Influence of Sintering Process on Mechanical and Tribological Properties of 3D-Mesh-Structure-Reinforced Cu-Based Friction Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

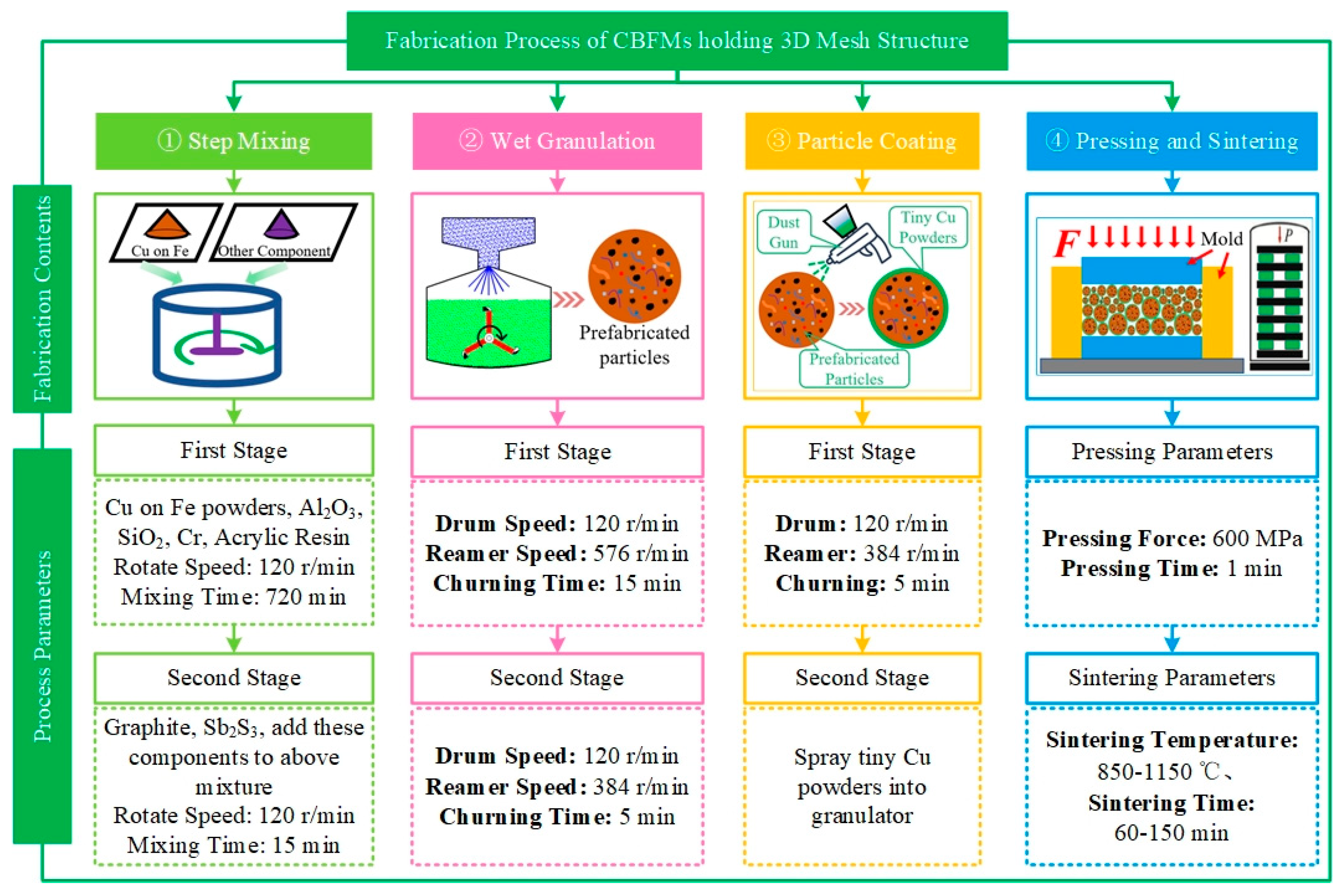

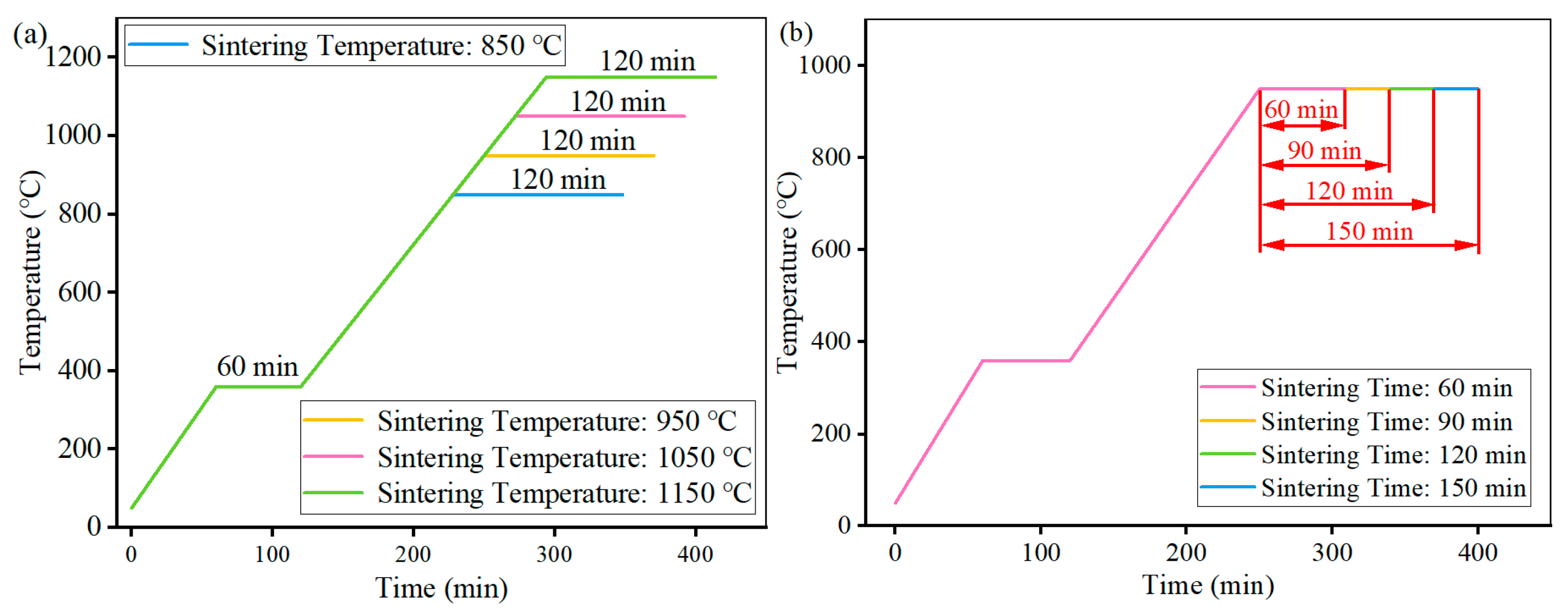

2.2. Fabrication of CBFMs Holding 3D Mesh Reinforcement Structures

2.3. Phase Analysis and Mechanical and Tribological Properties Test

3. Results and Discussion

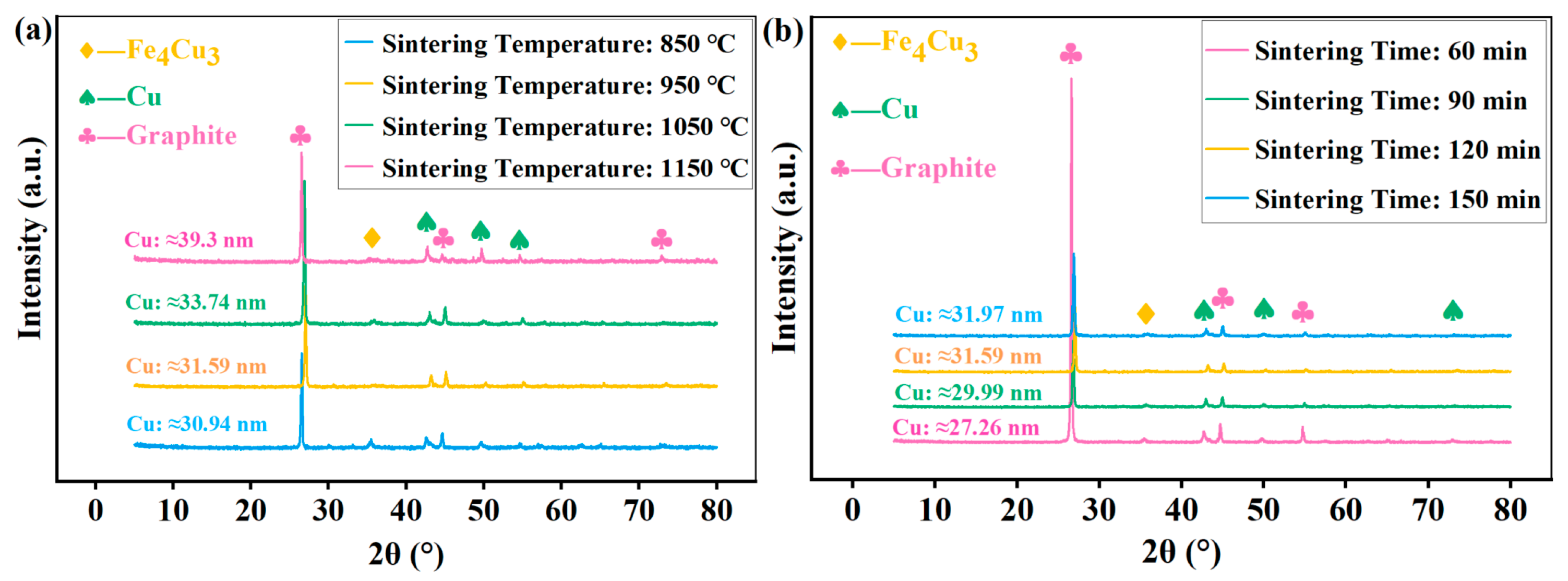

3.1. Phase Analysis

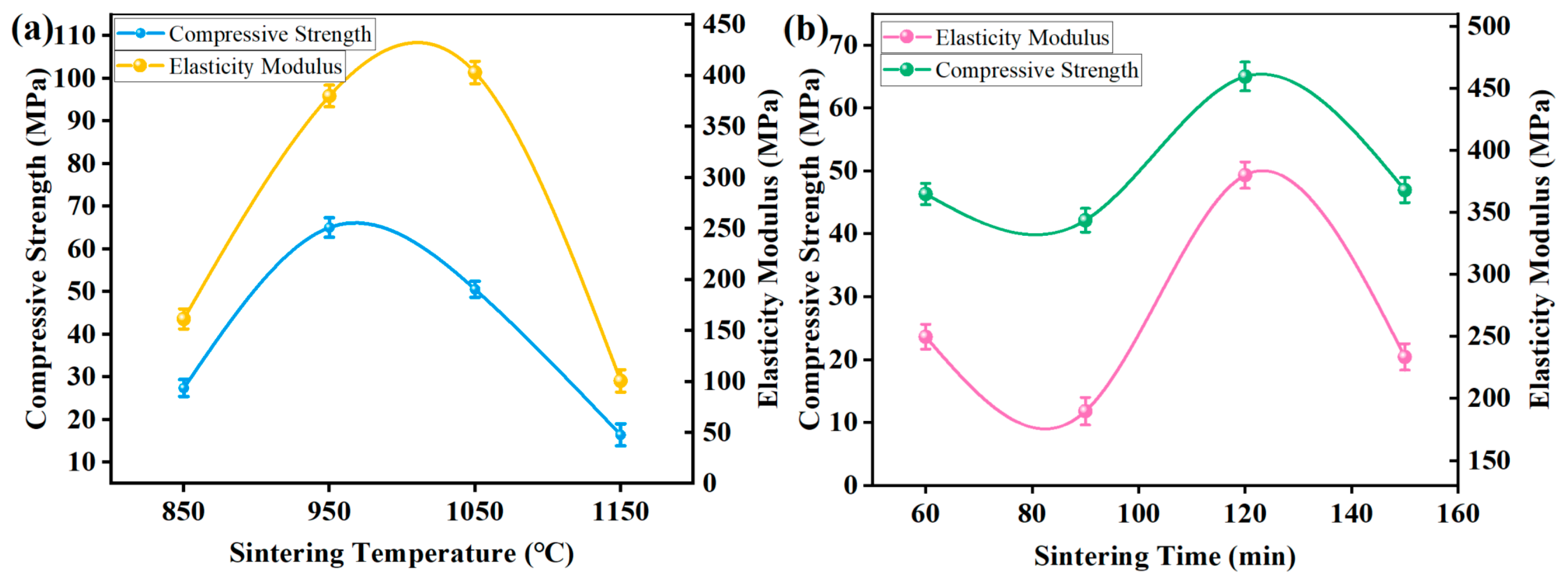

3.2. Physical–Mechanical Properties

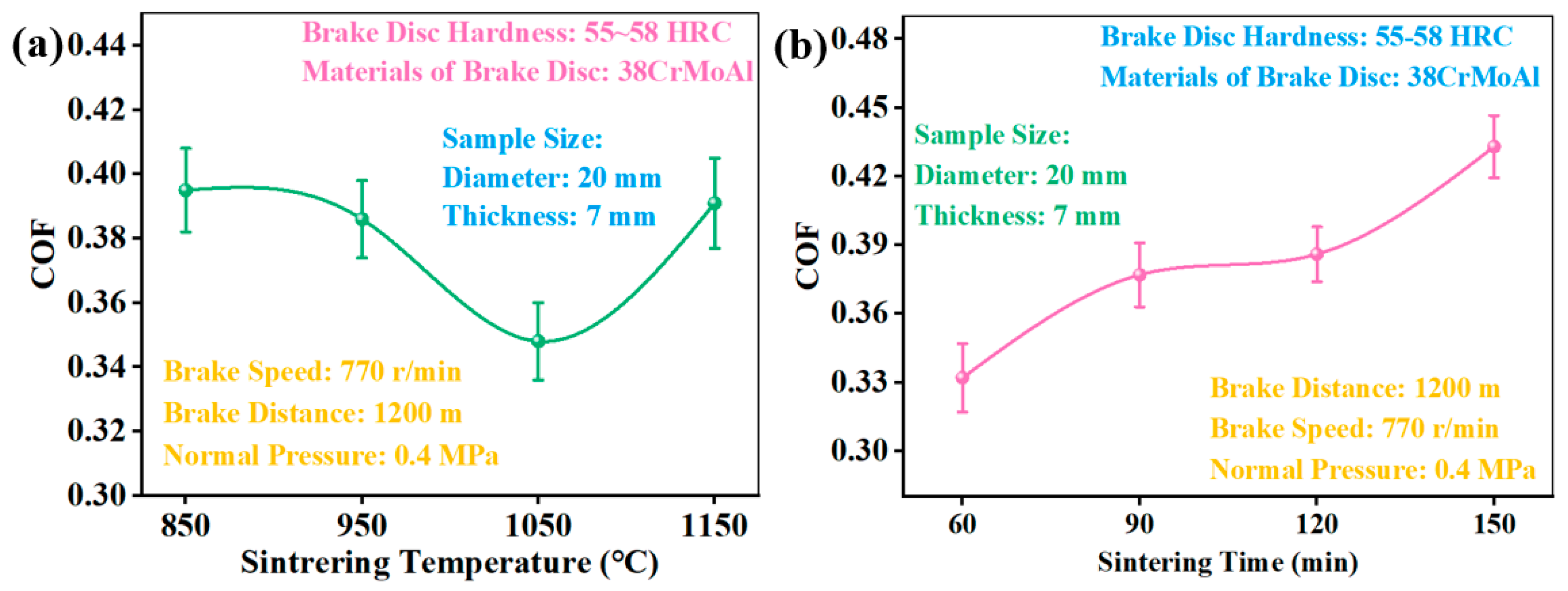

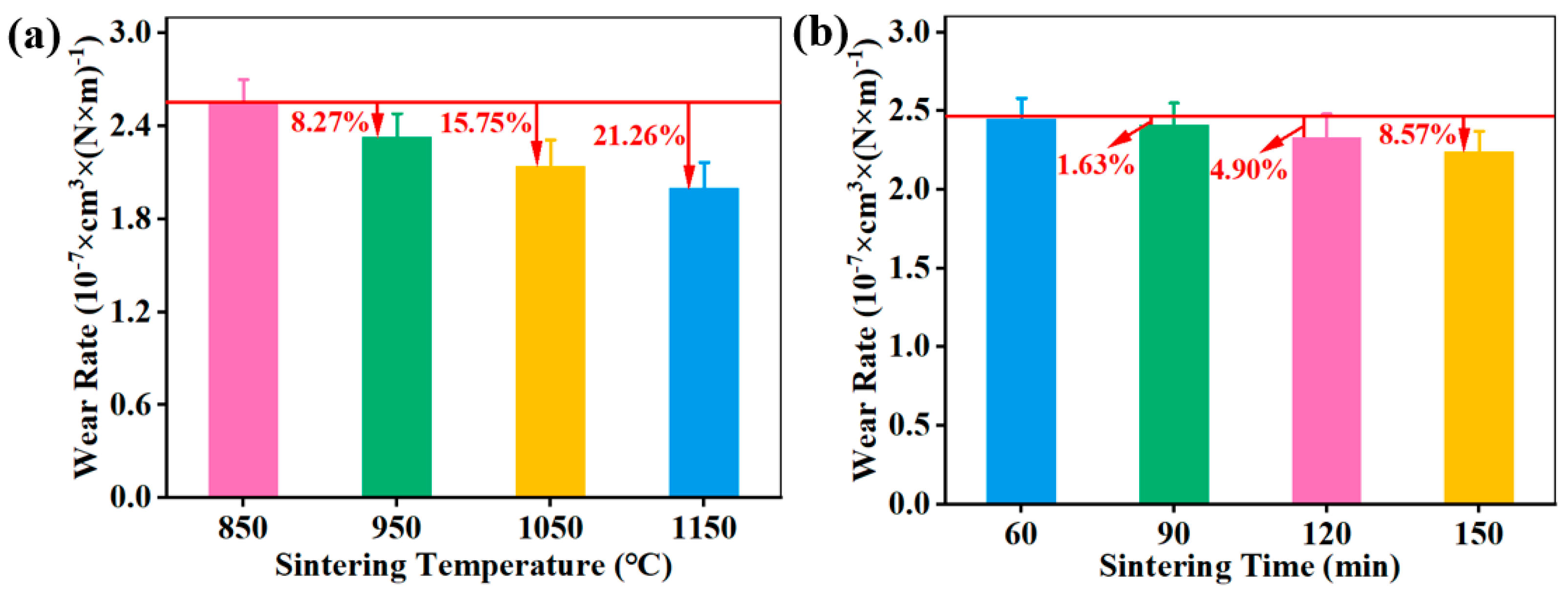

3.3. Tribological Properties

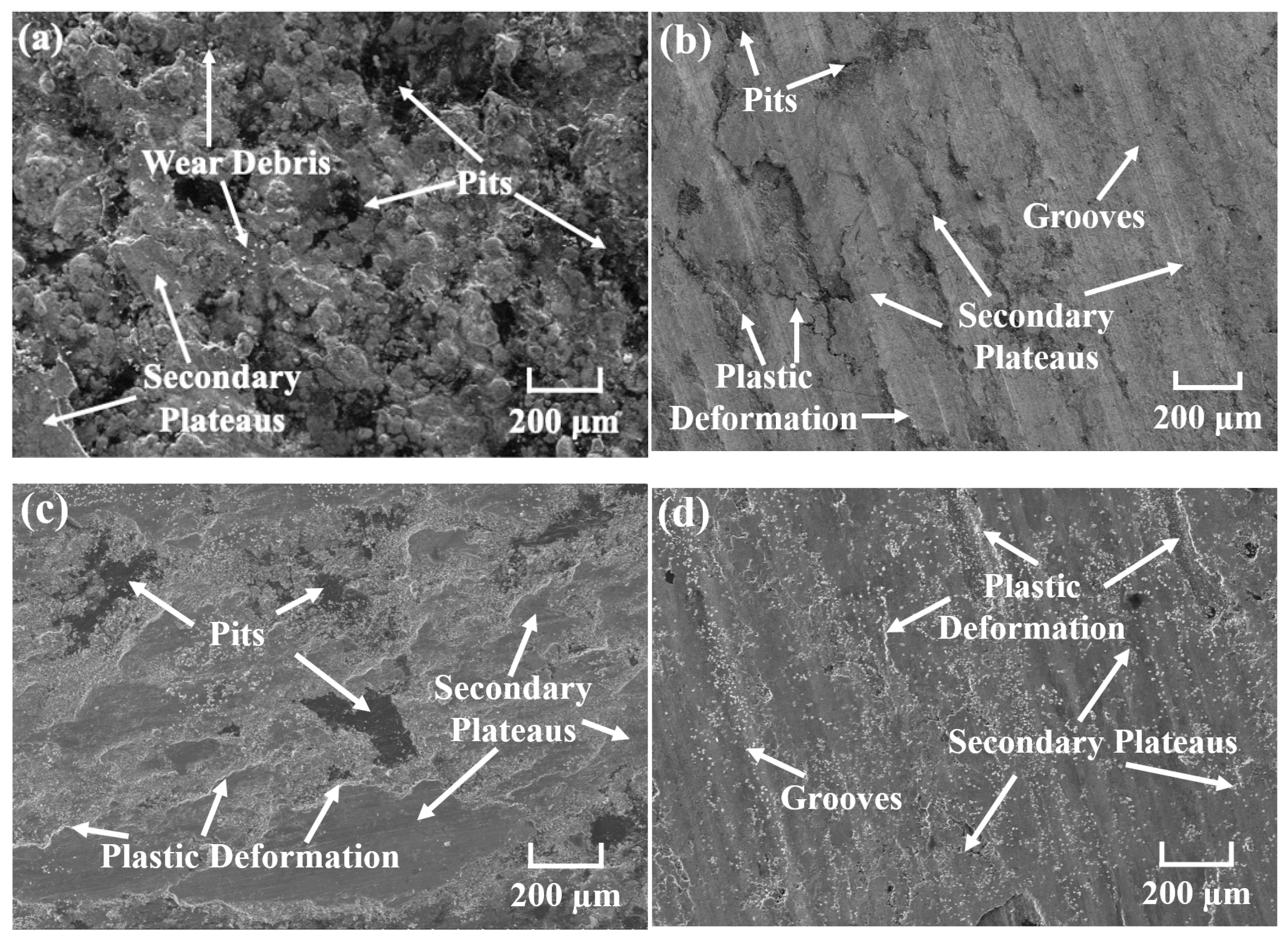

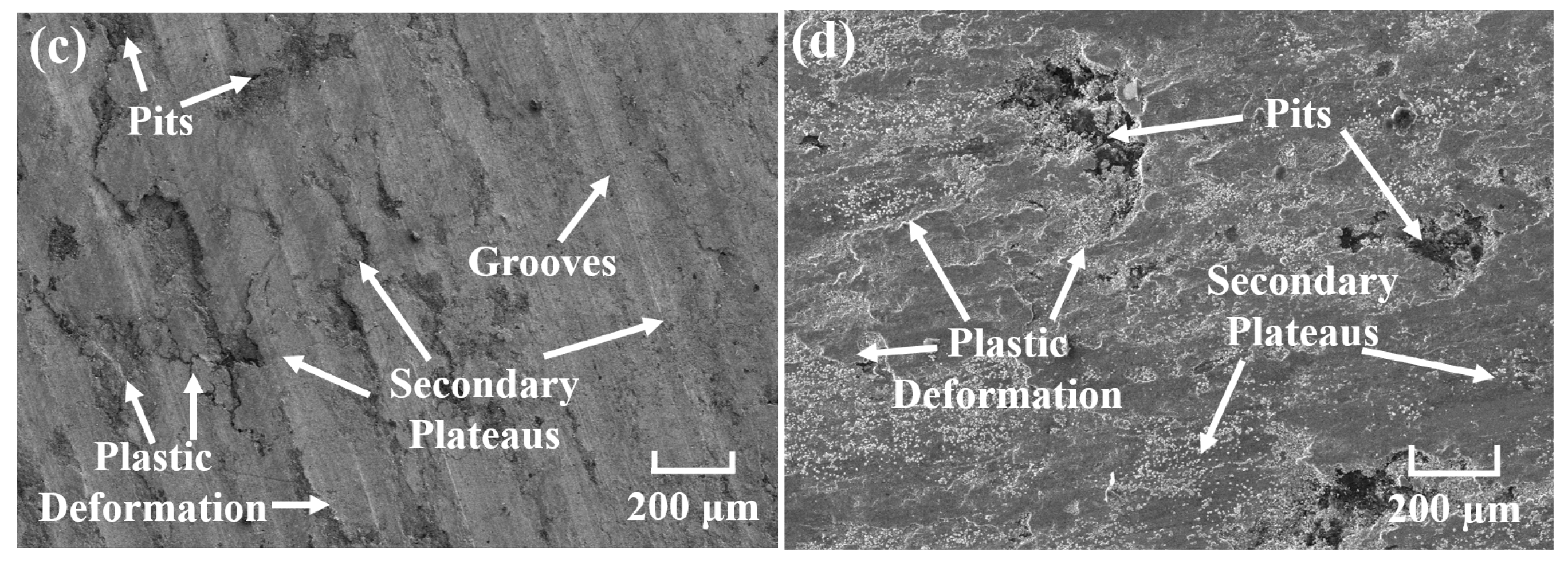

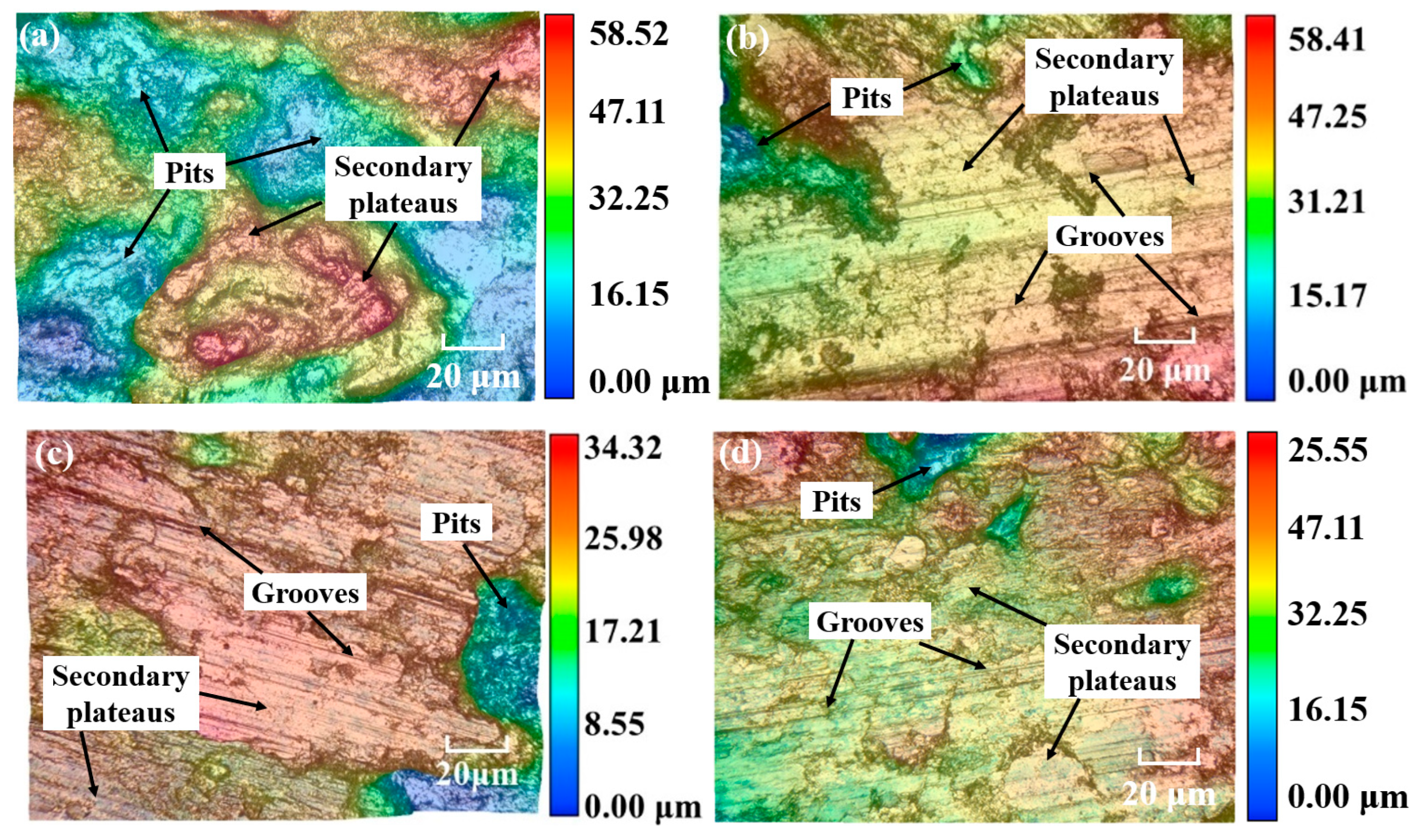

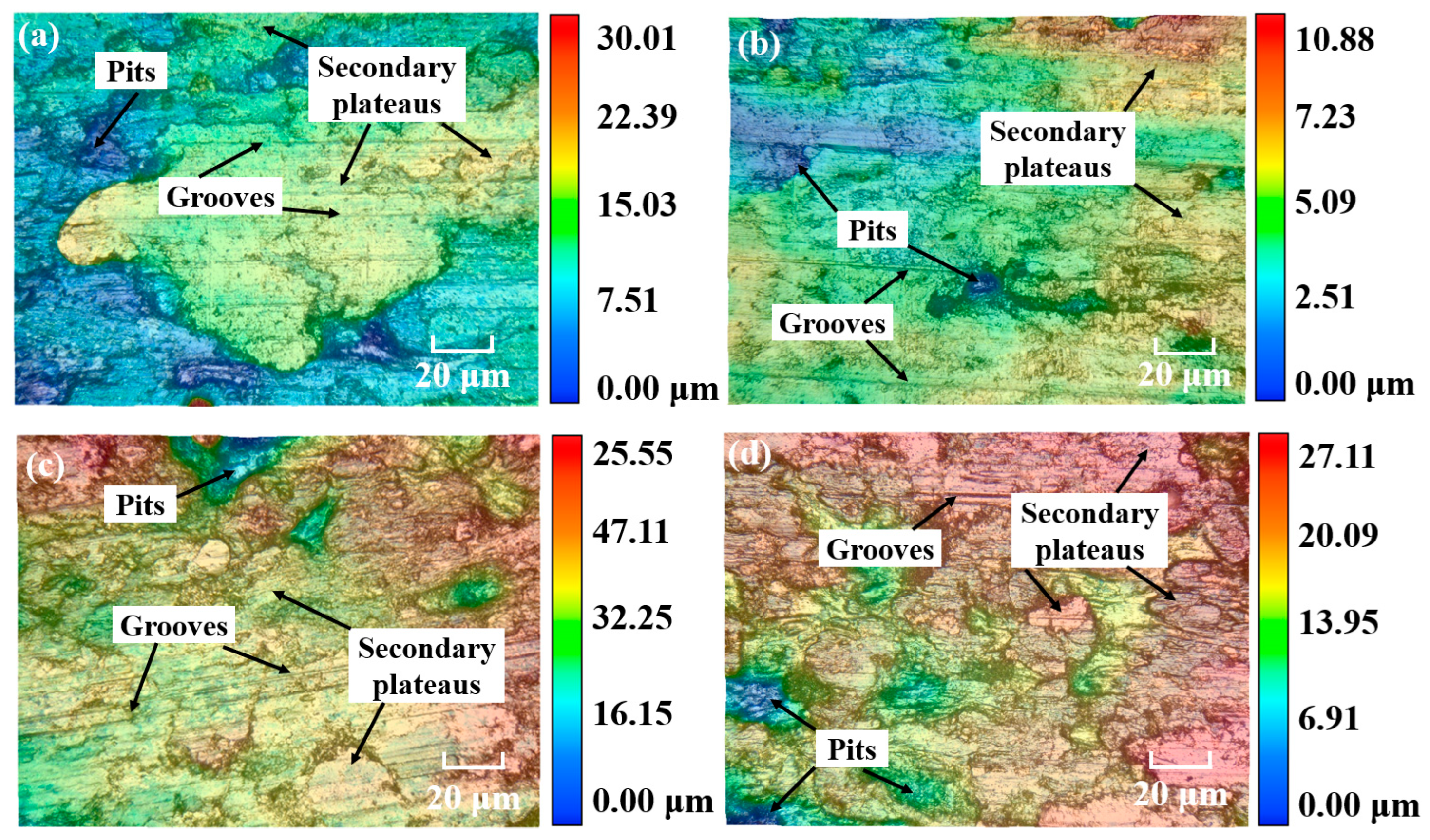

3.4. Wear Mechanisms

4. Conclusions

- (1)

- Overall, the influence of sintering temperature on the physical–mechanical properties (such as density and compressive strength) and tribological properties (such as COF and wear rate) of CBFMs holding 3D mesh reinforcement structures was greater than that of sintering time.

- (2)

- Sintering temperature and sintering time exhibited different regulation patterns on the compressive strength of CBFMs holding 3D mesh reinforcement structures. The compressive strength increased first and then decreased with the increase in sintering temperature. The sample sintered at 1150 °C obtained the minimum compressive strength, and the sample sintered at 950 °C obtained the maximum compressive strength. Moreover, sample sintered at 120 min showed the best compressive strength.

- (3)

- Sintering temperature and sintering time had a significant influence on the tribological properties of CBFMs holding 3D mesh reinforcement structures. Specifically, as the sintering temperature increased, COF increased first, then decreased, and finally increased. The sample obtained the minimum COF of 0.348 at 1050 °C. With the increase in sintering time, the COF showed an increasing trend.

- (4)

- Increasing sintering temperature can enhance the wear resistance of CBFMs holding 3D mesh reinforcement structures, and this could mainly be attributed to the improved bonding strength among matrix particles and the increased strength of the 3D mesh reinforcement structure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CBFMs | Cu-Based Friction Materials |

| COF | Friction Coefficient |

| SEM | Scanning Electron Microscope |

References

- Agrawal, J.P.; Gupta, N.K.; Somani, N. Effect of TiC particle size on physical, mechanical and tribological properties of Cu-TiC metal matrix composites. Eng. Res. Express 2023, 5, 035009. [Google Scholar] [CrossRef]

- Gao, Z.; Li, Z.; Wen, G.; Wu, J.; Li, Y.; Nie, H.; Wei, M. Synergistic reinforcement mechanisms of Cu/graphite composites with MAX phase Ti2AlN and ZrO2-B4C ceramics: Enhancements in mechanical, thermal, and tribological properties. Ceram. Int. 2024, 50, 48799–48813. [Google Scholar] [CrossRef]

- Su, Y.; Jiang, F.; Xiao, Z.; Wu, F.; Long, M. Microstructure and tribological properties of copper/graphite composites with Ti3AlC2 addition prepared by rapid hot press sintering. Tribol. Int. 2024, 194, 109537. [Google Scholar] [CrossRef]

- Xu, W.; Hu, D.; Xu, Z.; Yi, M.; Zhong, M.; Wu, H.; Huang, M. Synergy between carbon fibers and copper-plated graphite on tribological performance of Cu-based composites. Wear 2023, 534–535, 205159. [Google Scholar] [CrossRef]

- Yan, Y.-F.; Kou, S.-Q.; Yang, H.-Y.; Shao, Y.; Qiu, F.; Shu, S.-L. Synergistic optimization of mechanical and tribological properties of TiC modified copper-graphite composites by direct current in-situ sintering. Ceram. Int. 2023, 49, 27069–27078. [Google Scholar] [CrossRef]

- Zhong, M.; Duan, S.; Wu, X.; Min, X.; Huang, Z.; Fang, M.; Li, H.; Ding, H.; Luo, B. Enhanced mechanical and tribological properties of low-cost core-shell structured microcrystalline graphite/Cu composites. Wear 2024, 536–537, 205155. [Google Scholar] [CrossRef]

- Dong, Y.; Ma, B.; Xiong, C.; Zhao, Q.; Chen, H.; Zhang, Y.; Xie, G. Tribological and Wear Properties of Cu-Based Composite Reinforced by Core–Shell Structure in Multi-disk Clutch. Tribol. Lett. 2024, 72, 66. [Google Scholar] [CrossRef]

- Ekinci, S.; Asilturk, I.; Akkus, H.; Mahammadzade, A. Examination of the Wear Behavior of Cu-Based Brake Pads Used in High-Speed Trains and Prediction Through Statistical and Neural Network Models. Surf. Rev. Lett. 2023, 31, 2450062. [Google Scholar] [CrossRef]

- Poudel, S.; Bajwa, R.; Khan, Z.; Liu, Y.; Green, E.M.; Xia, Y.; Zhang, Y.; Zhu, Y. Synthesis and characterization of multiwall carbon nanotubes/Cu composites with improved physical and tribological properties. Compos. Commun. 2025, 55, 102299. [Google Scholar] [CrossRef]

- Zhang, J.; Tian, Y.; Zhao, X.; Lai, J.; Chen, Q.; Guo, S. Fabrication of Cu-Matrix Composites Reinforced by ZTA Particles Through Spontaneous Infiltration and Evaluation of the Tribological Properties. JOM 2024, 77, 851–862. [Google Scholar] [CrossRef]

- Li, L.; Zhu, J.; Yao, Z.; Zhuansun, Y.; Ma, Y. Evaluation of mechanical and tribological properties of Cu-based friction materials reinforced by 3D mesh structure. Tribol. Int. 2024, 200, 110167. [Google Scholar] [CrossRef]

- Ma, Y.; Tian, Y.; Li, L. Design and regulation of 3D mesh structure inside Cu-based friction materials and the tribological behaviors. J. Mater. Res. Technol. 2025, 39, 1456–1465. [Google Scholar] [CrossRef]

- Kasi, R.; Ramalingam, V.; Myilsamy, G.; Kumar, S. Influence of rare earth oxide and graphite on the mechanical and tribological properties of Fe/Cu based sintered friction materials. Sci. Sinter. 2024, 56, 15–30. [Google Scholar] [CrossRef]

- Ma, L.; Ding, S.; Zhang, C.; Huang, Y.; Zhang, X. Study on the wear performance of high-speed railway brake materials at low temperatures under continuous braking conditions. Wear 2023, 512–513, 204556. [Google Scholar] [CrossRef]

- Zhuang, J.; Liu, Y.; Cao, Z.; Li, Y. The Influence of Technological Process on Dry Sliding Wear Behaviour of Titanium Carbide Reinforcement Copper Matrix Composites. Mater. Trans. 2010, 51, 2311–2317. [Google Scholar] [CrossRef]

- Lasio, B.; Torre, F.; Orrù, R.; Cao, G.; Cabibbo, M.; Delogu, F. Fabrication of Cu-graphite metal matrix composites by ball milling and spark plasma sintering. Mater. Lett. 2018, 230, 199–202. [Google Scholar] [CrossRef]

- Rajkumar, K.; Aravindan, S. Tribological performance of microwave sintered copper–TiC–graphite hybrid composites. Tribol. Int. 2011, 44, 347–358. [Google Scholar] [CrossRef]

- Peng, T.; Yan, Q.-z.; Zhan, X.-l.; Shi, X.-j. Solid FeS lubricant: A possible alternative to MoS2 for Cu–Fe-based friction materials. Int. J. Miner. Metall. Mater. 2017, 24, 1278–1283. [Google Scholar] [CrossRef]

- Kwabena Gyimah, G.; Huang, P.; Chen, D. Dry Sliding Wear Studies of Copper-Based Powder Metallurgy Brake Materials. J. Tribol. 2014, 136, 041601. [Google Scholar] [CrossRef]

- Xiong, X.; Sheng, H.-c.; Chen, J.; Yao, P.-p. Effects of sintering pressure and temperature on microstructure and tribological characteristic of Cu-based aircraft brake material. Trans. Nonferrous Met. Soc. China 2007, 17, 669–675. [Google Scholar] [CrossRef]

- Yuanming, S.; Feng, J.; Mengjun, L.; Feifei, W.; Zeyu, X.; Mingjin, W. Microstructure and frictional properties of copper-tin composites containing graphite and MoS2 by rapid hot-press sintering. Tribol. Int. 2023, 183, 108392. [Google Scholar]

- Liu, D.; Tian, H.; Lin, L.; Shi, W. Microstructure, mechanical and elevated temperature tribological behaviors of the diamond/Cu composites prepared by spark plasma sintering method. Diam. Relat. Mater. 2019, 91, 138–143. [Google Scholar] [CrossRef]

- Pellizzari, M.; Cipolloni, G. Tribological behaviour of Cu based materials produced by mechanical milling/alloying and spark plasma sintering. Wear 2017, 376–377, 958–967. [Google Scholar] [CrossRef]

- Li, L.; Zhuang, J.; Tong, T.; Tong, J.; Zhao, X.; Cao, F.; Song, W.; Wang, D.; Tian, Y.; Ma, Y.; et al. Effect of Wet Granulation on Tribological Behaviors of Cu-Based Friction Materials. Materials 2023, 16, 1075. [Google Scholar] [CrossRef]

- Chen, B.; Bi, Q.; Yang, J.; Xia, Y.; Hao, J. Tribological properties of Cu-based composites and in situ synthesis of TiN/TiB2. Mater. Sci. Eng. A 2008, 491, 315–320. [Google Scholar] [CrossRef]

- Rui, S.; Xiaosong, J.; Jiaxin, R.; Degui, Z. Microstructure and mechanical properties of nano-carbon reinforced Cu-based powder metallurgy friction materials produced by hot isostatic pressing. Mater. Test. 2018, 60, 809–817. [Google Scholar]

- Fan, J.; Wang, N.; Wang, X.; Hao, Y.; Wu, S.; Wang, Y.; Liu, J. Effect of the Coke/Flake Graphite Ratio on the Microstructure and Properties of Cu-Based Powder Metallurgy Friction Materials. J. Mater. Eng. Perform. 2022, 31, 10378–10392. [Google Scholar] [CrossRef]

- Zhang, J.; Xiang, Z.; Zhang, Q.; Feng, S.; Yu, Z.; Wang, X.; Mo, J.; He, D. A method to improve the tribological performance of Cu-based powder metallurgy friction materials for the high-speed trains braking system: Enhancement of the performance of the friction block disc spring. Wear 2025, 566–567, 205751. [Google Scholar] [CrossRef]

- Zhang, R.; Qi, Y.; Luo, Z.; Meng, J. Tribological behavior and mechanism of Ti3SiC2/Cu composites in a wide temperature range under lubrication condition. Tribol. Int. 2024, 200, 110144. [Google Scholar] [CrossRef]

- Zhang, Z.; Pei, X.; Yu, Z.; Wang, Y.; Lin, L.; Wang, Q.; Wang, T. Tribological synergy of copper-based metal–organic frameworks, carbon fibers and SiO2 in modifying the friction and wear properties of epoxy composites. Polym. Compos. 2024, 45, 11673–11686. [Google Scholar] [CrossRef]

- Kong, D.; Gong, Y.; Wei, H. Cr3C2 reinforced Cu-graphite composites fabricated by a novel in-situ decomposition using Cu-coated graphite and Cu-coated Cr2AlC. Vacuum 2024, 220, 112834. [Google Scholar] [CrossRef]

- Nautiyal, H.; Gautam, R.K.; Singh, S.; Goswami, R.; Gautam, G.; Raturi, A.; Khatri, O.P.; Tyagi, R. Influence of sintering temperature on mechanical and tribological characteristics of copper based composite reinforced by 2D hybrid material. Proc. Inst. Mech. Eng. Part E-J. Process Mech. Eng. 2023, 238, 1747–1755. [Google Scholar] [CrossRef]

- Xiong, X.; Chen, J.; Yao, P.; Li, S.; Huang, B. Friction and wear behaviors and mechanisms of Fe and SiO2 in Cu-based P/M friction materials. Wear 2007, 262, 1182–1186. [Google Scholar] [CrossRef]

- Amanov, A.; Cho, I.-S.; Kim, D.-E. Effectiveness of high-frequency ultrasonic peening treatment on the tribological characteristics of Cu-based sintered materials on steel substrate. Mater. Des. 2013, 45, 118–124. [Google Scholar] [CrossRef]

- Liu, J.; Sun, K.; Zeng, L.; Wang, J.; Xiao, X.; Liu, J.; Guo, C.; Ding, Y. Microstructure and Properties of Copper–Graphite Composites Fabricated by Spark Plasma Sintering Based on Two-Step Mixing. Metals 2020, 10, 1506. [Google Scholar] [CrossRef]

- Moazami-Goudarzi, M.; Nemati, A. Tribological behavior of self lubricating Cu/MoS2 composites fabricated by powder metallurgy. Trans. Nonferrous Met. Soc. China 2018, 28, 946–956. [Google Scholar] [CrossRef]

- Gong, T.; Yao, P.; Xiong, X.; Zhou, H.; Zhang, Z.; Xiao, Y.; Zhao, L.; Deng, M. Microstructure and tribological behavior of interfaces in Cu-SiO2 and Cu-Cr metal matrix composites. J. Alloys Compd. 2019, 786, 975–985. [Google Scholar] [CrossRef]

| Components | Content (ωt %) | Powder Size (Mesh) | Manufacturer |

|---|---|---|---|

| Wrap of Cu on Fe | 61.5 | 300 | Henan Taihe Huijin Powder Technology Co., Ltd., Jiaozuo, China |

| Graphite | 11 | 100 | Shanghai Youmo Composite Materials Co., Ltd., Shanghai, China |

| MoS2 | 5 | 200 | Nangong Chunxu Metal Material Factory, Xingtai, China |

| Sb2S3 | 5 | 200 | Zhongke Yanuo (Beijing) Technology Co., Ltd., Beijing, China |

| Al2O3 | 3 | 100 | Suiye Electronic Applied Materials Co., Ltd., Dongguan, China |

| SiO2 | 0.8 | 200 | Hebei Keze Metal Materials Co., Ltd., Handan, China |

| Cr | 3.7 | 500 | Nangong Xindun Alloy Electrode Spray Co., Ltd., Xingtai, China |

| Tiny Cu powders | 10 | 2000 | Nangong Xindun Alloy Electrode Spray Co., Ltd., Xingtai, China |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Ma, Y.; Zhang, Z.; Li, L. Influence of Sintering Process on Mechanical and Tribological Properties of 3D-Mesh-Structure-Reinforced Cu-Based Friction Materials. Materials 2025, 18, 5371. https://doi.org/10.3390/ma18235371

Zhu J, Ma Y, Zhang Z, Li L. Influence of Sintering Process on Mechanical and Tribological Properties of 3D-Mesh-Structure-Reinforced Cu-Based Friction Materials. Materials. 2025; 18(23):5371. https://doi.org/10.3390/ma18235371

Chicago/Turabian StyleZhu, Juxiang, Yunhai Ma, Zhaoliang Zhang, and Lekai Li. 2025. "Influence of Sintering Process on Mechanical and Tribological Properties of 3D-Mesh-Structure-Reinforced Cu-Based Friction Materials" Materials 18, no. 23: 5371. https://doi.org/10.3390/ma18235371

APA StyleZhu, J., Ma, Y., Zhang, Z., & Li, L. (2025). Influence of Sintering Process on Mechanical and Tribological Properties of 3D-Mesh-Structure-Reinforced Cu-Based Friction Materials. Materials, 18(23), 5371. https://doi.org/10.3390/ma18235371