Research on Selected Properties of Concrete Composite with the Addition of Post-Production Metallic Dust

Abstract

1. Introduction

2. Purpose and Scope of the Research

- Series 1 (K0)—reference concrete with superplasticizer;

- Series 2 (KF)—a variant in which Series 1 has been modified with the addition of dispersed reinforcement in the form of steel fibers;

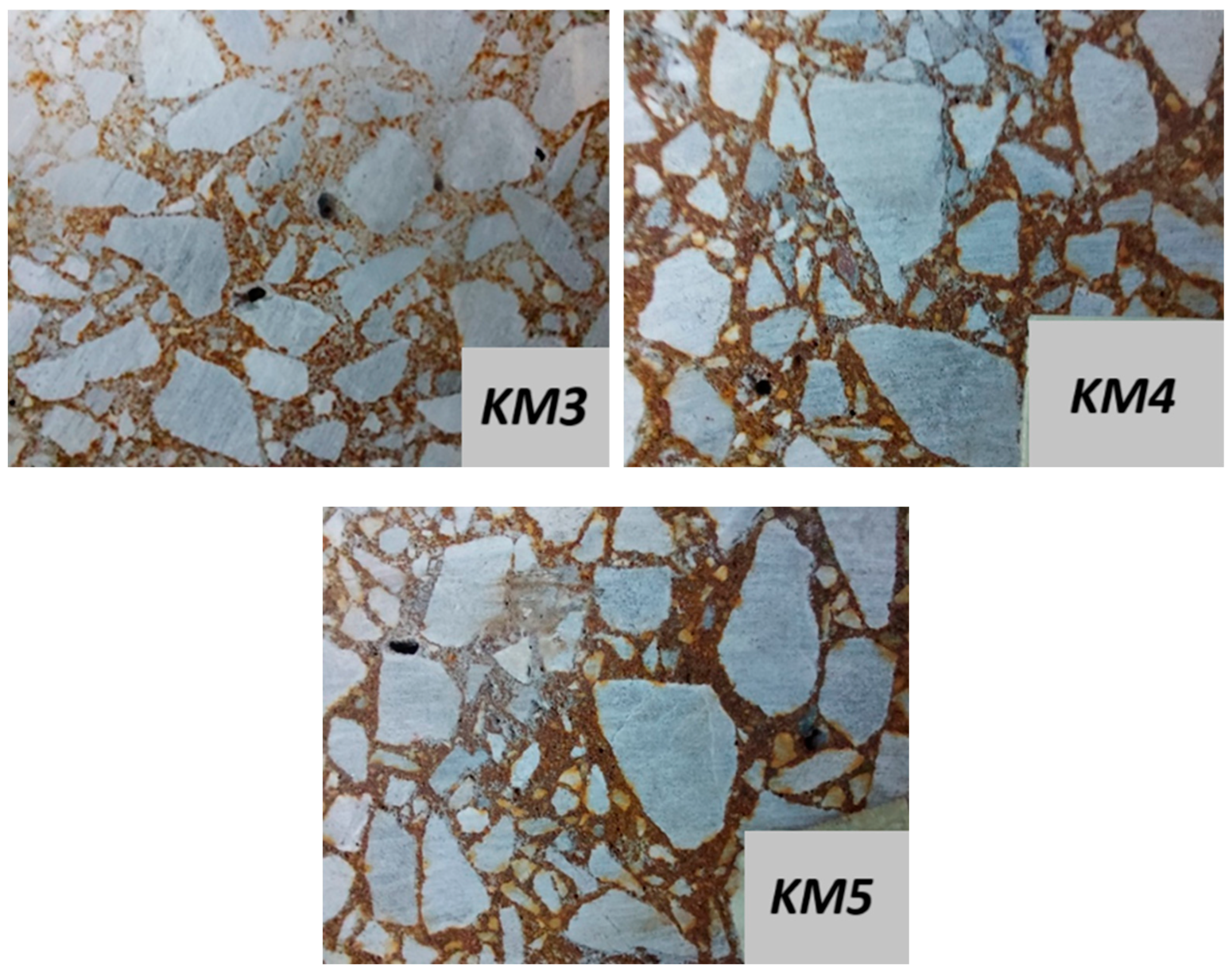

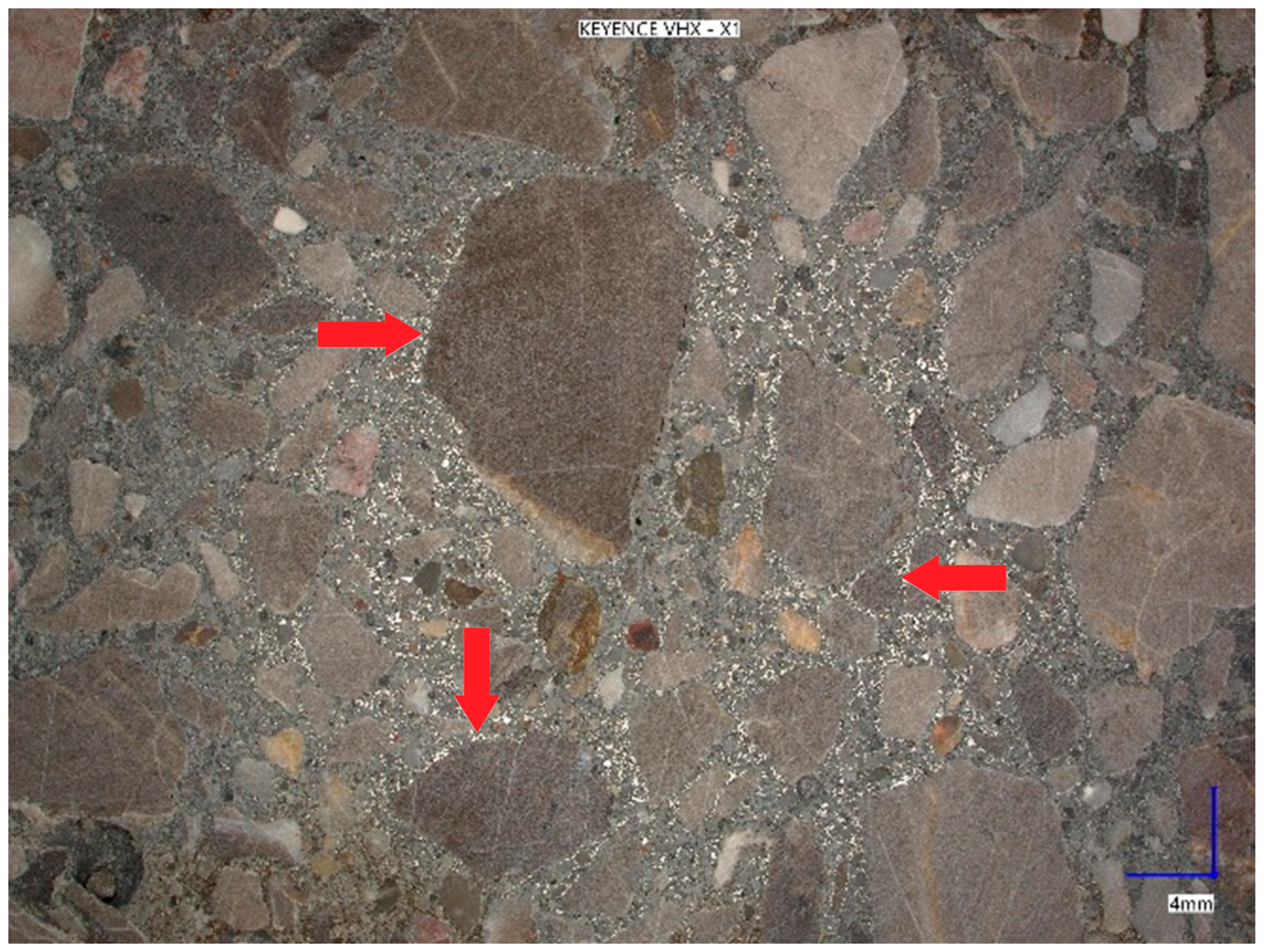

- Series 3–7 (KM) variants, in which Series 1 was modified with the addition of metallic dust, used as a partial replacement for fine aggregate in amounts of 10, 20, 30, 40, and 50% (5 series KM1 to KM5).

- Testing the consistency of concrete mixtures;

- Marking the density of concrete composites;

- Testing the abrasion resistance;

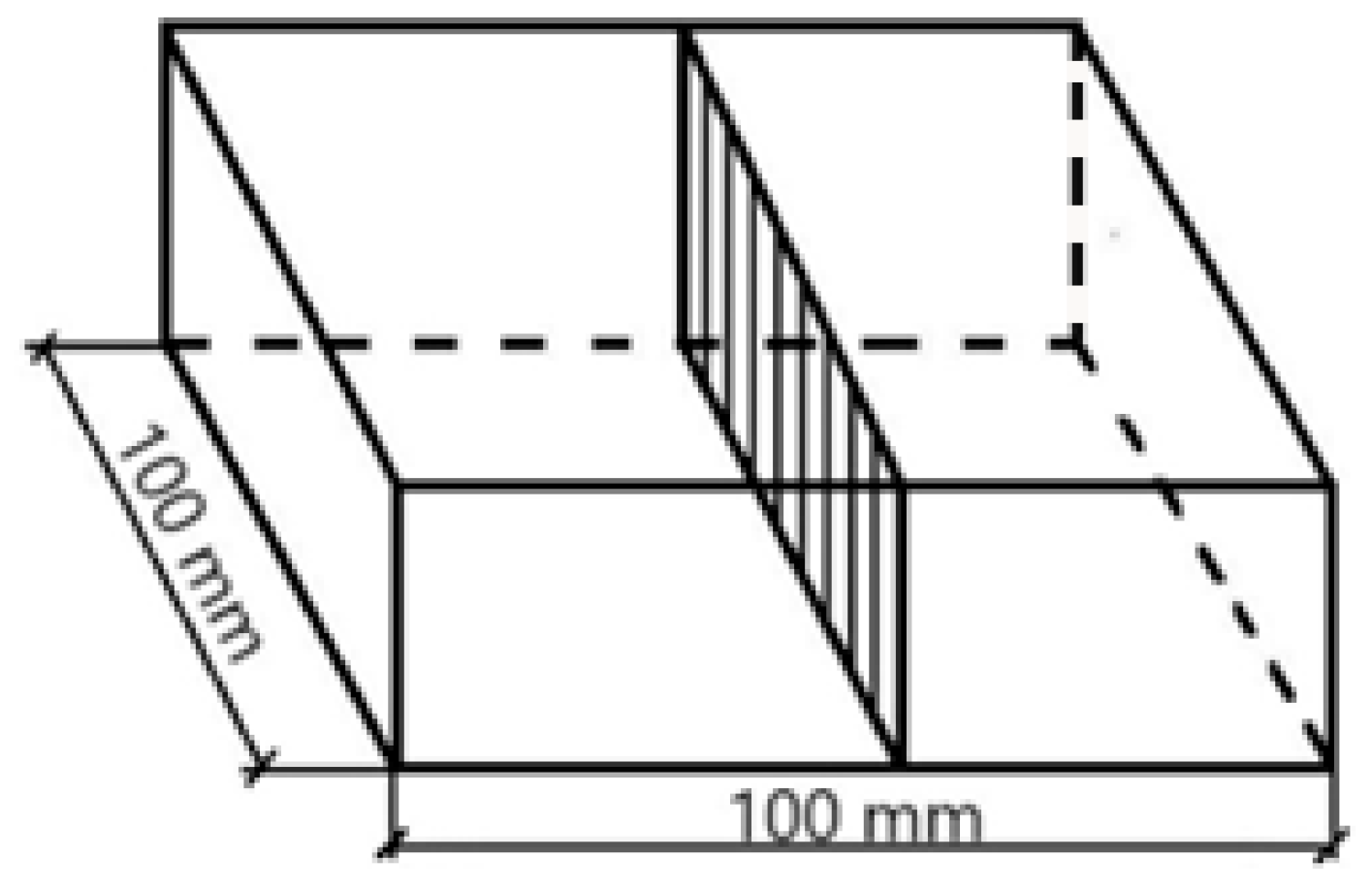

- Evaluation of compressive and bending strength;

- Frost resistance assessment;

- Salt chamber test;

- Testing for air content in hardened concrete.

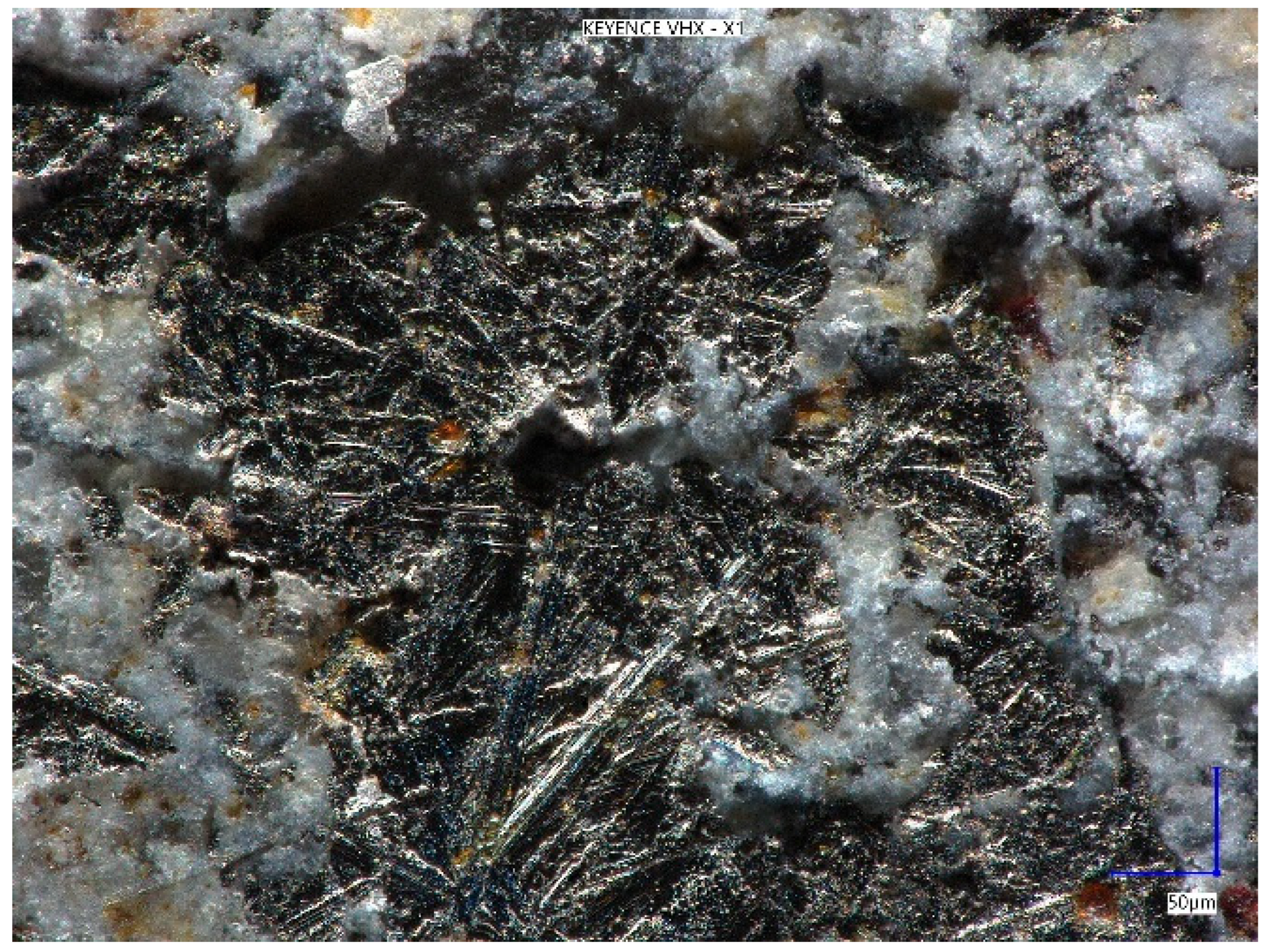

3. Composition of Tested Concrete Composites

4. Research Methodology

5. Research Results

5.1. Consistency of Concrete Mixtures

5.2. Marking the Density of Concrete Composites

5.3. Abrasion Resistance

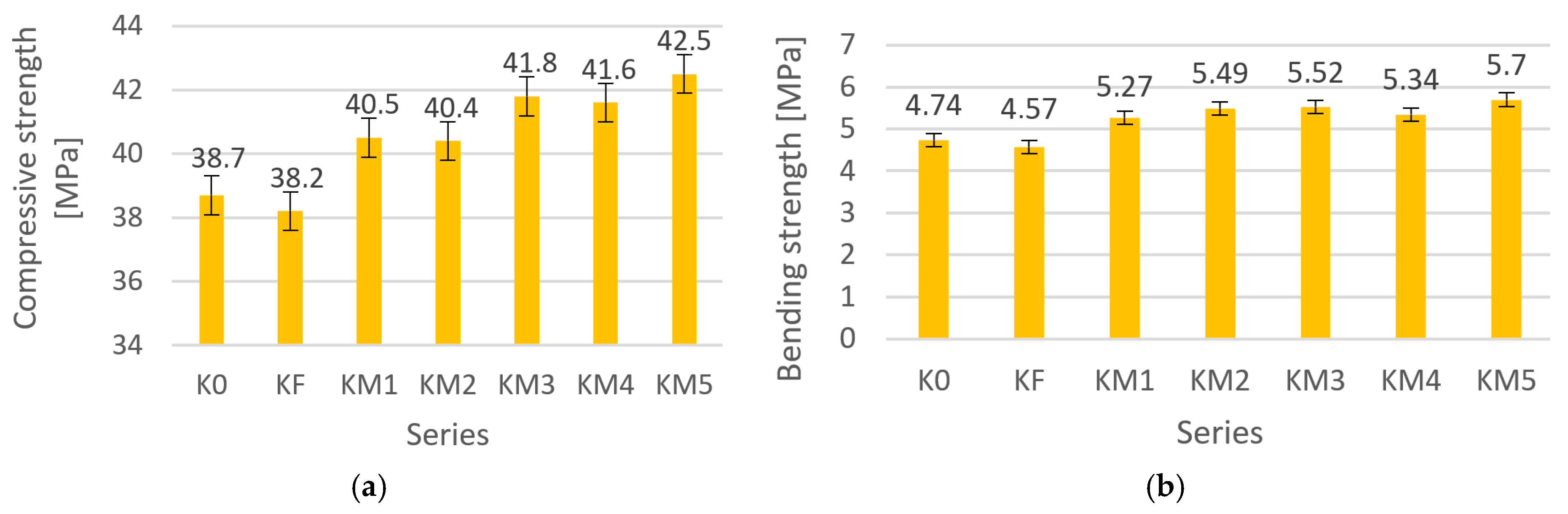

5.4. Evaluation of Compressive and Bending Strength After 28 Days of Curing

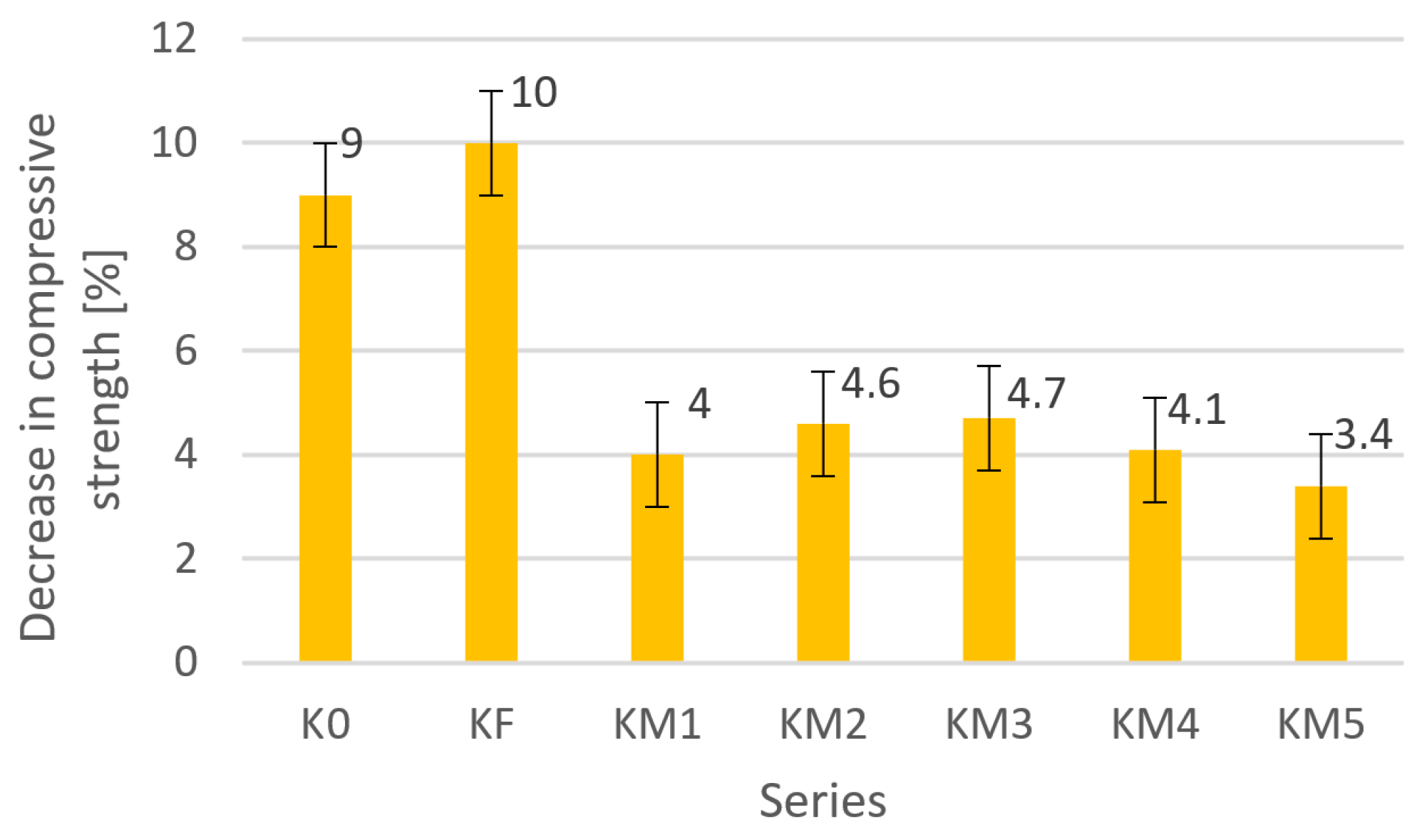

5.5. Frost Resistance Assessment

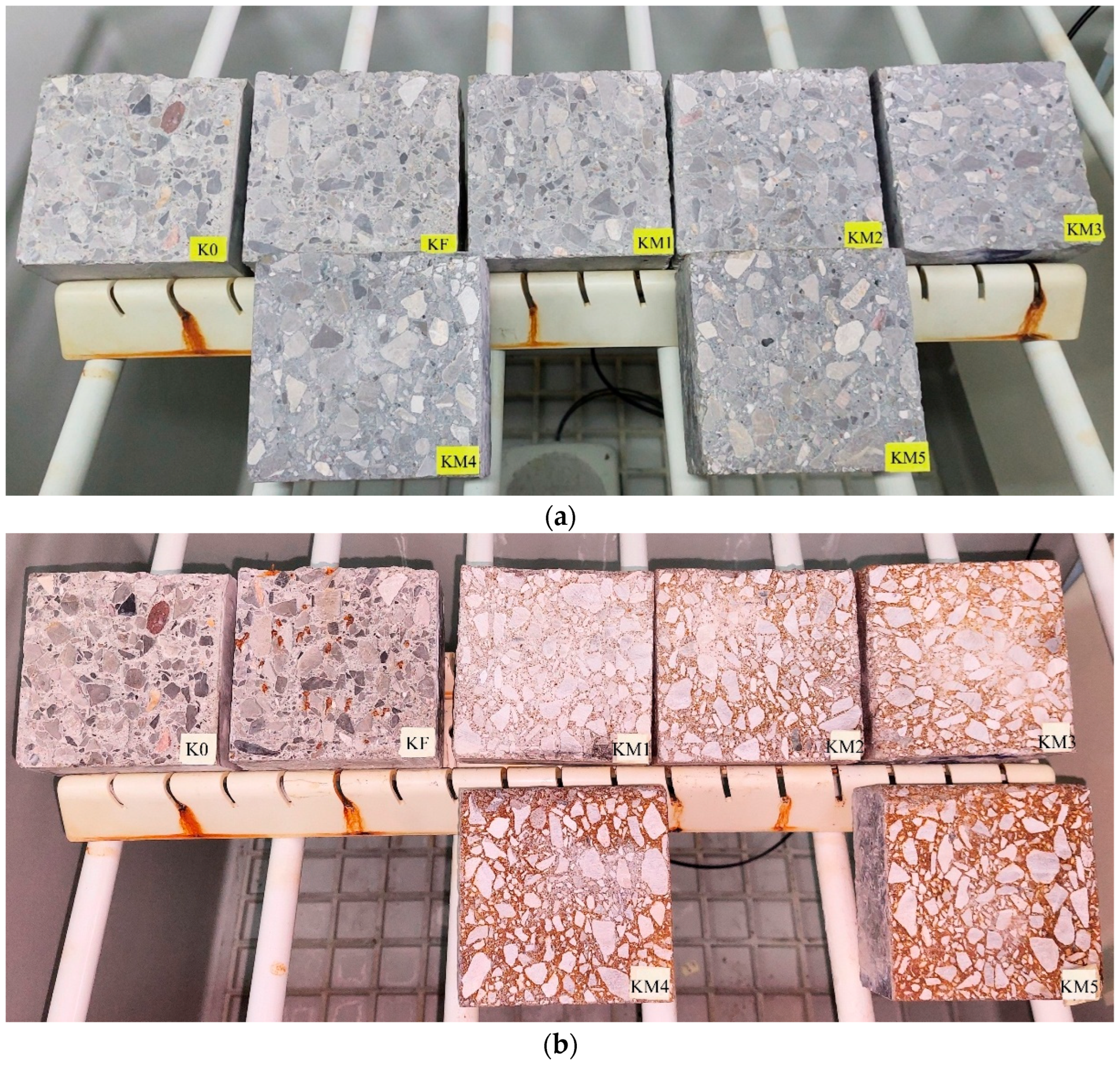

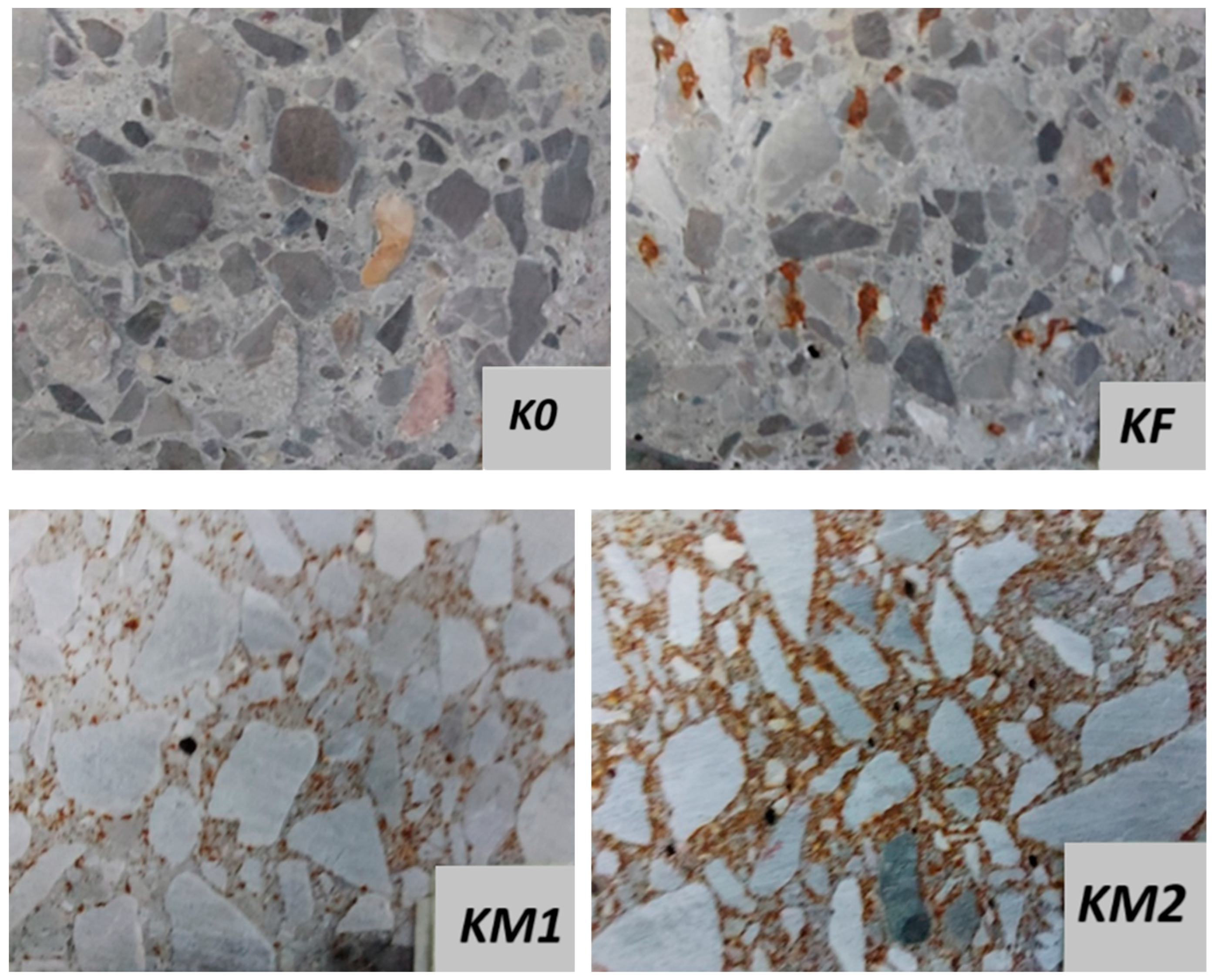

5.6. Salt Chamber Test

5.7. Testing for Air Content in Hardened Concrete

6. Discussion

7. Conclusions

- Concrete composites with the addition of metal dust require an increased amount of a fluidifying admixture in order to maintain the fluidity of the concrete mixture due to their higher water demand;

- The used fine aggregate substitute had a significant effect on the abrasion of concrete composites, reducing the volume loss in the KM4 series by up to 29% compared to the reference K0 series, which indicates their potential use as reinforcement of industrial floors, contributing to improving the quality of the surface and extending its service life including protection, e.g., with a hydrophobic impregnation that penetrates deep into the concrete, thus providing effective protection against the penetration of contaminants and possible corrosion;

- Metal dust in the tested concrete composites in each case improved the bending and compressive strength, and for the KM5 series, the increase in compressive strength was about 10% compared to the reference K0 series;

- In the study of changes in compressive strength over a period of up to 6 months, no negative impact of the metal dust used was found;

- The used fine aggregate substitute improved the frost resistance of concrete after 50 freezing and thawing cycles. In each case of modification of the concrete composite with metal dust, the decrease in compressive strength after the test was lower than in the K0 control series. The KM5 series achieved a decrease in compressive strength lower by more than 50% compared to the K0 series;

- The process of processing waste materials into raw materials brings benefits in the form of reduced consumption of natural resources and, at the same time, contributes to reducing the costs of transporting waste to landfills, which extends the service life of the landfill;

- Statistical validation of the obtained results was performed using one-way ANOVA to evaluate the significance of differences between the reference series (K0) and modified concretes (KM1–KM5). The analysis confirmed that the addition of metallic dust caused statistically significant improvements in compressive and flexural strength and a reduction in abrasion loss. Therefore, the observed enhancement in performance parameters is statistically supported.

- Further studies are needed to evaluate long-term durability under real environmental conditions, including exposure to aggressive chemical agents and variable climates;

- Optimization of mixture design and exploration of combined use with other industrial by-products could further enhance the mechanical and durability properties of sustainable concrete composites;

- The practical implementation of metallic dust in structural and industrial concrete offers a promising strategy for eco-friendly construction and industrial waste management.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Turk, O.; Yehia, S.; Abdelfatah, A.; Elchalakani, M. Sustainable concrete production: The potential of utilizing recycled waste materials. J. Build. Eng. 2024, 98, 111467. [Google Scholar] [CrossRef]

- Major, M.; Halbiniak, J. Effect of adhesion between EPS granules and cement matrix on the characteristics of lightweight concretes. IOP Conf. Ser.-Mater. Sci. 2019, 603, 032054. [Google Scholar] [CrossRef]

- Brito, J.; Silva, R.V. Use of waste materials in the production of concrete. Key Eng. Mater. 2014, 634, 85–96. [Google Scholar] [CrossRef]

- Assaad, J.J.; Khatib, J.M.; Ghanem, R. Bond to bar reinforcement of PET-modified concrete containing natural or recycled coarse aggregates. Environments 2022, 9, 8. [Google Scholar] [CrossRef]

- Juki, M.I.; Awang, M.; Annas, M.M.K.; Boon, K.H.; Othman, N.; Binti Abdul Kadir, A.; Khalid, F.S. Relationship between compressive, splitting tensile and flexural strength of concrete containing granulated waste polyethylene terephthalate (PET) bottles as fine aggregate. Adv. Mater. Res. 2013, 795, 356–359. [Google Scholar] [CrossRef]

- Katzer, J.; Halbiniak, J.; Langier, B.; Major, M.; Major, I. Influence of varied waste ceramic fillers on the resistance of concrete to freeze–thaw cycles. Materials 2021, 14, 624. [Google Scholar] [CrossRef] [PubMed]

- Langier, B.; Katzer, J.; Major, M.; Halbiniak, J.; Major, I. Strength and durability characteristics of concretes with crushed side window glass as partial aggregate substitution. Arch. Civ. Eng. 2023, 69, 5–21. [Google Scholar] [CrossRef]

- Wen, Y.; Liu, X.; Sun, G.; Shen, W. Mechanical properties and stress-strain relationship of steel fiber reinforced geopolymer recycled concrete. Structures 2025, 75, 108697. [Google Scholar] [CrossRef]

- Thomas, B.S.; Kumar, S.; Mehra, P.; Gupta, R.C.; Joseph, M.; Csetenyi, L.J. Abrasion resistance of sustainable green concrete containing waste tire rubber particles. Constr. Build. Mater. 2016, 124, 906–909. [Google Scholar] [CrossRef]

- Etxeberria, M.; Pacheco, C.; Meneses, J.M.; Berridi, I. Properties of concrete using metallurgical industrial by-products as aggregates. Constr. Build. Mater. 2010, 24, 1594–1600. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Cillari, G.; Ricciardi, P.; Miino, M.C.; Torretta, V.; Rada, E.C.; Abbà, A. The Production of Sustainable Concrete with the Use of Alternative Aggregates: A Review. Sustainability 2020, 12, 7903. [Google Scholar] [CrossRef]

- Giergiczny, Z. (Ed.) Vademecum Technologa Betonu (Concrete Technologist’s Vademecum); Heidelberg Cement Group: Chorula, Poland, 2017; p. 139. (In Polish) [Google Scholar]

- Kozioł, W.; Machniak, Ł.; Borcz, A.; Baic, I. Górnictwo kruszyw w Polsce–szanse i zagrożenia (Mining of aggregates in Poland–opportunities and threats). Inżynieria Miner. 2016, 17, 175–182. (In Polish) [Google Scholar]

- Latosińska, J.; Gawdzik, J.; Honus, S.; Orman, Ł.J.; Radek, N. Waste for building material production as a method of reducing environmental load and energy recovery. Front. Energy Res. 2023, 11, 1279337. [Google Scholar] [CrossRef]

- Chen, L.; Yang, M.; Chen, Z.; Xie, Z.; Huang, L.; Osman, A.I.; Farghali, M.; Sandanayake, M.; Liu, E.; Han Ahn, Y.; et al. Conversion of waste into sustainable construction materials: A review of recent developments and prospects. Mater. Today Sustain. 2024, 27, 100930. [Google Scholar] [CrossRef]

- Rutkowska, G.; Wichowski, P.; Świgoń, K.; Sobieski, P. Properties of concrete with fly ash addition from sewage sludge thermal treatment. Cem. Wapno Beton 2017, 2, 113–119. [Google Scholar]

- Mustafa Al Bakri, A.M.; Norazian, M.N.; Kamarudin, H.; Mohd Salleh, M.A.A.; Alida, A. Strength of concrete based cement using recycled ceramic waste as aggregate. Adv. Mater. Res. 2013, 740, 734–738. [Google Scholar] [CrossRef]

- Xu, W.; Zhu, Y.; Zhang, L.; Yan, T.; Song, Z.; Niu, X. Fracture behavior of concrete with waste ceramic coarse aggregates: Insights from digital image correlation and acoustic emission. Constr. Build. Mater. 2025, 489, 142263. [Google Scholar] [CrossRef]

- Halbiniak, J.; Katzer, J.; Major, M.; Langier, B.; Major, I. An example of harnessing crushed ceramic pots for the production of watertight concrete. Struct. Concr. 2021, 22, E308–E314. [Google Scholar] [CrossRef]

- Liu, G.; Wan, H.; Wei, H.; Gao, L.; Yuan, S.; Liu, Z.; Zhou, K.; Teng, J.; Shi, N. A study on the impact resistance and hybrid fiber reinforcement of recycled aggregate concrete modified by composite activators. Constr. Build. Mater. 2025, 489, 142164. [Google Scholar] [CrossRef]

- Neupane, B.; Sahani, K.; Khadka, S.S. Experimental testing and numerical simulation of recycled concrete aggregate in a concrete mix. Int. J. Concr. Struct. Mater. 2025, 19, 5. [Google Scholar] [CrossRef]

- Hassan, A.; Galal, S.; Hassan, A.; Salman, A. Utilization of carbon nanotubes and steel fibers to improve the mechanical properties of concrete pavement. Beni-Suef Univ. J. Basic Appl. Sci. 2022, 11, 121. [Google Scholar] [CrossRef]

- Khan, M.; McNally, C. A holistic review on the contribution of civil engineers for driving sustainable concrete construction in the built environment. Dev. Built Environ. 2023, 16, 100273. [Google Scholar] [CrossRef]

- Jeron, R.; Stalin, J.Y. Investigating porosity and strength characteristics of novel concrete design based on recycled ceramics, steel fiber, and industrial chip wastes using novel deep learning. J. Build. Eng. 2025, 111, 113123. [Google Scholar] [CrossRef]

- Sejm. Rozporządzenie Ministra Klimatu z Dnia 2 Stycznia 2020 r. w Sprawie Katalogu Odpadów (Regulation of the Minister of Climate of 2 January 2020 on the Waste Catalogue), Dz.U. 2020 poz. 10; Sejm: Warsaw, Poland, 2020. (In Polish) [Google Scholar]

- Borowski, G.; Kuczmaszewski, J. Utylizacja Drobnoziarnistych Odpadów Metalowych (Disposal of Fine-Grained Metal Waste); Wydawnictwo Politechniki Lubelskiej: Lublin, Poland, 2005; p. 168. (In Polish) [Google Scholar]

- Pawłowski, A.; Pawłowski, L. Realizacja zasady zrównoważonego rozwoju w przemyśle cementowym (Implementation of the principle of sustainable development in the cement industry). In Ochrona i Inżynieria Środowiska; Monografie Komitetu Inżynierii Środowiska PAN: Lublin, Poland, 2004; Volume 25. (In Polish) [Google Scholar]

- Saeed, N.M.; Ali, B.H.; Khidir, S.F.; Kareem, A.S.; Ahmed, B.S.; Khalid, I.Z.; Hassan, H.Z. Effects of steel dust waste incorporation on the mechanical properties of concrete. Archit. Struct. Constr. 2025, 5, 20. [Google Scholar] [CrossRef]

- Galupino, J.; Adajar, M.A. Sustainable concrete: Enhanced concrete strength with metal dusts. In Building Resilient, Innovative, and Sustainable Societes, Conference: DLSU Research Congress 2020; De La Salle University: Manila, Philippines, 2020. [Google Scholar]

- Jahami, A.; Younes, H.; Khatib, J. Enhancing reinforced concrete beams: Investigating steel dust as a cement substitute. Infrastructures 2023, 8, 157. [Google Scholar] [CrossRef]

- Rubio-Cintas, M.D.; Barnett, S.J.; Perez-García, F.; Parron-Rubio, M.E. Mechanical-strength characteristics of concrete made with stainless steel industry wastes as binders. Constr. Build. Mater. 2019, 204, 675–683. [Google Scholar] [CrossRef]

- Li, P.; Chen, G.; Qiu, J.; Qian, J.; Ding, D.; Jian, B.; Zhang, X.; Xiong, G. Experimental and numerical investigation into the load-carrying capacity of aluminium alloy H-sectional stocky columns under axial compression. J. Build. Eng. 2024, 87, 108777. [Google Scholar] [CrossRef]

- PN-EN 14889-1:2007; Fibres for Concrete—Part 1: Steel Fibres—Definitions, Specifications and Conformity. Polish Committee for Standardization: Warsaw, Poland, 2013.

- PN-EN 12350-2:2019-07; Testing Fresh Concrete—Part 2: Slump Test. Polish Committee for Standardization: Warsaw, Poland, 2019.

- Starczyk-Kołbyk, A.; Małek, M. Analysis of the Life Cycle and Properties of Concrete with the Addition of Waste Car Glass. Sustainability 2023, 15, 10836. [Google Scholar] [CrossRef]

- PN-EN 12390-7:2019-08; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. Polish Committee for Standardization: Warsaw, Poland, 2019.

- PN-EN 14157:2004-12; Natural Stones—Determination of Abrasion Resistance. Polish Committee for Standardization: Warsaw, Poland, 2017.

- PN-EN 12390-3:2019-07; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. Polish Committee for Standardization: Warsaw, Poland, 2019.

- PN-EN 12390-5:2019-08; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. Polish Committee for Standardization: Warsaw, Poland, 2019.

- PN-88/B-06250:1988; Ordinary Concrete. Polish Committee for Standardization: Warsaw, Poland, 1998.

- PN-EN 480-11:2008; Admixtures for Concrete, Mortar and Grout-Test Methods—Part 11: Determination of Air Void Characteristics in Hardened Concrete. Polish Committee for Standardization: Warsaw, Poland, 2008.

| Iron(III) Oxide Fe2O3 | Silicon Dioxide SiO2 | Aluminum Oxide Al2O3 | Sulfur Trioxide SO3 | Phosphorus Pentoxide P2O5 | Manganese Mn | Magnesium Oxide MgO | Calcium Oxide Ca |

|---|---|---|---|---|---|---|---|

| 88.51 | 7.979 | 2.176 | 0.5852 | 0.471 | 0.532 | 0.196 | 0.1188 |

| C | Si | Mn | P | S | Cr | Ni | Mo | Mg |

|---|---|---|---|---|---|---|---|---|

| % | ||||||||

| 3.34 | 2.32 | 0.53 | 0.031 | 0.014 | 0.052 | 0.024 | 0.017 | 0.009 |

| % | 10 | 50 | 90 |

|---|---|---|---|

| <µm | 37.46 | 90.79 | 170.11 |

| Fraction [mm] | Contents [%] |

|---|---|

| 0–0.063 | 0.5 |

| 0.063–0.125 | 2.5 |

| 0.125–0.25 | 10 |

| 0.25–0.5 | 14 |

| 0.5–1.0 | 7 |

| 1.0–2.0 | 5 |

| 2.0–4.0 | 13 |

| 4.0–8.0 | 18 |

| 8.0–16.0 | 30 |

| Series | K0 | KF | KM1 | KM2 | KM3 | KM4 | KM5 |

|---|---|---|---|---|---|---|---|

| [kg] | |||||||

| Cement | 290 | ||||||

| Water | 174 | ||||||

| Superplasticizer | 3.77 | 3.77 | 4.35 | 4.35 | 5.8 | 5.8 | 7.25 |

| Sand | 677 | 677 | 609.3 | 541.6 | 473.9 | 406.2 | 338.5 |

| Basalt 4–16 mm | 1303 | ||||||

| Metallic dust | -- | -- | 67.7 | 135.4 | 203.1 | 270.8 | 338.5 |

| Aggregate Ʃ | 1980 | ||||||

| Steel fiber | -- | 30 | -- | -- | -- | -- | -- |

| Class | Slump [mm] |

|---|---|

| S1 | 10–40 |

| S2 | 50–90 |

| S3 | 100–150 |

| S4 | 160–210 |

| S5 | >210 |

| Series | K0 | KF | KM1 | KM2 | KM3 | KM4 | KM5 |

|---|---|---|---|---|---|---|---|

| Slump test [mm] | 140 | 120 | 115 | 110 | 100 | 120 | 115 |

| Consistency class | S3 | S3 | S3 | S3 | S3 | S3 | S3 |

| Bulk Density [kg/dm3] | ||||||

|---|---|---|---|---|---|---|

| K0 | KF | KM1 | KM2 | KM3 | KM4 | KM5 |

| 2.385 | 2.426 | 2.444 | 2.461 | 2.488 | 2.507 | 2.557 |

| Abrasion-Volume Loss [mm3] | ||||||

|---|---|---|---|---|---|---|

| K0 | KF | KM1 | KM2 | KM3 | KM4 | KM5 |

| 14.9 | 9.77 | 11.7 | 11.3 | 11.1 | 10.5 | 10.9 |

| --- | ↓34% | ↓21.5% | ↓24% | ↓25.5% | ↓29.5% | ↓26.8% |

| Series | K0 | KF | KM1 | KM2 | KM3 | KM4 | KM5 |

|---|---|---|---|---|---|---|---|

| fcm—compressive strength [MPa] | 38.7 | 38.2 | 40.5 | 40.4 | 41.8 | 41.6 | 42.5 |

| Standard deviation | 0.70 | 0.89 | 0.63 | 0.47 | 0.85 | 0.31 | 0.63 |

| Coefficient of variation | 0.018 | 0.023 | 0.016 | 0.012 | 0.020 | 0.007 | 0.015 |

| Percentage change with respect to K0 [%] | ---- | ↓1.3 | ↑4.7 | ↑4.4 | ↑8.0 | ↑7.5 | ↑9.8 |

| fzg—bending strength [MPa] | 4.74 | 4.57 | 5.27 | 5.49 | 5.52 | 5.34 | 5.7 |

| Standard deviation | 0.14 | 0.147 | 0.487 | 0.369 | 0.124 | 0.222 | 0.483 |

| Coefficient of variation | 0.029 | 0.032 | 0.092 | 0.067 | 0.022 | 0.042 | 0.085 |

| Percentage change with respect to K0 [%] | ---- | ↓3.6 | ↑11.2 | ↑15.8 | ↑16.5 | ↑12.7 | ↑20.2 |

| Compressive Strength After 6 Months [MPa] | |||||||

|---|---|---|---|---|---|---|---|

| Series | K0 | KF | KM1 | KM2 | KM3 | KM4 | KM5 |

| fcm—compressive strength [MPa] | 46.0 | 45.8 | 48.7 | 49.2 | 50.3 | 49.5 | 49.7 |

| Standard deviation | 0.32 | 0.35 | 0.71 | 0.56 | 0.50 | 0.67 | 0.55 |

| Coefficient of variation | 0.007 | 0.008 | 0.015 | 0.011 | 0.010 | 0.013 | 0.011 |

| Percentage change [%] | 18.9 | 19.7 | 20.4 | 21.7 | 20.4 | 19.0 | 17.0 |

| Series | K0 | KF | KM1 | KM2 | KM3 | KM4 | KM5 |

|---|---|---|---|---|---|---|---|

| Total air content in concrete A [%] | 3.0 | 3.2 | 2.9 | 2.8 | 2.6 | 2.4 | 2.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Langier, B.; Major, I. Research on Selected Properties of Concrete Composite with the Addition of Post-Production Metallic Dust. Materials 2025, 18, 5197. https://doi.org/10.3390/ma18225197

Langier B, Major I. Research on Selected Properties of Concrete Composite with the Addition of Post-Production Metallic Dust. Materials. 2025; 18(22):5197. https://doi.org/10.3390/ma18225197

Chicago/Turabian StyleLangier, Bogdan, and Izabela Major. 2025. "Research on Selected Properties of Concrete Composite with the Addition of Post-Production Metallic Dust" Materials 18, no. 22: 5197. https://doi.org/10.3390/ma18225197

APA StyleLangier, B., & Major, I. (2025). Research on Selected Properties of Concrete Composite with the Addition of Post-Production Metallic Dust. Materials, 18(22), 5197. https://doi.org/10.3390/ma18225197