Research on Mixing Uniformity Evaluation and Molding Method for Crumb Rubber Asphalt Mixtures

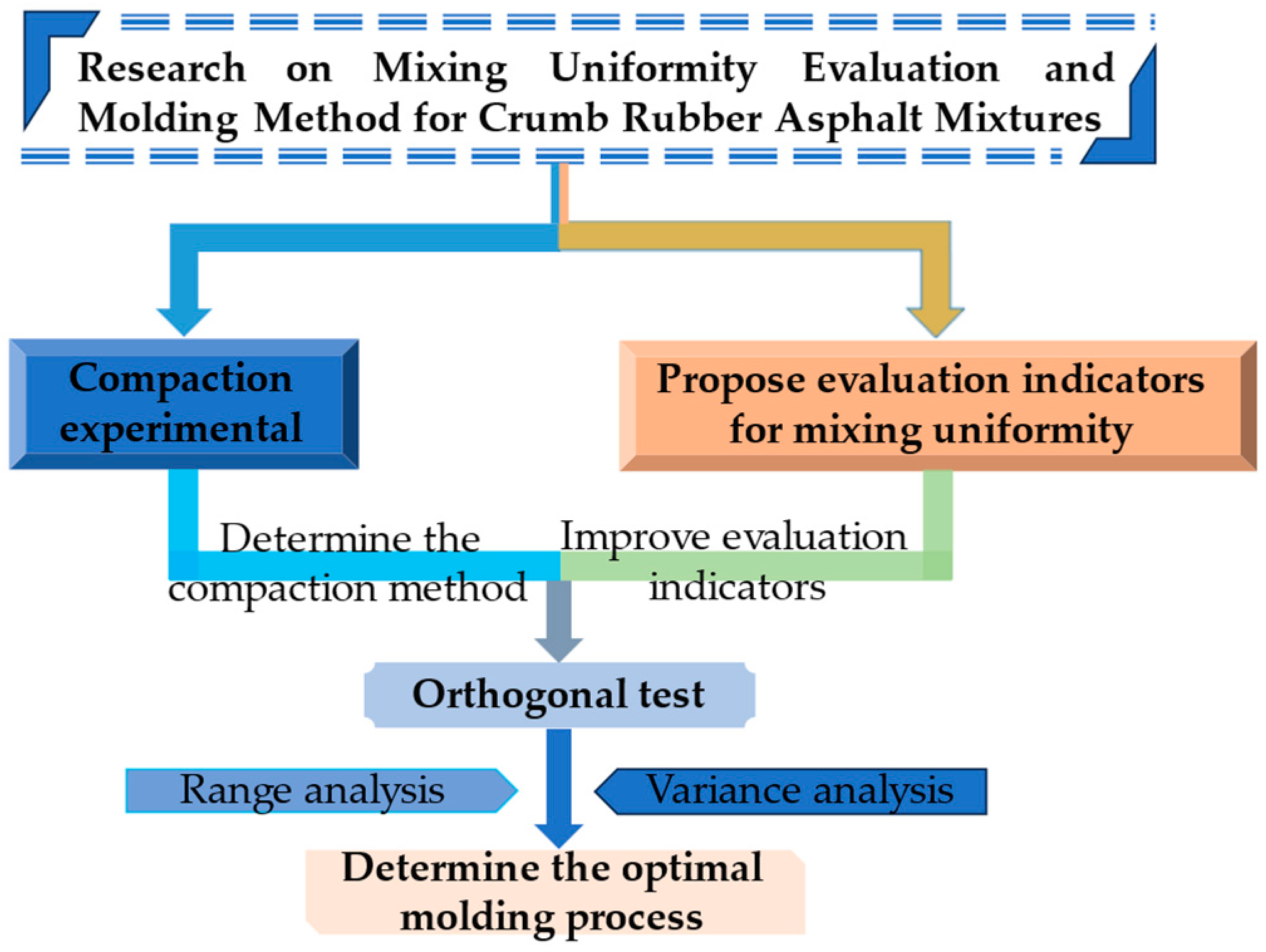

Abstract

1. Introduction

1.1. Background

1.2. Objective and Scope

2. Materials and Gradation Design

2.1. Asphalt

2.2. Aggregates

2.3. Crumb Rubber

2.4. Filler

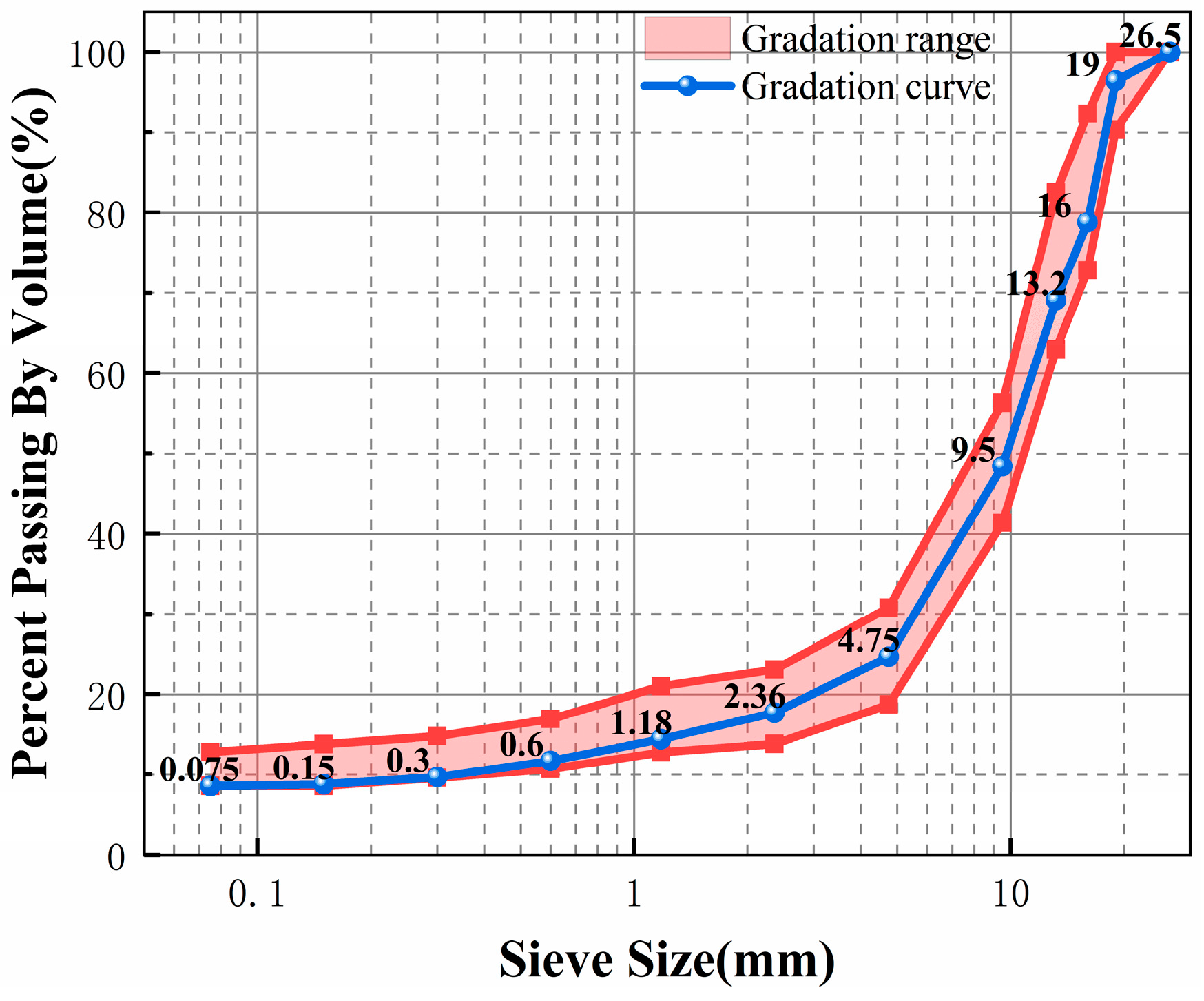

2.5. Crumb Rubber Asphalt Gradation Design

3. Experimental Design and Method

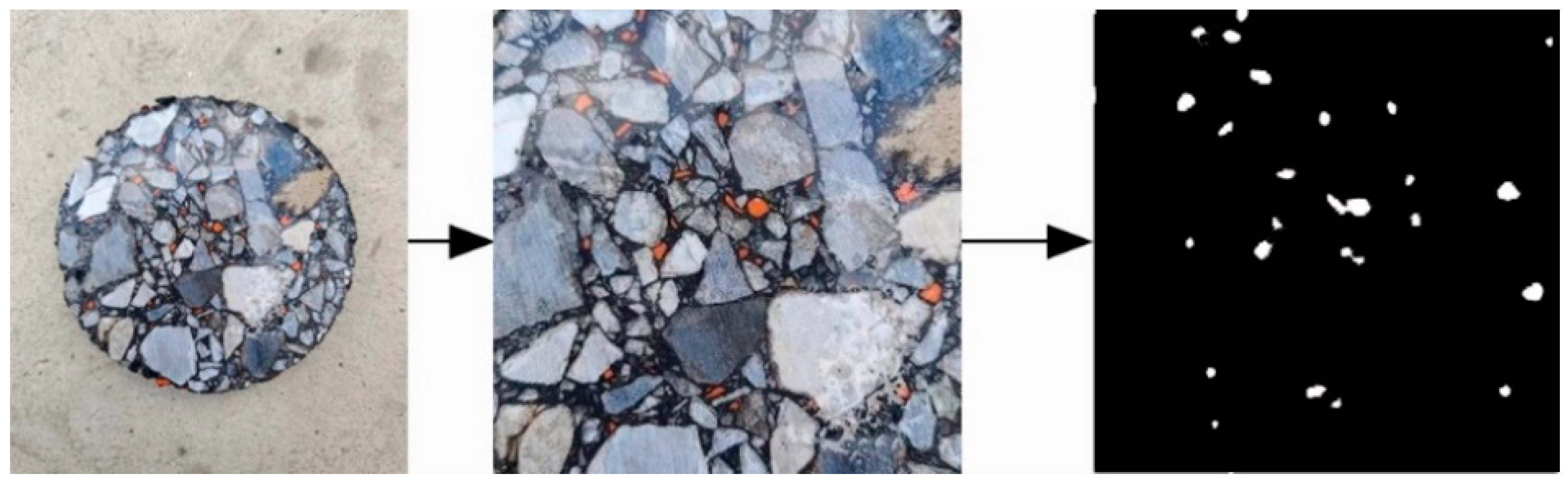

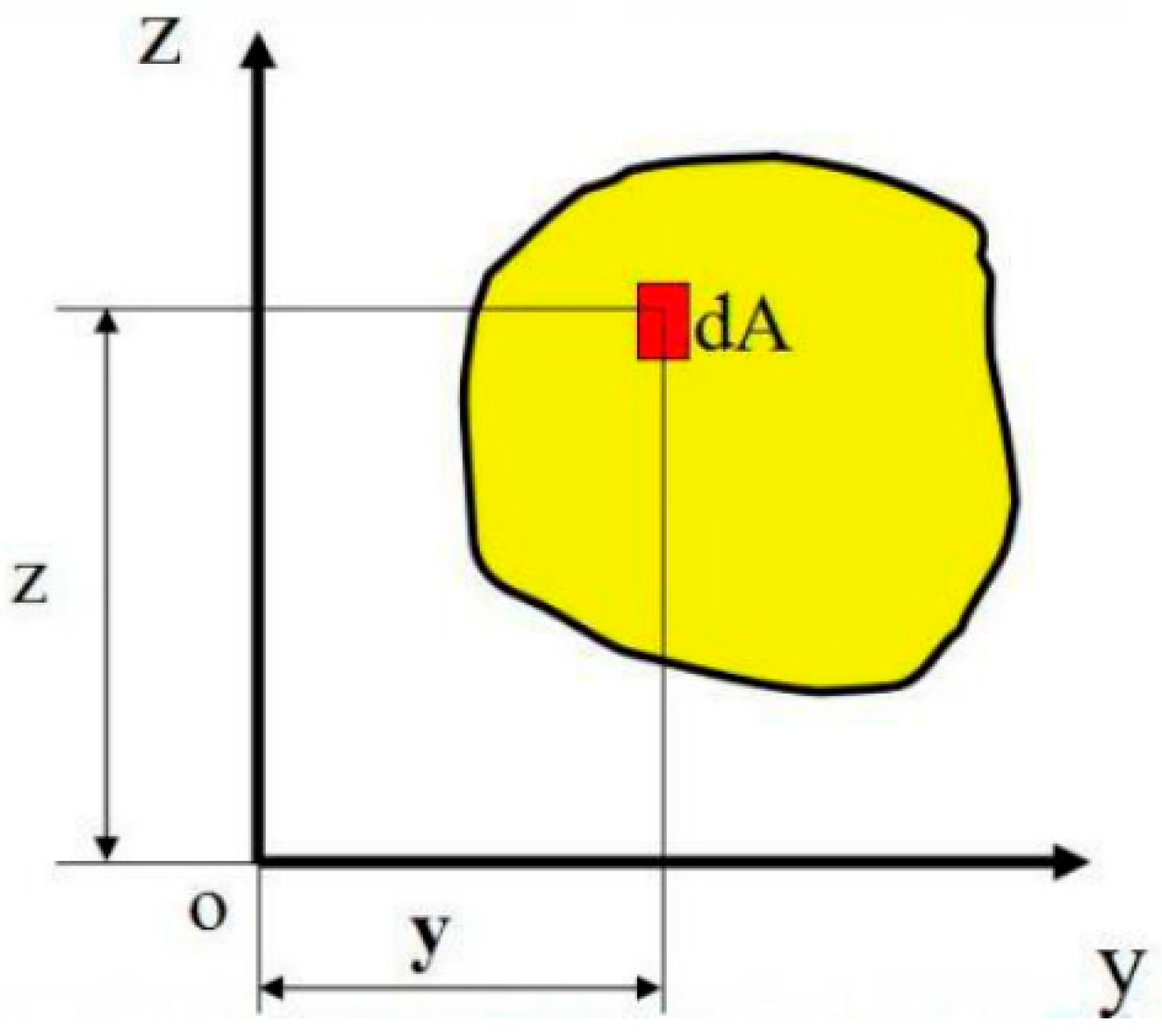

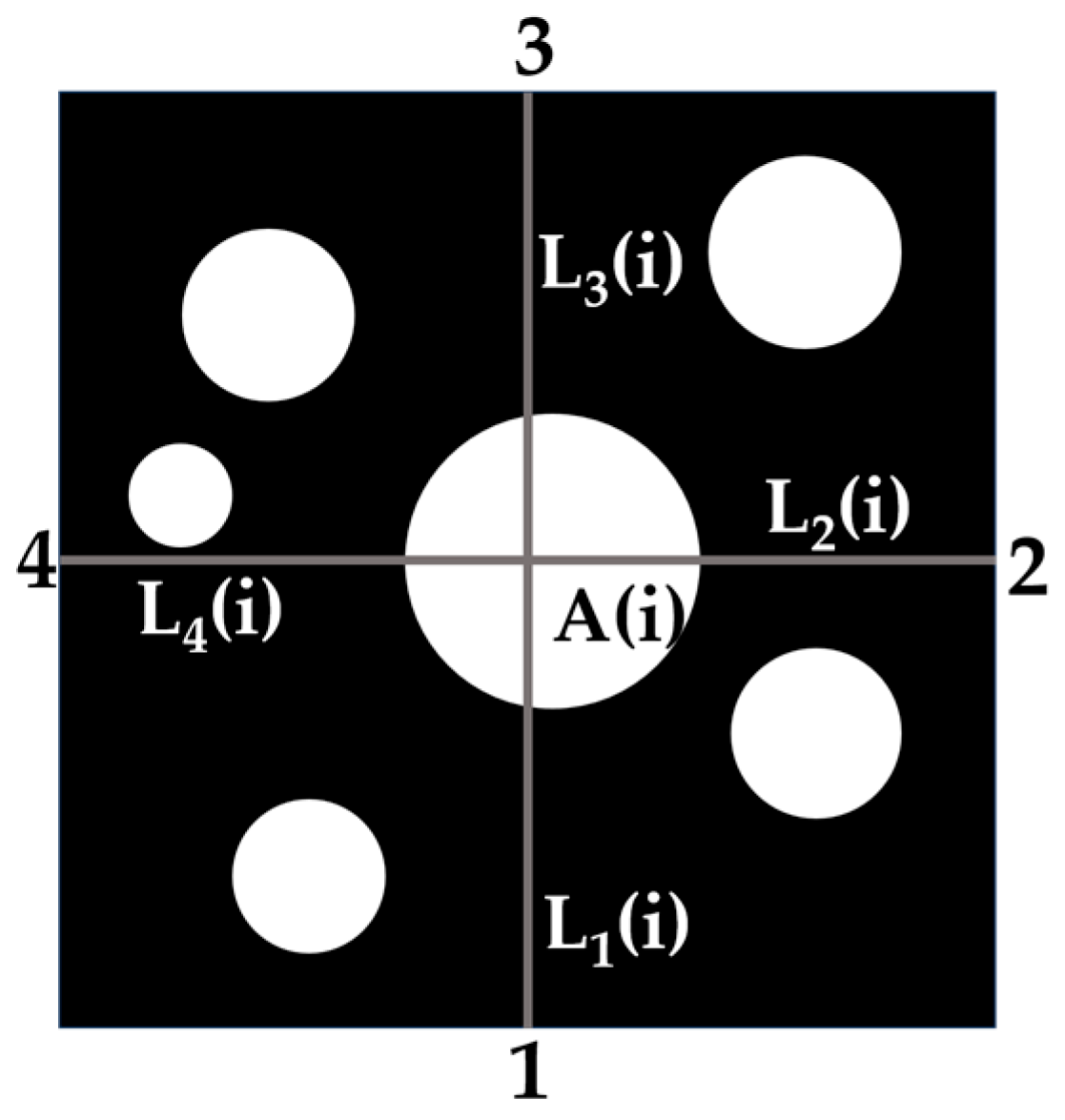

3.1. Evaluation Indicator for Crumb Rubber Mixing Uniformity

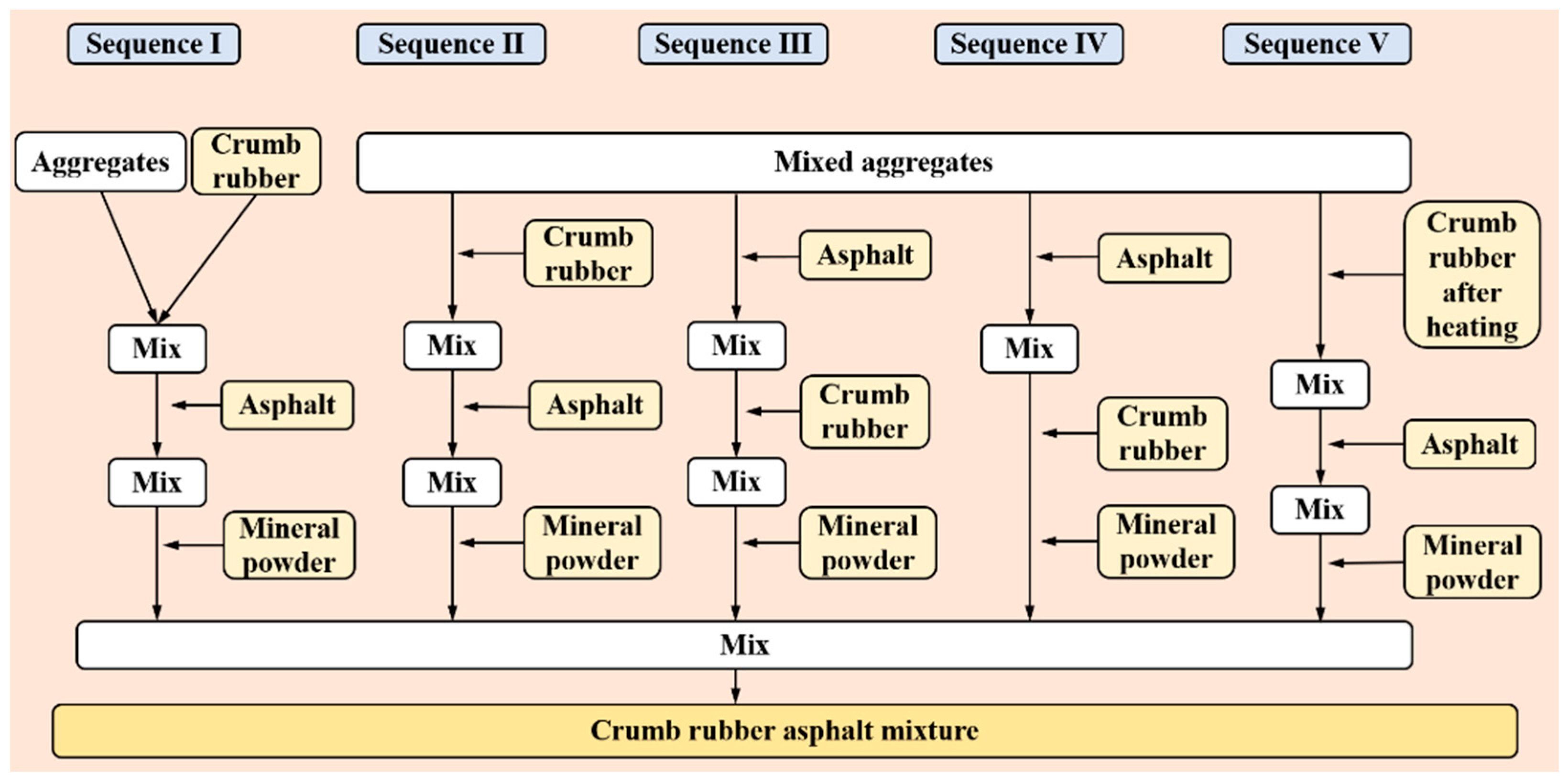

3.2. Crumb Rubber Asphalt Mixtures Molding Experimental Design

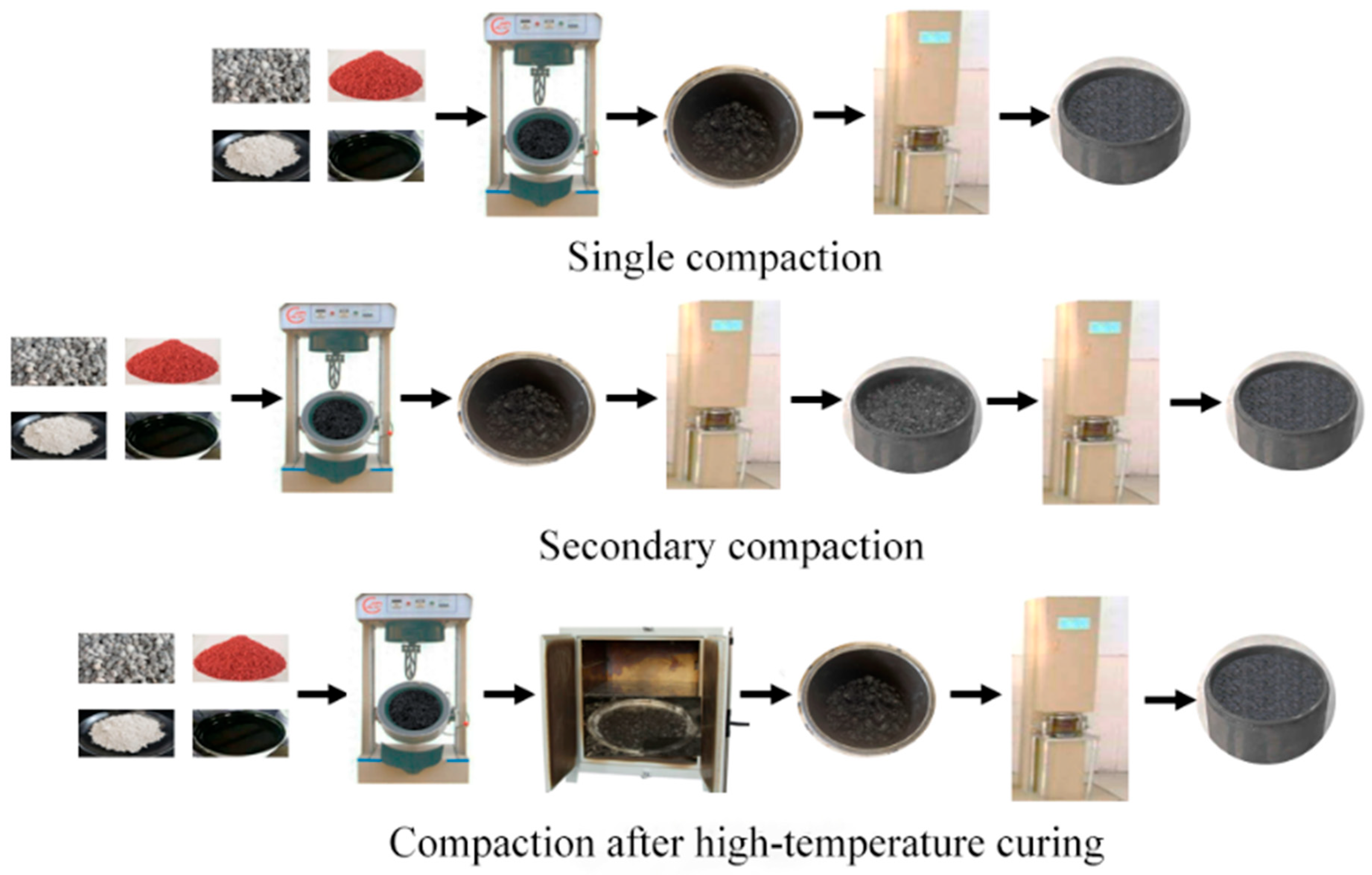

3.2.1. Compaction Experimental Design

3.2.2. Orthogonal Test Design

4. Experimental Results and Analysis

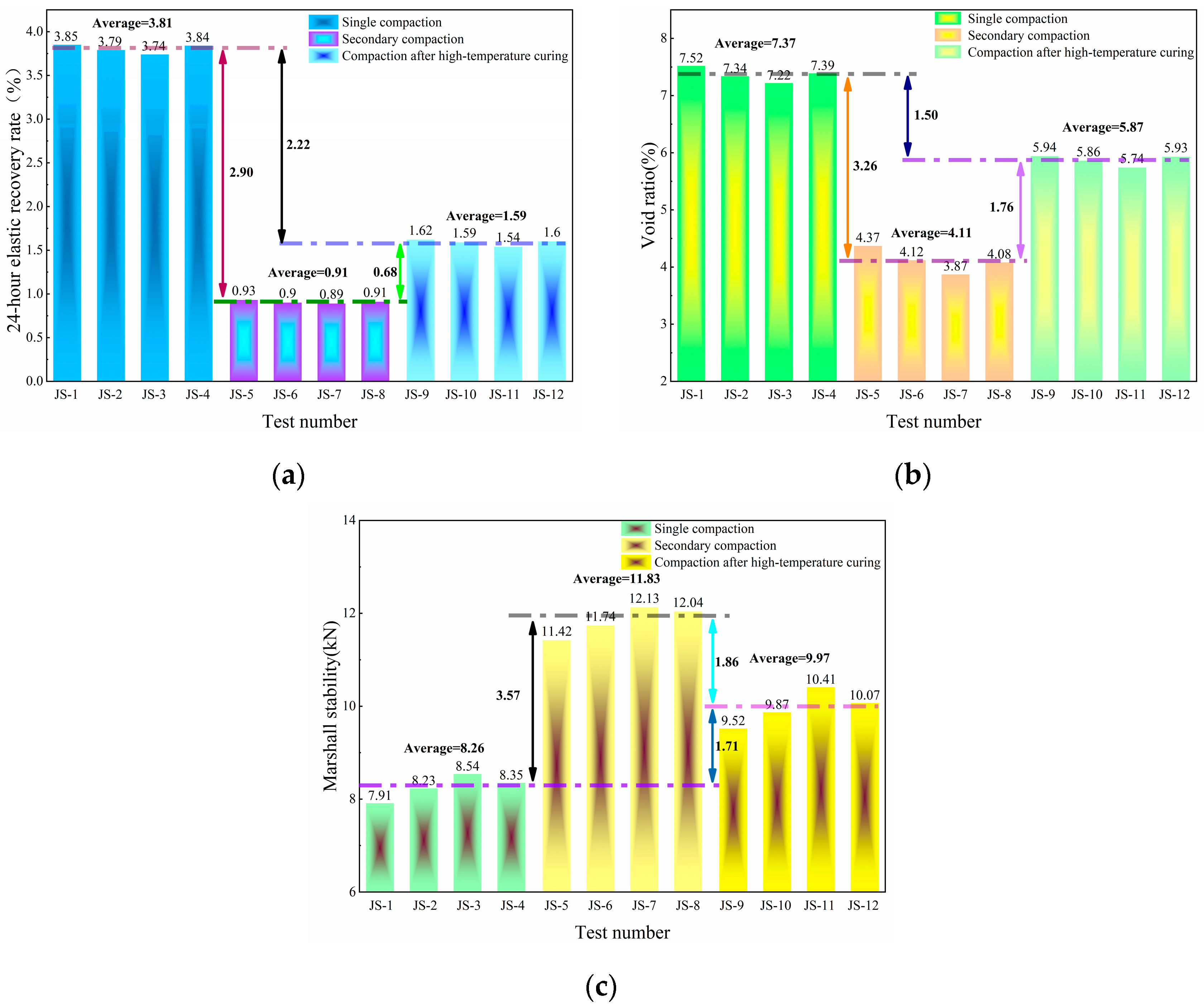

4.1. Analysis of Compaction Experiment Results

4.2. Analysis of Orthogonal Test Results

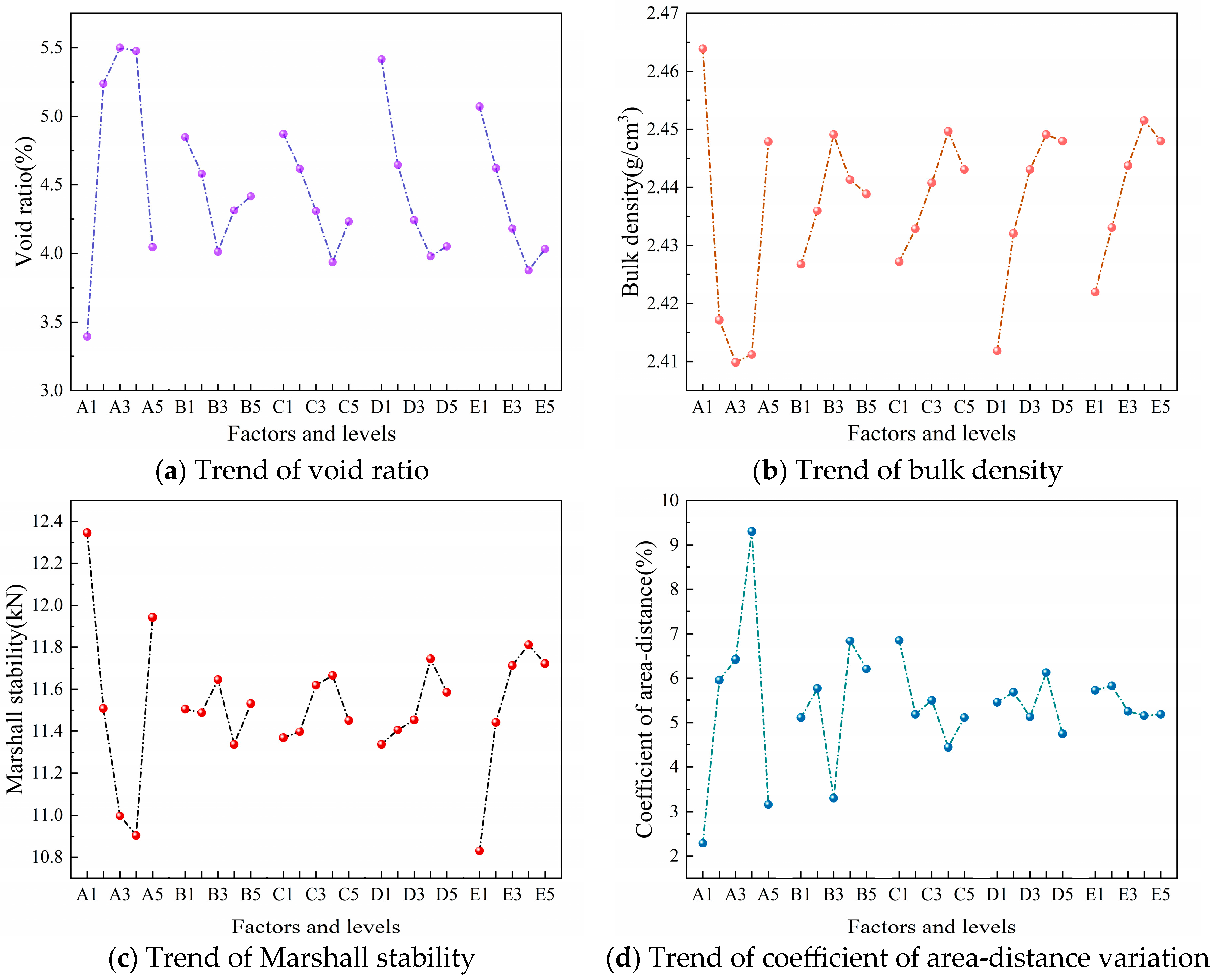

4.2.1. Range Analysis

4.2.2. Variance Analysis

4.2.3. Comprehensive Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CRAM | Crumb Rubber Asphalt Mixtures |

| dB | Decibel |

| EPDM | Ethylene Propylene Diene Monomer |

| SMA | Stone Mastic Asphalt |

| px | Pixel |

References

- Nassiri, P.; Karimi, E.; Monazzam, M.R.; Abbaspour, M.; Taghavi, L. Analytical comparison of traffic noise indices—A case study in District 14 of Tehran City. J. Low Freq. Noise Vib. Act. Control. 2016, 35, 221–229. [Google Scholar] [CrossRef]

- Singh, D.; Kumari, N.; Sharma, P. A Review of Adverse Eeffcts of Road Traffic Noise on Human Health. Fluct. Noise Lett. 2018, 17, 1830001. [Google Scholar] [CrossRef]

- Münzel, T.; Sorensen, M.; Daiber, A. Transportation noise pollution and cardiovascular disease. Nat. Rev. Cardiol. 2021, 18, 619–636. [Google Scholar] [CrossRef]

- Fu, X.R.; Wang, L.K.; Yuan, L.J.; Hu, H.F.; Li, T.Z.; Zhang, J.L.; Ke, Y.M.; Wang, M.M.; Gao, Y.J.; Huo, W.F.; et al. Long-Term Exposure to Traffic Noise and Risk of Incident Cardiovascular Diseases: A Systematic Review and Dose-Response Meta-Analysis. J. Urban Health-Bull. N. Y. Acad. Med. 2023, 100, 788–801. [Google Scholar] [CrossRef] [PubMed]

- Tan, X.; Mu, X.; Gao, P.; Zhao, G.; Sun, W.; Gu, C. Spatiotemporal changes in snow cover over China during 1960–2013. Atmos. Res. 2019, 218, 183–194. [Google Scholar]

- Yin, Y.Y.; Han, S.; Zhu, Y.Q.; Wu, S. Functional durability evaluation of asphalt mixture containing ecologically friendly hydrophobic anti-icing additives. Constr. Build. Mater. 2023, 367, 129781. [Google Scholar] [CrossRef]

- Chen, Z.; Xiong, G.G.; Sun, Y.; Li, Y.; Li, Y. An Internet-of-Things-Enabled System for Road Icing Detection and Prediction. IEEE Internet Things J. 2022, 9, 20257–20269. [Google Scholar] [CrossRef]

- Gao, Y.L.; Qu, L.C.; He, B.; Dai, K.M.; Fang, Z.S.; Zhu, R.J. Study on effectiveness of anti-icing and deicing performance of super-hydrophobic asphalt concrete. Constr. Build. Mater. 2018, 191, 270–280. [Google Scholar] [CrossRef]

- Sun, Z.L.; Chen, J.; Liu, S.; Qian, J.B.; Huang, R. Evaluation of the performance of SBS/CR composite-modified deicing asphalt mixture prepared for ultra-thin wearing course. Constr. Build. Mater. 2024, 416, 135085. [Google Scholar] [CrossRef]

- Cheng, Y.; Yu, D.; Gong, Y.; Zhu, C.; Tao, J.; Wang, W. Laboratory evaluation on performance of eco-friendly basalt fiber and diatomite compound modified asphalt mixture. Materials 2018, 11, 2400. [Google Scholar] [CrossRef]

- Pereira, S.M.; Oliveira, J.R.; Freitas, E.F.; Machado, P. Mechanical performance of asphalt mixtures produced with cork or rubber granulates as aggregate partial substitutes. Constr. Build. Mater. 2013, 41, 209–215. [Google Scholar] [CrossRef]

- Paje, S.E.; Bueno, M.; Terán, F.; Miró, R.; Pérez-Jiménez, F.; Martínez, A.H. Acoustic field evaluation of asphalt mixtures with crumb rubber. Appl. Acoust. 2010, 71, 578–582. [Google Scholar] [CrossRef]

- Wulandari, P.S.; Tjandra, D. The effect of crumb rubber in dense graded and open graded cold mixture asphalt. IOP Conf. Ser. Earth Environ. Sci. 2021, 907, 012008. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Wei, J.T.; Chen, Q.S.; Du, J.Y.; Liu, K.F.; Jiang, K. Study on the Durability of Acid Rain Erosion-Resistant Asphalt Mixtures. Materials 2022, 15, 1849. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.S.; Shen, A.Q.; Cui, H.X.; Dai, X.Q.; Li, Y.; Wang, J.W. Effect of Crumb Rubber Particles on Antisliding and Noise-Reduction Performance of Asphalt Pavement. J. Mater. Civ. Eng. 2023, 35. [Google Scholar] [CrossRef]

- Picado-Santos, L.G.; Capitao, S.D.; Neves, J.M.C. Crumb rubber asphalt mixtures: A literature review. Constr. Build. Mater. 2020, 247, 118577. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.G.; Zhang, L.W. Pavement and Noise Reduction Performance of Open-Graded Asphalt Friction Course Improved by Waste Tire Crumb Rubber. Adv. Civ. Eng. 2021, 2021. [Google Scholar] [CrossRef]

- Wang, T.; Xiao, F.P.; Zhu, X.Y.; Huang, B.S.; Wang, J.G.; Amirkhanian, S. Energy consumption and environmental impact of rubberized asphalt pavement. J. Clean. Prod. 2018, 180, 139–158. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Zhong, K.; Sun, M.Z.; Chang, R.H. Performance evaluation of high-elastic/salt-storage asphalt mixture modified with Mafilon and rubber particles. Constr. Build. Mater. 2018, 193, 153–161. [Google Scholar] [CrossRef]

- Zhu, B.H.; Xing, C.W.; Li, M.C.; Li, H.Z.Y.; Tang, S.X.; Wu, W.J.; Zhou, W.C. Review on Reactive Rejuvenators: Classification, Mechanism, Impact, Challenges, and Opportunities. Energy Fuels 2025, 39, 20165–20185. [Google Scholar] [CrossRef]

- Fini, E.H.; Hosseinnezhad, S.; Oldham, D.; McLaughlin, Z.; Alavi, Z.; Harvey, J. Bio-modification of rubberised asphalt binder to enhance its performance. Int. J. Pavement Eng. 2019, 20, 1216–1225. [Google Scholar] [CrossRef]

- Gandhi, T.; Wurst, T.; Rice, C.; Milar, B. Laboratory and field compaction of warm rubberized mixes. Constr. Build. Mater. 2014, 67, 285–290. [Google Scholar] [CrossRef]

- Tahami, S.A.; Mirhosseini, A.F.; Dessouky, S.; Mork, H.; Kavussi, A. The use of high content of fine crumb rubber in asphalt mixes using dry process. Constr. Build. Mater. 2019, 222, 643–653. [Google Scholar] [CrossRef]

- Bakheit, I.; Huang, X.M. Modification of the dry method for mixing crumb rubber modifier with aggregate and asphalt based on the binder mix design. Constr. Build. Mater. 2019, 220, 278–284. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, I.; Cavalli, M.C.; Poulikakos, L.D.; Bueno, M. Long-Term Aging Behaviour of Asphalt Mixtures Modified with Crumb Rubber Using the Dry Process. In Proceedings of the 5th International Symposium on Asphalt Pavements and Environment (APE), Padova, Italy, 11–13 September 2019; pp. 224–232. [Google Scholar]

- Quan, E.M.; Xu, H.K.; Sun, Z.Y. Composition Optimization and Damping Performance Evaluation of Porous Asphalt Mixture Containing Recycled Crumb Rubber. Sustainability 2022, 14, 2696. [Google Scholar] [CrossRef]

- Farouk, A.I.B.; Hassan, N.A.; Mahmud, M.Z.H.; Mirza, J.; Jaya, R.P.; Hainin, M.R.; Yaacob, H.; Yusoff, N.I.M. Effects of mixture design variables on rubber-bitumen interaction: Properties of dry mixed rubberized asphalt mixture. Mater. Struct. 2017, 50, 12. [Google Scholar] [CrossRef]

- Bueno, M.; Haag, R.; Heeb, N.; Mikhailenko, P.; Boesiger, L.; Poulikakos, L.D. Functional and environmental performance of plant-produced crumb rubber asphalt mixtures using the dry process. Mater. Struct. 2021, 54, 194. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Wu, G.; Zhou, J.; Easa, S. Proposed Compaction Procedure for Dry Process Crumb Rubber Modified Asphalt Mixtures Using Air Void Content and Expansion Ratio. J. Test. Eval. 2014, 42, 328–338. [Google Scholar] [CrossRef]

- Yu, M.; Wu, G.X.; Liu, W.; Wang, X.Y.; Zhang, L. The shaping process research on crumb rubber modified asphalt mixture. In Proceedings of the 2nd International Conference on Civil Engineering, Architecture and Building Materials (CEABM 2012), Yantai, China, 25–27 May 2012; pp. 1568–1572. [Google Scholar]

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- JTG 3432-2024; Test Methods of Aggregates for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2024.

- GB/T 19208-2020; Ground Vulcanized Rubber. State Administration for Market Regulation & National Standardization Administration: Beijing, China, 2020.

- GB/T 6343-2009; Cellular Plastics and Rubbers-Determination of Apparent Density. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China & National Standardization Administration: Beijing, China, 2009.

- JT/T 797-2019; Ground Vulcanized Rubber of Scrap Tires for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2019.

- ASTM D297; Standard Test Methods for Rubber Products—Chemical Analysis. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2022.

- ASTM D4791; Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2023.

- ASTM D2240; Standard Test Method for Rubber Property—Durometer Hardness. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2021.

- Li, H. Researches on Noise Reduction Performance of Skeleton Dense Structure Asphalt Mixture with Crumb Rubber; Inner Mongolia Agricultural University: Hohhot, China, 2010. [Google Scholar]

- Jacinta, O.N.; Dominic, O.O.; Chizoo, E. Activated Rice Husk as a Heterogeneous Catalyst Over Optimised Waste Cooking Oil Biodiesel Production. Int. J. Res. Innov. Appl. Sci. 2024, 9, 53–64. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Shi, Y.; Tong, Z.; Ren, Q.; Li, Z.; Wang, J. Modification of the Crumb Rubber Asphalt by Eucommia Ulmoides Gum under a High-Temperature Mixing Process. Coatings 2024, 14, 1059. [Google Scholar] [CrossRef]

- Liang, M.; Qiu, Z.; Luan, X.; Qi, C.; Guo, N.; Liu, Z.; Su, L.; Yao, Z.; Zhang, J. The effects of activation treatments for crumb rubber on the compatibility and mechanical performance of modified asphalt binder and mixture by the dry method. Front. Mater. 2022, 9, 845718. [Google Scholar] [CrossRef]

- Ban, I.; Barišić, I.; Cuculić, M.; Zvonarić, M. Performance Evaluation of Waste Rubber-Modified Asphalt Mixtures: A Comparative Study of Asphalt Concrete and Stone Mastic Asphalt Gradings. Infrastructures 2025, 10, 107. [Google Scholar] [CrossRef]

- Li, H.; Cui, C.; Temitope, A.A.; Feng, Z.; Zhao, G.; Guo, P. Effect of SBS and crumb rubber on asphalt modification: A review of the properties and practical application. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 836–863. [Google Scholar] [CrossRef]

- Balık, G.; Yılmaz, M.; Kök, B.V.; Alataş, T. Effects of mixing temperature on the mechanical properties of hot mix asphalt. Teknik Dergi 2019, 30, 9221–9241. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, M.; Li, Y.; Zou, Y.; Chen, A.; Wang, F.; Liu, L.; Gu, D.; Zhou, S. Swelled mechanism of crumb rubber and technical properties of crumb rubber modified bitumen. Materials 2022, 15, 7987. [Google Scholar] [CrossRef] [PubMed]

- Bilema, M.; Yuen, C.W.; Alharthai, M.; Al-Saffar, Z.H.; Al-Sabaeei, A.; Yusoff, N.I.M. A review of rubberised asphalt for flexible pavement applications: Production, content, performance, motivations and future directions. Sustainability 2023, 15, 14481. [Google Scholar] [CrossRef]

| Test Properties | Requirements | Test Results | Test Method |

|---|---|---|---|

| Penetration (25 °C, 0.1 mm) | 60~80 | 68 | JTG F40-T0604 [33] |

| Softening point (°C) | >55 | 84 | JTG F40-T0606 |

| Ductility (5 °C, cm) | >30 | 40.7 | JTG F40-T0605 |

| Flash point (°C) | >230 | 292 | JTG F40-T0611 |

| Density (15 °C, g·cm−3) | Measured | 0.925 | JTG F40-T0603 |

| After RTFOT | |||

| Mass change (%) | ±1.0 | −0.208 | JTG F40-T0610 |

| Penetration ratio (%) | >61 | 66 | JTG F40-T0604 |

| Ductility (5 °C, cm) | >20 | 31 | JTG F40-T0605 |

| Test Properties | Requirements | Test Results | Test Method | |

|---|---|---|---|---|

| Aggregate crushing value (%) | ≤26 | 12.3 | JTG 3432-T0316 [34] | |

| Los Angeles abrasion loss (%) | ≤28 | 11.8 | JTG 3432-T0317 | |

| Soundness (%) | ≤12 | 7.1 | JTG 3432-T0314 | |

| Flat and elongated particle content (%) | ≤15 | 7.4 | JTG 3432-T0312 | |

| Adhesion with asphalt | ≥Level 5 | Level 5 | JTG 3432-T0616 | |

| Water washing method ≮ 0.075 Particle content (%) | ≤0.8 | 0.3 | JTG 3432-T0310 | |

| Apparent specific gravity (g·cm−3) | 19~26.5 mm | ≥2.6 | 2.82 | JTG 3432-T0304 |

| 16~19 mm | 2.78 | |||

| 13.2~16 mm | 2.79 | |||

| 9.5~13.2 mm | 2.66 | |||

| 4.75~9.5 mm | 2.80 | |||

| Test Properties | Requirements | Test Results | Test Method |

|---|---|---|---|

| Apparent specific gravity (g·cm−3) | ≥2.5 | 2.63 | JTG 3432-T0328 |

| Soundness (%) | ≥12 | 14.2 | JTG 3432-T0340 |

| Mud content (%) | ≤15 | 8.4 | JTG 3432-T0333 |

| Sand equivalent value (%) | ≥60 | 74 | JTG 3432-T0334 |

| Sieve Size (mm) | Percent Passing (%) | Test Method |

|---|---|---|

| >4.75 | 0 | JTG 3432-T0307 |

| 2.36~4.75 | 66.9 | |

| 1.18~2.36 | 30 |

| Test Properties | Test Results | Test Method |

|---|---|---|

| Water content (%) | 0.16 | GB/T 19208-6.1.1 [35] |

| Apparent specific gravity (g·cm−3) | 1.43 | GB/T 6343 [36] |

| Fiber and impurity content (%) | 0.34 | JT/T 797-6.2.3 [37] |

| Rubber hydrocarbon content (%) | 22 | ASTM D297 [38] |

| Flat and elongated particles content (%) | 15 | ASTM D4791 [39] |

| Shore A hardness (%) | 67 | ASTM D2240 [40] |

| Test Properties | Requirements | Test Results | Test Method |

|---|---|---|---|

| Apparent specific gravity (g·cm−3) | >2.5 | 2.54 | JTG 3432-T0352 |

| Water content (%) | <1 | 0.6 | JTG 3432-T0103 |

| Appearance | No granular agglomeration observed | No granular agglomeration observed | - |

| Hydrophilic coefficient | <1 | 0.5 | JTG 3432-T0353 |

| Sieve Size (mm) | 26.5 | 19 | 16.0 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Percent passing by volume (%) | 100 | 96.4 | 78.8 | 69.1 | 48.4 | 24.7 | 17.7 | 14.4 | 11.7 | 9.7 | 8.8 | 8.6 |

| Test Number | Compaction Method | Compaction Temperature | Compaction Times | ||

|---|---|---|---|---|---|

| The First-Stage Compaction (°C) | The Second-Stage Compaction (°C) | The First-Stage Compaction (Time) | The Second-Stage Compaction (Time) | ||

| JS-1 | Single compaction | 170 | n/a | 60 | n/a |

| JS-2 | 65 | ||||

| JS-3 | 70 | ||||

| JS-4 | 75 | ||||

| JS-5 | Secondary compaction | 170 | 80 | 40 | 20 |

| JS-6 | 43 | 22 | |||

| JS-7 | 47 | 23 | |||

| JS-8 | 50 | 25 | |||

| JS-9 | Compaction after high-temperature curing | 170 | n/a | 60 | n/a |

| JS-10 | 65 | ||||

| JS-11 | 70 | ||||

| JS-12 | 75 | ||||

| Factors | Symbol | Levels | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| Mixing process | A | Sequence Ⅰ | Sequence Ⅱ | Sequence Ⅲ | Sequence Ⅳ | Sequence Ⅴ |

| Mixing time after adding crumb rubber (s) | B | 20 | 30 | 40 | 50 | 60 |

| Mixing time after adding asphalt (s) | C | 50 | 60 | 70 | 80 | 90 |

| Mixing temperature (°C) | D | 150 | 160 | 170 | 180 | 190 |

| Compaction temperature (°C) | E | 140 | 150 | 160 | 170 | 180 |

| Test Number | Mixing Process | Mixing Time After Adding Crumb Rubber (s) | Mixing Temperature (°C) | Compaction Temperature (°C) | Mixing Time After Adding Asphalt (s) |

|---|---|---|---|---|---|

| BH-1 | Ⅰ | 20 | 150 | 140 | 50 |

| BH-2 | Ⅰ | 30 | 170 | 170 | 60 |

| BH-3 | Ⅰ | 40 | 190 | 150 | 70 |

| BH-4 | Ⅰ | 50 | 160 | 180 | 80 |

| BH-5 | Ⅰ | 60 | 180 | 160 | 90 |

| BH-6 | Ⅱ | 20 | 190 | 170 | 90 |

| BH-7 | Ⅱ | 30 | 160 | 150 | 50 |

| BH-8 | Ⅱ | 40 | 180 | 180 | 60 |

| BH-9 | Ⅱ | 50 | 150 | 160 | 70 |

| BH-10 | Ⅱ | 60 | 170 | 140 | 80 |

| BH-11 | Ⅲ | 20 | 180 | 150 | 80 |

| BH-12 | Ⅲ | 30 | 150 | 180 | 90 |

| BH-13 | Ⅲ | 40 | 170 | 160 | 50 |

| BH-14 | Ⅲ | 50 | 190 | 140 | 60 |

| BH-15 | Ⅲ | 60 | 160 | 170 | 70 |

| BH-16 | Ⅳ | 20 | 170 | 180 | 70 |

| BH-17 | Ⅳ | 30 | 190 | 160 | 80 |

| BH-18 | Ⅳ | 40 | 160 | 140 | 90 |

| BH-19 | Ⅳ | 50 | 180 | 170 | 50 |

| BH-20 | Ⅳ | 60 | 150 | 150 | 60 |

| BH-21 | Ⅴ | 20 | 160 | 160 | 60 |

| BH-22 | Ⅴ | 30 | 180 | 140 | 70 |

| BH-23 | Ⅴ | 40 | 150 | 170 | 80 |

| BH-24 | Ⅴ | 50 | 170 | 150 | 90 |

| BH-25 | Ⅴ | 60 | 190 | 180 | 50 |

| Test Number | Void Ratio (%) | Bulk Density (g·cm−3) | Marshall Stability (kN) | Coefficient of Area–Distance Variation (%) |

|---|---|---|---|---|

| BH-1 | 3.40 | 2.460 | 12.350 | 23.49 |

| BH-2 | 4.84 | 2.425 | 11.508 | 31.33 |

| BH-3 | 4.87 | 2.427 | 11.368 | 36.22 |

| BH-4 | 5.41 | 2.412 | 11.334 | 32.29 |

| BH-5 | 5.07 | 2.422 | 10.826 | 33.15 |

| BH-6 | 5.24 | 2.417 | 11.508 | 33.81 |

| BH-7 | 4.58 | 2.436 | 11.494 | 33.16 |

| BH-8 | 4.62 | 2.433 | 11.398 | 31.72 |

| BH-9 | 4.65 | 2.432 | 11.404 | 32.97 |

| BH-10 | 4.63 | 2.433 | 11.448 | 33.36 |

| BH-11 | 5.50 | 2.410 | 11.000 | 35.05 |

| BH-12 | 4.01 | 2.449 | 11.652 | 26.31 |

| BH-13 | 4.32 | 2.441 | 11.618 | 32.52 |

| BH-14 | 4.24 | 2.443 | 11.456 | 31.40 |

| BH-15 | 4.18 | 2.444 | 11.710 | 31.79 |

| BH-16 | 5.48 | 2.411 | 10.902 | 43.06 |

| BH-17 | 4.32 | 2.441 | 11.334 | 36.13 |

| BH-18 | 3.95 | 2.450 | 11.668 | 29.56 |

| BH-19 | 3.98 | 2.449 | 11.744 | 34.27 |

| BH-20 | 3.88 | 2.452 | 11.816 | 31.51 |

| BH-21 | 4.04 | 2.448 | 11.942 | 25.93 |

| BH-22 | 4.41 | 2.439 | 11.532 | 34.40 |

| BH-23 | 4.23 | 2.443 | 11.448 | 31.32 |

| BH-24 | 4.05 | 2.448 | 11.582 | 30.37 |

| BH-25 | 4.04 | 2.448 | 11.720 | 31.53 |

| Factors | Range(R) | |||

|---|---|---|---|---|

| Void Ratio | Bulk Density | Marshall Stability | Coefficient of Area–Distance Variation | |

| Mixing process | 2.11 | 0.054 | 1.448 | 17.13 |

| Mixing time after adding crumb rubber | 0.83 | 0.024 | 0.318 | 9.82 |

| Mixing time after adding asphalt | 0.92 | 0.023 | 0.32 | 2.95 |

| Mixing temperature | 1.43 | 0.037 | 0.41 | 3.92 |

| Compaction temperature | 1.19 | 0.03 | 0.99 | 1.85 |

| Evaluation Indicators | Priority Order of Impact of Factors |

|---|---|

| Void ratio | A > D > E > C > B |

| Bulk density | A > D > E > B > C |

| Marshall stability | A > E > D > B > C |

| Coefficient of area–distance variation | A > B > C > D > E |

| Evaluation Indicators | Optimal Combination |

|---|---|

| Void ratio | A1B3C4D4E4 |

| Bulk density | A1B3C4D4E4 |

| Marshall stability | A1B3C4D4E4 |

| Coefficient of area–distance variation | A1B3C4D5E4 |

| Factors | Sum of Squared Deviations | df | F | p | Significant |

|---|---|---|---|---|---|

| A | 18.302 | 4 | 9.65 | 0.025 | ** |

| B | 1.897 | 4 | 1.00 | 0.500 | |

| C | 2.535 | 4 | 1.34 | 0.393 | |

| D | 6.927 | 4 | 3.65 | 0.119 | |

| E | 4.711 | 4 | 2.48 | 0.200 | |

| e | 1.897 | 4 | |||

| Factors | Sum of Squared Deviations | df | F | p | Significant |

|---|---|---|---|---|---|

| A | 0.01205 | 4 | 9.444 | 0.0257 | ** |

| B | 0.00128 | 4 | 1.000 | 0.5000 | |

| C | 0.00160 | 4 | 1.257 | 0.4150 | |

| D | 0.00475 | 4 | 4.187 | 0.0972 | * |

| E | 0.00298 | 4 | 2.339 | 0.2154 | |

| e | 0.00128 | 4 | |||

| Factors | Sum of Squared Deviations | df | F | p | Significant |

|---|---|---|---|---|---|

| A | 1.517 | 4 | 22.465 | 0.0053 | *** |

| B | 0.068 | 4 | 1.000 | 0.5000 | |

| C | 0.073 | 4 | 1.076 | 0.4725 | |

| D | 0.105 | 4 | 1.553 | 0.3401 | |

| E | 0.649 | 4 | 9.612 | 0.0250 | ** |

| e | 0.068 | 4 | |||

| Factors | Sum of Squared Deviations | df | F | p | Significant |

|---|---|---|---|---|---|

| A | 243.796 | 4 | 73.479 | 0.001 | *** |

| B | 56.60 | 4 | 17.068 | 0.009 | *** |

| C | 24.16 | 4 | 7.298 | 0.040 | ** |

| D | 8.94 | 4 | 2.669 | 0.182 | |

| E | 3.11 | 4 | 1.000 | 0.500 | |

| e | 3.11 | 4 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Lu, Y.; Kong, L.; Yan, W.; Li, Y.; Zheng, M.; Lu, C.; Qu, G. Research on Mixing Uniformity Evaluation and Molding Method for Crumb Rubber Asphalt Mixtures. Materials 2025, 18, 5245. https://doi.org/10.3390/ma18225245

Wang W, Lu Y, Kong L, Yan W, Li Y, Zheng M, Lu C, Qu G. Research on Mixing Uniformity Evaluation and Molding Method for Crumb Rubber Asphalt Mixtures. Materials. 2025; 18(22):5245. https://doi.org/10.3390/ma18225245

Chicago/Turabian StyleWang, Wenhua, Yi Lu, Lingdi Kong, Wenke Yan, Yilong Li, Mulian Zheng, Chuan Lu, and Guanglei Qu. 2025. "Research on Mixing Uniformity Evaluation and Molding Method for Crumb Rubber Asphalt Mixtures" Materials 18, no. 22: 5245. https://doi.org/10.3390/ma18225245

APA StyleWang, W., Lu, Y., Kong, L., Yan, W., Li, Y., Zheng, M., Lu, C., & Qu, G. (2025). Research on Mixing Uniformity Evaluation and Molding Method for Crumb Rubber Asphalt Mixtures. Materials, 18(22), 5245. https://doi.org/10.3390/ma18225245