Comfort During Motion: Analyzing the Pressure Profile of Auxetic Bra Pads

Abstract

1. Introduction

2. Materials and Methods

2.1. Participants

2.2. Bra Samples

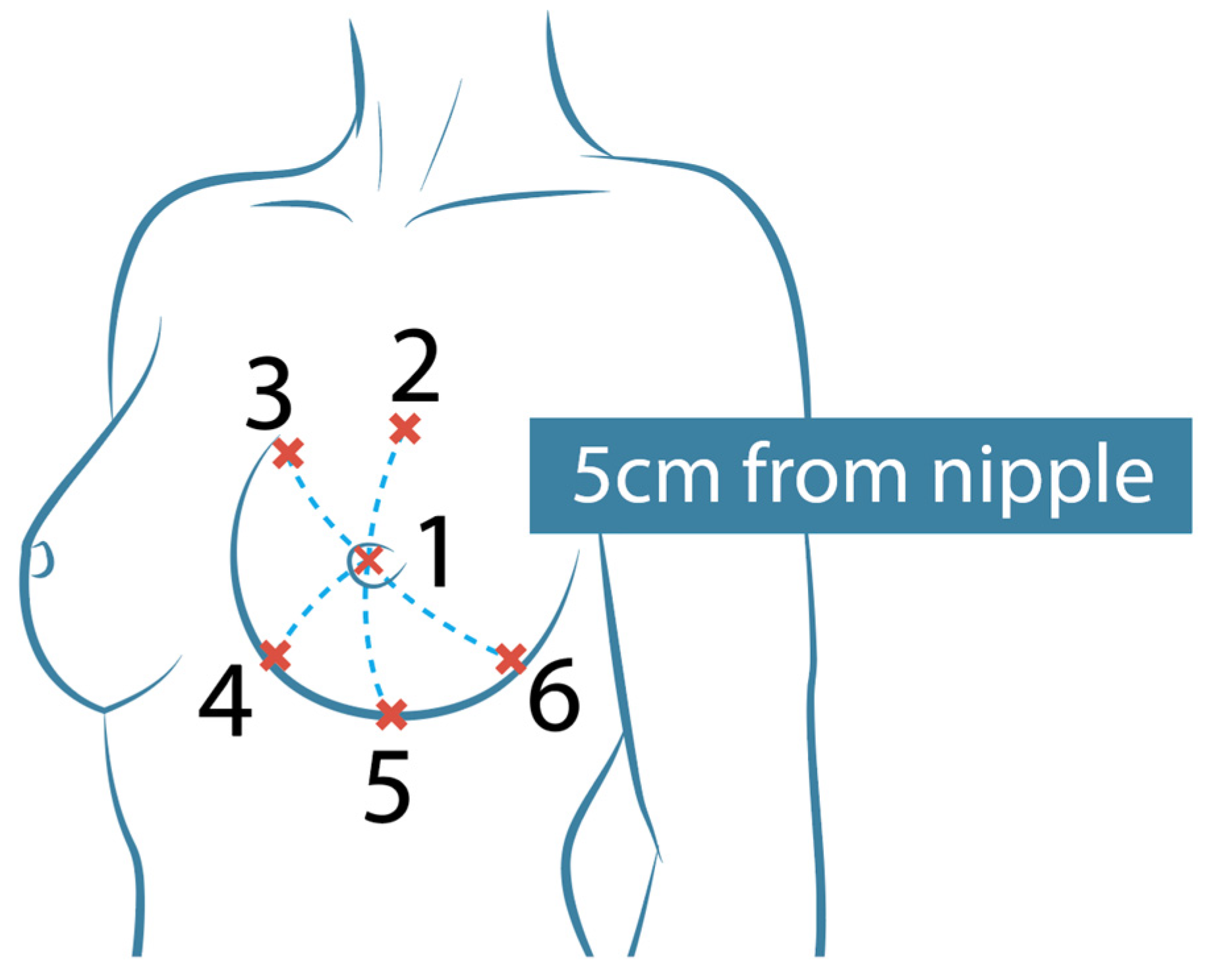

2.3. Experimental Procedure

3. Results

3.1. Anthropometric Breast Measurements Across Postures

3.2. Pressure Distribution of Bras Across Six Points

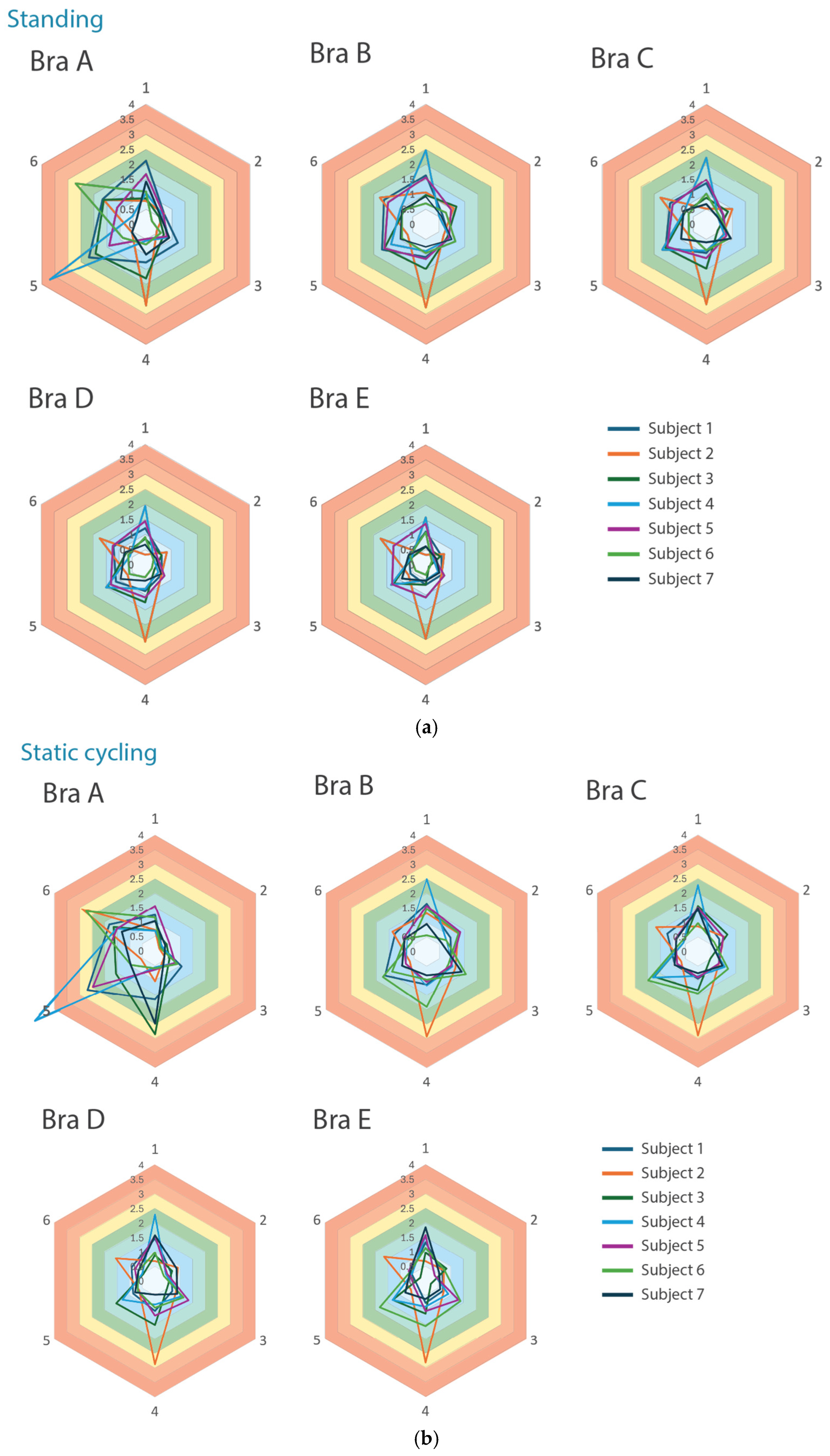

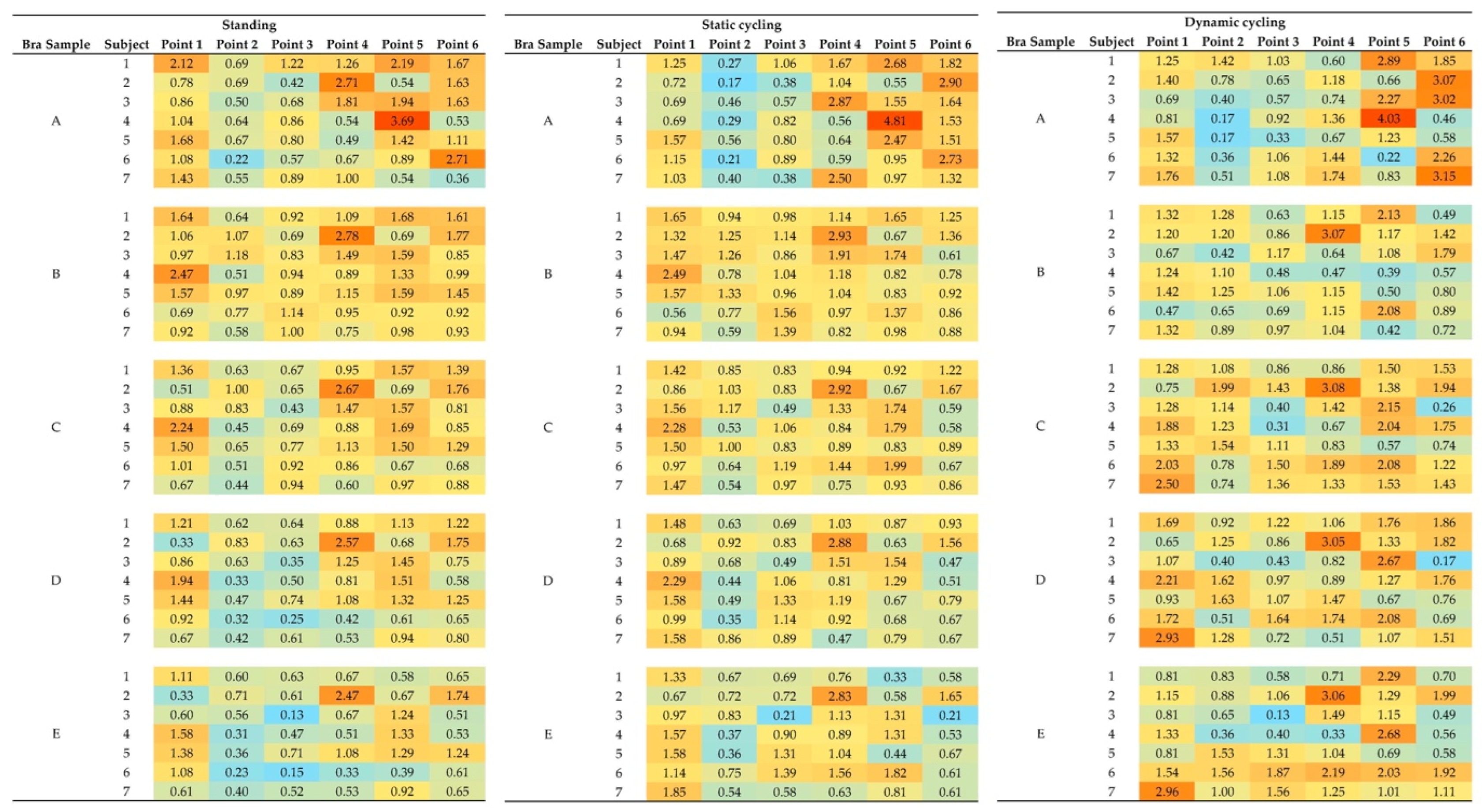

3.2.1. Standing Pose

3.2.2. Static Cycling Pose

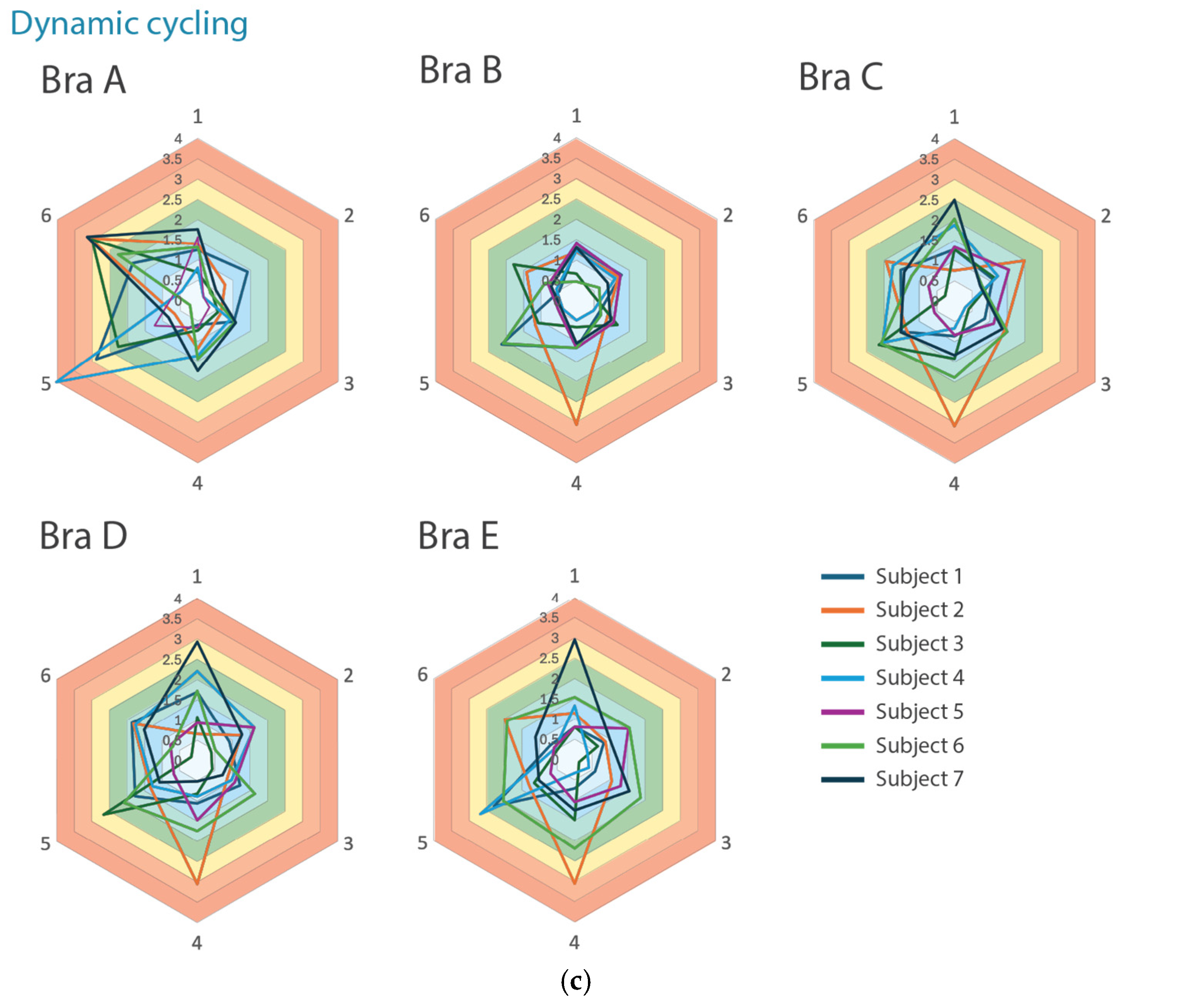

3.2.3. Dynamic Cycling Pose

3.3. Comparative Pressure Performance of Bras Under Various Poses

3.4. Performance of Pressure Distribution in Bra Pads

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gilmer, G.; Xu, E.; Franklin, C.; Adams, N.; Rizzone, K. The Impact of Breasts and Bras on Physical Activity Amongst Women and Girls: A Systematic Review and Meta-Analysis. J. Women’s Sports Med. 2024, 4, 39–54. [Google Scholar] [CrossRef]

- Illidi, C.R.; Jensen, D. Supported to perform: Sports bras and breast volume do not impair cycling performance in females. Front. Sports Act. Living 2024, 6, 1439403. [Google Scholar] [CrossRef]

- Zhu, C.L.; Long, W.; Ying, B.A.; Qi, J. Finite element simulation of the dynamic pressure distribution of a typical compression sports bra during wearing. J. Fiber Bioeng. Inform. 2020, 13, 211–219. [Google Scholar] [CrossRef]

- Haworth, L.; May, K.; Janssen, J.; Selfe, J.; Chohan, A. The impact of breast support garments on fit, support and posture of larger breasted women. Appl. Ergon. 2022, 101, 103701. [Google Scholar] [CrossRef]

- McGhee, D.E.; Steele, J.R. Biomechanics of breast support for active women. Exerc. Sport Sci. Rev. 2020, 48, 99–109. [Google Scholar] [CrossRef]

- Guo, N.; Li, Z.; Chen, N.; Dai, H.; Liu, K.; Xue, W.; Zhang, P. Optimized design of sports bras with pressure comfort, thermal comfort, and shaping support. Text. Res. J. 2024, 94, 180–191. [Google Scholar] [CrossRef]

- Burbage, J.; Rawcliffe, A.J.; Saunders, S.; Corfield, L.; Izard, R. The incidence of breast health issues and the efficacy of a sports bra fit and issue service in British Army recruits. Ergonomics 2021, 64, 1052–1061. [Google Scholar] [CrossRef]

- Ocran, F.M.; Ji, X.; Zhai, L. A study to evaluate pressure distribution of different sports bras. J. Eng. Fibers Fabr. 2022, 17, 15589250221118643. [Google Scholar] [CrossRef]

- Ocran, F.M.; Ji, X.; Zhai, L. The impact of sports bra features on measured and perceived pressure for torso movement of the upper body. J. Eng. Fibers Fabr. 2022, 17, 15589250221127393. [Google Scholar] [CrossRef]

- Norris, M.; Blackmore, T.; Horler, B.; Wakefield-Scurr, J. How the characteristics of sports bras affect their performance. Ergonomics 2021, 64, 410–425. [Google Scholar] [CrossRef] [PubMed]

- Lu, M.; Qiu, J.; Wang, G.; Dai, X. Mechanical analysis of breast–bra interaction for sports bra design. Mater. Today Commun. 2016, 6, 28–36. [Google Scholar] [CrossRef]

- Ramzan, M.B.; Imran, A.; Zaman, S.U.; Ali, M.; Islam, T.; Rasheed, A. Design and development of auxetic structures for enhancing ergonomic comfort in women’s intimate apparel (brassiere). J. Eng. Fibers Fabr. 2023, 18, 15589250231219760. [Google Scholar] [CrossRef]

- Wilfling, J.; Havenith, G.; Raccuglia, M.; Hodder, S. Consumer expectations and perception of clothing comfort in sports and exercise garments. Res. J. Text. Appar. 2022, 26, 293–309. [Google Scholar] [CrossRef]

- Exell, T.A.; Milligan, A.; Burbage, J.; Risius, D.; Sanchez, A.; Horler, B.; Mills, C.; Wakefield-Scurr, J. There are two sides to every story: Implications of asymmetry on breast support requirements for sports bra manufacturers. Sports Biomech. 2021, 20, 866–878. [Google Scholar] [CrossRef]

- Musilova, B.; Nemcokova, R.; Svoboda, M. Testing methods of pressure distribution of bra cups on breasts soft tissue. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 142016. [Google Scholar] [CrossRef]

- Chen, J.; Keung, Y.C.D.; Sun, Y.; Yip, J.; Yick, K.-L. Exploration of breast motion under different activities and intensities. J. Eng. Fibers Fabr. 2025, 20, 15589250251352192. [Google Scholar] [CrossRef]

- Sun, Y.; Yick, K.L.; Cai, Y.; Yu, W.; Chen, L.; Lau, N.; Zhang, S. Finite element analysis on contact pressure and 3D breast deformation for application in women’s bras. Fibers Polym. 2021, 22, 2910–2921. [Google Scholar] [CrossRef]

- Tahir, D.; Zhang, M.; Hu, H. Auxetic materials for personal protection: A review. Phys. Status Solidi (B) 2022, 259, 2200324. [Google Scholar] [CrossRef]

- Bohara, R.P.; Linforth, S.; Nguyen, T.; Ghazlan, A.; Ngo, T. Anti-blast and-impact performances of auxetic structures: A review of structures, materials, methods, and fabrications. Eng. Struct. 2023, 276, 115377. [Google Scholar] [CrossRef]

- Keung, Y.C.; Yick, K.L.; Yu, A.; Yip, J. Exploring re-entrant auxetic silicone structures to design bra pads. Polym. Test. 2024, 135, 108462. [Google Scholar] [CrossRef]

- Okabe, K.; Kurokawa, T. Relationship between wearing comfort and clothing pressure for designing comfortable brassieres. Bull. Jpn. Soc. Sci. Des. 2004, 51, 31–38. [Google Scholar]

- Daemen, J.H.; Loonen, T.G.; Verhulst, A.C.; Maal, T.J.; Maessen, J.G.; Vissers, Y.L.; Hulsewé, K.W.E.; de Loos, E.R. Three-dimensional imaging of the chest wall: A comparison between three different imaging systems. J. Surg. Res. 2021, 259, 332–341. [Google Scholar] [CrossRef] [PubMed]

- Spears, S.D.; Lester, T.; Torii, R.; Kalaskar, D.M. Comparative evaluation of Artec Leo hand-held scanner and iPad Pro for 3D scanning of cervical and craniofacial data: Assessing precision, accuracy, and user experience. 3D Print. Med. 2024, 10, 39. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.J.; Han, W.Y.; Eom, J.S.; Kim, E.K.; Han, H.H. Analysis on the difference between the practical brassiere size and real breast volume. Plast. Reconstr. Surg. Glob. Open 2023, 11, e5141. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.W.; Yick, K.L.; Ng, S.P.; Yip, J. Soft manikin as tool to evaluate bra features and pressure. Int. J. Fash. Des. Technol. Educ. 2020, 13, 204–212. [Google Scholar] [CrossRef]

- Mendes, L.P.D.S.; Vieira, D.S.R.; Gabriel, L.S.; Ribeiro-Samora, G.A.; De Andrade, A.D.; Brandão, D.C.; Goes, M.C.; Fregonezi, G.A.F.; Britto, R.R.; Parreira, V.F. Influence of posture, sex, and age on breathing pattern and chest wall motion in healthy subjects. Braz. J. Phys. Ther. 2020, 24, 240–248. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, H. A review on auxetic structures and polymeric materials. Sci. Res. Essays 2010, 5, 1052–1063. [Google Scholar]

- Pothier, S.; Roufail, R.; Malton, M. Unit cell modelling of auxetic structure. J. Miner. Mater. Charact. Eng. 2022, 10, 360–369. [Google Scholar] [CrossRef]

- Coltman, C.E.; McGhee, D.E.; Steele, J.R. How much error is associated with calculating breast volume from three-dimensional breast scans obtained when women are standing? Implications for bra design and bra fit. Ergonomics 2023, 66, 330–337. [Google Scholar] [CrossRef]

| Subject | Standing | Leaning | ||||||

|---|---|---|---|---|---|---|---|---|

| Underbust Girth (cm) | Full Bust Girth (cm) | Difference (cm) | Cup Size | Underbust Girth (cm) | Full Bust Girth (cm) | Difference (cm) | Cup Size | |

| 1 | 76.5 | 90 | 13.5 | B | 80 | 93 | 13 | B |

| 2 | 77 | 90 | 13 | B | 88.5 | 91.5 | 3 | AAA |

| 3 | 74 | 87 | 13 | B | 79.5 | 90 | 11 | A |

| 4 | 74 | 88 | 14 | B | 79 | 90 | 11 | A |

| 5 | 73 | 86 | 13 | B | 77.5 | 87.5 | 10 | A |

| 6 | 75 | 90 | 15 | B | 79 | 94 | 15 | C |

| 7 | 74.5 | 88 | 13.5 | B | 77 | 93 | 16 | C |

| Subject | Under Bust | Full Bust | ||||

|---|---|---|---|---|---|---|

| Standing (cm) | Leaning (cm) | Percentage of Change (%) | Standing (cm) | Leaning (cm) | Percentage of Change (%) | |

| 1 | 76.5 | 80 | 4.6% | 90 | 93 | 3.3% |

| 2 | 77 | 88.5 | 14.9% | 90 | 91.5 | 1.7% |

| 3 | 74 | 79.5 | 7.4% | 87 | 90 | 3.4% |

| 4 | 74 | 79 | 6.8% | 88 | 90 | 2.3% |

| 5 | 73 | 77.5 | 6.2% | 86 | 87.5 | 1.7% |

| 6 | 75 | 79 | 5.3% | 90 | 94 | 4.4% |

| 7 | 74.5 | 77 | 3.4% | 88 | 93 | 5.7% |

| Condition | Bra Sample | Mean Pressure (kPa) | Maximum Pressure (kPa) | Standard Deviation | 95% CI (kPa) |

|---|---|---|---|---|---|

| Standing | A | 1.53 | 3.69 | 1.23 | 0.972, 2.088) |

| B | 1.34 | 2.78 | 0.805 | (0.973, 1.707) | |

| C | 1.21 | 2.67 | 0.841 | (0.826, 1.594) | |

| D | 1.13 | 2.57 | 0.852 | (0.742, 1.518) | |

| E | 1.09 | 2.47 | 0.832 | (0.713, 1.467) | |

| Static cycling | A | 1.46 | 4.81 | 1.70 | (0.688, 2.232) |

| B | 1.45 | 2.93 | 0.769 | (1.100, 1.800) | |

| C | 1.33 | 2.92 | 0.851 | (0.946, 1.714) | |

| D | 1.25 | 2.88 | 0.864 | (0.858, 1.642) | |

| E | 1.21 | 2.83 | 0.893 | (0.817, 1.603) | |

| Dynamic cycling | A | 1.51 | 4.03 | 1.40 | (0.875, 2.145) |

| B | 1.49 | 3.07 | 0.794 | (1.130, 1.850) | |

| C | 1.76 | 3.08 | 0.789 | (1.403, 2.117) | |

| D | 1.49 | 3.05 | 0.912 | (1.077, 1.903) | |

| E | 1.85 | 3.06 | 0.930 | (1.435, 2.265) |

| Sum of Squares | df | Mean Square | F | p | ||

|---|---|---|---|---|---|---|

| Bra_sample | Standing | 3.78 | 4 | 0.945 | 2.34 | 0.078 |

| Static cycling | 7.59 | 4 | 1.896 | 4.97 | 0.003 | |

| Dynamic cycling | 3.71 | 4 | 0.928 | 2.33 | 0.079 | |

| Residuals | Standing | 12.10 | 30 | 0.403 | ||

| Static cycling | 11.45 | 30 | 0.382 | |||

| Dynamic cycling | 11.97 | 30 | 0.399 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Keung, Y.-c.; Yick, K.-l.; Yip, J.; Yu, A. Comfort During Motion: Analyzing the Pressure Profile of Auxetic Bra Pads. Materials 2025, 18, 5071. https://doi.org/10.3390/ma18225071

Keung Y-c, Yick K-l, Yip J, Yu A. Comfort During Motion: Analyzing the Pressure Profile of Auxetic Bra Pads. Materials. 2025; 18(22):5071. https://doi.org/10.3390/ma18225071

Chicago/Turabian StyleKeung, Yin-ching, Kit-lun Yick, Joanne Yip, and Annie Yu. 2025. "Comfort During Motion: Analyzing the Pressure Profile of Auxetic Bra Pads" Materials 18, no. 22: 5071. https://doi.org/10.3390/ma18225071

APA StyleKeung, Y.-c., Yick, K.-l., Yip, J., & Yu, A. (2025). Comfort During Motion: Analyzing the Pressure Profile of Auxetic Bra Pads. Materials, 18(22), 5071. https://doi.org/10.3390/ma18225071