Review of Component Materials and Diverse Applications of Polymer Concrete

Abstract

1. Introduction

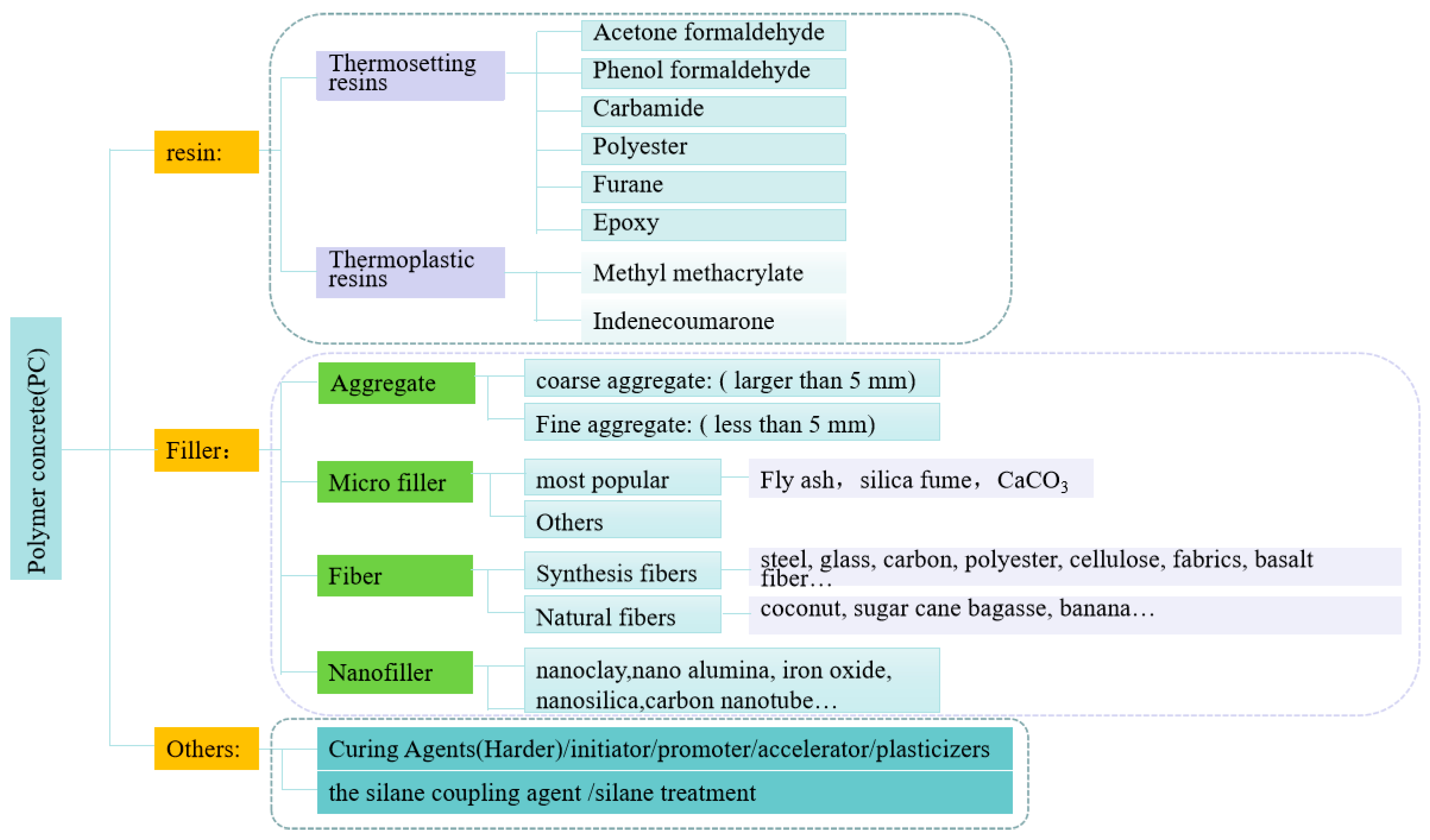

2. Commonly Used Components/Materials of Polymer Concrete

2.1. Resin

2.2. Filler

2.2.1. Aggregate

2.2.2. Microfillers

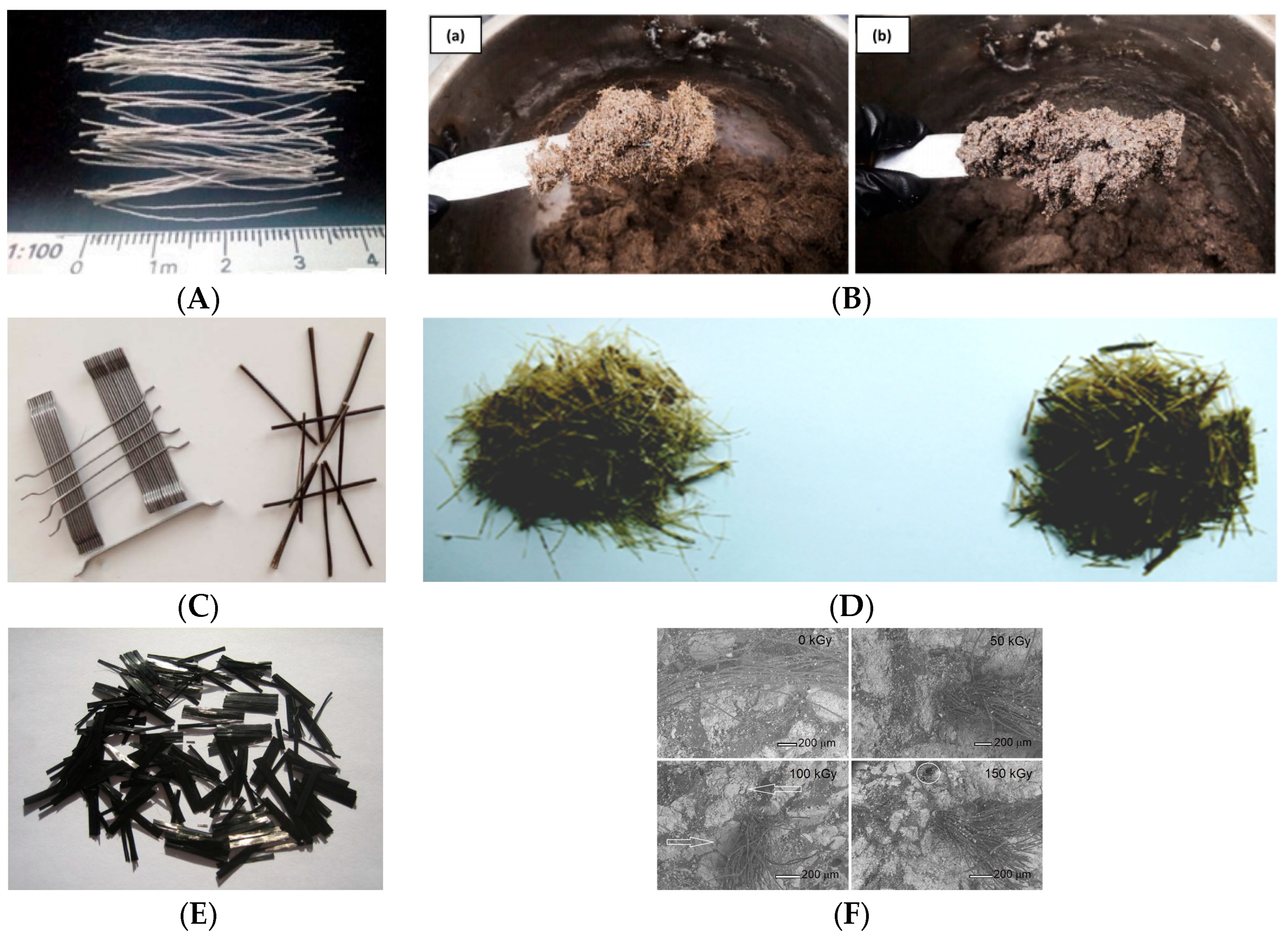

2.2.3. Fiber

2.2.4. Nanofiller

2.3. Others

2.3.1. Curing Agents (Harder)/Initiator/Promoter/Accelerator/Plasticizers

2.3.2. The Silane Coupling Agent/Silane Treatment

3. Review of Polymer Concrete and Application of Polymer Concrete

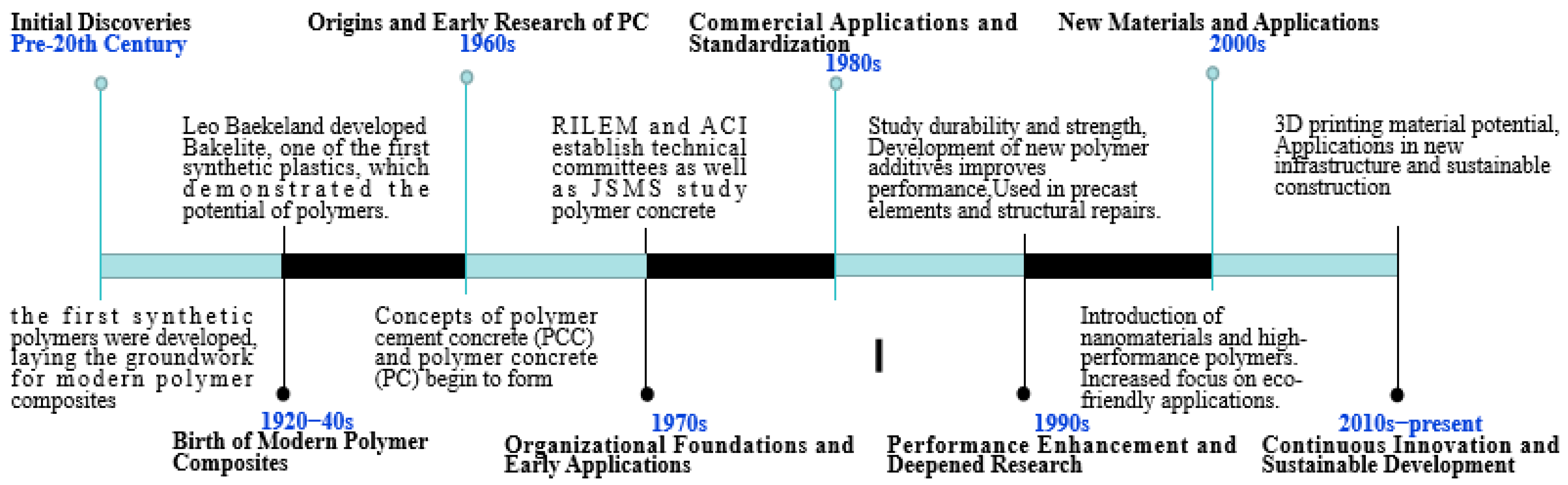

3.1. Review of Polymer Concrete Research

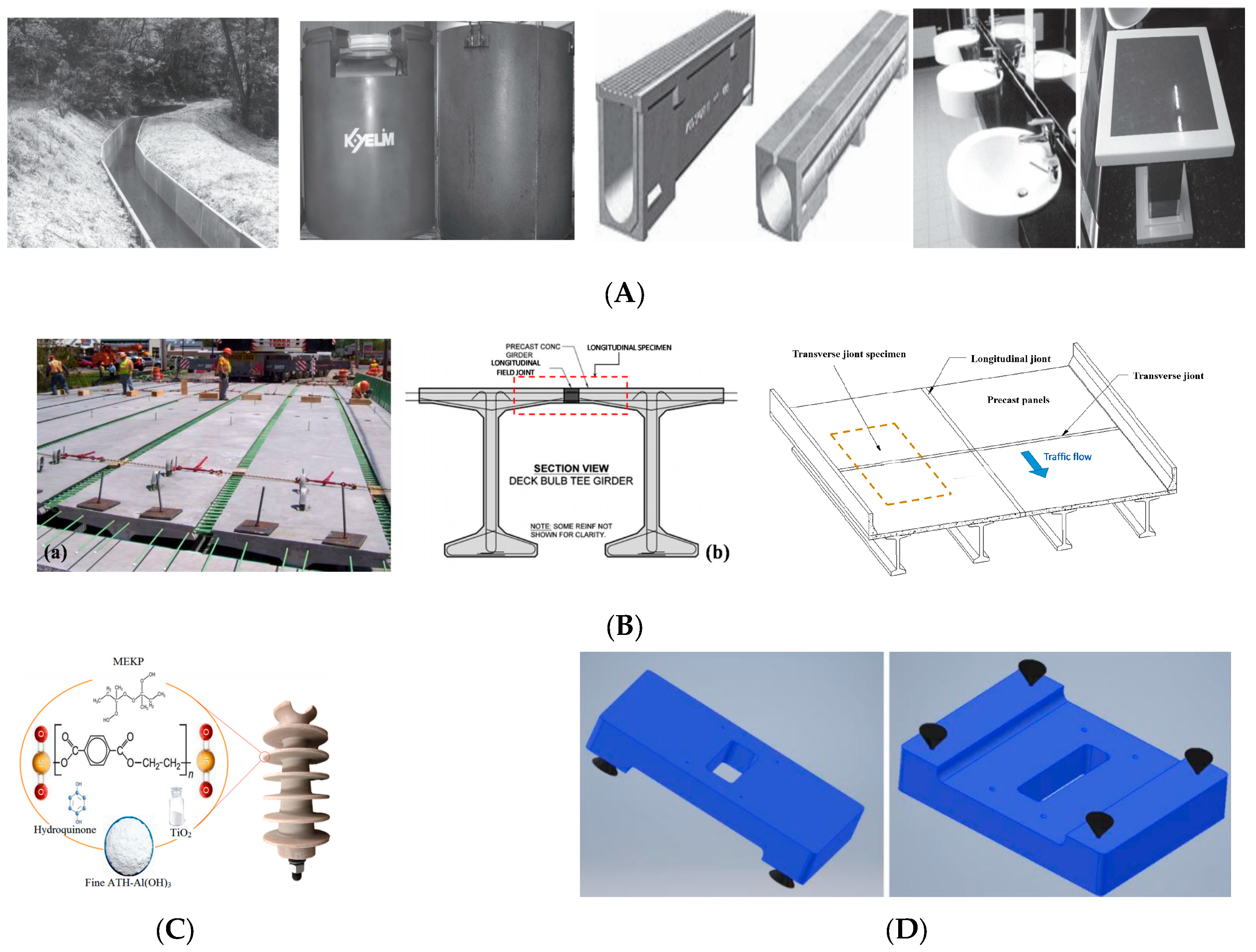

3.2. Applications of Polymer Concrete

3.3. Sustainability of Polymer Concrete

3.3.1. Reducing Landfill Dependency

3.3.2. Reducing Carbon Emission Mitigation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bedi, R.; Chandra, R.; Singh, S.P. Mechanical Properties of Polymer Concrete. J. Compos. 2013, 2013, 948745. [Google Scholar] [CrossRef]

- Figovsky, O.; Beilin, D. Advanced Polymer Concretes and Compounds; Taylor & Francis: Boca Raton, FL, USA, 2014. [Google Scholar]

- Ohama, Y. Recent progress in concrete-polymer composites. Adv. Cem. Based Mater. 1997, 5, 31–40. [Google Scholar] [CrossRef]

- Nodehi, M. Epoxy, polyester and vinyl ester based polymer concrete: A review. Innov. Infrastruct. Solut. Off. J. Soil-Struct. Interact. Group Egypt (SSIGE) 2022, 7, 64. [Google Scholar] [CrossRef]

- Mani, P.; Gupta, A.K.; Krishnamoorthy, S. Comparative study of epoxy and polyester resin-based polymer concretes. Int. J. Adhes. Adhes. 1987, 7, 157–163. [Google Scholar] [CrossRef]

- Vipulanandan, C.; Paul, E. Characterization of Polyester Polymer and Polymer Concrete. J. Mater. Civ. Eng. 1993, 5, 62–82. [Google Scholar] [CrossRef]

- Mebarkia, S.; Vipulanandan, C. Mechanical Properties and Water Diffusion in Polyester Polymer Concrete. J. Eng. Mech. 1995, 121, 1359–1365. [Google Scholar] [CrossRef]

- Ahn, N. Effects of metallic monomer powders on the mechanical properties of hardened polyester and acrylic polymer concrete. J. Appl. Polym. Sci. 2006, 101, 3106–3113. [Google Scholar] [CrossRef]

- Bărbuţă, M.; Harja, M.; Baran, I. Comparison of Mechanical Properties for Polymer Concrete with Different Types of Filler. J. Mater. Civ. Eng. 2010, 22, 696–701. [Google Scholar] [CrossRef]

- Yeon, K.-S.; Cha, J.-Y.; Yeon, J. Effects of DMT and TMPTMA on Working Life of Acrylic Polymer Concrete Exposed to Low Curing Temperatures. Polymers 2015, 7, 1587–1598. [Google Scholar] [CrossRef]

- Douba, A. Mechanical Characterization of Polymer Concrete with Nanomaterials. Master’s Thesis, University of New Mexico, Albuquerque, NM, USA, 2017. [Google Scholar]

- Emiroglu, M.; Douba, A.E.; Tarefder, R.A.; Kandil, U.F.; Taha, M.R. New Polymer Concrete with Superior Ductility and Fracture Toughness Using Alumina Nanoparticles. J. Mater. Civ. Eng. 2017, 29, 04017069. [Google Scholar] [CrossRef]

- Hassani Niaki, M.; Fereidoon, A.; Ghorbanzadeh Ahangari, M. Experimental study on the mechanical and thermal properties of basalt fiber and nanoclay reinforced polymer concrete. Compos. Struct. 2018, 191, 231–238. [Google Scholar] [CrossRef]

- Douba, A.; Emiroglu, M.; Kandil, U.F.; Reda Taha, M.M. Very ductile polymer concrete using carbon nanotubes. Constr. Build. Mater. 2019, 196, 468–477. [Google Scholar] [CrossRef]

- Byron, D.; Pacheli Heitman, A.; Neves, J.; de Souza, P.P.; de Oliveira Patricio, P.S. Evaluation of properties of polymer concrete based on epoxy resin and functionalized carbon nanotubes. Constr. Build. Mater. 2021, 309, 125155. [Google Scholar] [CrossRef]

- Asdollah-Tabar, M.; Heidari-Rarani, M.; Aliha, M.R.M. The effect of recycled PET bottles on the fracture toughness of polymer concrete. Compos. Commun. 2021, 25, 100684. [Google Scholar] [CrossRef]

- Kępczak, N.; Rosik, R.; Urbaniak, M. Material-removing machining wastes as a filler of a polymer concrete (industrial chips as a filler of a polymer concrete). Sci. Eng. Compos. Mater. 2021, 28, 343–351. [Google Scholar] [CrossRef]

- Farooq, M.; Banthia, N. Strain-hardening fiber reinforced polymer concrete with a low carbon footprint. Constr. Build. Mater. 2022, 314, 125705. [Google Scholar] [CrossRef]

- Kępniak, M.; Załęgowski, K.; Woyciechowski, P.; Pawłowski, J.; Nurczyński, J. Feasibility of Using Biochar as an Eco-Friendly Microfiller in Polymer Concretes. Polymers 2022, 14, 4701. [Google Scholar] [CrossRef]

- Zhang, Y.; He, M.; Wang, L.; Yan, J.; Ma, B.; Zhu, X.; Ok, Y.S.; Mechtcherine, V.; Tsang, D.C.W. Biochar as construction materials for achieving carbon neutrality. Biochar 2022, 4, 59. [Google Scholar] [CrossRef]

- Li, J.; Wang, C.; Zhang, X. The mechanical properties and failure criteria of epoxy polymer concrete under triaxial compression. Constr. Build. Mater. 2025, 470, 140617. [Google Scholar] [CrossRef]

- Ajir, K.; Toufigh, V.; Ghaemian, M. Health monitoring of polymer concrete subjected to various temperatures utilizing sinusoidal ultrasonic signals and an agglomeration of artificial intelligence techniques. Mech. Syst. Signal Process. 2025, 234, 112828. [Google Scholar] [CrossRef]

- Hu, W.; Sun, N.; Zhang, H.; Zhou, B.; Wang, Y. Damage evolution and size effect of epoxy polymer concrete under axial compression based on fractal dimension. Eng. Fail. Anal. 2025, 170, 109312. [Google Scholar] [CrossRef]

- Özdemir, A.E.; Ünal, S.; Büyüksungur, A.; Canbaz, M. Acid effect on permeable polymer concrete containing different resin and aggregate types. J. Build. Eng. 2025, 106, 112668. [Google Scholar] [CrossRef]

- Acharya, S.; Moustafa, M.A.; Shoaib, S. Tensile characteristics of polymethyl methacrylate polymer concrete under different strain rates. Case Stud. Constr. Mater. 2025, 22, e04759. [Google Scholar] [CrossRef]

- Bouchelaghem, H.; Boumediri, H.; Bezazi, A.; del Pino, G.; Ellagoune, S.; Scarpa, F.; Reis, P.N.B. Prediction of Mechanical Properties of Polymer Concretes Under 3-Point Bending Loading Using Artificial Neural Networks. Mech. Compos. Mater. 2025, 61, 439–454. [Google Scholar] [CrossRef]

- Haibe, A.A.; Vemuganti, S. Flexural Response Comparison of Nylon-Based 3D-Printed Glass Fiber Composites and Epoxy-Based Conventional Glass Fiber Composites in Cementitious and Polymer Concretes. Polymers 2025, 17, 218. [Google Scholar] [CrossRef]

- Raut, J.M.; Pimpalshende, A.; Chandak, M.A.; Patil, T.R.; Pinjarkar, L.; Nair, S. A novel multi-method framework for 3D printed fiber-reinforced polymer concrete utilizing advance additive manufacturing techniques. Asian J. Civ. Eng. 2025, 26, 1655–1668. [Google Scholar] [CrossRef]

- Krčma, M.; Škaroupka, D.; Vosynek, P.; Zikmund, T.; Kaiser, J.; Palousek, D. Use of polymer concrete for large-scale 3D printing. Rapid Prototyp. J. 2021, 27, 465–474. [Google Scholar] [CrossRef]

- Reis, J.M.L.; Ferreira, A.J.M. Assessment of fracture properties of epoxy polymer concrete reinforced with short carbon and glass fibers. Constr. Build. Mater. 2004, 18, 523–528. [Google Scholar] [CrossRef]

- Kapustin, F.L.; Kapustin, A.F. Influence of Plasticizers on the Properties of Fine-Grained Polymer Concrete. Solid State Phenom. 2020, 299, 72–77. [Google Scholar] [CrossRef]

- Jozefiak, K.; Michalczyk, R. Prediction of Structural Performance of Vinyl Ester Polymer Concrete Using FEM Elasto-Plastic Model. Materials 2020, 13, 4034. [Google Scholar] [CrossRef]

- Mohan, M.M.D. Studies on Furan Polymer Concrete. J. Polym. Res. 2005, 12, 231–241. [Google Scholar]

- Hao, H.; Hao, P.; Jianheng, H.; Peitao, Y.; Jialin, L.; Mangeng, L.; Bing, L. Influence of hard segment content and soft segment length on the microphase structure and mechanical performance of polyurethane-based polymer concrete. Constr. Build. Mater. 2021, 284, 122388. [Google Scholar] [CrossRef]

- Bondarev, B.A.; Borkov, P.V.; Bondarev, A.B. An Outlook on the Application of Glass-Reinforced Plastic and Polymer Concrete Components in Bridge Construction. Procedia Eng. 2016, 150, 1617–1622. [Google Scholar] [CrossRef][Green Version]

- Martínez-Barrera, G.; Gencel, O.; Martínez-López, M. Performance improvement of polymer concrete produced with unsaturated resin, by a post-cure process, polyester fibers and gamma radiation. J. Build. Eng. 2022, 59, 105117. [Google Scholar] [CrossRef]

- Niaki, M.H.; Fereidoon, A.; Ahangari, M.G. Effect of basalt, silica sand and fly ash on the mechanical properties of quaternary polymer concretes. Bull. Mater. Sci. 2018, 41, 69. [Google Scholar] [CrossRef]

- Malchiodi, B.; Siligardi, C.; Pozzi, P. Unsaturated Polyester-Based Polymer Concrete Containing Recycled Cathode Ray Tube Glass Aggregate. J. Compos. Sci. 2022, 6, 47. [Google Scholar] [CrossRef]

- Sarde, B.; Patil, Y.D.; Dholakiya, B.; Pawar, V. Effect of Red Mud and Palm Oil Fuel Ash as Cement Replacement on the Properties of PET Resin-Modified MMA Polymer Concrete at Elevated Temperatures. J. Mater. Civ. Eng. 2024, 36, 04023488. [Google Scholar] [CrossRef]

- Khalid, N.H.A.; Hussin, M.W.; Mirza, J.; Ariffin, N.F.; Ismail, M.A.; Lee, H.-S.; Mohamed, A.; Jaya, R.P. Palm oil fuel ash as potential green micro-filler in polymer concrete. Constr. Build. Mater. 2016, 102, 950–960. [Google Scholar] [CrossRef]

- Huang, H.; Pang, H.; Huang, J.; Zhao, H.; Liao, B. Synthesis and characterization of ground glass fiber reinforced polyurethane-based polymer concrete as a cementitious runway repair material. Constr. Build. Mater. 2020, 242, 117221. [Google Scholar] [CrossRef]

- Hwang, E.-H.; Kim, J.-M.; Yeon, J.H. Characteristics of polyester polymer concrete using spherical aggregates from industrial by-products. J. Appl. Polym. Sci. 2013, 129, 2905–2912. [Google Scholar] [CrossRef]

- Susilawati; Husna, A.U.; Ferdiansyah, B. Synthesis and characterization of polymer concrete withpumice aggregate and singkut leaf fiber as filler. J. Phys. Conf. Ser. 2021, 1811, 012041. [Google Scholar] [CrossRef]

- Mohammadyan-Yasouj, S.E.; Ahangar, H.A.; Oskoei, N.A.; Shokravi, H.; Koloor, S.S.R.; Petrů, M. Experimental Study on the Effect of Basalt Fiber and Sodium Alginate in Polymer Concrete Exposed to Elevated Temperature. Processes 2021, 9, 510. [Google Scholar] [CrossRef]

- Liu, G.-J.; Bai, E.-L.; Xu, J.-Y.; Yang, N.; Wang, T.-j. Dynamic compressive mechanical properties of carbon fiber-reinforced polymer concrete with different polymer-cement ratios at high strain rates. Constr. Build. Mater. 2020, 261, 119995. [Google Scholar] [CrossRef]

- Naik, G.P.; Hemalatha, K.; Konik, S.; Kosaraju, S.; Bobba, P.; Singh, S. Flexural performance of Hybrid Fiber Reinforced Polymer Concrete using PVA fiber. E3S Web Conf. 2021, 309, 01172. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Karimi, H.r.; Abedi, M. The role of mix design and short glass fiber content on mode-I cracking characteristics of polymer concrete. Constr. Build. Mater. 2022, 317, 126139. [Google Scholar] [CrossRef]

- Chikhradze, N.; Marquis, F.; Abashidze, G.; Tsverava, D. Production of Corrosion-Resistant Polymer Concrete Reinforced with Various Fibers. IOP Conf. Ser. Earth Environ. Sci. 2019, 362, 012118. [Google Scholar] [CrossRef]

- Hu, B.; Zhang, N.; Liao, Y.; Pan, Z.; Liu, Y.; Zhou, L.; Liu, Z.; Jiang, Z. Enhanced flexural performance of epoxy polymer concrete with short natural fibers. Sci. China Technol. Sci. 2018, 61, 1107–1113. [Google Scholar] [CrossRef]

- Martínez-Barrera, G.; Gencel, O.; Martínez-López, M. Polyester polymer concrete modified by polyester fibers and gamma rays. Constr. Build. Mater. 2022, 356, 129278. [Google Scholar] [CrossRef]

- Reis, J.M.L. Fracture and flexural characterization of natural fiber-reinforced polymer concrete. Constr. Build. Mater. 2006, 20, 673–678. [Google Scholar] [CrossRef]

- Barbuta, M.; Serbanoiu, A.A.; Teodorescu, R.; Rosca, B.; Mitroi, R.; Bejan, G. Characterization of polymer concrete with natural fibers. IOP Conf. Ser. Mater. Sci. Eng. 2017, 246, 012033. [Google Scholar] [CrossRef]

- Maghfirah, A.; Zega, A.F.; Sudiati; Sinuhaji, P.; Nabilla, T.; Utari, G.T. Utilization Of Pahae Natural Zeolite In The Production Of Polymer Concrete Using Corn Shell Fiber And Polyurethane Resin As Adhesive. J. Phys. Conf. Ser. 2023, 2672, 012003. [Google Scholar] [CrossRef]

- Rokbi, M.; Baali, B.; Rahmouni, Z.E.A.; Latelli, H. Mechanical properties of polymer concrete made with jute fabric and waste marble powder at various woven orientations. Int. J. Environ. Sci. Technol. 2019, 16, 5087–5094. [Google Scholar] [CrossRef]

- Milawarni, M.; Nurlaili; Misriana; Radhiah. Analysis of the mechanical properties of coffee shell fiber composites with polypropylene resin for polymer concrete applications. AIP Conf. Proc. 2023, 2431, 150001. [Google Scholar]

- Avram, S.E.; Tudoran, L.B.; Cuc, S.; Borodi, G.; Birle, B.V.; Petean, I. Natural Fiber Reinforcement of Ceramic Slurry Compacts. J. Compos. Sci. 2024, 8, 542. [Google Scholar] [CrossRef]

- Martínez-López, Á.; Martínez-Barrera, G.; Vigueras-Santiago, E.; Martínez-López, M.; Gencel, O. Mechanical improvement of polymer concrete by using aged polyester resin, nanosilica and gamma rays. J. Build. Eng. 2022, 58, 105083. [Google Scholar] [CrossRef]

- Avram, S.E.; Birle, B.V.; Tudoran, L.B.; Borodi, G.; Petean, I. Investigation of Used Water Sediments from Ceramic Tile Fabrication. Water 2024, 16, 1027. [Google Scholar] [CrossRef]

- Aghdam, A.A.; Hassani Niaki, M. Influence of high temperatures on modes I and II fracture toughness and energy of nanoclay-reinforced polymer concrete. Mag. Concr. Res. 2024, 76, 591–599. [Google Scholar] [CrossRef]

- Jo, B.-W.; Park, S.-K.; Kim, D.-K. Mechanical properties of nano-MMT reinforced polymer composite and polymer concrete. Constr. Build. Mater. 2008, 22, 14–20. [Google Scholar] [CrossRef]

- Daghash, S.M.; Soliman, E.M.; Kandil, U.F.; Reda Taha, M.M. Improving Impact Resistance of Polymer Concrete Using CNTs. Int. J. Concr. Struct. Mater. 2016, 10, 539–553. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Gao, S.; Zheng, Y. Improvement effects of nano-silica on bonding performance of polymer concrete for repairing damaged concrete. Constr. Build. Mater. 2023, 409, 133768. [Google Scholar] [CrossRef]

- Zhang, K.; Hou, D.; Li, S.; Wang, M. Molecular Dynamics Simulation of Polymer Concrete Enhanced by Carbon Nanoparticles: Effect of Surface Functional Groups. Langmuir 2025, 41, 8975–8984. [Google Scholar] [CrossRef] [PubMed]

- Douba, A.; Genedy, M.; Matteo, E.N.; Kandil, U.F.; Stormont, J.; Reda Taha, M.M. The significance of nanoparticles on bond strength of polymer concrete to steel. Int. J. Adhes. Adhes. 2017, 74, 77–85. [Google Scholar] [CrossRef]

- Niaki, M.H.; Ahangari, M.G. Polymer Concretes: Advanced Construction Materials, 1st ed.; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Chikhradze, N.; Abashidze, G.; Tsverava, D. Production of Polymer Concrete Compositions Effective in Underground Aggressive Medium. In Proceedings of the International Multidisciplinary Scientific GeoConference: SGEM, Sofia, Bulgaria, 2–8 July 2018; pp. 409–416. [Google Scholar]

- Sankar, V.R.; Natarajan, M. Investigation on performance of fibre reinforced polymer concrete made with plastic aggregates. In Proceedings of the International Conference on Minerals, Materials and Manufacturing Methods (Icmmmm), Washington, DC, USA, 18–20 August 2023. [Google Scholar]

- Lokuge, W.; Aravinthan, T. Effect of fly ash on the behaviour of polymer concrete with different types of resin. Mater. Des. 2013, 51, 175–181. [Google Scholar] [CrossRef]

- Haque, E.; Armeniades, C.D. Montmorillonite polymer concrete: Zero-shrinkage and expanding polymer concrete with enhanced strength. Polym. Eng. Sci. 2004, 26, 1524–1530. [Google Scholar] [CrossRef]

- Mahdi, F.; Abbas, H.; Khan, A.A. Flexural, shear and bond strength of polymer concrete utilizing recycled resin obtained from post consumer PET bottles. Constr. Build. Mater. 2013, 44, 798–811. [Google Scholar] [CrossRef]

- Andiç-Çakır, Ö.; Üzüm, O.; Yüksel, C.; Sarikanat, M. Waste glass aggregate for cementitious and polymer concrete. Proc. Inst. Civ. Eng.—Constr. Mater. 2016, 169, 106–116. [Google Scholar] [CrossRef]

- Yeon, K.S.; Choi, Y.S.; Kawakami, M.; Seung, I.B.; Yeon, J.H. Strength Development Characteristics and Economic Efficiency of Low Temperature Cured Acrylic Polymer Concrete: The Effect of Additive Type. Adv. Mater. Res. 2013, 687, 124–129. [Google Scholar] [CrossRef]

- Yeon, K.-S.; Yeon, J.H.; Choi, Y.-S.; Min, S.-H. Deformation behavior of acrylic polymer concrete: Effects of methacrylic acid and curing temperature. Constr. Build. Mater. 2014, 63, 125–131. [Google Scholar] [CrossRef]

- Hirano, T.; Nagano, N.; Katsuse, K.; Inuzuka, M. Glycerol methacrylate/styrene polymer concrete for low-temperature curing. Adv. Compos. Mater. 1992, 2, 51–67. [Google Scholar] [CrossRef]

- Sugama, T.; Kukacka, L.E.; Horn, W. Properties of water-compatible furfuryl alcohol polymer concrete. Cem. Concr. Res. 1981, 11, 497–506. [Google Scholar] [CrossRef]

- Cakir, F.; Yildirim, P. Effect of Methyl Ethyl Ketone Peroxide (MEKP) on Mechanical Properties of Polymer Concrete (PC). 2019. Available online: https://www.researchgate.net/publication/333162083_Effect_of_Methyl_Ethyl_Ketone_Peroxide_MEKP_on_Mechanical_Properties_of_Polymer_Concrete_PC (accessed on 20 May 2025).

- Griffiths, R.; Ball, A. An assessment of the properties and degradation behaviour of glass-fibre-reinforced polyester polymer concrete. Compos. Sci. Technol. 2000, 60, 2747–2753. [Google Scholar] [CrossRef]

- Gunasekaran, M. Polymer concrete high voltage insulation: A decade of progress. In Proceedings of the 1985 EIC 17th Electrical/Electronics Insulation Conference, Boston, MA, USA, 30 September–3 October 1985; pp. 64–67. [Google Scholar]

- Gunasekaran, M. World-wide long-term outdoor performance of polymer concrete insulation. In Proceedings of the 1994 4th International Conference on Properties and Applications of Dielectric Materials (ICPADM), Brisbane, QLD, Australia, 3–8 July 1994; Volume 512, pp. 515–518. [Google Scholar]

- Yeon, K.-S. Polymer Concrete as Construction Materials. Int. J. Soc. Mater. Eng. Resour. 2010, 17, 107–111. [Google Scholar] [CrossRef]

- Allahvirdizadeh, R.; Rashetnia, R.; Dousti, A.; Shekarchi, M.J.C.S. Application of polymer concrete in repair of concrete structures: A literature review. Concr. Solut. 2011, 435–444. [Google Scholar] [CrossRef]

- Bedi, R.; Chandra, R.; Singh, S.P. Reviewing some properties of polymer concrete. Indian Concr. J. 2014, 88, 47–68. [Google Scholar]

- Momtazi, A.S.; Kohani Khoshkbijari, R.; Sabagh Mogharab, S. Polymers in concrete: Applications and specifications. Eur. Online J. Nat. Soc. Sci. Proc. 2015, 4, 62–72. [Google Scholar]

- Kumar, R. A Review on Epoxy and Polyester Based Polymer Concrete and Exploration of Polyfurfuryl Alcohol as Polymer Concrete. J. Polym. 2016, 2016, 7249743. [Google Scholar] [CrossRef]

- Ali-Askari, K.O.; Singh, V.P.; Dalezios, N.R.; Crusberg, T.C. Polymer concrete. Int. J. Hydrol. 2018, 2, 630–635. [Google Scholar] [CrossRef]

- Venkatesh, B.; Student, U.G. Review on performance of polymer concrete with resins and its applications. Int. J. Pure Appl. Math 2018, 119, 175–184. [Google Scholar]

- Hassani Niaki, M. Fracture mechanics of polymer concretes: A review. Theor. Appl. Fract. Mech. 2023, 125, 103922. [Google Scholar] [CrossRef]

- Palamarchuk, A.; Yudaev, P.; Chistyakov, E. Polymer Concretes Based on Various Resins: Modern Research and Modeling of Mechanical Properties. J. Compos. Sci. 2024, 8, 503. [Google Scholar] [CrossRef]

- Mandaokar, A. Polymer Concrete—Global Market Outlook (2021–2030). 2024. Available online: https://www.marketresearchfuture.com/reports/polymer-concrete-market-6011 (accessed on 20 May 2025).

- Abokifa, M.; Moustafa, M.A. Experimental behavior of poly methyl methacrylate polymer concrete for bridge deck bulb tee girders longitudinal field joints. Constr. Build. Mater. 2021, 270, 121840. [Google Scholar] [CrossRef]

- Abokifa, M.; Moustafa, M.A.; Itani, A.M. Comparative structural behavior of bridge deck panels with polymer concrete and UHPC transverse field joints. Eng. Struct. 2021, 247, 113195. [Google Scholar] [CrossRef]

- Fallah-Arani, H.; Tehrani, F.S.; Koohani, H.; Elmdoust, B.; Nodoushan, N.J.; Shafiei, Z. Optimization of resin content to improve electrical and mechanical properties of polymer-concrete line-post insulators used in electrical distribution networks. Electr. Power Syst. Res. 2023, 220, 109357. [Google Scholar] [CrossRef]

- Poklemba, R.; Duplakova, D.; Zajac, J.; Duplak, J.; Simkulet, V.; Goldyniak, D. Design and Investigation of Machine Tool Bed Based on Polymer Concrete Mixture. Int. J. Simul. Model. 2020, 19, 291–302. [Google Scholar] [CrossRef]

- Moldamuratov, Z.N.; Imambayeva, R.S.; Imambaev, N.S.; Iglikov, A.A.; Tattibayev, S.Z. Polymer concrete production technology with improved characteristics based on furfural for use in hydraulic engineering construction. Nanotechnologies Constr. A Sci. Internet-J. 2022, 14, 306–318. [Google Scholar] [CrossRef]

- Yelemessov, K.; Krupnik, L.; Bortebayev, S.; Beisenov, B.; Baskanbayeva, D.; Igbayeva, A.; Voloshyn, O.; Liu, B.; Kryzhanivskyi, Y.; Heyets, V.; et al. Polymer concrete and fibre concrete as efficient materials for manufacture of gear cases and pumps. E3S Web Conf. 2020, 168, 00018. [Google Scholar] [CrossRef]

- Kępczak, N.; Witkowski, B. Modal Assurance Criterion as an iron cast and hybrid machine tool’s body comparison tool. J. Manuf. Process. 2022, 79, 881–886. [Google Scholar] [CrossRef]

- Stucki, S.; Kelch, S.; Mamie, T.; Burckhardt, U.; Grönquist, P.; Elsener, R.; Schubert, M.; Frangi, A.; Burgert, I. High-performance timber-concrete-composites with polymer concrete and beech wood. Constr. Build. Mater. 2024, 411, 134069. [Google Scholar] [CrossRef]

- Ahn, S.; Kwon, S.; Hwang, Y.-T.; Koh, H.-I.; Kim, H.-S.; Park, J. Complex structured polymer concrete sleeper for rolling noise reduction of high-speed train system. Compos. Struct. 2019, 223, 110944. [Google Scholar] [CrossRef]

- Chahade, T.; Schober, K.-U. Experimental investigations on the pull-out strength of steel rods bonded in Douglas fir roundwood specimens with polymer concrete. Eur. J. Wood Wood Prod. 2022, 81, 439–450. [Google Scholar] [CrossRef]

- Caluk, N.; Seisdedos, G.; Azizinamini, A. Destructive and non-destructive testing of potential lunar polymer concrete for future lunar habitable infrastructure. Constr. Build. Mater. 2023, 405, 133395. [Google Scholar] [CrossRef]

- Chouaybi, I.; Azifa, A.; Moujahid, E.M.; Bettach, M. Waste to wealth: Synthesis of hydrocalumite from Moroccan phosphogypsum and aluminum wastes. Waste Manag. 2023, 171, 26–31. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Lu, H.; Zeng, D.; Meng, D.; Chen, J.; Liu, K.; Ran, J.; Su, X. Highly oriented arrangement of phosphogypsum crystals and structure of phosphogypsum/Polystyrene composites. J. Polym. Res. 2022, 29, 461. [Google Scholar] [CrossRef]

- Díaz-Jiménez, C.; Grimaldi, G.; Sánchez-González, J.; Hipólito-Ojalvo, F.; Díaz-Parralejo, A. Manufacture and characterization of polymer concrete combining inorganic and organic fillers. J. Sustain. Cem. Based Mater. 2025, 14, 167–177. [Google Scholar] [CrossRef]

- Reis, J.M.L.d. Effect of Textile Waste on the Mechanical Properties of Polymer Concrete. Mater. Res. 2009, 12, 63–67. [Google Scholar] [CrossRef]

| Commonly Used Polymeric Resins | Most Significant Disadvantages and Their Viscosity Values |

|---|---|

| epoxy resin [30] | Expensive, high viscosity (11–14 Pa·s at 25 °C) |

| polyester resin [31] | Toxicity in the uncured state (0.4 Pa·s at 25 °C) |

| vinyl ester resin [32] | High shrinkage, harder to handle, deterioration due to thermally induced cracks and bond failure between concrete and overlay; (0.2–0.35 Pa·s at 25 °C) |

| furan resins [33] | Short-term pot life, toxicity in the uncured state, high self-heating temperature causing significant thermal stresses, affecting strength (0.02~0.05 Pa·s at 20 °C) |

| polyurethane resins [34] | The thermal resistance is generally poor; prolonged exposure to elevated temperatures may lead to softening, strength degradation, or decomposition (0.2–2 Pa·s at 25 °C) |

| Poly(methyl methacrylate) [8] | Low flash point of the MMA monomer, posing safety problems (0.56 Pa·s at 20 °C) |

| Carbamide (urea-formaldehyde) [35] | Relatively low physical and mechanical properties (lower than 0.1 Pa·s at 25 °C) |

| Type of Resin/PC | Agent |

|---|---|

| epoxy resin [30]. | harder: aliphatic amine |

| epoxy resin ROPOXID 701 [9] | curing agent (Harder:): ROMANID 407 |

| polyester resin [66] | curing agents: Akcobalt 6% (cobalt 2-ethylhexanoate mixture) and Akperox A1 (Methyl Ethyl Ketone Peroxide-MEKP) |

| polyester resin [31] | plasticizer: dibutyl-phthalate, chlorinated paraffin, technical glycerin, and engine oil |

| polyester resins [67] | superplasticizer: CONPLAST SP430 |

| polyester resin (MEKP-NR20) [68] | initiator: Methyl ethyl ketone peroxide (MEKP) in dimethyl phthalate (DMP) |

| unpromoted polyester-MMT PC [69] | initiators: 0.3% weight of Benzoyl peroxide |

| unsaturated polyester resin [70]. | initiator promoter: methyl ethyl ketone peroxide (MEKP) and cobalt naphthenate (CoNp)/Benzoyl peroxide (BPO) and N,N-diethyl aniline (NNDA) |

| unsaturated polyester resin [71] | hardener: 2 wt% methyl ethyl ketone peroxide (MEKP) accelerator: 1 wt% cobalt octoate |

| acrylic polymer concrete [72] | initiator: Benzoyl peroxide (BPO) catalyst: N, N-Dimethylaniline and N,N-Dimethyl-p-toluidine auxiliary accelerator: MAA, a type of polar monomer cross-linking agent: TMPTMA coupling agent: silane (3-methacryl oxypropyl trimethoxy silane) |

| acrylic resin [73] | initiator: benzoyl peroxide (BPO) accelerator: N,N-dimethylaniline (DMA) auxiliary accelerator: methacrylic acid (MAA) |

| acrylic resin [10] | initiator: benzoyl peroxide(BPO) promoter: N,N-dimethyl-p-toluidine(DMT) cross-linking agent: trimethylolpropane trimethacrylate(TMPTMA), a highly reactive tri-functional monomer, promoting hardening reactions by free radical polymerization |

| vinyl ester [32] | initiator: benzoyl peroxide(BPO) (function as harder) with dimethylaniline and cobalt naphthenate(function as an accelerant) |

| glycerol methacrylate/styrene polymer concrete [74] | initiators: methyl acetoacetate peroxide (MAAPO) accelerators: cobalt naphthenate (CoN) |

| furfuryl alcohol(FA) [75] | initiators: benzenesulfonic acid, p-toluenesulfonic acid, trichloroacetic acid, a, a, a-trichlorotoluene, a, a-dichlorotoluene, and a-chlorotoluene |

| Year/Author | Main Review Work | Brief Findings |

|---|---|---|

| 1985 [78] Gunasekaran, M | Development of PC for high-voltage insulation applications, highlighting the progress made in the previous decade and emphasizing its versatility as a composite material. | PC insulators perform well in the field and are highly competitive with cycloaliphatic epoxy and standard electrical porcelain. |

| 1994 [79] Gunasekaran, M | Performance of different types of polymer concrete insulation systems, discussing their durability and opportunities for improvement in field applications. | PC insulation can replace porcelain and is versatile for both insulating and structural applications in the electric power industry. |

| 2010 [80] Yeon, K.-S. | Physical and mechanical properties, product applications, economic analysis, and environmental impacts of PC. The prospects of polymer concrete in the construction market. | Besides mechanical strengths, it turned out that PC has beneficial performance as construction materials in overall properties. |

| 2011 [81] Allahvirdizadeh, R | Discusses concrete repair methods and materials, analyzes different effects on PC behavior, evaluates wear resistance, and provides repair scenario examples. | PC is not suitable for high temperatures but is resistant to freeze–thaw cycles and deicing solutions, requires careful selection, and is allowed for use in inaccessible cases. |

| 2013 [1] Bedi, R. | Summarizes the efforts on selecting ingredients, optimizing processing parameters, controlling curing conditions, and their impacts on the mechanical properties of PC. | Epoxy PC outperforms polyester in key properties. Using locally available materials reduces costs, while optimizing aggregate mix maximizes strength. Aggregate moisture below 0.5% and adding silane coupling agents are both benefits. |

| 2014 [82] Bedi, R. | Ingredient selection, processing parameters, curing conditions, and their influence on the mechanical properties of the material. | Resin dosage ranges from 10% to 20% by weight in PC. Assisted drying and the use of gap-graded aggregates are beneficial, while 1% silane relative to resin weight yields optimal outcomes. |

| 2015 [83] Momtazi, A.S. | Modern construction techniques and recent research advancements in PC applications and improvements. | Epoxy polymer concrete can store anti-ice fluids and then release them during snowfall and severe weather conditions (frost). |

| 2016 [84] Kumar, R. | Formulations and properties of epoxy and polyester-based polymer concrete, highlighting mechanical, thermal, and water resistance properties. | The shift to polyfurfuryl alcohol (PFA) as a sustainable bioresin for PC offers superior chemical resistance compared to traditional thermoset polymers. |

| 2018 [85] Ali-Askari, K.O | Compares features between PC and OPC, examining compound system functions and presenting various applications of polymer concrete. | PC displays shapeability after loading, has a lower elasticity modulus, exhibits nearly double the linear thermal expansion coefficient of ordinary concrete, and has lower penetrance and higher chemical resistance. |

| 2018 [86] Venkatesh, B. | Discusses resin and fiber proportions, mechanical properties, mix design, advantages, and applications of resin-based PC. | The addition of fly ash as filler material in polymer resin concrete results in an economical mixture, and the ductility can be improved with increasing resin content. |

| 2022 [4] Nodehi, M. | Fresh, mechanical, and durability properties of PC; comparative analyses of different resins and their performance results. | PC provides superior strength, corrosion resistance, and chemical durability. Adjusting fillers and cementitious materials allows customization of its flowability and properties. |

| 2023 [87] Hassani Niaki | Evaluate fracture properties of PC, exploring governing equations, fracture patterns, and parameters affecting fracture behaviors. | Exposure to high temperatures, thermal cycles, and chemical solutions, as well as exposure to atmospheric conditions, can have destructive effects on the fracture properties of PC. |

| 2024 [88] Aleksandr, P | Polymer Concretes Based on Various Resins: Modern Research and Modeling of Mechanical Properties | The most promising polymers for use in the field of road surface repair are polymer concretes with poly(meth)acrylic resins. The most adequate and productive models are the deep machine learning model and the extreme gradient boosting model. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Gu, J.; Xu, Y.; Li, S.; Zhang, R. Review of Component Materials and Diverse Applications of Polymer Concrete. Materials 2025, 18, 2745. https://doi.org/10.3390/ma18122745

Li X, Gu J, Xu Y, Li S, Zhang R. Review of Component Materials and Diverse Applications of Polymer Concrete. Materials. 2025; 18(12):2745. https://doi.org/10.3390/ma18122745

Chicago/Turabian StyleLi, Xiaolei, Jinyuan Gu, Yunsheng Xu, Shen Li, and Rui Zhang. 2025. "Review of Component Materials and Diverse Applications of Polymer Concrete" Materials 18, no. 12: 2745. https://doi.org/10.3390/ma18122745

APA StyleLi, X., Gu, J., Xu, Y., Li, S., & Zhang, R. (2025). Review of Component Materials and Diverse Applications of Polymer Concrete. Materials, 18(12), 2745. https://doi.org/10.3390/ma18122745