Google Scholar] [CrossRef]

- Ahmadli, M.; Gjersvik, T.B.; Sangesland, S. Design assessment and optimization of a barrier valve for subsea applications. In Proceedings of the ASME 2023 42nd International Conference on Ocean, Offshore and Arctic Engineering, Melbourne, Australia, 11–16 June 2023; Volume 3: Materials Technology; Pipelines, Risers, and Subsea Systems 3. p. V003T04A053. [Google Scholar] [CrossRef]

- Ahmadli, M.; Gjersvik, T.B.; Sangesland, S.; Ratnayake, R.C. Analysis of friction and wear behavior of polycrystalline diamond compact (pdc) for application in subsea valves. J. Offshore Mech. Arct. Eng. 2025, 147, 1–19. [Google Scholar] [CrossRef]

- Barrett, R.T. Fastener Design Manual (NASA Reference Publication 1228); NASA Lewis Research Center: Cleveland, OH, USA, 1990. [Google Scholar]

- Zhong, L.; Li, Z.; Wang, G.; He, H.; Wei, G.; Zheng, S.; Feng, G.; Xie, N.; Zhang, R. Erosion resistance of valve core surface combined with WC-10Co-4Cr coating process under different pretreatments. Materials 2022, 15, 8140. [Google Scholar] [CrossRef]

- Vornberger, A.; Pötschke, J.; Gestrich, T.; Herrmann, M.; Michaelis, A. Influence of Microstructure on Hardness and Thermal Conductivity of Hardmetals. Int. J. Refract. Met. Hard Mater. 2020, 88, 105170. [Google Scholar] [CrossRef]

- Wang, H.; Webb, T.; Bitler, J.W. Study of thermal expansion and thermal conductivity of cemented WC–Co compo-site. Int. J. Refract. Met. Hard Mater. 2015, 49, 170–177. [Google Scholar] [CrossRef]

- Al-Mutairi, S.; Hashmi, M.–S.J.; Yilbas, B.S.; Stokes, J. Microstructural characterization of HVOF/plasma thermal spray of micro/nano WC–12%Co powders. Surf. Coat. Technol. 2015, 264, 175–186. [Google Scholar] [CrossRef]

- Fan, K.; Jiang, W.; Luzin, V.; Gong, T.; Feng, W.; Ruiz-Hervias, J.; Yao, P. Influence of WC Particle Size on the Mechanical Properties and Residual Stress of HVOF Thermally Sprayed WC–10Co–4Cr Coatings. Materials 2022, 15, 5537. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Lei, T.; Liu, B. Tribological Behaviour of Surface Textured Polycrystalline Diamond Compact (PDC) Cutters under Dry Friction. Wear 2025, 584–585, 206387. [Google Scholar] [CrossRef]

- Yang, X.; Deng, F. Synthesis and characterisation of Φ62 mm polycrystalline diamond compact. Diam. Relat. Mater. 2019, 100, 107594. [Google Scholar] [CrossRef]

- Miranzo, P.; Sanchez-Martín, M.J.; Yue, Y.; Castrillón, J.L.; Belzunce, F.J. Thermal conductivity enhancement in cutting tools by chemical vapour deposition diamond coating. Diam. Relat. Mater. 2002, 11, 703–707. [Google Scholar] [CrossRef]

- Jaworska, L. The Influence of the Binder Phase on the Properties of High-Pressure Sintered Diamond Polycrystals or Composites for Cutting Tool Applications. Materials 2025, 18, 634. [Google Scholar] [CrossRef]

- Liu, X.M.; Yue, C.Y.; Gao, Y.; Zhao, Z.; Zhang, W.; Liu, Y.; Song, X.Y. Effect of interlayers on thermal residual stresses in diamond/MPEA composites predicted by finite element method. Int. J. Refract. Met. Hard Mater. 2025, 129, 107080. [Google Scholar] [CrossRef]

- Li, Z.; Jia, H.; Ma, H.; Guo, W.; Liu, X.; Huang, G.; Li, R.; Jia, X. FEM analysis on the effect of cobalt content on thermal residual stress in polycrystalline diamond compact (PDC). Sci. China Phys. Mech. Astron. 2012, 55, 639–643. [Google Scholar] [CrossRef]

- Finnie, I. Erosion of surfaces by solid particles. Wear 1960, 3, 87–103. [Google Scholar] [CrossRef]

- McLaury, B.S.; Shirazi, S.A.; Shadley, J.R.; Rybicki, E.F. Modeling erosion in chokes. In ASME-Publications-Fed; ASME: New York, NY, USA, 1996; Volume 236, pp. 773–782. [Google Scholar]

- Oka, Y.; Yoshida, T. Practical estimation of erosion damage caused by solid particle impact: Part 2: Mechanical properties of materials directly associated with erosion damage. Wear 2005, 259, 102–109. [Google Scholar] [CrossRef]

- Ri, J.H.; Ripeanu, R.G.; Dinita, A. Erosion modeling of coated gate valves. Tribol. Ind. 2022, 44, 113–122. [Google Scholar] [CrossRef]

- Messa, G.V.; Negri, M.; Wang, Y.; Malavasi, S. Estimation of the useful life of a gate valve subjected to impact erosion. In Proceedings of the XXIII Conference of the Italian Association of Theoretical and Applied Mechanics, Gechi Edizioni, Salerno, Italy, 4–7 September 2017; pp. 147–163. [Google Scholar]

- Frank, T.; Lifante, C.; Prasser, H.M.; Menter, F. Simulation of turbulent and thermal mixing in t-junctions using urans and scale-resolving turbulence models in ansys cfx. Nucl. Eng. Des. 2010, 240, 2313–2328. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Menter, F.; Kuntz, M.; Langtry, R. Ten years of industrial experience with the SST turbulence model. Heat Mass Transf. 2003, 4, 625–632. [Google Scholar]

- Menter, F. Review of the shear-stress transport turbulence model experience from an industrial perspective. Int. J. Comput. Fluid Dyn. 2009, 23, 305–316. [Google Scholar] [CrossRef]

- Ahmadli, M.; Gjersvik, T.B.; Sangesland, S.; Reynes, C. Analysis of all-electric subsea gate valve designs and system overview. In Proceedings of the SPE Norway Subsurface Conference, Bergen, Norway, 17 April 2024; p. D011S008R004. [Google Scholar] [CrossRef]

- API 6A; Specification for Wellhead and Christmas Tree Equipment. American Petroleum Institute: Washington, DC, USA, 2021.

- ISO 10414-1:2008; Petroleum and Natural Gas Industries—Field Testing of Drilling Fluids—Part 1: Water-Based Fluids. International Organization for Standardization: Geneva, Switzerland, 2008.

- Adedeji, O.E.; Yu, W.; Sanders, R.S. Analysis of local wear variables for high-precision erosion modelling in complex geometries. Wear 2019, 426–427, 562–569. [Google Scholar] [CrossRef]

- ANSYS, Inc. 2019 R3, Help System, Theory Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2019. [Google Scholar]

- Li, G.; Liu, G.; Wang, H.; Liu, Y.; Cai, B.; Fang, X.; Li, G. Throttle valve erosion in the oil and gas industry. J. Mater. Sci. 2024, 59, 20874–20899. [Google Scholar] [CrossRef]

- Liu, H.; Yang, S.; Wang, L.; Li, Y.; Mi, L.; Yuan, F.; Ye, C. Numerical analysis of the sediment erosion of the balance valve in a buoyancy regulation system. J. Mar. Sci. Eng. 2024, 12, 1344. [Google Scholar] [CrossRef]

- Ni, Y.; Tan, Y.; Tan, D. Multi-physical Modeling and Adjusting for Ultrasonic Assisted Soft Abrasive Flow Processing. Chin. J. Mech. Eng. 2023, 36, 75. [Google Scholar] [CrossRef]

- ASTM E384-22; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM E18-24; Standard Test Methods for Rockwell Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM G99-23; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM E1461-13(2022); Standard Test Method for Thermal Diffusivity by the Flash Method. ASTM International: West Conshohocken, PA, USA, 2022.

- ISO 22007-2:2022; Plastics—Determination of Thermal Conductivity and Thermal Diffusivity—Part 2: Transient Plane Heat Source (Hot Disc) Method. International Organization for Standardization: Geneva, Switzerland, 2022.

- ASTM E228-22; Standard Test Method for Linear Thermal Expansion of Solid Materials with a Push-Rod Dilatometer. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C633-13(2021); Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings. ASTM International: West Conshohocken, PA, USA, 2013.

- ISO 20502:2005; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Adhesion of Ceramic Coatings by Scratch Testing. International Organization for Standardization: Geneva, Switzerland, 2005.

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Face-to-face dimension | Gate seat area | ||

| Body width | Substrate material | 25Cr super duplex | |

| Bore diameter | Material density (WC) | ||

| Gate port diameter | Material density (PDC) |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Fluid phase | Freshwater | Particle phase | Silica sand |

| Fluid density | Particle density | ||

| Fluid viscosity | Particle diameter | ||

| Flow rate | Particle mass flow rate | ||

| Inlet velocity | Pressure (closed) | 400 |

| Opening (%) | Max. Erosion Rate WC Coating (mg/m2 ∙ s) | Max. Erosion Rate WC Coating (mg/m2 ∙ s) |

|---|---|---|

| 10 | ||

| 30 | ||

| 50 | ||

| 70 | ||

| 90 | ||

| 100 | 1.98 |

| Step No. | Flowrate | Gate Position | Duration (Hours) | g/m2 | g/m2 |

|---|---|---|---|---|---|

| 1 | 0.300 | fully open | 50.00 | 0.713 | 0.036 |

| 2 | 0.300 | 7 cycles/min | 1.190 | 94.37 | 3.790 |

| A Cycle | Slurry Test Step 1 | Slurry Test Step 2 | Slurry Test SUM | |

|---|---|---|---|---|

| 1.431 | 5.407 | 715.7 | 721.1 | |

| 0.057 | 0.273 | 28.74 | 29.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmadli, M.; Gjersvik, T.B.; Sangesland, S. Subsea Gate Valve—PDC Material and Sand Slurry Test. Materials 2025, 18, 5546. https://doi.org/10.3390/ma18245546

Ahmadli M, Gjersvik TB, Sangesland S. Subsea Gate Valve—PDC Material and Sand Slurry Test. Materials. 2025; 18(24):5546. https://doi.org/10.3390/ma18245546

Chicago/Turabian StyleAhmadli, Mehman, Tor Berge Gjersvik, and Sigbjørn Sangesland. 2025. "Subsea Gate Valve—PDC Material and Sand Slurry Test" Materials 18, no. 24: 5546. https://doi.org/10.3390/ma18245546

APA StyleAhmadli, M., Gjersvik, T. B., & Sangesland, S. (2025). Subsea Gate Valve—PDC Material and Sand Slurry Test. Materials, 18(24), 5546. https://doi.org/10.3390/ma18245546