Effect of Cryo-Rolling on the Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Alloy

Abstract

1. Introduction

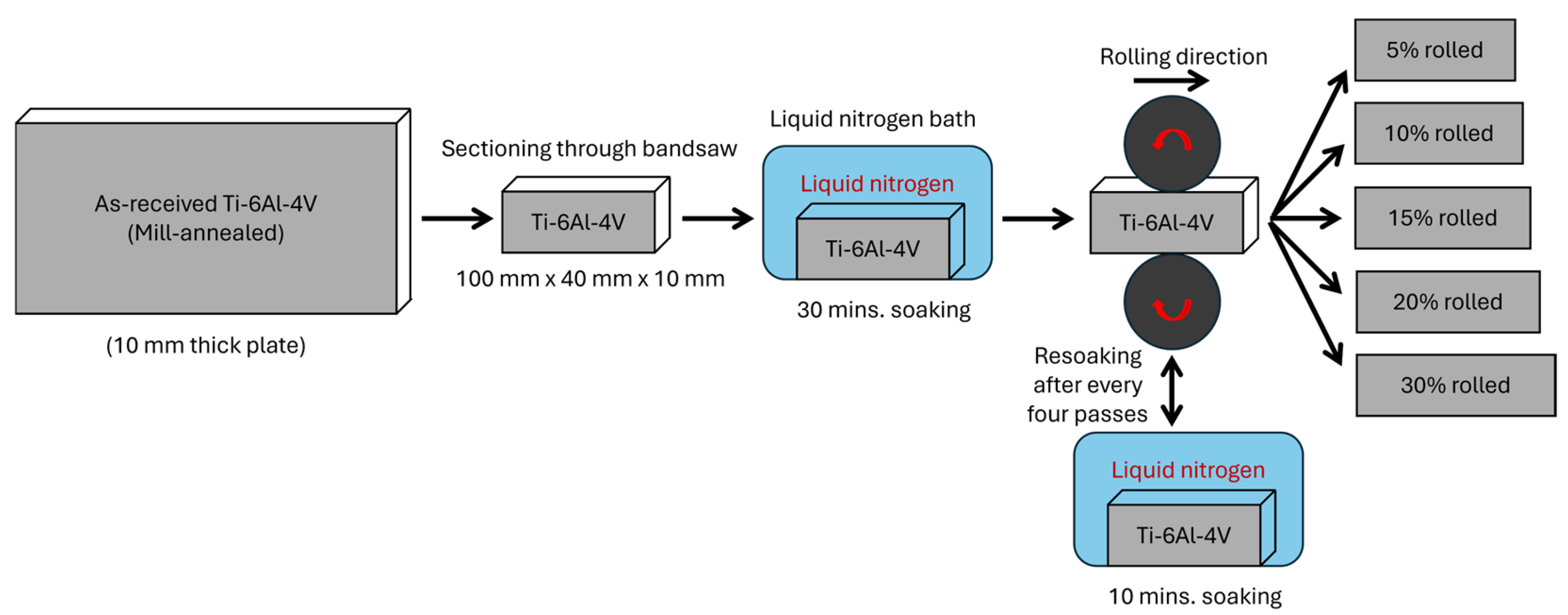

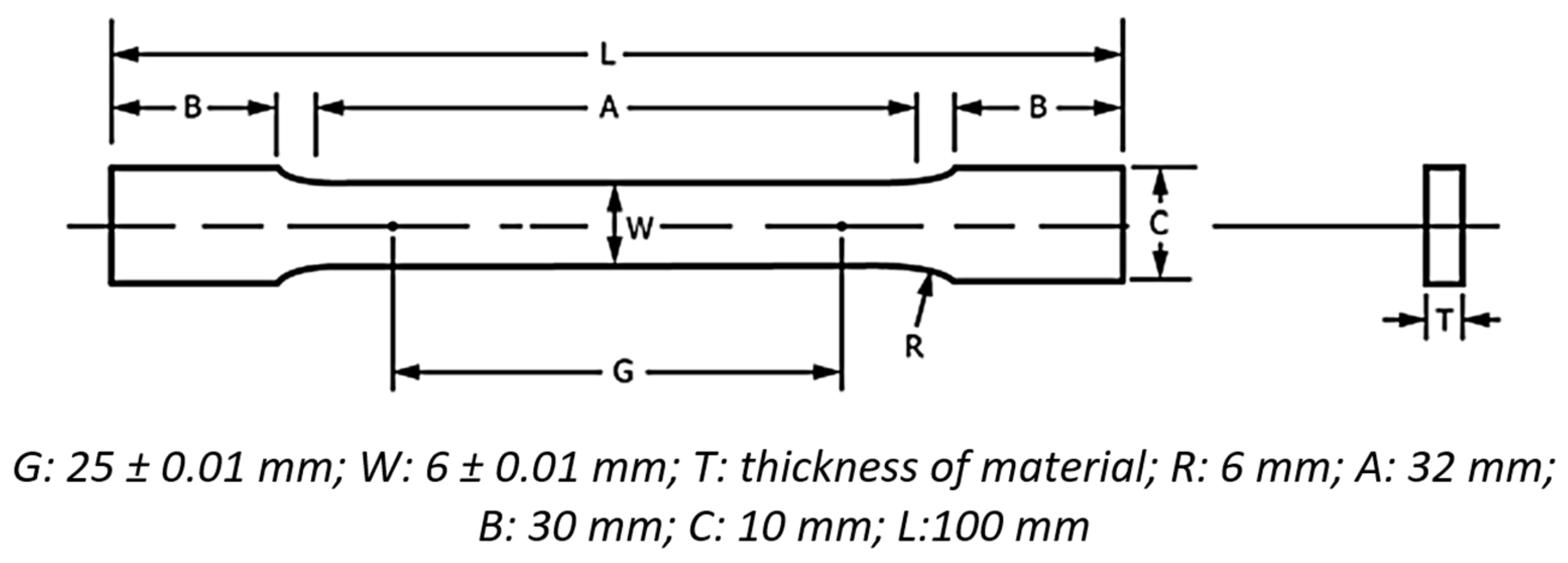

2. Materials and Methods

3. Results and Discussion

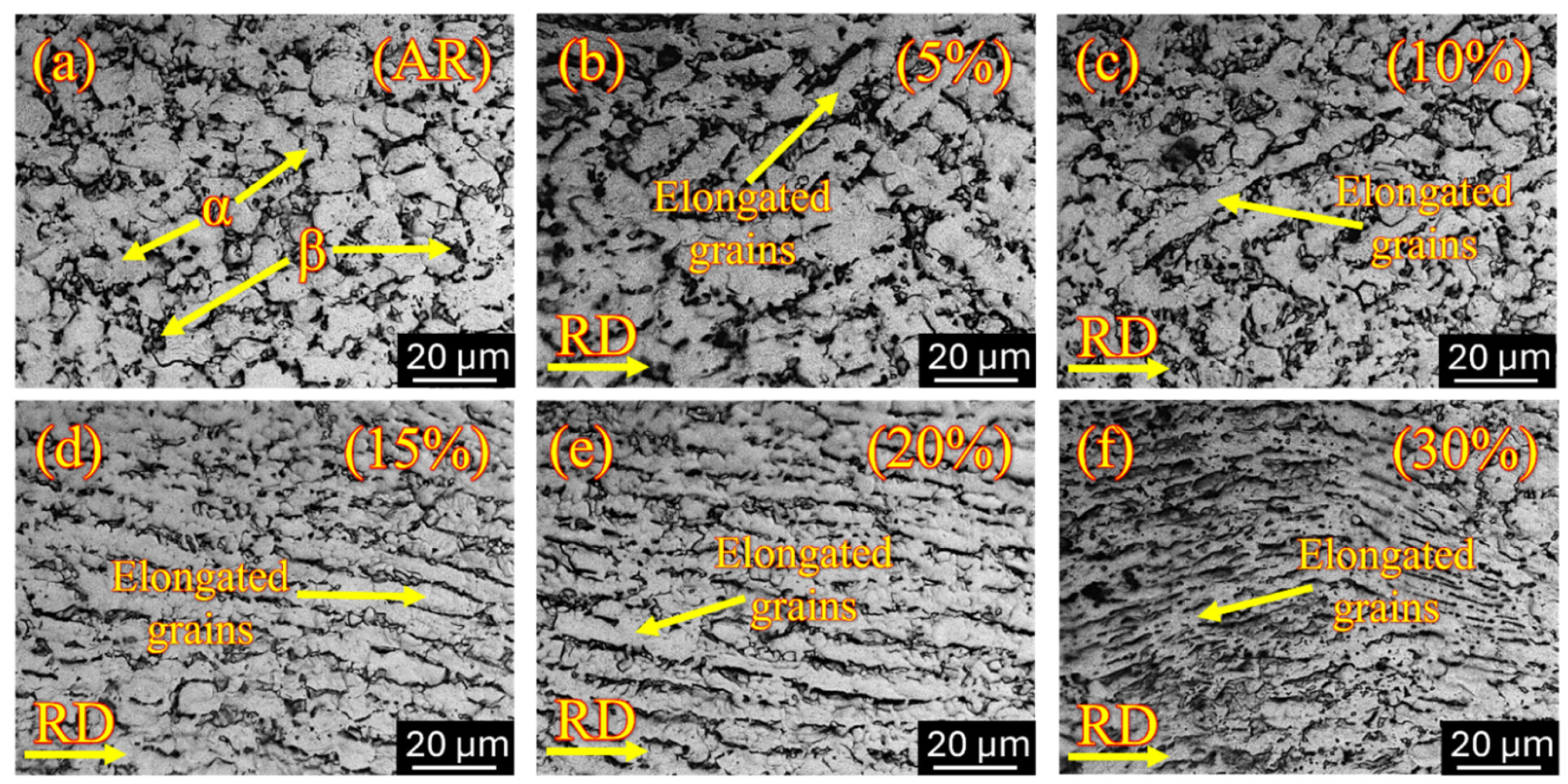

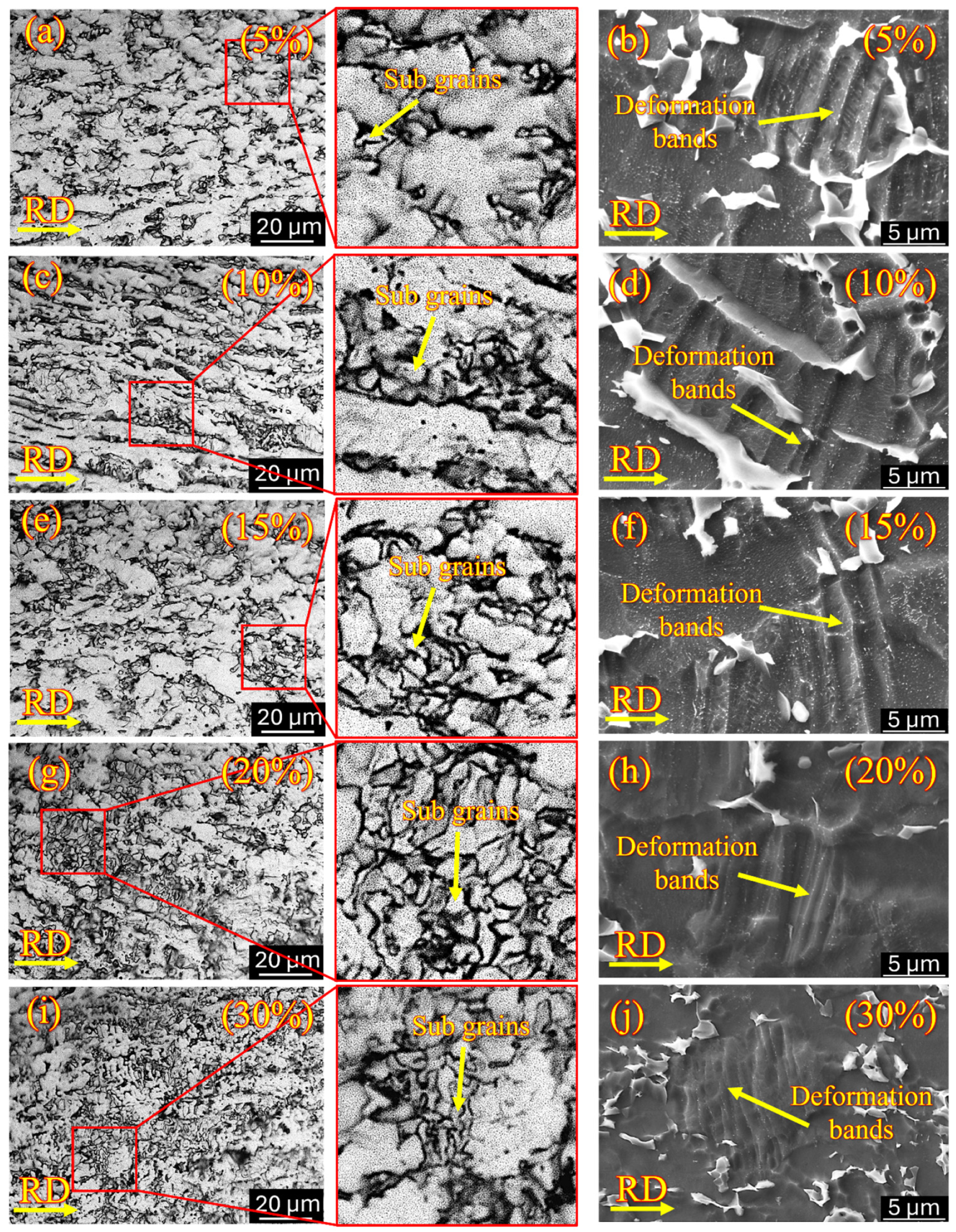

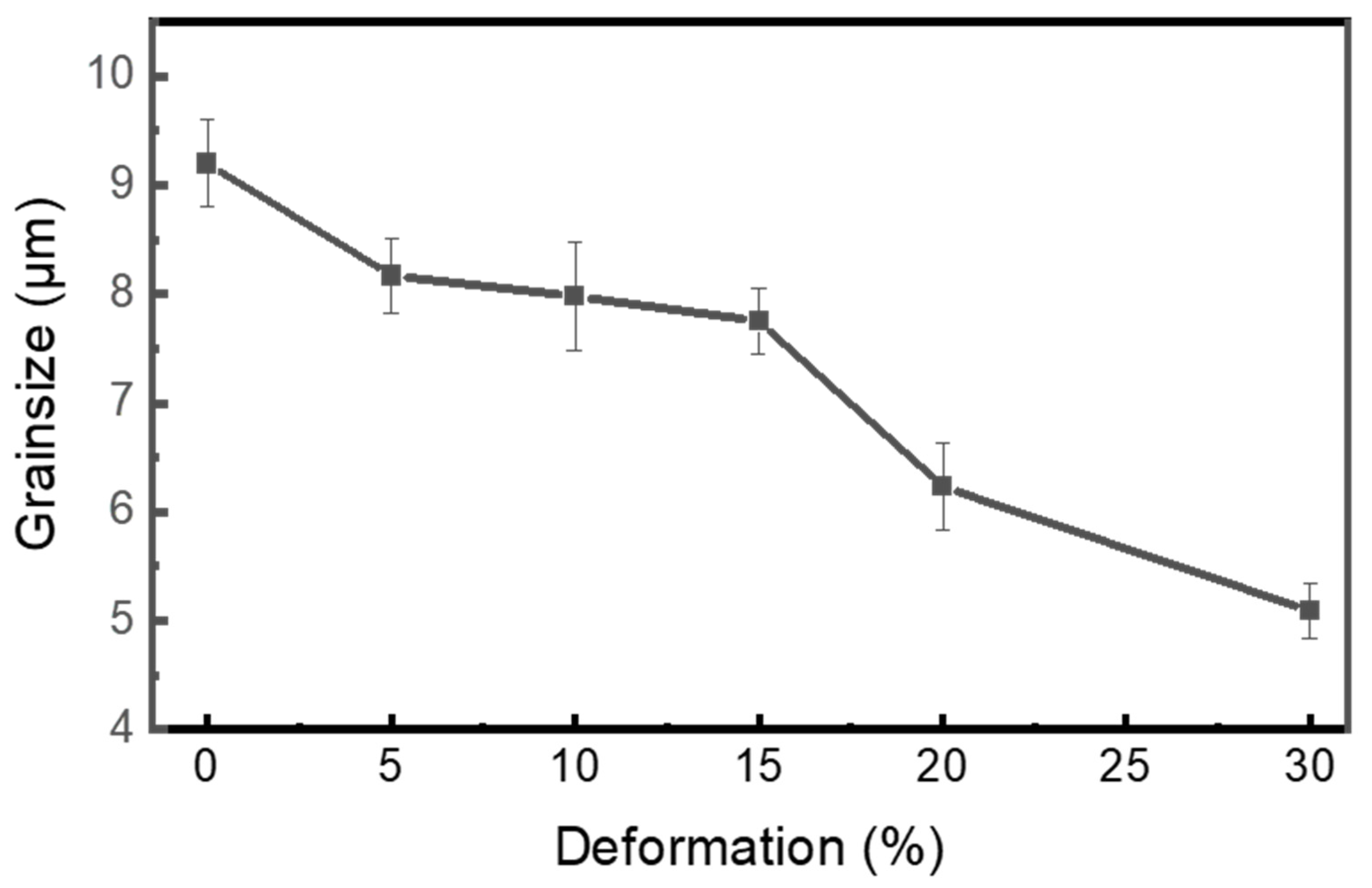

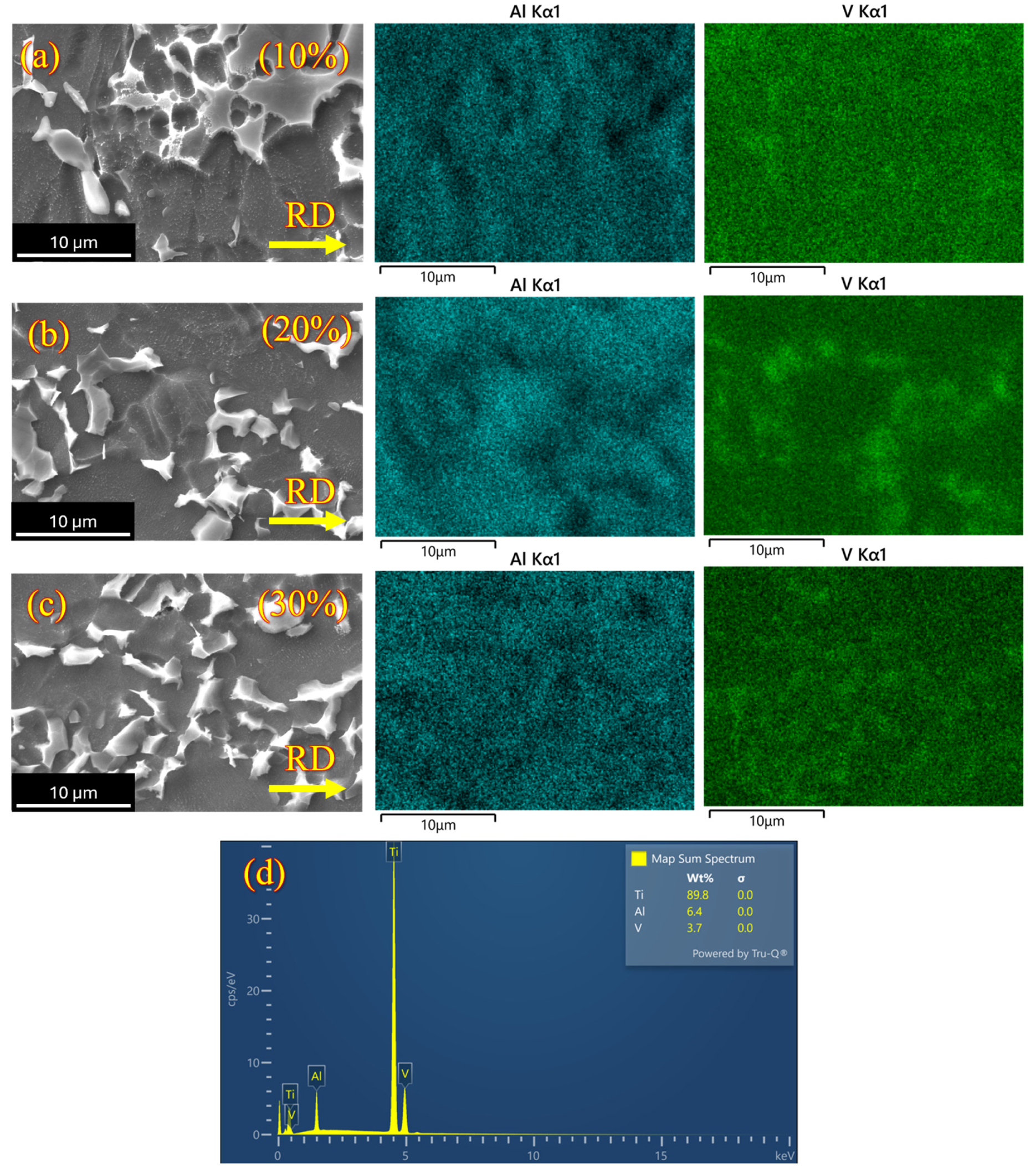

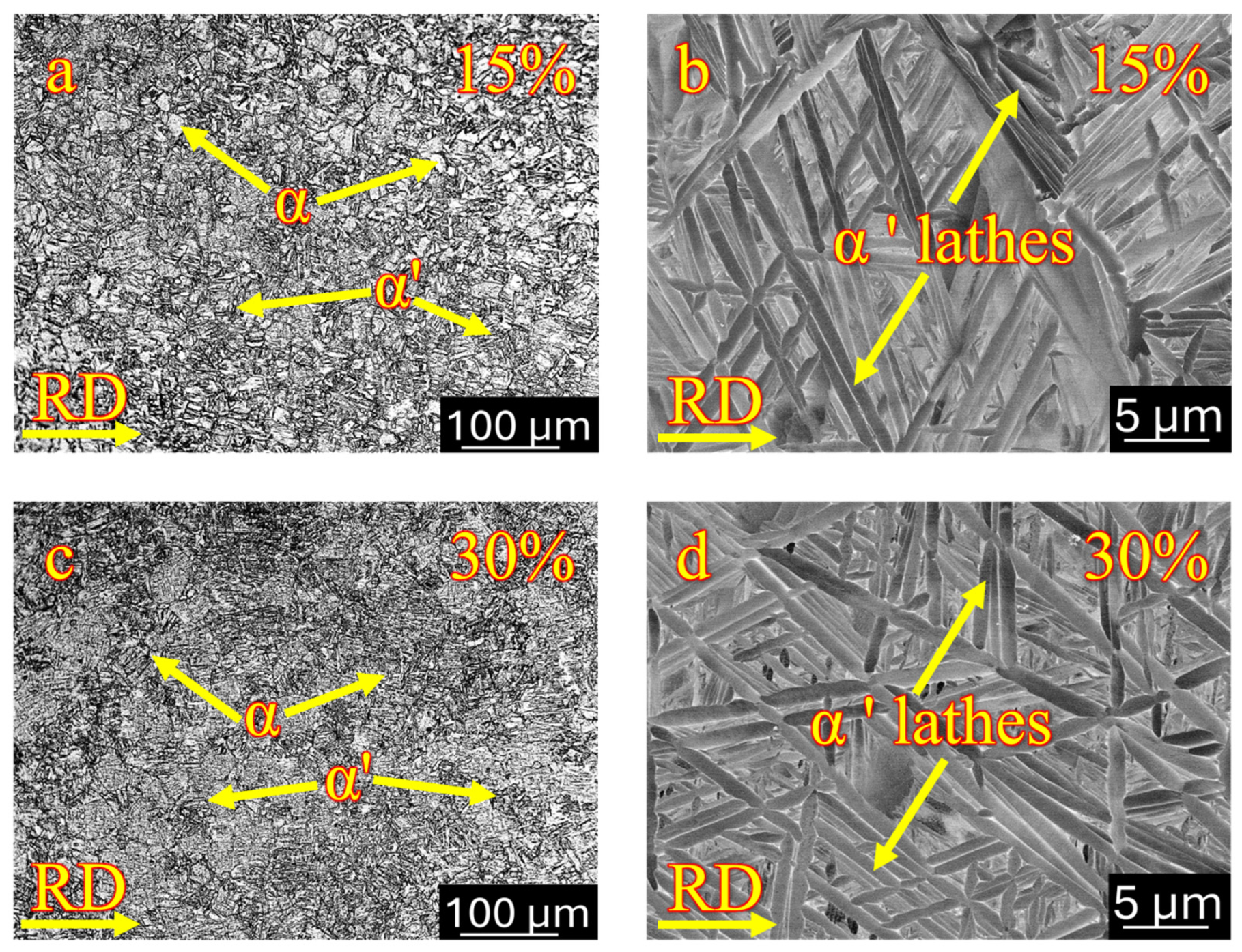

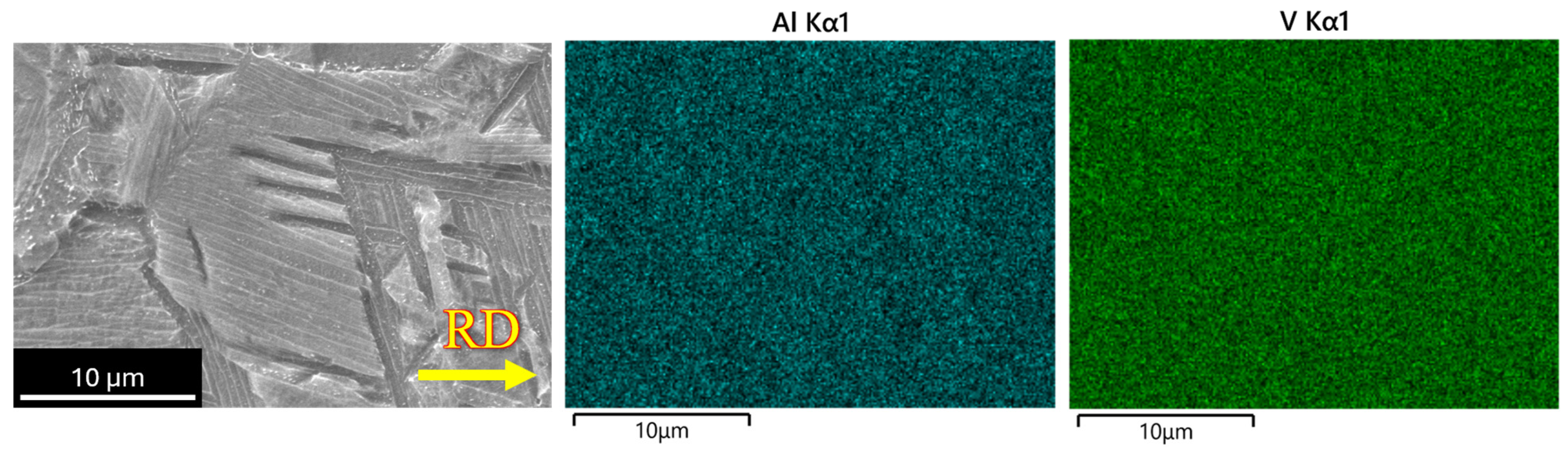

3.1. Microstructure Analysis

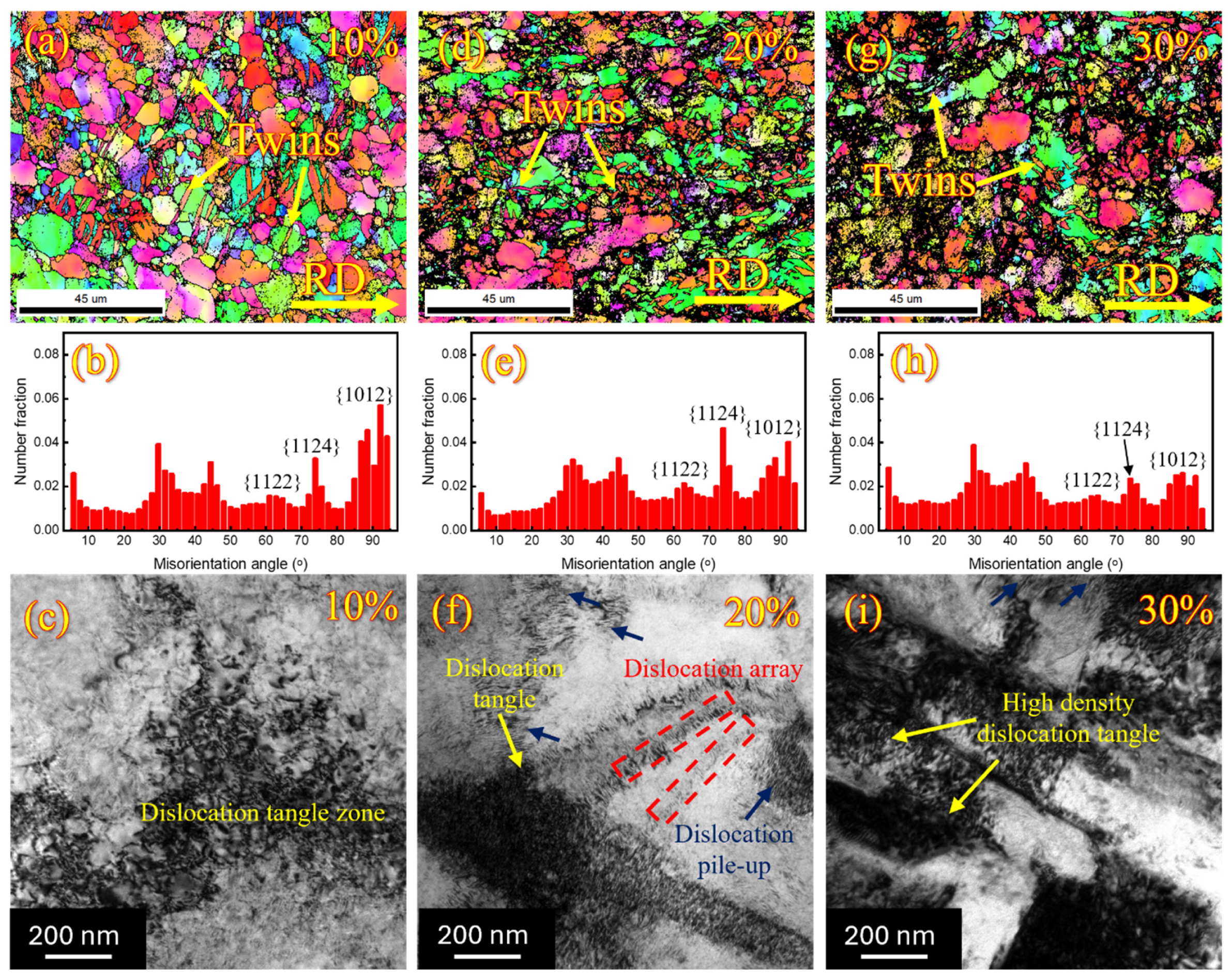

3.2. Deformation Mechanism

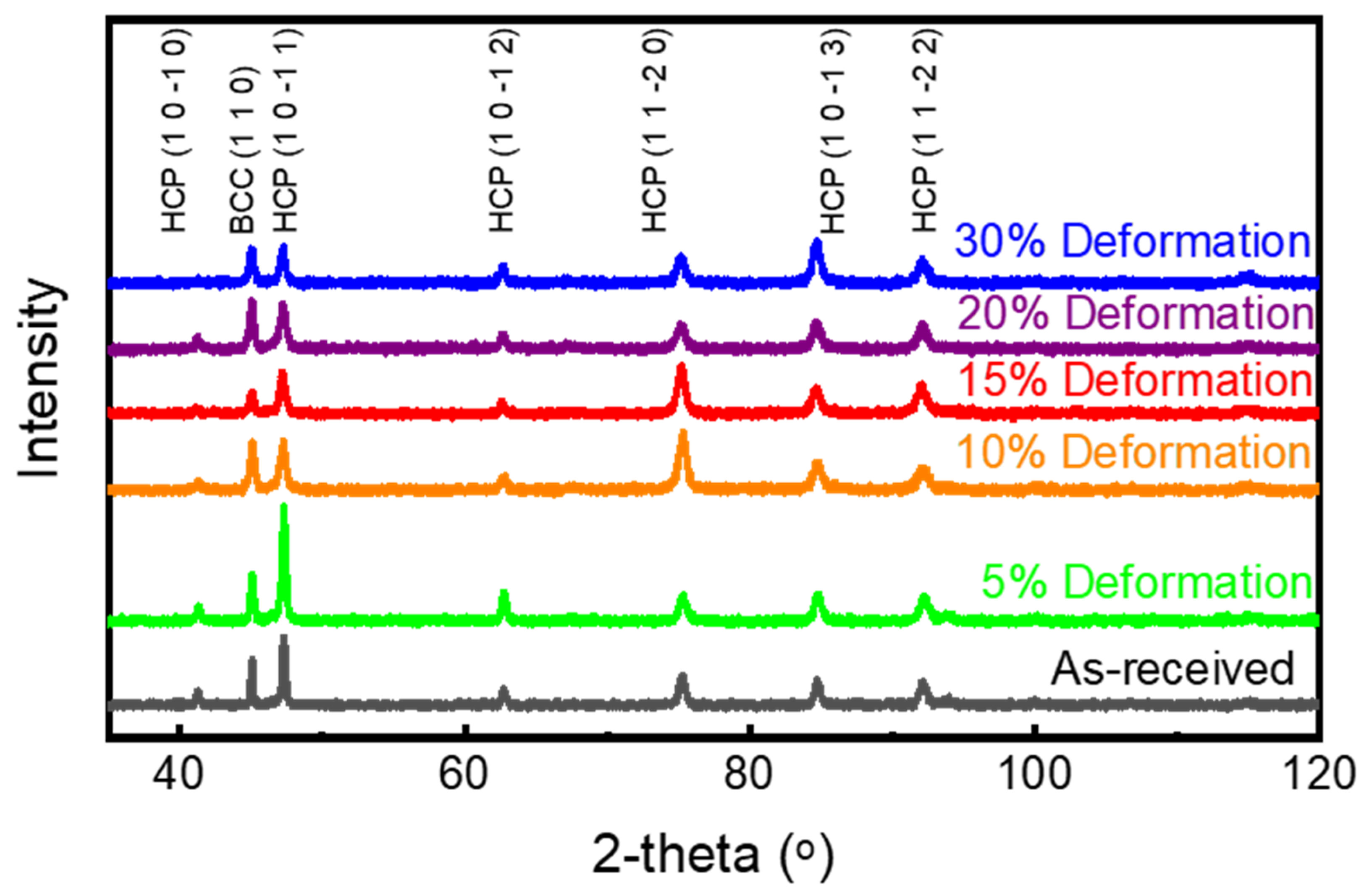

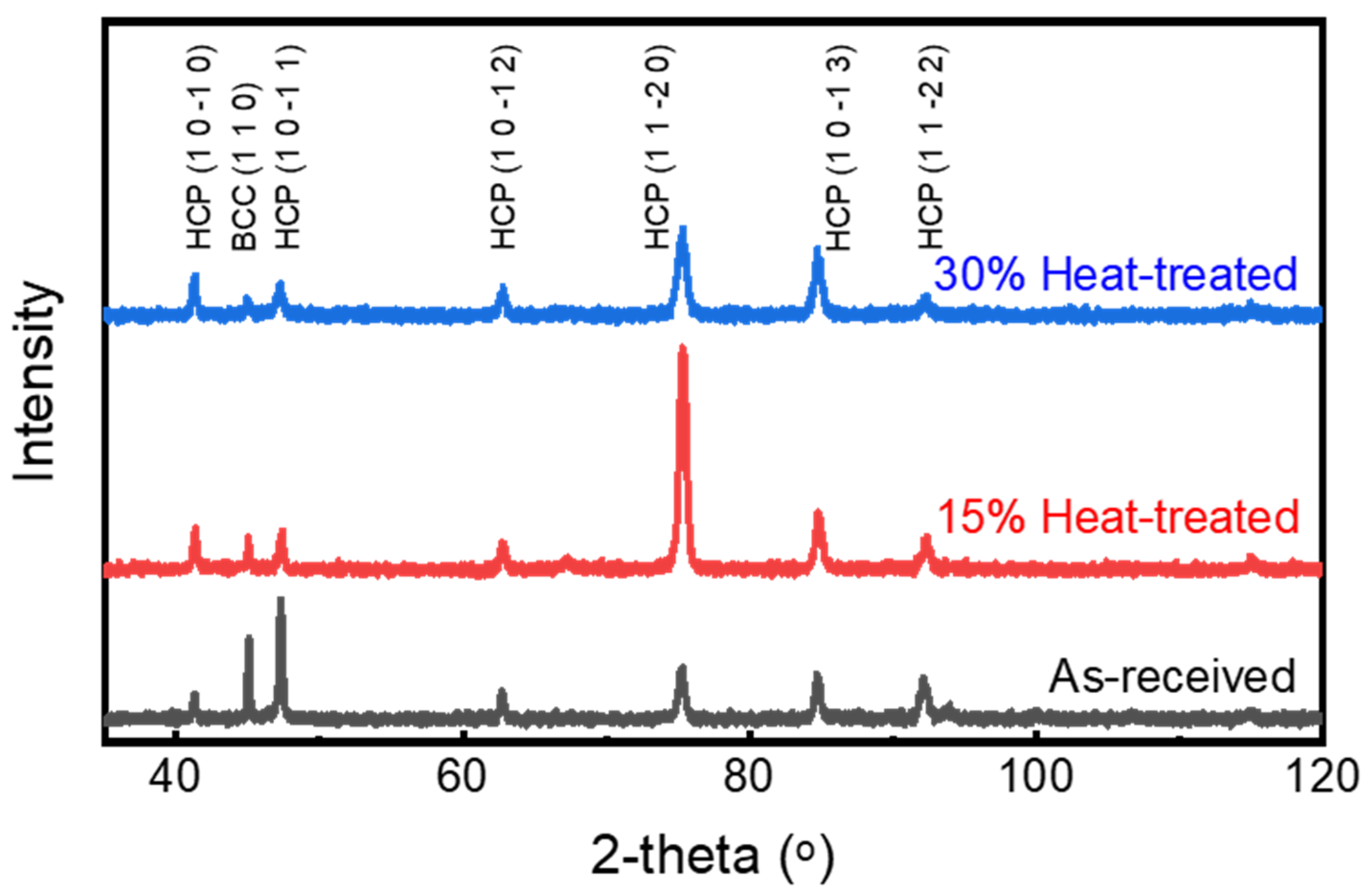

3.3. Phase Analysis After Cryo-Rolling

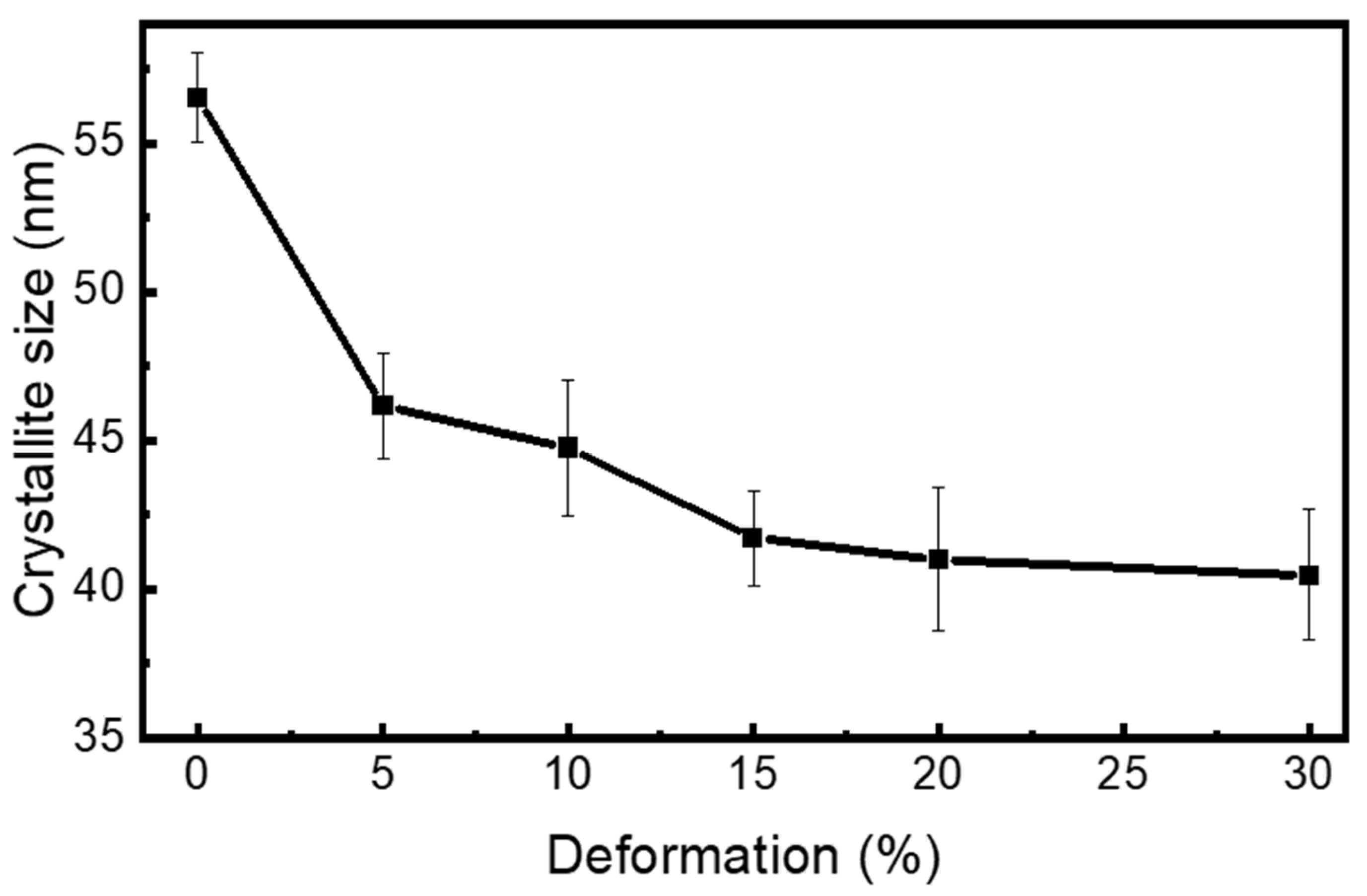

- A reduction in crystallite size, caused by the formation of dislocation cells, and

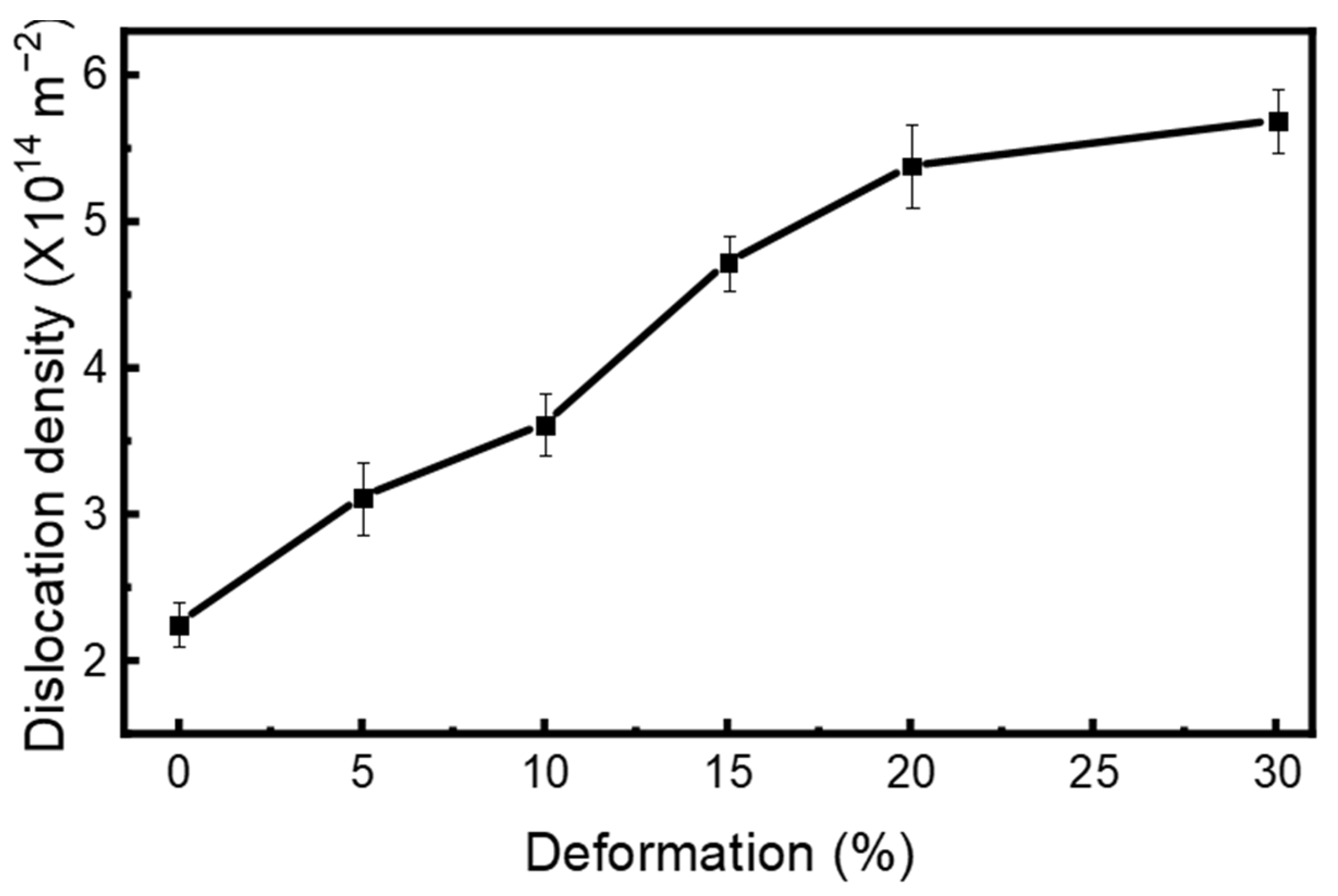

- An increase in micro-strain, resulting from the increase in dislocation density, occurs during cryo-rolling processing.

3.3.1. Crystallite Size

3.3.2. Dislocation Density

3.4. Mechanical Properties Measurement

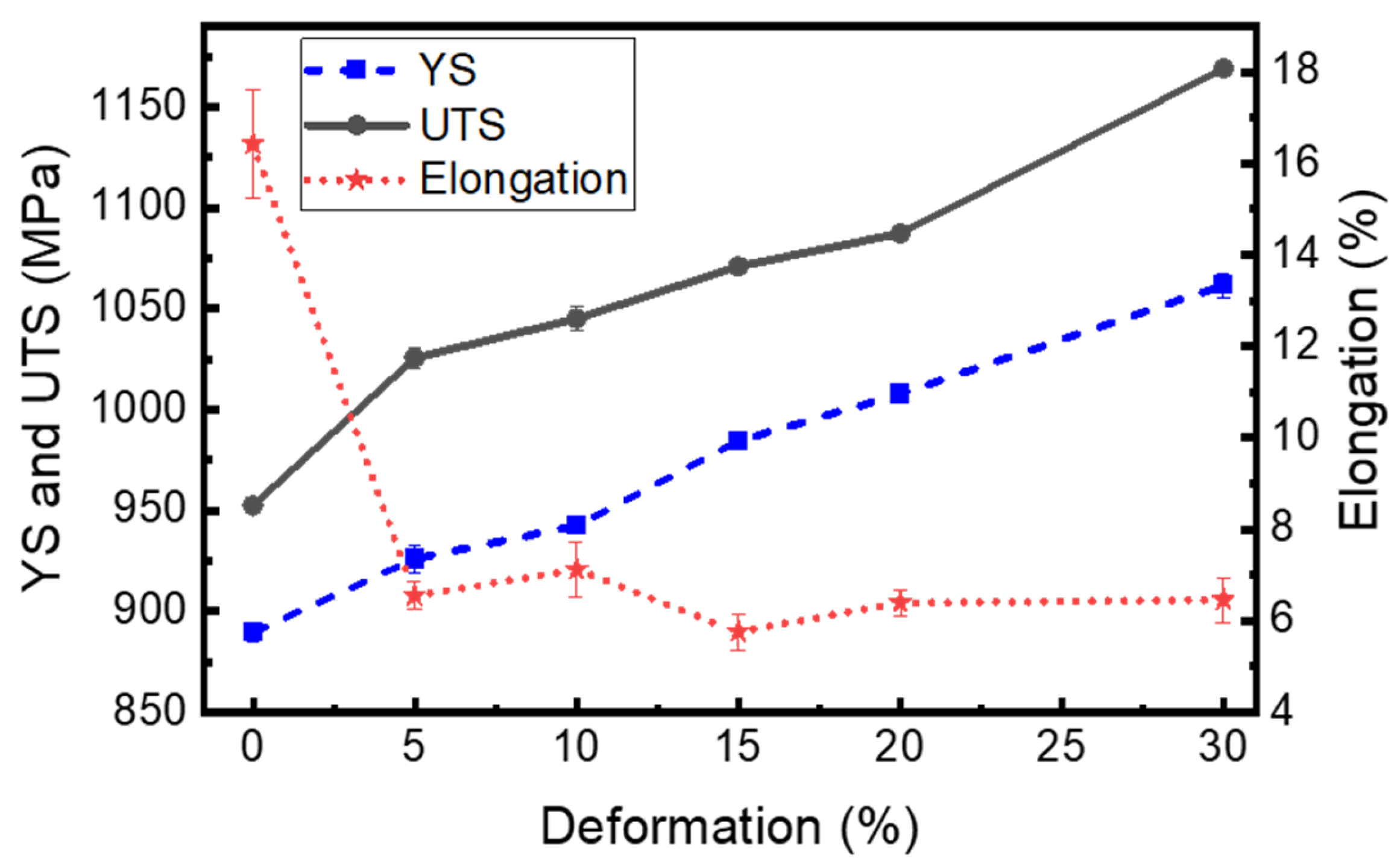

3.4.1. Tensile Properties

- Twinning induced strengthening occurs at the early stages of deformation, followed by dislocation strengthening as dislocation density increases with an increasing percentage of cryogenic deformation.

- Grain boundary strengthening occurs through the Hall–Petch effect, which results from microstructural refinement and elongation of α grains, and

- Low processing temperature during cryo-rolling hinders dynamic recovery by causing high strain energy retention and stabilizing deformation structures.

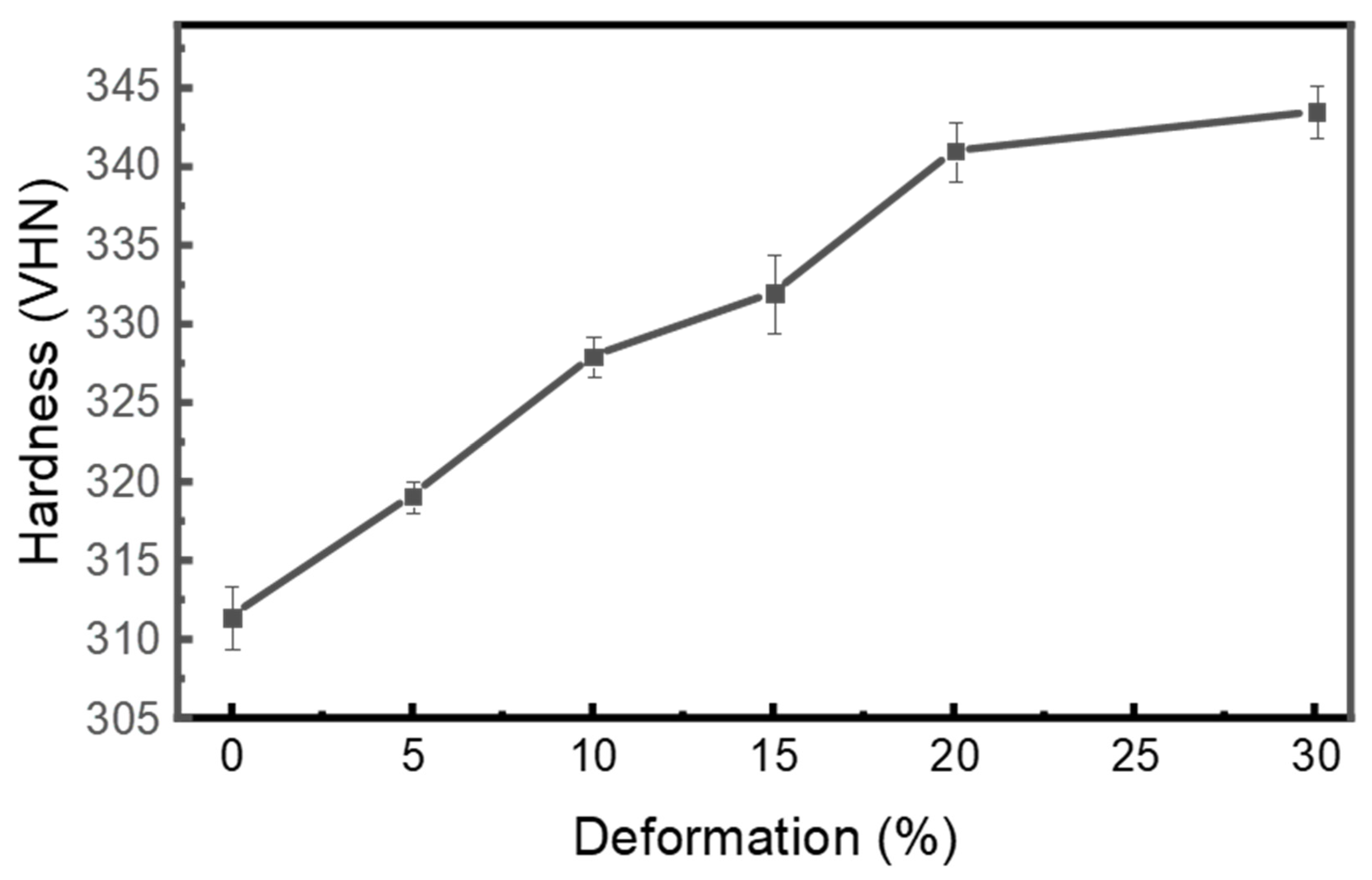

3.4.2. Hardness Behaviour

3.5. Effect of Post-Heat Treatment on Cryo-Rolling

4. Conclusions

- Rolling at liquid nitrogen temperature suppressed dynamic recovery, enhancing dislocation density and subsequently grain refinement took place. The results obtained from the optical microscopy, SEM and EDS analysis show an intensification in elongated grains, reduction in grain size, sub-grain formation, densification of deformation bands and fragmentation of β grains with the increase in rolling percentage.

- Due to the limitations of slip systems, at lower strain, initiation of deformation took place via twinning. As the strain increases with an increase in thickness reduction, twinning became less favourable, and the formation of new twins became increasingly difficult. Twinning-induced deformation transformed into deformation via dislocation slip, with the formation of high-density dislocations.

- The presence of α (HCP) and β (BCC) phases has been verified through XRD. There is no phase transformation or formation of any metastable phases that take place during cryo-rolling. With increasing strain, a slight peak broadening and intensity changes have been identified due to the microstructural refinement. Williamson–Hall analysis is used to quantify the reduction in crystallite size and enhancement in dislocation density due to strain hardening with increasing rolling percentage.

- Enhancement of the mechanical properties like YS, UTS and hardness has been observed via tensile and hardness tests, respectively, with increasing deformation percentage, while the ductility corresponding to all the cryo-rolled samples remains relatively stable, resulting from the simultaneous occurrence of limited dislocation movement and higher internal strain energy and fragmentation of β phase.

- During heat treatment following cryo-rolling, partial recovery and recrystallization facilitated the formation of a duplex microstructure and the removal of internal stains, leading to grain coarsening, homogeneous distribution of α and β phases throughout the microstructure and a reduction in the material’s hardness.

- The relationship between microstructure evolution, deformation mechanisms, and mechanical properties demonstrates the effect of cryo-rolling on modifying grain boundaries and dislocations in Ti-6Al-4V. These findings resemble a strong bond between the structure, property and performance, signifying the role of deformation mechanisms in the enhancement of mechanical properties during cryo-rolling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| UFG | Ultrafine grains |

| HPT | High-pressure torsion |

| SPD | Severe plastic deformation |

| ECAP | Equal channel angular pressing |

| LPBF | Laser powder bed fusion |

| ICP-OES | Inductively coupled plasma-optical emission spectrometry |

| LECO | Laboratory Equipment Corporation |

| SEM | Scanning electron microscopy |

| EDS | Energy dispersive X-ray spectroscopy |

| EBSD | Electron backscattered diffraction |

| TEM | Transmission electron microscopy |

| XRD | X-ray diffraction |

| FEG | Field-emission gun |

| EDM | Electrical discharge machining |

| RD | Rolling direction |

| PPM | Parts per million |

| AR | As received |

| HT | Heat-treated |

| IPF | Inverse pole figure |

| CSL | Coincident-site lattice |

| HCP | Hexagonal close-packed |

| BCC | Body-centred cubic |

| WH | Williamson hall |

| FWHM | Full width at half maximum |

| YS | Yield strength |

| UTS | Ultimate tensile strength |

| VHN | Vickers hardness number |

References

- Gloria, A.; Montanari, R.; Richetta, M.; Varone, A. Alloys for aeronautic applications: State of the art and perspectives. Metals 2019, 9, 662. [Google Scholar] [CrossRef]

- Ma, H.Y.; Wang, J.; Qin, P.; Liu, Y.; Chen, L.; Wang, L.; Zhang, L. Advances in additively manufactured titanium alloys by powder bed fusion and directed energy deposition: Microstructure, defects, and mechanical behavior. J. Mater. Sci. Technol. 2024, 183, 32–62. [Google Scholar] [CrossRef]

- Welsch, G.; Boyer, R.; Collings, E. Materials Properties Handbook: Titanium Alloys; ASM International: Almere, The Netherlands, 1993. [Google Scholar]

- Rautray, T.R.; Narayanan, R.; Kim, K.-H. Ion implantation of titanium based biomaterials. Prog. Mater. Sci. 2011, 56, 1137–1177. [Google Scholar] [CrossRef]

- Zhang, L.C.; Chen, L.Y. A review on biomedical titanium alloys: Recent progress and prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, K. Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater. Sci. Eng. C 2019, 102, 844–862. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Sha, W.; Malinov, S. Titanium Alloys: Modelling of Microstructure, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Khorasani, A.M.; Goldberg, M.; Doeven, E.H.; Littlefair, G. Titanium in biomedical applications—Properties and fabrication: A review. J. Biomater. Tissue Eng. 2015, 5, 593–619. [Google Scholar] [CrossRef]

- Froes, F. Titanium: Physical Metallurgy, Processing and Applications; ASM International: Almere, The Netherlands, 2015. [Google Scholar]

- Lütjering, G.; Williams, J.C. Titanium matrix composites. In Titanium; Springer: Berlin/Heidelberg, Germany, 2007; pp. 313–328. [Google Scholar]

- Collings, E. The Physical Metallurgy of Titanium Alloys; American Society for Metals: Metals Park, OH, USA, 1984; Volume 3. [Google Scholar]

- Pushp, P.; Dasharath, S.; Arati, C. Classification and applications of titanium and its alloys. Mater. Today Proc. 2022, 54, 537–542. [Google Scholar] [CrossRef]

- Veiga, C.; Davim, J.P.; Loureiro, A. Properties and applications of titanium alloys: A brief review. Rev. Adv. Mater. Sci. 2012, 32, 133–148. [Google Scholar]

- Jung, H.-D. Titanium and its alloys for biomedical applications. Metals 2021, 11, 1945. [Google Scholar] [CrossRef]

- Marin, E.; Lanzutti, A. Biomedical applications of titanium alloys: A comprehensive review. Materials 2023, 17, 114. [Google Scholar] [CrossRef]

- Abd-Elaziem, W.; Darwish, M.A.; Hamada, A.; Daoush, W.M. Titanium-Based alloys and composites for orthopedic implants Applications: A comprehensive review. Mater. Des. 2024, 241, 112850. [Google Scholar] [CrossRef]

- Oldani, C.; Dominguez, A. Titanium as a Biomaterial for Implants. Recent Adv. Arthroplast. 2012, 218, 149–162. [Google Scholar]

- Alaraby, H.A.; Lswalhia, M.; Ahmed, T. A study of mechanical properties of titanium alloy Ti-6Al-4V used as dental implant material. Int. J. Sci. Rep. 2017, 3, 288–291. [Google Scholar] [CrossRef]

- Pederson, R. Microstructure and Phase Transformation of Ti-6Al-4V. Ph.D. Thesis, Luleå Tekniska Universitet, Luleå, Sweden, 2002. [Google Scholar]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium alloys for aerospace applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Ritchie, R.; Boyce, B.; Campbell, J.; Roder, O.; Thompson, A.; Milligan, W. Thresholds for high-cycle fatigue in a turbine engine Ti–6Al–4V alloy. Int. J. Fatigue 1999, 21, 653–662. [Google Scholar] [CrossRef]

- Francis, J.A. Titanium. Mater. Sci. Technol. 2019, 35, 247. [Google Scholar] [CrossRef]

- Donachie, M.J. Titanium: A Technical Guide; ASM International: Almere, The Netherlands, 2000. [Google Scholar]

- Liu, Y.; Li, M. Nanocrystallization mechanism of beta phase in Ti-6Al-4V subjected to severe plastic deformation. Mater. Sci. Eng. A 2016, 669, 7–13. [Google Scholar] [CrossRef]

- Niu, L.; Wang, S.; Chen, C.; Qian, S.F.; Liu, R.; Li, H.; Liao, B.; Zhong, Z.H.; Lu, P.; Wang, M.P.; et al. Mechanical behavior and deformation mechanism of commercial pure titanium foils. Mater. Sci. Eng. A 2017, 707, 435–442. [Google Scholar] [CrossRef]

- Li, Z.; Sun, Y.; Lavernia, E.J.; Shan, A. Mechanical Behavior of Ultrafine-Grained Ti-6Al-4V Alloy Produced by Severe Warm Rolling: The Influence of Starting Microstructure and Reduction Ratio. Metall. Mater. Trans. A 2015, 46, 5047–5057. [Google Scholar] [CrossRef]

- Saitova, L.; Höppel, H.; Göken, M.; Semenova, I.; Raab, G.; Valiev, R. Fatigue behavior of ultrafine-grained Ti–6Al–4V ‘ELI’alloy for medical applications. Mater. Sci. Eng. A 2009, 503, 145–147. [Google Scholar] [CrossRef]

- Semenova, I.P.; Selivanov, K.S.; Valiev, R.R.; Modina, I.M.; Smyslova, M.K.; Polyakov, A.V.; Langdon, T.G. Enhanced Creep Resistance of an Ultrafine-Grained Ti–6Al–4V Alloy with Modified Surface by Ion Implantation and (Ti + V) N Coating. Adv. Eng. Mater. 2020, 22, 1901219. [Google Scholar] [CrossRef]

- Sergueeva, A.V.; Stolyarov, V.V.; Valiev, R.Z.; Mukherjee, A.K. Advanced mechanical properties of pure titanium with ultrafine grained structure. Scr. Mater. 2001, 45, 747–752. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Horita, Z.; Nemoto, M.; Langdon, T.G. The process of grain refinement in equal-channel angular pressing. Acta Mater. 1998, 46, 3317–3331. [Google Scholar] [CrossRef]

- Nakashima, K.; Horita, Z.; Nemoto, M.; Langdon, T.G. Influence of channel angle on the development of ultrafine grains in equal-channel angular pressing. Acta Mater. 1998, 46, 1589–1599. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Sergueeva, A.V.; Stolyarov, V.V.; Valiev, R.Z.; Mukherjee, A.K. Enhanced superplasticity in a Ti-6Al-4V alloy processed by severe plastic deformation. Scr. Mater. 2000, 43, 819–824. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Kostjuchenko, S.; Kudryavtsev, E.A.; Malysheva, S.; Murzinova, M.A.; Salishchev, G.A. Mechanical Properties of Ultrafine Grained Two-Phase Titanium Alloy Produced by “abc” Deformation. Mater. Sci. Forum 2012, 706–709, 1859–1863. [Google Scholar] [CrossRef]

- Semenova, I.; Valiev, R.; Yakushina, E.; Salimgareeva, G.; Lowe, T. Strength and fatigue properties enhancement in ultrafine-grained Ti produced by severe plastic deformation. J. Mater. Sci. 2008, 43, 7354–7359. [Google Scholar] [CrossRef]

- Saitova, L.; Semenova, I.; Höppel, H.; Valiev, R.; Göken, M. Enhanced superplastic deformation behavior of ultrafine-grained Ti-6Al-4V alloy. Mater. Werkst. Entwickl. Fert. Prüfung Eig. Anwendungen Tech. Werkst. 2008, 39, 367–370. [Google Scholar] [CrossRef]

- Semenova, I.; Raab, G.; Saitova, L.; Valiev, R. The effect of equal-channel angular pressing on the structure and mechanical behavior of Ti–6Al–4V alloy. Mater. Sci. Eng. A 2004, 387, 805–808. [Google Scholar] [CrossRef]

- Ko, Y.G.; Jung, W.S.; Shin, D.H.; Lee, C.S. Effects of temperature and initial microstructure on the equal channel angular pressing of Ti–6Al–4V alloy. Scr. Mater. 2003, 48, 197–202. [Google Scholar] [CrossRef]

- Fernandes, D.J.; Elias, C.N.; Valiev, R.Z. Properties and performance of ultrafine grained titanium for biomedical applications. Mater. Res. 2015, 18, 1163–1175. [Google Scholar] [CrossRef]

- Pazhanivel, B.; Sathiya, P.; Sozhan, G. Ultra-fine bimodal (α+ β) microstructure induced mechanical strength and corrosion resistance of Ti-6Al-4V alloy produced via laser powder bed fusion process. Opt. Laser Technol. 2020, 125, 106017. [Google Scholar] [CrossRef]

- Li, Y.; Sun, K.; Liu, P.; Liu, Y.; Chui, P. Surface nanocrystallization induced by fast multiple rotation rolling on Ti-6Al-4V and its effect on microstructure and properties. Vacuum 2014, 101, 102–106. [Google Scholar] [CrossRef]

- Yu, H.; Yan, M.; Li, J.; Godbole, A.; Lu, C.; Tieu, K.; Li, H.; Kong, C. Mechanical properties and microstructure of a Ti-6Al-4V alloy subjected to cold rolling, asymmetric rolling and asymmetric cryorolling. Mater. Sci. Eng. A 2018, 710, 10–16. [Google Scholar] [CrossRef]

- Gu, K.; Zhang, H.; Zhao, B.; Wang, J.; Zhou, Y.; Li, Z. Effect of cryogenic treatment and aging treatment on the tensile properties and microstructure of Ti–6Al–4V alloy. Mater. Sci. Eng. A 2013, 584, 170–176. [Google Scholar] [CrossRef]

- Yu, H.L.; Lu, C.; Tieu, A.K.; Li, H.J.; Godbole, A.; Zhang, S.H. Special rolling techniques for improvement of mechanical properties of ultrafine-grained metal sheets: A review. Adv. Eng. Mater. 2016, 18, 754–769. [Google Scholar] [CrossRef]

- Kang, H.-H.; Han, S.-C.; Ji, M.-K.; Lee, J.-R.; Jun, T.-S. Achieving synergistic improvement of wear and mechanical properties in Ti–6Al–4V alloy by multiple cryogenic treatment. J. Mater. Res. Technol. 2024, 29, 5118–5125. [Google Scholar] [CrossRef]

- Gu, K.X.; Li, Z.Q.; Wang, J.J.; Zhou, Y.; Zhang, H.; Zhao, B.; Ji, W. The effect of cryogenic treatment on the microstructure and properties of Ti-6Al-4V titanium alloy. Mater. Sci. Forum 2013, 747–748, 899–903. [Google Scholar] [CrossRef]

- ASTM B 265–20a; Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM E8; Standard Test Methods for Tension Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2025.

- Gaur, V.; Gupta, R.; Kumar, V.A. Electron Beam Welding and Gas Tungsten Arc Welding Studies on Commercially Pure Titanium Sheets. In Proceedings of the International Conference on Advances in Materials Processing: Challenges and Opportunities, Roorkee, India, 17–19 October 2022; Springer: Berlin/Heidelberg, Germany, 2022; pp. 89–94. [Google Scholar]

- Ramdan, R.; Jauhari, I.; Izman, S.; Kadir, M.A.; Prawara, B.; Hamzah, E.; Nur, H.; Gu, K.; Li, Z.; Wang, J. Shear mechanisms during cryogenic treatment of Ti6Al4V. In Proceedings of the 12th International Conference on QiR (Quality in Research), Bali, Indonesia, 4–7 July 2011; pp. 1390–1396. [Google Scholar]

- Zheng, X.; Xie, W.; Zeng, L.; Wei, H.; Zhang, X.; Wang, H. Achieving high strength and ductility in a heterogeneous-grain-structured CrCoNi alloy processed by cryorolling and subsequent short-annealing. Mater. Sci. Eng. A 2021, 821, 141610. [Google Scholar] [CrossRef]

- Song, X.; Luo, J.; Zhang, J.; Zhuang, L.; Cui, H.; Qiao, Y. Twinning behavior of commercial-purity titanium subjected to cryorolling. JOM 2019, 71, 4071–4078. [Google Scholar] [CrossRef]

- Xue, Q.; Meyers, M.A.; Nesterenko, V.F. Self-organization of shear bands in titanium and Ti–6Al–4V alloy. Acta Mater. 2002, 50, 575–596. [Google Scholar] [CrossRef]

- Ding, R.; Guo, Z.; Wilson, A. Microstructural evolution of a Ti–6Al–4V alloy during thermomechanical processing. Mater. Sci. Eng. A 2002, 327, 233–245. [Google Scholar] [CrossRef]

- Trivedi, D.B.; Atrey, M.D.; Joshi, S.S. Microstructural Analysis and Integrity of Drilling Surfaces on Titanium Alloy (Ti–6Al–4V) Using Heat-Sink-Based Cryogenic Cooling. Metallogr. Microstruct. Anal. 2023, 12, 814–833. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Wang, B.; Cui, S.; Chen, R.; Valiev, R.Z.; Meyers, M.A. The effects of ultra-fine-grained structure and cryogenic temperature on adiabatic shear localization in titanium. Acta Mater. 2019, 181, 408–422. [Google Scholar] [CrossRef]

- Ryu, D.; Kim, Y.; Nahm, S.; Kang, L. Recent developments in plastic deformation behavior of titanium and its alloys during the rolling process: A review. Materials 2024, 17, 6060. [Google Scholar] [CrossRef]

- Philippe, M.; Esling, C.; Hocheid, B. Role of twinning in texture development and in plastic deformation of hexagonal materials. Texture Stress Microstruct. 1988, 7, 265–301. [Google Scholar] [CrossRef]

- Salinas-Rodriguez, A. Grain size effects on the texture evolution of α-Zr. Acta Metall. Mater. 1995, 43, 485–498. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Bishoyi, B.; Sabat, R.; Sahu, J.; Sahoo, S. Effect of temperature on microstructure and texture evolution during uniaxial tension of commercially pure titanium. Mater. Sci. Eng. A 2017, 703, 399–412. [Google Scholar] [CrossRef]

- Li, X.; Duan, Y.; Xu, G.; Peng, X.; Dai, C.; Zhang, L.; Li, Z. EBSD characterization of twinning in cold-rolled CP-Ti. Mater. Charact. 2013, 84, 41–47. [Google Scholar] [CrossRef]

- Cai, S.; Li, Z.; Xia, Y. Evolution equations of deformation twins in metals—Evolution of deformation twins in pure titanium. Phys. B Condens. Matter 2008, 403, 1660–1665. [Google Scholar] [CrossRef]

- Bozzolo, N.; Chan, L.; Rollett, A.D. Misorientations induced by deformation twinning in titanium. Appl. Crystallogr. 2010, 43, 596–602. [Google Scholar] [CrossRef]

- Hu, Y.; Randle, V. An electron backscatter diffraction analysis of misorientation distributions in titanium alloys. Scr. Mater. 2007, 56, 1051–1054. [Google Scholar] [CrossRef]

- Bozzolo, N.; Dewobroto, N.; Wenk, H.; Wagner, F. Microstructure and microtexture of highly cold-rolled commercially pure titanium. J. Mater. Sci. 2007, 42, 2405–2416. [Google Scholar] [CrossRef]

- Chun, Y.B.; Yu, S.-H.; Semiatin, S.; Hwang, S.-K. Effect of deformation twinning on microstructure and texture evolution during cold rolling of CP-titanium. Mater. Sci. Eng. A 2005, 398, 209–219. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Lojkowski, W.; Mazur, A.; Salishchev, G. Structure and properties of hydrostatically extruded commercially pure titanium. Mater. Sci. Eng. A 2010, 527, 5596–5603. [Google Scholar] [CrossRef]

- Mironov, S.Y.; Myshlyaev, M. Evolution of dislocation boundaries during cold deformation of microcrystalline titanium. Phys. Solid State 2007, 49, 858–864. [Google Scholar] [CrossRef]

- Eddahbi, M.; Del Valle, J.; Pérez-Prado, M.T.; Ruano, O.A. Comparison of the microstructure and thermal stability of an AZ31 alloy processed by ECAP and large strain hot rolling. Mater. Sci. Eng. A 2005, 410, 308–311. [Google Scholar] [CrossRef]

- Stanford, N.; Carlson, U.; Barnett, M. Deformation twinning and the Hall–Petch relation in commercial purity Ti. Metall. Mater. Trans. A 2008, 39, 934–944. [Google Scholar] [CrossRef]

- Ostapovets, A.; Šedá, P.; Jäger, A.; Lejček, P. Characteristics of coincident site lattice grain boundaries developed during equal channel angular pressing of magnesium single crystals. Scr. Mater. 2011, 64, 470–473. [Google Scholar] [CrossRef]

- Zhong, Y.; Yin, F.; Nagai, K. Role of deformation twin on texture evolution in cold-rolled commercial-purity Ti. J. Mater. Res. 2008, 23, 2954–2966. [Google Scholar] [CrossRef]

- Randle, V. A methodology for grain boundary plane assessment by single-section trace analysis. Scr. Mater. 2001, 44, 2789–2794. [Google Scholar] [CrossRef]

- Williamson, G.; Hall, W. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Manh, D.H.; Nha, T.T.N.; Phong, L.T.H.; Nam, P.H.; Thanh, T.D.; Phong, P.T. Determination of the crystalline size of hexagonal La1−xSrxMnO3 (x = 0.3) nanoparticles from X-ray diffraction—A comparative study. RSC Adv. 2023, 13, 25007–25017. [Google Scholar] [CrossRef]

- Li, Z.; Gu, H.; Luo, K.; Kong, C.; Yu, H. Achieving High Strength and Tensile Ductility in Pure Nickel by Cryorolling with Subsequent Low-Temperature Short-Time Annealing. Engineering 2024, 33, 190–203. [Google Scholar] [CrossRef]

- Susila, P.; Sturm, D.; Heilmaier, M.; Murty, B.; Sarma, V.S. Microstructural studies on nanocrystalline oxide dispersion strengthened austenitic (Fe–18Cr–8Ni–2W–0.25Y2O3) alloy synthesized by high energy ball milling and vacuum hot pressing. J. Mater. Sci. 2010, 45, 4858–4865. [Google Scholar] [CrossRef]

- Muiruri, A.; Maringa, M.; Preez, W.D. Evaluation of Dislocation Densities in Various Microstructures of Additively Manufactured Ti6Al4V (Eli) by the Method of X-ray Diffraction. Materials 2020, 13, 5355. [Google Scholar] [CrossRef]

- He, W.; Chen, X.; Liu, N.; Luan, B.; Yuan, G.; Liu, Q. Cryo-rolling enhanced inhomogeneous deformation and recrystallization grain growth of a zirconium alloy. J. Alloys Compd. 2017, 699, 160–169. [Google Scholar] [CrossRef]

- Hu, Z.-Y.; Cheng, X.-W.; Zhang, Z.-H.; Wang, H.; Li, S.-L.; Korznikova, G.F.; Gunderov, D.V.; Wang, F.-C. The influence of defect structures on the mechanical properties of Ti-6Al-4V alloys deformed by high-pressure torsion at ambient temperature. Mater. Sci. Eng. A 2017, 684, 1–13. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Yu, F.; Zhang, Y.; Kong, C.; Yu, H. Microstructure and mechanical properties of Ti–6Al–4V alloy sheets via room-temperature rolling and cryorolling. Mater. Sci. Eng. A 2022, 834, 142600. [Google Scholar] [CrossRef]

- Du, Z.; He, Q.; Chen, R.; Liu, F.; Zhang, J.; Yang, F.; Zhao, X.; Cui, X.; Cheng, J. Rolling reduction-dependent deformation mechanisms and tensile properties in a β titanium alloy. J. Mater. Sci. Technol. 2022, 104, 183–193. [Google Scholar] [CrossRef]

- Xu, T.; Wang, S.; Li, X.; Wu, M.; Wang, W.; Mitsuzaki, N.; Chen, Z. Effects of strain rate on the formation and the tensile behaviors of multimodal grain structure titanium. Mater. Sci. Eng. A 2020, 770, 138574. [Google Scholar] [CrossRef]

- Shanmugasundaram, T.; Murty, B.; Sarma, V.S. Development of ultrafine grained high strength Al–Cu alloy by cryorolling. Scr. Mater. 2006, 54, 2013–2017. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Dyakonov, G.; Salem, A.; Sokolenko, V.; Salishchev, G.; Semiatin, S. Formation of nanostructures in commercial-purity titanium via cryorolling. Acta Mater. 2013, 61, 1167–1178. [Google Scholar] [CrossRef]

- Yang, D.; Cizek, P.; Fabijanic, D.; Wang, J.; Hodgson, P. Work hardening in ultrafine-grained titanium: Multilayering and grading. Acta Mater. 2013, 61, 2840–2852. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, X.; Ni, H.; Cheng, Y.; Zhu, Y.; Liu, Q. Effect of twinning on microstructure and texture evolutions of pure Ti during dynamic plastic deformation. Mater. Sci. Eng. A 2013, 564, 22–33. [Google Scholar] [CrossRef]

- Yu, F.; Zhang, Y.; Kong, C.; Yu, H. High strength and toughness of Ti–6Al–4V sheets via cryorolling and short-period annealing. Mater. Sci. Eng. A 2022, 854, 143766. [Google Scholar] [CrossRef]

- Won, J.W.; Lee, J.H.; Jeong, J.S.; Choi, S.-W.; Lee, D.J.; Hong, J.K.; Hyun, Y.-T. High strength and ductility of pure titanium via twin-structure control using cryogenic deformation. Scr. Mater. 2020, 178, 94–98. [Google Scholar] [CrossRef]

- Singh, R.; Sachan, D.; Verma, R.; Goel, S.; Jayaganthan, R.; Kumar, A. Mechanical behavior of 304 Austenitic stainless steel processed by cryogenic rolling. Mater. Today Proc. 2018, 5 Pt 1, 16880–16886. [Google Scholar] [CrossRef]

- Bahl, S.; Xiong, L.; Allard, L.F.; Michi, R.A.; Poplawsky, J.D.; Chuang, A.C.; Singh, D.; Watkins, T.R.; Shin, D.; Haynes, J.A.; et al. Aging behavior and strengthening mechanisms of coarsening resistant metastable θ’ precipitates in an Al–Cu alloy. Mater. Des. 2021, 198, 109378. [Google Scholar] [CrossRef]

- Hussain, M.; Rao, P.N.; Singh, D.; Jayaganthan, R.; Goel, S.; Saxena, K.K. Insight to the evolution of nano precipitates by cryo rolling plus warm rolling and their effect on mechanical properties in Al 6061 alloy. Mater. Sci. Eng. A 2021, 811, 141072. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.; Gysler, A. Microstructure and mechanical properties of titanium alloys. In Microstructure and Properties of Materials; World Scientific Publishing: Singapore, 2000; Volume 2, pp. 1–77. [Google Scholar]

| Elements | Al (wt.%) | V (wt.%) | Fe (wt.%) | C (wt.%) | N (ppm) | O (ppm) | H (ppm) | Ti (wt.%) |

|---|---|---|---|---|---|---|---|---|

| Composition | 6.2 | 3.8 | 0.08 | 0.05 | 4 | 50 | 62.7 | Balance |

| Twinning Type | Twinning System | Rotation Axis | Misorientation Angle (°) |

|---|---|---|---|

| Tensile | {2} <10> | <> | 44.4 |

| Compressive | {2} <> | <0> | 64.6 |

| Compressive | {4} <> | <0> | 74.5 |

| Tensile | {2} <> | <0> | 86.7 |

| Specimen | AR | 5% | 10% | 15% | 20% | 30% |

|---|---|---|---|---|---|---|

| YS (MPa) | 889.63 ± 5 | 925.91 ± 7 | 942.56 ± 3 | 984.34 ± 3 | 1007.93 ± 4 | 1061.66 ± 6 |

| UTS (MPa) | 952.65 ± 2 | 1025.59 ± 5 | 1045.07 ± 6 | 1071.09 ± 3 | 1087.42 ± 4 | 1169.10 ± 4 |

| Elongation (%) | 16.43 ± 1.2 | 6.55 ± 0.3 | 7.12 ± 0.6 | 5.76 ± 0.4 | 6.39 ± 0.3 | 6.45 ± 0.5 |

| Hardness | AR | 5% | 10% | 15% | 20% | 30% |

|---|---|---|---|---|---|---|

| VHN | 311.5 ± 2 | 319.17 ± 1 | 328 ± 1.3 | 332 ± 2.5 | 341 ± 1.9 | 343.5 ± 1.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaur, V.; Vashishtha, P.; Sahoo, B.K.; Bandari, R.K.; Das, R. Effect of Cryo-Rolling on the Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Alloy. Materials 2025, 18, 5296. https://doi.org/10.3390/ma18235296

Gaur V, Vashishtha P, Sahoo BK, Bandari RK, Das R. Effect of Cryo-Rolling on the Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Alloy. Materials. 2025; 18(23):5296. https://doi.org/10.3390/ma18235296

Chicago/Turabian StyleGaur, Vaibhav, Pargam Vashishtha, Biraj Kumar Sahoo, Ravi Kumar Bandari, and Raj Das. 2025. "Effect of Cryo-Rolling on the Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Alloy" Materials 18, no. 23: 5296. https://doi.org/10.3390/ma18235296

APA StyleGaur, V., Vashishtha, P., Sahoo, B. K., Bandari, R. K., & Das, R. (2025). Effect of Cryo-Rolling on the Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Alloy. Materials, 18(23), 5296. https://doi.org/10.3390/ma18235296