Mechanical Performance of Wool-Reinforced Epoxy Composites: Tensile, Flexural, Compressive, and Impact Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

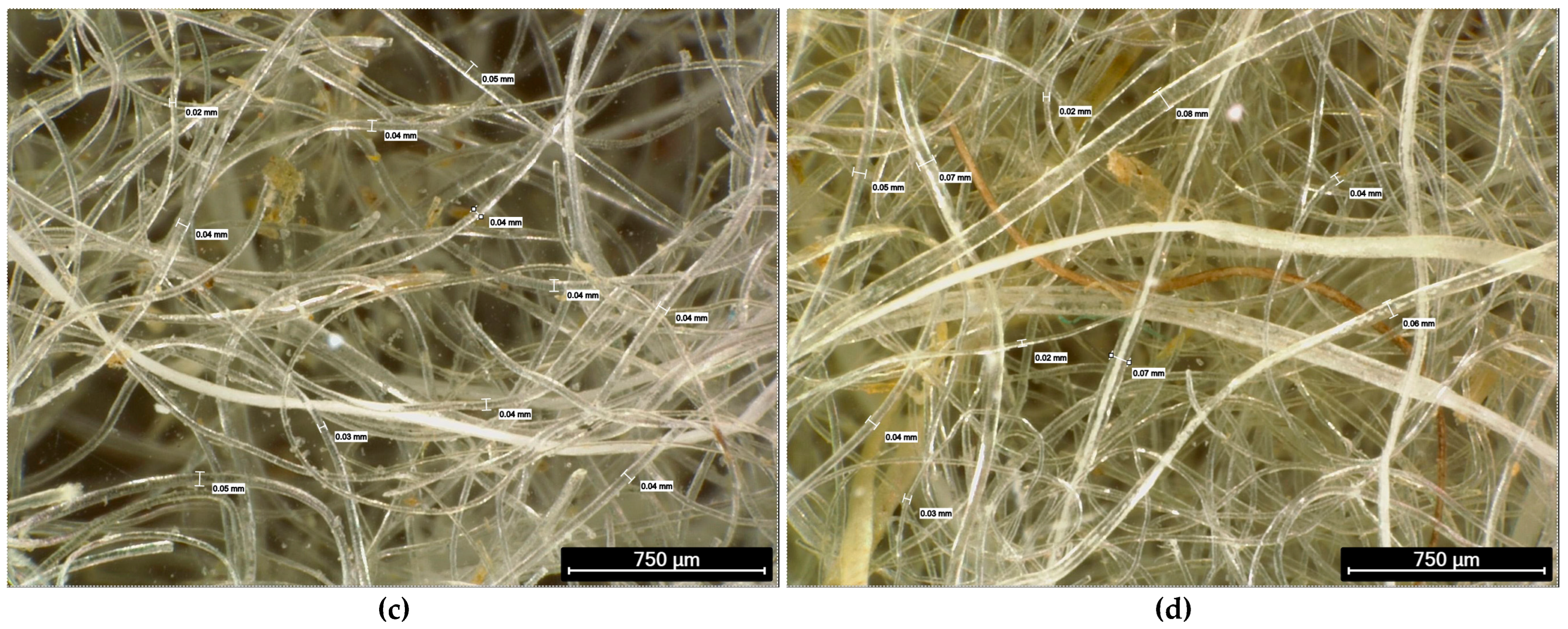

2.2. Equipment

2.3. Methods

3. Results and Discussion

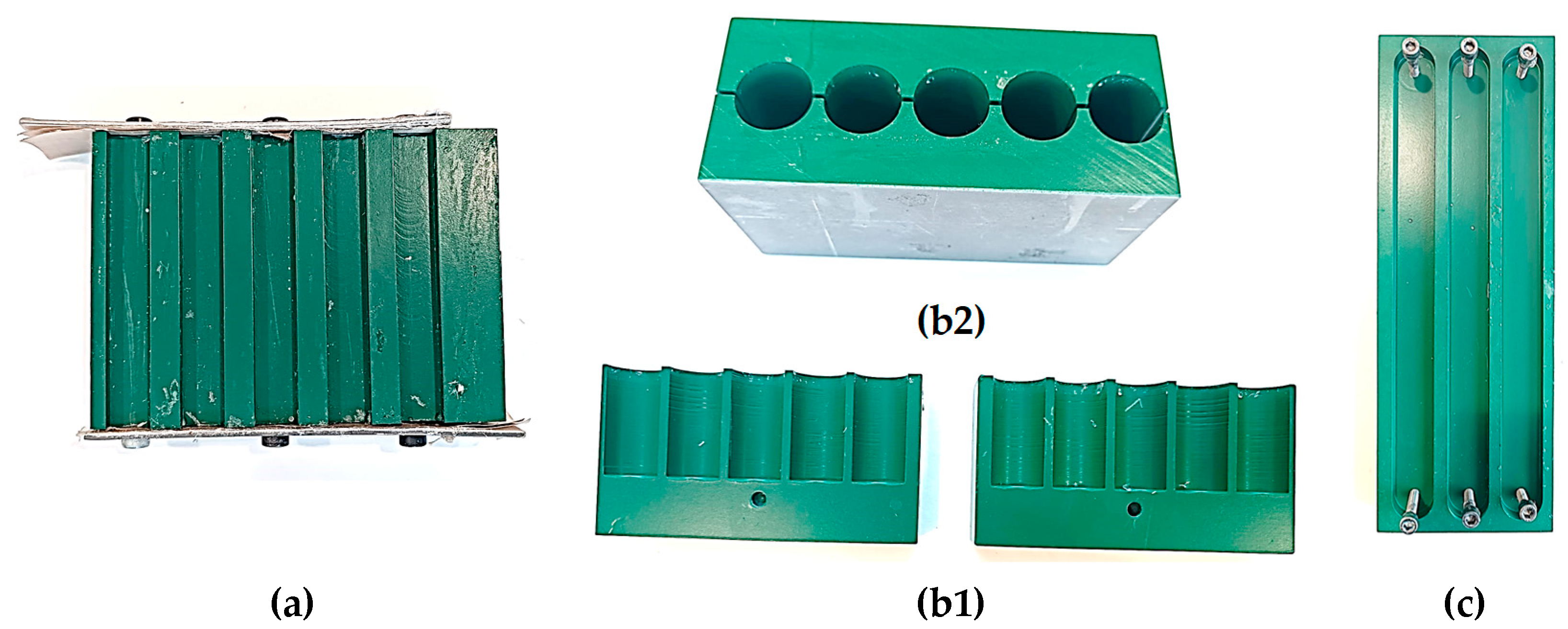

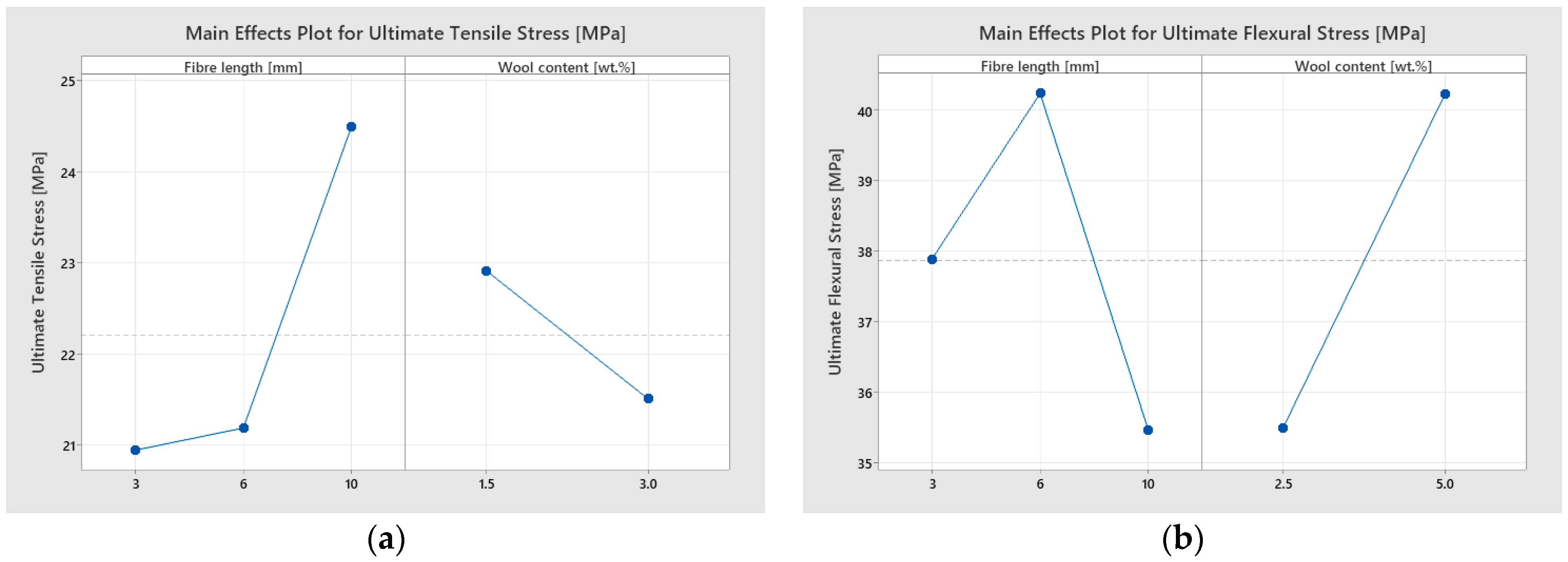

3.1. Tensile Test Results and Analysis

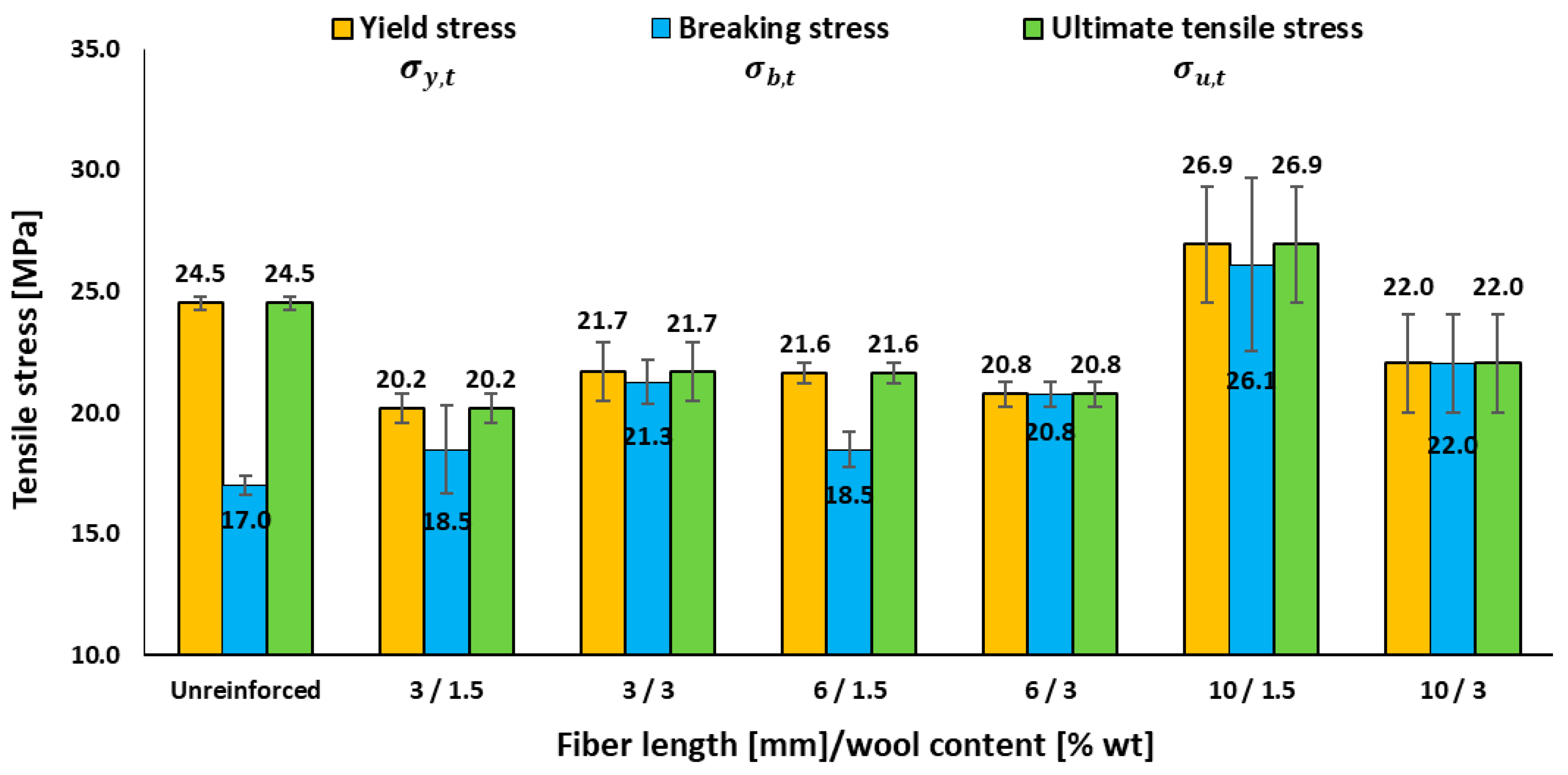

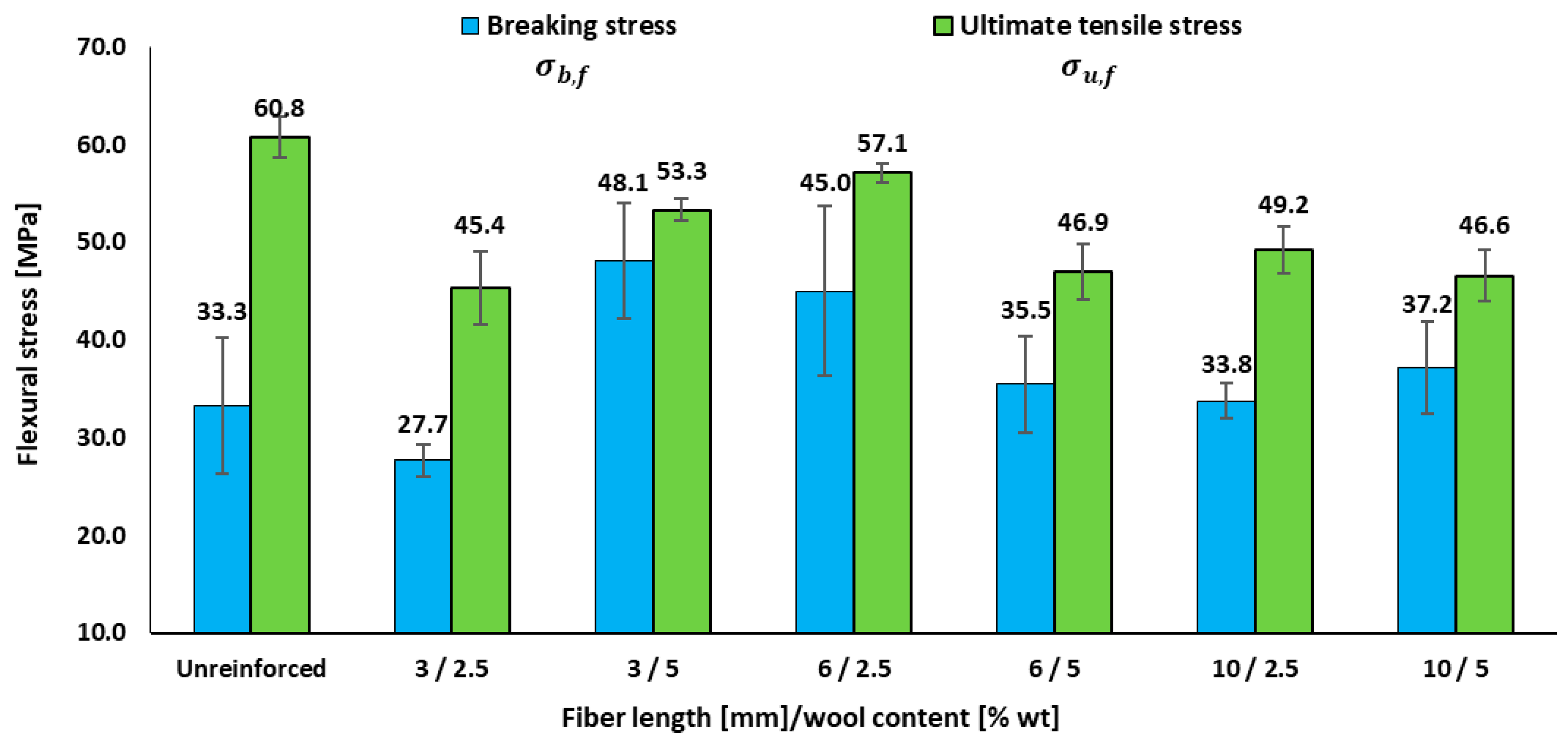

3.2. Flexural Test Results and Analysis

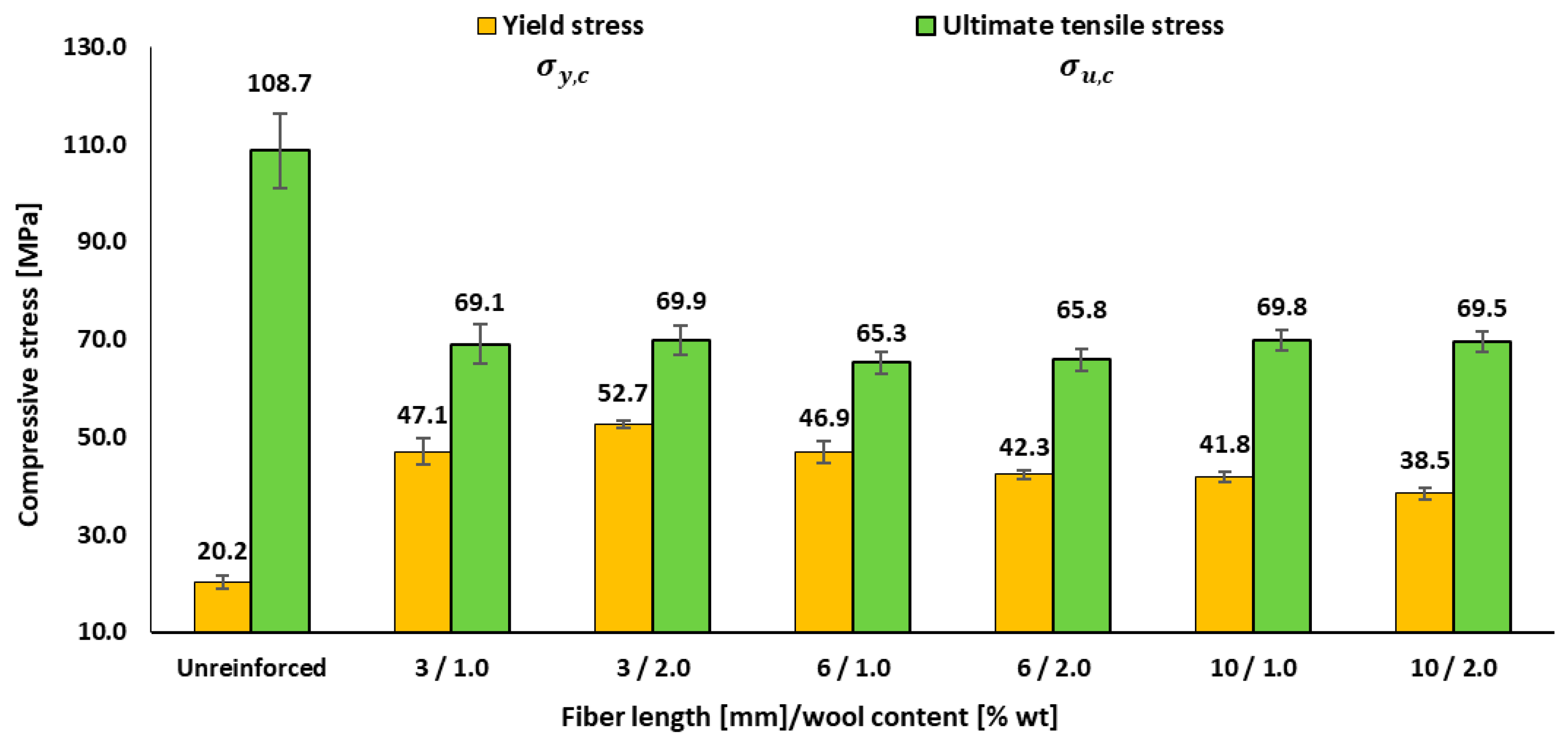

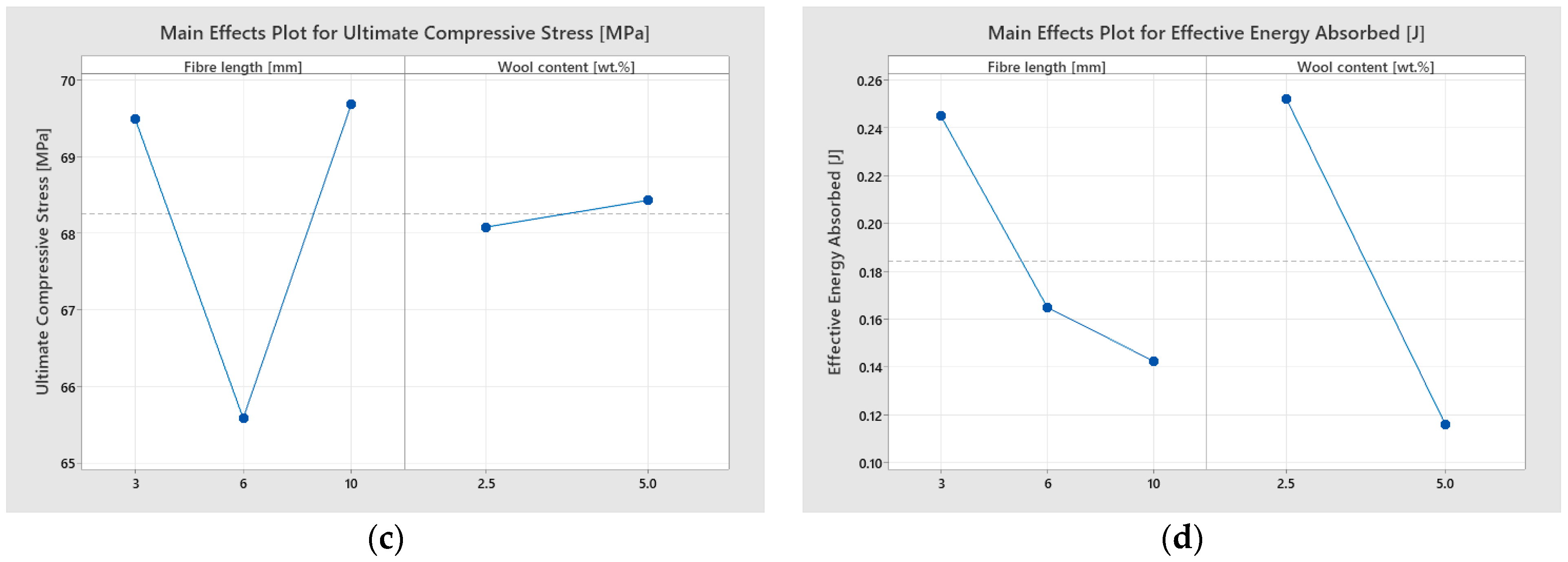

3.3. Compressive Test Results and Analysis

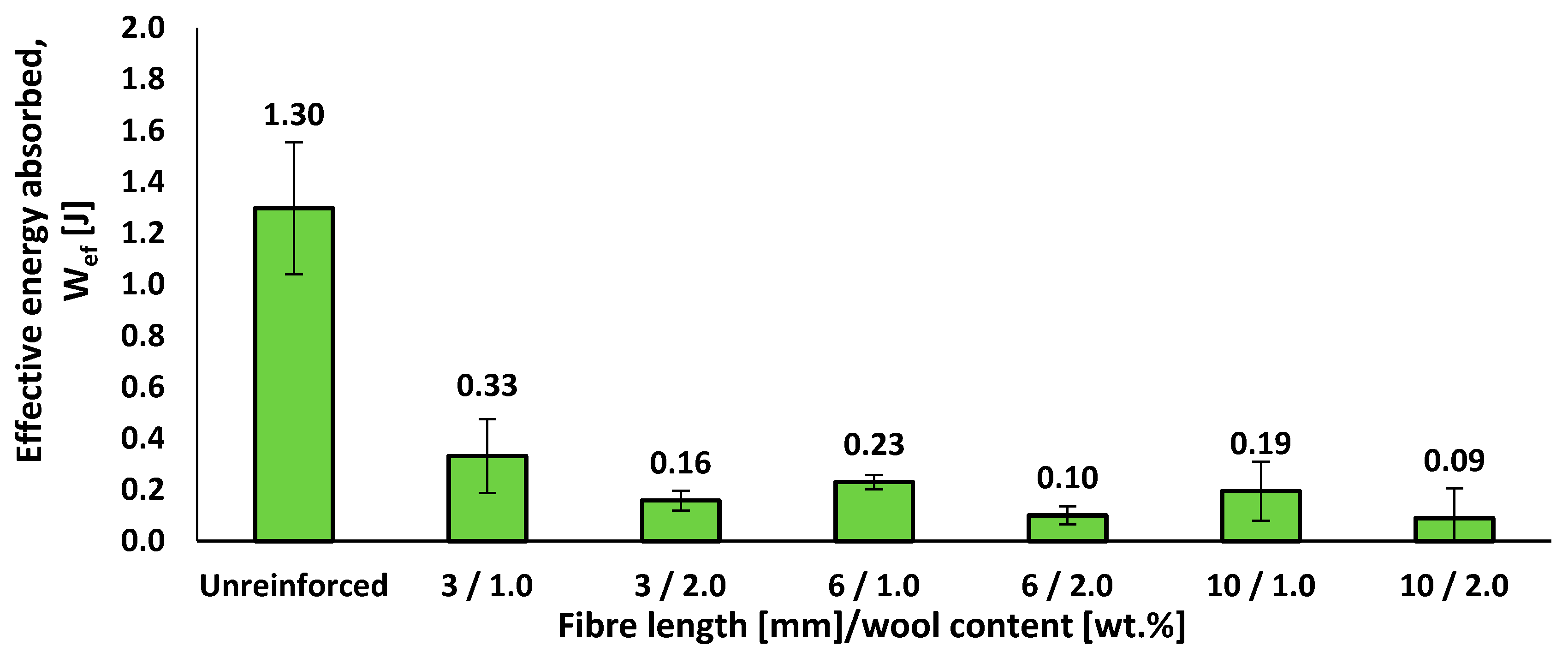

3.4. Charpy Impact Test Results and Analysis

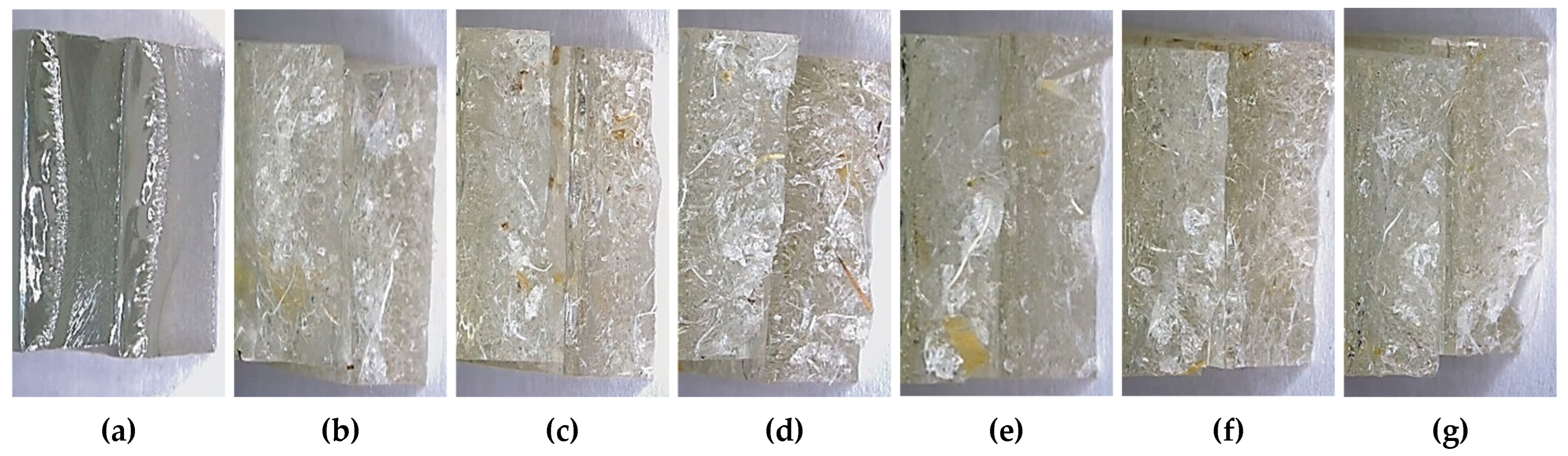

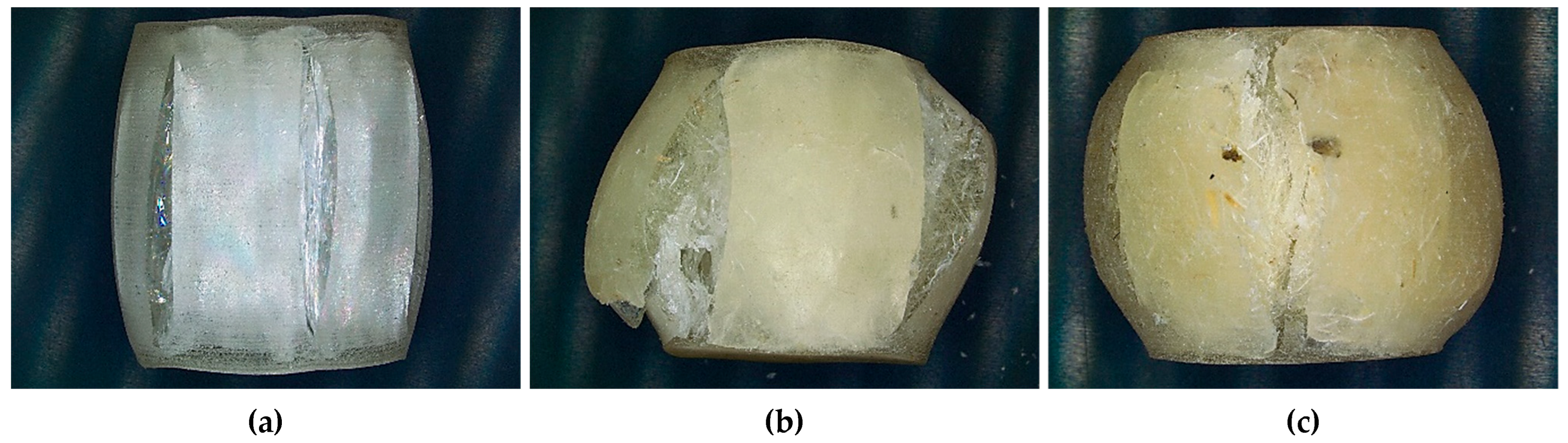

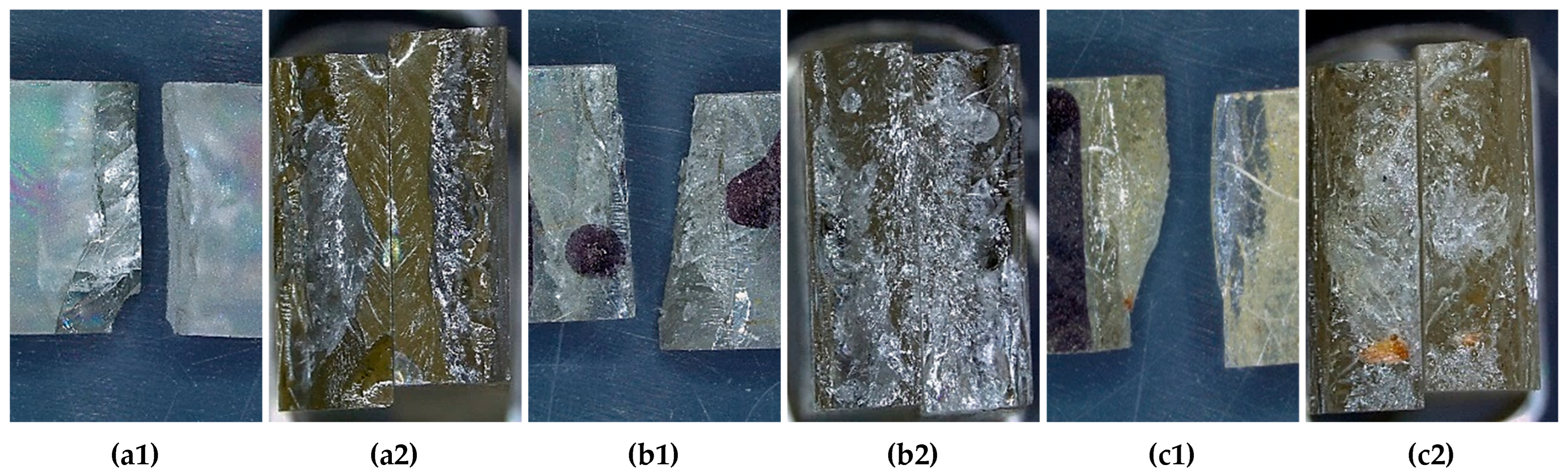

3.5. Fracture Analysis and Visual Inspection

3.6. Statistical Analysis

| Response | Equation | |

| σu,t | 22.210 − 1.265·IL = 3 − 1.022·IL = 6 + 2.287·IL = 10 + 0.703·IW = 1.5 − 0.703·IW = 3.0 − 1.465·IL = 3·IW = 1.5 + 1.465·IL = 3·IW = 3.0 −0.282·IL = 6·IW = 1.5 + 0.282·IL = 6·IW = 3.0 + 1.747·IL = 10·IW = 1.5 − 1.747·IL = 10·IW = 3.0. | (1) |

| σu,f | 37.86 + 0.02·IL = 3 + 2.37·IL = 6 − 2.40·IL = 10 − 2.36·IW = 2.5 + 2.36·IW = 5.0 − 7.82·IL = 3·IW = 2.5 + 7.82·IL = 3·IW = 5.0 + 7.14·IL = 6·IW = 2.5 − 7.14·IL = 6·IW = 5.0 + 0.68·IL = 10·IW = 2.5 − 0.68·IL = 10·IW = 5.0 | (2) |

| σu,c | 68.256 + 1.242·IL = 3 − 2.673·IL = 6 + 1.431·IL = 10 − 0.174·IW = 1.0 + 0.174·IW = 2.0 − 0.257·IL = 3·IW = 1.0 + 0.257·IL = 3·IW = 2.0 + 0.075·IL = 6·IW = 1.0 − 0.075·IL = 6·IW = 2.0 + 0.332·IL = 10·IW = 1.0 − 0.332·IL = 10·IW = 2.0 | (3) |

| Wef | 0.1842 + 0.0608·IL = 3 − 0.0192·IL = 6 − 0.0417·IL = 10 + 0.0682·IW = 1.0 − 0.0682·IW = 2.0 + 0.0188·IL = 3·IW = 1.0 − 0.0188·IL = 3·IW = 2.0 − 0.0032·IL = 6·IW = 1.0 + 0.0032·IL = 6·IW = 2.0 − 0.0157·IL = 10·IW = 1.0 + 0.0157·IL = 10·IW = 2.0 | (4) |

- Ultimate Tensile Stress

- Ultimate Flexural Stress

- Ultimate Compressive Stress

- Effective Energy Absorbed

4. Conclusions

- 1.

- Tension: The best-performing formulation (10 mm/1.5 wt.%) increased the ultimate tensile stress by ≈10% and tensile modulus by ≈50%, while very short fibres at low content (3 mm/1.5 wt.%) reduced tensile strength by ≈17.5%.

- 2.

- Flexure: Wool decreased the flexural modulus by ≈15–35%, but selected combinations (3–6 mm/5 wt.%) increased the flexural fracture stress by ≈35–45%.

- 3.

- Compression: The highest improvement was obtained for 3 mm/2 wt.% fibres, with an increase of ≈160% in compressive yield stress compared with neat epoxy.

- 4.

- Impact: All wool-filled composites exhibited reduced Charpy impact energy (≈75–93% decrease), with the least severe drop occurring for 3 mm/1 wt.%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- de Rancourt, M.; Fois, N.; Lavín, M.P.; Tchakérian, E.; Vallerand, F. Mediterranean Sheep and Goats Production: An Uncertain Future. Small Rumin. Res. 2006, 62, 167–179. [Google Scholar] [CrossRef]

- Zygoyiannis, D. Sheep Production in the World and in Greece. Small Rumin. Res. 2006, 62, 143–147. [Google Scholar] [CrossRef]

- Midolo, G.; Porto, S.M.C.; Cascone, G.; Valenti, F. Sheep Wool Waste Availability for Potential Sustainable Re-Use and Valorization: A GIS-Based Model. Agriculture 2024, 14, 872. [Google Scholar] [CrossRef]

- Lal, B.; Sharma, S.C.; Meena, R.L.; Sarkar, S.; Sahoo, A.; Balai, R.C.; Gautam, P.; Meena, B.P. Utilization of Byproducts of Sheep Farming as Organic Fertilizer for Improving Soil Health and Productivity of Barley Forage. J. Environ. Manag. 2020, 269, 110765. [Google Scholar] [CrossRef]

- Szczecina, J.; Niemiec, M.; Szatkowski, P. Using the Natural Properties of Sheep Wool in the Design of Drought-Reducing Composites. Anim. Sci. Genet. 2025, 21, 65–74. [Google Scholar] [CrossRef]

- European Commission. Life Greenwoolf—Green Hydrolysis Conversion of Wool Wastes into Organic Nitrogen Fertilisers (LIFE12 ENV/IT/000439) 2012; European Commission: Brussels, Belgium, 2012. [Google Scholar]

- Zheljazkov, V.D.; Stratton, G.W.; Pincock, J.; Butler, S.; Jeliazkova, E.A.; Nedkov, N.K.; Gerard, P.D. Wool-Waste as Organic Nutrient Source for Container-Grown Plants. Waste Manag. 2009, 29, 2160–2164. [Google Scholar] [CrossRef]

- European Commission. Circular Economy Action Plan 2020; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Ismadi; Amin, Y.; Damayanti, R.; Lubis, M.A.R.; Wulandari, A.P.; Nurindah; Iswanto, A.H.; et al. A Comprehensive Review on Natural Fibers: Technological and Socio-Economical Aspects. Polymers 2021, 13, 4280. [Google Scholar] [CrossRef]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural Fiber–Reinforced Composites: A Review on Material, Manufacturing, and Machinability. J. Thermoplast. Compos. Mater. 2021, 34, 238–284. [Google Scholar] [CrossRef]

- May, C. (Ed.) Epoxy Resins: Chemistry and Technology, 2nd ed.; Routledge: New York, NY, USA, 2018; ISBN 978-0-203-75671-3. [Google Scholar]

- Petrie, E.M. Epoxy Adhesive Formulations; McGraw-Hill Professional: New York, NY, USA, 2005. [Google Scholar]

- Sam-Daliri, O.; Jiang, Y.; Flaherty, D.; Walls, M.; Kennedy, C.; Flanagan, M.; Ghabezi, P.; Finnegan, W. Mechanical Analysis of Unidirectional Glass Fibre Reinforced Epoxy Composite Joints Manufactured by Adhesive Bonding and Co-Curing Techniques. Mater. Des. 2025, 258, 114739. [Google Scholar] [CrossRef]

- Hudson, T.B.; Georgiou, N.A.; Smith, A.J.; Cano, R.J.; Kang, J.H. Co-Bonding of Aerospace Composite Joints with Reflowable Adherend Interfaces. J. Compos. Mater. 2025. [Google Scholar] [CrossRef]

- Puglia, D.; Biagiotti, J.; Kenny, J.M. A Review on Natural Fibre-Based Composites—Part II: Application of Natural Reinforcements in Composite Materials for Automotive Industry. J. Nat. Fibers 2005, 1, 23–65. [Google Scholar] [CrossRef]

- Zolfakkar, M.; El-Tayeb, N.; Halawa, T. Towards Sustainable Composites: Evaluation of Mechanical Properties, Erosion Behavior and Applications of Natural Fiber-Epoxy Composites. J. Compos. Mater. 2024, 58, 2151–2168. [Google Scholar] [CrossRef]

- Zach, J.; Korjenic, A.; Petránek, V.; Hroudová, J.; Bednar, T. Performance Evaluation and Research of Alternative Thermal Insulations Based on Sheep Wool. Energy Build. 2012, 49, 246–253. [Google Scholar] [CrossRef]

- Patrucco, A.; Zoccola, M.; Anceschi, A. Exploring the Potential Applications of Wool Fibers in Composite Materials: A Review. Polymers 2024, 16, 2360. [Google Scholar] [CrossRef]

- Semitekolos, D.; Pardou, K.; Georgiou, P.; Koutsouli, P.; Bizelis, I.; Zoumpoulakis, L. Investigation of Mechanical and Thermal Insulating Properties of Wool Fibres in Epoxy Composites. Polym. Polym. Compos. 2021, 29, 1412–1421. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Lauke, B. Effects of Fiber Length and Fiber Orientation Distributions on the Tensile Strength of Short-Fiber-Reinforced Polymers. Compos. Sci. Technol. 1996, 56, 1179–1190. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W.R. Tensile Properties of Fibre-Reinforced Metals: Copper/Tungsten and Copper/Molybdenum. J. Mech. Phys. Solids 1965, 13, 329–350. [Google Scholar] [CrossRef]

- Thomason, J.L.; Rudeiros-Fernández, J.L. A Review of the Impact Performance of Natural Fiber Thermoplastic Composites. Front. Mater. 2018, 5, 60. [Google Scholar] [CrossRef]

- Thomason, J. The Influence of Fibre Cross Section Shape and Fibre Surface Roughness on Composite Micromechanics. Micro 2023, 3, 353–368. [Google Scholar] [CrossRef]

- Islam, A.; Ahamed, B.; Saifullah, A.; Bhuiyan, A.H.; Haq, E.; Sayeed, A.; Dhakal, H.N.; Sarker, F. Response of Short Jute Fibre Preform Based Epoxy Composites Subjected to Low-Velocity Impact Loadings. Compos. Part C Open Access 2024, 14, 100488. [Google Scholar] [CrossRef]

- UNE-EN ISO 527-1:2020; Plastics—Determination of Tensile Properties—Part 1: General Principles (ISO 527-1:2019). AENOR Asociación Española de Normalización: Madrid, Spain, 2020.

- UNE-EN ISO 527-4:2024; Plastics—Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites (ISO 527-4:2023). AENOR Asociación Española de Normalización: Madrid, Spain, 2024.

- UNE-EN ISO 178-1:2020; Plastics—Plastics—Determination of Flexural Properties (ISO 178:2019). AENOR Asociación Española de Normalización: Madrid, Spain, 2020.

- UNE-EN ISO 604:2003; Plastics—Determination of Compressive Properties (ISO 604:2002). AENOR Asociación Española de Normalización: Madrid, Spain, 2003.

- UNE-EN ISO 179-1:2024; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test (ISO 179-1:2023). AENOR Asociación Española de Normalización: Madrid, Spain, 2024.

- Lubineau, G.; Alfano, M.; Tao, R.; Wagih, A.; Yudhanto, A.; Li, X.; Almuhammadi, K.; Hashem, M.; Hu, P.; Mahmoud, H.A.; et al. Harnessing Extrinsic Dissipation to Enhance the Toughness of Composites and Composite Joints: A State-of-the-Art Review of Recent Advances. Adv. Mater. 2024, 36, 2407132. [Google Scholar] [CrossRef]

- Nagaraja, S.; Anand, P.B.; K, M.K.; Ammarullah, M.I. Synergistic Advances in Natural Fibre Composites: A Comprehensive Review of the Eco-Friendly Bio-Composite Development, Its Characterization and Diverse Applications. RSC Adv. 2024, 14, 17594–17611. [Google Scholar] [CrossRef]

- Larsson, R.; Brambati, G.; Gutkin, R. Compressive Failure and Kink-Band Formation Modeling. Eur. J. Mech.-A/Solids 2023, 99, 104909. [Google Scholar] [CrossRef]

- Thomason, J.L. The Influence of Fibre Length, Diameter and Concentration on the Impact Performance of Long Glass-Fibre Reinforced Polyamide 6,6. Compos. Part A Appl. Sci. Manuf. 2009, 40, 114–124. [Google Scholar] [CrossRef]

- Aliotta, L.; Lazzeri, A. A Proposal to Modify the Kelly-Tyson Equation to Calculate the Interfacial Shear Strength (IFSS) of Composites with Low Aspect Ratio Fibers. Compos. Sci. Technol. 2020, 186, 107920. [Google Scholar] [CrossRef]

- Seid, A.M.; Adimass, S.A. Review on the Impact Behavior of Natural Fiber Epoxy Based Composites. Heliyon 2024, 10, e39116. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.; Mo, Z.; Chouw, N.; Jayaraman, K.; Xu, Z. A Critical Review on the Properties of Natural Fibre Reinforced Concrete Composites Subjected to Impact Loading. J. Build. Eng. 2023, 77, 107497. [Google Scholar] [CrossRef]

- Zhao, X.; Li, J.; Su, S.; Jiang, N. Prediction Models of Mechanical Properties of Jute/PLA Composite Based on X-Ray Computed Tomography. Polymers 2024, 16, 160. [Google Scholar] [CrossRef]

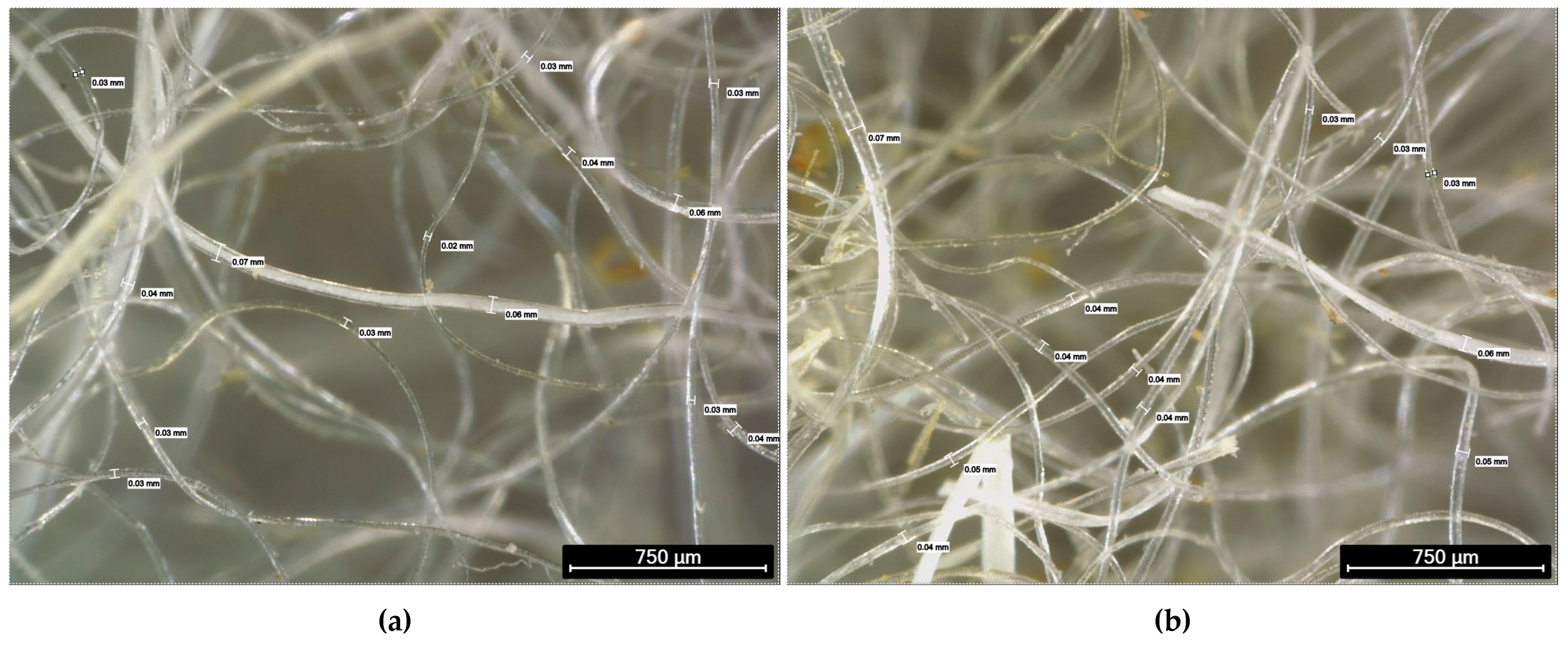

| Figure | Colour 1 | Residue Type 1 | Residue Quantity 1 | Max. Fibre Diam. (μm) | Min. Fibre Diam. (μm) | Mean Fibre Diam. (μm) |

|---|---|---|---|---|---|---|

| 1a | Light white | Straw | Low | 70 | 20 | 45 |

| 1b | Light white | Straw | Low | 60 | 30 | 45 |

| 1c | White/yellow | Soil/straw | Low | 60 | 30 | 45 |

| 1d | White/yellow | Soil/straw | Low | 70 | 20 | 45 |

| Test | Fibre Length (mm) | Wool Load (%) | Replicates | Dimensions |

|---|---|---|---|---|

| Tensile | 0 | 0 | 3 | 250 × 25 × 4 |

| 3 | 1.5 | |||

| 3 | 3.0 | |||

| 6 | 1.5 | |||

| 6 | 3.0 | |||

| 10 | 1.5 | |||

| 10 | 3.0 | |||

| Flexural | 0 | 0 | 5 | 100 × 10 × 4 |

| 3 | 2.5 | |||

| 3 | 5.0 | |||

| 6 | 2.5 | |||

| 6 | 5.0 | |||

| 10 | 2.5 | |||

| 10 | 5.0 | |||

| Compressive Charpy Impact | 0 | 0 | 5 | Ø20 × 25 1 10 × 4 × 80 2 |

| 3 | 1.0 | |||

| 3 | 2.0 | |||

| 6 | 1.0 | |||

| 6 | 2.0 | |||

| 10 | 1.0 | |||

| 10 | 2.0 |

| Specimen Type | Modulus of Elasticity Et (MPa) | Strain at Break εb,t (%) | ||||

|---|---|---|---|---|---|---|

| Unreinforced | 331.0 | ± | 39.2 | 5.65 | ± | 1.33 |

| 3 mm/1.5 wt.% | 331.6 | ± | 89.6 | 0.14 | ± | 0.20 |

| 3 mm/3.0 wt.% | 282.7 | ± | 20.6 | 0.00 | ± | 0.00 |

| 6 mm/1.5 wt.% | 269.2 | ± | 72.7 | 0.12 | ± | 0.10 |

| 6 mm/3.0 wt.% | 238.0 | ± | 4.1 | 0.06 | ± | 0.09 |

| 10 mm/1.5 wt.% | 490.4 | ± | 101.5 | 0.19 | ± | 0.20 |

| 10 mm/3.0 wt.% | 251.0 | ± | 27.3 | 0.34 | ± | 0.29 |

| Specimen Type | Modulus of Elasticity Ef (MPa) | ||

|---|---|---|---|

| Unreinforced | 1961.3 | ± | 134.5 |

| 3 mm/2.5 wt.% | 1526.4 | ± | 85.8 |

| 3 mm/5.0 wt.% | 1672.9 | ± | 45.4 |

| 6 mm/2.5 wt.% | 1670.4 | ± | 64.6 |

| 6 mm/5.0 wt.% | 1476.1 | ± | 171.1 |

| 10 mm/2.5 wt.% | 1580.5 | ± | 85.4 |

| 10 mm/5.0 wt.% | 1237.2 | ± | 149.9 |

| Specimen Type | Strain at Yield εy,c (%) | Strain at Break εb,c (%) | ||||

|---|---|---|---|---|---|---|

| Unreinforced | 6.6 | ± | 0.5 | 62.8 | ± | 1.8 |

| 3 mm/1.0 wt.% | 9.9 | ± | 0.8 | 42.2 | ± | 16.7 |

| 3 mm/2.0 wt.% | 10.7 | ± | 1.1 | 46.3 | ± | 1.4 |

| 6 mm/1.0 wt.% | 9.7 | ± | 0.3 | 49.5 | ± | 0.8 |

| 6 mm/2.0 wt.% | 9.4 | ± | 0.2 | 50.8 | ± | 1.0 |

| 10 mm/1.0 wt.% | 9.2 | ± | 0.3 | 50.3 | ± | 0.9 |

| 10 mm/2.0 wt.% | 9.5 | ± | 0.4 | 51.8 | ± | 0.8 |

| Test | Variable | Source | DF | Adj SS | Adj Ms | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Tensile | σu,t | L (mm) | 2 | 47.237 | 23.619 | 7.76 | 0.007 |

| W (wt.%) | 1 | 8.904 | 8.904 | 2.93 | 0.113 | ||

| L (mm) × W (wt.%) | 2 | 31.658 | 15.829 | 5.20 | 0.024 | ||

| Error | 12 | 36.500 | 3.042 | ||||

| Total | 17 | 124.300 | |||||

| Flexural | σu,f | L (mm) | 2 | 113.8 | 56.89 | 1.66 | 0.211 |

| W (wt.%) | 1 | 167.7 | 167.7 | 4.89 | 0.037 | ||

| L (mm) × W (wt.%) | 2 | 1125.9 | 562.93 | 16.42 | 0.000 | ||

| Error | 24 | 822.6 | 34.28 | ||||

| Total | 29 | 2229.9 | |||||

| Compressive | σu,c | L (mm) | 2 | 107.360 | 53.6799 | 7.16 | 0.004 |

| W (wt.%) | 1 | 0.907 | 0.9071 | 0.12 | 0.731 | ||

| L (mm) × W (wt.%) | 2 | 1.815 | 0.9076 | 0.12 | 0.887 | ||

| Error | 24 | 179.984 | 7.4994 | ||||

| Total | 29 | 290.067 | |||||

| Charpy Impact | Wef | L (mm) | 2 | 0.054321 | 0.027161 | 3.38 | 0.052 |

| W (wt.%) | 1 | 0.128678 | 0.128678 | 16.02 | 0.001 | ||

| L (mm) × W (wt.%) | 2 | 0.005576 | 0.002788 | 0.35 | 0.710 | ||

| Error | 22 | 0.176660 | 0.008030 | ||||

| Total | 27 | 0.370971 |

| Variable | S | R2 [%] |

|---|---|---|

| Ultimate Tensile Stress, σu,t [MPa] | 1.74404 | 58.40 |

| Ultimate Flexural Stress, σu,f [MPa] | 5.85461 | 63.11 |

| Ultimate Compressive Stress, σu,c [MPa] | 2.73849 | 37.95 |

| Effective Energy Absorbed, Wef [J] | 0.0896103 | 52.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz-Díaz, C.; Guerrero-Vacas, G.; Rodríguez-Alabanda, Ó. Mechanical Performance of Wool-Reinforced Epoxy Composites: Tensile, Flexural, Compressive, and Impact Analysis. Materials 2025, 18, 5391. https://doi.org/10.3390/ma18235391

Ruiz-Díaz C, Guerrero-Vacas G, Rodríguez-Alabanda Ó. Mechanical Performance of Wool-Reinforced Epoxy Composites: Tensile, Flexural, Compressive, and Impact Analysis. Materials. 2025; 18(23):5391. https://doi.org/10.3390/ma18235391

Chicago/Turabian StyleRuiz-Díaz, Carlos, Guillermo Guerrero-Vacas, and Óscar Rodríguez-Alabanda. 2025. "Mechanical Performance of Wool-Reinforced Epoxy Composites: Tensile, Flexural, Compressive, and Impact Analysis" Materials 18, no. 23: 5391. https://doi.org/10.3390/ma18235391

APA StyleRuiz-Díaz, C., Guerrero-Vacas, G., & Rodríguez-Alabanda, Ó. (2025). Mechanical Performance of Wool-Reinforced Epoxy Composites: Tensile, Flexural, Compressive, and Impact Analysis. Materials, 18(23), 5391. https://doi.org/10.3390/ma18235391