Damage Identification in Composite Wind Turbine Blades Using Relative Natural Frequency Changes and Bayesian Probability

Abstract

1. Introduction

1.1. Background of Modal Analysis in Structural Health Monitoring

1.2. Current Status of Modal-Based Damage-Detecting Methods for Wind Turbine Blades

1.3. Research Gaps and Contributions

- Even though much existing research has analyzed behaviors of natural frequency under different damage conditions on simple geometries (e.g., beams), there are limited investigations into complicated structures like WTBs. Moreover, comparative studies of natural frequency characteristics in damaged structures across analytical techniques and numerical simulations are lacking.

- Most natural frequency-based damage detection methods have been developed and validated on simple structures, such as beams or plates. However, their applicability to complex, non-uniform geometries, like WTBs, remains limited. The transition from idealized models to realistic structures requires further investigation.

- Initially, the B-RNFC method was first applied to a fixed-fixed beam. It successfully identified the structural damage. However, using the B-RNFC method to cantilever beams and fixed-free WTBs is more challenging.

- In the beginning state of beam damage detection, calculation of the normalized RNFC curve—which serves as a spatial damage reference dataset in the B-RNFC method—does not account for damage size. For real-world structures, the effect of damage size on this curve must be investigated.

- Based on existing research, the B-RNFC method can detect damage at specific locations, but does not quantify and map the detectable locations along the structures. Moreover, this spatial sensitivity of the B-RNFC method has not been discovered for the WTBs.

- The research provides a comparative analysis of the relationship between natural frequencies and damage conditions (damage severities and locations) of cantilever beams and WTBs. Moreover, the obtained simulation results are verified through analytical analysis.

- This research extends the B-RNFC method to complex WTBs. It demonstrates applicability to realistic structures, highlighting the pros and cons of this proposed method.

- The normalized RNFC curves from different damage sizes are introduced to address the limitation of prior research and to provide a more robust understanding of reference parameters for damage detection in real structures.

- This study systematically varies damage locations along the cantilever beams and blades and discovers the detectable damage locations. It provides the B-RNFC’s strengths and blind spots in practical implementation.

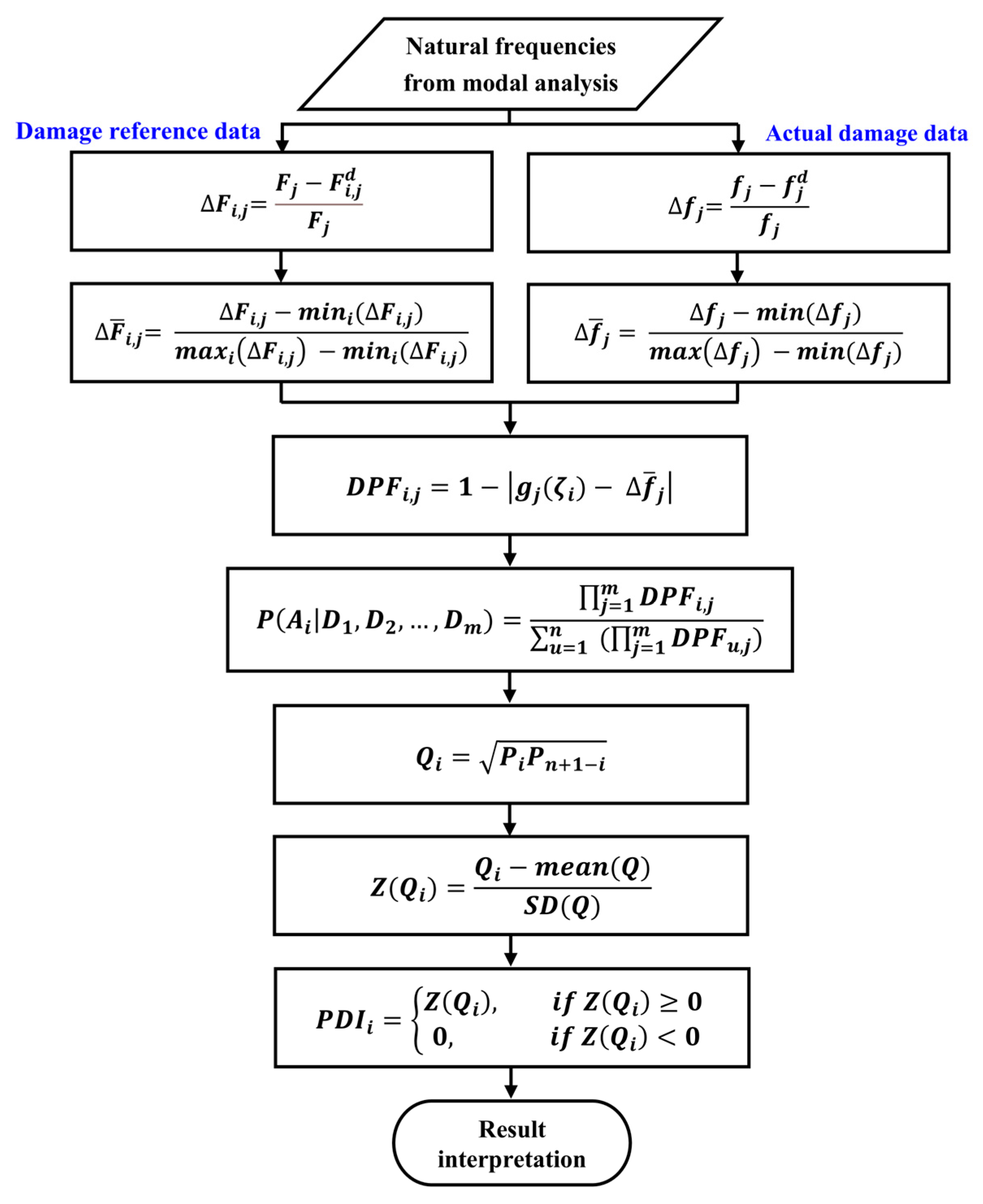

2. Formulation of the B-RNFC Method

2.1. Normalized RNFC Curves and Normalized RNFC Values

2.2. Damage-Localizing Algorithms

2.3. Research Procedure

3. Numerical Simulation and Case Studies

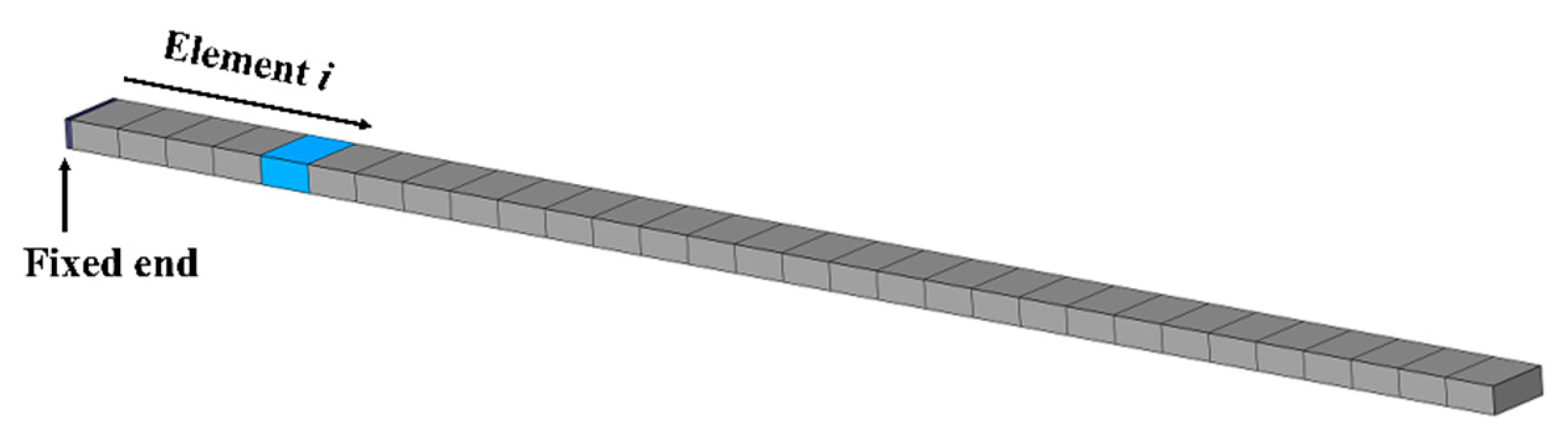

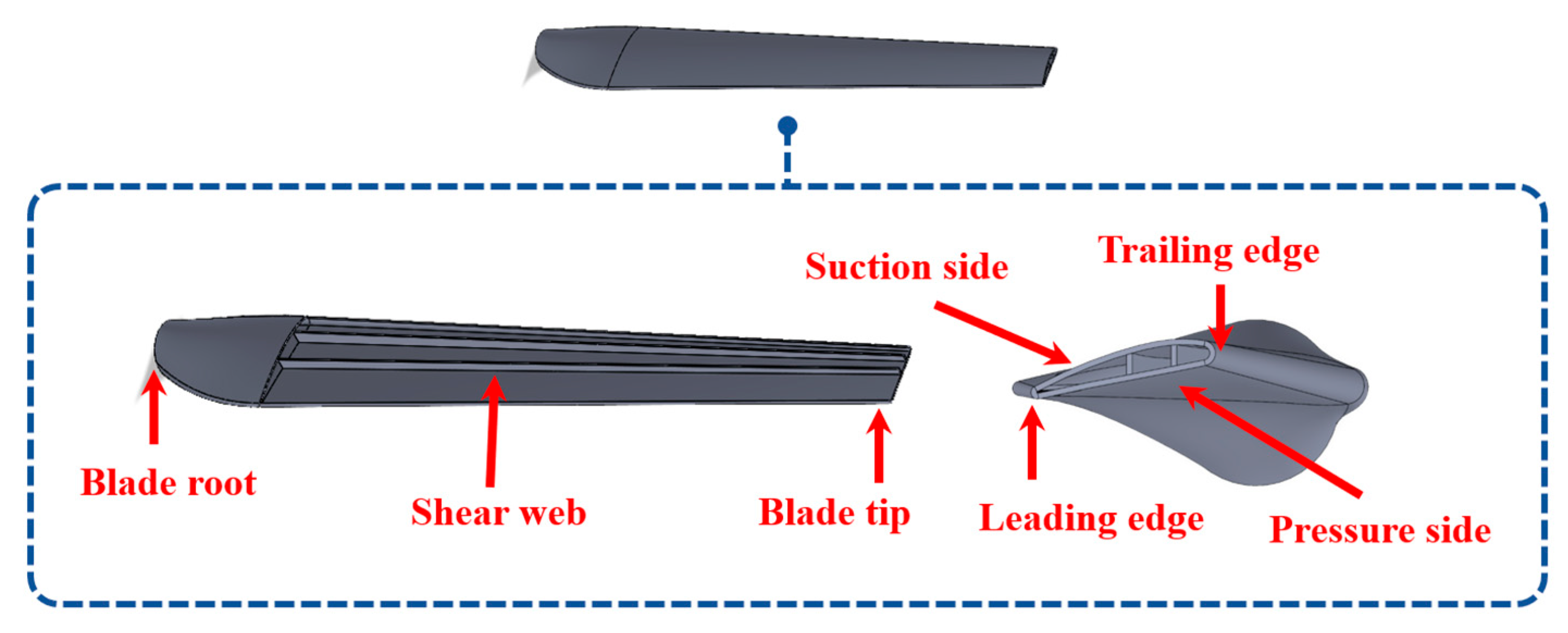

3.1. Numerical Simulation

3.2. Damage Setup

4. Results and Discussions

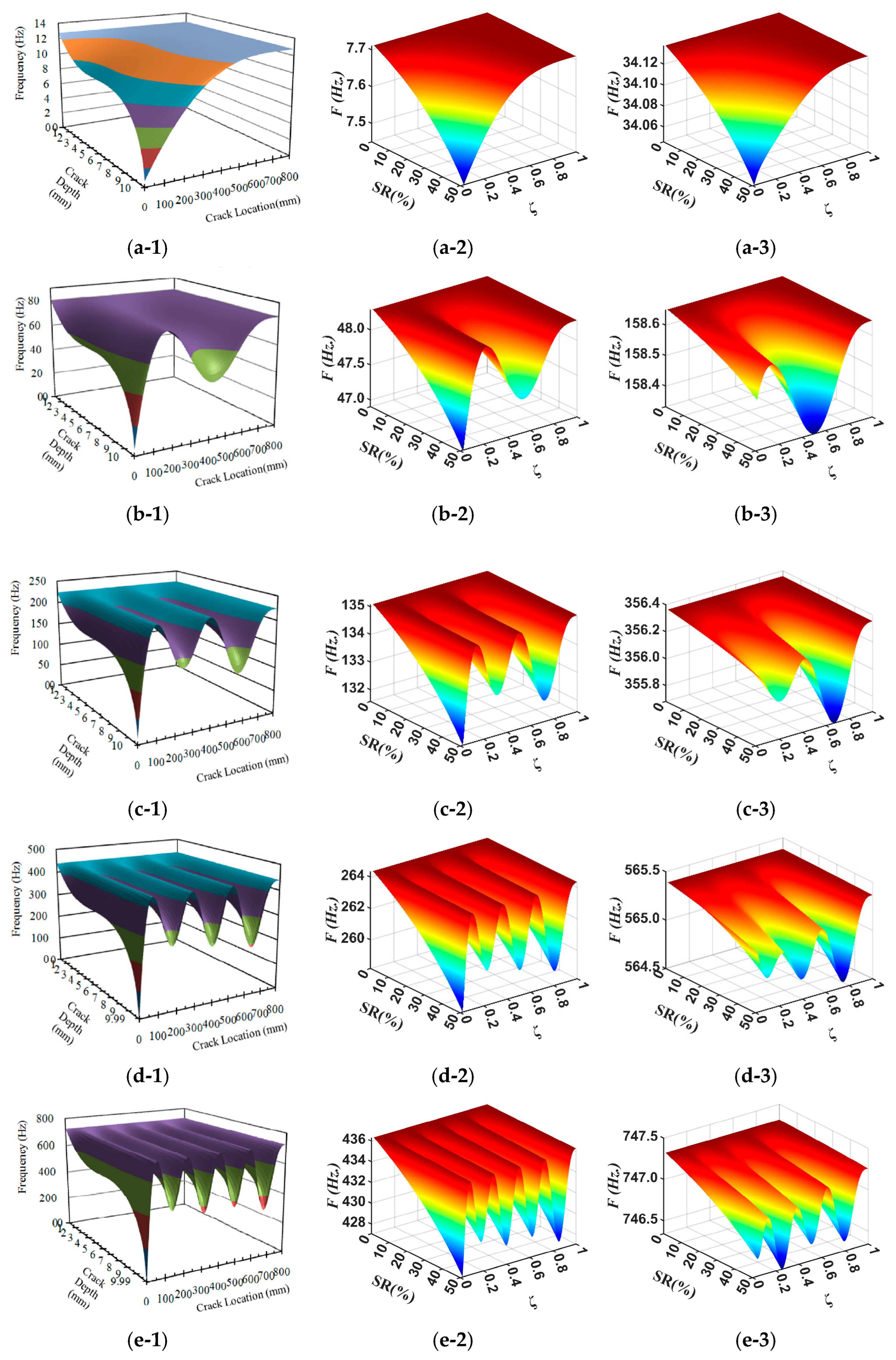

4.1. Relationship Between Natural Frequencies and Damage Conditions

4.2. Study of Normalized RNFC Curves Under Different Damage Sizes

4.3. Effectiveness of the B-RNFC Method in Damage Detection for Wind Turbine Blades

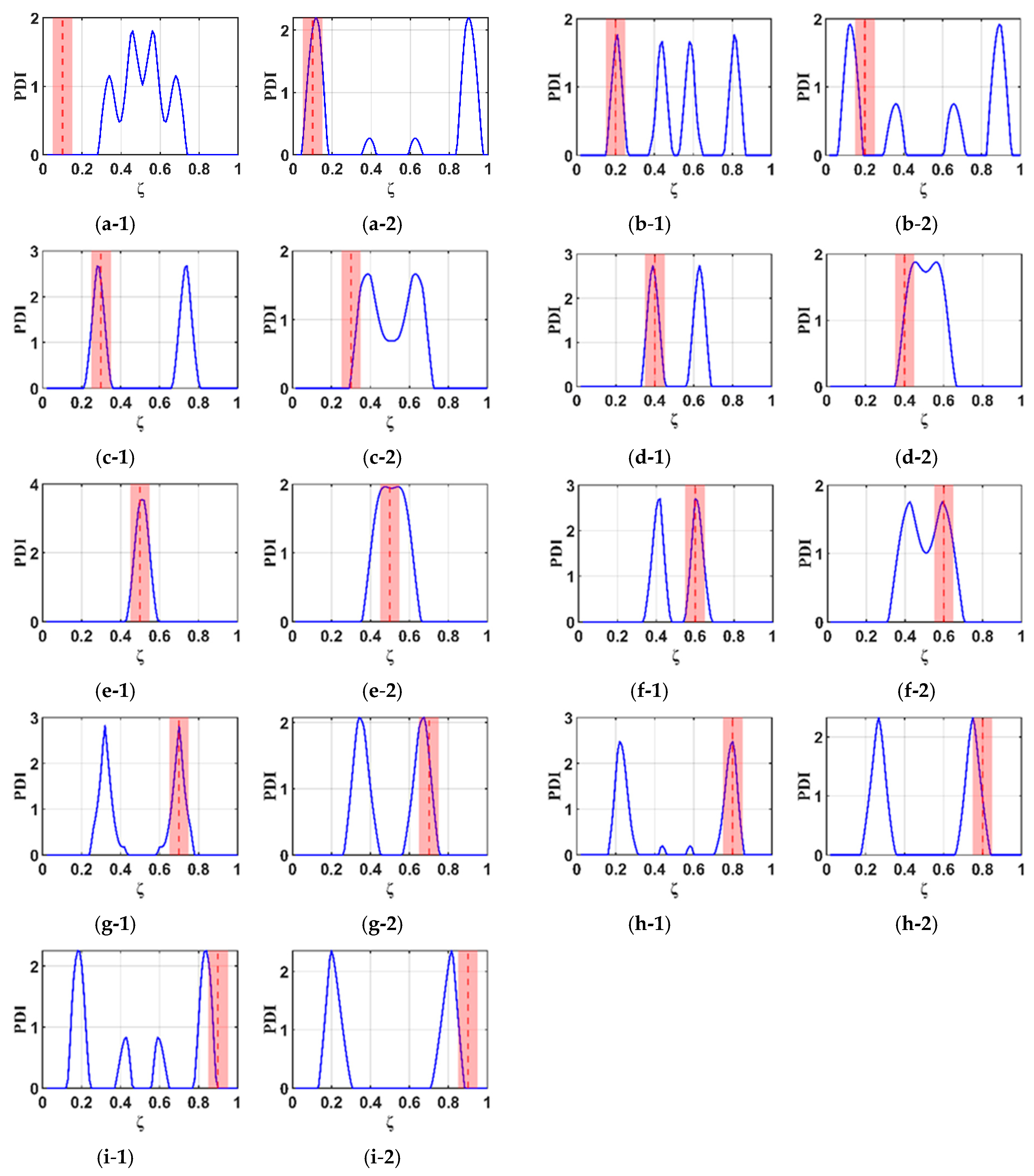

4.4. Effectiveness of the B-RNFC Method for Multiple Damage Localization

5. Conclusions

- The relationship between natural frequencies and damage characteristics in composite cantilever beams and WTBs exhibits consistent trends, deviating only at the root area () due to limitations in the modeling of damage.

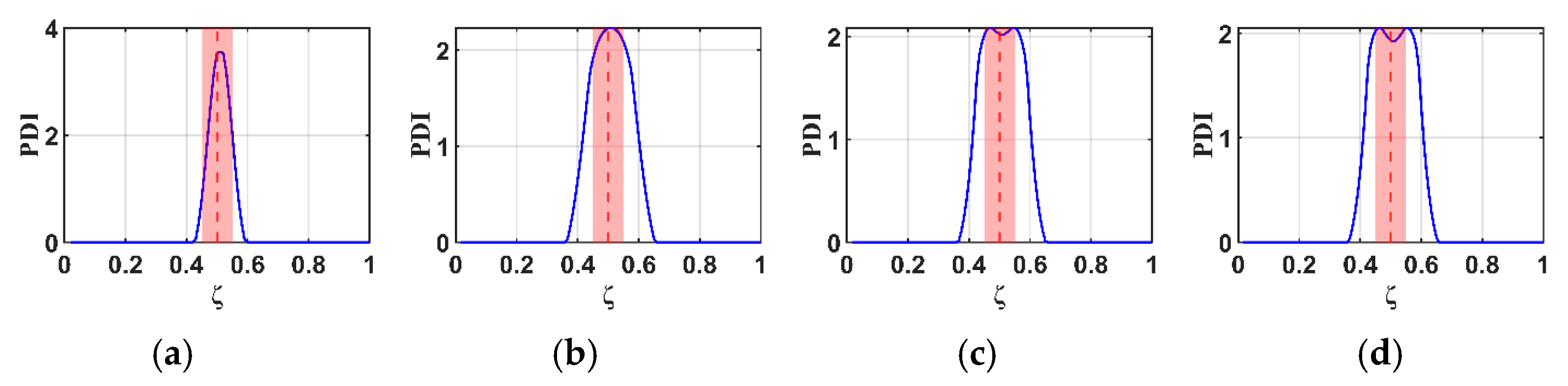

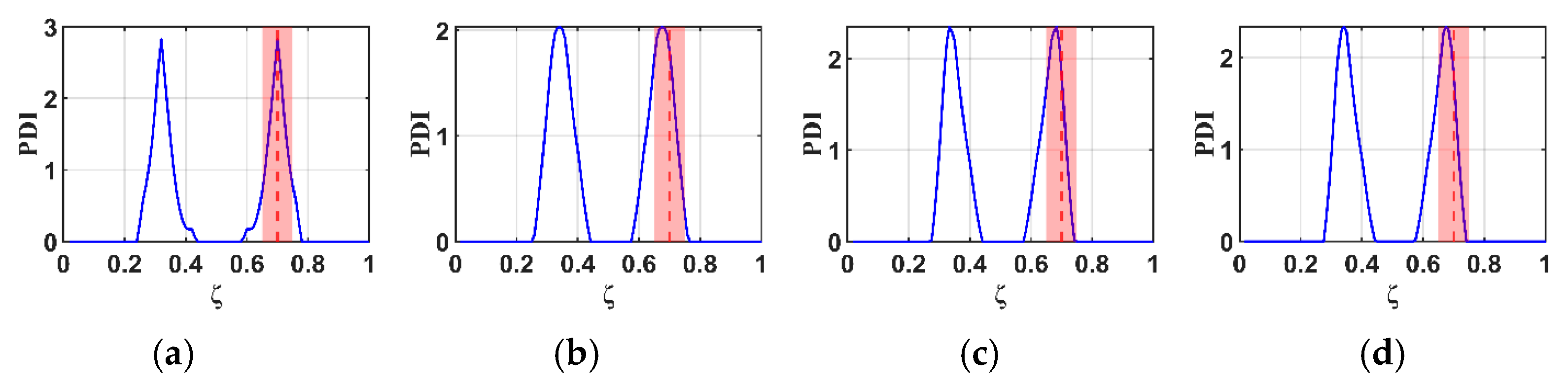

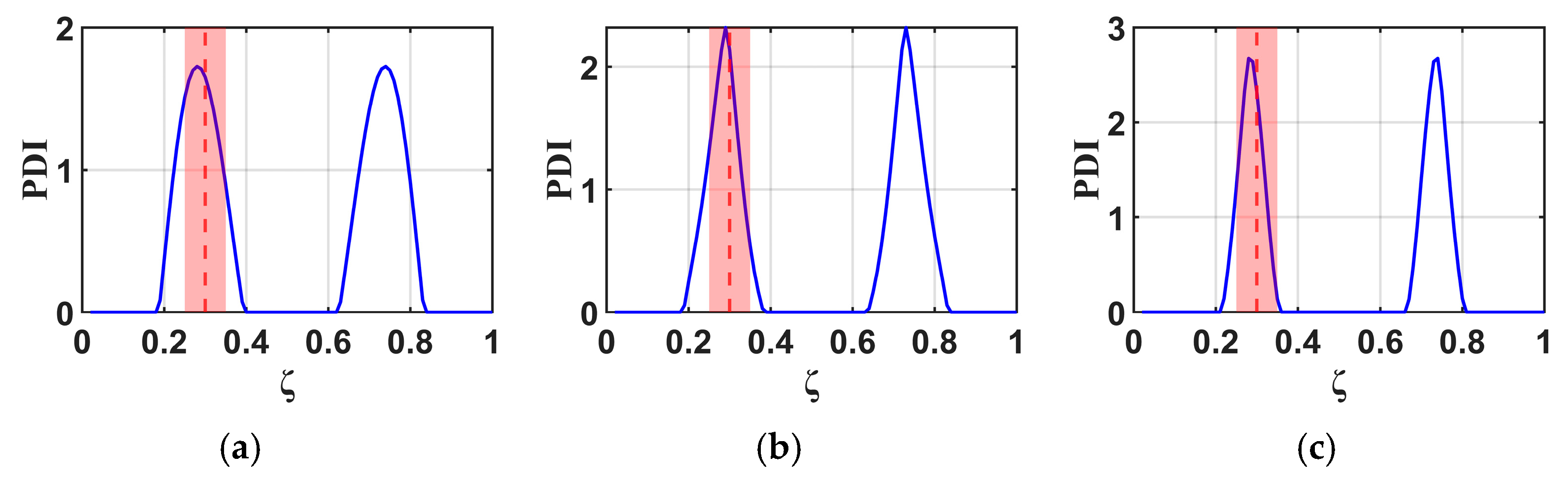

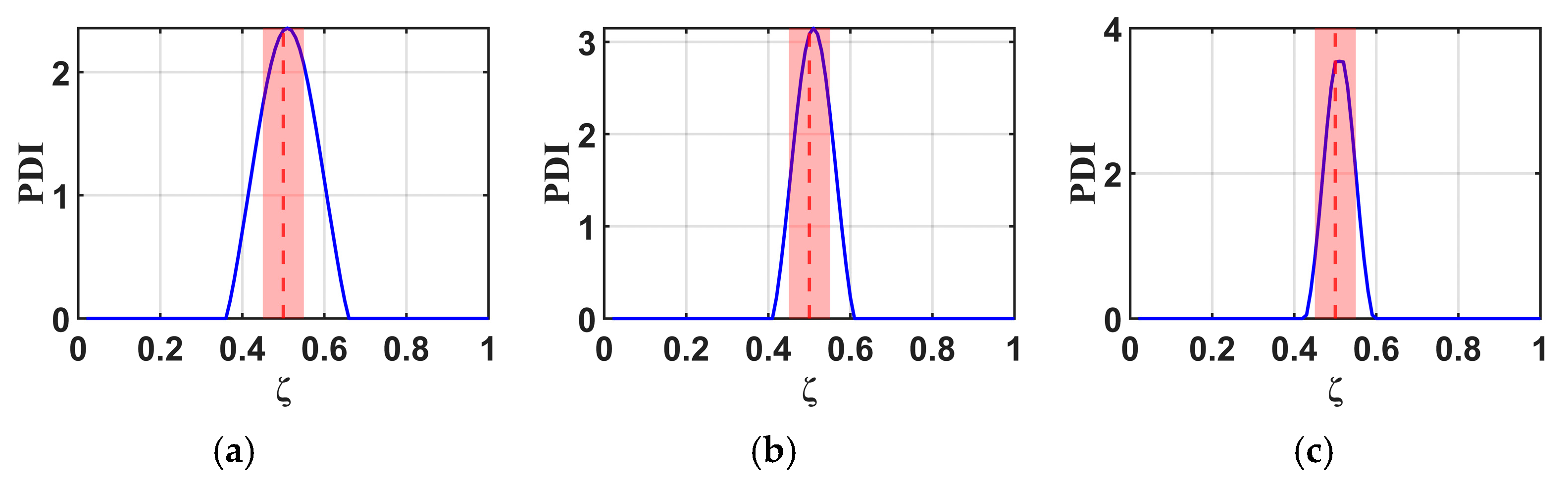

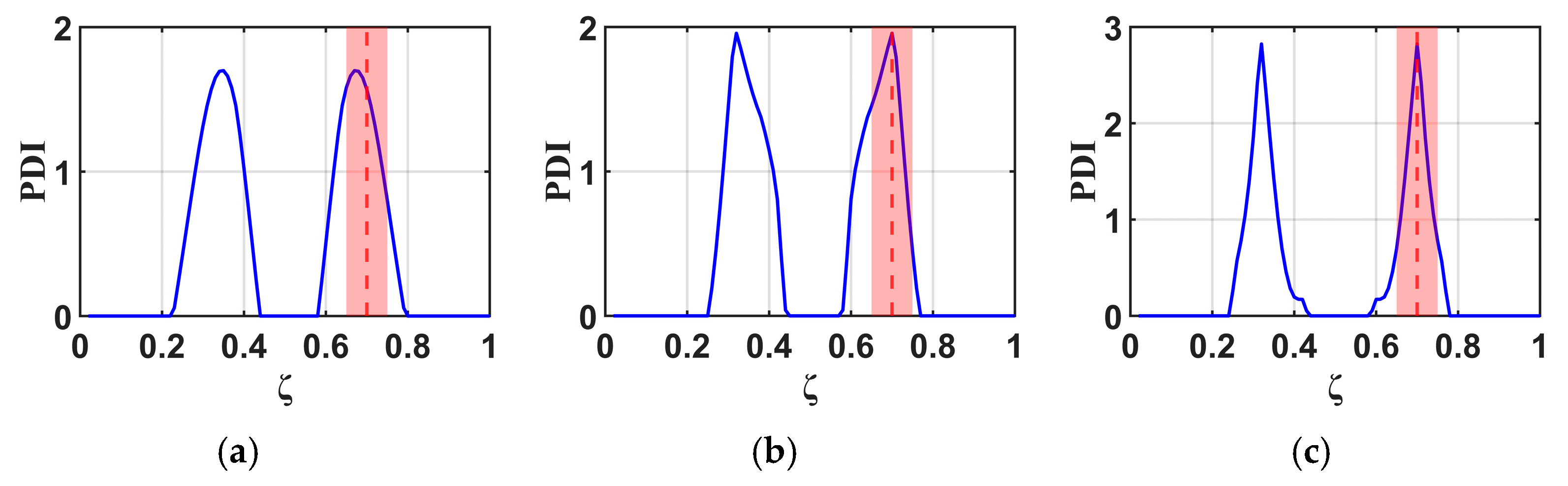

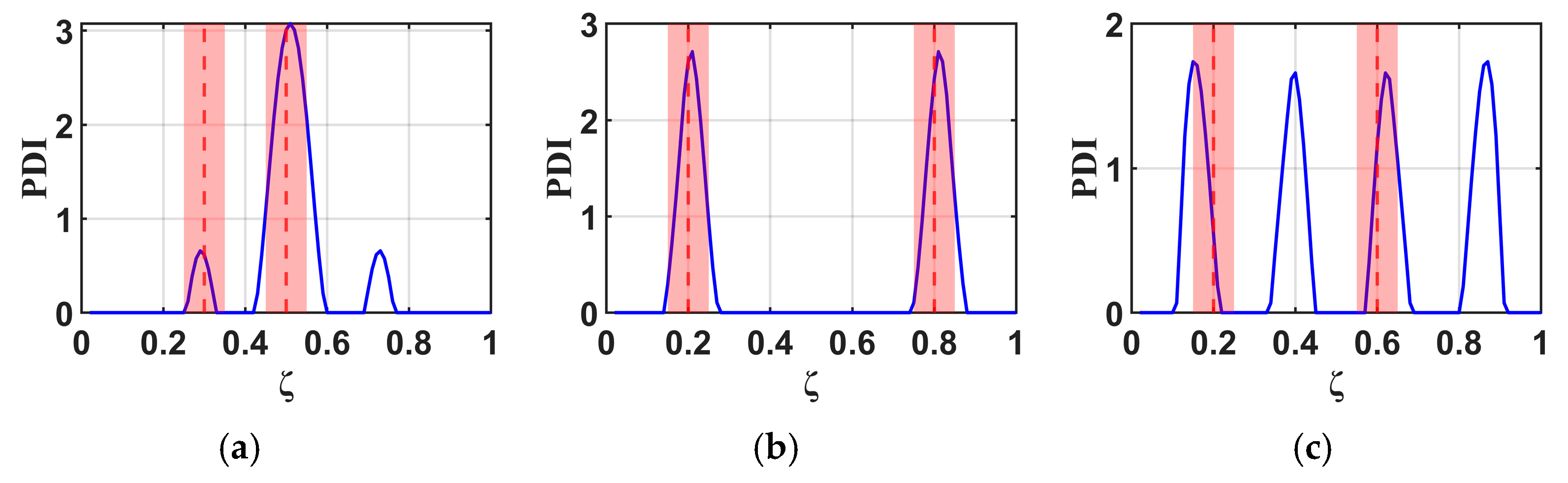

- Fundamentally, the B-RNFC method was developed based on the principle of relative frequency change applied to spatial data and the concept of structural symmetry (e.g., geometry and boundary condition). This foundation directly influences the results, as each single damage location produces symmetric peaks corresponding to the actual damage location and its false counterpart. If a single damage is located at the mid-span (mirror point), the two peaks converge and appear as a single peak.

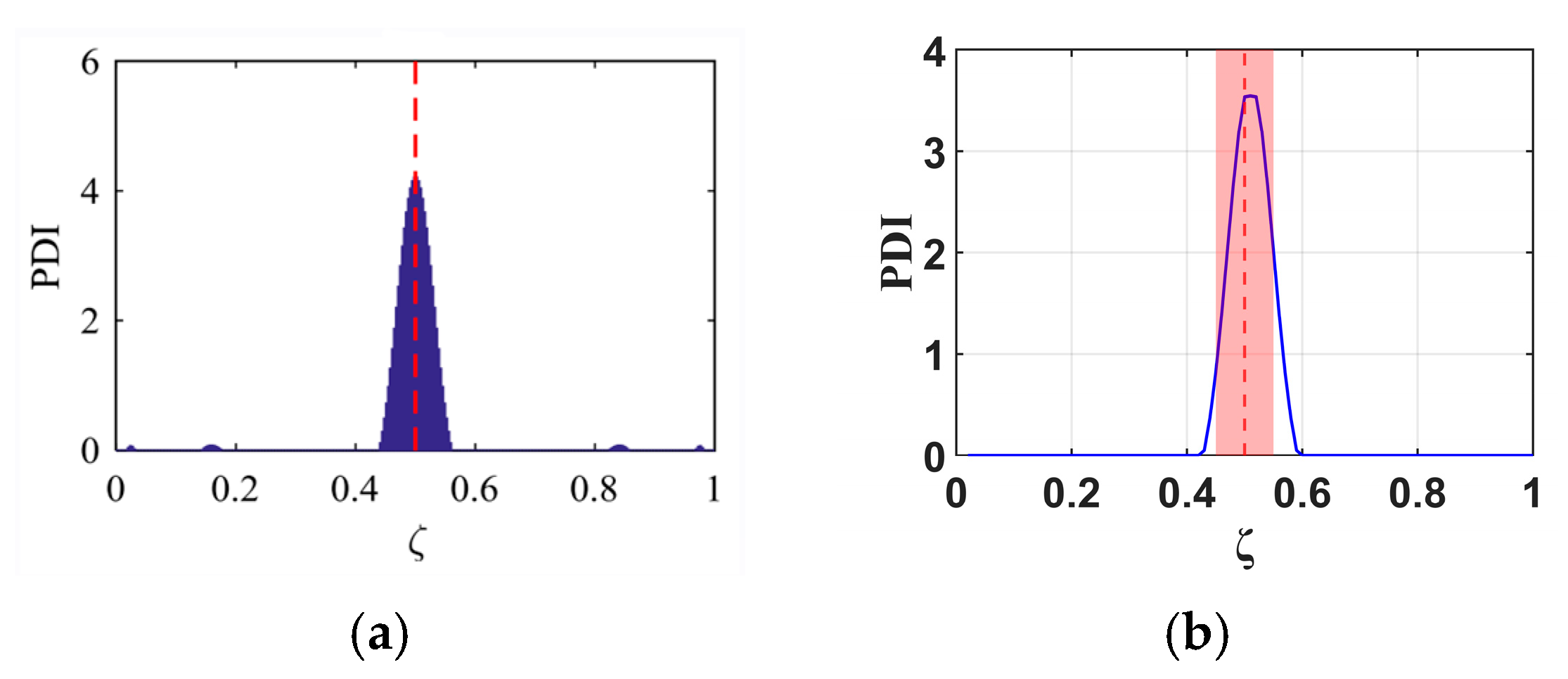

- The proposed method demonstrates an effective damage detection range of for the cantilever beam and for the wind turbine blade. Due to the symmetry theory formulated in the B-RNFC framework, the damage detectable range of the cantilever beam (symmetric shape) is wider than that of WTB (complex geometry).

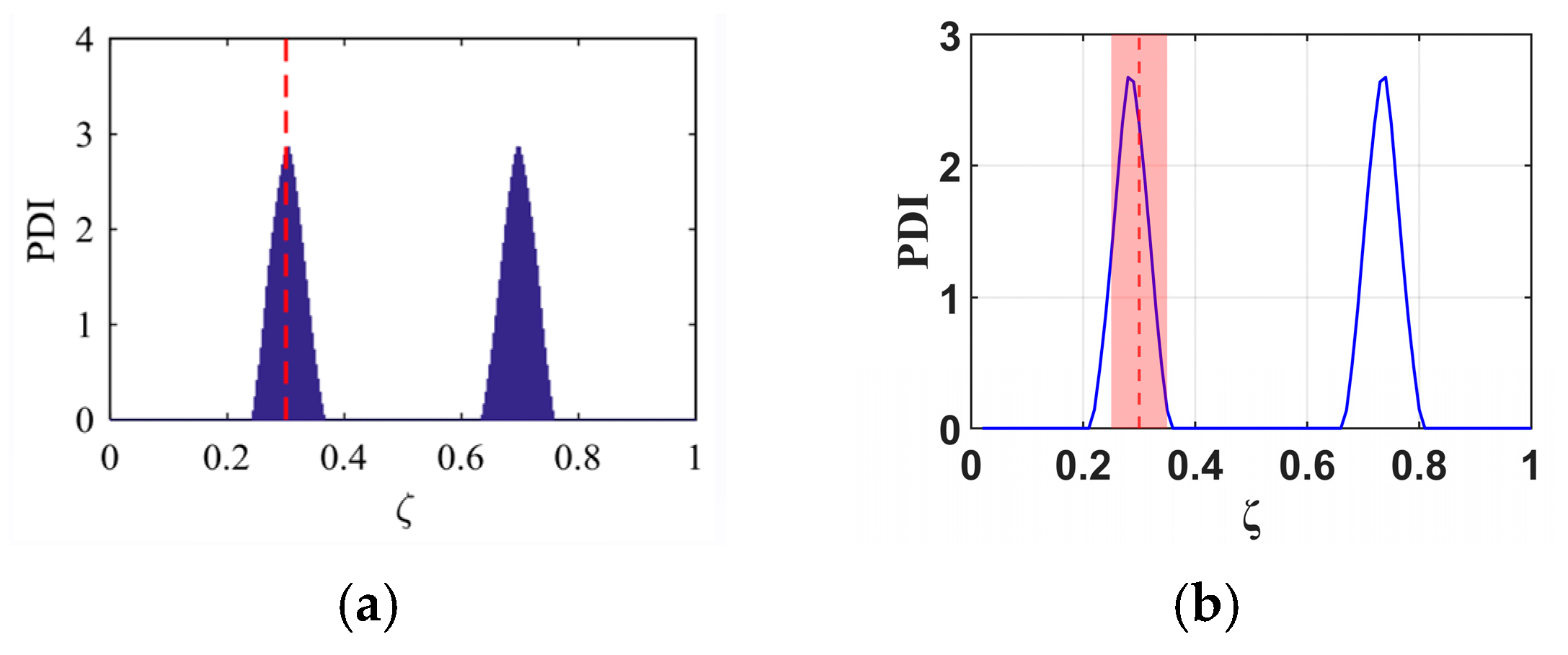

- The B-RNFC method effectively identifies multiple damages (2 damages) on the cantilever beam, particularly when the damages are symmetrically located or when one damage is at the mid-span. However, for non-symmetrical damage configurations, the method exhibited some deviation in accuracy. In this case, one damage is correctly identified, while the second damage appears outside the acceptable detection range.

- For the WTBs, the normalized RNFC curves from various damage sizes provide a slight difference in damage detection outcomes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| B-RNFC | Bayesian-relative natural frequency change |

| DPF | Damage position function |

| EMA | Experimental modal analysis |

| MAC | Modal assurance criteria |

| NDT | Non-destructive testing |

| OMA | Operational modal analysis |

| PDI | Probabilistic damage indicator |

| Q | Improved probability |

| RNFC | Relative natural frequency change |

| SD | Standard deviation |

| SHM | Structural health monitoring |

| SR | Stiffness reduction |

| WTB | Wind turbine blade |

| Z | Z-score |

References

- Zhou, H.F.; Dou, H.Y.; Qin, L.Z.; Chen, Y.; Ni, Y.Q.; Ko, J.M. A Review of Full-Scale Structural Testing of Wind Turbine Blades. Renew. Sustain. Energy Rev. 2014, 33, 177–187. [Google Scholar] [CrossRef]

- Jasiüniené, E.; Raišutis, R.; Šliteris, R.; Voleišis, A.; Vladišauskas, A.; Mitchard, D.; Amos, M. NDT of Wind Turbine Blades Using Adapted Ultrasonic and Radiographic Techniques. Insight Non-Destr. Test. Cond. Monit. 2009, 51, 477–483. [Google Scholar] [CrossRef]

- Ye, G.; Neal, B.; Boot, A.; Kappatos, V.; Selcuk, C.; Gan, T.H. Development of an Ultrasonic NDT System for Automated In-Situ Inspection of Wind Turbine Blades. In Proceedings of the 7th European Workshop on Structural Health Monitoring, Nantes, France, 8–11 July 2014; pp. 826–833. [Google Scholar]

- Kaewniam, P.; Cao, M.; Alkayem, N.F.; Li, D.; Manoach, E. Recent advances in damage detection of wind turbine blades: A state-of-the-art review. Renew. Sustain. Energy Rev. 2022, 167, 112723. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, L.; Zhang, W.; Ai, Y. Non-Destructive Testing of Wind Turbine Blades Using an Infrared Thermography: A Review. In Proceedings of the 2013 International Conference on Materials for Renewable Energy and Environment, Chengdu, China, 19–21 August 2013; IEEE: Chengdu, China, 2013; pp. 407–410. [Google Scholar]

- Hwang, S.; An, Y.K.; Sohn, H. Continuous Line Laser Thermography for Damage Imaging of Rotating Wind Turbine Blades. Procedia Eng. 2017, 188, 225–232. [Google Scholar] [CrossRef]

- Avdelidis, N.P.; Gan, T.H. Non-Destructive Evaluation (NDE) of Composites: Infrared (IR) Thermography of Wind Turbine Blades. In Non-Destructive Evaluation (NDE) of Polymer Matrix Composites: Techniques and Applications; Karbhari, V.M., Ed.; Woodhead Publishing: Cambridge, UK, 2013; pp. 634–648. ISBN 9780857093448. [Google Scholar]

- Doroshtnasir, M.; Worzewski, T.; Krankenhagen, R.; Röllig, M. On-Site Inspection of Potential Defects in Wind Turbine Rotor Blades with Thermography. Wind. Energy 2016, 19, 1407–1422. [Google Scholar] [CrossRef]

- Worzewski, T.; Krankenhagen, R.; Doroshtnasir, M.; Röllig, M.; Maierhofer, C.; Steinfurth, H. Thermographic Inspection of a Wind Turbine Rotor Blade Segment Utilizing Natural Conditions as Excitation Source, Part I: Solar Excitation for Detecting Deep Structures in GFRP. Infrared Phys. Technol. 2016, 76, 756–766. [Google Scholar] [CrossRef]

- Tang, J.; Soua, S.; Mares, C.; Gan, T.H. An Experimental Study of Acoustic Emission Methodology for in Service Condition Monitoring of Wind Turbine Blades. Renew. Energy 2016, 99, 170–179. [Google Scholar] [CrossRef]

- Xu, D.; Liu, P.F.; Chen, Z.P.; Leng, J.X.; Jiao, L. Achieving Robust Damage Mode Identification of Adhesive Composite Joints for Wind Turbine Blade Using Acoustic Emission and Machine Learning. Compos. Struct. 2020, 236, 111840. [Google Scholar] [CrossRef]

- Sun, X.; Ilanko, S.; Mochida, Y.; Tighe, R.C. A Review on Vibration-Based Damage Detection Methods for Civil Structures. Vibration 2023, 6, 51. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Tan, X. Review on Vibration-Based Structural Health Monitoring Techniques and Technical Codes. Symmetry 2021, 13, 1998. [Google Scholar] [CrossRef]

- Manoach, E.; Warminski, J.; Kloda, L.; Teter, A. Numerical and Experimental Studies on Vibration Based Methods for Detection of Damage in Composite Beams. Compos. Struct. 2017, 170, 26–39. [Google Scholar] [CrossRef]

- Ewins, D.J. Modal Testing: Theory, Practice and Application, 2nd ed.; Roberts, J.B., Ed.; Research Studies Press Ltd.: Hertfordshire, UK, 2000; ISBN 0-86380-218-4. [Google Scholar]

- Zahid, F.B.; Ong, Z.C.; Khoo, S.Y. A Review of Operational Modal Analysis Techniques for In-Service Modal Identification. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 398. [Google Scholar] [CrossRef]

- Chinka, S.S.B.; Putti, S.R.; Adavi, B.K. Modal Testing and Evaluation of Cracks on Cantilever Beam Using Mode Shape Curvatures and Natural Frequencies. Structures 2021, 32, 1386–1397. [Google Scholar] [CrossRef]

- Sha, G.; Radzieński, M.; Cao, M.; Ostachowicz, W. A Novel Method for Single and Multiple Damage Detection in Beams Using Relative Natural Frequency Changes. Mech. Syst. Signal Process 2019, 132, 335–352. [Google Scholar] [CrossRef]

- Gillich, G.R.; Maia, N.M.M.; Wahab, M.A.; Tufisi, C.; Korka, Z.I.; Gillich, N.; Pop, M.V. Damage Detection on a Beam with Multiple Cracks: A Simplified Method Based on Relative Frequency Shifts. Sensors 2021, 21, 5215. [Google Scholar] [CrossRef]

- Gillich, G.R.; Praisach, Z.I. Modal Identification and Damage Detection in Beam-like Structures Using the Power Spectrum and Time-Frequency Analysis. Signal Process. 2014, 96, 29–44. [Google Scholar] [CrossRef]

- Gorgin, R. Damage Identification Technique Based on Mode Shape Analysis of Beam Structures. Structures 2020, 27, 2300–2308. [Google Scholar] [CrossRef]

- Páleník, M.; Musil, M.; Úradníček, J. Detection, Localisation and Quantification of Structural Damage Using Changes in Modal Characteristics. Appl. Sci. 2023, 13, 10777. [Google Scholar] [CrossRef]

- Yang, C.; Oyadiji, S.O. Damage Detection Using Modal Frequency Curve and Squared Residual Wavelet Coefficients-Based Damage Indicator. Mech. Syst. Signal Process 2017, 83, 385–405. [Google Scholar] [CrossRef]

- Wei, Q.; Shen, L.; Kövesdi, B.; Dunai, L.; Cao, M. A Lightweight Stochastic Subspace Identification-Based Modal Parameters Identification Method of Time-Varying Structural Systems. J. Sound Vib. 2024, 570, 118092. [Google Scholar] [CrossRef]

- Altunışık, A.C.; Okur, F.Y.; Kahya, V. Modal Parameter Identification and Vibration Based Damage Detection of a Multiple Cracked Cantilever Beam. Eng. Fail. Anal. 2017, 79, 154–170. [Google Scholar] [CrossRef]

- Mia, M.S.; Islam, M.S.; Ghosh, U. Modal Analysis of Cracked Cantilever Beam by Finite Element Simulation. Procedia Eng. 2017, 194, 509–516. [Google Scholar] [CrossRef]

- Elshamy, M.; Crosby, W.A.; Elhadary, M. Crack Detection of Cantilever Beam by Natural Frequency Tracking Using Experimental and Finite Element Analysis. Alex. Eng. J. 2018, 57, 3755–3766. [Google Scholar] [CrossRef]

- Sharma, J.K. Theoretical and Experimental Modal Analysis of Beam. In Engineering Vibration, Communication and Information Processing; Springer: Singapore, 2018; Volume 478, pp. 177–186. [Google Scholar]

- Xu, Y.; Brownjohn, J.M.W.; Hester, D. Enhanced Sparse Component Analysis for Operational Modal Identification of Real-Life Bridge Structures. Mech. Syst. Signal Process 2019, 116, 585–605. [Google Scholar] [CrossRef]

- Wickramasinghe, W.R.; Thambiratnam, D.P.; Chan, T.H.T. Damage Detection in a Suspension Bridge Using Modal Flexibility Method. Eng. Fail. Anal. 2020, 107, 104194. [Google Scholar] [CrossRef]

- Jayasundara, N.; Thambiratnam, D.P.; Chan, T.H.T.; Nguyen, A. Damage Detection and Quantification in Deck Type Arch Bridges Using Vibration Based Methods and Artificial Neural Networks. Eng. Fail. Anal. 2020, 109, 104265. [Google Scholar] [CrossRef]

- Hwang, J.S.; Noh, J.T.; Lee, S.H.; Kareem, A. Experimental Verification of Modal Identification of a High-Rise Building Using Independent Component Analysis. Int. J. Concr. Struct. Mater. 2019, 13, 4. [Google Scholar] [CrossRef]

- Sarlo, R.; Tarazaga, P.A.; Kasarda, M.E. High Resolution Operational Modal Analysis on a Five-Story Smart Building under Wind and Human Induced Excitation. Eng. Struct. 2018, 176, 279–292. [Google Scholar] [CrossRef]

- Mugabo, I.; Barbosa, A.R.; Riggio, M. Dynamic Characterization and Vibration Analysis of a Four-Story Mass Timber Building. Front. Built Environ. 2019, 5, 86. [Google Scholar] [CrossRef]

- Shabani, A.; Feyzabadi, M.; Kioumarsi, M. Model Updating of a Masonry Tower Based on Operational Modal Analysis: The Role of Soil-Structure Interaction. Case Stud. Constr. Mater. 2022, 16, e00957. [Google Scholar] [CrossRef]

- Ferraioli, M.; Miccoli, L.; Abruzzese, D.; Mandara, A. Dynamic Characterisation and Seismic Assessment of Medieval Masonry Towers. Nat. Hazards 2017, 86, 489–515. [Google Scholar] [CrossRef]

- Pellegrini, D.; Girardi, M.; Lourenço, P.B.; Masciotta, M.G.; Mendes, N.; Padovani, C.; Ramos, L.F. Modal Analysis of Historical Masonry Structures: Linear Perturbation and Software Benchmarking. Constr. Build. Mater. 2018, 189, 1232–1250. [Google Scholar] [CrossRef]

- Bhowmik, C.; Chakraborti, P.; Das, S.S. Dynamic Analysis of Typical Composite Electric Power Transmission Tower Structure by ANSYS. Int. J. Comput. Intell. IoT 2018, 1, 32–35. [Google Scholar]

- Kaewniam, P.; Cao, M.; Alkayem, N.F.; Wei, Q.; Gu, H. Damage Identification of Wind Turbine Blades Using Continuous Wavelet Transform: A Comprehensive Study. Nondestruct. Test. Eval. 2025. [Google Scholar] [CrossRef]

- Xu, W.; Ding, K.; Liu, J.; Cao, M.; Radzieński, M.; Ostachowicz, W. Non-Uniform Crack Identification in Plate-like Structures Using Wavelet 2D Modal Curvature under Noisy Conditions. Mech. Syst. Signal Process 2019, 126, 469–489. [Google Scholar] [CrossRef]

- Shi, B.; Cao, M.; Wang, Z.; Ostachowicz, W. A Directional Continuous Wavelet Transform of Mode Shape for Line-Type Damage Detection in Plate-Type Structures. Mech. Syst. Signal Process 2022, 167, 108510. [Google Scholar] [CrossRef]

- Alkayem, N.F.; Cao, M.; Ragulskis, M. Damage Diagnosis in 3D Structures Using a Novel Hybrid Multiobjective Optimization and FE Model Updating Framework. Complexity 2018, 2018, 3541676. [Google Scholar] [CrossRef]

- Alkayem, N.F.; Shen, L.; Al-hababi, T.; Qian, X.; Cao, M. Inverse Analysis of Structural Damage Based on the Modal Kinetic and Strain Energies with the Novel Oppositional Unified Particle Swarm Gradient-Based Optimizer. Appl. Sci. 2022, 12, 11689. [Google Scholar] [CrossRef]

- Oliveira, G.; Magalhães, F.; Cunha, Á.; Caetano, E. Vibration-Based Damage Detection in a Wind Turbine Using 1 Year of Data. Struct. Control Health Monit. 2018, 25, e2238. [Google Scholar] [CrossRef]

- Oliveira, G.; Magalhães, F.; Cunha, Á.; Caetano, E. Continuous Dynamic Monitoring of an Onshore Wind Turbine. Eng. Struct. 2018, 164, 22–39. [Google Scholar] [CrossRef]

- Sellami, T.; Berriri, H.; Darcherif, A.M.; Jelassi, S.; Mimouni, M.F. Modal and Harmonic Analysis of Three-Dimensional Wind Turbine Models. Wind. Eng. 2016, 40, 518–527. [Google Scholar] [CrossRef]

- Adams, D.; White, J.; Rumsey, M.; Farrar, C. Structural Health Monitoring of Wind Turbines: Method and Application to a HAWT. Wind. Energy 2011, 14, 603–623. [Google Scholar] [CrossRef]

- Ou, Y.; Chatzi, E.N.; Dertimanis, V.K.; Spiridonakos, M.D. Vibration-Based Experimental Damage Detection of a Small-Scale Wind Turbine Blade. Struct. Health Monit. 2017, 16, 79–96. [Google Scholar] [CrossRef]

- Doliński, L.; Krawczuk, M. Damage Detection in Turbine Wind Blades by Vibration Based Methods. J. Phys. Conf. Ser. 2009, 181, 012086. [Google Scholar] [CrossRef]

- Ulriksen, M.D.; Tcherniak, D.; Kirkegaard, P.H.; Damkilde, L. Operational Modal Analysis and Wavelet Transformation for Damage Identification in Wind Turbine Blades. Struct. Health Monit. 2015, 15, 381–388. [Google Scholar] [CrossRef]

- Huang, T.; Schröder, K.U. A Bayesian Probabilistic Approach for Damage Identification in Plate Structures Using Responses at Vibration Nodes. Mech. Syst. Signal Process 2020, 146, 106998. [Google Scholar] [CrossRef]

- Yin, T.; Jiang, Q.H.; Yuen, K.V. Vibration-Based Damage Detection for Structural Connections Using Incomplete Modal Data by Bayesian Approach and Model Reduction Technique. Eng. Struct. 2017, 132, 260–277. [Google Scholar] [CrossRef]

- Huang, Q.; Gardoni, P.; Hurlebaus, S. A Probabilistic Damage Detection Approach Using Vibration-Based Nondestructive Testing. Struct. Saf. 2012, 38, 11–21. [Google Scholar] [CrossRef]

- Jiang, H.; Jiang, Y.; Xiang, J. Quantitative Detection of Multiple Damages in Wind Turbine Blade Based on the Operating Deflection Shape and Natural Frequencies. Ocean. Eng. 2023, 278, 114387. [Google Scholar] [CrossRef]

- Doliński, Ł.; Krawczuk, M.; Zak, A. Detection of Delamination in Laminate Wind Turbine Blades Using One-Dimensional Wavelet Analysis of Modal Responses. Shock. Vib. 2018, 2018, 4507879. [Google Scholar] [CrossRef]

- Lorenzo, E.D.; Petrone, G.; Manzato, S.; Peeters, B.; Desmet, W.; Marulo, F. Damage Detection in Wind Turbine Blades by Using Operational Modal Analysis. Struct. Health Monit. 2016, 15, 289–301. [Google Scholar] [CrossRef]

- ANSYS. ANSYS Material Library [Computer Software]. Available online: https://www.ansys.com/ (accessed on 29 October 2025).

- Gillich, N.; Tufisi, C.; Sacarea, C.; Rusu, C.V.; Gillich, G.R.; Praisach, Z.I.; Ardeljan, M. Beam Damage Assessment Using Natural Frequency Shift and Machine Learning. Sensors 2022, 22, 1118. [Google Scholar] [CrossRef] [PubMed]

- Gilbert-Rainer, G.; Zeno-Iosif, P. Detection and Quantitative Assessment of Damages in Beam Structures Using Frequency and Stiffness Changes. Key Eng. Mater. 2013, 569–570, 1013–1020. [Google Scholar] [CrossRef]

- Khalkar, V.R.; Ramachandran, S. Study of Free Undamped and Damped Vibrations of a Cracked Cantilever Beam. J. Eng. Sci. Technol. 2018, 13, 449–462. [Google Scholar]

- Tufisi, C.; Gillich, G.R.; Nedelcu, D.; Hamat, C.O. Numerical Study on Complex Shaped Cracks in Cantilever Beams Concerning Frequency and Stiffness Changes. Vibroeng. Procedia 2018, 19, 253–258. [Google Scholar] [CrossRef][Green Version]

| Property | Value | Unit |

|---|---|---|

| Density | 1490 | kg/m3 |

| Young’s Modulus (X-direction) | 8.6 × 109 | Pa |

| Young’s Modulus (Y-direction) | 12.1 × 1010 | Pa |

| Young’s Modulus (Z-direction) | 8.6 × 109 | Pa |

| Shear Modulus XY | 4.7 × 109 | Pa |

| Shear Modulus YZ | 4.7 × 109 | Pa |

| Shear Modulus XZ | 3.1 × 109 | Pa |

| Poisson’s Ratio XY | 0.01919 | |

| Poisson’s Ratio YZ | 0.27 | |

| Poisson’s Ratio XZ | 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaewniam, P.; Wei, Q.; Gu, H.; Alkayem, N.F.; Cao, M. Damage Identification in Composite Wind Turbine Blades Using Relative Natural Frequency Changes and Bayesian Probability. Materials 2025, 18, 5263. https://doi.org/10.3390/ma18235263

Kaewniam P, Wei Q, Gu H, Alkayem NF, Cao M. Damage Identification in Composite Wind Turbine Blades Using Relative Natural Frequency Changes and Bayesian Probability. Materials. 2025; 18(23):5263. https://doi.org/10.3390/ma18235263

Chicago/Turabian StyleKaewniam, Panida, Qingyang Wei, Haoan Gu, Nizar Faisal Alkayem, and Maosen Cao. 2025. "Damage Identification in Composite Wind Turbine Blades Using Relative Natural Frequency Changes and Bayesian Probability" Materials 18, no. 23: 5263. https://doi.org/10.3390/ma18235263

APA StyleKaewniam, P., Wei, Q., Gu, H., Alkayem, N. F., & Cao, M. (2025). Damage Identification in Composite Wind Turbine Blades Using Relative Natural Frequency Changes and Bayesian Probability. Materials, 18(23), 5263. https://doi.org/10.3390/ma18235263