Gamma-Ray and Thermal Neutron Shielding of Fe-Based Bilayer Composites with a Boron-Enriched Matrix and Tungsten Surface Coatings: Lead Benchmarks Included

Abstract

1. Introduction

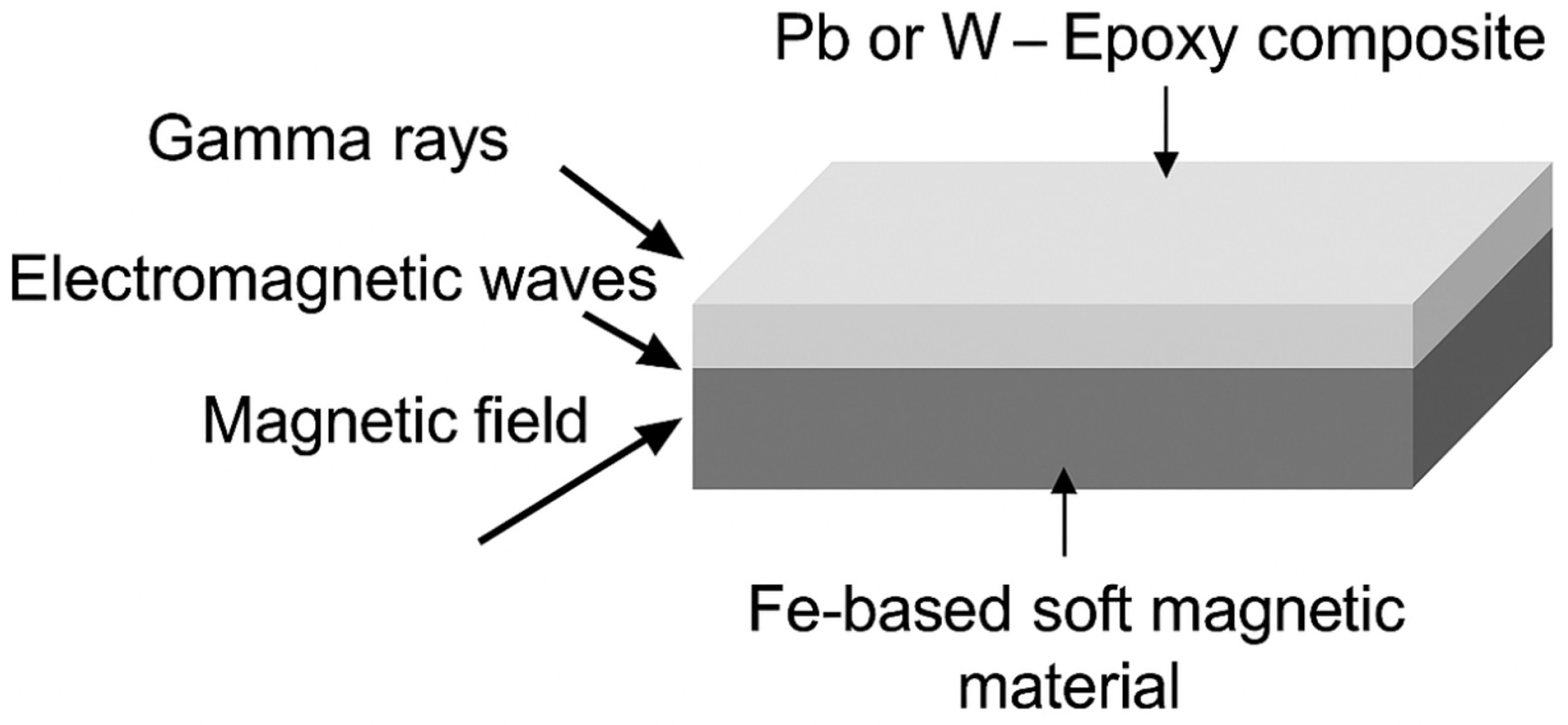

2. Materials and Methods

2.1. Composite Fabrication

2.2. Material Composition and Coating Structure

2.3. Experimental Setup for Gamma-Ray Shielding

2.4. Experimental Setup for Thermal Neutron Shielding

3. Results

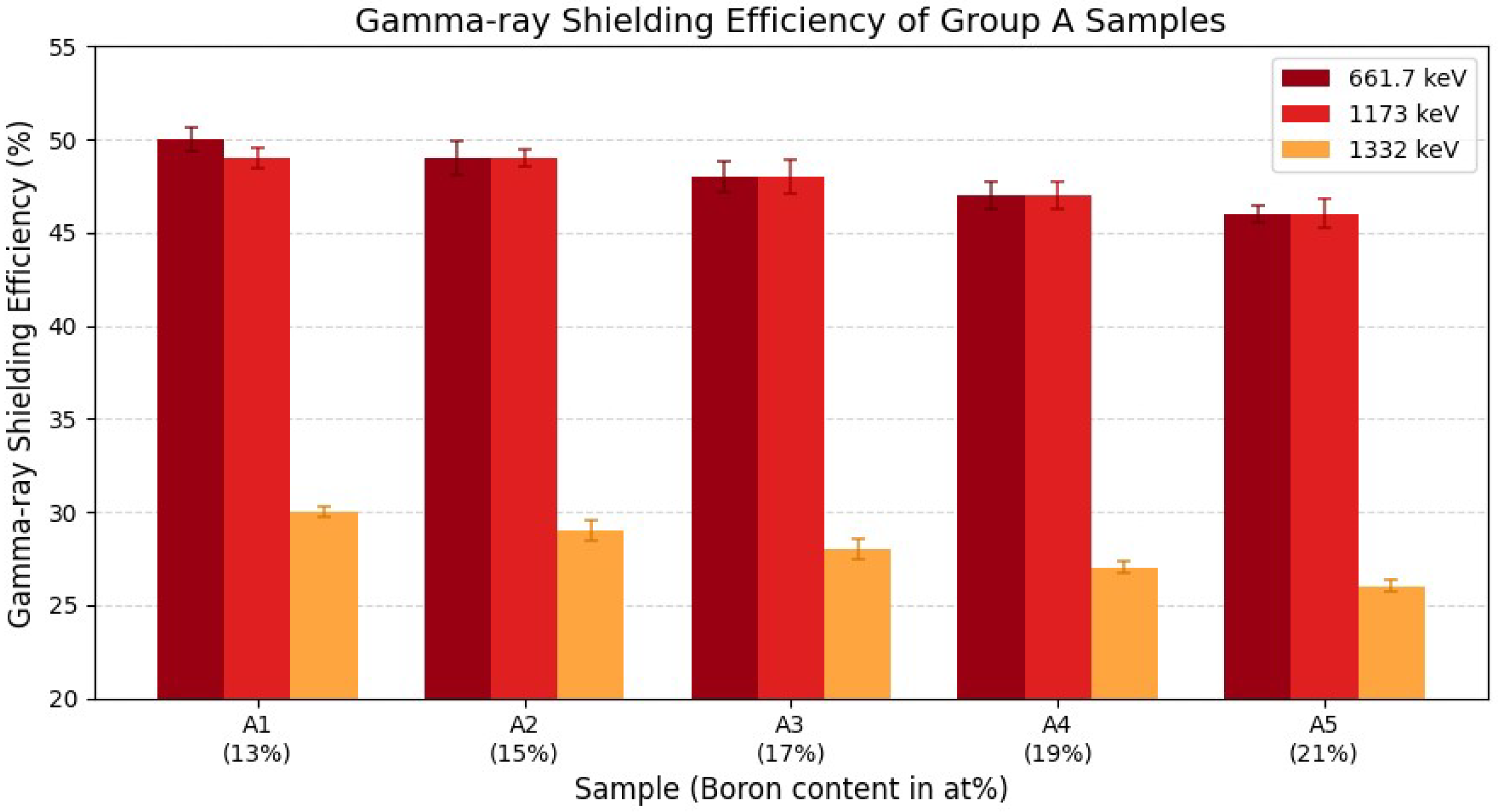

3.1. Gamma-Ray Attenuation Performance

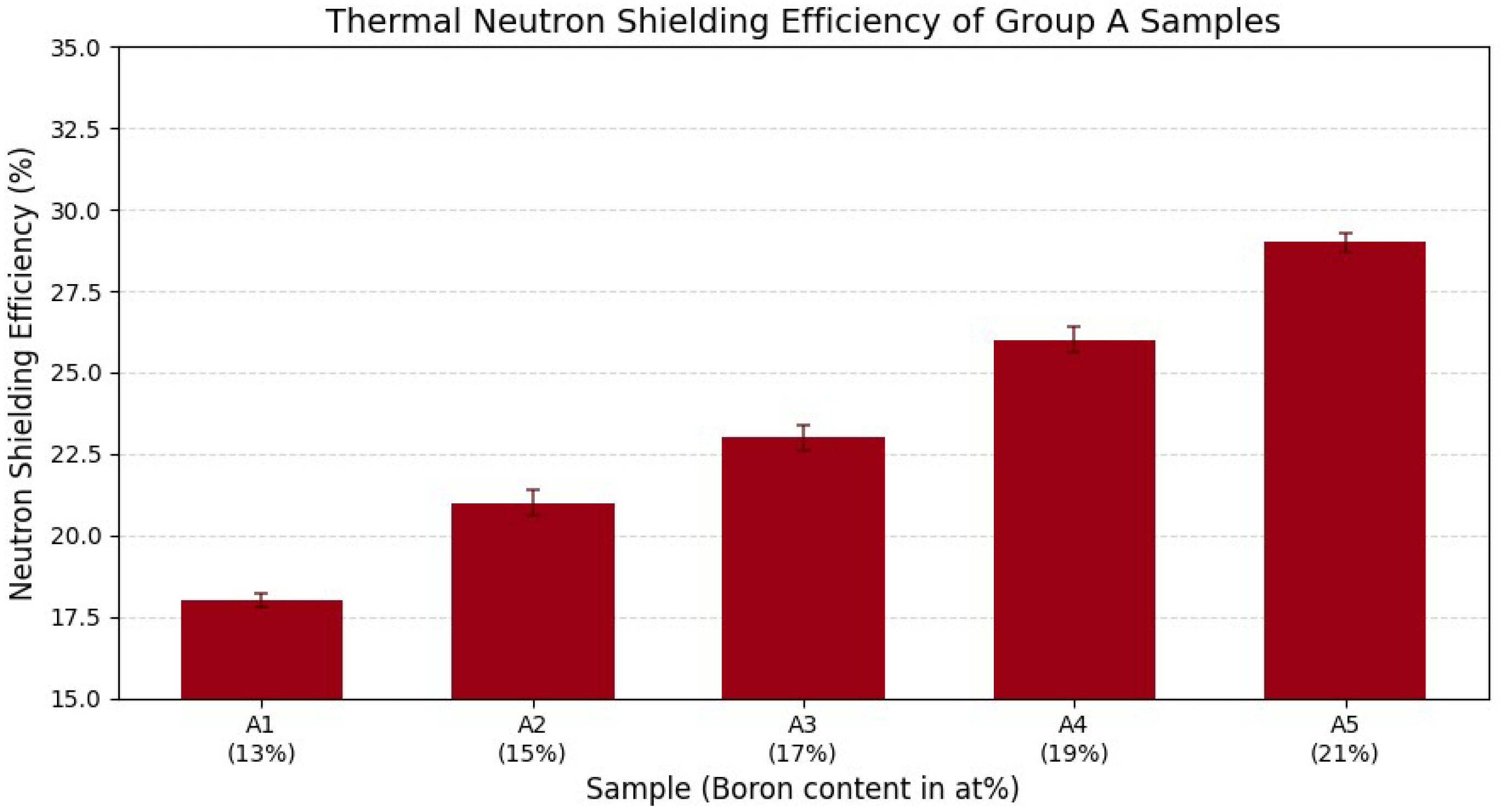

3.2. Neutron Shielding Performance

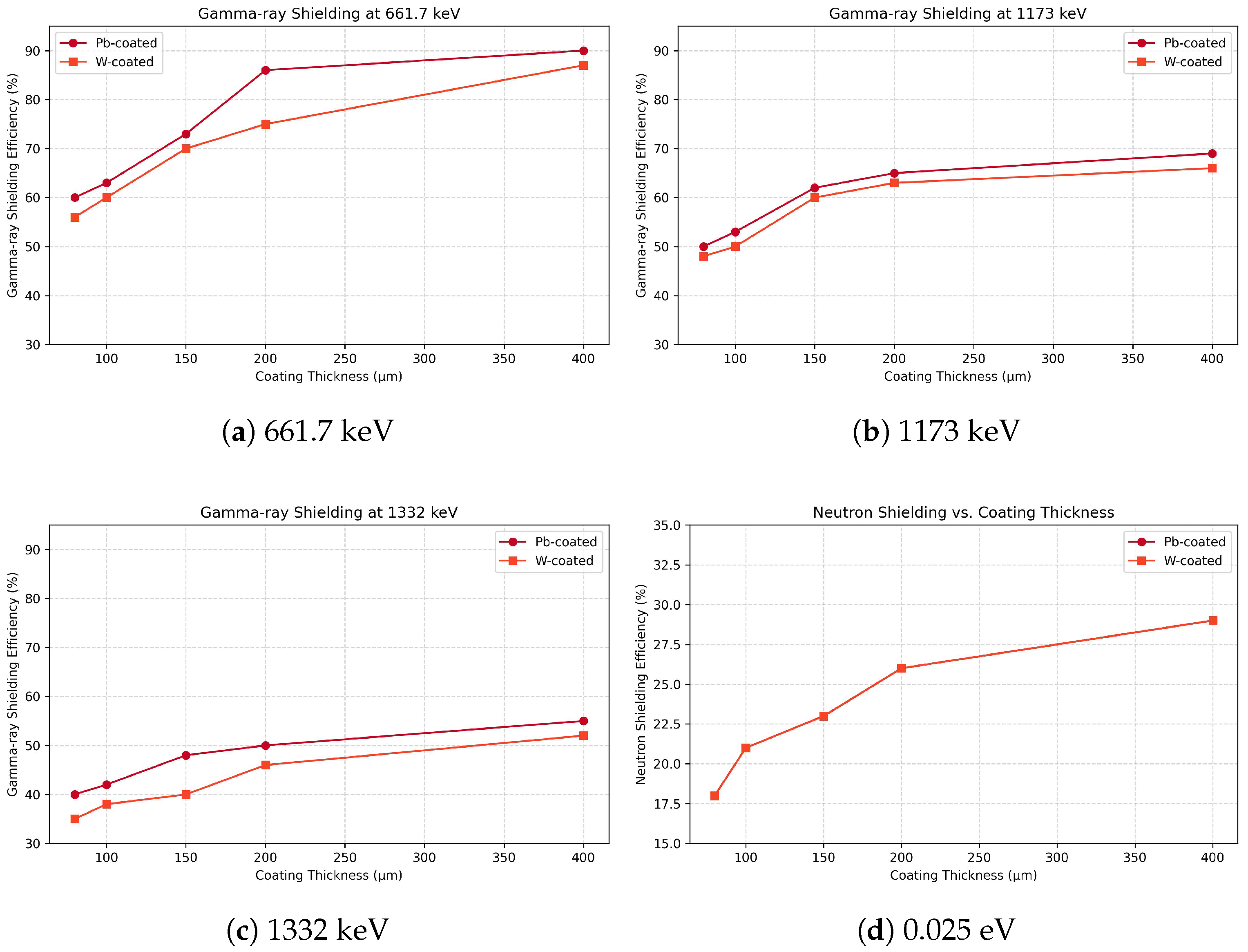

3.3. Gamma-Ray and Neutron Shielding Performance by Pb and W Coating Thickness

4. Discussion

4.1. Dual-Shielding Mechanisms and Material Design

4.2. Comparison Between Pb and W Coatings

4.3. Implications for Aerospace and Engineering Applications

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Adeli, R.; Shirmardi, S.P.; Ahmadi, S.J. Neutron irradiation tests on B4C/epoxy composite for neutron shielding application and the parameters assay. Radiat. Phys. Chem. 2016, 127, 140–146. [Google Scholar] [CrossRef]

- Zhao, D.; Jia, W.; Hei, D.; Cheng, C.; Li, J.; Cai, P.; Chen, Y. Design of a neutron shielding performance test system based on Am–Be neutron source. Radiat. Phys. Chem. 2022, 193, 109954. [Google Scholar] [CrossRef]

- Shukla, V. Review of electromagnetic interference shielding materials fabricated by iron ingredients. Nanoscale Adv. 2019, 1, 1640–1671. [Google Scholar] [CrossRef]

- Mann, H.S.; Brar, G.S.; Mann, K.S.; Mudahar, G.S. Experimental investigation of clay fly ash bricks for gamma-ray shielding. Nucl. Eng. Technol. 2016, 48, 1230–1236. [Google Scholar] [CrossRef]

- Okuno, K.; Kawai, M.; Yamada, H. Development of novel neutron shielding concrete. Nucl. Technol. 2009, 168, 545–552. [Google Scholar] [CrossRef]

- Zeng, C.; Kang, Q.; Duan, Z.; Qin, B.; Feng, X.; Lu, H.; Lin, Y. Development of polymer composites in radiation shielding applications: A review. J. Inorg. Organomet. Polym. Mater. 2023, 33, 2191–2239. [Google Scholar] [CrossRef]

- Zheng, W.; Ye, W.; Yang, P.; Wang, D.; Xiong, Y.; Liu, Z.; Qi, J.; Zhang, Y. Recent progress in iron-based microwave absorbing composites: A review and prospective. Molecules 2022, 27, 4117. [Google Scholar] [CrossRef]

- Yılmaz, E.; Baltas, H.; Kırıs, E.; Ustabas, İ.; Cevik, U.; El-Khayatt, A.M. Gamma ray and neutron shielding properties of some concrete materials. Ann. Nucl. Energy 2011, 38, 2204–2212. [Google Scholar] [CrossRef]

- More, C.V.; Alsayed, Z.; Badawi, M.S.; Thabet, A.A.; Pawar, P.P. Polymeric composite materials for radiation shielding: A review. Environ. Chem. Lett. 2021, 19, 2057–2090. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.M.; Lee, Y.H.; Lee, K.J. Cracking effect on gamma-ray shielding performance in concrete structure. Prog. Nucl. Energy 2007, 49, 303–312. [Google Scholar] [CrossRef]

- Naito, M.; Kitamura, H.; Koike, M.; Kusano, H.; Kusumoto, T.; Uchihori, Y.; Endo, T.; Hagiwara, Y.; Kiyono, N.; Kodama, H.; et al. Applicability of composite materials for space radiation shielding of spacecraft. Life Sci. Space Res. 2021, 31, 71–79. [Google Scholar] [CrossRef]

- Cherkashina, N.I.; Pavlenko, V.I.; Noskov, A.V. Radiation shielding properties of polyimide composite materials. Radiat. Phys. Chem. 2019, 159, 111–117. [Google Scholar] [CrossRef]

- Akkurt, I.; El-Khayatt, A.M. The effect of barite proportion on neutron and gamma-ray shielding. Ann. Nucl. Energy 2013, 51, 5–9. [Google Scholar] [CrossRef]

- Dong, M.; Xue, X.; Li, Z.; Yang, H.; Sayyed, M.I.; Elbashir, B.O. Preparation, shielding properties and mechanism of a novel neutron shielding material made from natural szaibelyite resource. Prog. Nucl. Energy 2018, 106, 140–145. [Google Scholar] [CrossRef]

- Li, R.; Gu, Y.; Zhang, G.; Yang, Z.; Li, M.; Zhang, Z. Radiation shielding property of structural polymer composite: Continuous basalt fiber reinforced epoxy matrix composite containing erbium oxide. Compos. Sci. Technol. 2017, 143, 67–74. [Google Scholar] [CrossRef]

- Jakubas, A.; Łada-Tondyra, E.; Makówka, M.; Suchecki, Ł. A study on the possibility of using iron scale in the construction of electromagnetic field shields. Energies 2022, 15, 1332. [Google Scholar] [CrossRef]

- Li, F.; Zhao, R.; Liu, Y.; Xiao, Y.; Sun, P.; Luo, J.; Wen, J.; Chen, Z.; Hu, J.; Qi, Z. Magnetic shielding properties of an iron-based nanocrystalline alloy for induction heating systems. Heliyon 2024, 10, e37119. [Google Scholar] [CrossRef]

- Fugaru, V.; Bercea, S.; Postolache, C.; Manea, S.; Moanta, A.; Petre, I.; Gheorghe, M. Gamma ray shielding properties of some concrete materials. Acta Phys. Pol. A 2015, 127, 1427–1429. [Google Scholar] [CrossRef]

- Qi, Z.; Yang, Z.; Li, J.; Guo, Y.; Yang, G.; Yu, Y.; Zhang, J. The advancement of neutron-shielding materials for the transportation and storage of spent nuclear fuel. Materials 2022, 15, 3255. [Google Scholar] [CrossRef]

- Piotrowski, T. Neutron shielding evaluation of concretes and mortars: A review. Constr. Build. Mater. 2021, 277, 122238. [Google Scholar] [CrossRef]

- Okonkwo, U.C.; Idumah, C.I.; Okafor, C.E.; Ohagwu, C.C.; Aronu, M.E.; Okokpujie, I.P.; Chukwu, N.N.; Chukwunyelu, C.E. Development, characterization, and properties of polymeric nanoarchitectures for radiation attenuation. J. Inorg. Organomet. Polym. Mater. 2022, 32, 4093–4113. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Hamad, M.K.; Mhareb, M.H.A.; Kurtulus, R.; Dwaikat, N.; Saleh, M.; Elsafi, M.; Taki, M.M.; Kavas, T.; Ziq, K.A.; et al. Assessment of radiation attenuation properties for novel alloys: An experimental approach. Radiat. Phys. Chem. 2022, 200, 110152. [Google Scholar] [CrossRef]

- Shahzad, K.; Kausar, A.; Manzoor, S.; Rakha, S.A.; Uzair, A.; Sajid, M.; Arif, A.; Khan, A.F.; Diallo, A.; Ahmad, I. Views on radiation shielding efficiency of polymeric composites/nanocomposites and multi-layered materials: Current state and advancements. Radiation 2022, 3, 1–20. [Google Scholar] [CrossRef]

- Fu, X.; Ji, Z.; Lin, W.; Yu, Y.; Wu, T. The advancement of neutron shielding materials for the storage of spent nuclear fuel. Sci. Technol. Nucl. Install. 2021, 2021, 5541047. [Google Scholar] [CrossRef]

- Ayub, S.; Guan, B.H.; Ahmad, F.; Oluwatobi, Y.A.; Nisa, Z.U.; Javed, M.F.; Mosavi, A. Graphene and iron reinforced polymer composite electromagnetic shielding applications: A review. Polymers 2021, 13, 2580. [Google Scholar] [CrossRef]

- Xu, W.; Liu, N.; Lu, Z. Recent progress of iron-based magnetic absorbers and its applications in elastomers: A review. Materials 2024, 17, 4058. [Google Scholar] [CrossRef]

- Alanazi, S.; Hanfi, M.; Marashdeh, M.W.; Aljaafreh, M.J.; Mahmoud, K.A. Evaluating the Effects of Metallic Waste on the Structural and Gamma-Ray Shielding Properties of Epoxy Composites. Polymers 2024, 16, 1415. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.P.; Badiger, N.M. Gamma ray and neutron shielding properties of some alloy materials. Ann. Nucl. Energy 2014, 64, 301–310. [Google Scholar] [CrossRef]

- Gan, B.; Liu, S.; He, Z.; Chen, F.; Niu, H.; Cheng, J.; Tan, B.; Yu, B. Research progress of metal-based shielding materials for neutron and gamma rays. Acta Metall. Sin. Engl. Lett. 2021, 34, 1609–1617. [Google Scholar] [CrossRef]

- Aubrey, J.; Esfandiari, N.; Baracos, V.E.; Buteau, F.A.; Frenette, J.; Putman, C.T.; Mazurak, V.C. Measurement of skeletal muscle radiation attenuation and basis of its biological variation. Acta Physiol. 2014, 210, 489–497. [Google Scholar] [CrossRef]

- Lu, D.; You, G.; Peng, L.; Yao, F.; Zhou, K. Microstructures and properties of a multilayered Al/W composite fabricated for γ-ray-shielding applications. Radiat. Phys. Chem. 2022, 198, 110209. [Google Scholar] [CrossRef]

- Özdoğan, H.; Üncü, Y.A.; Akman, F.; Polat, H.; Kaçal, M.R. Detailed Analysis of Gamma-Shielding Characteristics of Ternary Composites Using Experimental, Theoretical and Monte Carlo Simulation Methods. Polymers 2024, 16, 1778. [Google Scholar] [CrossRef] [PubMed]

- Hoang, A.; Faruqe, O.; Bury, E.; Park, C.; Koh, A. Homogeneity of Liquid Metal Polymer Composites: Impact on Mechanical, Electrical, and Sensing Behavior. Soft Matter 2023, 19, 7202–7215. [Google Scholar] [CrossRef]

- Kim, E.-H.; Jung, Y.-G.; Jo, C.-Y. Microstructure and Mechanical Properties of Heterogeneous Ceramic–Polymer Composite Using Interpenetrating Network. J. Nanomater. 2012, 2012, 932059. [Google Scholar] [CrossRef]

- Wang, K.; Ma, L.; Yang, C.; Bian, Z.; Zhang, D.; Cui, S.; Wang, M.; Chen, Z.; Li, X. Recent progress in Gd-containing materials for neutron shielding applications: A review. Materials 2023, 16, 4305. [Google Scholar] [CrossRef]

- Das, A.; Ray, A.; Singh, T. Tungsten-based polymer composite, a new lead-free material for efficient shielding of coupled neutron-gamma radiation fields: A FLUKA simulation study. Phys. Scr. 2023, 98, 115302. [Google Scholar] [CrossRef]

| Sample | Fe (at%) | B (at%) | Si (at%) |

|---|---|---|---|

| #1 | 78 | 13 | 9 |

| #2 | 76 | 15 | 9 |

| #3 | 74 | 17 | 9 |

| #4 | 72 | 19 | 9 |

| #5 | 70 | 21 | 9 |

| Sample | Coating | Thickness (μm) | Neutron Shielding (%) |

|---|---|---|---|

| #6–#10 | Pb | 80–400 | 18–29 |

| #11–#15 | W | 80–400 | 18–29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, J.; Kang, K.; Chi, H.S.; Kang, C.; Lee, S.; Kim, J.K. Gamma-Ray and Thermal Neutron Shielding of Fe-Based Bilayer Composites with a Boron-Enriched Matrix and Tungsten Surface Coatings: Lead Benchmarks Included. Materials 2025, 18, 5208. https://doi.org/10.3390/ma18225208

Chai J, Kang K, Chi HS, Kang C, Lee S, Kim JK. Gamma-Ray and Thermal Neutron Shielding of Fe-Based Bilayer Composites with a Boron-Enriched Matrix and Tungsten Surface Coatings: Lead Benchmarks Included. Materials. 2025; 18(22):5208. https://doi.org/10.3390/ma18225208

Chicago/Turabian StyleChai, Jiho, Ku Kang, Ho Sub Chi, Changwoo Kang, Sangmin Lee, and Jin Kook Kim. 2025. "Gamma-Ray and Thermal Neutron Shielding of Fe-Based Bilayer Composites with a Boron-Enriched Matrix and Tungsten Surface Coatings: Lead Benchmarks Included" Materials 18, no. 22: 5208. https://doi.org/10.3390/ma18225208

APA StyleChai, J., Kang, K., Chi, H. S., Kang, C., Lee, S., & Kim, J. K. (2025). Gamma-Ray and Thermal Neutron Shielding of Fe-Based Bilayer Composites with a Boron-Enriched Matrix and Tungsten Surface Coatings: Lead Benchmarks Included. Materials, 18(22), 5208. https://doi.org/10.3390/ma18225208