Performance Evaluation of Eco-Friendly Recycled Powder in Foamed Concrete: Influence of Powder Types and Replacement Ratios

Abstract

1. Introduction

2. Materials and Experiments

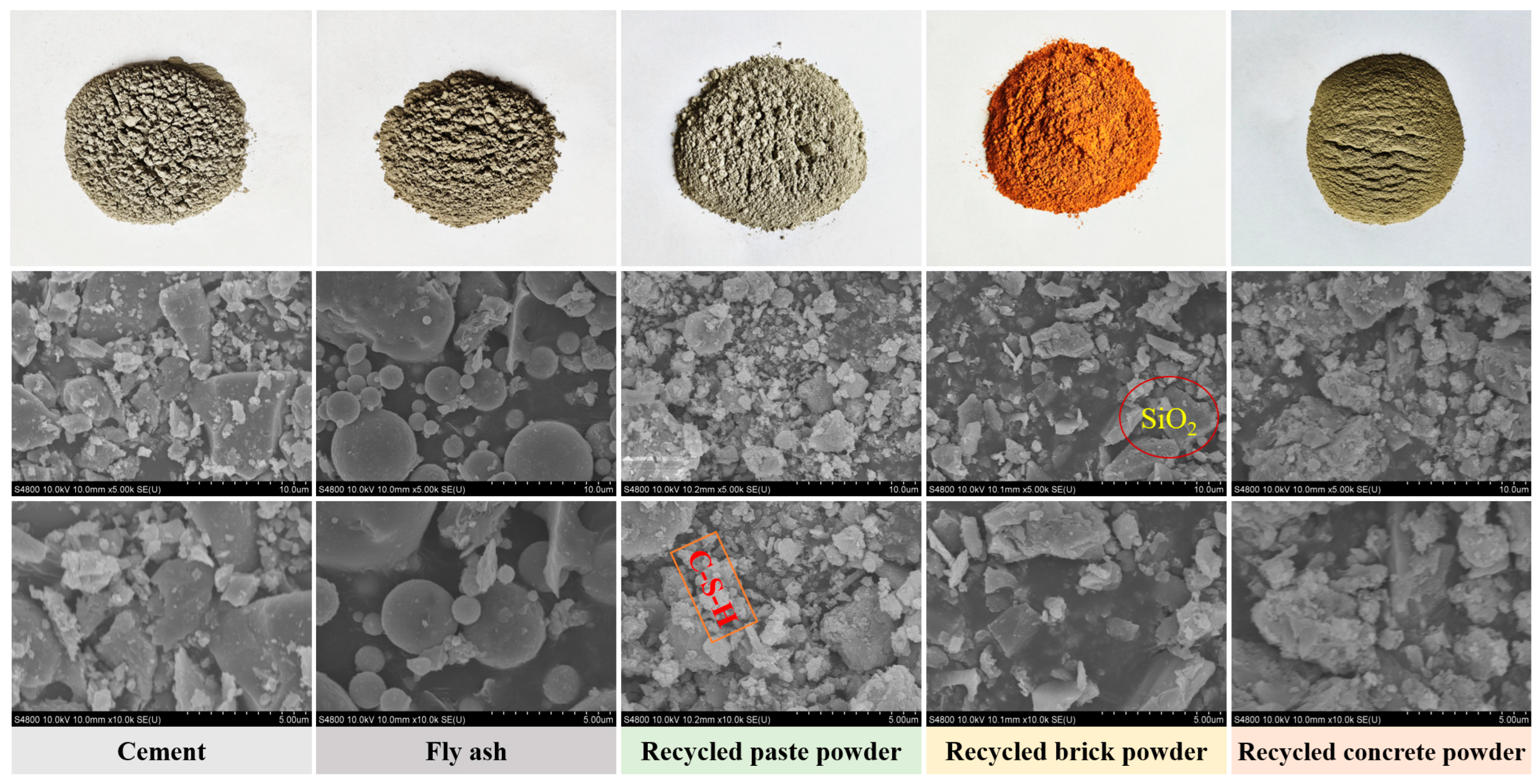

2.1. Raw Materials

2.2. Mix Proportion and Preparation

2.3. Micro-Characteristics Determination

2.4. Workability, Thermal Conductivity and Drying Shrinkage

2.5. Compressive Strength, Softening Coefficient, and Carbonation Coefficient

3. Results and Discussion

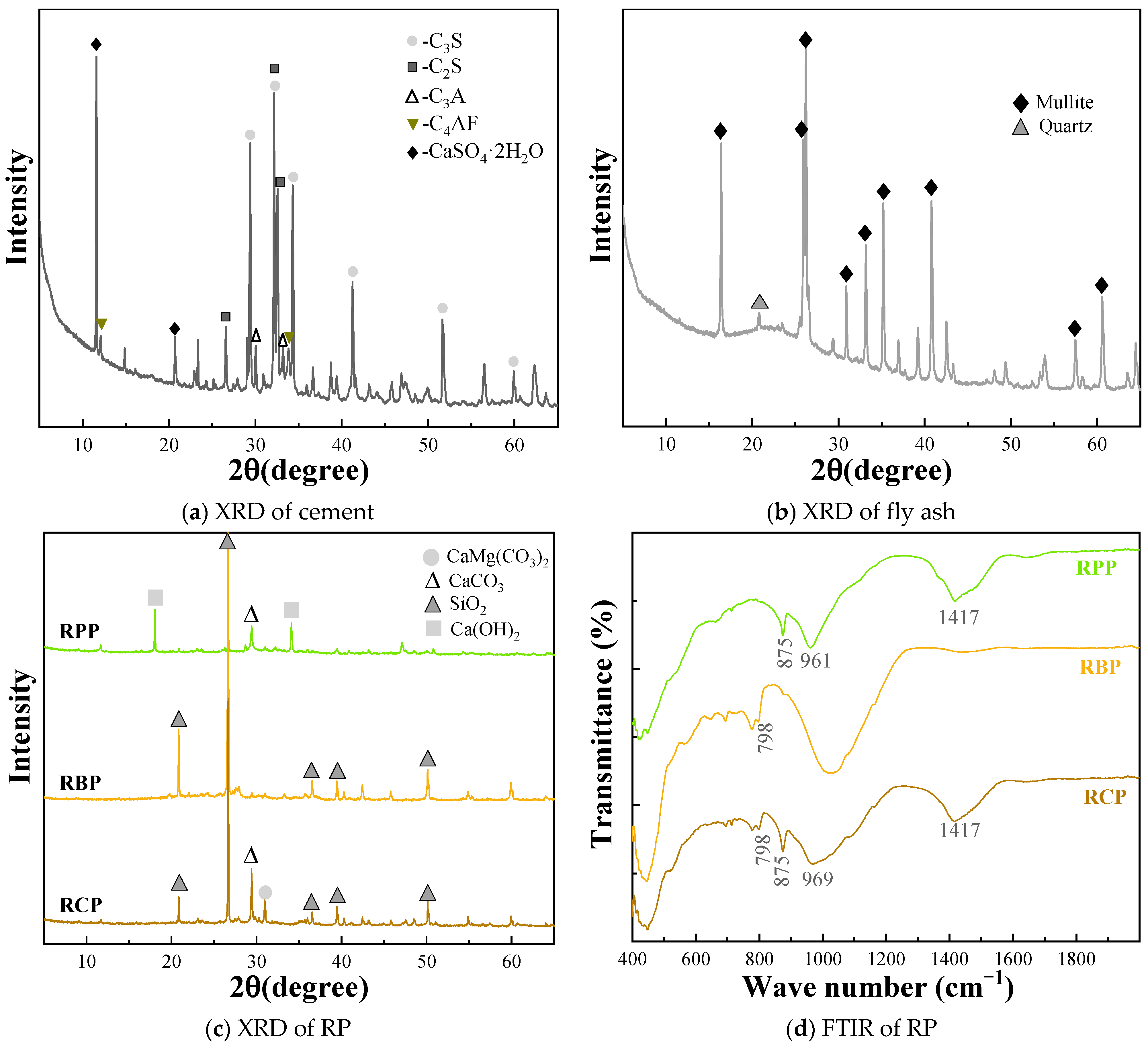

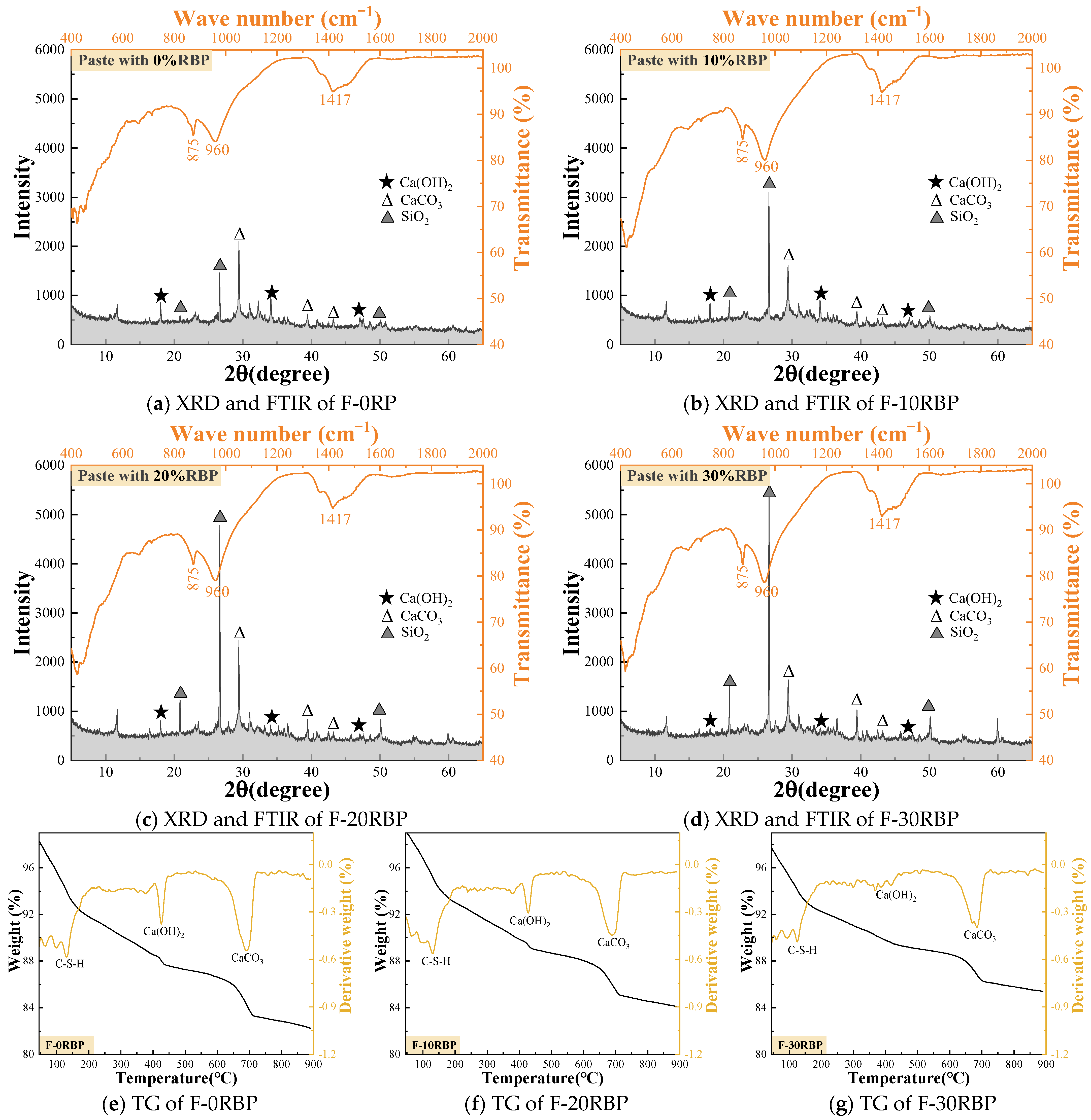

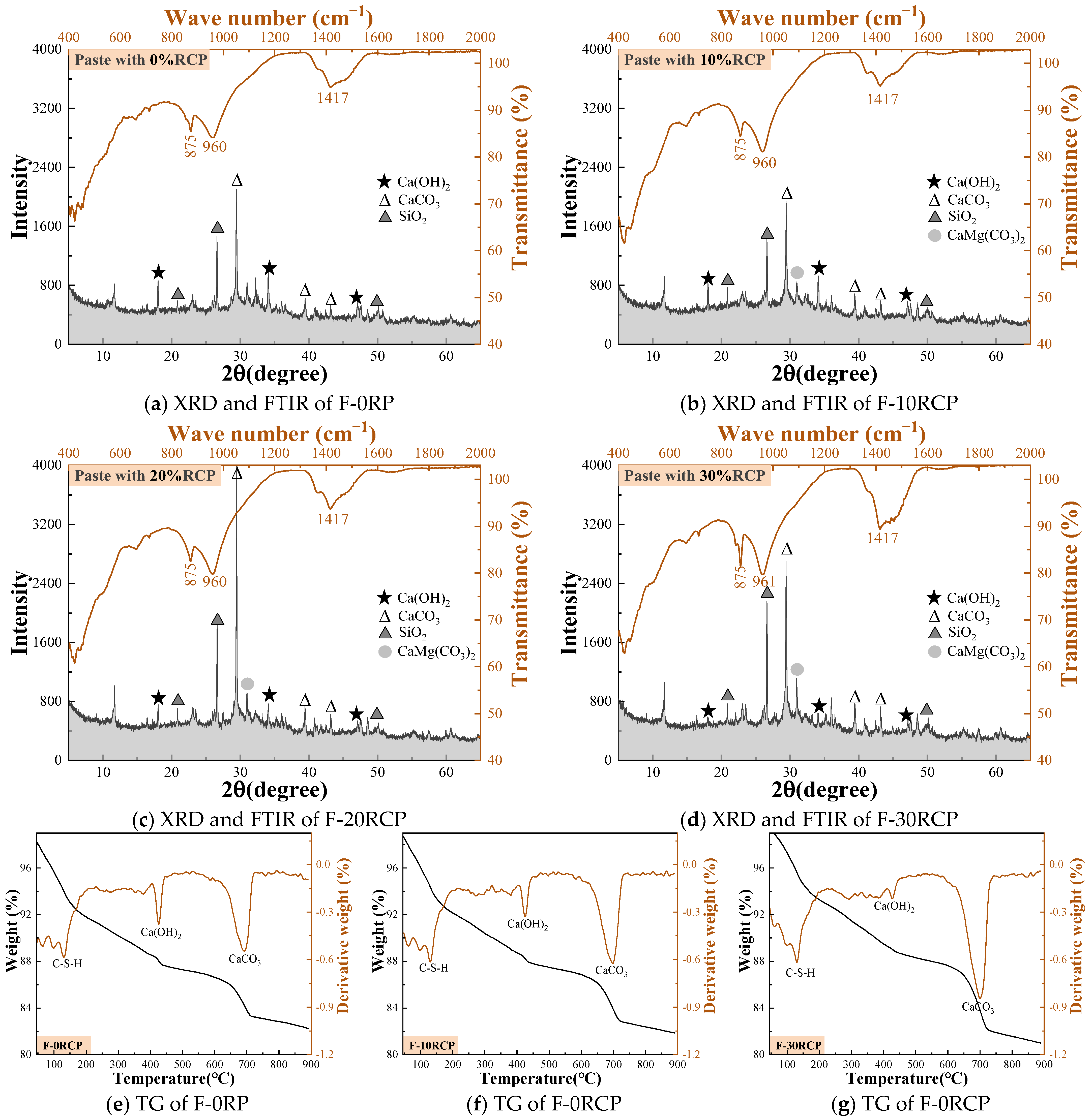

3.1. Micro-Properties

3.2. Flowability of RPFC

3.3. Compressive Strength of RPFC

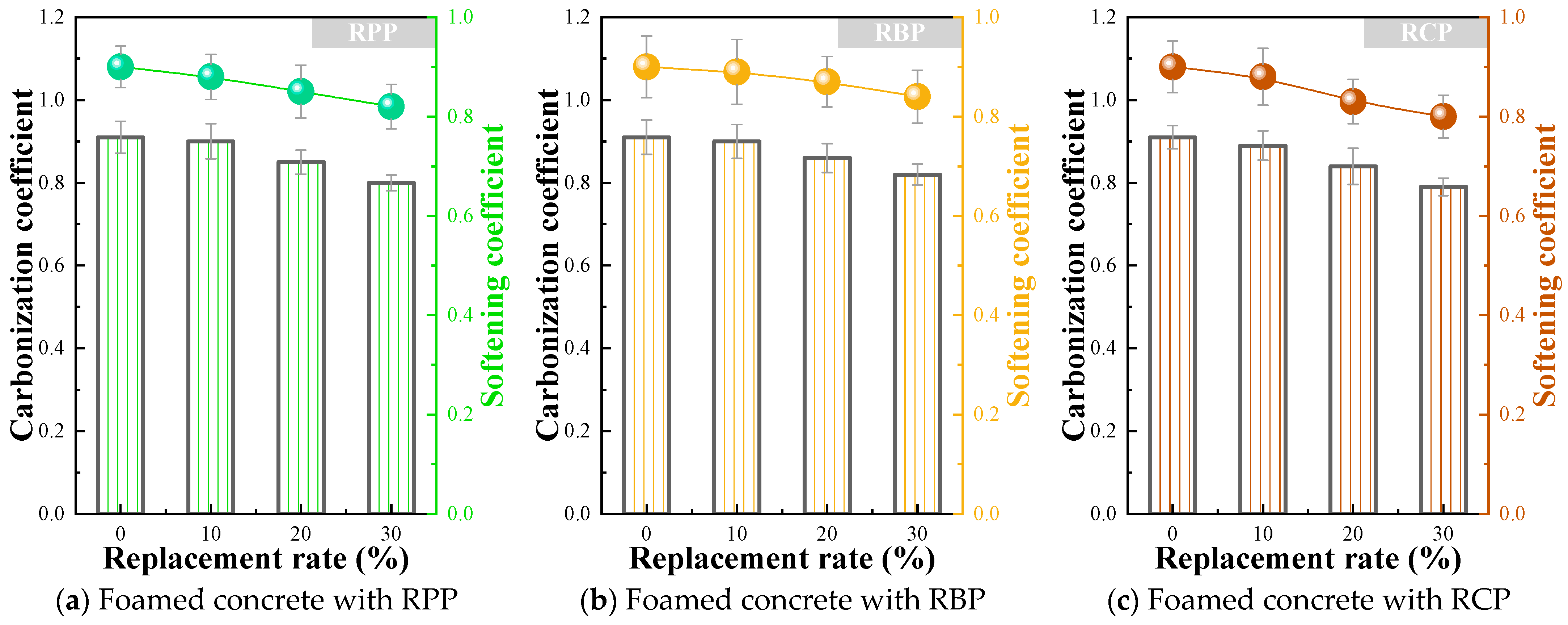

3.4. Carbonation Coefficient and Softening Coefficient of RPFC

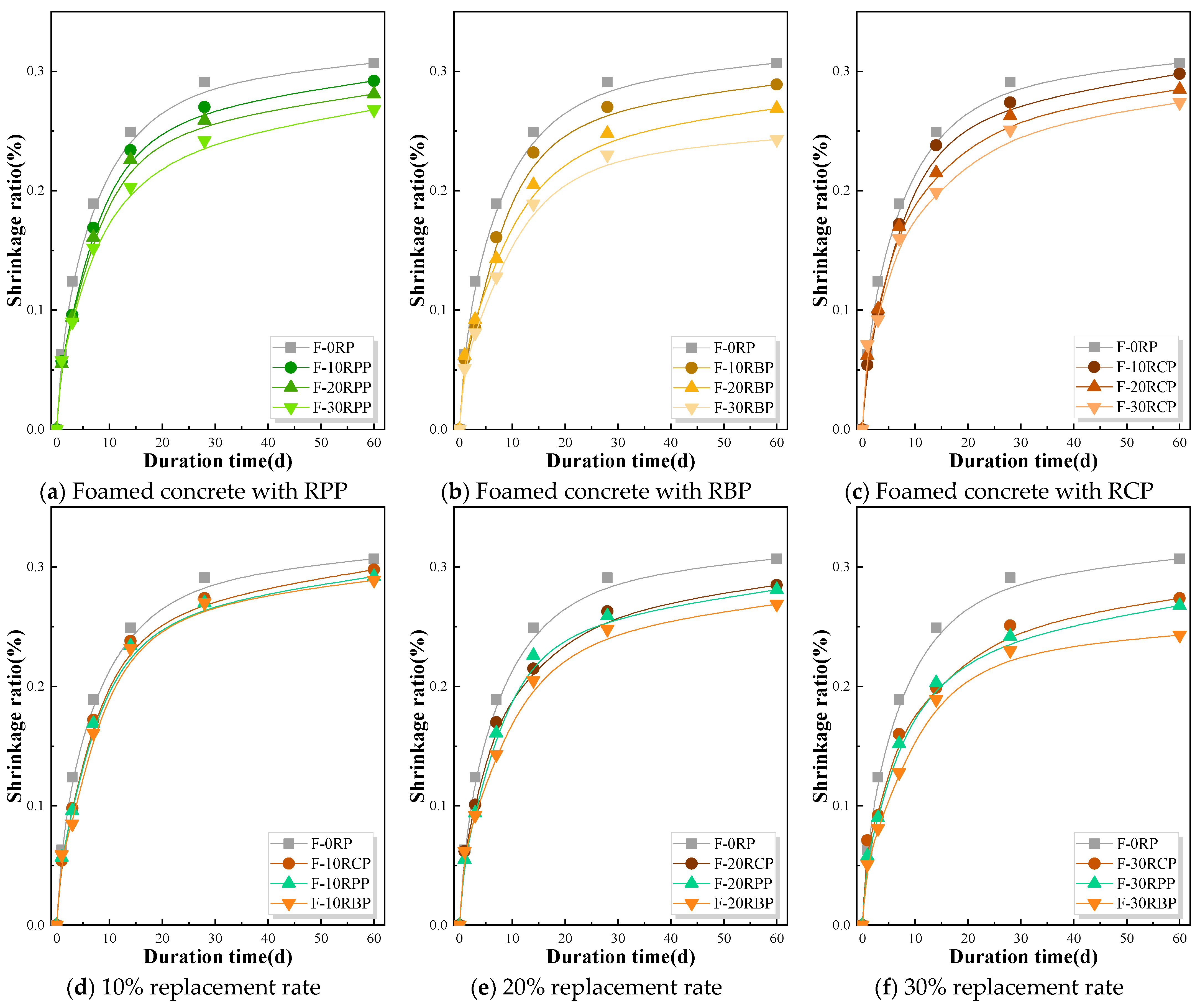

3.5. Drying Shrinkage of RPFC

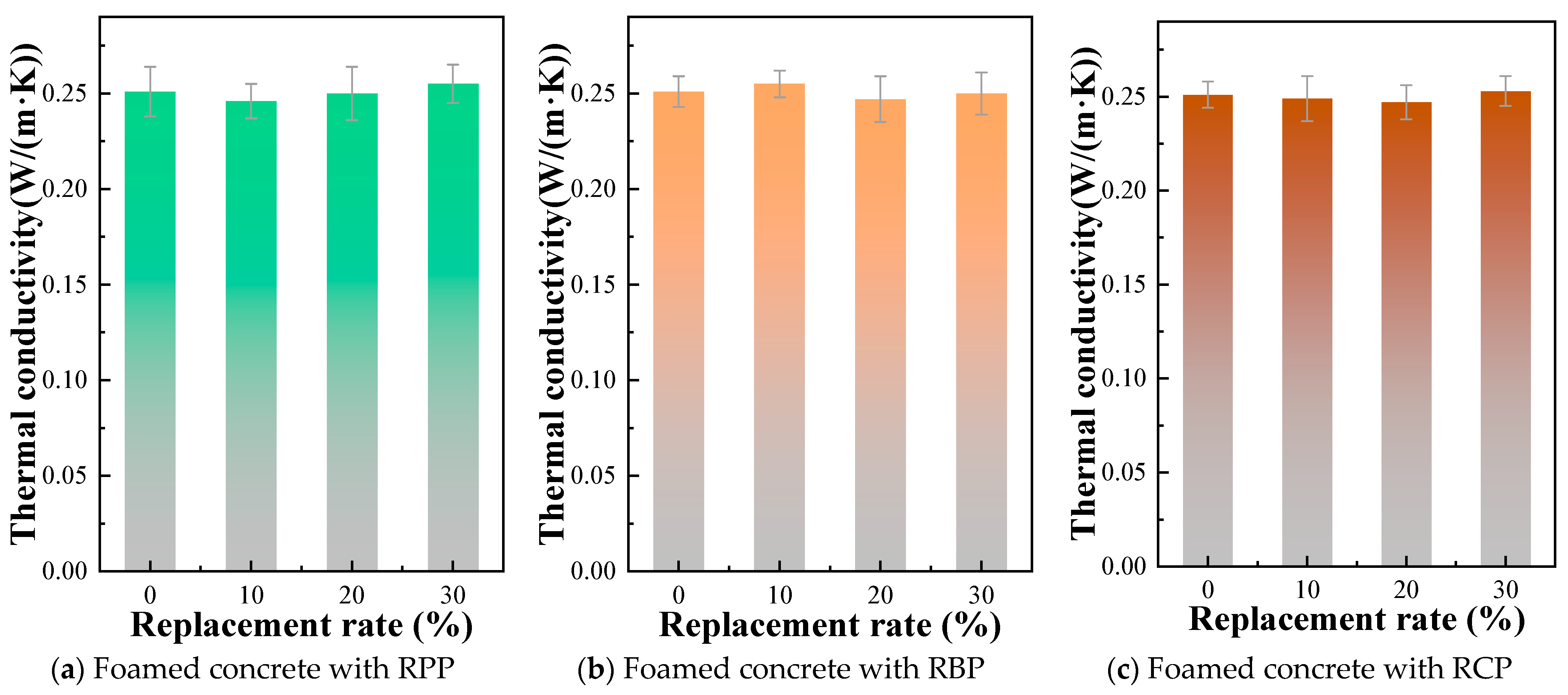

3.6. Thermal Conductivity of RPFC

4. Conclusions

- Three types of RP all exhibit irregular microstructures, but their chemical compositions differ significantly. For example, RPP contains Ca(OH)2, RBP contains a large amount of SiO2, and RCP contains CaMg(CO3)2. When these powders are partially substituted for cement, the matrix’s microstructure progressively exhibits signs of degradation. XRD and TG results indicate that, with increasing RP substitution ratios, the amount of Ca(OH)2 in the matrix gradually decreases.

- Different types of RP have a negative impact on the flowability and mechanical properties of foam concrete. With the increase in the RP substitution ratio, the compressive strength of the foam concrete gradually decreases. The decline in mechanical properties is particularly significant when the RP substitution ratio reaches 30%. However, at the same substitution ratio, the recycled brick powder group shows better compressive strength. For example, the 28 d compressive strength of F-30RBP is 28.61% and 39.20% higher than that of F-30RPP and F-30RCP, respectively.

- The incorporation of all three types of RP contributes to the suppression of drying shrinkage in foam concrete, with the drying shrinkage gradually decreasing when the RP substitution ratio increases. Notably, the RBP group demonstrates superior performance in inhibiting the drying shrinkage of foam concrete.

- As the substitution ratio of the three types of RP increases, both the carbonation coefficient and the softening coefficient of RPFC show a decreasing trend. Furthermore, the incorporation of RP has a minimal effect on the thermal conductivity of RPFC, indicating its good applicability in foam concrete.

- Although this study systematically investigates the microstructural and macroscopic properties of foam concrete prepared with different types of RP, research on the pore structure remains limited. Future studies will focus on the rheological properties of foam concrete slurry, aiming to further optimize its pore structure and achieve precise control over the performance of foam concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, B.; Xiao, J.; Zheng, Z.; Gan, W.; Shen, J.; Wang, J. Assessment of construction spoil generation: A case study in China. J. Clean. Prod. 2025, 532, 146879. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, M.; Tang, Q.; Liang, C.; Duan, Z. Chloride permeability of recycled aggregate concrete under the coupling effect of freezing-thawing, elevated temperature or mechanical damage. Constr. Build. Mater. 2020, 237, 117648. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, Q.; Wu, F.; Dong, S.; Zhang, Q.; Wang, J.; Luo, P.; Yang, X. Performance study on preparation of mine backfill materials using industrial solid waste in combination with construction waste. Materials 2025, 18, 3716. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; Wang, L.; Yang, R.; Hou, W.; Zhang, S.; Guo, X.; Zhao, W. Pollution characteristics and risk assessment of heavy metals in the soil of a construction waste landfill site. Ecol. Inform. 2022, 70, 101700. [Google Scholar] [CrossRef]

- Yin, X.; Rahman, M.; Pan, H.; Ma, Y.; Sun, Y.; Wang, J. Experimental investigation of mechanical properties and microstructure in cement-soil modified with waste brick powder and polyvinyl alcohol fibers. Materials 2025, 18, 3586. [Google Scholar] [CrossRef]

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting future carbon emissions from cement production in developing countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [CrossRef]

- He, Z.; Zhu, X.; Wang, J.; Mu, M.; Wang, Y. Comparison of CO2 emissions from OPC and recycled cement production. Constr. Build. Mater. 2019, 211, 965–973. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Vatin, N.; Huei Lee, Y.; Murali, G.; Ozbakkaloglu, T.; Klyuev, S.; Alabduljabber, H. Fibre-reinforced foamed concretes: A review. Materials 2020, 13, 4323. [Google Scholar] [CrossRef]

- Xiong, Y.; Wang, S.; Ma, L.; Wang, T.; Zhou, M.; Hu, Z.; Wang, Z. Unveiling the influence of activators on stability and pore features of foamed concrete. Materials 2025, 18, 3320. [Google Scholar] [CrossRef]

- Raj, A.; Sathyan, D.; Mini, K.M. Physical and functional characteristics of foam concrete: A review. Constr. Build. Mater. 2019, 221, 787–799. [Google Scholar] [CrossRef]

- Tong, X.; Yan, Y.; Tang, Y.; Xu, F.; Liu, M.; Gong, Y. Effect of recycled powder from construction and demolition waste on the macroscopic properties and microstructure of foamed concrete with different dry density grades. Buildings 2025, 15, 3395. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Hatungimana, D.; Ramyar, K. Effect of fly ash and silica fume on hardened properties of foam concrete. Constr. Build. Mater. 2019, 194, 1–11. [Google Scholar] [CrossRef]

- Li, S.; Li, H.; Yan, C.; Ding, Y.; Zhang, X.; Zhao, J. Investigating the mechanical and durability characteristics of fly ash foam concrete. Materials 2022, 15, 6077. [Google Scholar] [CrossRef]

- Chen, L.; Chen, X.; Wang, L.; Ning, Y.; Ji, T. Compressive strength, pore structure, and hydration products of slag foam concrete under sulfate and chloride environment. Constr. Build. Mater. 2023, 394, 132141. [Google Scholar] [CrossRef]

- Şeker, B.Ş.; Gökçe, M.; Toklu, K. Investigation of the effect of silica fume and synthetic foam additive on cell structure in ultra-low density foam concrete. Case Stud. Constr. Mat. 2022, 16, e01062. [Google Scholar] [CrossRef]

- Tokareva, A.; Waldmann, D. Durability assessment of cement mortars with recycled ceramic powders. Materials 2025, 18, 4420. [Google Scholar] [CrossRef]

- Ahmed, H.A.; Tanoli, W.A. Experimental and numerical assessment of sustainable concrete using recycled concrete powder (RCP) as a partial replacement for cement. Materials 2025, 18, 3108. [Google Scholar] [CrossRef]

- Zhang, H.; Cheng, X.; Zhang, C. Utilizing recycled concrete powder (RCP) in ultra-high performance concrete (UHPC) by taking a constrained dense suspension packing (DSP) theory: Towards ensured mechanical properties, lower shrinkage and enhancing sustainability. Constr. Build. Mater. 2025, 494, 143449. [Google Scholar] [CrossRef]

- Barbir, D.; Dabić, P.; Jakić, M.; Weber, I. Evaluating the heat of hydration, conductivity, and microstructural properties of cement composites with recycled concrete powder. Buildings 2025, 15, 2613. [Google Scholar] [CrossRef]

- Wu, H.; Yang, D.; Xu, J.; Liang, C.; Ma, Z. Water transport and resistance improvement for the cementitious composites with eco-friendly powder from various concrete wastes. Constr. Build. Mater. 2021, 290, 123247. [Google Scholar] [CrossRef]

- Luo, S.; Ding, S.; Yang, L.; Liu, X.; Xie, Y.; Sun, G. Investigation into the impact of autoclaved curing on the properties of recycled concrete powder. Constr. Build. Mater. 2025, 496, 143758. [Google Scholar] [CrossRef]

- Zhu, P.; Du, S.; Heng, P.; Zhang, L.; Zhang, S.; Wu, Y. Investigation on mix proportions of ultra-high performance concrete with recycled powder and recycled sand. Buildings 2025, 15, 1048. [Google Scholar] [CrossRef]

- Wen, Q.; Jiang, Z.; Ou, W.; Abbas, M.A.A.M.; Li, P. Recycling high-volume waste brick powder in sustainable ultra-high performance concrete for mass concrete application. Mater. Lett. 2026, 405, 139678. [Google Scholar] [CrossRef]

- Chen, D.; Chen, M.; Zhang, Y.; Yang, X.; Zhang, J.; Zhao, Y.; Wu, Y. Development of an environmental foamed concrete incorporating recycled cement concrete powder with carbonation. Constr. Build. Mater. 2024, 422, 135833. [Google Scholar] [CrossRef]

- Yao, T.; Tian, Q.; Zhang, M.; Qi, S.; Wang, C.; Ruan, M.; Xu, G.; Cai, J. Experimental research on the preparation and properties of foamed concrete using recycled waste concrete powder. Constr. Build. Mater. 2023, 407, 133370. [Google Scholar] [CrossRef]

- Yang, D.; Liu, M.; Ma, Z. Properties of the foam concrete containing waste brick powder derived from construction and demolition waste. J. Build. Eng. 2020, 32, 101509. [Google Scholar] [CrossRef]

- Cho, Y.K.; Jung, S.H.; Choi, Y.C. Effects of chemical composition of fly ash on compressive strength of fly ash cement mortar. Constr. Build. Mater. 2019, 204, 255–264. [Google Scholar] [CrossRef]

- Ding, S.; Chen, L.; Wan, X.; Wang, P.; Zhang, J.; Zhang, D.W.; Wang, J. Structure characterization of carbon and fluorine-doped silicon oxide films with low dielectric constant. Mater. Chem. Phys. 2001, 71, 125–130. [Google Scholar] [CrossRef]

- Liu, M.; Wang, C.; Wu, H.; Yang, D.; Ma, Z. Reusing recycled powder as eco-friendly binder for sustainable GGBS-based geopolymer considering the effects of recycled powder type and replacement rate. J. Clean. Prod. 2022, 364, 132656. [Google Scholar] [CrossRef]

- Mollah, M.; Lu, F.; Cocke, D.L. An X-ray diffraction (XRD) and Fourier transform infrared spectroscopic (FT-IR) characterization of the speciation of arsenic (V) in portland cement type-V. Sci. Total Environ. 1998, 224, 57–68. [Google Scholar] [CrossRef]

- Yang, D.; Liu, M.; Zhang, Z.; Yao, P.; Ma, Z. Properties and modification of sustainable foam concrete including eco-friendly recycled powder from concrete waste. Case Stud. Constr. Mat. 2022, 16, e826. [Google Scholar] [CrossRef]

- GB/T 43487-2023; Test Methods for Foamed Concrete and Its Products. China Standard Press: Beijing, China, 2023.

- Ma, Z.; Tang, Q.; Wu, H.; Xu, J.; Liang, C. Mechanical properties and water absorption of cement composites with various fineness and contents of waste brick powder from C&D waste. Cem. Concr. Compos. 2020, 114, 103758. [Google Scholar] [CrossRef]

- Qian, Y.; Yang, D.; Xia, Y.; Gao, H.; Ma, Z. Properties and improvement of ultra-high performance concrete with coarse aggregates and polypropylene fibers after high-temperature damage. Constr. Build. Mater. 2023, 364, 129925. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, J.; Zhan, B.; Gao, P.; Yu, Q.; Li, R.; Wang, J.; Wang, A.; Liu, G.; Zhang, Y. Study on hydration characteristics and mechanism of recycled powder-cement binary and multivariate systems. Constr. Build. Mater. 2024, 420, 135646. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, M.; Duan, Z.; Liang, C.; Wu, H. Effects of active waste powder obtained from C&D waste on the microproperties and water permeability of concrete. J. Clean. Prod. 2020, 257, 120518. [Google Scholar] [CrossRef]

- Liu, M.; Wu, H.; Yao, P.; Wang, C.; Ma, Z. Microstructure and macro properties of sustainable alkali-activated fly ash mortar with various construction waste fines as binder replacement up to 100%. Cem. Concr. Compos. 2022, 134, 104733. [Google Scholar] [CrossRef]

- Luo, X.; Li, S.; Xu, Z.; Guo, Z.; Liu, C.; Chen, X.; Gao, J. Effect of recycled brick powder on the hydration process of cement paste. J. Sustain. Cem-Based 2023, 12, 1307–1321. [Google Scholar] [CrossRef]

- Wu, H.; Liang, C.; Xiao, J.; Xu, J.; Ma, Z. Early-age behavior and mechanical properties of cement-based materials with various types and fineness of recycled powder. Struct. Concrete 2022, 23, 1253–1272. [Google Scholar] [CrossRef]

- Wu, H.; Yang, D.; Wang, C.; Ma, Z. Effects of construction waste powder on micro-macro properties of green high-strength cement paste with low water-to-binder ratio. Constr. Build. Mater. 2023, 385, 131493. [Google Scholar] [CrossRef]

| Cement/kg | Fly Ash/kg | RPP/kg | RBP/kg | RCP/kg | Water/kg | Calcium Stearate/kg | Foam/m3 | |

|---|---|---|---|---|---|---|---|---|

| F-0RP | 720.45 | 80.05 | 0 | 0 | 0 | 400.25 | 6.00 | 0.508 |

| F-10RPP | 648.41 | 80.05 | 72.04 | 0 | 0 | 400.25 | 6.00 | 0.508 |

| F-20RPP | 576.36 | 80.05 | 144.09 | 0 | 0 | 400.25 | 6.00 | 0.508 |

| F-30RPP | 504.31 | 80.05 | 216.14 | 0 | 0 | 400.25 | 6.00 | 0.508 |

| F-10RBP | 648.41 | 80.05 | 0 | 72.04 | 0 | 400.25 | 6.00 | 0.508 |

| F-20RBP | 576.36 | 80.05 | 0 | 144.09 | 0 | 400.25 | 6.00 | 0.508 |

| F-30RBP | 504.31 | 80.05 | 0 | 216.14 | 0 | 400.25 | 6.00 | 0.508 |

| F-10RCP | 648.41 | 80.05 | 0 | 0 | 72.04 | 400.25 | 6.00 | 0.508 |

| F-20RCP | 576.36 | 80.05 | 0 | 0 | 144.09 | 400.25 | 6.00 | 0.508 |

| F-30RCP | 504.31 | 80.05 | 0 | 0 | 216.14 | 400.25 | 6.00 | 0.508 |

| Flowability (mm) | Compressive Strength (MPa) | Carbonation Coefficient | Softening Coefficient | Drying Shrinkage (%) | Thermal Conductivity (W/(m·K)) | |

|---|---|---|---|---|---|---|

| F-0RP | 321.33 | 13.24 | 0.91 | 0.90 | 0.307 | 0.251 |

| F-10RPP | 312.99 | 11.77 | 0.90 | 0.88 | 0.292 | 0.246 |

| F-20RPP | 279.56 | 9.49 | 0.85 | 0.85 | 0.281 | 0.250 |

| F-30RPP | 253.21 | 7.62 | 0.80 | 0.82 | 0.268 | 0.255 |

| F-10RBP | 310.25 | 12.50 | 0.90 | 0.89 | 0.289 | 0.255 |

| F-20RBP | 285.92 | 10.65 | 0.86 | 0.87 | 0.269 | 0.247 |

| F-30RBP | 264.38 | 9.80 | 0.82 | 0.84 | 0.243 | 0.250 |

| F-10RCP | 312.25 | 11.80 | 0.89 | 0.88 | 0.298 | 0.249 |

| F-20RCP | 295.64 | 8.85 | 0.84 | 0.83 | 0.285 | 0.247 |

| F-30RCP | 278.11 | 7.04 | 0.79 | 0.80 | 0.274 | 0.253 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, X.; Zhang, Z.; Zhang, M.; Jie, Z.; Gong, Y. Performance Evaluation of Eco-Friendly Recycled Powder in Foamed Concrete: Influence of Powder Types and Replacement Ratios. Materials 2025, 18, 5470. https://doi.org/10.3390/ma18235470

Tong X, Zhang Z, Zhang M, Jie Z, Gong Y. Performance Evaluation of Eco-Friendly Recycled Powder in Foamed Concrete: Influence of Powder Types and Replacement Ratios. Materials. 2025; 18(23):5470. https://doi.org/10.3390/ma18235470

Chicago/Turabian StyleTong, Xiaofang, Zhiyu Zhang, Mingyi Zhang, Zhenxiang Jie, and Yongfan Gong. 2025. "Performance Evaluation of Eco-Friendly Recycled Powder in Foamed Concrete: Influence of Powder Types and Replacement Ratios" Materials 18, no. 23: 5470. https://doi.org/10.3390/ma18235470

APA StyleTong, X., Zhang, Z., Zhang, M., Jie, Z., & Gong, Y. (2025). Performance Evaluation of Eco-Friendly Recycled Powder in Foamed Concrete: Influence of Powder Types and Replacement Ratios. Materials, 18(23), 5470. https://doi.org/10.3390/ma18235470