Influence of Waste Rubber Powder on the Mechanical and Abrasion Resistance Properties of Concrete

Abstract

1. Introduction

- (1)

- Although the incorporation of rubber powder does not alter the chemical properties of cement hydration products, it optimizes the internal packing structure of concrete, improves workability, significantly reduces brittleness, and enhances toughness, impact resistance, and crack resistance. This strengthens the material’s energy absorption capacity under dynamic loads (e.g., earthquakes, explosions). Additionally, rubberized concrete exhibits functional properties such as lightweight, sound insulation, and thermal insulation, enabling potential applications in seismic-resistant structures and road noise reduction [9,10,11,12].

- (2)

- This technology enables high-value resource utilization of waste rubber, offering both significant environmental benefits (reducing solid waste pollution) and economic advantages (lowering construction material costs).

- (3)

2. Materials and Methods

2.1. Materials

- (1)

- Cement: Ordinary Portland cement (P·O 42.5R) produced by Xinjiang Tianshan Cement Plant (Urumqi, China), with physical property indicators shown in Table 1.

- (2)

- Fine Aggregate: Natural medium sand with a fineness modulus of 2.9 was used as the fine aggregate, and its physical properties are presented in Table 2.

- (3)

- Coarse Aggregate: Continuously graded limestone crushed stone with a particle size range of 5–20 mm was used as the coarse aggregate, and its physical property indices are presented in Table 3.

- (4)

- (5)

- Admixture: A polycarboxylate superplasticizer produced by Shanxi Feikese Materials Technology Co., Ltd. (Yuncheng, China) was used.

- (6)

- Water: Standard laboratory tap water that meets the relevant specifications was used.

2.2. Mix Proportion of Materials

2.3. Test Methods

2.3.1. Compressive Performance Test

2.3.2. Anti-Impact Performance Test

2.3.3. Test Methods for Wear Rate and Abrasion Resistance Strength

2.3.4. Three-Dimensional Topography Measurement

2.3.5. Microstructural Analysis

3. Result and Discussion

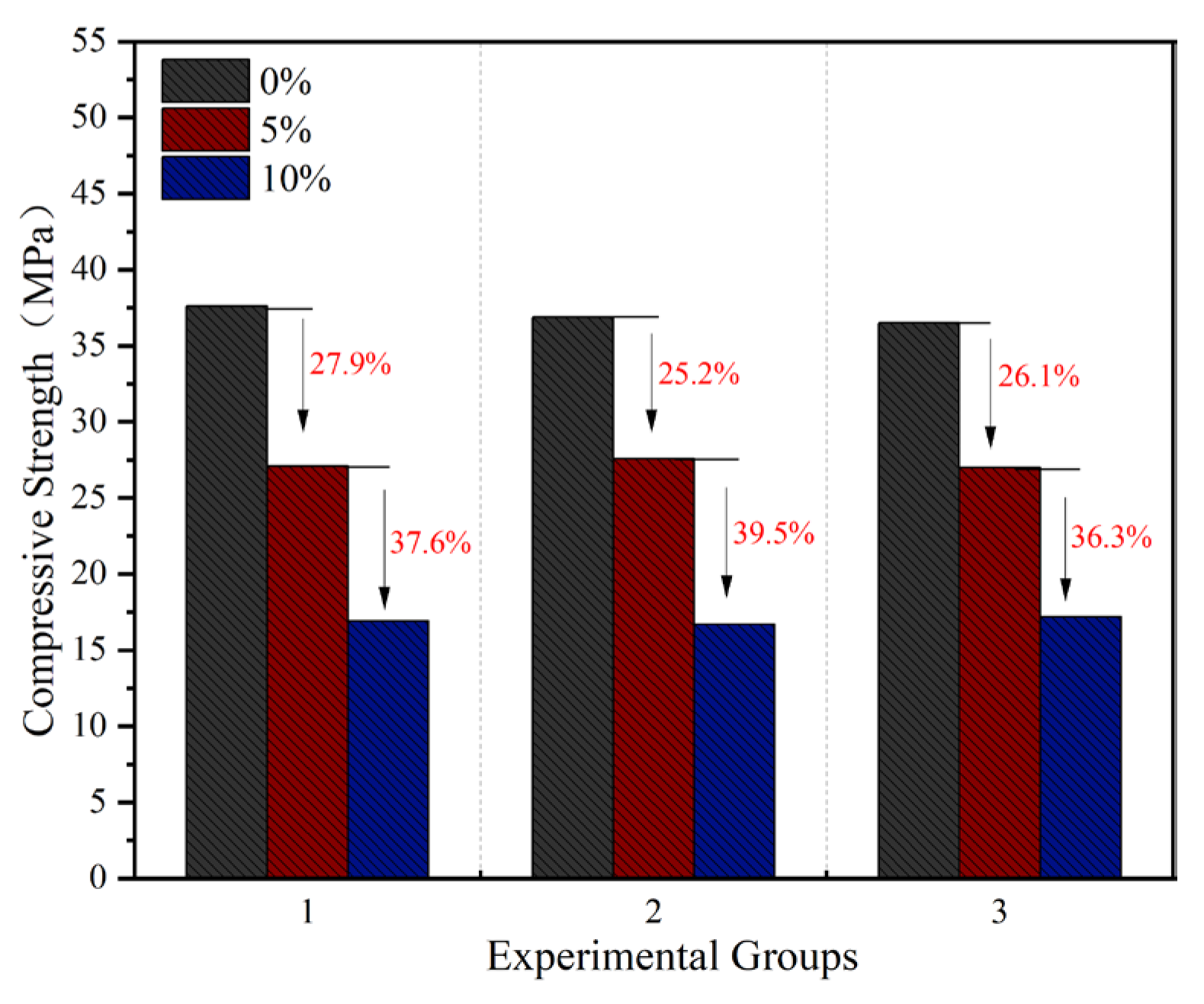

3.1. Compressive Strength

- (1)

- The elastic modulus of rubber particles is significantly lower than that of the surrounding cement matrix. Under external load, the rubber particles undergo larger elastic deformation, leading to stress concentration phenomena, thereby reducing the overall stiffness of the material.

- (2)

- The hydrophobic surface of rubber exhibits poor compatibility with the hydrophilic cement paste, resulting in a weak interfacial transition zone (ITZ). This zone is prone to become the path for micro-crack initiation and propagation.

- (3)

- The incorporation of rubber powder may increase the air content and reduce the compactness of the concrete, raising the overall porosity. This exacerbates stress concentration effects and promotes crack propagation.

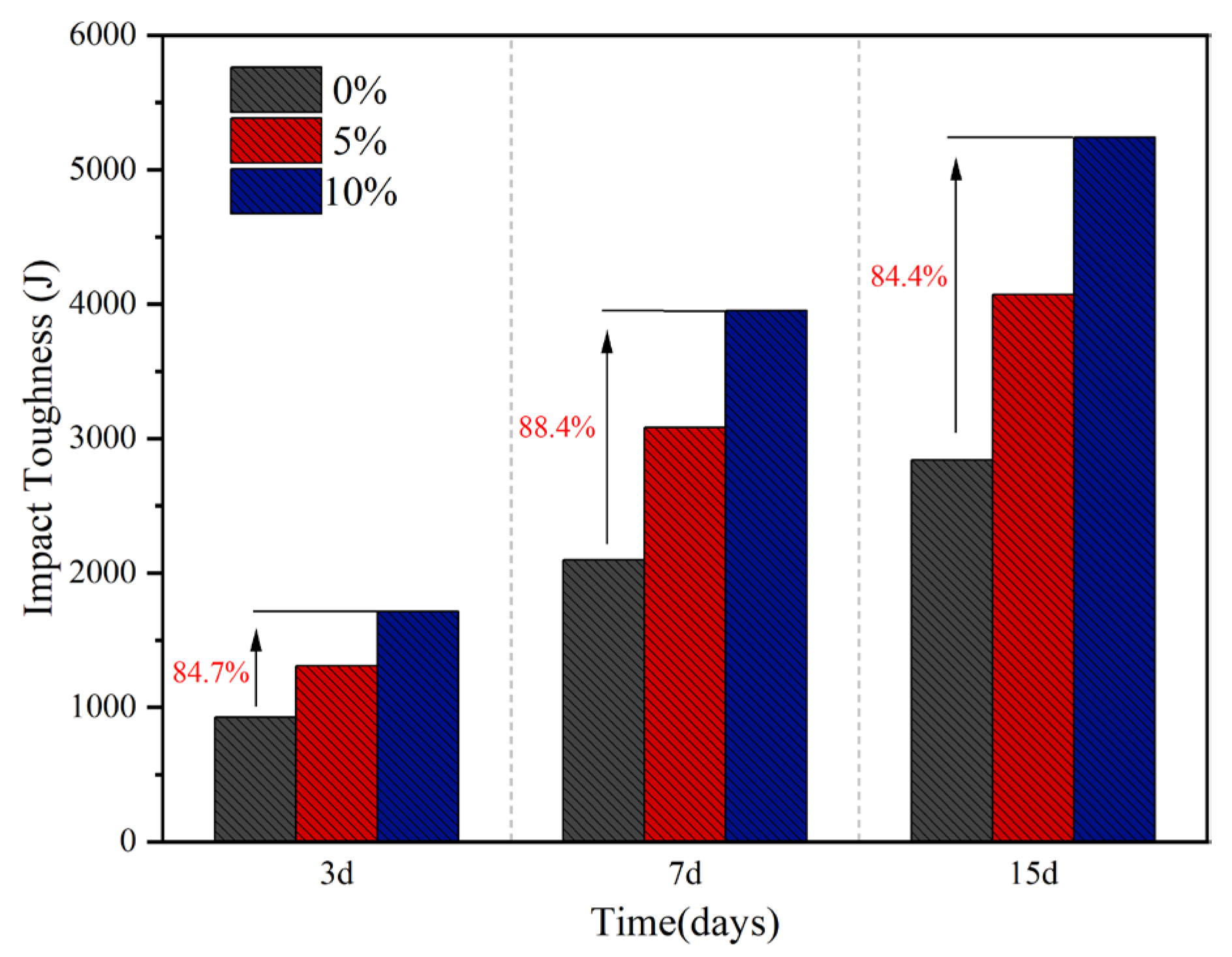

3.2. Impact Resistance Test

- (1)

- The low elastic modulus of rubber allows for large deformation under impact loading, thereby absorbing and dissipating energy and effectively reducing the peak stress.

- (2)

- As a soft phase within the matrix, rubber particles act as obstacles, causing crack deflection or branching during propagation, which delays macroscopic failure. Additionally, as cracks pass through the cement-rubber interface, they must overcome the interfacial bond strength and the deformation of the rubber itself, further consuming impact energy.

- (3)

- The rubber particles and cement matrix form a composite system that enhances overall toughness through coordinated deformation. Furthermore, the micro-porous structure resulting from the incorporation of rubber helps to absorb energy and alleviate local stress concentration.

3.3. Damage Layer Thickness

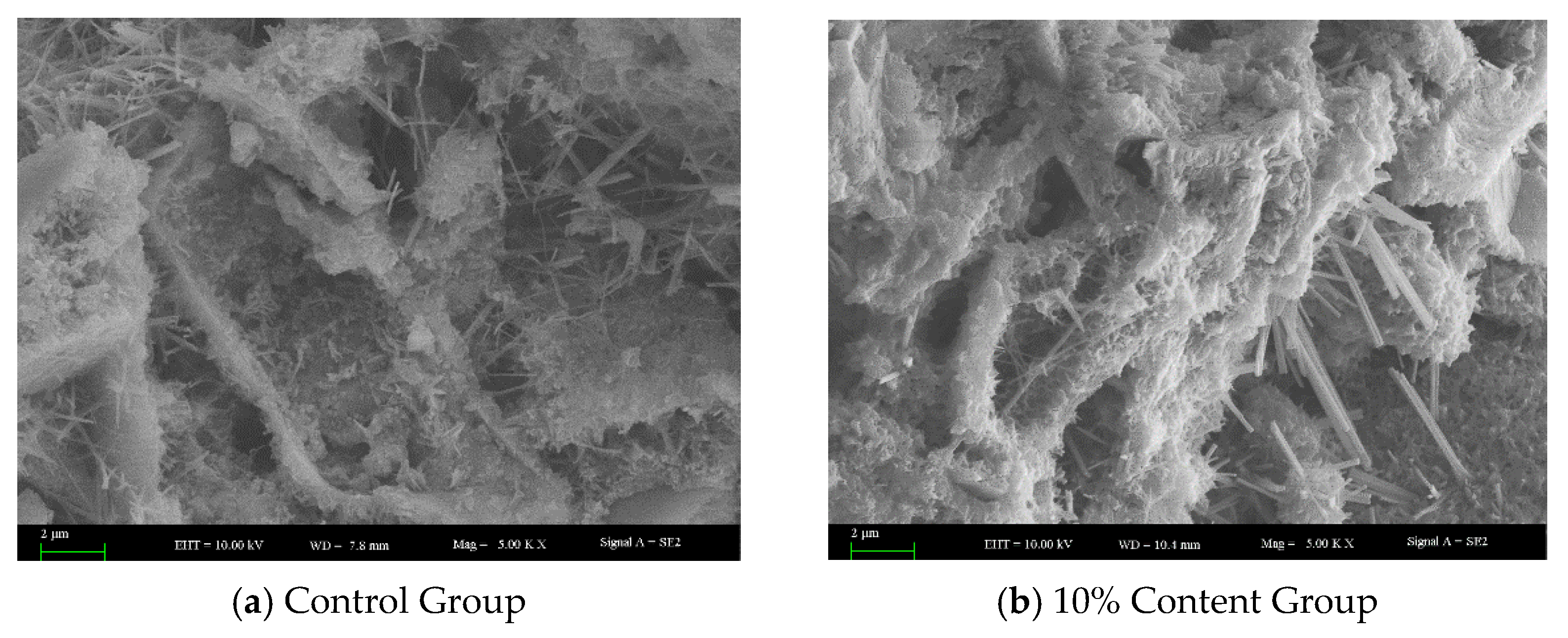

3.4. The Hydration Products

3.5. Microscopic Analysis and Discussion

4. Conclusions

- (1)

- The addition of rubber powder reduces the compressive strength of concrete through synergistic physical effects. Microscopically, rubber acts as an inert filler, diluting C–S–H gel formation and inhibiting cement hydration, which increases porosity—especially macropores—and weakens microstructural continuity. Macroscopically, the low stiffness of rubber causes stress concentration, while its hydrophobic nature creates a weak interfacial transition zone (ITZ) that promotes cracking. These microstructural and interfacial defects, compounded by increased air content, collectively account for the strength reduction.

- (2)

- Rubber particles improve concrete impact resistance through three mechanisms: energy absorption via elastic deformation, crack deflection through interface debonding, and stress relief from induced micro-porosity, collectively enhancing toughness and energy dissipation. The incorporation of rubber powder exerts a physical inhibitory effect on the cement hydration process, restricting the adequate dispersion and hydration reaction of cement particles, thereby significantly reducing the formation of delayed ettringite. This effect effectively mitigates the crystallization-induced internal stress generated by the formation of delayed ettringite in the later hardening stages, consequently alleviating the resulting deterioration in material toughness. As a result, the abrasion and impact resistance of rubberized concrete are significantly enhanced.

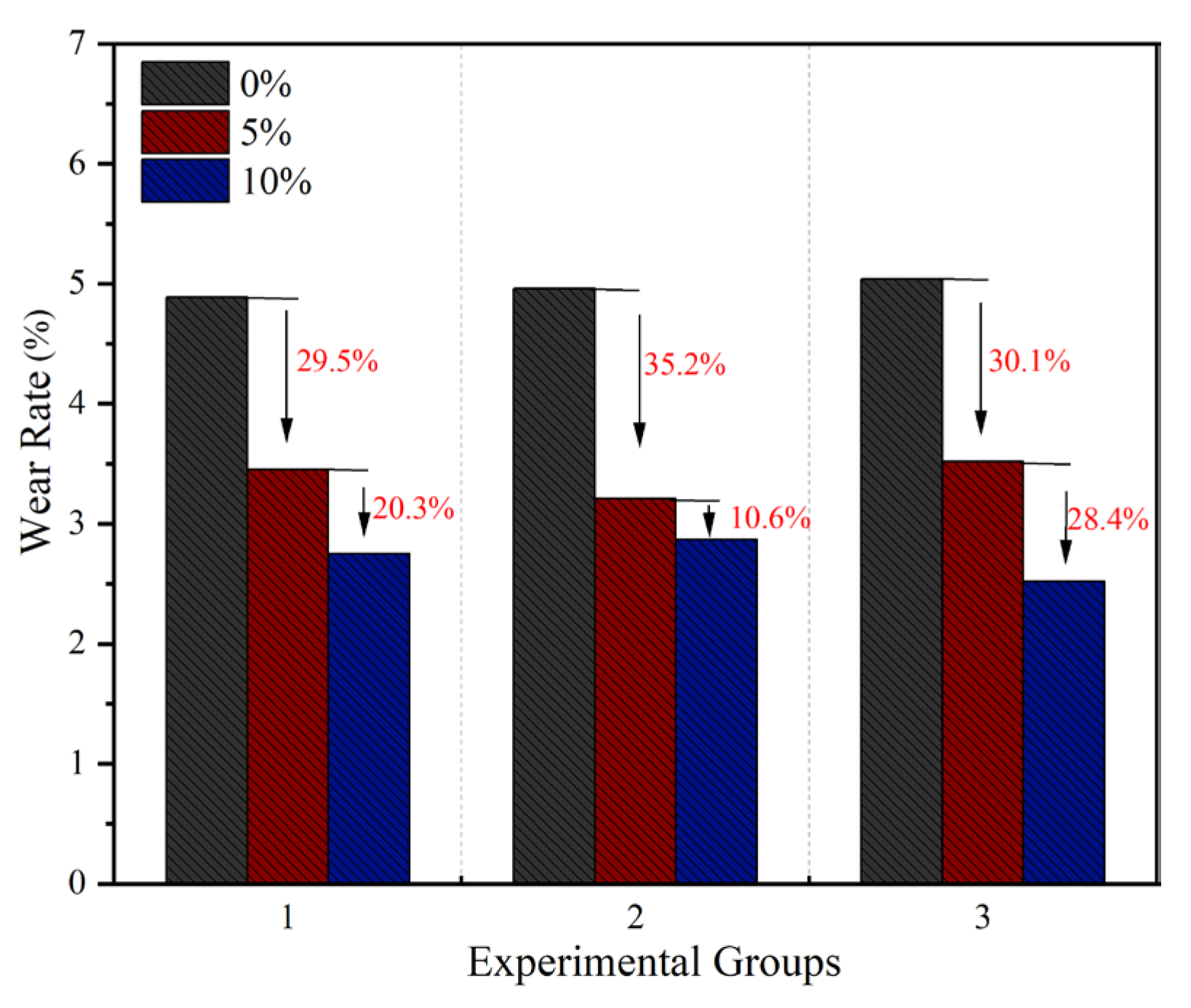

- (3)

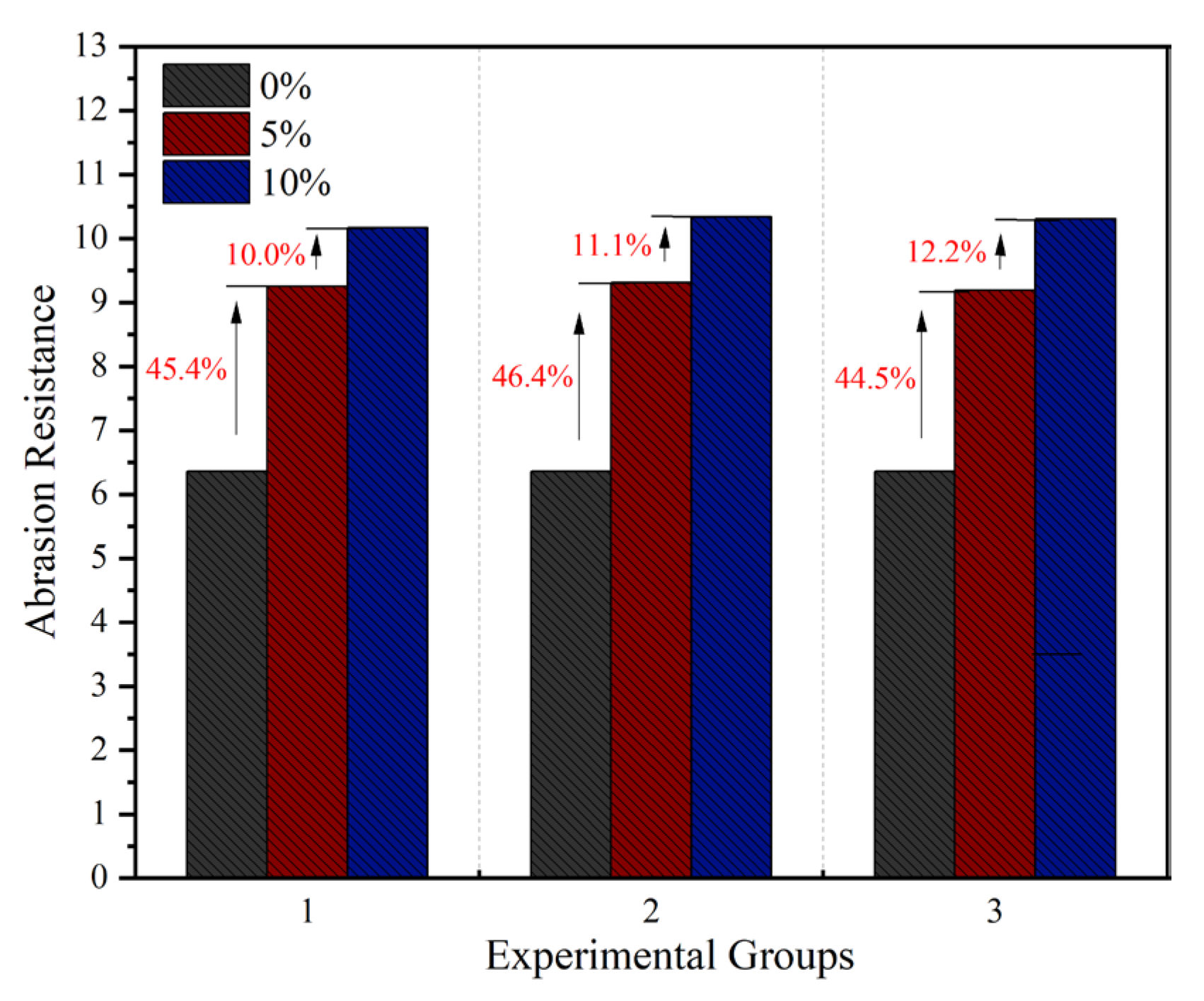

- Analysis of the wear rate, abrasion resistance strength, and three-dimensional topography revealed a significant improvement in the abrasion resistance of rubber powder concrete. This enhancement is attributed to the reduction in ettringite formation due to the incorporation of rubber powder, which decreased late-stage cracking. Furthermore, the uniform dispersion of rubber powder within the concrete matrix considerably enhanced the overall toughness of the material and promoted a more uniform distribution of impact stress over a wider area. The underlying strengthening mechanism primarily stems from the synergistic deformation behavior between the rubber particles and the cement mortar matrix: the rubber phase, through its viscoelastic response, transforms locally concentrated erosion energy into distributed dissipated energy, thereby effectively suppressing the initiation and propagation of macroscopic spalling pits.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hisbani, N.; Shafiq, N.; Shams, M.A.; Farhan, S.A.; Zahid, M. Properties of concrete containing crumb rubber as partial replacement of fine Aggregate—A review. Hybrid Adv. 2025, 10, 100481. [Google Scholar] [CrossRef]

- Jiang, C.; Li, S.; Jiang, L.; Tang, X. Evaluation of abrasion resistance of low-heat cement concrete under freeze-thaw cycles. J. Yangtze River Sci. Res. Inst. 2023, 40, 163–169. [Google Scholar]

- Li, M.; Gao, Y.; Wang, C.; Li, Y.; Fan, T. Impact Resistance Test and Numerical Simulation Study of Scrap Steel Fiber Rubber Concrete. Buildings 2025, 15, 2857. [Google Scholar] [CrossRef]

- Yang, C.; Wang, P.; Sun, M. Experimental study on air content and slump of waste rubber aggregate concrete mixture. Concrete 2014, 53–55. [Google Scholar]

- Wang, C.; Zhai, S.; Kang, J.; Hou, C.; Gao, S.; Chang, D.; Yu, Z.; Niu, X. Study on impact resistance and wear resistance of rubber aggregate concrete and mechanistic analysis. Concrete 2025, 103–109. [Google Scholar]

- European Tyre & Rubber Manufacturers’ Association. End-of-Life Tyres Management: Europe 2021 Figures; European Tyre & Rubber Manufacturers’ Association: Brussels, Belgium, 2022. [Google Scholar]

- Abobakr, H.; Raji, M.; Essabir, H.; Bensalah, M.O.; Bouhfid, R.; Qaiss, A.E.K. Sustainable Acoustic Insulation in Nonstructural Concrete: Enhancing Performance with Ground Tire Rubber. J. Constr. Eng. Manag. 2025, 151, 04025147. [Google Scholar] [CrossRef]

- Zhang, P. Numerical Simulation Study on Mechanical Properties of Rubber Concrete Based on Random Aggregate Model. Master’s Thesis, Shenyang University, Shenyang, China, 2024. [Google Scholar]

- Sharma, J.; Chaturvedy, G.K.; Pandey, U.K. Sustainable rubberized concrete: The role of nano-titanium dioxide in enhancing mechanical and durability properties. Front. Struct. Civ. Eng. 2025, 19, 1418–1439. [Google Scholar] [CrossRef]

- Khamees, A.A.; Tameemi, W.A.; Sulaiman, E.A.; Al-Rammahi, A.A. Structural and Mechanical Characteristics of Sustainable Concrete Composite Panels Reinforced with Pre-Treated Recycled Tire Rubber. Rev. Compos. Matériaux Avancés J. Compos. Adv. Mater. 2023, 33, 371–378. [Google Scholar] [CrossRef]

- Jin, H.; Wang, Z.; Zhao, C. Parameter inversion analysis of rubber-mortar cohesive zone model in rubberized concrete. Constr. Build. Mater. 2023, 409, 133996. [Google Scholar] [CrossRef]

- Hasan, K.; Rahaman, M.M.; Ali, M.B.; Urmi, M.A.; Fariha, N.A.; Islam, M.T.; Nahar, T.T.; Yahaya, F.M. A comprehensive review of the application of waste tire rubber in concrete/mortar as fine aggregate replacement. Archit. Struct. Constr. 2023, 4, 91–111. [Google Scholar] [CrossRef]

- Liu, Q.; Andersen, L.V.; Zhang, M.; Wu, M. Abrasion damage of concrete for hydraulic structures and mitigation measures: A comprehensive review. Constr. Build. Mater. 2024, 422, 135754. [Google Scholar] [CrossRef]

- Liu, Q.; Li, L.; Andersen, L.V.; Wu, M. Studying the abrasion damage of concrete for hydraulic structures under various flow conditions. Cem. Concr. Compos. 2023, 135, 104849. [Google Scholar] [CrossRef]

- Zhai, S.; Liu, G.; Pang, B.; Liu, C.; Zhang, Z.; Zhang, L.; Liu, L.; Yang, Y.; Liu, Z.; Zhang, Y. Investigation on the influence of modified waste rubber powder on the abrasion resistance of concrete. Constr. Build. Mater. 2022, 357, 129409. [Google Scholar] [CrossRef]

- Suresh, A.; Harsha, A.P.; Ghosh, M.K. Solid particle erosion of unidirectional fibre reinforced thermoplastic composites. Wear 2009, 267, 1516–1524. [Google Scholar] [CrossRef]

- Bušić, R.; Gazić, G.; Guljaš, I.; Miličević, I. Experimental determination of double-K fracture parameters for self-compacting concrete with waste tire rubber and silica fume. Theor. Appl. Fract. Mech. 2025, 139, 105021. [Google Scholar] [CrossRef]

- Abdo, A.; Elshazli, M.T.; Alashker, Y.; Ahmed, S. Improving flexural response of rubberized RC beams with multi-dimensional sustainable approaches. Constr. Build. Mater. 2024, 449, 138400. [Google Scholar] [CrossRef]

- Nawar, M.T.; Selim, M.; Zaghlal, M.; El-Zohairy, A.; Emara, M. Performance of GFRP-Confined Rubberized Engineered Cementitious Composite Columns. J. Compos. Sci. 2024, 8, 330. [Google Scholar] [CrossRef]

- Mohamed, S.; Elemam, H.; Seleem, M.H.; Sallam, H.E.-D.M. Effect of fiber addition on strength and toughness of rubberized concretes. Sci. Rep. 2024, 14, 4346. [Google Scholar] [CrossRef] [PubMed]

- Bouabaz, A.; Djebien, R.; Belachia, M. Effect of Brick and Ceramic Powders on Fresh and Hardened Properties of Rubberized Concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 49, 3713–3728. [Google Scholar] [CrossRef]

- Khaloo, A.R.; Dehestani, M.; Rahmatabadi, P. Mechanical Properties of Concrete Containing a High Volume of Tire-Rubber Particles. Waste Manag. 2008, 28, 2472–2482. [Google Scholar] [CrossRef]

- SL/T 352-2020; Test Code for Hydraulic Concrete. Benliu Electronic Audio-Visual Publishing (Beijing) Co., Ltd.: Beijing, China, 2020.

- DL/T 5330-2015; Specification for Mix Design of Hydraulic Concrete. China Electric Power Press: Beijing, China, 2015.

- Jiang, C.; Gong, J.; Jiang, L.; Chen, C.; Tang, X. Research on Time-varying Behavior and Its Influence Factors of Low Heat Cement Concrete Under Abrasion. Mater. Rep. 2023, 37, 155–160. [Google Scholar]

- Jiang, C.; An, S.; Li, S.; Wu, B. Evaluation and prediction of abrasion resistance of hydraulic concrete based on three-dimensional topography. China Concr. Cem. Prod. 2024, 82–87. [Google Scholar]

- Tran, T.Q.; Li, S.; Ji, B.; Zhao, X. Mitigating Zinc Leachate from End-of-Life Tire Rubber in Stabilized Clayey Soils. J. Geotech. Geoenviron. Eng. 2024, 150, 88–93. [Google Scholar] [CrossRef]

- Jie, Y.; Guan, R.; Di, H.; Peng, J.; Zhou, C. Experimental Study on Peak Shear Strength Criterion for Rock Joints. Rock Mech. Rock Eng. 2016, 49, 821–835. [Google Scholar]

- Xie, Z.; Xiang, G.; Zhong, F.; Tian, Y.; Li, H.; Lei, J.; Yuan, Q. Unveiling the impact of organic phase aging on the long-term damping capacity of cement-styrene butadiene rubber composites. Constr. Build. Mater. 2024, 437, 136916. [Google Scholar] [CrossRef]

- Yin, B.; Lin, Z.; Li, T.; Qi, D.; Wang, P.; Han, K.; Hou, D. Enhancing cement-based composites via regulated hydration and concurrent construction of robust organic-inorganic network. Constr. Build. Mater. 2024, 445, 137902. [Google Scholar] [CrossRef]

- Jing, Y.; Zhang, C.; Lin, G.; Niu, Y.; Zhao, M.; Lin, Z. Enhancing rubber concrete with supercritical fluid-assisted Nano-SiO2 embedding and high-temperature stirred waste rubber. J. Build. Eng. 2024, 96, 110530. [Google Scholar] [CrossRef]

- Gupta, T.; Siddique, S.; Sharma, R.K.; Chaudhary, S. Behaviour of waste rubber powder and hybrid rubber concrete in aggressive environment. Constr. Build. Mater. 2019, 217, 283–291. [Google Scholar] [CrossRef]

- Liu, X.; Sun, D.; Liu, D.; Meng, K.; Ni, C.; Shao, Z.; Sun, L. Simulation of ultrasonic propagation in porous cellular concrete materials. Constr. Build. Mater. 2021, 285, 122852. [Google Scholar] [CrossRef]

- Zhou, X.; Fu, Q.; Zhang, Z.; Fang, Y.; Wang, Y.; Wang, F.; Song, Y.; Pittman, C.U., Jr.; Wang, Q. Efficient flame-retardant hybrid coatings on wood plastic composites by layer-by-layer assembly. J. Clean. Prod. 2021, 321, 128949. [Google Scholar] [CrossRef]

| Density (g/cm2) | Blaine Specific Surface Area (m2/kg) | Water Requirement for Standard Consistency (%) | Setting Time (min) | Soundness | Flexural Strength (MPa) | Compressive Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|---|

| Initial Setting Time | Final Setting Time | 3d | 28d | 3d | 28d | ||||

| 3.1 | 364 | 26.9 | 182 | 224 | Qualified | 5.1 | 8.6 | 22.1 | 51.0 |

| Apparent Density (g/cm3) | Water Absorption (%) | Fineness Modulus | Clay Content (%) | Sulfide and Sulfate Content (%) | Organic Matter Content |

|---|---|---|---|---|---|

| 2.65 | 1.2 | 2.9 | 1.2 | 0.3 | Lighter than the standard color |

| Apparent Density (g/cm3) | Water Absorption (%) | Crushing Value (%) | Sulfide and Sulfate Content (%) | Organic Matter Content |

|---|---|---|---|---|

| 2.68 | 0.8 | 3 | 8 | Lighter than the standard color |

| Element | C | O | Ca | Zn | S | Na | Cl | K | Si | Fe | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 77.69 | 18.71 | 1.1 | 0.39 | 0.56 | 0.51 | 0.28 | 0.25 | 0.3 | 0.12 | 0.09 |

| Water-To-Binder Ratio | Water (kg/m3) | Cement (kg/m3) | Sand Ratio | Fine Aggregate (kg/m3) | Crushed Stone (kg/m3) | Superplasticizer (%) | Waste Rubber Powder (%) |

|---|---|---|---|---|---|---|---|

| 0.43 | 168.40 | 387.50 | 0.42 | 801.00 | 1109.40 | 0.6 | 0.0 |

| 0.43 | 159.98 | 368.13 | 0.42 | 760.95 | 1053.93 | 0.6 | 5.0 |

| 0.43 | 151.56 | 348.75 | 0.42 | 720.90 | 998.46 | 0.6 | 10.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Yu, D.; Jiang, C.; Feng, Z.; Zhao, M.; Li, Z. Influence of Waste Rubber Powder on the Mechanical and Abrasion Resistance Properties of Concrete. Materials 2025, 18, 5157. https://doi.org/10.3390/ma18225157

Li S, Yu D, Jiang C, Feng Z, Zhao M, Li Z. Influence of Waste Rubber Powder on the Mechanical and Abrasion Resistance Properties of Concrete. Materials. 2025; 18(22):5157. https://doi.org/10.3390/ma18225157

Chicago/Turabian StyleLi, Shuangxi, Dongzheng Yu, Chunmeng Jiang, Zhimin Feng, Mai Zhao, and Zhong Li. 2025. "Influence of Waste Rubber Powder on the Mechanical and Abrasion Resistance Properties of Concrete" Materials 18, no. 22: 5157. https://doi.org/10.3390/ma18225157

APA StyleLi, S., Yu, D., Jiang, C., Feng, Z., Zhao, M., & Li, Z. (2025). Influence of Waste Rubber Powder on the Mechanical and Abrasion Resistance Properties of Concrete. Materials, 18(22), 5157. https://doi.org/10.3390/ma18225157