On the Design of Ultra-High-Temperature Material Systems

Abstract

1. Introduction

2. UHTM System

3. Selection of Parts for the UHTM System

3.1. Synergy, Entanglement, Self-Regulation in the UHTM System

3.2. Complexity and Emergence in the UHTM System

4. Issues for the Design and Development of the UHTM System

4.1. Interaction and Connectivity

4.2. Relationships of Differentiation and Similarity

4.3. Self-Organising

4.4. Information and Knowledge

4.5. Learning and Adaptation

4.6. Meaning

4.7. Emergence and Emergent Properties

5. Conclusions and Future Prospects

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

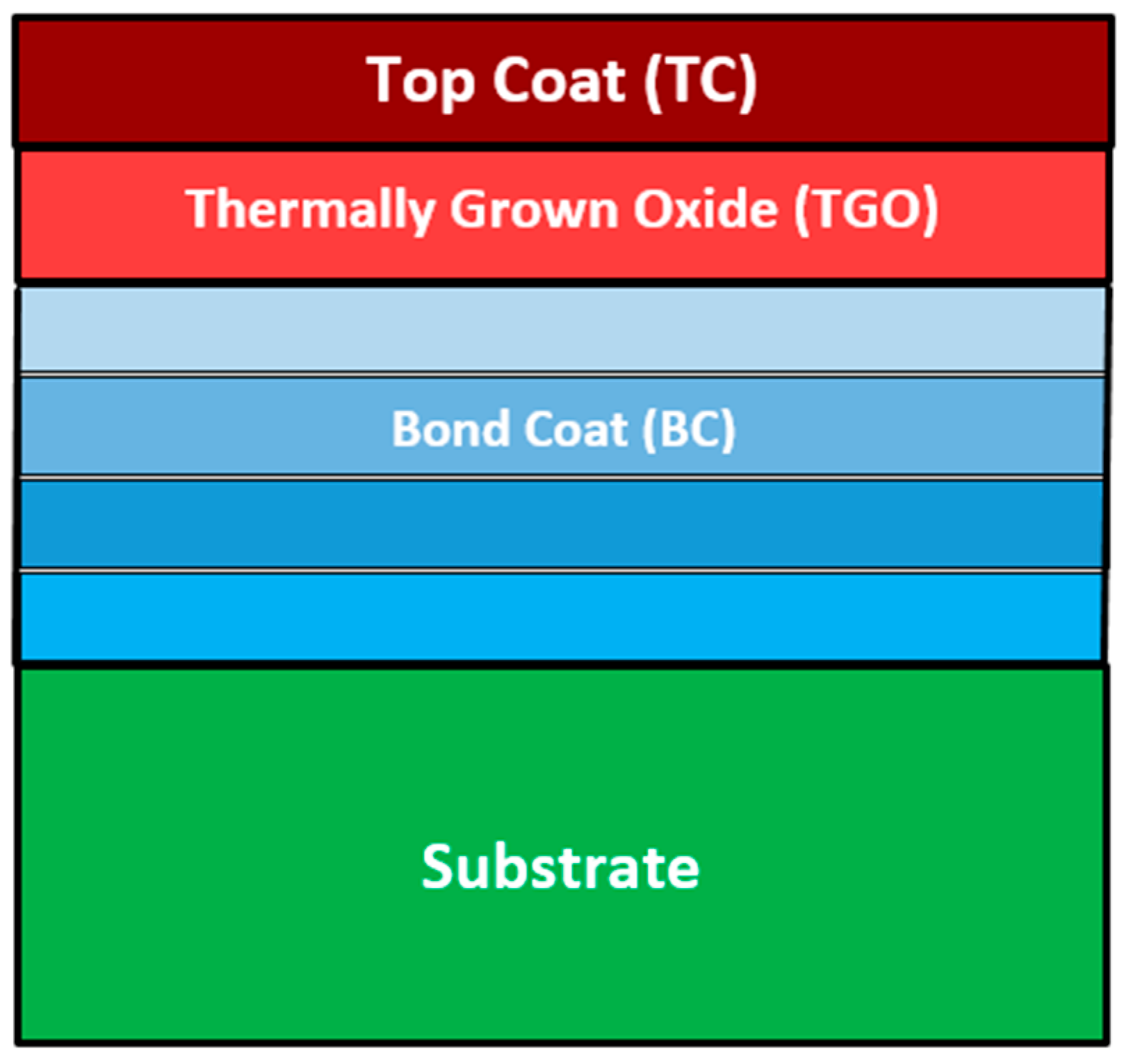

| BC | Bond coat |

| CEMI | Correlative environment material interactions (see Sections 3 and 7 in [6]) |

| CC | Complex concentrated (also compositionally complex) |

| DS | Directional solidification |

| EC | Environmental coating |

| ESSERE | Entanglement, synergy and self-regulation (see Sections 3 and 7 in [6]) |

| ETS | Evolution through survival (see Section 7 in [6]) |

| HE | High entropy |

| HPT | High-pressure turbine |

| HTM | High temperature material |

| IRIS | Interwoven risk (see Sections 3 and 7 in [6]) |

| ME | Metalloid element |

| NICE | Niobium intermetallic composite elaboration |

| RM | Refractory metal |

| RMIC | Refractory metal intermetallic composite |

| RHEA | Refractory metal high entropy alloy |

| RCCA | Refractory metal complex concentrated alloy |

| RMIC/RHEA | RMIC that also meets the definition of RHEA |

| RMIC/RCCA | RMIC that also meets the definition of RHEA |

| RHEA/RMIC | RHEA that is also a RMIC |

| RCCA/RMIC | RCCA that is also a RMIC |

| RM(Nb)IC | Refractory metal intermetallic composite based on Nb |

| RM(Nb)IC/RCCA | RM(Nb)IC that also meets the definition of RCCA |

| RM(Nb)IC/RHEA | RM(Nb)IC that also meets the definition of RHEA |

| RHEA/RM(Nb)IC | RHEA that is also a RM(Nb)IC |

| RCCA/RM(Nb)IC | RCCA that is also a RM(Nb)IC |

| SM | Simple metal |

| SX | Single crystal |

| TC | Top coat |

| TET | Turbine entry temperature |

| TGO | Thermally grown oxide |

| TM | Transition metal |

| UHTM | Ultra-high-temperature material |

Appendix A

References

- Balsone, S.J.; Bewlay, B.P.; Jackson, M.R.; Subramanian, P.R.; Zhao, J.C.; Chatterjee, A.; Heffernan, T.M. Materials beyond superalloys—Exploiting high-temperature composites. In Structural Intermetallics 2001; Hemker, K.J., Dimiduk, D.M., Clemens, H., Darolia, R., Inui, M., Larsen, J.M., Sikka, V.K., Thomas, W.J.D., Eds.; TMS: Warrendale, PA, USA, 2001. [Google Scholar]

- The Air and Space Academy (AAE); French Aerospace Society (3AF); Academy of Technologies. Aeronautical Materials for Today and Tomorrow; SAGEM: Paris, France, 2012; ISBN 978-2-913331-56-3/979-10-92518-09-2. [Google Scholar]

- Bewlay, B.P.; Jackson, M.R.; Gigliotti, M.F.X. Chapter 6: Niobium silicide high temperature in situ composites. In Intermetallic Compounds-Principles and Practice: Progress; Wiley: Hoboken, NJ, USA, 2002; Volume 3, pp. 541–560. [Google Scholar]

- Tsakiropoulos, P. On Nb Silicide Based Alloys: Alloy Design and Selection. Materials 2018, 11, 844. [Google Scholar] [CrossRef]

- Tsakiropoulos, P. Alloys for application at ultra-high temperatures: Nb-silicide in situ composites: Challenges, breakthroughs and opportunities. Prog. Mater. Sci. 2022, 123, 100714. [Google Scholar] [CrossRef]

- Tsakiropoulos, P. A Perspective of the Design and Development of Metallic Ultra-High Temperature Materials: Refractory Metal Intermetallic Composites, Refractory Complex Concentrated Alloys and Refractory High Entropy Alloys. Alloys 2023, 2, 184–212. [Google Scholar] [CrossRef]

- Tsakiropoulos, P. Refractory Metal Intermetallic Composites, High-Entropy Alloys, and Complex Concentrated Alloys: A Route to Selecting Substrate Alloys and Bond Coat Alloys for Environmental Coatings. Materials 2022, 15, 2832. [Google Scholar] [CrossRef]

- Cahn, R.W. Alloy design: A historical perspective. Proc. Indian. Acad. Sci. Eng. Sci. 1980, 3, 255–260. [Google Scholar] [CrossRef]

- Howe, A.; Farrugia, D. Alloy design: From composition to through process models. Mater. Sci. Technol. 1999, 15, 15–21. [Google Scholar] [CrossRef]

- Hafner, J.; Wolverton, C.; Ceder, G. Toward Computational Materials Design: The Impact of Density Functional Theory on Materials Research. MRS Bull. 2006, 31, 659–668. [Google Scholar] [CrossRef]

- Lukas, H.L.; Fries, S.G.; Sundman, B. Computational Thermodynamics: The Calphad Method; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- MacKay, R.A.; Gabb, T.P.; Smialek, J.L.; Nathal, M.V. Alloy Design Challenge: Development of Low Density Superalloys for Turbine Blade Applications; NASA/TM-2009-215819; NASA: Washington, DC, USA, 2009.

- Pollock, T.M.; Van der Ven, A. The evolving landscape for alloy design. MRS Bull. 2019, 44, 238–245. [Google Scholar] [CrossRef]

- Feyerabend, P. Science in a Free Society; Thetford Pres Ltd.: Norfolk, UK, 1978. [Google Scholar]

- Kuhn, T.S. The Structure of Scientific Revolutions; University of Chicago Press: Chicago, IL, USA, 1962. [Google Scholar]

- Thomson, G. The Inspiration of Science; Oxford University Press: London, UK, 1961. [Google Scholar]

- Feyerabend, P. Against Method; Thetford Press Ltd.: Norfolk, UK, 1975. [Google Scholar]

- Popper, K.R. The Myth of the Framework; Routledge: London, UK, 1994. [Google Scholar]

- Partelow, S. What is a framework? Understanding their purpose, value, development and use. J. Environ. Stud. Sci. 2023, 13, 510–519. [Google Scholar] [CrossRef]

- Tankov, N.; Utton, C.; Tsakiropoulos, P. Microstructure and Properties of Complex Concentrated C14–MCr2 Laves, A15–M3X and D8m M5Si3 Intermetallics in a Refractory Complex Concentrated Alloy. Alloys 2024, 3, 190–231. [Google Scholar] [CrossRef]

- Tankov, N.; Utton, C.; Tsakiropoulos, P. On the Microstructure and Properties of Complex Concentrated bcc Solid Solution and Tetragonal D8m M5Si3 Silicide Phases in a Refractory Complex Concentrated Alloy. Alloys 2024, 3, 59–95. [Google Scholar] [CrossRef]

- Strogatz, S.H. Exploring Complex Networks. Nature 2001, 410, 268–276. [Google Scholar] [CrossRef]

- Boccaletti, S.; Latora, V.; Moreno, Y.; Chavez, M.; Hwang, D.-U. Complex networks: Structure and dynamics. Phys. Rep. 2006, 424, 175–308. [Google Scholar] [CrossRef]

- Miller, E.K.; Brincat, S.L.; Roy, J.E. Cognition is an emergent property. Curr. Opin. Behav. Sci. 2024, 57, 101388. [Google Scholar] [CrossRef]

- Jackson, M.; Subramanian, P.; Zhao, J.-C.; Bewlay, B.; Darolia, R.; Schafrik, R. Turbine Blade for Extreme Temperature Conditions. US Patent Application US 2004/0126237 A1, 1 July 2004. [Google Scholar]

- Hernández-Negrete, O.; Tsakiropoulos, P. On the Microstructure and Isothermal Oxidation of Silica and Alumina Scale Forming Si-23Fe-15Cr-15Ti-1Nb and Si-25Nb-5Al-5Cr-5Ti (at.%) Silicide Alloys. Materials 2019, 12, 1091. [Google Scholar] [CrossRef]

- Nair, R.B.; Brabazon, D. Calcia magnesia alumino silicate (CMAS) corrosion attack on thermally sprayed thermal barrier coatings: A comprehensive review. npj Mater. Degrad. 2024, 8, 44. [Google Scholar] [CrossRef] [PubMed]

- Tsakiropoulos, P. On the Nb silicide based alloys: Part I—The bcc Nb solid solution. J. Alloys Compd. 2017, 708, 961–971. [Google Scholar] [CrossRef]

- Tsakiropoulos, P. Refractory Metal (Nb) Intermetallic Composites, High Entropy Alloys, Complex Concentrated Alloys and the Alloy Design Methodology NICE—Mise-en-scène Patterns of Thought and Progress. Materials 2021, 14, 989. [Google Scholar] [CrossRef]

- Vellios, N.; Tsakiropoulos, P. The Effect of Fe Addition in the RM(Nb)IC Alloy Nb–30Ti–10Si–2Al–5Cr–3Fe–5Sn–2Hf (at.%) on Its Microstructure, Complex Concentrated and High Entropy Phases, Pest Oxidation, Strength and Contamination with Oxygen, and a Comparison with Other RM(Nb)ICs, Refractory Complex Concentrated Alloys (RCCAs) and Refractory High Entropy Alloys (RHEAs). Materials 2022, 15, 5815. [Google Scholar] [CrossRef]

- Zacharis, E.; Utton, C.; Tsakiropoulos, P. A Study of the Effects of Hf and Sn on the Microstructure, Hardness and Oxidation of Nb-18Si Silicide-Based Alloys-RM(Nb)ICs with Ti Addition and Comparison with Refractory Complex Concentrated Alloys (RCCAs). Materials 2022, 15, 4596. [Google Scholar] [CrossRef]

- Vellios, N.; Tsakiropoulos, P. The role of Sn and Ti additions in the microstructure of Nb-18Si based alloys. Intermetallics 2007, 15, 1518–1528. [Google Scholar] [CrossRef]

- Xu, Z.; Utton, C.; Tsakiropoulos, P. A Study of the Effect of 5 at.% Sn on the Micro-Structure and Isothermal Oxidation at 800 and 1200 °C of Nb-24Ti-18Si Based Alloys with Al and/or Cr Additions. Materials 2020, 13, 245. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Utton, C.; Tsakiropoulos, P. A Study of the Effect of 2 at.% Sn on the Microstructure and Isothermal Oxidation at 800 and 1200 °C of Nb-24Ti-18Si-Based Alloys with Al and/or Cr Additions. Materials 2018, 11, 1826. [Google Scholar] [CrossRef]

- Jackson, M.R.; Bewlay, B.P.; Zhao, J.-C. Niobium Silicide Based Composites Resistant to Low Temperature Pesting. US Patent 6,419,765, 16 July 2002. [Google Scholar]

- Menon, E.S.K.; Mendiratta, M.G.; Dimiduk, D.M. High temperature oxidation mechanisms in Nb-silicide bearing multicomponent alloys. In Structural Intermetallics; Hemker, K.J., Dimiduk, D.M., Clemens, H., Darolia, R., Inui, H., Larsen, J.M., Sikka, V.K., Thomas, M., Whittenberger, J.D., Eds.; TMS: Warrendale, PA, USA, 2001; pp. 591–600. [Google Scholar]

- Geng, J.; Tsakiropoulos, P.; Shao, G. A thermo-gravimetric and microstructural study of the oxidation of Nbss/Nb5Si3-based in situ composites with Sn addition. Intermetallics 2007, 15, 270–281. [Google Scholar] [CrossRef]

- Knittel, S.; Mathieu, S.; Portebois, L.; Vilasi, M. Effect of tin addition on Nb-Si based in situ composites. Part II: Oxidation behavior. Intermetallics 2014, 47, 43–52. [Google Scholar] [CrossRef]

- Zhao, J.; Utton, C.; Tsakiropoulos, P. On the Microstructure and Properties of Nb-18Si-6Mo-5Al-5Cr-2.5W-1Hf Nb-Silicide Based Alloys with Ge, Sn and Ti Additions (at.%). Materials 2020, 13, 4548. [Google Scholar] [CrossRef]

- Hernández-Negrete, O.; Tsakiropoulos, P. On the Microstructure and Isothermal Oxidation at 800 and 1200 °C of the Nb-24Ti-18Si-5Al-5Cr-5Ge-5Sn (at.%) Silicide-Based Alloy. Materials 2020, 13, 722. [Google Scholar] [CrossRef] [PubMed]

- Thandorn, T.; Tsakiropoulos, P. On the Microstructure and Properties of Nb-Ti-Cr-Al-B-Si-X (X = Hf, Sn, Ta) Refractory Complex Concentrated Alloys. Materials 2021, 14, 7615. [Google Scholar] [CrossRef]

- Zhao, J.; Utton, C.; Tsakiropoulos, P. On the Microstructure and Properties of Nb-12Ti-18Si-6Ta-5Al-5Cr-2.5W-1Hf (at.%) Silicide-Based Alloys with Ge and Sn Additions. Materials 2020, 13, 3719. [Google Scholar] [CrossRef]

- Zhao, J.; Utton, C.; Tsakiropoulos, P. On the Microstructure and Properties of Nb-12Ti-18Si-6Ta-2.5W-1Hf (at.%) Silicide-Based Alloys with Ge and Sn Additions. Materials 2020, 13, 1778. [Google Scholar] [CrossRef]

- Jackson, M.R.; Bewlay, B.P.; Briant, C.L. Creep Resistant Nb-Silicide Based Two Phase Composites. US Patent 6,447,623 B1, 10 September 2002. [Google Scholar]

- Geng, J.; Tsakiropoulos, P. A study of the microstructures and oxidation of Nb-Si-Cr-Al-Mo in situ composites alloyed with Ti, Hf and Sn. Intermetallics 2007, 15, 382–395. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Jackson, M.R.; Zhao, J.-C.; Subramanian, P.R.; Mendiratta, M.G.; Lewandowski, J.J. Ultrahigh-Temperature Nb-Silicide-Based Composites. MRS Bull. 2003, 28, 646–653. [Google Scholar] [CrossRef]

- Zelenitsas, K.; Tsakiropoulos, P. Study of the role of Ta and Cr additions in the microstructure of Nb-Ti-Si-Al in situ composites. Intermetallics 2006, 14, 639–659. [Google Scholar] [CrossRef]

- Zifu Li, P Tsakiropoulos, Study of the effects of Ge addition on the microstructure of Nb–18Si in situ composites. Intermetallics 2010, 18, 1072–1078. [CrossRef]

- Li, Z.; Tsakiropoulos, P. The Effect of Ge Addition on the Oxidation of Nb-24Ti-18Si Silicide Based Alloys. Materials 2019, 12, 3120. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Tsakiropoulos, P. On The Microstructures and Hardness of The Nb-24Ti-18Si-5Al-5Cr-5Ge and Nb-24Ti-18Si-5Al-5Cr-5Ge-5Hf (at.%) Silicide Based Alloys. Materials 2019, 12, 2655. [Google Scholar] [CrossRef] [PubMed]

- McCaughey, C.; Tsakiropoulos, P. Type of Primary Nb5Si3 and Precipitation of Nbss in αNb5Si3 in a Nb-8.3Ti-21.1Si-5.4Mo-4W-0.7Hf (at.%) Near Eutectic Nb-Silicide-Based Alloy. Materials 2018, 11, 967. [Google Scholar] [CrossRef] [PubMed]

- Tsakiropoulos, P. On the Stability of Complex Concentrated (CC)/High Entropy (HE) Solid Solutions and the Contamination with Oxygen of Solid Solutions in Refractory Metal Intermetallic Composites (RM(Nb)ICs) and Refractory Complex Concentrated Alloys (RCCAs). Materials 2022, 15, 8479. [Google Scholar] [CrossRef] [PubMed]

- Zelenitsas, K.; Tsakiropoulos, P. Study of the role of Cr and Al additions in the microstructure of Nb-Ti-Si in situ composites. Intermetallics 2005, 13, 1079–1095. [Google Scholar] [CrossRef]

- Winston, H.C. Strengthening of refractory metals. In Refractory Metal and Alloys, Proceedings of the Conference Refractory Metals and Alloys, Detroit, MI, USA, 25–26 May 1960; Semchyshen, M., Harwood, J.J., Eds.; Interscience Publishers: New York, NY, USA, 1961; pp. 83–118. [Google Scholar]

- Wadsworth, J.; Nieh, T.G.; Stephens, J.J. Recent advances in aerospace refractory metal alloys. Intern. Mater. Rev. 1988, 33, 131–150. [Google Scholar] [CrossRef]

- Davidson, D.L.; Chan, K.S.; Loloee, R.; Crimp, M.A. Fatigue and fracture toughness of a Nb-Ti-Cr-Al-X single phase alloy at ambient temperature. Metall. Mater. Trans. A 2000, 31, 1075–1084. [Google Scholar] [CrossRef]

- Kim, W.-Y.; Tanaka, H.; Kim, M.-S.; Hanada, S. High temperature strength and room temperature fracture toughness of Nb–Mo–W refractory alloys with and without carbide dispersoids. Mater. Sci. Eng. A 2003, 346, 65–74. [Google Scholar] [CrossRef]

- Ma, C.L.; Li, J.G.; Tan, Y.; Tanaka, R.; Hanada, S. Microstructure and mechanical properties of Nb/Nb5Si3 in situ composites in Nb-Si-Mo and Nb-Si-W systems. Mater. Sci. Eng. A 2004, 386, 375–383. [Google Scholar] [CrossRef]

- Sha, J.; Hirai, H.; Tabaru, T.; Kitahara, A.; Ueno, H.; Hanada, S. High-temperature strength and room-temperature toughness of Nb–W–Si–B alloys prepared by arc-melting. Mater. Sci. Eng. A 2004, 364, 151–158. [Google Scholar] [CrossRef]

- Kang, Y.; Qu, S.; Song, J.; Huang, Q.; Han, Y. Microstructure and mechanical properties of Nb–Ti–Si–Al–Hf–xCr–yV multi-element in situ composite. Mater. Sci. Eng. A 2012, 534, 323–328. [Google Scholar] [CrossRef]

- Liu, C.M.; Wang, H.M.; Zhang, S.Q.; Tang, H.B.; Zhang, A.L. Microstructure and oxidation behaviour of new refractory high entropy alloys. J. Alloys Compd. 2014, 583, 162–169. [Google Scholar] [CrossRef]

- Zheng, J.; Hou, X.; Wang, X.; Meng, Y.; Zheng, X.; Zheng, L. Isothermal oxidation mechanism of a newly developed Nb-Ti-V-Cr-Al-W-Mo-Hf alloy at 800–1200 °C. Int. J. Refract. Met. Hard Mater. 2016, 54, 322–329. [Google Scholar] [CrossRef]

- Han, Z.D.; Chen, N.; Zhao, S.F.; Fan, L.W.; Yang, G.N.; Shao, Y.; Yao, K.F. Effect of Ti additions on mechanical properties NbMoTaW and VNbMoTaW refractory high entropy alloys. Intermetallics 2017, 84, 153–157. [Google Scholar] [CrossRef]

- Tsakiropoulos, P. Alloys. US patent 10,227,680, 12 March 2019. [Google Scholar]

- Hernández-Negrete, O.; Tsakiropoulos, P. On the Microstructure and Isothermal Oxidation at 800, 1200, and 1300 °C of the Al-25.5Nb-6Cr-0.5Hf (at %) Alloy. Materials 2019, 12, 2531. [Google Scholar] [CrossRef]

- Ghadyani, M.; Utton, C.; Tsakiropoulos, P. Microstructures and Isothermal Oxidation of the Alumina Scale Forming Nb1.7Si2.4Ti2.4Al3Hf0.5 and Nb1.3Si2.4Ti2.4Al3.5Hf0.4 Alloys. Materials 2019, 12, 222. [Google Scholar] [CrossRef]

- Ghadyani, M.; Utton, C.; Tsakiropoulos, P. Microstructures and Isothermal Oxidation of the Alumina Scale Forming Nb1.45Si2.7Ti2.25Al3.25Hf0.35 and Nb1.35Si2.3Ti2.3Al3.7Hf0.35 Alloys. Materials 2019, 12, 759. [Google Scholar] [CrossRef]

- Hernández-Negrete, O.; Tsakiropoulos, P. On the Microstructure and Isothermal Oxidation of the Si-22Fe-12Cr-12Al-10Ti-5Nb (at.%) Alloy. Materials 2019, 12, 1806. [Google Scholar] [CrossRef]

- Tsakiropoulos, P. On Nb silicide based alloys: Part II. J. Alloys Compd. 2018, 748, 569–576. [Google Scholar] [CrossRef]

- Tsakiropoulos, P. On the Nb5Si3 Silicide in Metallic Ultra-High Temperature Materials. Metals 2023, 13, 1023. [Google Scholar] [CrossRef]

- Tankov, N. Processing of Nb-Silicide Based Alloys. Master’s. Thesis, University of Sheffield, Sheffield, UK, 2023. [Google Scholar]

- Nelson, J.; Ghadyani, M.; Utton, C.; Tsakiropoulos, P. A Study of the Effects of Al, Cr, Hf, and Ti Additions on the Microstructure and Oxidation of Nb-24Ti-18Si Silicide Based Alloys. Materials 2018, 11, 1579. [Google Scholar] [CrossRef] [PubMed]

- Smith, B.C. Use and meaning. In The Oxford Companion to Philosophy, 2nd ed.; Honderich, T., Ed.; Oxford University Press: Oxford, UK, 2005; p. 936. [Google Scholar]

- Horwich, P. Meaning; Clarendon Press: Oxford, UK, 1998. [Google Scholar]

- Cohen, L.J. Philosophy and Science. In The Oxford Companion to Philosophy, 2nd ed.; Honderich, T., Ed.; Oxford University Press: Oxford, UK, 2005; pp. 711–714. [Google Scholar]

- Kant, I. Critique of Pure Reason; Cambridge University Press: Cambridge, UK, 1999; ISBN 9780521657297. [Google Scholar]

- Schiller, F. On the Aesthetic Education of Man; Wilkinson, E.M., Willoughby, L.A., Eds. and Translators; Oxford University Press: Oxford, UK, 1983; ISBN 9780198157861. [Google Scholar]

- Russell, B. An Outline of Philosophy; Routledge: New York, NY, USA, 1927. [Google Scholar]

- Feynman, R.P. The Feynman Lectures on Physics, Vol. II, New Millennium, ed.; Basic Books: New York, NY, USA, 2011; ISBN 0465024947. [Google Scholar]

- Schopenhauer, A. The World as Will and Representation; Cambridge University Press: Cambridge, UK, 2014; Volume 1, ISBN 9780521871846. [Google Scholar]

- Green, G. The Power and the Glory; Vintage Classics: New York, NY, USA, 2001; ISBN 978-0099286097. [Google Scholar]

- Cambridge Dictionary. Available online: https://dictionary.cambridge.org/ (accessed on 18 November 2024).

- Merriam Webster Dictionary. Available online: https://www.merriam-webster.com (accessed on 14 December 2024).

- Collins Dictionary. Available online: https://www.collinsdictionary.com (accessed on 15 November 2024).

- Britannica Dictionary. Available online: https://www.britannica.com (accessed on 20 November 2024).

- Weiner, E.; Simpson, J.A. The Oxford English Dictionary; Simpson, J., Weiner, E., Eds.; Clarendon Press: Oxford, UK, 1989. [Google Scholar]

- Binder, C.R.; Hinkel, J.; Bots, P.W.G.; Pahl-Wostl, C. Comparison of Frameworks for analyzing social-ecological systems. Ecol. Soc. 2013, 18, 26. [Google Scholar] [CrossRef]

- Cox, M.; Villamayor-tomas, S.; Epstein, G.; Evans, L.; Ban, N.C.; Fleischman, F.; Nenadovic, M.; Garcia-lopez, G. Synthesizing theories of natural resource management and governance. Glob. Environ. Change 2016, 39, 45–56. [Google Scholar] [CrossRef]

- Popper, K.R. Conjectures and Refutations; Routledge and Kegan Paul: London, UK, 1963. [Google Scholar]

- Bostock, D. Mathematics: History of the Philosophy of Mathematics. In The Oxford Companion to Philosophy, 2nd ed.; Honderich, T., Ed.; Oxford University Press: Oxford, UK, 2005; pp. 566–569. [Google Scholar]

- Shapiro, S. Philosophy of Mathematics: Structure and Ontology; Oxford University Press: Oxford, UK, 1997. [Google Scholar]

- Shapiro, S. Thinking About Mathematics: The Philosophy of Mathematics; Oxford University Press: Oxford, UK, 2000. [Google Scholar]

- Bunnin, N.; Yu, J. (Eds.) The Blackwell Dictionary of Western Philosophy; Wiley-Blackwell: Hoboken, NJ, USA, 2004; p. 473. [Google Scholar]

- Husserl, E. Ideas: General Introduction to Pure Phenomenology (Also Known as Ideas I); Gibson, W.B., Translator; Collier Books: New York, NY, USA, 1962; p. 238. [Google Scholar]

- Sokolowski, R. Introduction to Phenomenology; Cambridge University Press: Cambridge, UK, 2000; p. 59. [Google Scholar]

- Gurwitsch, A. The Collected Works of Aron Gurwitsch (1901–1973), 2010 ed.; Zaner, R.M., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; ISBN 9048133459/978-9048133451. [Google Scholar]

- Morehouse, R.E. Beginning Interpretive Inquiry; Routledge: Oxfordshire, UK, 2012; p. 32. [Google Scholar]

- National Academy of Sciences. Science, Evolution, and Creationism; The National Academies Press: Washington, DC, USA, 2008; ISBN 978-0-309-10586-6. [Google Scholar] [CrossRef]

- American Association for the Advancement of Science. Available online: https://www.aaas.org (accessed on 16 December 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsakiropoulos, P. On the Design of Ultra-High-Temperature Material Systems. Materials 2025, 18, 5203. https://doi.org/10.3390/ma18225203

Tsakiropoulos P. On the Design of Ultra-High-Temperature Material Systems. Materials. 2025; 18(22):5203. https://doi.org/10.3390/ma18225203

Chicago/Turabian StyleTsakiropoulos, Panos. 2025. "On the Design of Ultra-High-Temperature Material Systems" Materials 18, no. 22: 5203. https://doi.org/10.3390/ma18225203

APA StyleTsakiropoulos, P. (2025). On the Design of Ultra-High-Temperature Material Systems. Materials, 18(22), 5203. https://doi.org/10.3390/ma18225203