Comparative Analysis of the Structure, Properties and Internal Stresses of MAG Welded Joints Made of S960QL Steel Subjected to Heat Treatment and Pneumatic Needle Peening

Abstract

1. Introduction

2. Methods and Materials

2.1. Welding of the Test Plates

2.2. Interpass Peening

2.3. Post-Weld Stress Relief Heat Treatment

2.4. Acceptance Tests in Accordance with PN-EN ISO 15614-1:2017 [20]

- Tensile test in accordance with PN-EN ISO 4136:2022 [28];

- Transverse bending test in accordance with PN-EN ISO 5173:2023 [29];

- Impact test in accordance with PN-EN ISO 9016:2022 [30];

- Hardness test in accordance with PN-EN ISO 9015-1:2011 [31];

- Macroscopic test in accordance with PN-EN ISO 17639:2022 [32].

2.5. Microstructure Analysis Using Electron Backscatter Diffraction

2.6. Stress Measurement Using Barkhausen Effect

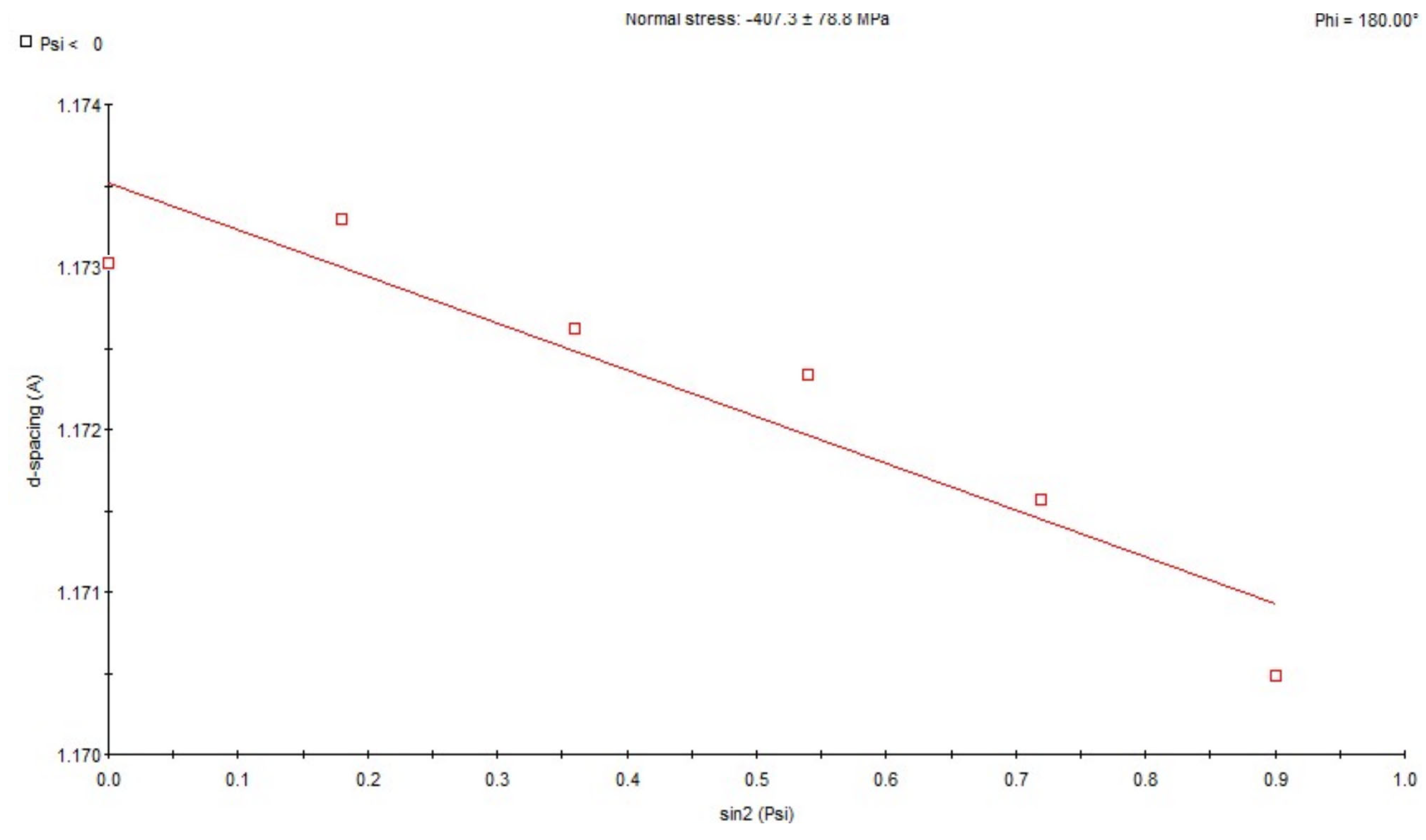

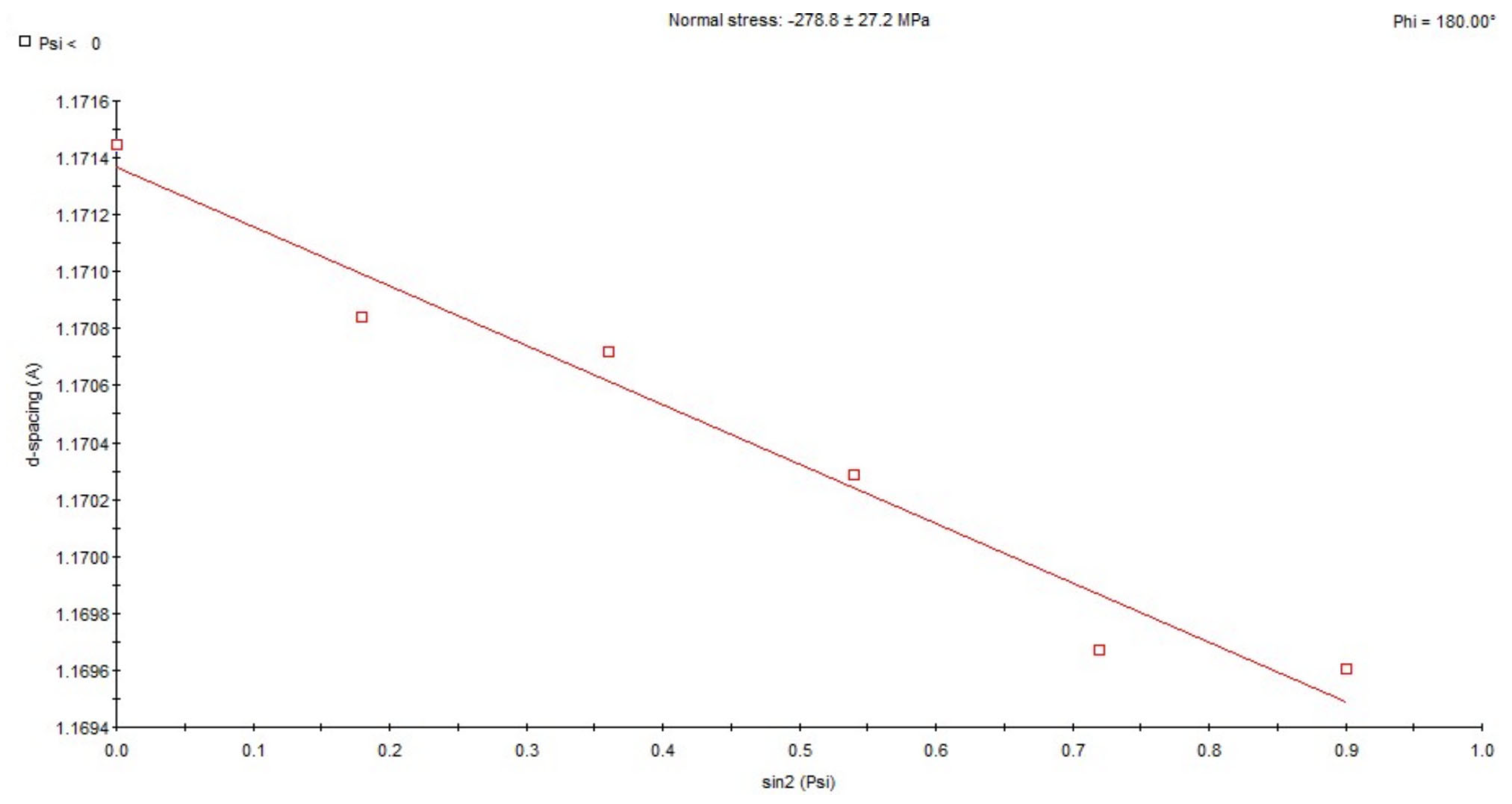

2.7. Quantitative Phase Analysis and Stress Measurements Using X-Ray Diffraction

3. Result and Discussion

3.1. Welding Technology Qualification Test Results

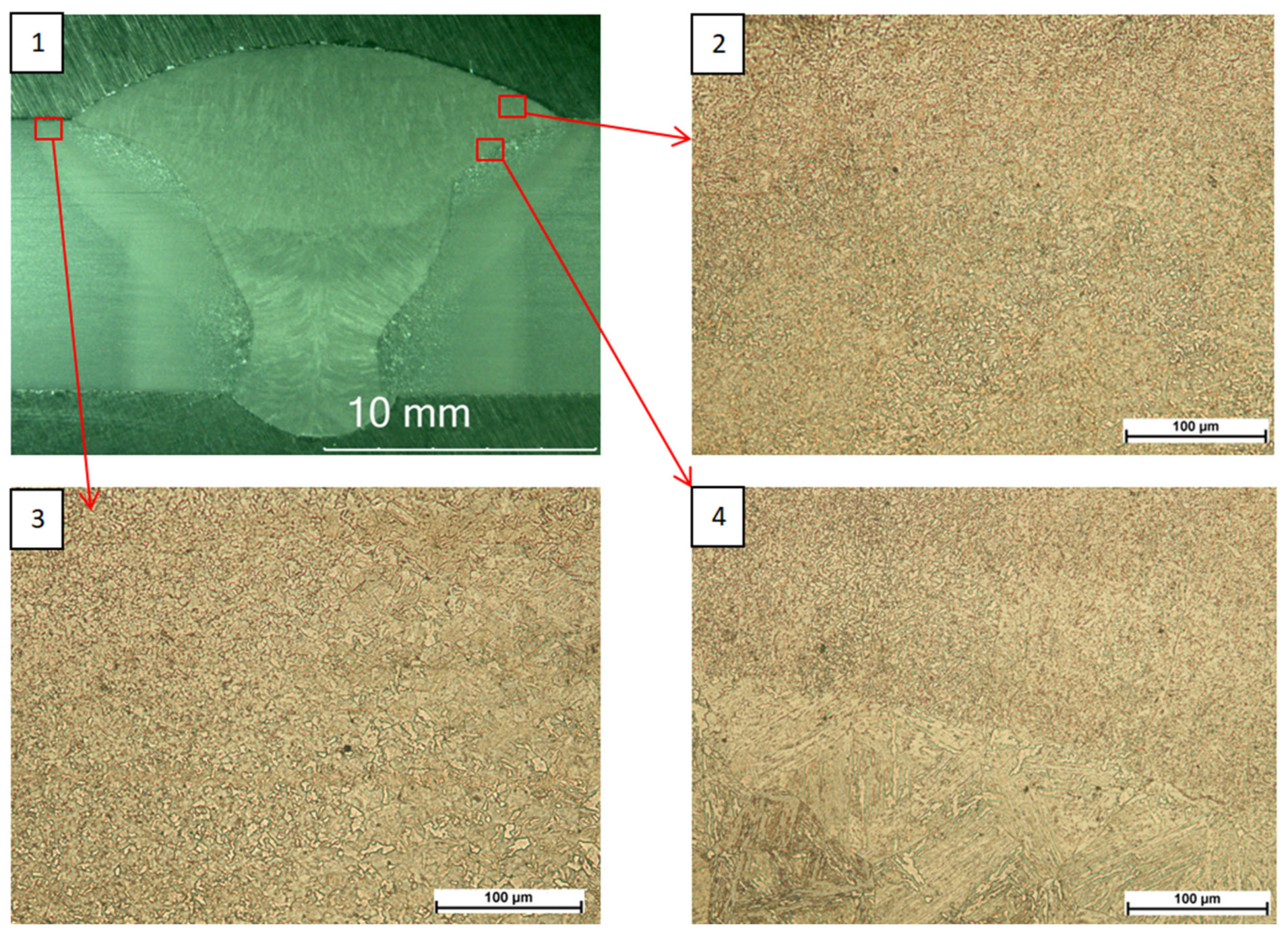

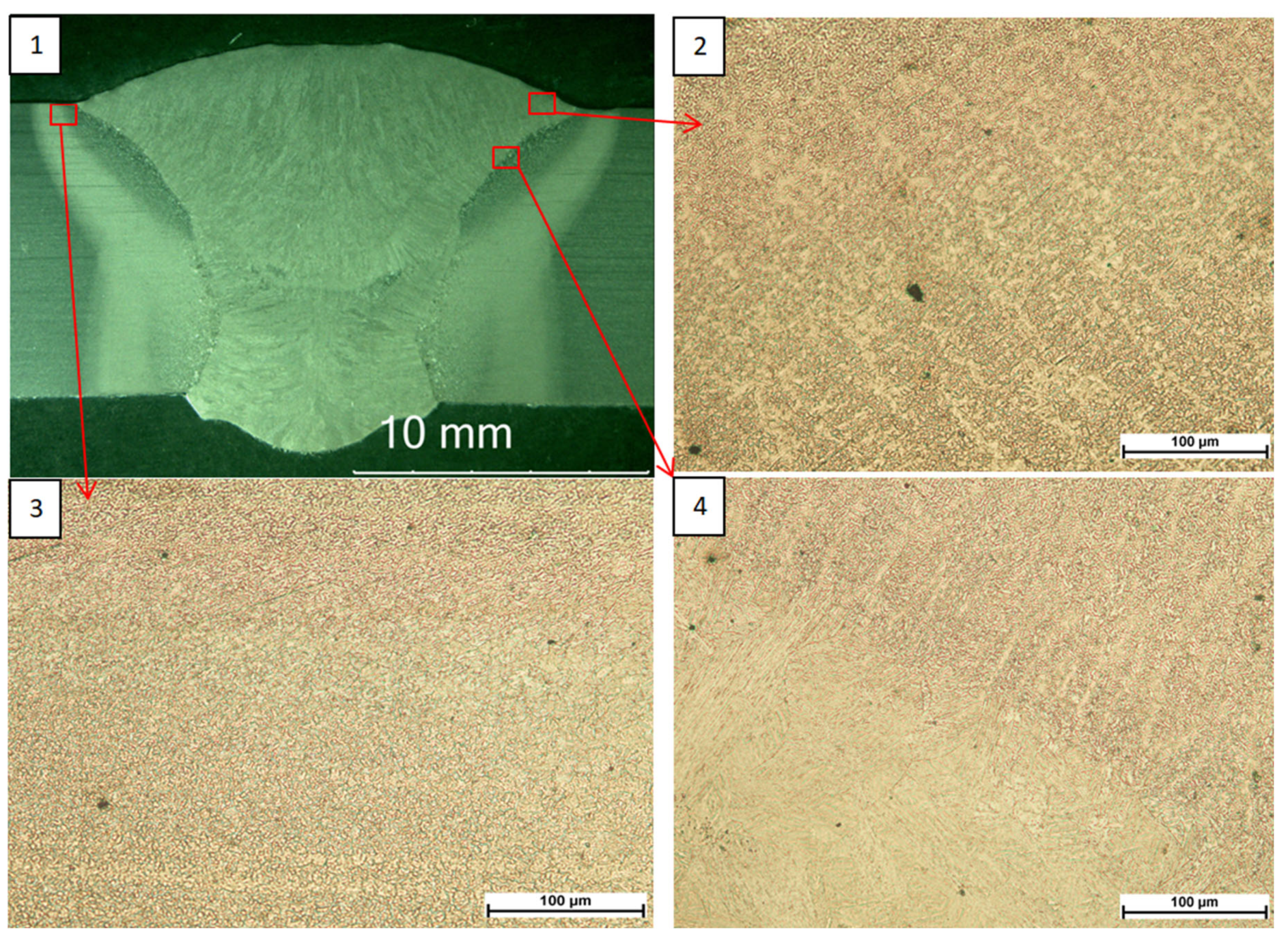

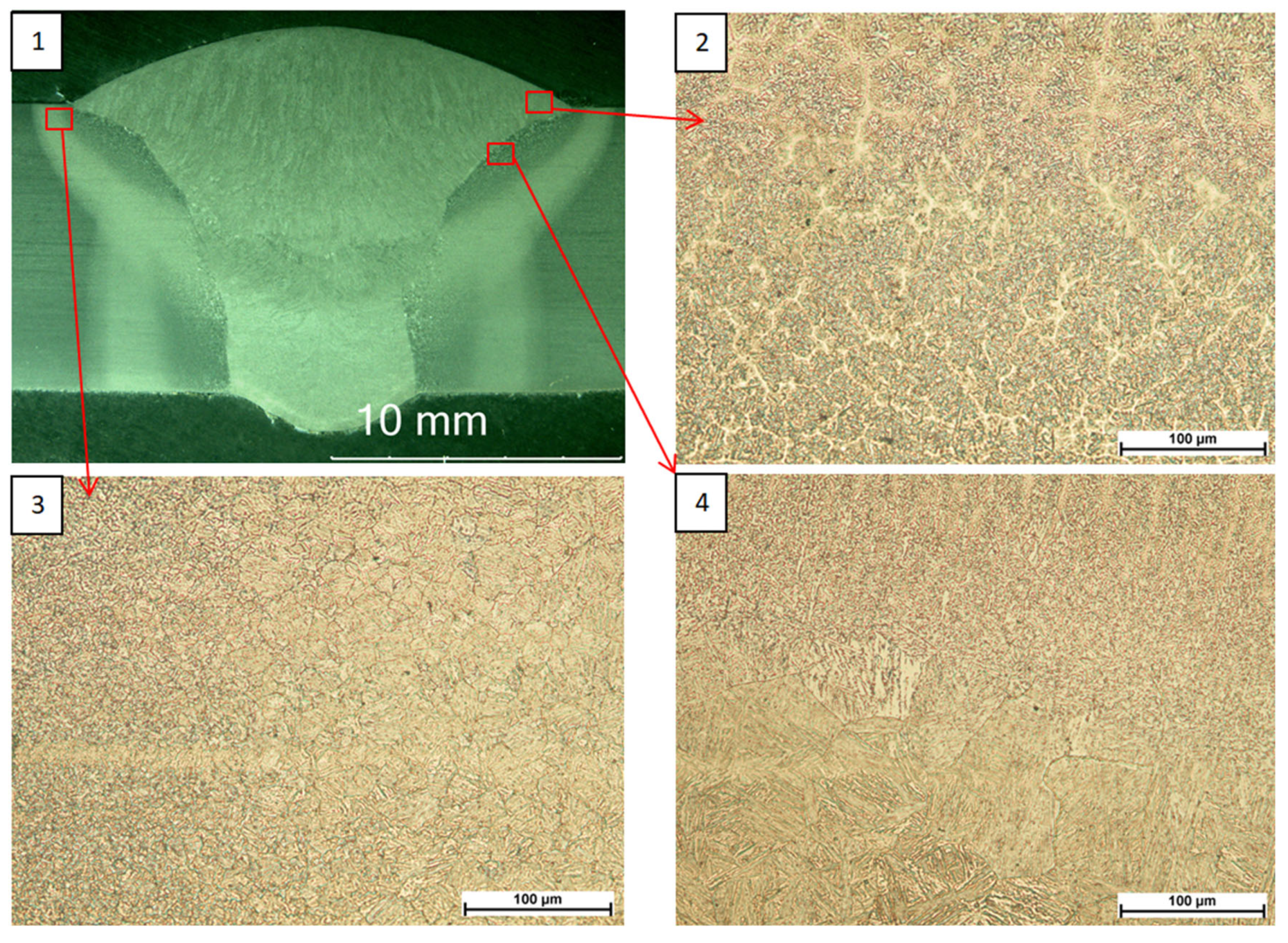

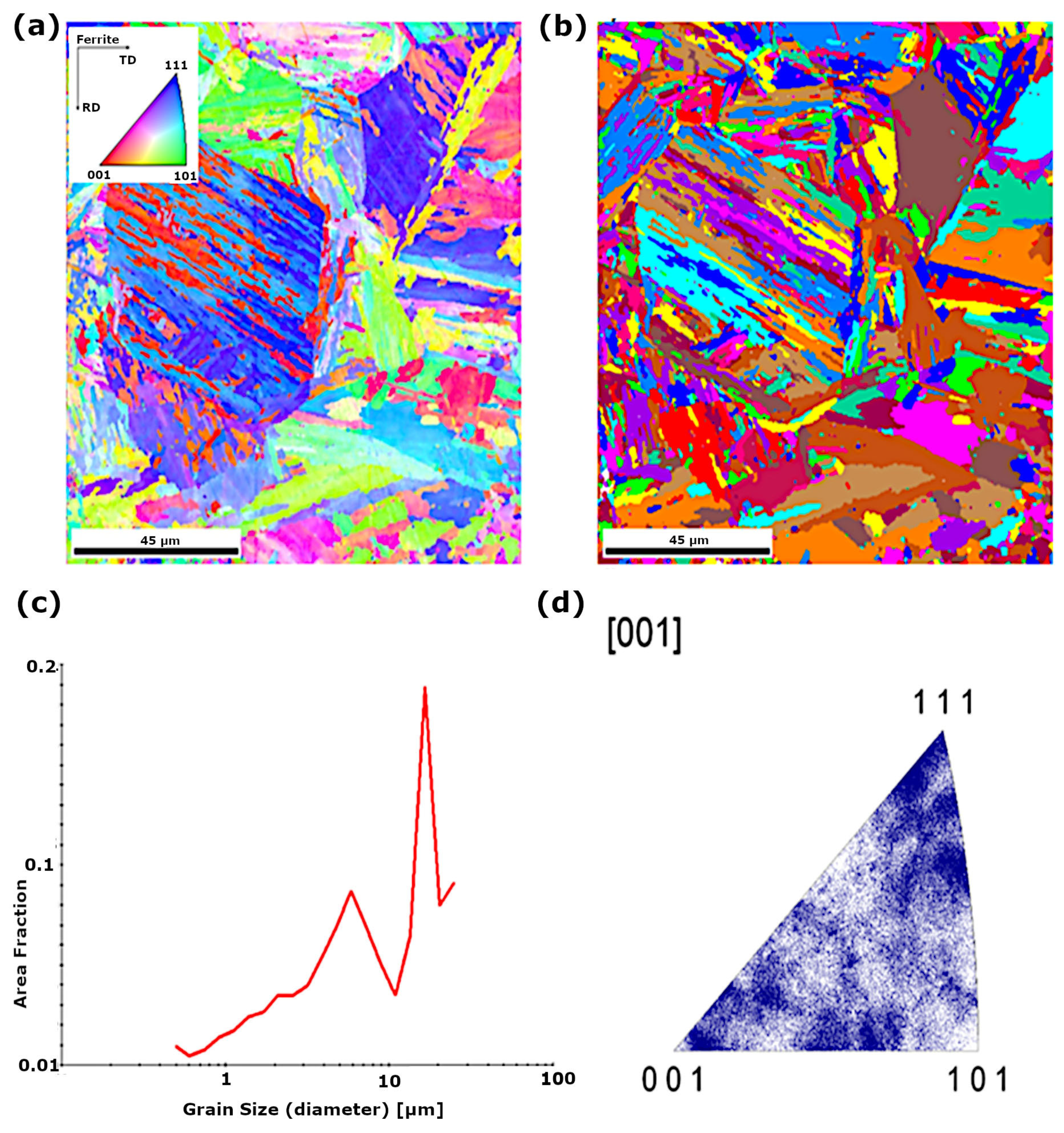

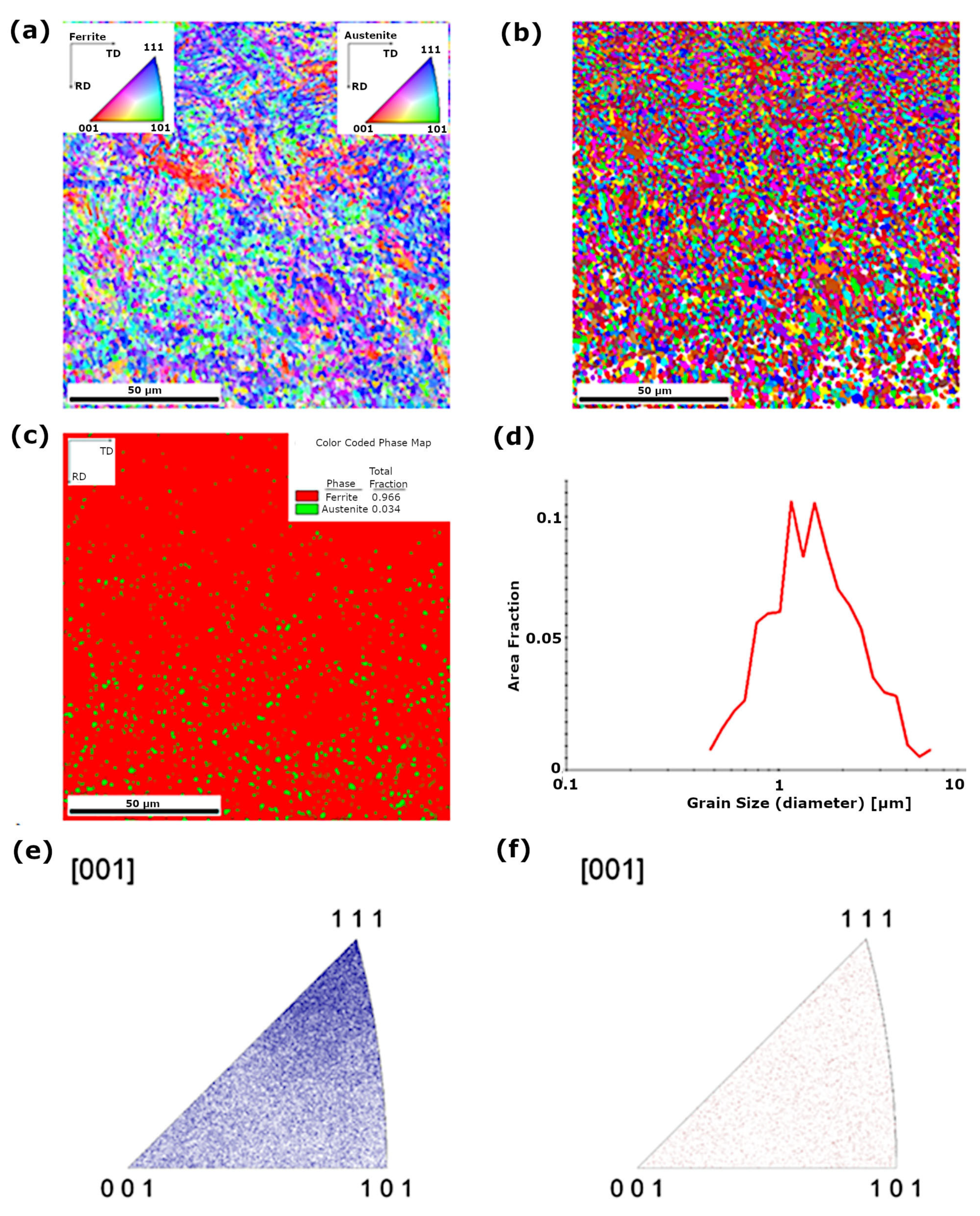

3.2. Joint Microstructure Analysis

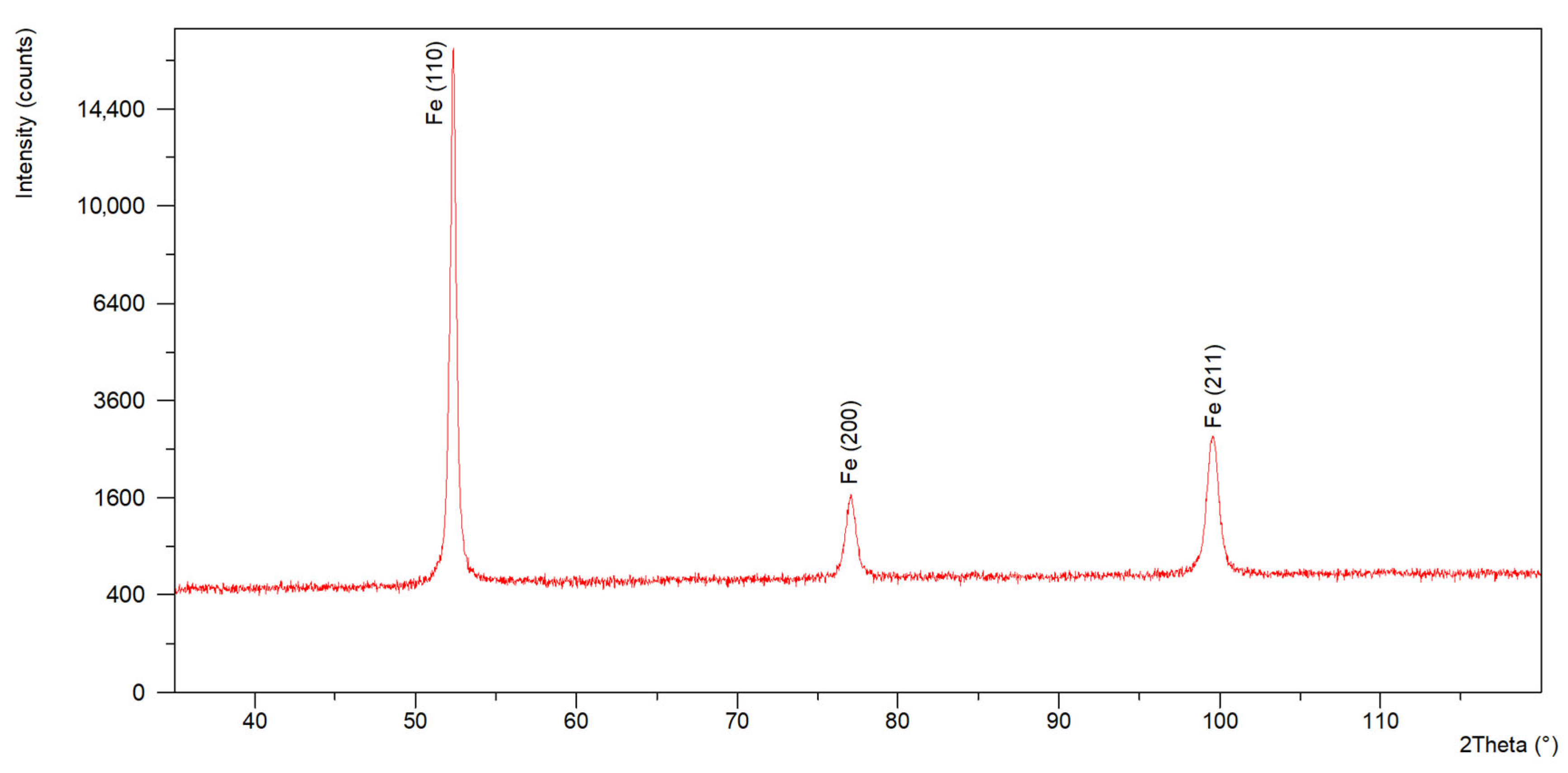

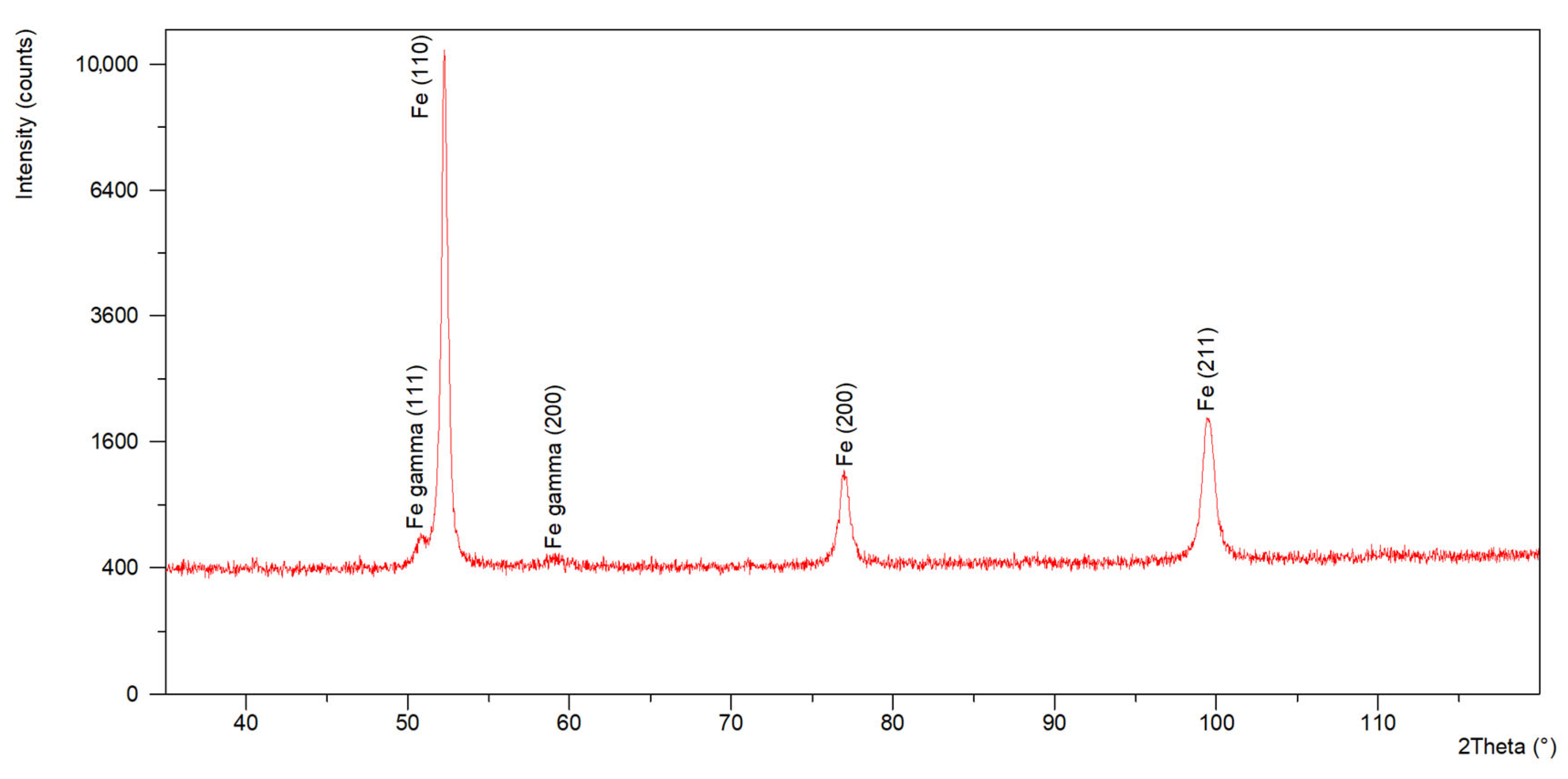

3.3. Phase Composition Analysis Using X-Ray Diffraction

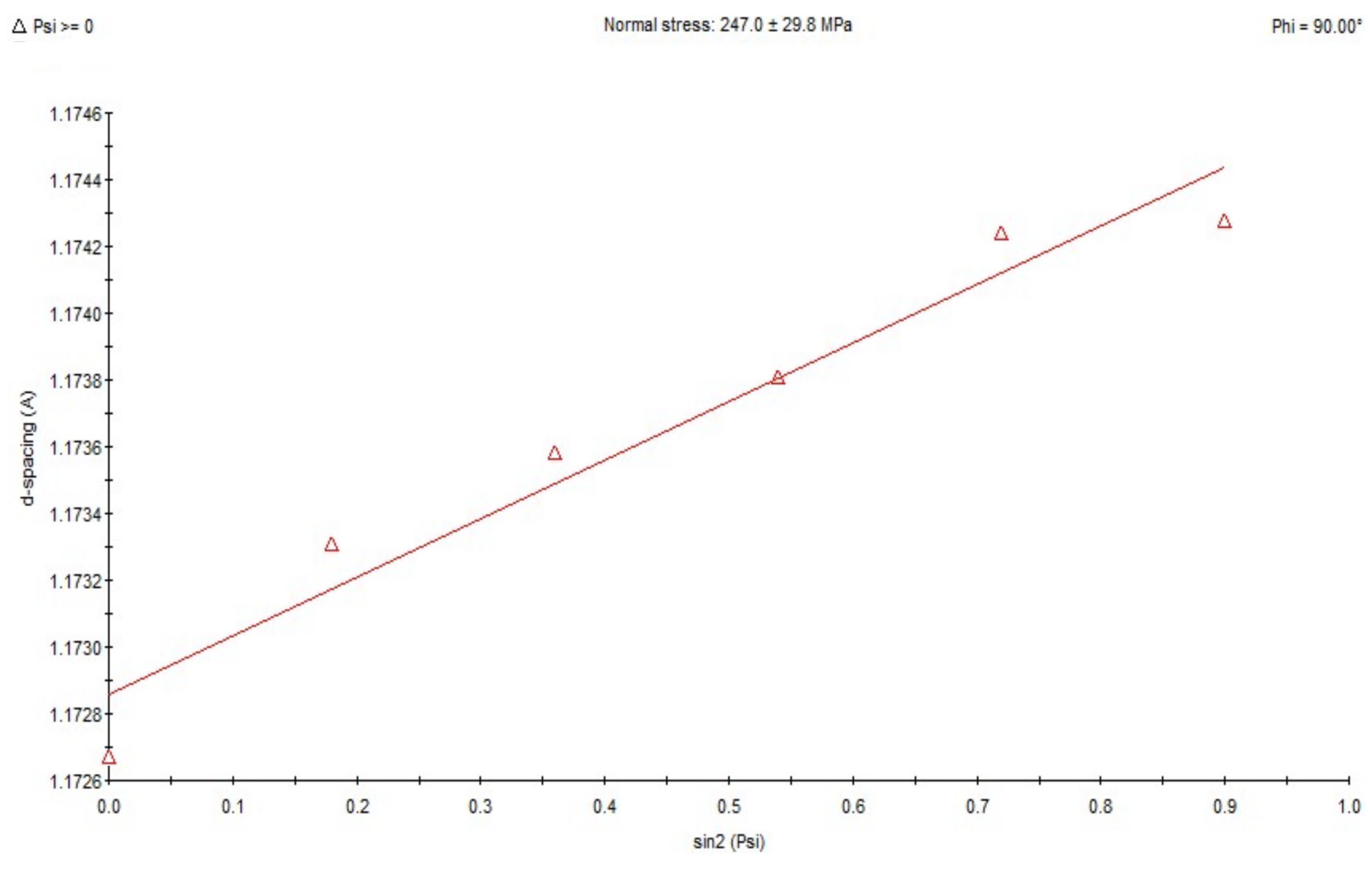

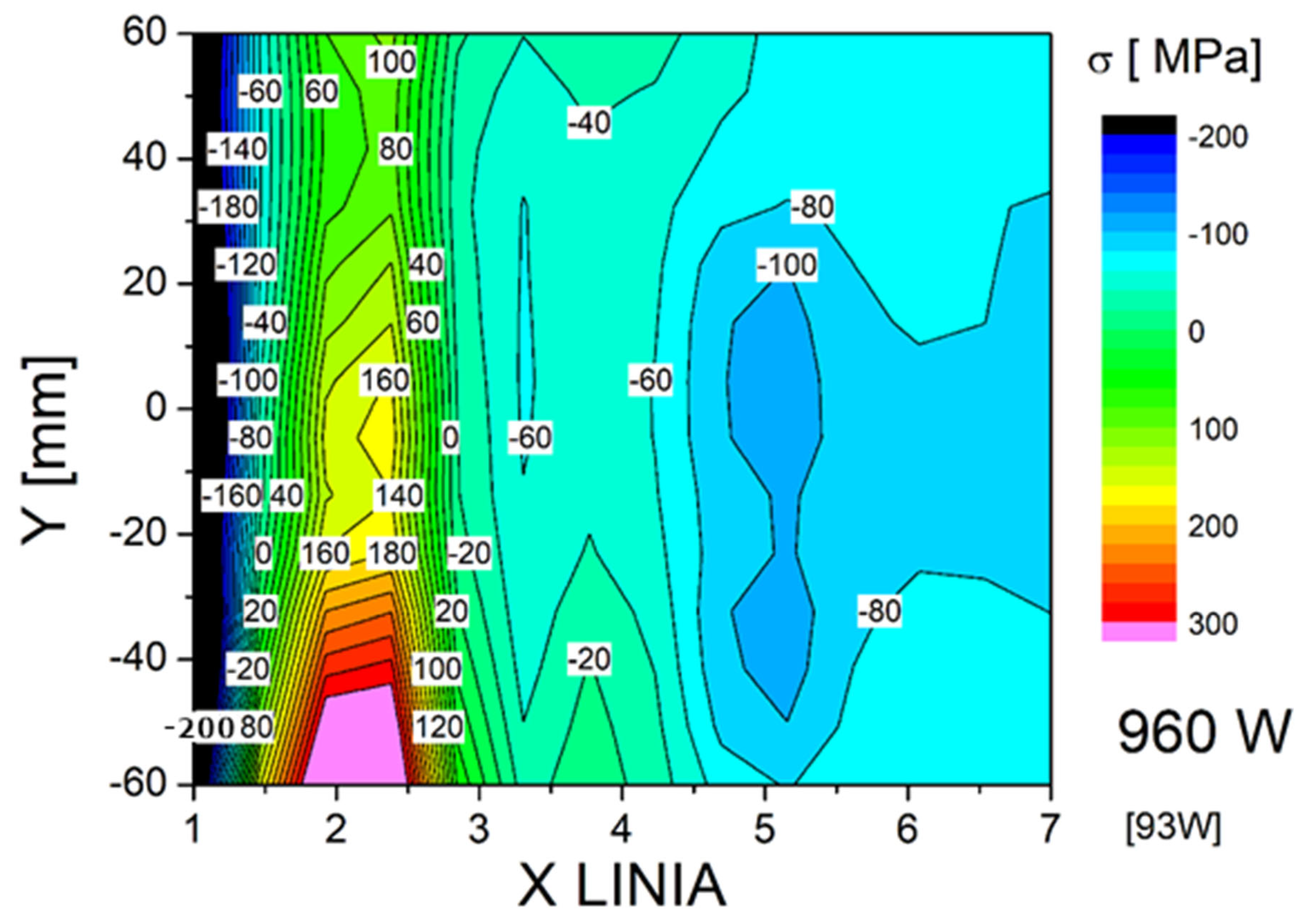

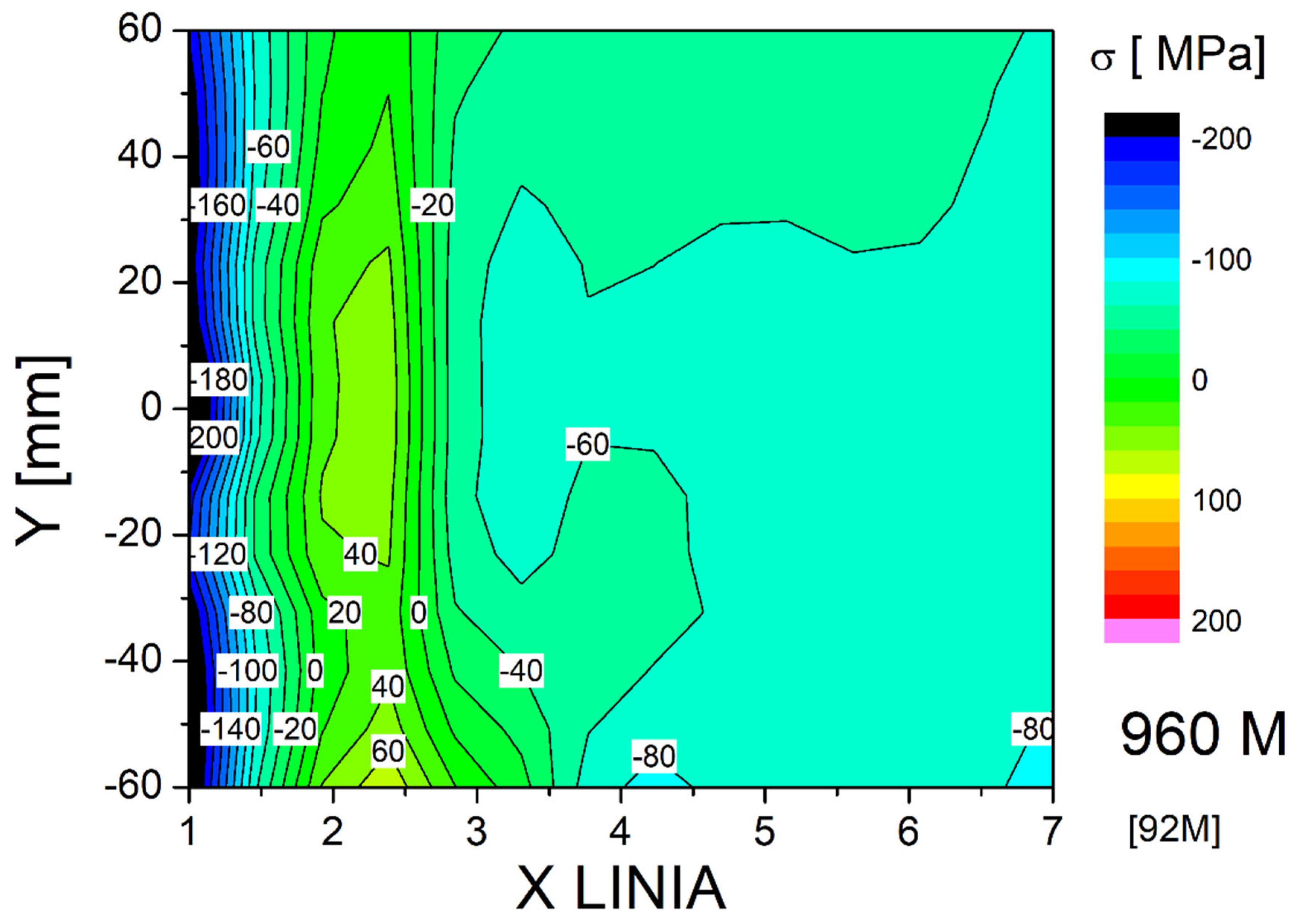

3.4. Stress Measurement Analysis

4. Conclusions

- ➢

- Transverse tensile testing of all three test plates showed tensile strength, Rm, results were over the required value of 980 N/mm2;

- ➢

- Transverse bending tests on samples with face tension and edge tension showed no non-conformities and met the ISO 15614-1:2017 requirements;

- ➢

- Impact testing of test plates in the as-welded state and with inter-stitch peening yielded similar results, and in the case of samples taken from the welded joints in the post-heat treatment state, the test results from the heat-affected zone were on average about 30J higher than for the other two plates. This may be due to a decrease in hardness in the HAZ as a result of stress relief annealing, which was confirmed during the test.

- ➢

- The hardness test of the welded joint in the as-welded condition in the parent material area showed an average value of 356 HV10; for the fusion zone, it was 345 HV10, and for the heat-affected zone, it was 315 HV10. In the case of the test plate after stress relief annealing, the values were as follows: parent material—357 HV10, fusion zone—365 HV10, and HAZ—307 HV10. In the case of the test plate after peening, the values were as follows: parent material—352 HV10, fusion zone—337 HV10, and HAZ—328 HV10. There is a noticeable increase in hardness in the HAZ area that has been peened.

- ➢

- Observation with a light microscope showed that in the HAZ area directly below the plate surface, the microstructure is fragmented, which is most likely caused by intense plastic deformation during the HFMI process and the resulting deformation. The observation of the microstructure under a light microscope was supplemented by EBSD analysis, which confirmed differences in grain size in the zone directly below the surface.

- ➢

- Phase composition analysis using X-ray diffraction, as well as EBSD analysis, showed that the fusion zone contains approximately 4% Fe-γ austenite by volume. This is due to the increased nickel content in the electrode wire used to weld these samples (2.24% by weight).

- ➢

- Both tested treatments resulted in significant improvement in HAZ stresses, with PWHT achieving better improvement. Both of the tested treatments did not negatively impact mechanical properties in any significant manner. While PWHT looks like a more promising technology, it possesses significant downsides vs. HFMI, mainly a higher cost.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Michaleris, P.; Dantzig, J.; Tortorelli, D. Minimization of welding residual stress and distortion in large structures. Weld. J. 1999, 78, 362–365. [Google Scholar]

- Radaj, D. Heat Effects of Welding—Temperature Field, Residual Stress, Distortion; Springer: Berlin/Heidelberg, Germany, 1992; ISBN 978-3-642-48642-5. [Google Scholar]

- Simunek, D.; Leitner, M.; Stoschka, M. Numerical simulation loop to investigate the local fatigue behaviour of welded and HFMI-treated joints. Adv. Eng. Softw. 2018, 120, 96–106. [Google Scholar] [CrossRef]

- Haagensen, P.J.; Maddox, S.J. IIW Recommendations on Methods for Improving the Fatigue Strength of Welded Joints, IIW-2142-10; Woodhead: Tameside, UK, 2013; ISBN 978-1-78242-065-1. [Google Scholar]

- Ernould, C. Numerical Simulation of Pin Kinetic and its Influence on the Material Hardening, Residual Stress Field and Topography During High Frequency Mechanical Impact (HFMI) Treatment. Master’s Thesis, Fraunofer IWM, Freiburg, Germany, 2017. [Google Scholar]

- Górka, J.; Przybyła, M. Research on the Influence of HMFI and PWHT Treatments on the Properties and Stress States of MAG-Welded S690QL Steel Joints. Materials 2024, 17, 3560. [Google Scholar] [CrossRef]

- Mičian, M.; Harmaniak, D.; Nový, F.; Winczek, J.; Moravec, J.; Trško, L. Effect of the t8/5 Cooling Time on the Properties of S960MC Steel in the HAZ of Welded Joints Evaluated by Thermal Physical Simulation. Metals 2020, 10, 229. [Google Scholar] [CrossRef]

- Colegrove, P.; Ikeagu, C.; Thistlethwaite, A.; Williams, S.; Nagy, T.; Suder, W.; Pirling, T. Welding process impact on residual stress and distortion. Sci. Technol. Weld. Join. 2009, 14, 717–725. [Google Scholar] [CrossRef]

- Skowronska, B.; Szulc, J.; Bober, M.; Baranowski, M.; Chmielewski, T. Selected properties of RAMOR 500 steel welded joints by hybrid PTA-MAG. J. Adv. Join. Process. 2022, 5, 100111. [Google Scholar] [CrossRef]

- Conrardy, C.; Huang, T.D.; Harwig, D.; Dong, P.; Kvidahl, L.; Evans, N.; Treaster, A. Practical Welding Techniques to Minimize Distortion in Lightweight Ship Structures. J. Ship Prod. 2006, 22, 239–247. [Google Scholar] [CrossRef]

- Górka, J.; Przybyla, M.; Szmul, M.; Chudzio, A.; Ladak, D. Orbital TIG welding of titanium tubes with perforated bottom made of titanium-clad steel. Adv. Mater. Sci. 2019, 19, 55–64. [Google Scholar] [CrossRef]

- Kasra, G. Fatigue Strength Improvement of Aluminum and High Strength Steel Welded Structures using High Frequency Mechanical Impact Treatment. Procedia Eng. 2015, 133, 473–476. [Google Scholar] [CrossRef]

- Żuk, M.; Górka, J.; Czupryński, A.; Adamiak, M. Properties and structure of the weld joints of quench and tempered 4330V steel. Metalurgija 2016, 55, 613–616. [Google Scholar]

- Friedrich, B.; Lechner, C.; Habersohn, C.; Obermair, M.; Heindl, F.; Rodriguez Ripoll, M. Improving the tribological characteristics of tool and mould surfaces by machine hammer peening. CIRP Ann. 2013, 62, 239–241. [Google Scholar] [CrossRef]

- Quilliec, G.; Lieurade, H.; Bousseau, M.; Drissi-Habti, M.; Inglebert, G.; Macquet, P.; Jubin, L. Fatigue Behaviour of Welded Joints Treated by High Frequency Hammer Peening: Part II, Numerical study. In Proceedings of the 64th Annual Assembly & International Conference of the International Institute of Welding (IIW 2011), Chennai, India, 17–23 July 2012. [Google Scholar]

- Abdullach, A.; Malaki, M.; Eskandari, A. Strength enhancement of the welded structures by ultrasonic peening. Mater. Des. 2012, 38, 7–18. [Google Scholar] [CrossRef]

- Mikkola, E.; Remes, H.; Marquis, G. Influence of residual stresses on elasto-plastic response in HFMI-Treated welded joint under different load ratios. In Proceedings of the 68th IIW Annual Assembly and International Conference, Helsinki, Finland, 28 June–3 July 2015. [Google Scholar]

- Harati, E.; Svensson, L.; Karlsson, L.; Hurtig, K. Effect of HFMI treatment on weld toe geometry and fatigue properties of high strength steel welds. Procedia Struct. Integr. 2016, 2, 3483–3490. [Google Scholar] [CrossRef]

- Krauss, G. Steels. Processing, Structure and Performance, 2nd ed.; ASM International: Materials Park, NA, USA, 2015; ISBN 978-1-62708-083-5. [Google Scholar]

- PN-EN ISO 15614-1:2017; Specification and Qualification of Welding Procedures for Metallic Materials—Welding Procedure Test—Part 1: Arc and Gas Welding of Steels and Arc Welding of Nickel and Nickel Alloys. PKN: Warsaw, Poland, 2017.

- Górka, J. Assessment of the Effect of Laser Welding on the Properties and Structure of TMCP Steel Butt Joints. Materials 2020, 13, 1312. [Google Scholar] [CrossRef]

- Long, H.; Gery, D.; Carlier, A.; Maropoulos, P.G. Prediction of welding distortion in butt joint of thin plates. Mater. Des. 2009, 30, 4126–4135. [Google Scholar] [CrossRef]

- Przybyła, M.; Górka, J.; Rzeźnikiewicz, A. Properties of joints welded using the MAG method S355j2+n steel after peening process. Int. J. Mod. Manuf. Technol. 2024, 16, 102–108. [Google Scholar] [CrossRef]

- PN-EN ISO 14175:2009; Welding Consumables—Gases and Gas Mixtures for Fusion Welding and Allied Processes. PKN: Warsaw, Poland, 2009.

- PN-EN ISO 17637:2017; Non-Destructive Testing of Welds—Visual Testing of Fusion-Welded Joints. PKN: Warsaw, Poland, 2017.

- PN-EN ISO 3452-1:2021; Non-Destructive Testing—Penetrant Testing—Part 1: General Principles. PKN: Warsaw, Poland, 2021.

- PN-EN ISO 17636-1:2023; Non-Destructive Testing of Welds—Radiographic Testing—Part 1: X- and Gamma-Ray Techniques with Film. PKN: Warsaw, Poland, 2023.

- PN-EN ISO 4136:2022; Destructive Tests on Welds in Metallic Materials—Transverse Tensile Test. PKN: Warsaw, Poland, 2022.

- PN-EN ISO 5173:2023; Destructive Tests on Welds in Metallic Materials—Bend Tests. PKN: Warsaw, Poland, 2023.

- PN-EN ISO 9016:2022; Destructive Tests on Welds in Metallic Materials—Impact Tests—Test Specimen Location, Notch Orientation and Examination. PKN: Warsaw, Poland, 2022.

- PN-EN ISO 9015-1:2011; Destructive Tests on Welds in Metallic Materials—Hardness Testing—Part 1: Hardness Test on Arc Welded Joints. PKN: Warsaw, Poland, 2011.

- PN-EN ISO 17639:2022; Destructive Tests on Welds in Metallic Materials—Macroscopic and Microscopic Examination of Welds. PKN: Warsaw, Poland, 2022.

- Lehto, P.; Remes, H. EBSD characterisation of grain size distribution and grain sub-structures for ferritic steel weld metals. Weld. World 2022, 66, 363–377. [Google Scholar] [CrossRef]

- Liskevych, O.; Fiorin, A. An Experimental Approach for Correlation of the Magnetic Barkhausen Noise to Microstructural Changes and Residual Stress in Welding Joints. Soldag. Inspeção 2004, 29, 2–3. [Google Scholar] [CrossRef]

- Ilker, H.; Ibrahim, C.; Hankan Gür, C. Non-destructive determination of residual stress state in steel weldments by Magnetic Barkhausen Noise technique. NDT E Int. 2010, 43, 29–33. [Google Scholar] [CrossRef]

- Vourna, P.; Ktena, A.; Tsakiridis, P.; Hristoforou, E. An accurate evaluation of the residual stress of welded electrical steels with magnetic Barkhausen noise. Measurement 2015, 71, 31–45. [Google Scholar] [CrossRef]

- Faryna, M. Analysis of the Crystallographic Relationships of Component Phases in Ceramic Matrix Composites; Institute of Metallurgy and Materials Engineering, PAN: Kraków, Poland, 2023; ISBN 83-915145-7-9. [Google Scholar]

- Walker, D. Residual Stress Measurement Techniques. Adv. Mater. Process. 2001, 159, 30–33. [Google Scholar]

- Kandil, F.A.; Lord, D.; Fry, A.T.; Grant, P.V. A Review of Residual Stress Measurement Methods. A Guide to Technique Selection; Technical Report; NPL: Teddington, UK, 2001. [Google Scholar]

- Bai, Y.; Guo, X.; Sun, X.; Liu, G.; Xie, X.; Wang, X.; Shang, J. Effect of heat input on microstructural characteristics and fatigue property of heat-affected zone in a FH690 heavy-gauge marine steel. Int. J. Fatigue 2025, 196, 108898. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, X.; Cui, J.; Wang, H.; Juang, L.; Zeng, W.; Zhang, H. Lifetime fatigue cracking behavior of weld defects in orthotropic steel bridge decks: Numerical and experimental study. Eng. Fail. Anal. 2025, 167, 108993. [Google Scholar] [CrossRef]

- Gupta, S.; Pratihar, B.; Pratihar, D. Study on AI-based approaches to replace costly heat-treatment process for obtaining enhanced mechanical properties of the weld. Weld. World 2025. [Google Scholar] [CrossRef]

| Plate | Element Concentration, wt% | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Cr | Mo | Ni | V | Cu | Al | Ti | Nb | As | |

| S960QL | 0.12 | 1.42 | 0.47 | 0.008 | 0.003 | 0.59 | 0.56 | 0.79 | 0.05 | 0.11 | 0.007 | 0.005 | 0.02 | 0.002 |

| Wire | Element Concentration, wt% | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Cr | Ni | V | Cu | Al | Mo | Ti + Zr | |

| ED-FK | 0.11 | 1.75 | 0.81 | 0.007 | 0.009 | 0.36 | 2.24 | 0.002 | 0.009 | 0.005 | 0.57 | 0.08 |

| Sample Designation | Bead No | Interpass Temperature [°C] | Average Welding Current [A] | Average Arc Voltage [V] | Welding Time [min] | Linear Energy [kJ/mm] |

|---|---|---|---|---|---|---|

| S960QL as welded | 1 | 28.6 | 201 | 23.9 | 2:35 | 1.07 |

| 2 | 82.5 | 203 | 27.0 | 1:27 | 0.70 | |

| 3 | 104.5 | 255 | 26.3 | 2:42 | 1.35 | |

| S960QL + HMFI | 1 | 47.5 | 200 | 23.8 | 2:38 | 1.04 |

| 2 | 89.6 | 202 | 27.1 | 1:29 | 0.71 | |

| 3 | 114.5 | 255 | 26.3 | 2:31 | 1.34 | |

| S960QL + PWHT | 1 | 36.0 | 202 | 24.0 | 2:51 | 1.06 |

| 2 | 92.4 | 202 | 27.0 | 1:27 | 0.71 | |

| 3 | 119.7 | 254 | 26.4 | 2:29 | 1.37 |

| Test Type | Sample | Result | Sample | Result | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S960QL as welded | |||||||||||||||||||

| Transverse tensile test | TT-1 | 1007 MPa | TT-2 | 1011 MPa | |||||||||||||||

| Transverse bending tests | TFBB1 | positive | TRBB1 | positive | |||||||||||||||

| TFBB2 | positive | TRBB2 | positive | ||||||||||||||||

| Charpy impact testing | VWT 0/2 | 58.9 J | VHT 0/2 | 82.4 J | |||||||||||||||

| VWT 0/2 | 54.9J | VHT 0/2 | 79.5 J | ||||||||||||||||

| VWT 0/2 | 59.8 J | VHT 0/2 | 74.6 J | ||||||||||||||||

| Hardness testing | Ma-1 HV10 | L1 | 367 | 370 | 356 | 313 | 301 | 335 | 341 | 331 | 330 | 352 | 285 | 334 | 365 | 353 | 357 | ||

| L2 | 350 | 351 | 345 | 279 | 290 | 334 | 366 | 349 | 356 | 349 | 316 | 279 | 340 | 359 | 356 | ||||

| S960QL peened | |||||||||||||||||||

| Transverse tensile test | TT-1 | 1011 MPa | TT-2 | 989 MPa | |||||||||||||||

| Transverse bending tests | TFBB1 | positive | TRBB1 | positive | |||||||||||||||

| TFBB2 | positive | TRBB2 | positive | ||||||||||||||||

| Charpy impact testing | VWT 0/2 | 58.9 J | VHT 0/2 | 66.7 J | |||||||||||||||

| VWT 0/2 | 58.9 J | VHT 0/2 | 70.6 J | ||||||||||||||||

| VWT 0/2 | 58.9 J | VHT 0/2 | 68.7 J | ||||||||||||||||

| Hardness testing | Ma-1 HV10 | L1 | 355 | 366 | 362 | 303 | 360 | 326 | 326 | 370 | 361 | 365 | 385 | 327 | 315 | 355 | 360 | ||

| L2 | 356 | 341 | 334 | 282 | 278 | 356 | 336 | 320 | 309 | 326 | 334 | 295 | 316 | 353 | 356 | ||||

| S960QL PWHT | |||||||||||||||||||

| Transverse tensile test | TT-1 | 998 MPa | TT-2 | 992 MPa | |||||||||||||||

| Transverse bending tests | TFBB1 | positive | TRBB1 | positive | |||||||||||||||

| TFBB2 | positive | TRBB2 | positive | ||||||||||||||||

| Charpy impact testing | VWT 0/2 | 52.0 J | VHT 0/2 | 117.7 J | |||||||||||||||

| VWT 0/2 | 96.1 J | VHT 0/2 | 116.7 J | ||||||||||||||||

| VWT 0/2 | 101.0 J | VHT 0/2 | 100.0 J | ||||||||||||||||

| Hardness testing | Ma-1 HV10 | L1 | 360 | 361 | 370 | 300 | 319 | 328 | 334 | 355 | 349 | 307 | 290 | 310 | 338 | 344 | 347 | ||

| L2 | 356 | 354 | 344 | 292 | 288 | 345 | 371 | 387 | 398 | 330 | 300 | 294 | 327 | 329 | 344 | ||||

| Mean Stress [MPa] | |||

|---|---|---|---|

| Test Sample | Fusion Zone | HAZ | Parent Material |

| S960QL as welded | −170 | +180 | −40 |

| S960QL peened | −150 | +30 | −65 |

| S960QL PWHT | −170 | −90 | −140 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Górka, J.; Przybyła, M.; Wyględacz, B. Comparative Analysis of the Structure, Properties and Internal Stresses of MAG Welded Joints Made of S960QL Steel Subjected to Heat Treatment and Pneumatic Needle Peening. Materials 2025, 18, 5363. https://doi.org/10.3390/ma18235363

Górka J, Przybyła M, Wyględacz B. Comparative Analysis of the Structure, Properties and Internal Stresses of MAG Welded Joints Made of S960QL Steel Subjected to Heat Treatment and Pneumatic Needle Peening. Materials. 2025; 18(23):5363. https://doi.org/10.3390/ma18235363

Chicago/Turabian StyleGórka, Jacek, Mateusz Przybyła, and Bernard Wyględacz. 2025. "Comparative Analysis of the Structure, Properties and Internal Stresses of MAG Welded Joints Made of S960QL Steel Subjected to Heat Treatment and Pneumatic Needle Peening" Materials 18, no. 23: 5363. https://doi.org/10.3390/ma18235363

APA StyleGórka, J., Przybyła, M., & Wyględacz, B. (2025). Comparative Analysis of the Structure, Properties and Internal Stresses of MAG Welded Joints Made of S960QL Steel Subjected to Heat Treatment and Pneumatic Needle Peening. Materials, 18(23), 5363. https://doi.org/10.3390/ma18235363