Residual Flexural Strength of Concrete Reinforced with Recycled Carbon Fibers from Wind Turbine Blades

Highlights

- Recycled carbon fibers enhance post-cracking strength of concrete.

- Fiber length and dosage strongly affect residual flexural behavior.

- New coefficients (Ri, E) quantify fiber efficiency in concrete.

- 38–50 mm fibers at 8 kg/m3 ensure optimal crack control and ductility.

- Results support recycling wind turbine blades for structural concrete.

- Provides a path toward sustainable, high-performance fiber concretes.

Abstract

1. Introduction

- Thermal recycling (pyrolysis). This method involves the decomposition of the polymer matrix in a controlled atmosphere (most often nitrogen) at temperatures of about 500–600 °C. The process offers high efficiency, with recovery of up to 75% of the material mass. The fibers largely retain their geometry and suffer limited degradation, provided the parameters are properly optimized. However, potential drawbacks include partial surface damage, gas emissions, and high energy demand (Figure 1) [6].

- 2.

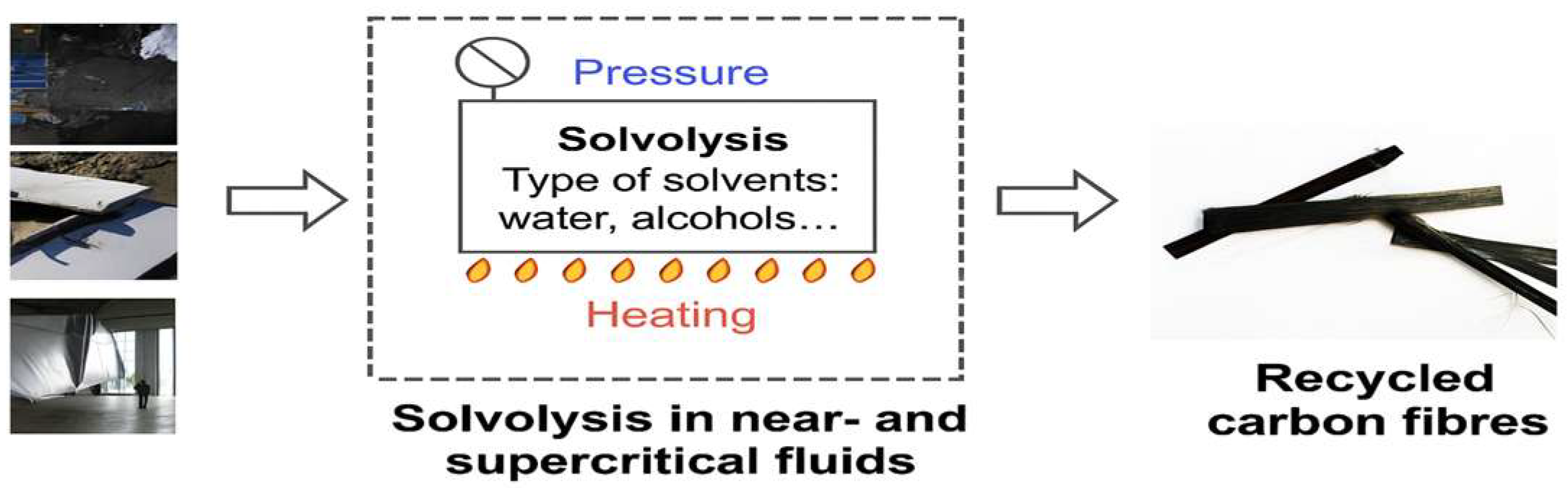

- Chemical recycling (solvolysis). This process involves depolymerization of the polymer matrix in a liquid medium using organic solvents or chemical agents, often under elevated pressure and temperature. The recovered fibers are of very high quality (clean, without resin residues) and exhibit high retention of their mechanical properties. However, the process requires costly equipment, is less easily scalable, and involves the use of potentially hazardous reagents (Figure 2) [7].

- 3.

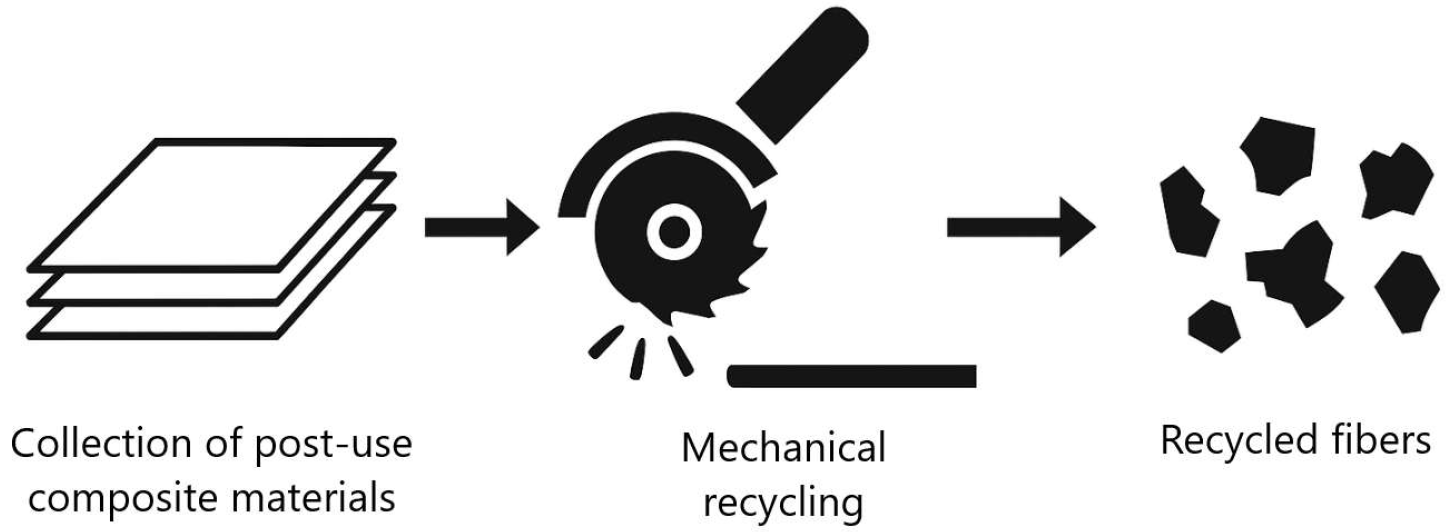

- Mechanical recycling. This is the simplest and least expensive method, based on shredding (cutting, milling, grinding) of entire blades or their fragments. The resulting fibers exhibit significant variation in length and damage, contain residual matrix, and show limited quality and mechanical performance of the secondary material (Figure 3) [9].

2. Experimental Program

2.1. Materials

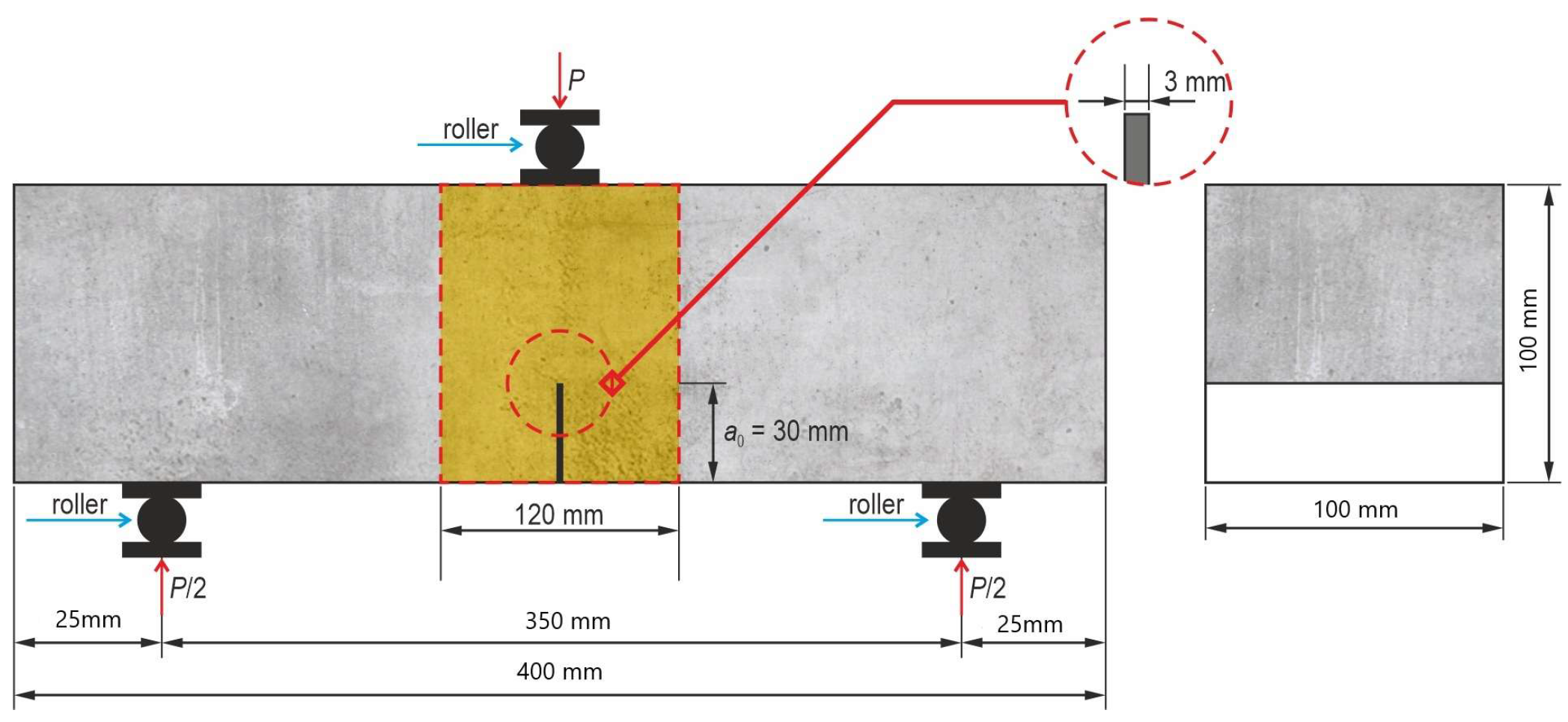

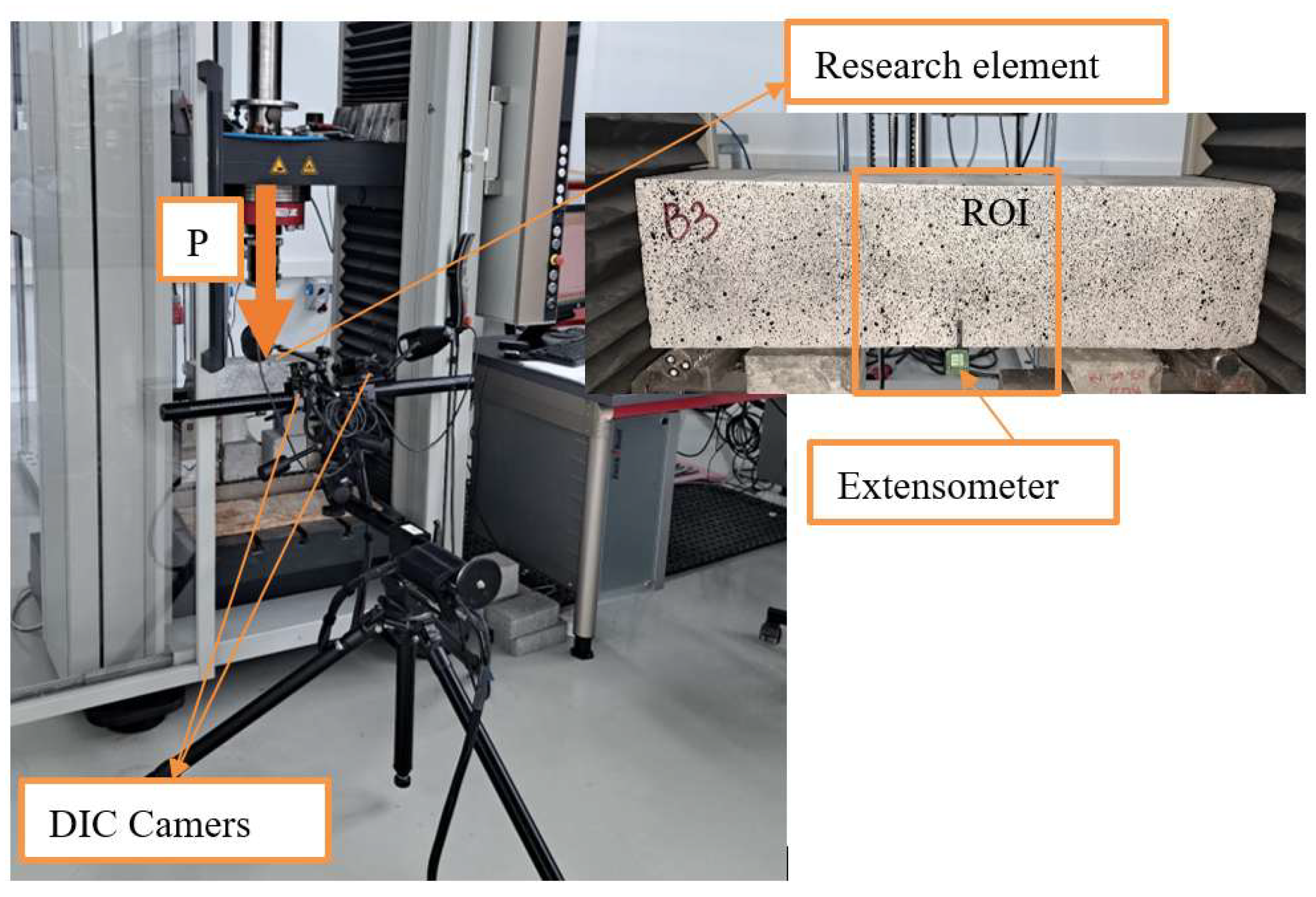

2.2. Testing Procedure

3. Analysis and Results

3.1. Compressive Strength

3.2. Modulus of Elasticity

3.3. Flexural Strength

3.4. Splitting Strength

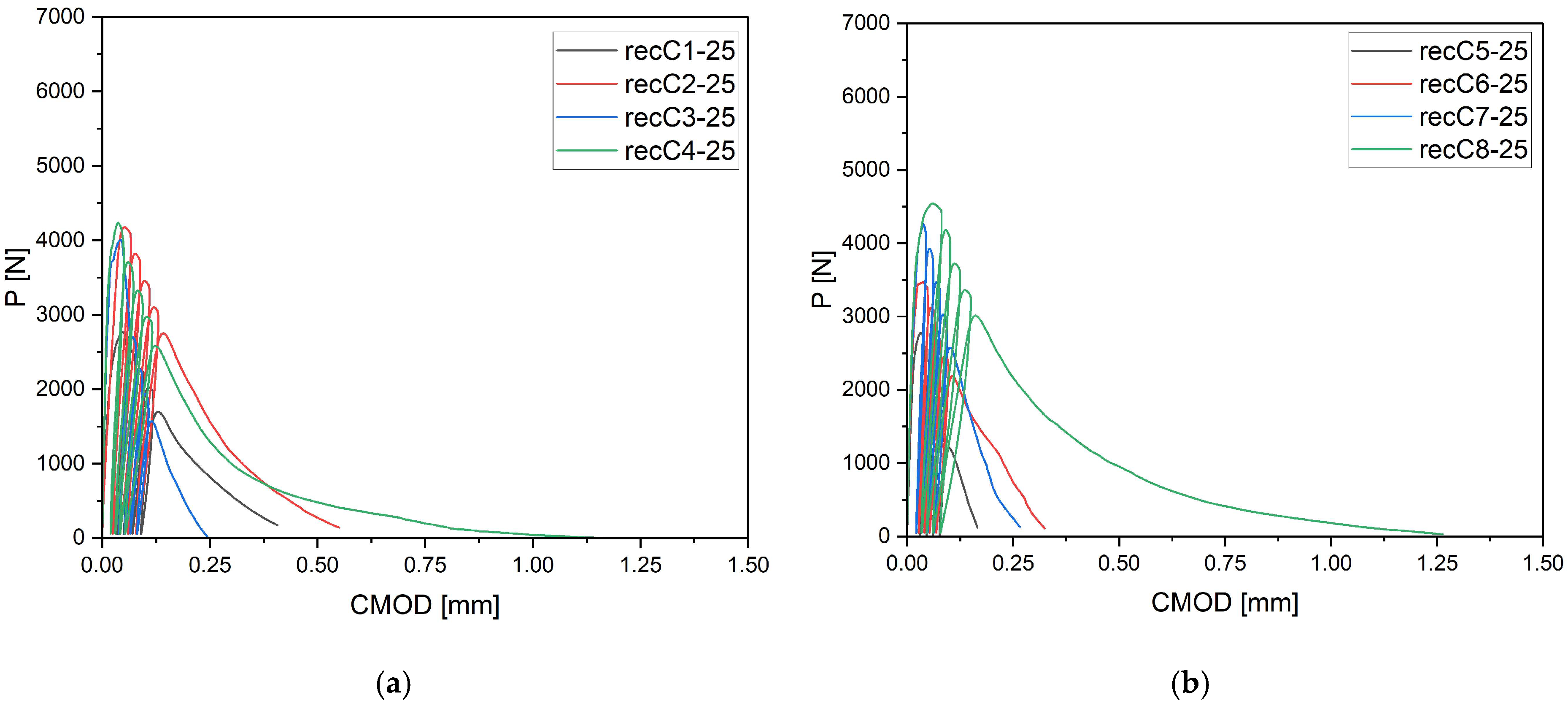

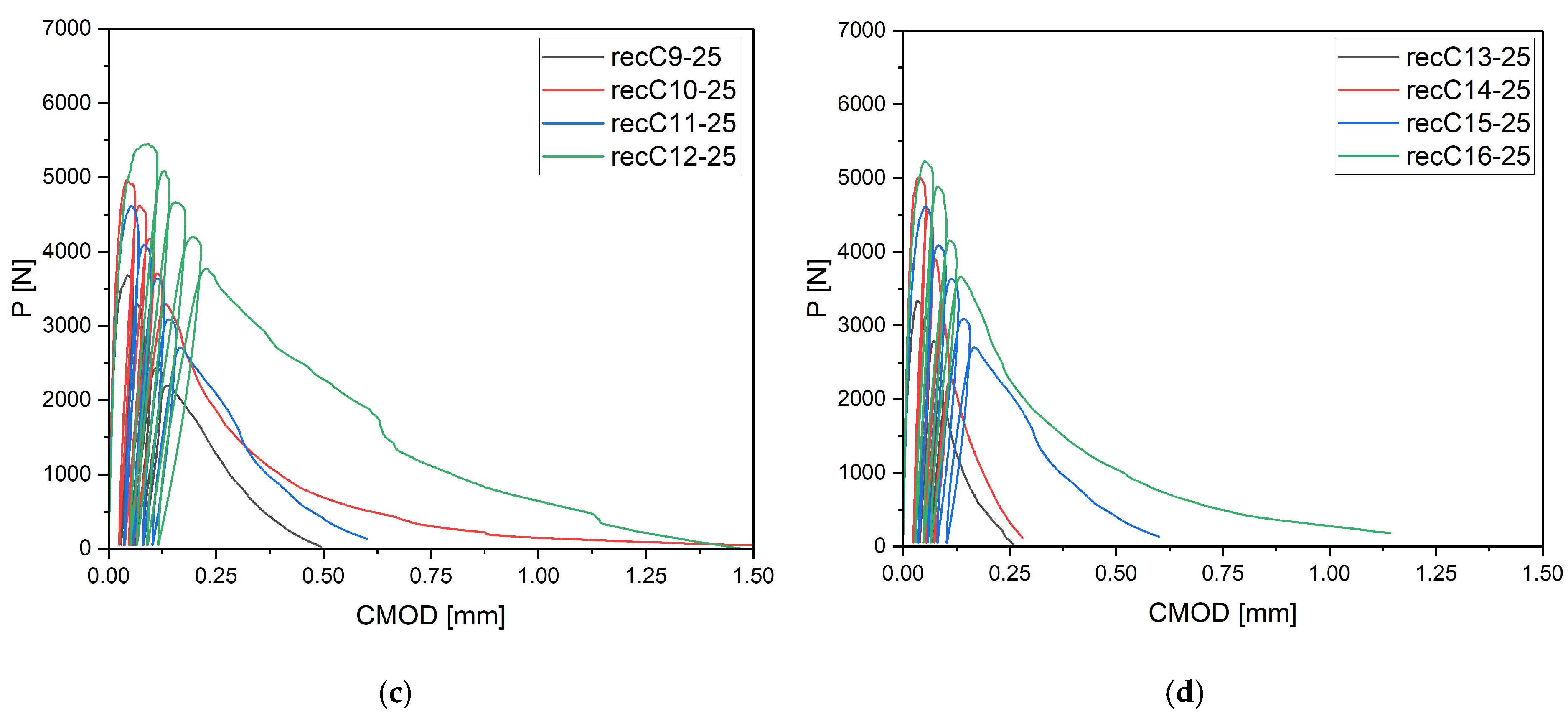

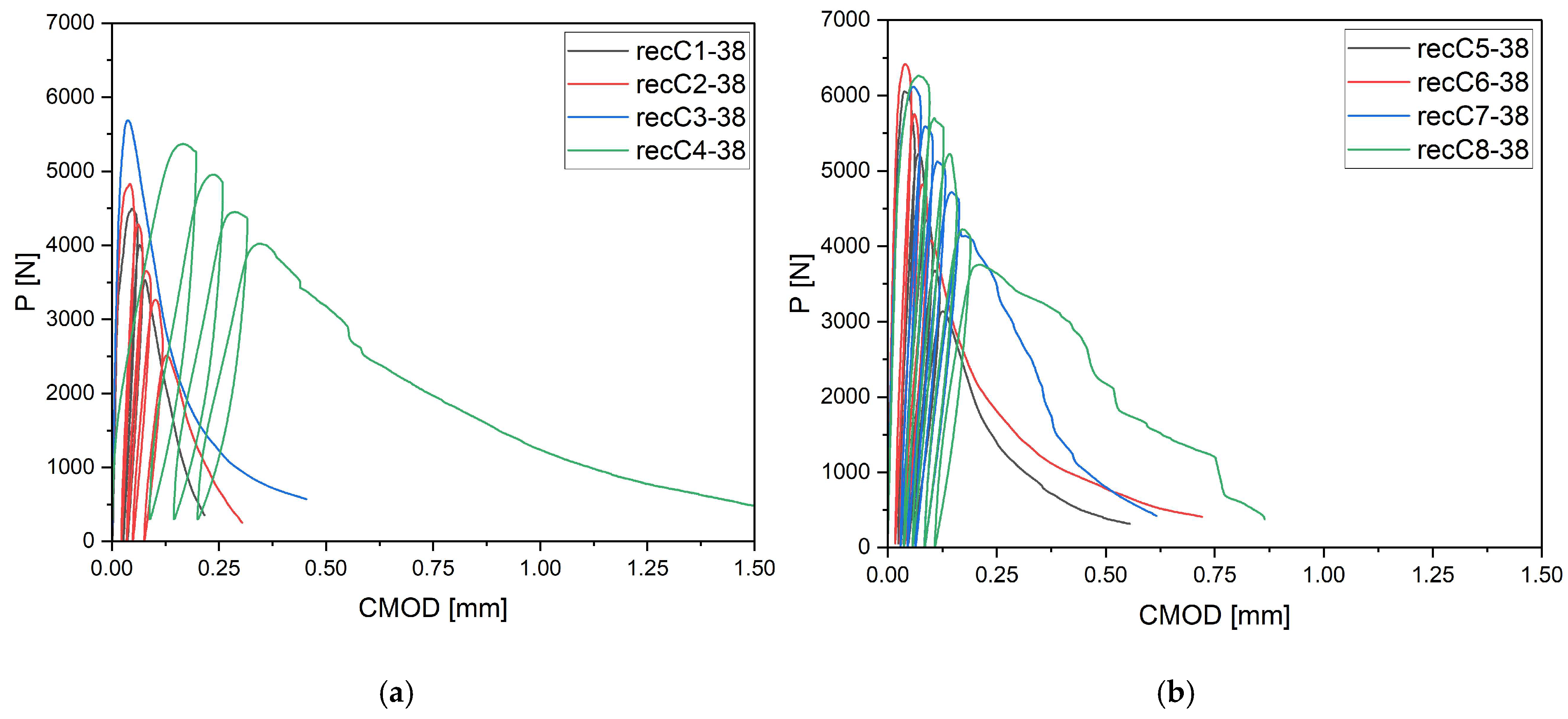

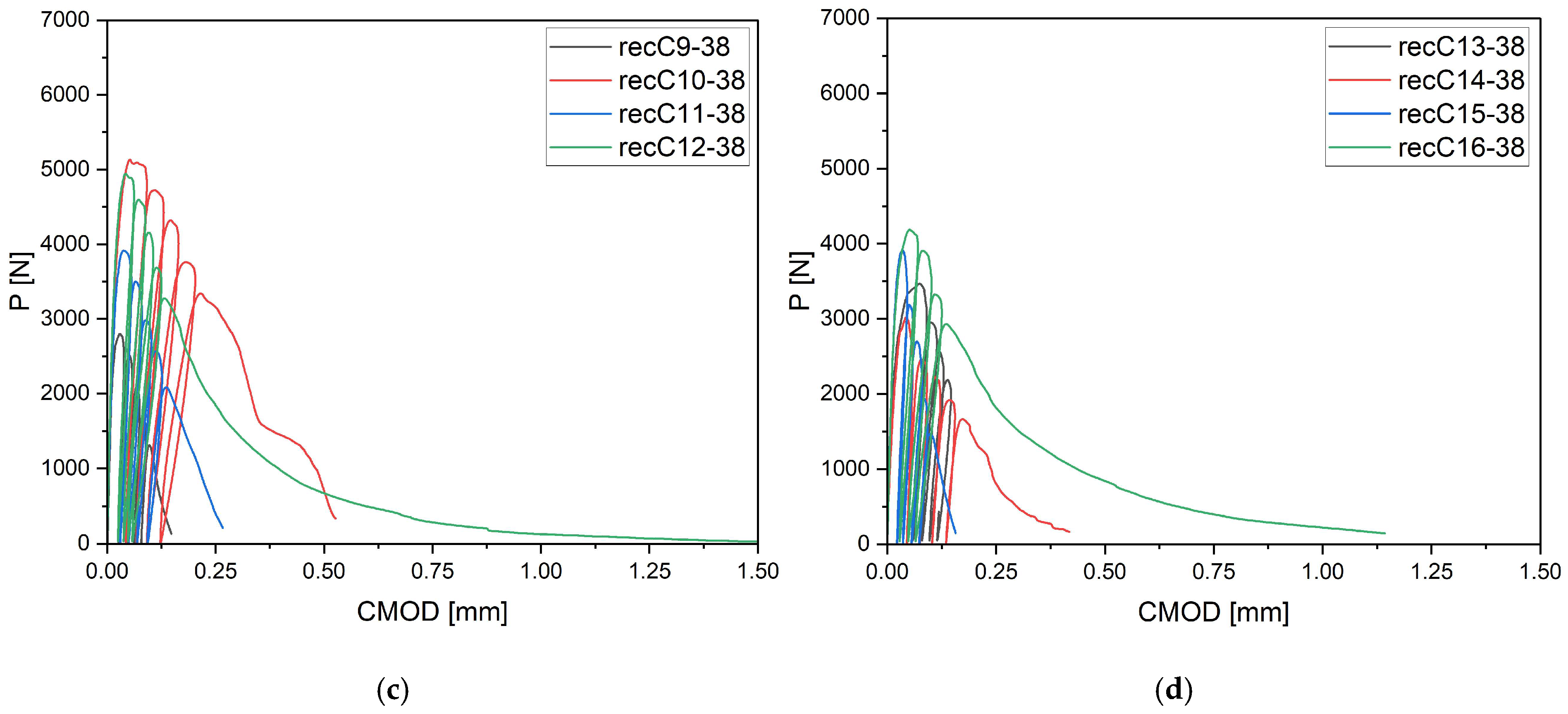

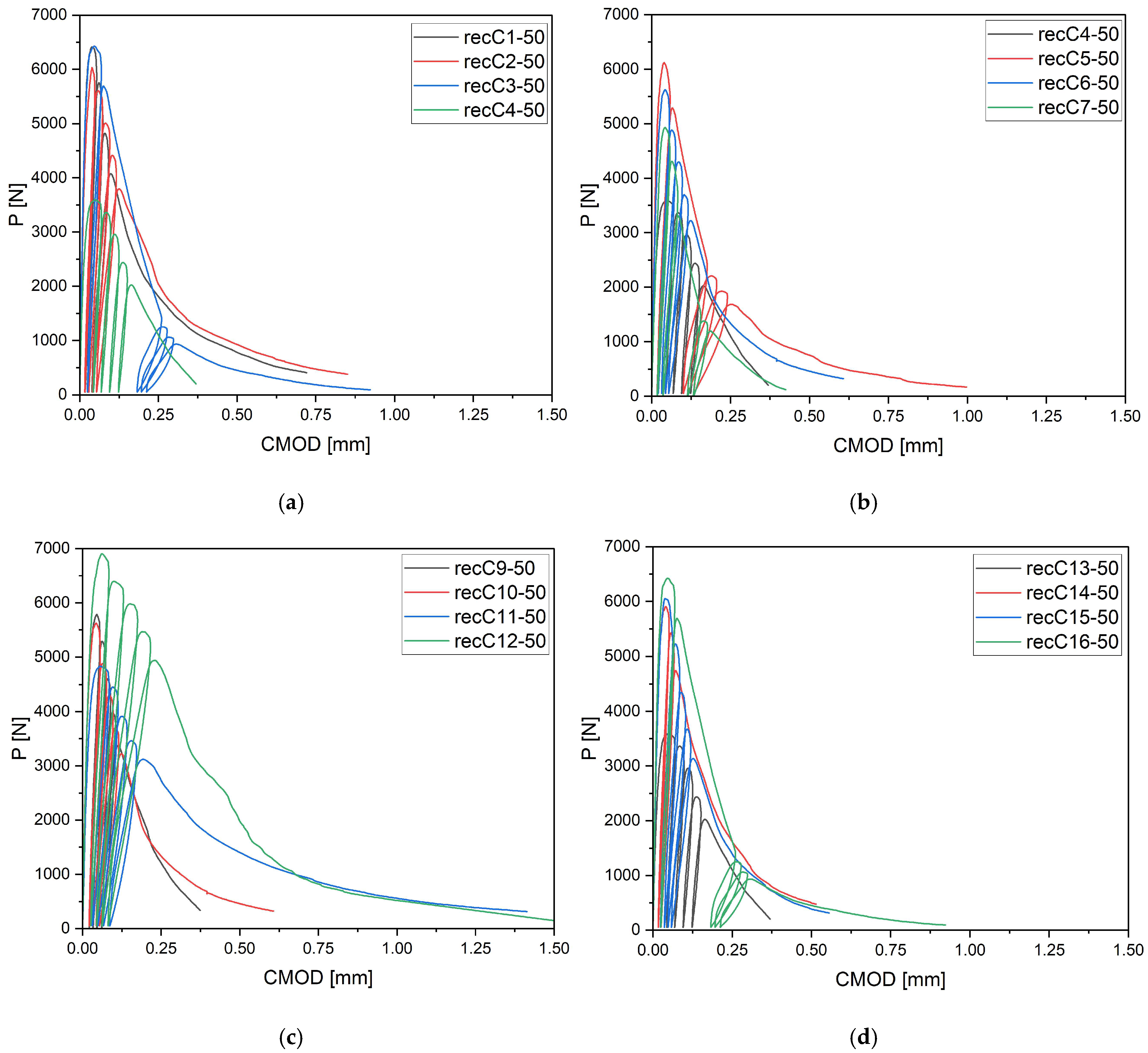

3.5. Load—Crack Mouth Opening Displacement (P-CMOD)

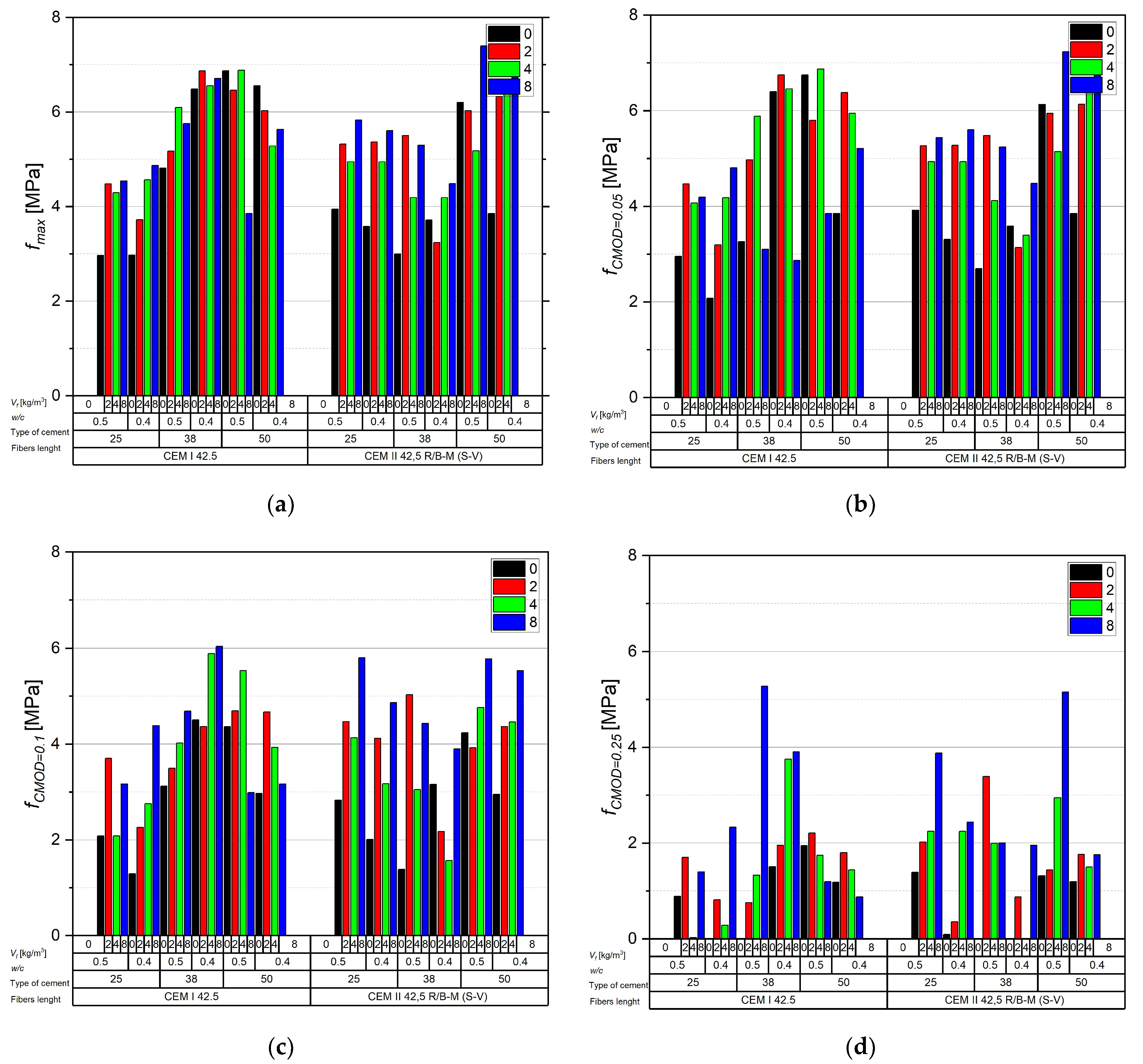

3.6. Residual Flexural Strength

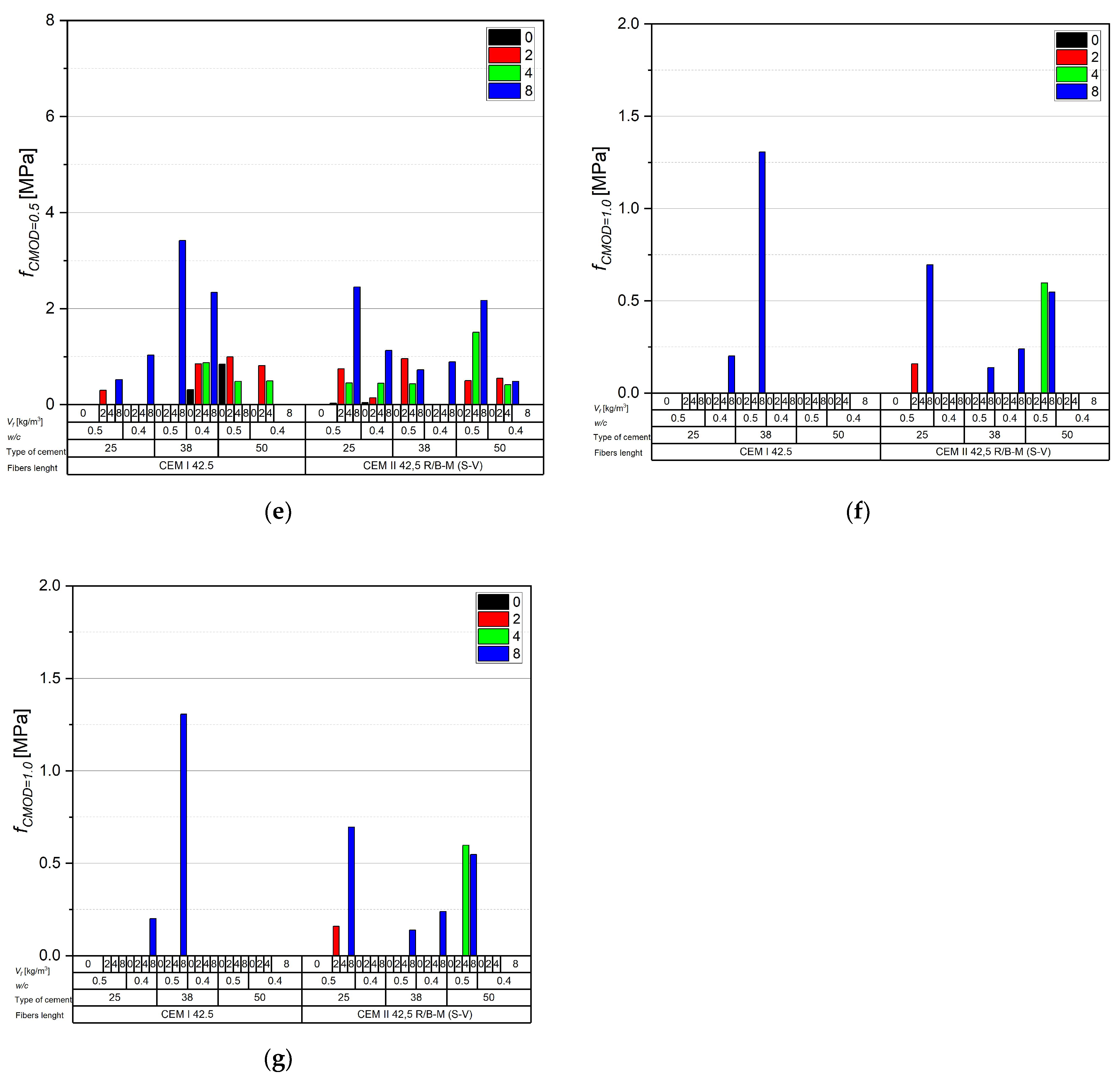

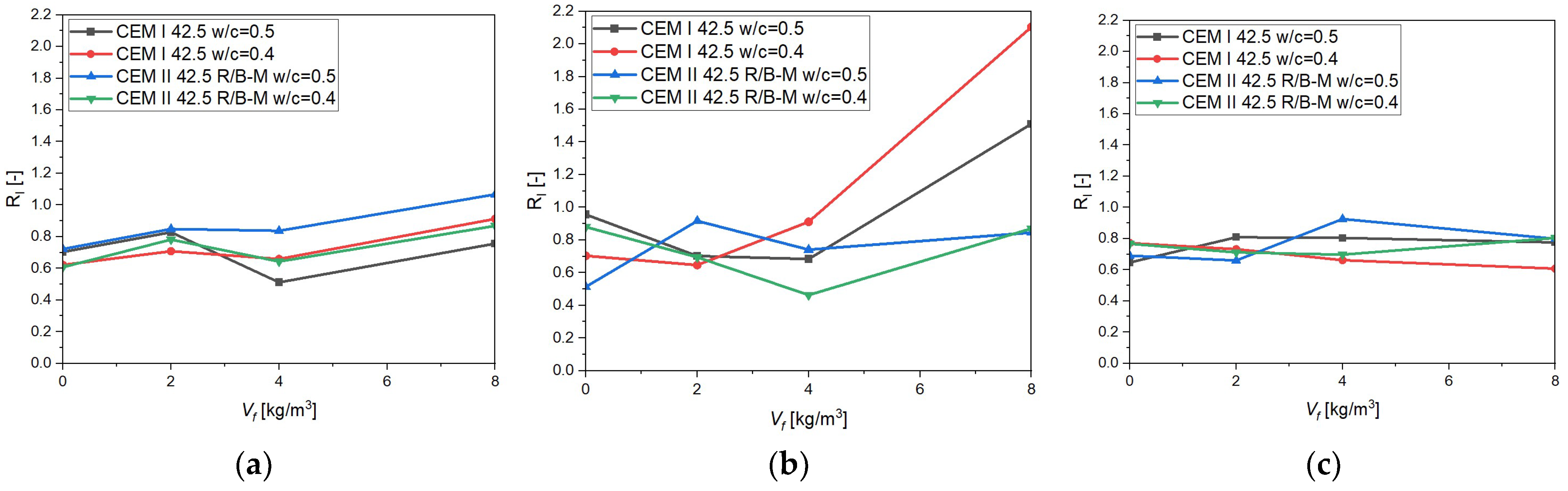

3.7. Residual Reinforcement Coefficient (Ri)

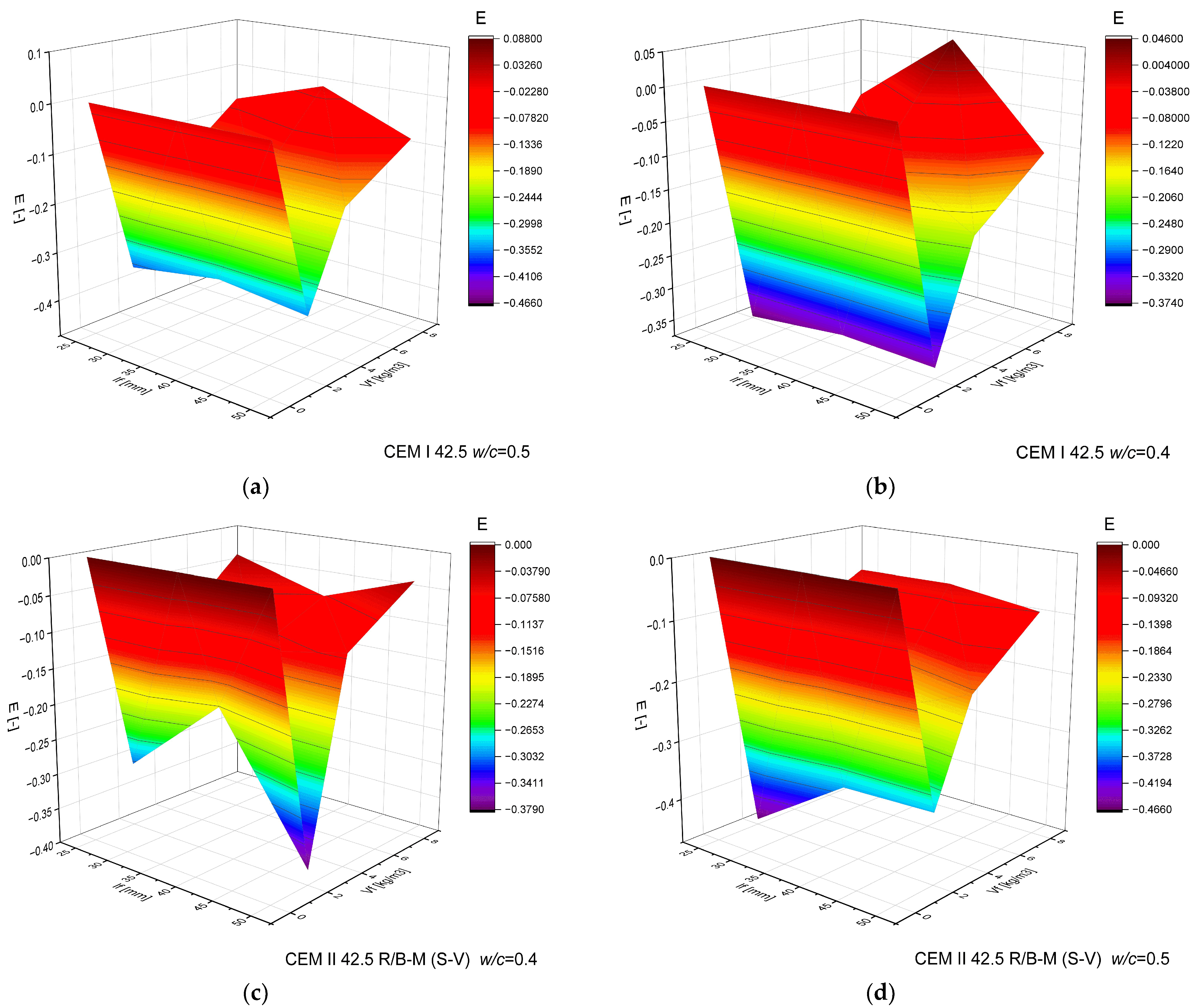

3.8. Fiber Efficiency Coefficient

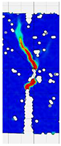

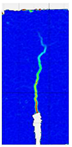

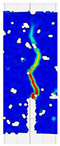

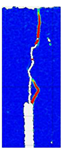

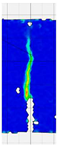

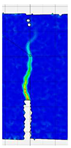

3.9. Analysis of DIC

4. Conclusions

- Fiber-reinforced concretes achieved high compressive strength (49.1–59.4 MPa). Strength increased slightly with higher fiber dosage, and the best performance was obtained for 50 mm fibers with CEM II 42.5 R/B-M (S-V) cement at 8 kg/m3. The influence of fiber length on compressive strength was minor (1–2 MPa difference). The amount of fibers did not have a significant effect on compressive strength.

- The secant modulus of elasticity (Ec,sec) showed moderate variation with fiber addition. At lower dosages (2–4 kg/m3), a slight increase in stiffness was observed, while at higher dosages (8 kg/m3) a small decrease occurred, likely due to the reduced homogeneity of the mix. This indicates the existence of an optimal fiber dosage range that improves effective stress transfer.

- The splitting tensile and flexural strengths increased significantly with higher fiber content, confirming the reinforcing and crack-bridging function of the fibers. Strength gains of up to 170% were achieved compared with reference concrete, particularly for 38–50 mm fibers at 8 kg/m3. It can be concluded that fiber length is a key parameter determining the fibers’ effectiveness in enhancing the concrete’s ability to carry tensile stresses.

- Load–CMOD curves showed that the presence of fibers delayed crack initiation and reduced the force drop beyond the proportional limit, leading to a more ductile post-cracking response. The failure of fiber-free beams was brittle and abrupt, in contrast to fiber-reinforced specimens, which were able to carry load even with increasing crack width (CMOD) and exhibited noticeable ductility. The most favorable behavior was obtained for 38 mm fibers at 8 kg/m3, providing an optimal balance between workability and crack-bridging efficiency.

- The analysis of residual flexural strength confirmed that fiber reinforcement was most effective at small and medium crack openings (CMOD ≤ 0.5 mm), demonstrating the ability of recycled carbon fibers to transfer tensile stresses after matrix cracking. To quantify this effect, the residual reinforcement coefficient (Ri) was introduced, defined as the ratio between the residual flexural strength at a given crack opening (CMOD = i) and that was recorded at CMOD = 0.05 mm. For 38 mm fibers at 8 kg/m3, Ri exceeded 2.0, indicating a strong crack-bridging effect and effective stress transfer during crack propagation. This parameter provides a clear, quantitative criterion for comparing different fiber geometries and mix compositions in terms of post-cracking behavior.

- The Fiber Efficiency Coefficient (E) was introduced to more accurately evaluate the effectiveness of recycled carbon fibers in enhancing the post-cracking behavior of concrete. The coefficient was defined as the increase in residual load-bearing capacity per unit of fiber content, determined from the difference between residual strengths at CMOD = 0.25 mm and CMOD = 0.05 mm. The analysis showed that E strongly depends on fiber length and cement type. The highest efficiency was obtained for 38 mm fibers at 8 kg/m3 in concretes with CEM I 42.5 and w/c = 0.5, where E reached +0.088, indicating a quantifiable improvement in post-cracking capacity. Short fibers (25 mm) exhibited negligible efficiency, while medium-length fibers provided the best balance between dispersion, interfacial bonding, and stress transfer. The results confirm that the coefficient E can serve as a quantitative criterion for comparing different fiber lengths, dosages, and cement matrices in terms of their contribution to the residual load-bearing capacity of fiber-reinforced concrete.

- Principal strain maps obtained from the DIC method showed that fiber reinforcement promoted more distributed and irregular crack propagation patterns.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Smoleń, J.; Olesik, P.; Jała, J.; Adamcio, A.; Kurtyka, K.; Godzierz, M.; Kozera, R.; Kozioł, M.; Boczkowska, A. The Use of Carbon Fibers Recovered by Pyrolysis from End-of-Life Wind Turbine Blades in Epoxy-Based Composite Panels. Polymers 2022, 14, 2925. [Google Scholar] [CrossRef] [PubMed]

- Jasińska, D.; Dutkiewicz, M. Waste Management of Wind Turbine Blades—A Review of Recycling Methods and Applications in Cementitious Composites. Sustainability 2025, 17, 805. [Google Scholar] [CrossRef]

- Crespo-López, L.; Coletti, C.; Morales-Ruano, S.; Cultrone, G. Use of Recycled Carbon Fibre as an Additive in the Manufacture of Porous Bricks More Durable against Salt Crystallization. Ceram. Int. 2024, 50, 9682–9696. [Google Scholar] [CrossRef]

- Kavaliauskas, Ž.; Kėželis, R.; Grigaitienė, V.; Marcinauskas, L.; Milieška, M.; Valinčius, V.; Uscila, R.; Snapkauskienė, V.; Gimžauskaitė, D.; Baltušnikas, A. Recycling of Wind Turbine Blades into Microfiber Using Plasma Technology. Materials 2023, 16, 3089. [Google Scholar] [CrossRef]

- Krassowska, J. Experimental and Analytical Study on Concrete Mechanical Properties of Recycled Carbon Fibers from Wind Turbine Blades. Materials 2025, 18, 4105. [Google Scholar] [CrossRef]

- Sarmah, A.; Sarikaya, S.; Thiem, J.; Upama, S.T.; Khalfaoui, A.N.; Dasari, S.S.; Arole, K.; Hawkins, S.A.; Naraghi, M.; Vashisth, A.; et al. Recycle and Reuse of Continuous Carbon Fibers from Thermoset Composites Using Joule Heating. ChemSusChem 2022, 15, e202200989. [Google Scholar] [CrossRef]

- Deng, J.; Xu, L.; Zhang, L.; Peng, J.; Guo, S.; Liu, J.; Koppala, S. Recycling of Carbon Fibers from CFRP Waste by Microwave Thermolysis. Processes 2019, 7, 207. [Google Scholar] [CrossRef]

- Morin, C.; Loppinet-Serani, A.; Cansell, F.; Aymonier, C. Near- and Supercritical Solvolysis of Carbon Fibre Reinforced Polymers (CFRPs) for Recycling Carbon Fibers as a Valuable Resource: State of the Art. J. Supercrit. Fluids 2012, 66, 232–240. [Google Scholar] [CrossRef]

- Wu, J.; Gao, X.; Wu, Y.; Wang, Y.; Nguyen, T.T.; Guo, M. Recycling Carbon Fiber from Carbon Fiber-Reinforced Polymer and Its Reuse in Photocatalysis: A Review. Polymers 2023, 15, 170. [Google Scholar] [CrossRef]

- Ashraf, M.J.; Idrees, M.; Akbar, A. Performance of Silica Fume Slurry Treated Recycled Aggregate Concrete Reinforced with Carbon Fibers. J. Build. Eng. 2023, 66, 105892. [Google Scholar] [CrossRef]

- Patchen, A.; Young, S.; Penumadu, D. An Investigation of Mechanical Properties of Recycled Carbon Fiber Reinforced Ultra-High-Performance Concrete. Materials 2022, 16, 314. [Google Scholar] [CrossRef]

- Xiong, C.; Lan, T.; Li, Q.; Li, H.; Long, W. Study of Mechanical Properties of an Eco-Friendly Concrete Containing Recycled Carbon Fiber Reinforced Polymer and Recycled Aggregate. Materials 2020, 13, 4592. [Google Scholar] [CrossRef] [PubMed]

- Kimm, M.; Pico, D.; Gries, T. Investigation of Surface Modification and Volume Content of Glass and Carbon Fibres from Fibre Reinforced Polymer Waste for Reinforcing Concrete. J. Hazard. Mater. 2020, 390, 121797. [Google Scholar] [CrossRef] [PubMed]

- Kimm, M.; Sabir, A.; Gries, T.; Suwanpinij, P. Potential of Using Recycled Carbon Fibers as Reinforcing Material for Fiber Concrete. In Proceedings of the Fibre Reinforced Concrete: Improvements and Innovations, Valencia, Spain, 20–22 September 2021; Serna, P., Llano-Torre, A., Martí-Vargas, J.R., Navarro-Gregori, J., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 949–960. [Google Scholar]

- Patchen, A.; Young, S.; Goodbred, L.; Puplampu, S.; Chawla, V.; Penumadu, D. Lower Carbon Footprint Concrete Using Recycled Carbon Fiber for Targeted Strength and Insulation. Materials 2023, 16, 5451. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Sun, L.; Li, A.; Li, W.; Guo, B. Effect of Modified Recycled Carbon Fibers on the Conductivity of Cement-Based Materials. Constr. Build. Mater. 2024, 415, 135033. [Google Scholar] [CrossRef]

- Xiong, C.; Li, Q.; Lan, T.; Li, H.; Long, W.; Xing, F. Sustainable Use of Recycled Carbon Fiber Reinforced Polymer and Crumb Rubber in Concrete: Mechanical Properties and Ecological Evaluation. J. Clean. Prod. 2021, 279, 123624. [Google Scholar] [CrossRef]

- EN 14651:2005+A1:2007; Test Method for Metallic Fibre Concrete. Measuring the Flexural Tensile Strength (Limit of Proportionality (LOP), Residual). British Standards Institution: London, UK, 2007.

- EN 12350-8:2010; Testing Fresh Concrete. Self-Compacting Concrete. Slump-Flow Test. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- EN 12390-7; Density of Hardened Concrete. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- EN 12390-3:2019-07; Testing of Concrete—Part 3: Compressive Strength of Test Specimens. British Standards Institution: London, UK, 2019.

- EN 12390-5:2019-08; Testing of Concrete—Part 5: Flexural Strength of Test Specimens. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- EN 12390-13:2021-12; Testing of Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression. European Committee for Standardization (CEN): Brussels, Belgium, 2021.

- Determination of the Fracture Energy of Mortars and Concretes by Means of Three-Point Bend Tests on Notched Beams. Materials and Structures. In Recommendation TC 50-FMT RILEM; Springer: Berlin/Heidelberg, Germany, 1985; pp. 285–290. [Google Scholar]

- Golewski, G.L. Determination of Fracture Mechanic Parameters of Concretes Based on Cement Matrix Enhanced by Fly Ash and Nano-Silica. Materials 2024, 17, 4230. [Google Scholar] [CrossRef]

- Jenq, Y.S.; Shah, S.P. A Fracture Toughness Criterion for Concrete. Eng. Fract. Mech. 1985, 21, 1055–1069. [Google Scholar] [CrossRef]

- Yusuf, M.S.; Isak, A.B.; Mohamud, G.A.; Warsame, A.H.; Osman, Y.I.; Ibrahim, A.H.; Elmi, L.A.A. Effect of Steel Fiber on Concrete’s Compressive Strength. Open J. Civ. Eng. 2023, 13, 192–197. [Google Scholar] [CrossRef]

- Larsen, I.L.; Thorstensen, R.T. The Influence of Steel Fibres on Compressive and Tensile Strength of Ultra High Performance Concrete: A Review. Constr. Build. Mater. 2020, 256, 119459. [Google Scholar] [CrossRef]

- Hosseinzadeh, H.; Masoud Salehi, A.; Mehraein, M.; Asadollahfardi, G. The Effects of Steel, Polypropylene, and High-Performance Macro Polypropylene Fibers on Mechanical Properties and Durability of High-Strength Concrete. Constr. Build. Mater. 2023, 386, 131589. [Google Scholar] [CrossRef]

- Abbas Ashour Alaraza, H.; Kharun, M.; Chiadighikaobi, P.C. The Effect of Minibars Basalt Fiber Fraction on Mechanical Properties of High-Performance Concrete. Cogent Eng. 2022, 9, 2136603. [Google Scholar] [CrossRef]

- Abed, F.; Alhafiz, A.R. Effect of Basalt Fibers on the Flexural Behavior of Concrete Beams Reinforced with BFRP Bars. Compos. Struct. 2019, 215, 23–34. [Google Scholar] [CrossRef]

- Kosior-Kazberuk, M.; Krassowska, J.; Vidales Barriguete, A.; Ramirez, C.P. Fracture Parameters of Basalt Fiber Reinforced Concrete. An. De Edif. 2018, 4, 52–59. [Google Scholar] [CrossRef]

- Nurbаyevа, M.; Аruovа, L.; Lukpаnov, R. Талшықтардың бетoнның беріктік сипаттамаларына әсерін бағалау. Bull. L.N. Gumilyov Eurasian Natl. Univ. Tech. Sci. Technol. Ser. 2023, 143, 36–45. [Google Scholar] [CrossRef]

- Al–Hail, H.H.A.; Fawzi, N.M. Carbon Fiber Effect on Compressive Strength of Lightweight Foamed Concrete. J. Eng. 2024, 30, 34–47. [Google Scholar] [CrossRef]

- Indra, S.; Rachma, N.; Erfan, M.; Yuwono, E.; Andinisari, R. Effects of Aluminum Fibers Additive on the Compressive Strength of a Concrete. J. Infrastruct. Plan. Eng. 2024, 3, 1–4. [Google Scholar] [CrossRef]

- Jirawattanasomkul, T.; Ueda, T.; Likitlersuang, S.; Zhang, D.; Hanwiboonwat, N.; Wuttiwannasak, N.; Horsangchai, K. Effect of Natural Fibre Reinforced Polymers on Confined Compressive Strength of Concrete. Constr. Build. Mater. 2019, 223, 156–164. [Google Scholar] [CrossRef]

- El-Abbasy, A.A. Tensile, Flexural, Impact Strength, and Fracture Properties of Ultra-High-Performance Fiber-Reinforced Concrete—A Comprehensive Review. Constr. Build. Mater. 2023, 408, 133621. [Google Scholar] [CrossRef]

- Abna, A.; Mazloom, M. Flexural Properties of Fiber Reinforced Concrete Containing Silica Fume and Nano-Silica. Mater. Lett. 2022, 316, 132003. [Google Scholar] [CrossRef]

- Li, C.; Zhu, H.; Niu, G.; Cheng, S.; Gu, Z.; Yang, L. Flexural Behavior and a New Model for Flexural Design of Concrete Beams Hybridly Reinforced by Continuous FRP Bars and Discrete Steel Fibers. Structures 2022, 38, 949–960. [Google Scholar] [CrossRef]

- Xia, L.; Xin, W.; Zhiyuan, C.; Kaidi, J.; Weitao, L.; Zhishen, W. Synergistic Effect of Hybrid Micro- and Macro- Fibers on the Flexural Properties of Concrete. Constr. Build. Mater. 2025, 462, 139901. [Google Scholar] [CrossRef]

- Jiao, Y.; Yang, H.; Wang, J.; Fang, M.; Shi, H. Effects of Fiber Properties on Flexural and Fracture Characteristics of Manufactured Sand Concrete Based on Acoustic Emission. J. Build. Eng. 2024, 84, 108308. [Google Scholar] [CrossRef]

- Krassowska, J. Fracture Behavior and Mechanical Properties of Basalt Chopped Fibers and Minibars Fiber-Reinforced Concrete. Structures 2025, 75, 108808. [Google Scholar] [CrossRef]

- Islam, T.; Safiuddin, M.; Roman, R.A.; Chakma, B.; Al Maroof, A. Mechanical Properties of PVC Fiber-Reinforced Concrete—Effects of Fiber Content and Length. Buildings 2023, 13, 2666. [Google Scholar] [CrossRef]

- Abadel, A.; Abbas, H.; Almusallam, T.; Al-Salloum, Y.; Siddiqui, N. Mechanical Properties of Hybrid Fibre-Reinforced Concrete—Analytical Modelling and Experimental Behaviour. Mag. Concr. Res. 2015, 68, 823–843. [Google Scholar] [CrossRef]

- Alshannag, M.; Alshmalani, M.; Alsaif, A.; Higazey, M. Flexural Performance of High-Strength Lightweight Concrete Beams Made with Hybrid Fibers. Case Stud. Constr. Mater. 2023, 18, e01861. [Google Scholar] [CrossRef]

- Alshahrani, A.; Kulasegaram, S.; Kundu, A. Utilisation of Simulation-Driven Fibre Orientation for Effective Modelling of Flexural Strength and Toughness in Self-Compacting Concrete. Constr. Build. Mater. 2025, 459, 139767. [Google Scholar] [CrossRef]

- Kang, T.H.-K.; Kim, W.; Kwak, Y.-K.; Hong, S.-G. Shear Testing of Steel Fiber-Reinforced Lightweight Concrete Beams without Web Reinforcement. ACI Struct. J. 2011, 108, 553–561. [Google Scholar] [CrossRef]

- Ali, B.; Kurda, R.; Herki, B.; Alyousef, R.; Mustafa, R.; Mohammed, A.; Raza, A.; Ahmed, H.; Fayyaz Ul-Haq, M. Effect of Varying Steel Fiber Content on Strength and Permeability Characteristics of High Strength Concrete with Micro Silica. Materials 2020, 13, 5739. [Google Scholar] [CrossRef]

- Mashrei, M.; Sultan, A.; Mahdi, A.M. Effects of Polypropylene Fibers on Compressive and Flexural Strength of Concrete Material. Int. J. Civ. Eng. Technol. 2018, 9, 2208–2217. [Google Scholar]

- Borhan, T.M. Thermal and Mechanical Properties of Basalt Fibre Reinforced Concrete. Int. J. Civ. Environ. Eng. 2013, 7, 313. [Google Scholar]

- Chellapandian, M.; Bhavani, R.; Santhiya, R.; Sneha, B. Effect of GFRP Reinforcement on the Shear Behavior of Natural Fiber Based Engineered Cementitious Composite Beams. In Proceedings of the Recent Developments in Structural Engineering, Nagpur, India, 7–9 December 2023; Kumar, R., Bakre, S.V., Goel, M.D., Eds.; Springer Nature: Singapore, 2025; Volume 2, pp. 111–118. [Google Scholar]

- Nagrockiene, D.; Girskas, G. Research into the Properties of Concrete Modified with Natural Zeolite Addition. Constr. Build. Mater. 2016, 113, 964–969. [Google Scholar] [CrossRef]

- Krassowska, J.; Kosior-Kazberuk, M. The Effect of Steel and Basalt Fibers on the Shear Behavior of Double-Span Fiber Reinforced Concrete Beams. Materials 2021, 14, 6090. [Google Scholar] [CrossRef] [PubMed]

- Bhosale, A.B.; Prakash, S.S. Crack Propagation Analysis of Synthetic vs. Steel vs. Hybrid Fibre-Reinforced Concrete Beams Using Digital Image Correlation Technique. Int. J. Concr. Struct. Mater. 2020, 14, 57. [Google Scholar] [CrossRef]

- Borhan, T.M. Properties of Glass Concrete Reinforced with Short Basalt Fibre | Request PDF. Mater. Des. 2012, 42, 265–271. [Google Scholar] [CrossRef]

- Wambeke, B.W.; Shield, C.K. Development Length of Glass Fiber-Reinforced Polymer Bars in Concrete. ACI Struct. J. 2006, 103, 11–17. [Google Scholar] [CrossRef]

- Khaleel, O.R.; Al Wahaibi, M.M.S.; Abed, M.J.; Dawood, M.; Fayyadh, M.M. Performance of Carbon Fibre Concrete Subjected to Fire. Mater. Today Proc. 2021, 42, 1160–1165. [Google Scholar] [CrossRef]

- Yang, J.; Chen, B.; Nuti, C. Influence of Steel Fiber on Compressive Properties of Ultra-High Performance Fiber-Reinforced Concrete. Constr. Build. Mater. 2021, 302, 124104. [Google Scholar] [CrossRef]

- RaviKumar, P.; Rajeshkumar, G.; Prakash Maran, J.; Al-Dhabi, N.A.; Karuppiah, P. Evaluation of Mechanical and Water Absorption Behaviors of Jute/Carbon Fiber Reinforced Polyester Hybrid Composites. J. Nat. Fibers 2022, 19, 6521–6533. [Google Scholar] [CrossRef]

- Smarzewski, P. Stany Zarysowania i Odkształcenia Belek Żelbetowych z Betonu Wysokowartościowego z Dodatkiem Włókien. Biul. Wojsk. Akad. Tech. 2014, 63, 135–145. [Google Scholar] [CrossRef]

- He, F.; Biolzi, L.; Carvelli, V. Effect of Fiber Hybridization on Mechanical Properties of Concrete. Mater. Struct. 2022, 55, 195. [Google Scholar] [CrossRef]

- Jin, A.; Woo, J.-S.; Yun, H.-D.; Kim, S.-W.; Park, W.-S.; Choi, W.-C. Influence of Concrete Strength and Fiber Properties on Residual Flexural Strength of Steel Fiber-Reinforced Concrete. Constr. Build. Mater. 2025, 489, 142366. [Google Scholar] [CrossRef]

| Cement | CEM I 42.5 | CEM II 42.5R/A-V | ||

|---|---|---|---|---|

| Water to cement ratio | w/c = 0.5 | w/c = 0.4 | ||

| Vf [kg/m3] | 0 | 2 | 4 | 8 |

| Recycled carbon fibers recC |  |  |  | |

| lf [mm] | 25 | 38 | 50 | |

| df [mm] | 0.8 | 0.8 | 0.8 | |

| Mixture Proportions | w/c = 0.5 | w/c = 0.4 |

|---|---|---|

| CEM I or CEM II, [kg/m3] | 320 | 320 |

| Water, [kg/m3] | 160 | 128 |

| Sand 0.125–2 mm, [kg/m3] | 732 | 742 |

| Aggregate 2/16, [kg/m3] | 1203 | 1203 |

| Sika Sikacem Superplast [kg/m3] | 3.2 | 6.4 |

| Series | Type of Cement | w/c | lf | Vf | Vf | fc | fctm | fcl | Ec,sec | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [-] | [-] | [mm] | [kg/m3] | [%] | [MPa] | [MPa] | [MPa] | [MPa] | |||||

| recC1-25 | CEM I 42.5 | 0.5 | 25 | 0 | 0 | 51.60 | ±6.32 | 2.63 | ±0.07 | 2.30 | ±0.57 | 47.82 | ±1.20 |

| recC2-25 | 0.5 | 2 | 0.11 | 52.10 | ±2.10 | 3.71 | ±0.12 | 3.31 | ±0.14 | 46.52 | ±0.78 | ||

| recC3-25 | 0.5 | 4 | 0.22 | 57.47 | ±4.87 | 4.21 | ±0.60 | 4.25 | ±0.78 | 48.16 | ±1.86 | ||

| recC4-25 | 0.5 | 8 | 0.44 | 58.03 | ±7.48 | 5.12 | ±0.79 | 5.24 | ±0.01 | 46.45 | ±3.50 | ||

| recC5-25 | 0.4 | 0 | 0 | 52.39 | ±2.57 | 2.48 | ±0.52 | 3.27 | ±0.20 | 46.12 | ±2.54 | ||

| recC6-25 | 0.4 | 2 | 0.11 | 53.87 | ±3.64 | 3.45 | ±0.09 | 4.81 | ±0.44 | 43.56 | ±0.98 | ||

| recC7-25 | 0.4 | 4 | 0.22 | 57.55 | ±6.58 | 5.78 | ±0.23 | 4.14 | ±0.01 | 49.55 | ±1.35 | ||

| recC8-25 | 0.4 | 8 | 0.44 | 58.65 | ±3.06 | 5.54 | ±0.01 | 6.47 | ±0.07 | 44.79 | ±4.20 | ||

| recC9-25 | CEM II 42.5 R/B-M (S-V) | 0.5 | 0 | 0 | 50.87 | ±3.06 | 2.70 | ±0.18 | 3.04 | ±0.01 | 41.59 | ±2.81 | |

| recC10-25 | 0.5 | 2 | 0.11 | 52.59 | ±2.00 | 3.28 | ±0.41 | 3.16 | ±0.03 | 47.07 | ±2.65 | ||

| recC11-25 | 0.5 | 4 | 0.22 | 54.81 | ±6.25 | 5.19 | ±1.09 | 4.97 | ±0.67 | 43.65 | ±1.14 | ||

| recC12-25 | 0.5 | 8 | 0.44 | 59.09 | ±6.42 | 7.87 | ±1.47 | 6.81 | ±0.01 | 40.08 | ±0.56 | ||

| recC13-25 | 0.4 | 0 | 0 | 49.91 | ±2.05 | 2.52 | ±0.06 | 3.27 | ±0.11 | 43.99 | ±1.51 | ||

| recC14-25 | 0.4 | 2 | 0.11 | 51.11 | ±8.29 | 3.24 | ±0.89 | 4.47 | ±0.57 | 43.47 | ±1.23 | ||

| recC15-25 | 0.4 | 4 | 0.22 | 54.97 | ±8.87 | 5.24 | ±0.79 | 5.09 | ±0.43 | 45.60 | ±3.12 | ||

| recC16-25 | 0.4 | 8 | 0.44 | 55.81 | ±3.68 | 6.25 | ±0.83 | 6.30 | ±0.48 | 43.04 | ±1.36 | ||

| recC1-38 | CEM I 42.5 | 0.5 | 38 | 0 | 0 | 50.13 | ±0.80 | 2.91 | ±0.87 | 2.68 | ±0.76 | 50.16 | ±3.29 |

| recC2-38 | 0.5 | 2 | 0.11 | 51.08 | ±9.21 | 3.63 | ±0.07 | 4.62 | ±0.41 | 48.39 | ±1.39 | ||

| recC3-38 | 0.5 | 4 | 0.22 | 54.24 | ±4.12 | 4.71 | ±0.12 | 4.64 | ±0.18 | 41.87 | ±0.51 | ||

| recC4-38 | 0.5 | 8 | 0.44 | 55.91 | ±1.75 | 5.21 | ±0.60 | 6.78 | ±0.82 | 48.02 | ±1.65 | ||

| recC5-38 | 0.4 | 0 | 0 | 50.35 | ±2.30 | 2.12 | ±0.79 | 3.11 | ±1.46 | 49.27 | ±3.22 | ||

| recC6-38 | 0.4 | 2 | 0.11 | 54.93 | ±2.57 | 4.48 | ±0.52 | 4.39 | ±0.11 | 47.82 | ±1.54 | ||

| recC7-38 | 0.4 | 4 | 0.22 | 57.49 | ±6.49 | 4.45 | ±0.09 | 4.52 | ±0.33 | 43.20 | ±2.32 | ||

| recC8-38 | 0.4 | 8 | 0.44 | 58.12 | ±2.35 | 5.78 | ±0.23 | 5.62 | ±0.76 | 41.81 | ±3.45 | ||

| recC9-38 | CEM II 42.5 R/B-M (S-V) | 0.5 | 0 | 0 | 50.92 | ±2.37 | 2.54 | ±0.01 | 2.57 | ±0.61 | 42.38 | ±3.14 | |

| recC10-38 | 0.5 | 2 | 0.11 | 52.45 | ±0.00 | 3.70 | ±0.18 | 3.57 | ±0.37 | 44.60 | ±1.57 | ||

| recC11-38 | 0.5 | 4 | 0.22 | 58.13 | ±6.60 | 4.28 | ±0.41 | 4.57 | ±0.88 | 45.75 | ±1.65 | ||

| recC12-38 | 0.5 | 8 | 0.44 | 59.37 | ±2.77 | 5.19 | ±1.09 | 5.96 | ±0.08 | 51.78 | ±0.98 | ||

| recC13-38 | 0.4 | 0 | 0 | 51.82 | ±4.31 | 3.87 | ±1.47 | 2.47 | ±0.45 | 41.51 | ±6.05 | ||

| recC14-38 | 0.4 | 2 | 0.11 | 53.18 | ±1.79 | 3.52 | ±0.06 | 5.60 | ±0.66 | 43.34 | ±1.07 | ||

| recC15-38 | 0.4 | 4 | 0.22 | 55.69 | ±6.60 | 5.24 | ±0.89 | 5.60 | ±0.10 | 40.46 | ±3.25 | ||

| recC16-38 | 0.4 | 8 | 0.44 | 58.36 | ±3.62 | 6.01 | ±1.72 | 6.87 | ±0.26 | 44.09 | ±4.11 | ||

| recC1-50 | CEM I 42.5 | 0.5 | 50 | 0 | 0 | 50.32 | ±1.06 | 2.30 | ±0.57 | 2.83 | ±0.76 | 42.64 | ±4.23 |

| recC2-50 | 0.5 | 2 | 0.11 | 51.52 | ±2.44 | 3.30 | ±0.57 | 4.51 | ±0.19 | 47.08 | ±1.65 | ||

| recC3-50 | 0.5 | 4 | 0.22 | 52.14 | ±3.74 | 4.16 | ±0.03 | 6.03 | ±0.53 | 42.45 | ±2.96 | ||

| recC4-50 | 0.5 | 8 | 0.44 | 55.58 | ±1.28 | 6.97 | ±0.67 | 6.55 | ±0.45 | 39.13 | ±4.54 | ||

| recC5-50 | 0.4 | 0 | 0 | 54.87 | ±1.82 | 2.26 | ±1.31 | 2.39 | ±0.22 | 42.18 | ±2.65 | ||

| recC6-50 | 0.4 | 2 | 0.11 | 56.54 | ±3.29 | 3.81 | ±0.01 | 4.73 | ±0.39 | 48.25 | ±0.87 | ||

| recC7-50 | 0.4 | 4 | 0.22 | 58.00 | ±1.53 | 3.14 | ±0.11 | 3.37 | ±0.21 | 49.01 | ±1.65 | ||

| recC8-50 | 0.4 | 8 | 0.44 | 58.22 | ±1.53 | 6.47 | ±0.57 | 5.00 | ±0.38 | 42.17 | ±1.74 | ||

| recC9-50 | CEM II 42.5 R/B-M (S-V) | 0.5 | 0 | 0 | 49.09 | ±1.00 | 2.04 | ±0.79 | 3.04 | ±0.22 | 47.51 | ±1.82 | |

| recC10-50 | 0.5 | 2 | 0.11 | 50.77 | ±3.13 | 3.31 | ±0.14 | 3.04 | ±0.28 | 39.09 | ±3.29 | ||

| recC11-50 | 0.5 | 4 | 0.22 | 52.99 | ±3.21 | 5.25 | ±0.78 | 4.62 | ±0.85 | 41.90 | ±1.53 | ||

| recC12-50 | 0.5 | 8 | 0.44 | 54.17 | ±1.03 | 6.24 | ±0.01 | 6.29 | ±0.09 | 51.66 | ±1.53 | ||

| recC13-50 | 0.4 | 0 | 0 | 50.88 | ±4.15 | 2.27 | ±0.20 | 2.95 | ±0.39 | 41.10 | ±1.00 | ||

| recC14-50 | 0.4 | 2 | 0.11 | 52.17 | ±4.44 | 3.10 | ±0.44 | 3.63 | ±0.71 | 39.48 | ±3.13 | ||

| recC15-50 | 0.4 | 4 | 0.22 | 53.70 | ±1.84 | 5.09 | ±0.01 | 5.45 | ±0.05 | 45.96 | ±3.21 | ||

| recC16-50 | 0.4 | 8 | 0.44 | 59.07 | ±3.98 | 6.54 | ±0.12 | 6.02 | ±0.27 | 46.48 | ±1.03 | ||

| Fiber Type | Typical Dosage | Strength Change | Citations |

|---|---|---|---|

| Steel | 1–3% by volume | +9–18% | [27,28,29] |

| Polypropylene | 0.2–0.5% by cement | +5–15% (modest) | [29] |

| Basalt | 0.1% by cement | +11% | [30,31,32] |

| Carbon | 1% by volume | +10% | [33,34] |

| Aluminum | 0.04–0.05% by vol. | +10% | [35] |

| Natural (NFRP) | External wrap | Significant | [36] |

| Fiber Type | Typical Dosage | Modulus Change | Citations |

|---|---|---|---|

| Steel | 0.5–2% by volume | Slight increase or neutral | [29,37] |

| Polypropylene | 0.2–1% by cement | Decrease or neutral | [38,39,40] |

| Basalt/PVA Hybrid | 0.25% total | Up to +35% | [40,41,42] |

| Natural (Abaca) | 0.15% by volume | +15% | [36] |

| PVC | 1% by cement | Increase, then decrease | [43] |

| Fiber Type/Combination | Typical Dosage | Flexural Strength Change | Citations |

|---|---|---|---|

| Steel | 1–3% by volume | +50–180% | [29,37] |

| Polypropylene (PP) | 0.15–0.2% by cement | +10–30% (modest) | [38,39,40] |

| Hybrid (macro + micro) | Varies | +127–443% | [44,45] |

| Fiber alignment (longitud.) | N/A | Up to +104% | [36,46,47] |

| Fiber Type/Combination | Typical Dosage | Splitting Strength Change | Citations |

|---|---|---|---|

| Steel | 0.5–2% by volume | +41–162% | [27,28] |

| Polyester | 0.2–0.3% by volume | +41–66% | [9,12,29,48] |

| Polypropylene | 0.5% by volume | +43% | [40,41] |

| Basalt/Hybrid | Varies | +22–29% (hybrid) | [12,42,49,50] |

| Natural (Coconut, etc.) | 1–1.5% by mass | Significant, optimal at 1.5% | [36,51,52] |

| Fiber Type | Typical Dosage | Flexural Strength Increase | Toughness/Residual Strength | Citations |

|---|---|---|---|---|

| Synthetic (PP) | 2.5% by volume | +26.9% | 4.75× toughness | [54,58] |

| Basalt | 0.1–0.5% by volume | +20.8–43.5% | 4.64× toughness | [9,30,42,53] |

| Glass | 2.5% by volume | +27.9% | 4.86× toughness | [55,56] |

| Carbon | Not specified | Highest among all | Superior residual strength | [3,12,57,59,60] |

| Series | 0.1 Pmax | 0.5 Pmax | 0.9 Pmax | Pmax | |

|---|---|---|---|---|---|

| recC1-25 |  |  |  |  |  |

| recC2-25 |  |  |  |  | |

| recC3-25 |  |  |  |  | |

| recC4-25 |  |  |  |  | |

| recC5-25 |  |  |  |  | |

| recC6-25 |  |  |  |  | |

| recC7-25 |  |  |  |  | |

| recC8-25 |  |  |  |  | |

| recC9-25 |  |  |  |  | |

| recC10-25 |  |  |  |  | |

| recC11-25 |  |  |  |  | |

| recC12-25 |  |  |  |  | |

| recC13-25 |  |  |  |  | |

| recC14-25 |  |  |  |  | |

| recC15-25 |  |  |  |  | |

| recC16-25 |  |  |  |  | |

| recC1-38 |  |  |  |  | |

| recC2-38 |  |  |  |  | |

| recC3-38 |  |  |  |  | |

| recC4-38 |  |  |  |  | |

| recC5-38 |  | - | - |  | |

| recC6-38 |  |  |  |  | |

| recC7-38 |  |  |  |  | |

| recC8-38 |  |  |  |  | |

| recC9-38 | - |  | - |  | |

| recC10-38 |  |  |  |  | |

| recC11-38 |  |  |  |  | |

| recC12-38 |  |  |  |  | |

| recC13-38 |  |  |  |  | |

| recC14-38 |  |  |  |  | |

| recC15-38 |  |  |  |  | |

| recC16-38 |  |  |  |  | |

| recC1-50 |  |  |  |  | |

| recC2-50 |  |  |  |  | |

| recC3-50 |  |  |  |  | |

| recC4-50 |  |  |  |  | |

| recC5-50 |  |  |  |  | |

| recC6-50 |  |  |  |  | |

| recC7-50 |  |  |  |  | |

| recC8-50 |  |  |  |  | |

| recC9-50 |  |  |  |  | |

| recC10-50 |  |  |  |  | |

| recC11-50 |  |  |  |  | |

| recC12-50 |  |  |  |  | |

| recC13-50 |  |  |  |  | |

| recC14-50 |  |  |  |  | |

| recC15-50 |  |  |  |  | |

| recC16-50 |  |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krassowska, J. Residual Flexural Strength of Concrete Reinforced with Recycled Carbon Fibers from Wind Turbine Blades. Materials 2025, 18, 5195. https://doi.org/10.3390/ma18225195

Krassowska J. Residual Flexural Strength of Concrete Reinforced with Recycled Carbon Fibers from Wind Turbine Blades. Materials. 2025; 18(22):5195. https://doi.org/10.3390/ma18225195

Chicago/Turabian StyleKrassowska, Julita. 2025. "Residual Flexural Strength of Concrete Reinforced with Recycled Carbon Fibers from Wind Turbine Blades" Materials 18, no. 22: 5195. https://doi.org/10.3390/ma18225195

APA StyleKrassowska, J. (2025). Residual Flexural Strength of Concrete Reinforced with Recycled Carbon Fibers from Wind Turbine Blades. Materials, 18(22), 5195. https://doi.org/10.3390/ma18225195