Development of an Ergonomic Additively Manufactured Modular Saddle for Rehabilitation Cycling

Abstract

1. Introduction

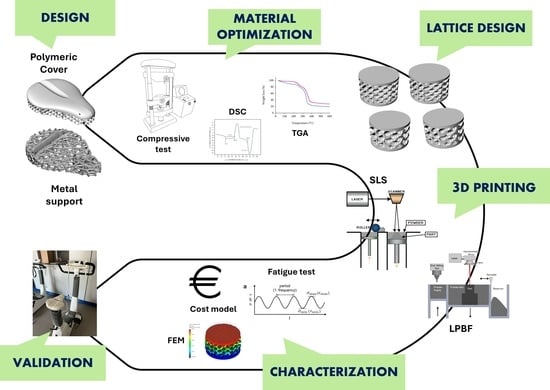

2. Materials and Methods

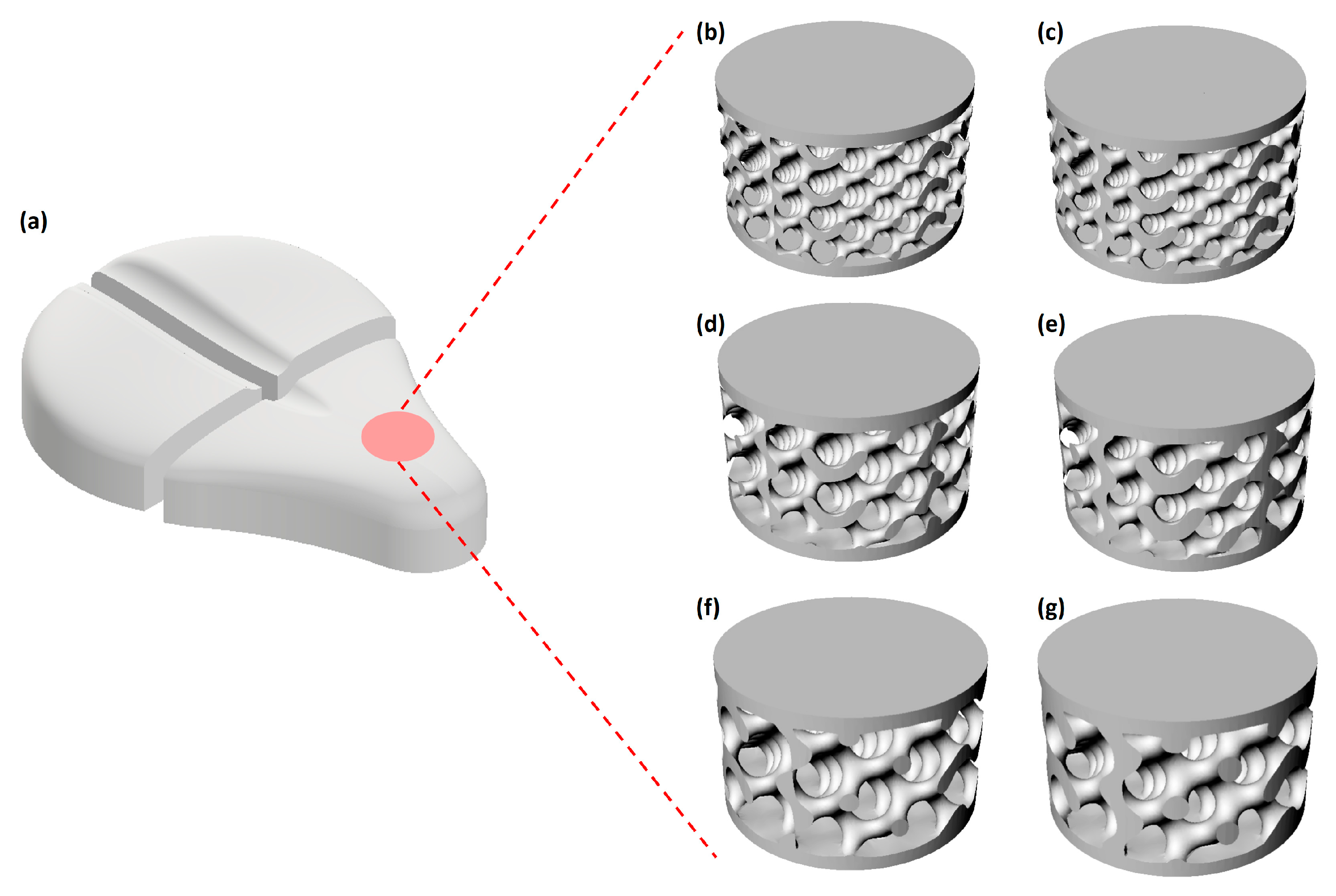

2.1. Design Process

2.2. Metallic Support: Design and Fabrication

2.3. Polymeric Covering Design and Material Selection

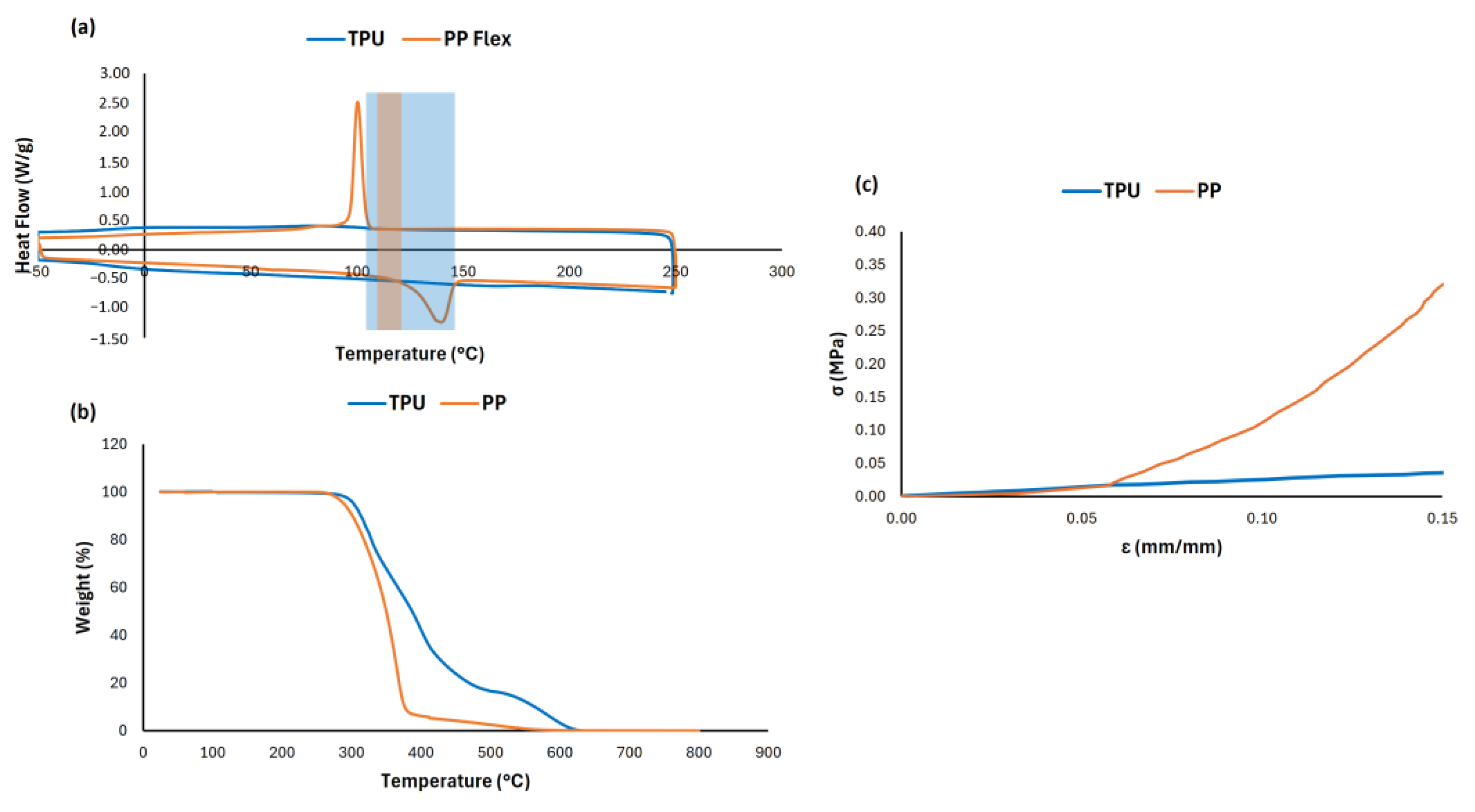

2.4. Preliminary Thermal and Mechanical Analysis

2.5. Three-Dimensional Printing of the Saddle

2.6. Saddle Characterization

2.6.1. Density Measurement

2.6.2. Mechanical Testing

2.6.3. FEM Simulation and Validation

2.6.4. Cost Model

3. Results

3.1. Thermal and Mechanical Preliminary Results

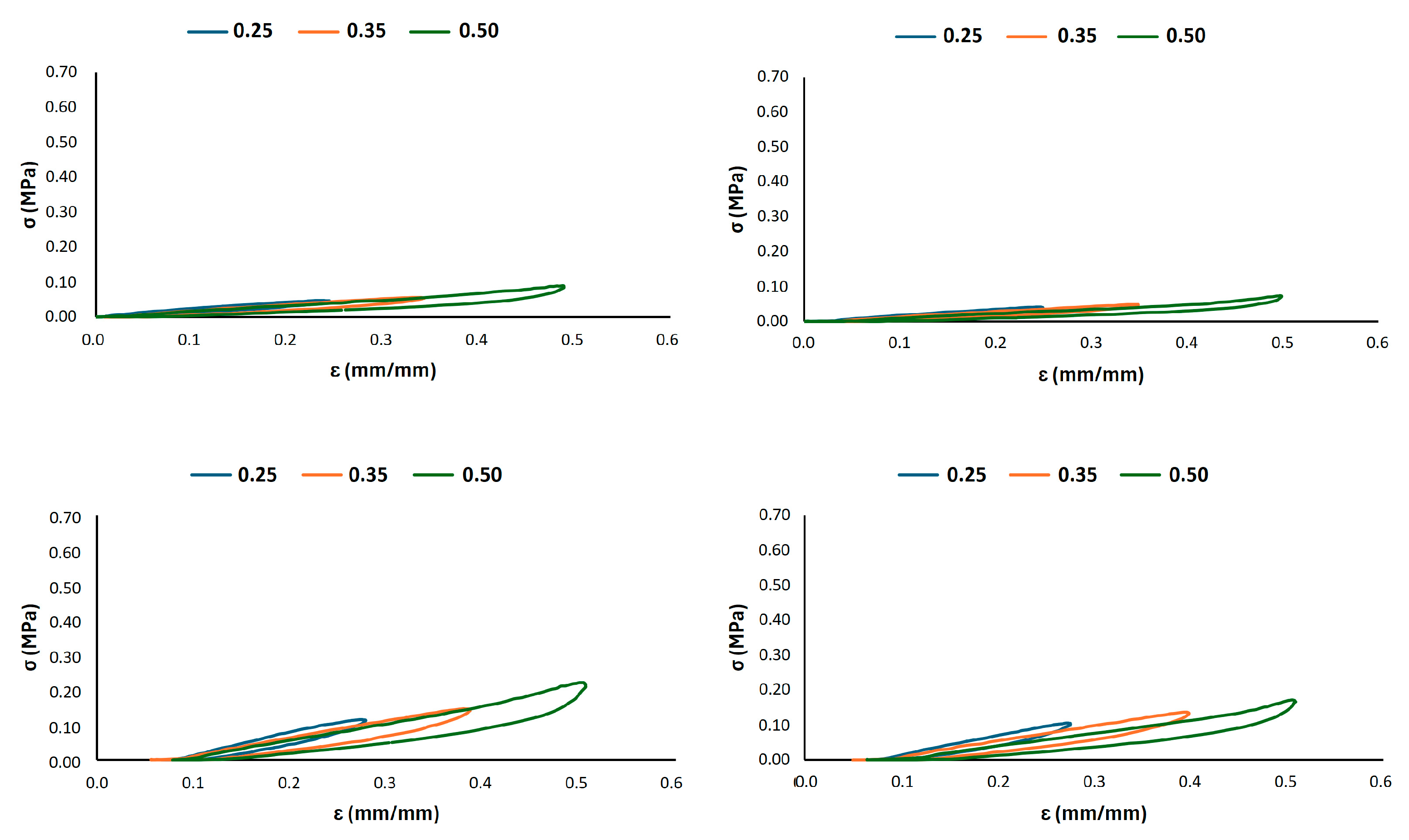

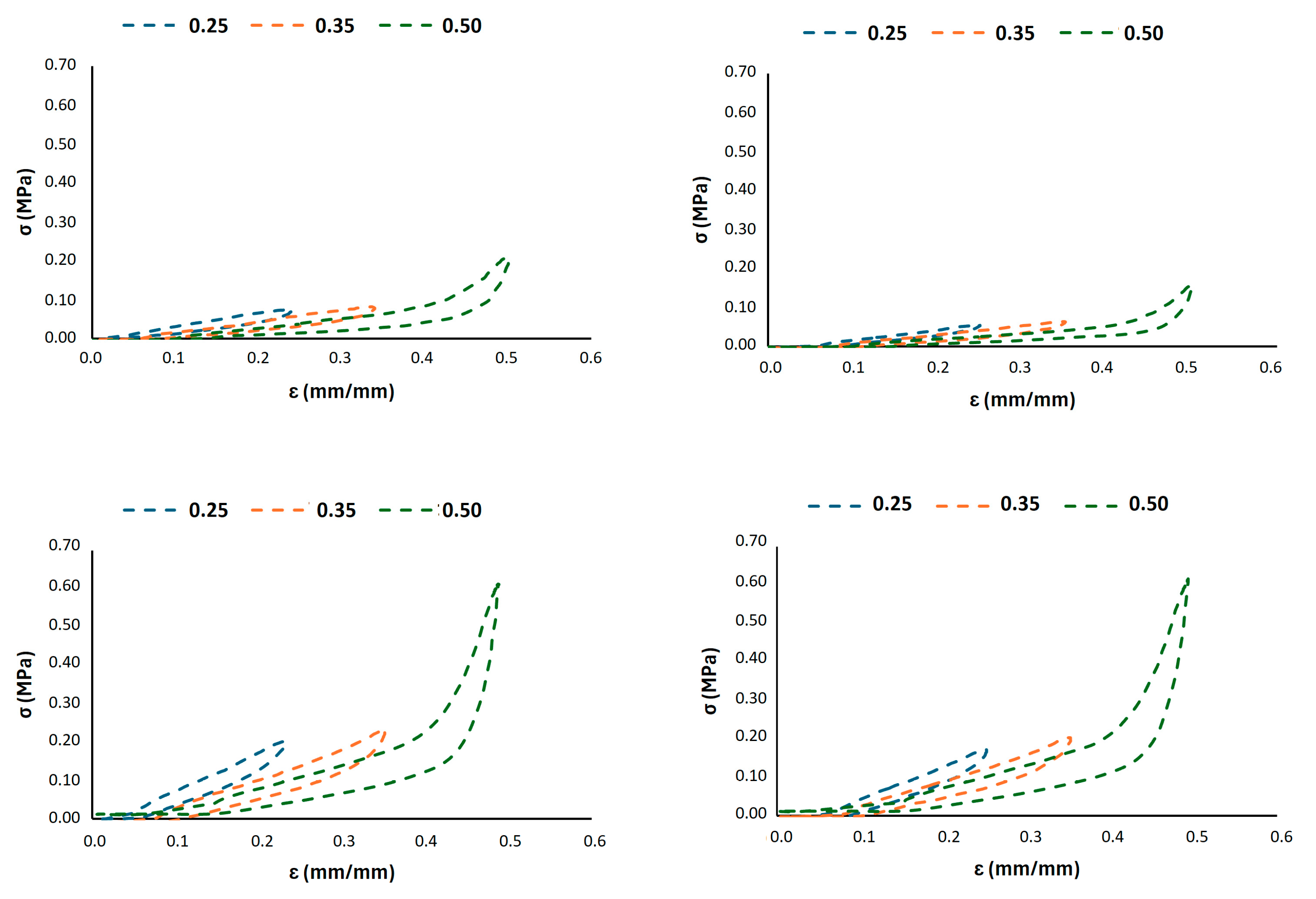

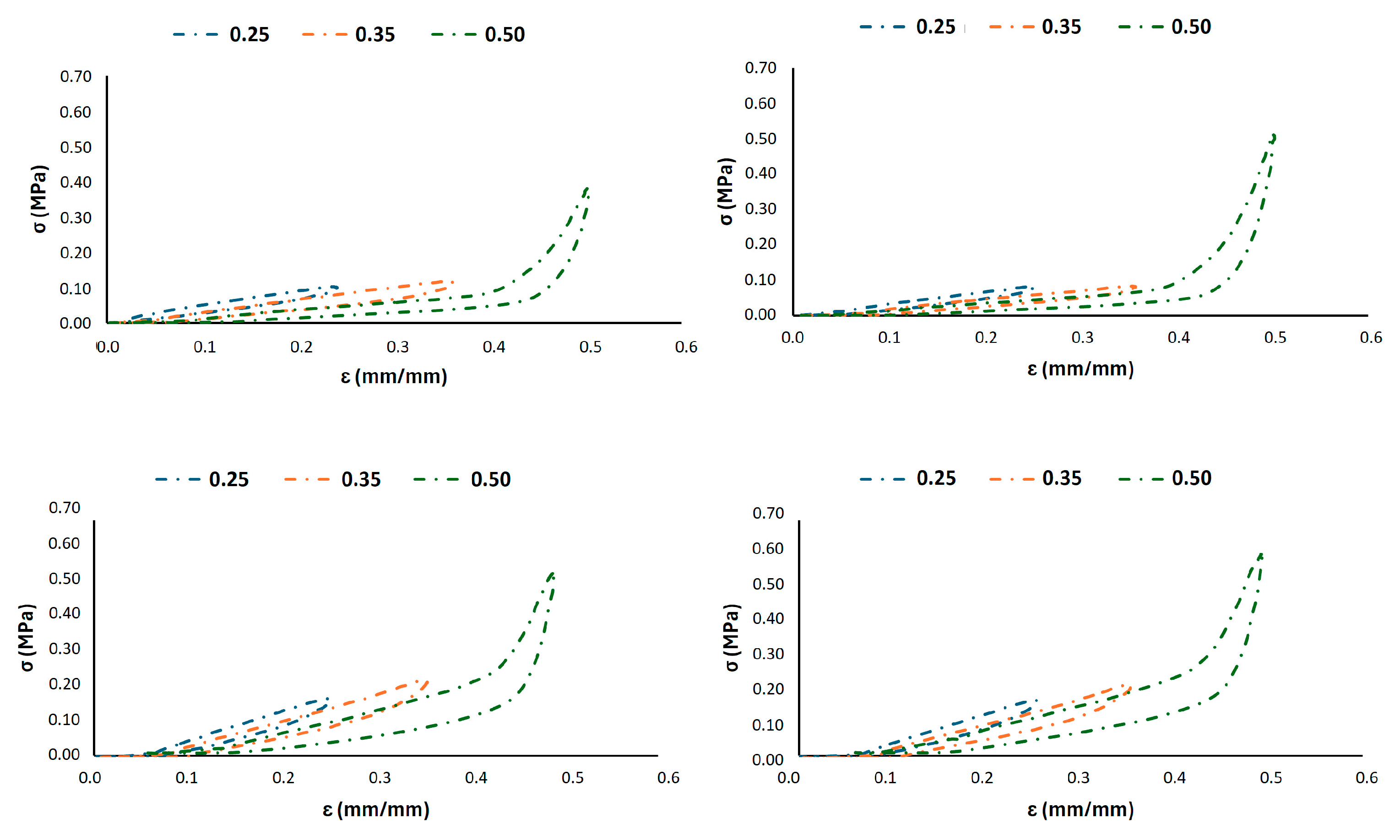

3.2. Porosity Analysis and Fatigue Resistance

- Infill percentage (wall thickness) is the primary driver for fatigue stability. The 0.3 mm wall thickness consistently outperformed the 0.2 across all cell sizes, showing minimal stress decay and superior structural integrity under cyclic deformation.

- Cell size modulates stiffness and stress distribution. Larger cell sizes (10 mm) enhance compliance and reduce stress concentrations, leading to improved fatigue life. Smaller cells (6 mm) increase stiffness but are more susceptible to stress localization and damage accumulation if not coupled with sufficient density.

- G8_0.3 offers an optimal balance. It combines adequate compliance (for comfort) with exceptional fatigue resistance and energy dissipation, as evidenced by its stable hysteretic response and low permanent deformation. This configuration effectively mitigates cyclic softening while maintaining the elastic recovery necessary for long-term use in rehabilitation cycling.

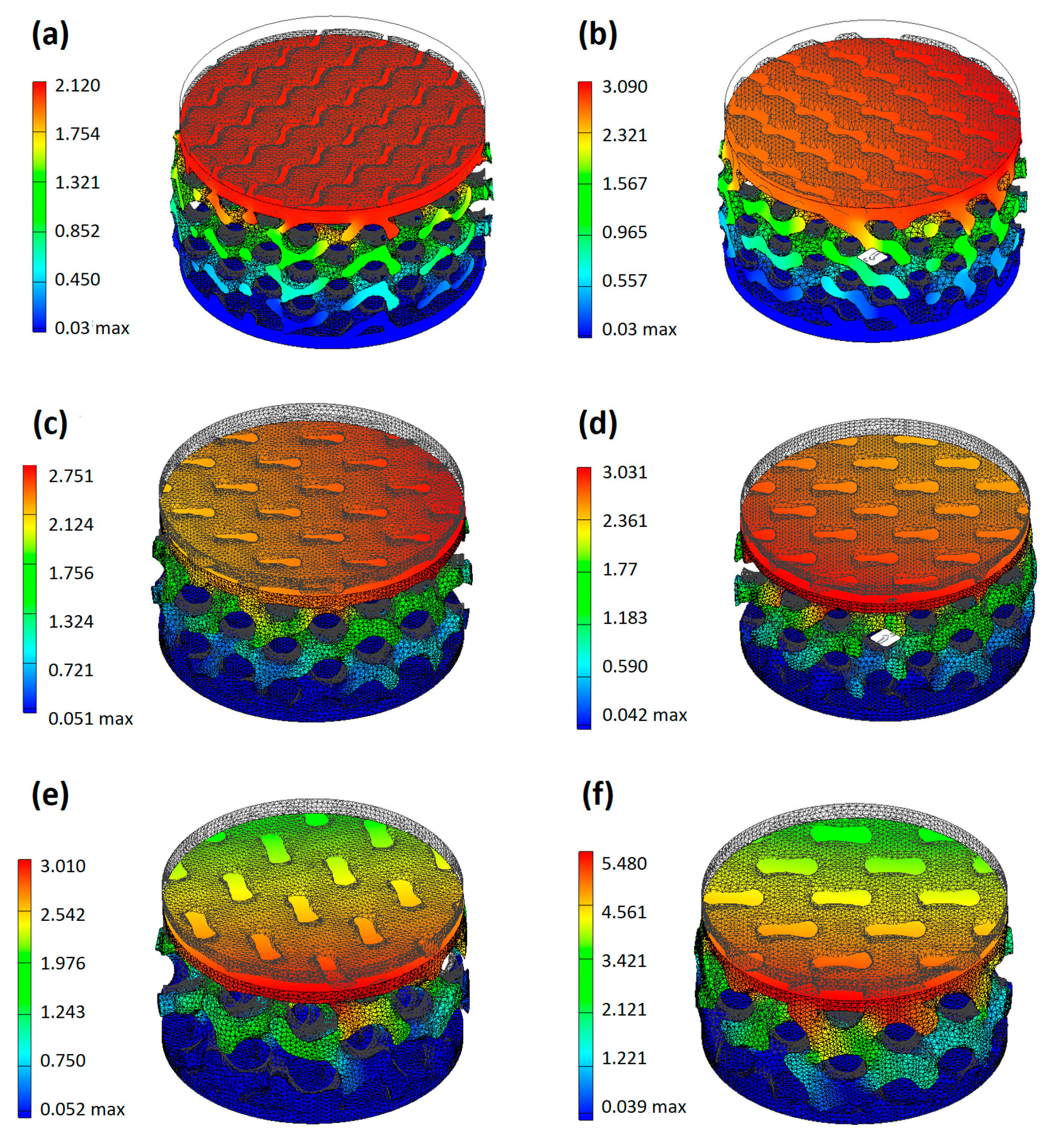

3.3. FEM Simulation and Mechanical Test Validation

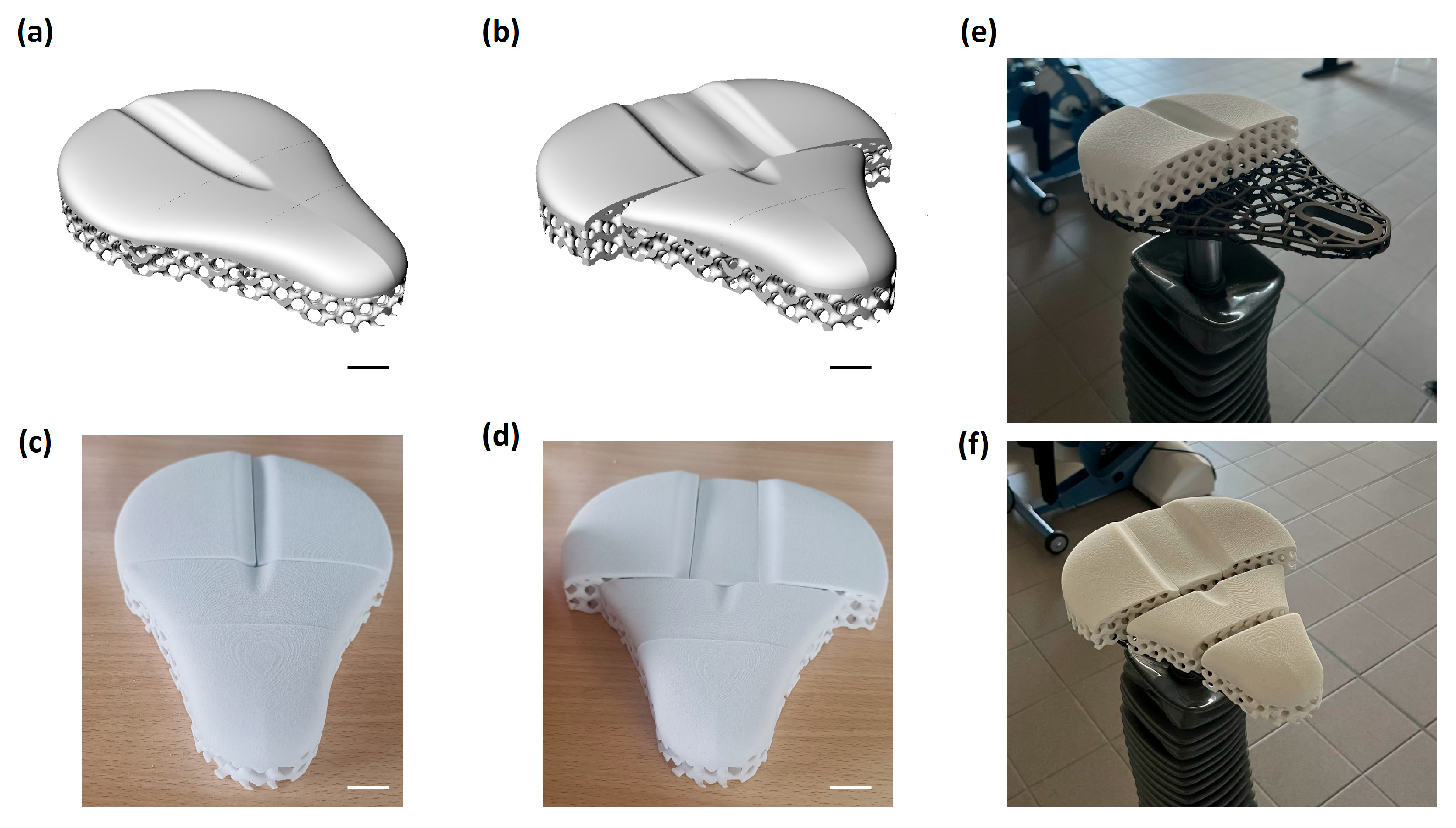

3.4. Modular Saddle 3D Printing and Cost Model

4. Discussions

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AISI | American Iron and Steel Institute |

| AM | Additive Manufacturing |

| ASME | American Society of Mechanical Engineers |

| ASTM | American Society for Testing and Materials |

| CAD | Computer-Aided Design |

| DSC | Differential Scanning Calorimetry |

| FDM | Fused Deposition Modeling |

| FEA | Finite Element Analysis |

| FEM | Finite Element Method |

| LPBF | Laser Powder Bed Fusion |

| MEX | Material Extrusion |

| MJF | Multi Jet Fusion |

| PBF | Powder Bed Fusion |

| PP | Polypropylene |

| SD | Standard deviation |

| SLS | Selective Laser Sintering |

| STL | Standard Tessellation Language (file format) |

| TGA | Thermogravimetric Analysis |

| TPU | Thermoplastic Polyurethane |

| VPP | Vat Photopolymerization |

References

- Attaran, M. The Rise of 3-D Printing: The Advantages of Additive Manufacturing over Traditional Manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Wohlers, T.; Campbell, R.I.; Diegel, O.; Huff, R.; Kowen, J. Wohlers Report 2023: 3D Printing and Additive Manufacturing: Global State of the Industry; Newton, R., Van Rensburg, J., Scott, C., ASTM International, Eds.; Wohlers Associates: Fort Collins, CO, USA, 2023; ISBN 978-1-62204-966-0. [Google Scholar]

- Boschetto, A.; Bottini, L.; Macera, L.; Vatanparast, S. Additive Manufacturing for Lightweighting Satellite Platform. Appl. Sci. 2023, 13, 2809. [Google Scholar] [CrossRef]

- Arena, M.; Ambrogiani, P.; Raiola, V.; Bocchetto, F.; Tirelli, T.; Castaldo, M. Design and Qualification of an Additively Manufactured Manifold for Aircraft Landing Gears Applications. Aerospace 2023, 10, 69. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive Manufacturing Methods and Modelling Approaches: A Critical Review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser Sintering of Polyamides and Other Polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Ronca, A.; Abbate, V.; Redaelli, D.F.; Storm, F.A.; Cesaro, G.; De Capitani, C.; Sorrentino, A.; Colombo, G.; Fraschini, P.; Ambrosio, L. A Comparative Study for Material Selection in 3D Printing of Scoliosis Back Brace. Materials 2022, 15, 5724. [Google Scholar] [CrossRef]

- Kim, S.; Tang, Y.; Park, S.; Rosen, D.W. A Systematic Design Method for Additive Manufacturing: Reconceptualizing Product Architecture. J. Mech. Sci. Technol. 2024, 38, 4545–4555. [Google Scholar] [CrossRef]

- Kermavnar, T.; Shannon, A.; O’Sullivan, L.W. The Application of Additive Manufacturing/3D Printing in Ergonomic Aspects of Product Design: A Systematic Review. Appl. Ergon. 2021, 97, 103528. [Google Scholar] [CrossRef]

- Xu, J.; Tu, Z.; Zhang, S.; Tan, J.; Wang, G. Customized Design for Ergonomic Products via Additive Manufacturing Considering Joint Biomechanics. Chin. J. Mech. Eng. Addit. Manuf. Front. 2023, 2, 100085. [Google Scholar] [CrossRef]

- Gibson, L.J. Cellular Solids. MRS Bull. 2003, 28, 270–274. [Google Scholar] [CrossRef]

- Pan, C.; Han, Y.; Lu, J. Design and Optimization of Lattice Structures: A Review. Appl. Sci. 2020, 10, 6374. [Google Scholar] [CrossRef]

- Georges, H.; García Solera, D.; Aguilar Borasteros, C.; Metar, M.; Song, G.; Mandava, R.; Becker, W.; Mittelstedt, C. Mechanical Performance Comparison of Sandwich Panels with Graded Lattice and Honeycomb Cores. Biomimetics 2024, 9, 96. [Google Scholar] [CrossRef]

- Chen, W.; Chen, C.; Zhang, Y.; Li, P.; Li, M.; Li, X. Study on the Deformation Mode and Energy Absorption Characteristics of Protective Honeycomb Sandwich Structures Based on the Combined Design of Lotus Root Nodes and Leaf Stem Veins. J. Mar. Sci. Eng. 2024, 12, 652. [Google Scholar] [CrossRef]

- Alknery, Z.; Sktani, Z.D.I.; Arab, A. Effect of Cell Geometry on the Mechanical Properties of 3D Voronoi Tessellation. J. Funct. Biomater. 2022, 13, 302. [Google Scholar] [CrossRef]

- Kedziora, S.; Decker, T.; Museyibov, E. Application of Functionally Graded Shell Lattice as Infill in Additive Manufacturing. Materials 2023, 16, 4401. [Google Scholar] [CrossRef]

- Geyer, S.; Schwemmer, J.; Hölzl, C. Development and Evaluation of Customized Bike Saddle Pads Using Innovative Design for AM Approaches and Suitable Additive Manufacturing Processes. Appl. Sci. 2025, 15, 472. [Google Scholar] [CrossRef]

- Yum, H.; Kim, H.; Lee, T.; Park, M.S.; Lee, S.Y. Cycling Kinematics in Healthy Adults for Musculoskeletal Rehabilitation Guidance. BMC Musculoskelet. Disord. 2021, 22, 1044. [Google Scholar] [CrossRef]

- Visentini, P.J.; McDowell, A.H.; Pizzari, T. Factors Associated with Overuse Injury in Cyclists: A Systematic Review. J. Sci. Med. Sport 2022, 25, 391–398. [Google Scholar] [CrossRef]

- AdornThemes Joyseat. Available online: https://posedla.com/products/joyseat (accessed on 29 September 2025).

- Custom Bike Seats. Infinity Bike Seat 2024. Available online: https://infinitybikeseat.com/shop/custom-seat (accessed on 29 September 2025).

- Custom Saddles Are the Best Comfort Upgrade I Made to My Road and Gravel Bikes—Will One Improve Your Rides? Available online: https://www.bicycling.com/bikes-gear/a64817765/custom-bike-seat-test/ (accessed on 29 September 2025).

- Fiocchi, J.; Bregoli, C.; Gerosa, G.; Tuissi, A.; Biffi, C.A. Tuning of Static and Dynamic Mechanical Response of Laser Powder Bed Fused AlSi10Mg Lattice Structures through Heat Treatments. Adv. Eng. Mater. 2021, 23, 2100418. [Google Scholar] [CrossRef]

- Chang, C.; Wu, W.; Zhang, H.; Chen, J.; Xu, Y.; Lin, J.; Ding, L. Mechanical Characteristics of Superimposed 316L Lattice Structures under Static and Dynamic Loading. Adv. Eng. Mater. 2021, 23, 2001536. [Google Scholar] [CrossRef]

- Fiocchi, J.; Biffi, C.A.; Scaccabarozzi, D.; Saggin, B.; Tuissi, A. Enhancement of the Damping Behavior of Ti6 Al4 V Alloy through the Use of Trabecular Structure Produced by Selective Laser Melting. Adv. Eng. Mater. 2020, 22, 1900722. [Google Scholar] [CrossRef]

- Lin, Z.-J.; Wang, H.-H.; Chen, C.-H. The Effect of Bicycle Saddle Widths on Saddle Pressure in Female Cyclists. J. Sports Sci. Med. 2023, 22, 425–430. [Google Scholar] [CrossRef]

- Potter, J.J.; Sauer, J.L.; Weisshaar, C.L.; Thelen, D.G.; Ploeg, H.-L. Gender Differences in Bicycle Saddle Pressure Distribution during Seated Cycling. Med. Sci. Sports Exerc. 2008, 40, 1126–1134. [Google Scholar] [CrossRef] [PubMed]

- Spears, I.R.; Cummins, N.K.; Brenchley, Z.; Donohue, C.; Turnbull, C.; Burton, S.; Macho, G.A. The Effect of Saddle Design on Stresses in the Perineum during Cycling. Med. Sci. Sports Exerc. 2003, 35, 1620–1625. [Google Scholar] [CrossRef]

- Lowe, B.D.; Schrader, S.M.; Breitenstein, M.J. Effect of Bicycle Saddle Designs on the Pressure to the Perineum of the Bicyclist. Med. Sci. Sports Exerc. 2004, 36, 1055–1062. [Google Scholar] [CrossRef]

- Yang, L.; Mertens, R.; Ferrucci, M.; Yan, C.; Shi, Y.; Yang, S. Continuous Graded Gyroid Cellular Structures Fabricated by Selective Laser Melting: Design, Manufacturing and Mechanical Properties. Mater. Des. 2019, 162, 394–404. [Google Scholar] [CrossRef]

- Lu, C.; Zhang, Y.; Aziz, M.; Wen, P.; Zhang, C.; Shen, Q.; Chen, F. Mechanical Behaviors of Multidimensional Gradient Gyroid Structures under Static and Dynamic Loading: A Numerical and Experimental Study. Addit. Manuf. 2022, 59, 103187. [Google Scholar] [CrossRef]

- Holmes, D.W.; Singh, D.; Lamont, R.; Daley, R.; Forrestal, D.P.; Slattery, P.; Pickering, E.; Paxton, N.C.; Powell, S.K.; Woodruff, M.A. Mechanical Behaviour of Flexible 3D Printed Gyroid Structures as a Tuneable Replacement for Soft Padding Foam. Addit. Manuf. 2022, 50, 102555. [Google Scholar] [CrossRef]

- Li, D.; Liao, W.; Dai, N.; Xie, Y.M. Comparison of Mechanical Properties and Energy Absorption of Sheet-Based and Strut-Based Gyroid Cellular Structures with Graded Densities. Materials 2019, 12, 2183. [Google Scholar] [CrossRef]

- ASTM D638-08; Test Method for Tensile Properties of Plastics. D20 Committee ASTM International: West Conshohocken, PA, USA, 2010. [CrossRef]

- ASTM D695-23; Test Method for Compressive Properties of Rigid Plastics. D20 Committee ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- ASTM E1131-20; Test Method for Compositional Analysis by Thermogravimetry. E37 Committee ASTM International: West Conshohocken, PA, USA, 2025. [CrossRef]

- Major, Z.; Lackner, M.; Hössinger-Kalteis, A.; Lück, T. Characterization of the Fatigue Behavior of SLS Thermoplastics. Procedia Struct. Integr. 2021, 34, 191–198. [Google Scholar] [CrossRef]

- Redaelli, D.F.; Abbate, V.; Storm, F.A.; Ronca, A.; Sorrentino, A.; De Capitani, C.; Biffi, E.; Ambrosio, L.; Colombo, G.; Fraschini, P. 3D Printing Orthopedic Scoliosis Braces: A Test Comparing FDM with Thermoforming. Int. J. Adv. Manuf. Technol. 2020, 111, 1707–1720. [Google Scholar] [CrossRef]

- Ruffo, M.; Hague, R. Cost Estimation for Rapid Manufacturing—Simultaneous Production of Mixed Components Using Laser Sintering. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 1585–1591. [Google Scholar] [CrossRef]

- Yim, S.; Rosen, D. Build Time and Cost Models for Additive Manufacturing Process Selection. In Proceedings of the ASME Design Engineering Technical Conference, Chicago, IL, USA, 12–15 August 2012. [Google Scholar]

- Dadbakhsh, S.; Verbelen, L.; Vandeputte, T.; Strobbe, D.; Van Puyvelde, P.; Kruth, J.-P. Effect of Powder Size and Shape on the SLS Processability and Mechanical Properties of a TPU Elastomer. Phys. Procedia 2016, 83, 971–980. [Google Scholar] [CrossRef]

- Yeole, S.N.; Kode, J.P.; Maddineni, P.; Bolisetti, L.M.; Vajah, J.B. An Additively Manufactured and Optimized Bicycle Saddle Prototype for Low Weight. In Proceedings of the ASME 2024 International Mechanical Engineering Congress and Exposition, Volume 2: Advanced Manufacturing. Portland, OR, USA, 17–21 November 2024; p. V002T03A012. [Google Scholar]

- Sprigle, S. Research Priorities: Seating and Positioning. Disabil. Rehabil. Assist. Technol. 2007, 2, 181–187. [Google Scholar] [CrossRef]

- Ryan, S.E.; Campbell, K.A.; Rigby, P.J.; Fishbein-Germon, B.; Hubley, D.; Chan, B. The Impact of Adaptive Seating Devices on the Lives of Young Children with Cerebral Palsy and Their Families. Arch. Phys. Med. Rehabil. 2009, 90, 27–33. [Google Scholar] [CrossRef] [PubMed]

- Wendt, O. Assistive Technology: Principles and Applications for Communication Disorders and Special Education; Brill: Leiden, The Netherlands, 2011; ISBN 978-1-78052-295-1. [Google Scholar]

| Parameters | Values |

|---|---|

| Scanning strategy | Meander |

| Laser spot size [µm] | 30 |

| Platform temperature (°C) | 25 |

| Atmosphere | Ar (O2 < 100 ppm) |

| Hatch distance [µm] | 90 |

| Point distance [µm] | 50 |

| Thickness layer [µm] | 50 |

| Power [W] | 200 |

| Scanning time [µs] | 70 |

| Sample | Cell Size (mm) | Wall Thickness (mm) | Theoretical Porosity (%) | Measured Porosity (%) | Δε (%) |

|---|---|---|---|---|---|

| G6_0.2 | 6 | 0.2 | 79.62 | 75.01 ± 2.16 | 11.22 ± 0.48 |

| G6_0.3 | 6 | 0.3 | 69.46 | 66.92 ± 1.29 | 0.95 ± 0.06 |

| G8_0.2 | 8 | 0.2 | 79.69 | 75.06 ± 0.19 | 8.94 ± 0.88 |

| G8_0.3 | 8 | 0.3 | 69.79 | 64.50 ± 0.37 | 0.77 ± 0.05 |

| G10_0.2 | 10 | 0.2 | 79.59 | 76.51 ± 0.27 | 5.12 ± 0.23 |

| G10_0.3 | 10 | 0.3 | 69.52 | 63.00 ± 0.17 | 0.98 ± 0.34 |

| Parameters | TPU | PP |

|---|---|---|

| Laser Power (W) | 6.3 | 2.8 |

| Scan Speed (mm/s) | 2400 | 2400 |

| Scan Spacing (µm) | 100 | 100 |

| Layer Height (µm) | 100 | 100 |

| Atmosphere | Air | Air |

| Powder Bed Temp (°C) | 120 | 135 |

| Sample | E1 (J·m−3) | E10000 (J·m−3) | ΔE (%) | E1 (J) | E10000 (J) |

|---|---|---|---|---|---|

| G6_0.2 | 2.6 ± 0.1 × 103 | 3.1 ± 0.2 × 103 | +23% | 0.064 | 0.079 |

| G6_0.3 | 5.8 ± 0.2 × 102 | 6.1 ± 0.3 × 102 | +4% | 0.015 | 0.015 |

| G8_0.2 | 3.3 ± 0.1 × 103 | 3.0 ± 0.2 × 103 | −11% | 0.084 | 0.074 |

| G8_0.3 | 5.2 ± 0.2 × 102 | 5.1 ± 0.1 × 102 | −1.9% | 0.013 | 0.013 |

| G10_0.2 | 2.0 ± 0.1 × 103 | 2.3 ± 0.4 × 103 | +15% | 0.050 | 0.058 |

| G10_0.3 | 3.5 ± 0.4 × 102 | 3.3 ± 0.3 × 102 | −7.6% | 0.0088 | 0.0082 |

| Sample | Force (N) | FEM Displacement (mm) | Experimental Displacement (mm) | Δ (%) |

|---|---|---|---|---|

| G6_0.2 | 55 | 2.12 | 3.01 ± 0.34 | 29.50 |

| G6_0.3 | 176 | 3.09 | 3.81 ± 0.27 | 22.30 |

| G8_0.2 | 60 | 2.75 | 3.52 ± 0.24 | 21.87 |

| G8_0.3 | 182 | 3.03 | 3.19 ± 0.16 | 5.01 |

| G10_0.2 | 75 | 3.01 | 3.25 ± 0.22 | 7.38 |

| G10_0.3 | 235 | 5.48 | 5.90 ± 0.19 | 7.77 |

| Unit cell length [mm] | 8 | |

| Wall thickness [mm] | 0.2 | 0.3 |

| Build time—Tb [h] | 2.97 | 2.97 |

| Purchase price—Pc [€] | 12,000 | 12,000 |

| Expected life—Ylife [years] | 7 | 7 |

| Machine cost—P [€] | 0.66 | 0.66 |

| Operation rate—Co [€ /h] | 4.75 | 4.75 |

| Operative cost—O [€] | 14.13 | 14.13 |

| Recycling factor (Kr) | 1 | 1 |

| Support material factor—Ks | 1 | 1 |

| Number of parts—N | 1 | 1 |

| Part volume—ν [cm3] | 164.48 | 185.47 |

| Material rate per unit weight—Cm [€/kg] | 51.5 | 51.5 |

| Material density—ρ [g/cm3] | 0.65 | 0.65 |

| Material cost—M [€] | 5.51 | 6.21 |

| Labour time—Tl [h] | 1 | 1 |

| Labour rate—Cl [€/h] | 33 | 33 |

| Labour cost—L [€] | 33.00 | 33.00 |

| Overall Cost—C [€/part] | 52.30 | 53.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iglesias Calcedo, A.; Bregoli, C.; Abbate, V.; Mondellini, M.; Fiocchi, J.; Rollo, G.; De Capitani, C.; Lavorgna, M.; Sacco, M.; Sorrentino, A.; et al. Development of an Ergonomic Additively Manufactured Modular Saddle for Rehabilitation Cycling. Materials 2025, 18, 5242. https://doi.org/10.3390/ma18225242

Iglesias Calcedo A, Bregoli C, Abbate V, Mondellini M, Fiocchi J, Rollo G, De Capitani C, Lavorgna M, Sacco M, Sorrentino A, et al. Development of an Ergonomic Additively Manufactured Modular Saddle for Rehabilitation Cycling. Materials. 2025; 18(22):5242. https://doi.org/10.3390/ma18225242

Chicago/Turabian StyleIglesias Calcedo, Alberto, Chiara Bregoli, Valentina Abbate, Marta Mondellini, Jacopo Fiocchi, Gennaro Rollo, Cristina De Capitani, Marino Lavorgna, Marco Sacco, Andrea Sorrentino, and et al. 2025. "Development of an Ergonomic Additively Manufactured Modular Saddle for Rehabilitation Cycling" Materials 18, no. 22: 5242. https://doi.org/10.3390/ma18225242

APA StyleIglesias Calcedo, A., Bregoli, C., Abbate, V., Mondellini, M., Fiocchi, J., Rollo, G., De Capitani, C., Lavorgna, M., Sacco, M., Sorrentino, A., Tuissi, A., Biffi, C. A., & Ronca, A. (2025). Development of an Ergonomic Additively Manufactured Modular Saddle for Rehabilitation Cycling. Materials, 18(22), 5242. https://doi.org/10.3390/ma18225242