Evaluation and Control of Variability in RAP Properties Through Refined Fractionation Processing Methods

Abstract

1. Introduction

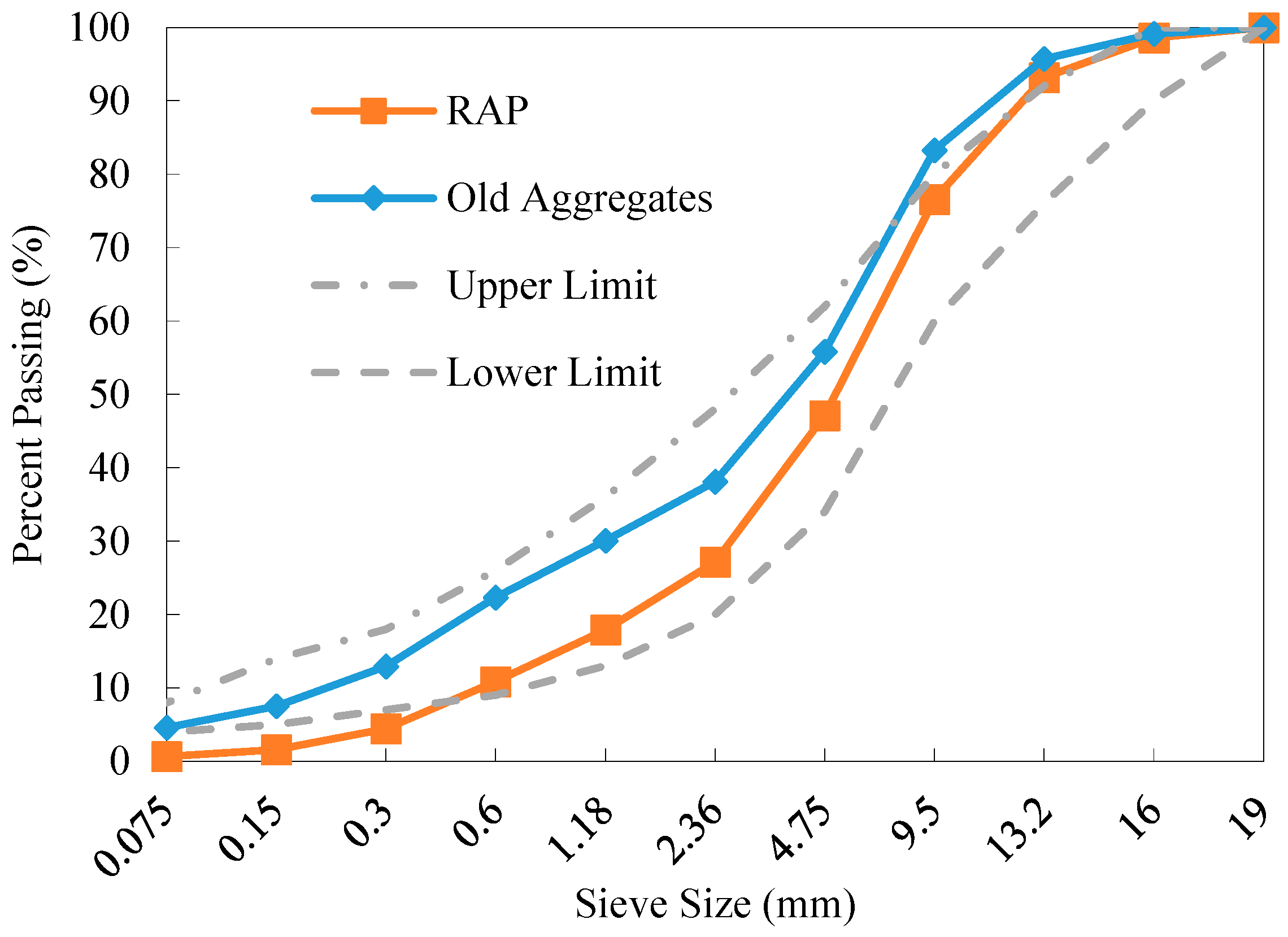

2. Materials

3. Methodology

3.1. Fractionation Processing Methods

3.2. Proportioning RAP Fractions into Reference Materials

3.3. Determining Moisture Contents of RAP Materials

3.4. Determining Asphalt Contents of RAP Materials

3.5. Evaluating RAP Variability

4. Results and Discussion

4.1. Variability Analysis of Moisture Contents of Reference RAP Materials

4.2. Variability Analysis of Asphalt Contents of Reference RAP Materials

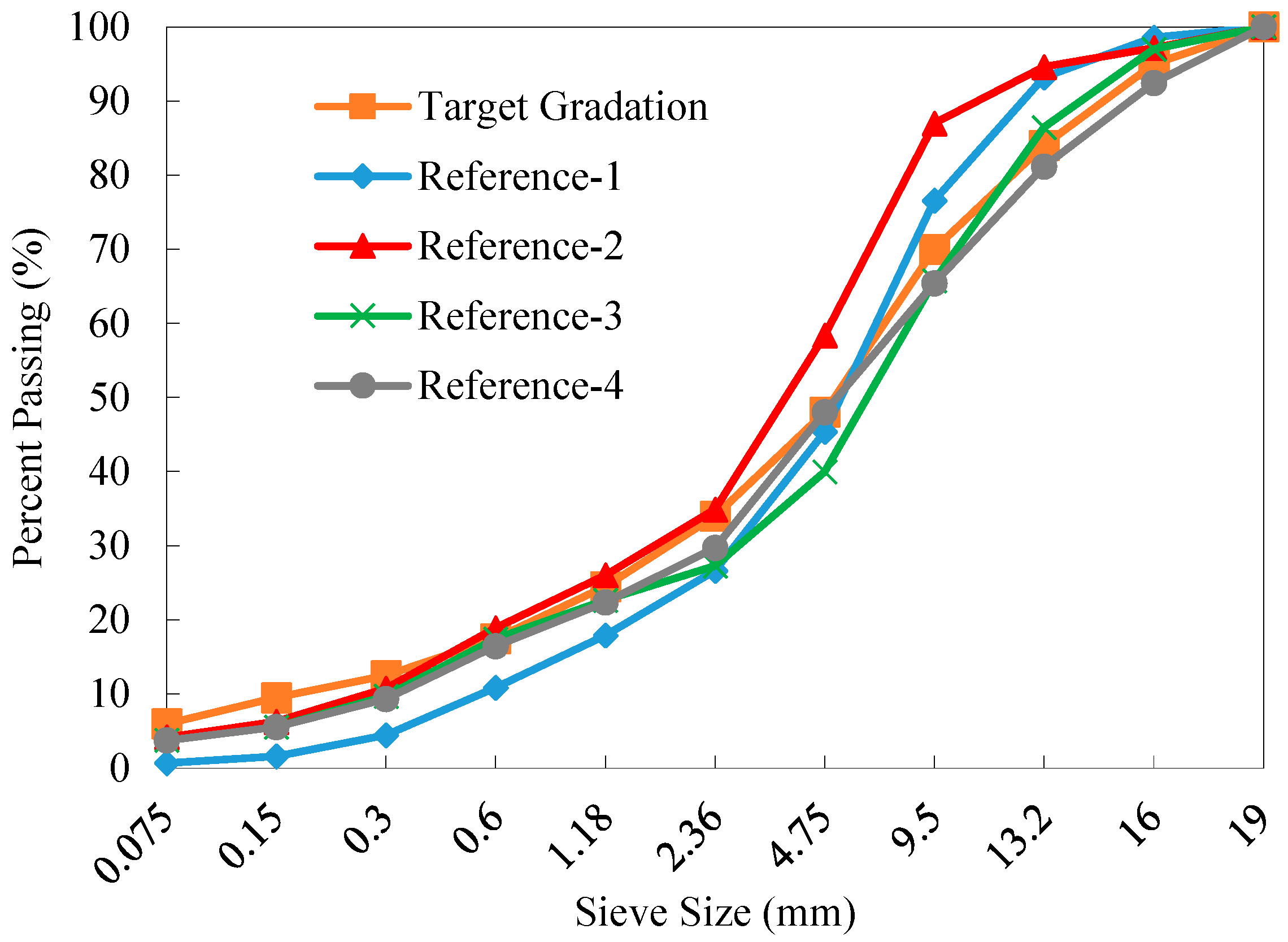

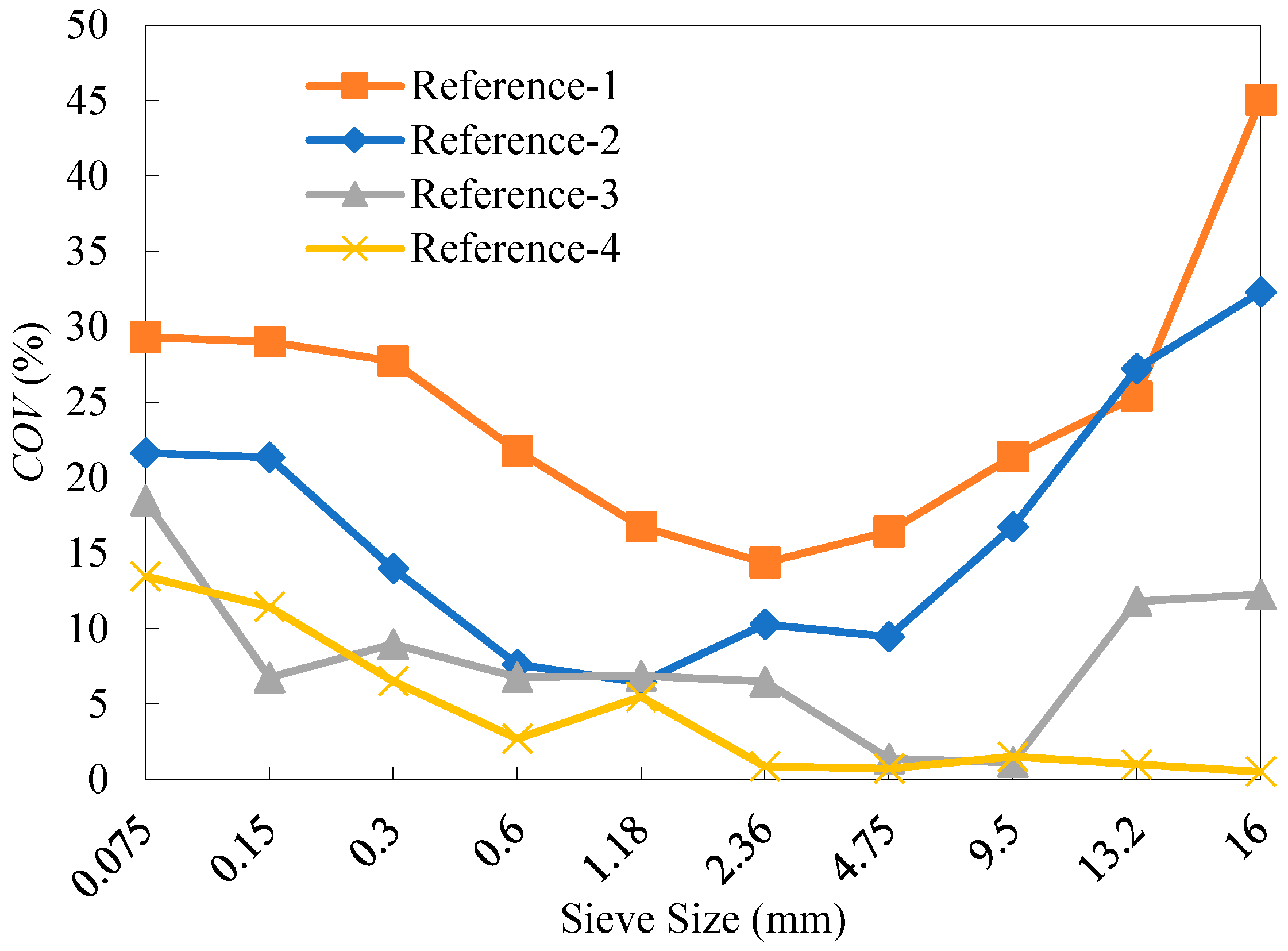

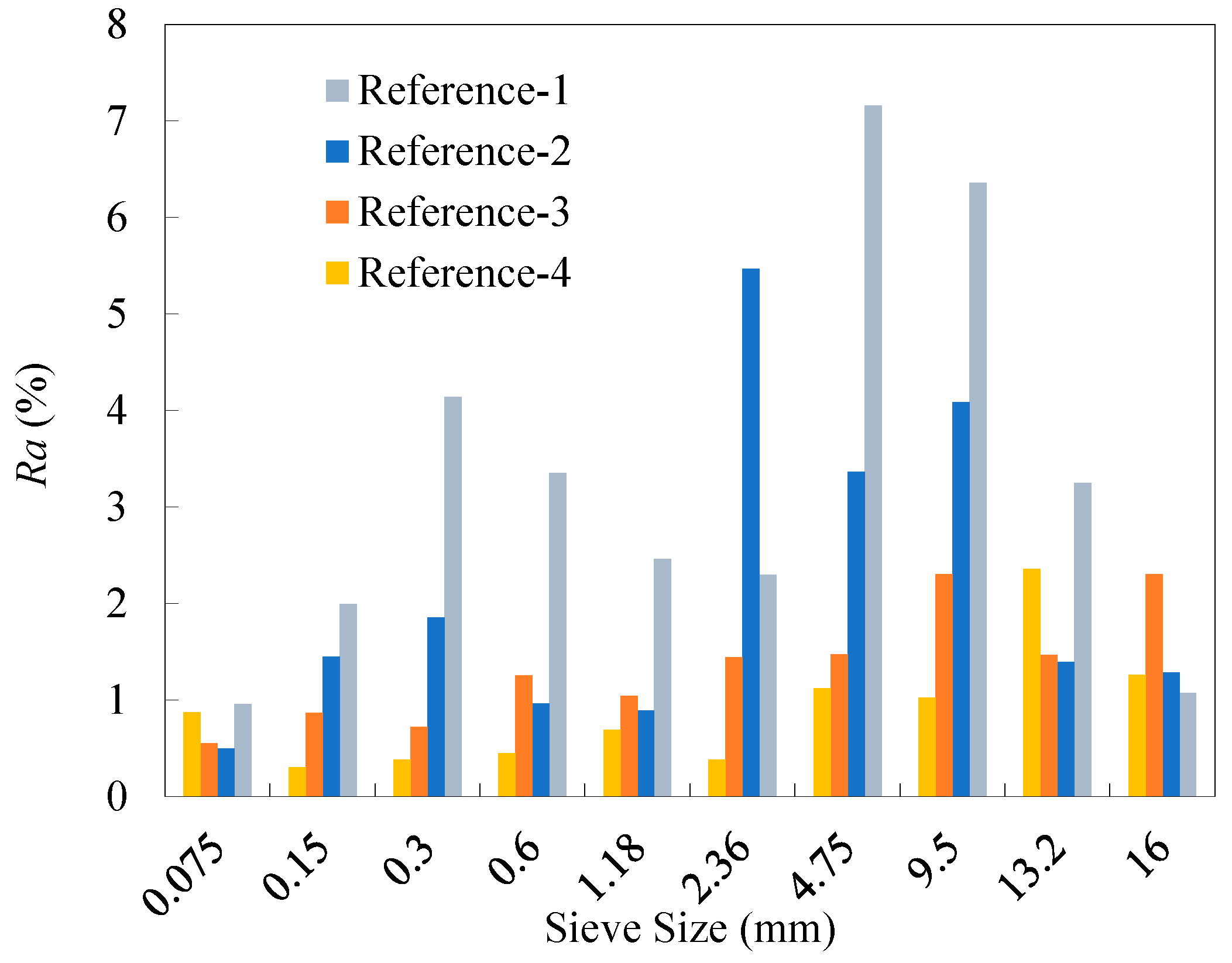

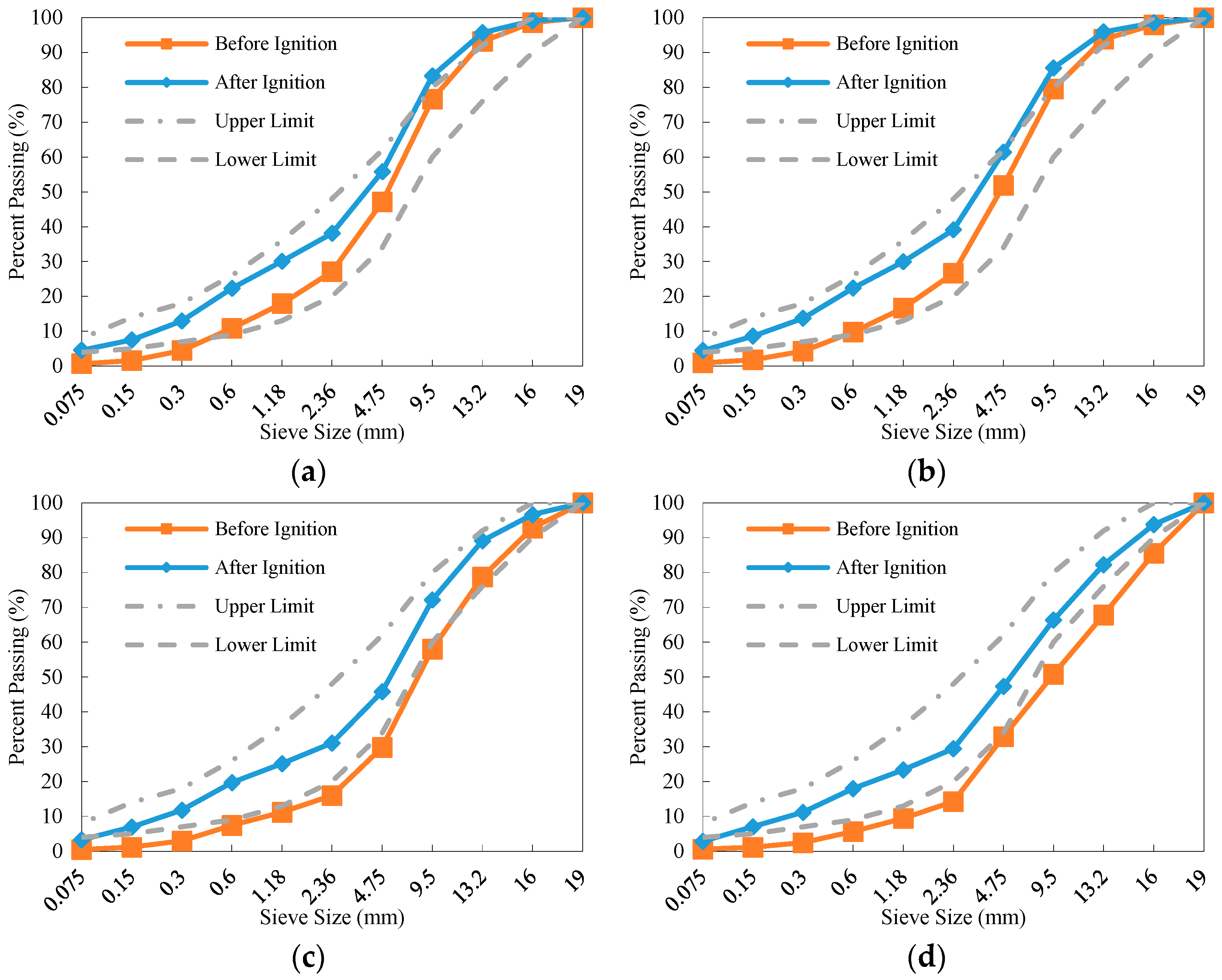

4.3. Variability Analysis of Gradations of Reference RAP Materials and Old Aggregates

5. Summary and Conclusions

- (1)

- The unfractionated method and commonly used two-fraction processing struggle to efficiently control the variability of RAP properties, particularly the gradation of old aggregates.

- (2)

- Compared to unfractionated RAP materials, the variability of RAP materials subjected to fractionation processing showed significant improvement. Moreover, as the number of fractions increased, the degree of variability in the RAP materials remarkably decreased. Specifically, compared with the COV values from the commonly used two-fraction processing, those from the refined four-fraction and six-fraction processing methods declined by up to 51.5% and 73.5%, respectively.

- (3)

- Fractionating RAP materials into four fractions in a refined manner represented the most economically viable and technically reasonable processing strategy, as it effectively controlled the variability in the properties of the RAP materials.

- (4)

- The GRA affords a simple and effective approach for directly calculating the proportions of RAP fractions in terms of geometric similarity between grading curves without performing a nonlinear minimization algorithm on a target error function.

- (5)

- Proportioning RAP fractions into reference materials with desirable gradations can be a potential approach for controlling the high-RAP recycled mixture with low variability and superior performance.

- (6)

- Additional research efforts are required to investigate other factors that may cause RAP variability, like RAP source, particle agglomeration, asphalt aging, and binder activity. In addition, assessment on the effect of reduced RAP variability caused by refined fractionation processing on the performance of the corresponding recycled asphalt mixtures is required in future studies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hu, M.; Ji, S.; Sun, Y.; Zhu, K. Understanding the low-temperature fracture behavior of rejuvenated high viscosity modified asphalt utilizing a combined microstructure-component analysis. Constr. Build. Mater. 2025, 471, 140717. [Google Scholar] [CrossRef]

- Li, M.; Yuan, J.; Jin, T.; Wang, W.; Sun, Y.; Cheng, H. Investigation of performance evolution in recycled asphalt mixtures: The impact of virgin and RAP binder blending. Constr. Build. Mater. 2025, 469, 140519. [Google Scholar] [CrossRef]

- Xu, H.; Chen, J.; Sun, Y.; Zhu, X.; Wang, W.; Liu, J. Rheological and physico-chemical properties of warm-mix recycled asphalt mastic containing high percentage of RAP binder. J. Clean. Prod. 2021, 289, 125134. [Google Scholar] [CrossRef]

- Katla, B.; Raju, S.; Waim, A.R.; Danam, V.A. Utilization of Higher Percentages of RAP for Improved Mixture Performance by Adopting the Process of Fractionation. Int. J. Pavement Res. Technol. 2021, 15, 349–366. [Google Scholar] [CrossRef]

- Xu, H.; Sun, Y.; Chen, J.; Li, J.; Yu, B.; Qiu, G.; Zhang, Y.; Xu, B. Investigation into Rheological Behavior of Warm-Mix Recycled Asphalt Binders with High Percentages of RAP Binder. Materials 2023, 16, 1599. [Google Scholar] [CrossRef] [PubMed]

- Hu, M.; Sun, D.; Hofko, B.; Sun, Y.; Mirwald, J.; Xu, L. Multiscale optimization on polymer-based rejuvenators for the efficient recycling of aged high-viscosity modified asphalt: Molecular dynamics simulation and experimental analysis. J. Clean. Prod. 2024, 449, 141736. [Google Scholar] [CrossRef]

- Solaimanian, M.; Tahmoressi, M. Variability Analysis of Hot-Mix Asphalt Concrete Containing High Percentage of Reclaimed Asphalt Pavement. Transp. Res. Rec. J. Transp. Res. Board 1996, 1543, 89–96. [Google Scholar] [CrossRef]

- Li, M.; Han, Z.; Cheng, H.; Yang, R.; Yuan, J.; Jin, T. Low-temperature performance improvement strategies for high RAP content recycled asphalt mixtures: Focus on RAP gradation variability and mixing process. Fuel 2025, 387, 134362. [Google Scholar] [CrossRef]

- Xu, G.; Shen, Z.; Hao, S.; Du, M.; Hu, J. Mitigating RAP variability through detailed particle size classification: Applications in high RAP content asphalt mixtures. Case Stud. Constr. Mater. 2025, 23, e04993. [Google Scholar] [CrossRef]

- Montañez, J.; Caro, S.; Carrizosa, D.; Calvo, A.; Sánchez, X. Variability of the mechanical properties of Reclaimed Asphalt Pavement (RAP) obtained from different sources. Constr. Build. Mater. 2020, 230, 116968. [Google Scholar] [CrossRef]

- Austerman, A.J.; Mogawer, W.S.; Stuart, K.D. Variability of Reclaimed Asphalt Pavement (RAP) Properties within a State and Its Effects on RAP Specifications. Transp. Res. Rec. J. Transp. Res. Board 2020, 2674, 73–84. [Google Scholar] [CrossRef]

- Aurangzeb, Q.; Al-Qadi, I.L.; Abuawad, I.M.; Pine, W.J.; Trepanier, J.S. Achieving Desired Volumetrics and Performance for Mixtures with High Percentage of Reclaimed Asphalt Pavement. Transp. Res. Rec. J. Transp. Res. Board 2012, 2294, 34–42. [Google Scholar] [CrossRef]

- Wang, J.; Xu, J.; Liu, L. Variability Investigation of Reclaimed Asphalt Pavement Materials. J. Mater. Civ. Eng. 2024, 36, 04023558. [Google Scholar] [CrossRef]

- Hong, F.; Guo, R.; Zhou, F. Impact of recycled asphalt pavement material variability on pavement performance. Road Mater. Pavement Des. 2014, 15, 841–855. [Google Scholar] [CrossRef]

- Pan, Y.; Li, J.; Yang, T.; Liu, G.; Zhou, J.; Guo, P.; Zhao, Y. Optimization of gradation design of recycled asphalt mixtures based on fractal and Mohr-Coulomb theories. Constr. Build. Mater. 2020, 248, 118649. [Google Scholar] [CrossRef]

- Rema, A.; Swamy, A.K. Response Surface–Based Approach to Quantify Variability in Recycled-Asphalt Concrete Mixtures. J. Mater. Civ. Eng. 2022, 34, 04022315. [Google Scholar] [CrossRef]

- Zaumanis, M.; Oga, J.; Haritonovs, V. How to reduce reclaimed asphalt variability: A full-scale study. Constr. Build. Mater. 2018, 188, 546–554. [Google Scholar] [CrossRef]

- Zaumanis, M.; Boesiger, L.; Kunz, B.; Mazzoni, H.; Bruhin, P.; Mazor, S.; Poulikakos, L. Three indexes to characterise crushing and screening of reclaimed asphalt pavement. Int. J. Pavement Eng. 2021, 23, 4977–4990. [Google Scholar] [CrossRef]

- R., A.; Radhakrishnan, V.; Bharath, G. Effect of RAP Dissociation and Agglomeration on Recycled Asphalt Binder Availability. J. Mater. Civ. Eng. 2024, 36, 04024264. [Google Scholar] [CrossRef]

- He, J.; Ma, Y.; Zheng, K.; Cheng, Z.; Xie, S.; Xiao, R.; Huang, B. Quantifying the agglomeration effect of reclaimed asphalt pavement on performance of recycled hot mix asphalt. J. Clean. Prod. 2024, 442, 141044. [Google Scholar] [CrossRef]

- Ferreira, W.L.G.; Castelo Branco, V.T.F.; Vasconcelos, K.; Bhasin, A.; Sreeram, A. The impact of aging heterogeneities within RAP binder on recycled asphalt mixture design. Constr. Build. Mater. 2021, 300, 124260. [Google Scholar] [CrossRef]

- Sreeram, A.; Leng, Z. Variability of rap binder mobilisation in hot mix asphalt mixtures. Constr. Build. Mater. 2019, 201, 502–509. [Google Scholar] [CrossRef]

- Zhu, J.; Ma, T.; Fang, Z. Characterization of agglomeration of reclaimed asphalt pavement for cold recycling. Constr. Build. Mater. 2020, 240, 117912. [Google Scholar] [CrossRef]

- Gao, J.; Yang, J.; Yu, D.; Jiang, Y.; Ruan, K.; Tao, W.; Sun, C.; Luo, L. Reducing the variability of multi-source reclaimed asphalt pavement materials: A practice in China. Constr. Build. Mater. 2021, 278, 122389. [Google Scholar] [CrossRef]

- De Lira, R.R.; Cortes, D.D.; Pasten, C. Reclaimed asphalt binder aging and its implications in the management of RAP stockpiles. Constr. Build. Mater. 2015, 101, 611–616. [Google Scholar] [CrossRef]

- Yu, X.; Tang, W.; Li, N.; Jiang, M.; Huang, J.; Wang, D. Refined decomposition: A new separation method for RAP materials and its effect on aggregate properties. Constr. Build. Mater. 2022, 358, 129452. [Google Scholar] [CrossRef]

- Wang, P.; Chen, J.; Wang, J.; Li, J.; Ning, H.; Liang, C.; Ge, X.; Wang, X. Evaluation of the Refined Decomposition Effect of Reclaimed Asphalt Pavement Materials. Buildings 2023, 13, 2240. [Google Scholar] [CrossRef]

- Shannon, C.; Mokhtari, A.; Lee, H.D.; Tang, S.; Williams, C.; Schram, S. Effects of High Reclaimed Asphalt-Pavement Content on the Binder Grade, Fatigue Performance, Fractionation Process, and Mix Design. J. Mater. Civ. Eng. 2017, 29, 04016218. [Google Scholar] [CrossRef]

- Nanda, H.; Siddagangaiah, A.K. Effect of RAP fractionation and dosage on design and mechanical behaviour of cold asphalt mixes. Constr. Build. Mater. 2024, 422, 135773. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Miller, J.A. Effects of Rejuvenating Agents on Superpave Mixtures Containing Reclaimed Asphalt Pavement. J. Mater. Civ. Eng. 2007, 19, 376–384. [Google Scholar] [CrossRef]

- JTG 3432-2024; Test Methods of Aggregates for Highway Engineering. China Communications Press: Beijing, China, 2024.

- ASTM D5404/D5404M; Standard Practice for Recovery of Asphalt Binder from Solution Using the Rotary Evaporator. ASTM International: West Conshohocken, PA, USA, 2024.

- JTG/T 5521-2019; Technical Specifications for Highway Asphalt Pavement Recycling. China Communications Press: Beijing, China, 2019.

- Liu, S. Grey Systems Analysis: Methods, Models and Applications; Springer: Singapore, 2025. [Google Scholar]

- Guo, K. The Study on Pavement Performance of the Different Mixing Rate Regeneration Mixture Based on Reference Material Synthesis. Chongqing Jiaotong University, Chongqing, China, 2013. [Google Scholar]

- ASTM D6307; Standard Test Method for Asphalt Content of Asphalt Mixture by Ignition Method. ASTM International: West Conshohocken, PA, USA, 2019.

| Material | Property | Requirement [33] | Measurement |

|---|---|---|---|

| Aged asphalt | Penetration at 25 °C (0.1 mm) | >20 | 27.9 |

| Softening point (°C) | — | 67.1 | |

| Ductility at 15 °C (mm) | — | 89.8 | |

| Apparent viscosity at 135 °C (Pa·s) | — | 0.697 | |

| Old coarse aggregate | Flat and elongated particle fraction (%) | ≤15 | 14.1 |

| Aggregate crushing value (%) | ≤26 | 14.4 |

| Reference RAP | Number of Fractions | Particle Sizes for RAP Fractions (mm) |

|---|---|---|

| Reference-1 | 1 | 0~19 |

| Reference-2 | 2 | 0~4.75 and 4.75~19 |

| Reference-3 | 4 | 0~4.75, 4.75~9.5, 9.5~13.2 and 13.2~19 |

| Reference-4 | 6 | 0~2.36, 2.36~4.75, 4.75~9.5, 9.5~13.2, 13.2~16 and 16~19 |

| Sieve Size (mm) | Target (%) | Fraction 1 (%) | Fraction 2 (%) | Fraction 3 (%) | Fraction 4 (%) | Fraction 5 (%) | Fraction 6 (%) |

|---|---|---|---|---|---|---|---|

| 19 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| 16 | 95.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 47.4 |

| 13.2 | 84.0 | 100.0 | 100.0 | 100.0 | 100.0 | 43.7 | 37.7 |

| 9.5 | 70.0 | 100.0 | 100.0 | 100.0 | 29.2 | 27.2 | 30.6 |

| 4.75 | 48.0 | 100.0 | 100.0 | 25.5 | 16.9 | 23.3 | 22.0 |

| 2.36 | 34.0 | 100.0 | 22.4 | 15.3 | 13.2 | 20.2 | 15.9 |

| 1.18 | 24.5 | 71.2 | 15.9 | 13.7 | 11.3 | 16.3 | 11.8 |

| 0.6 | 17.5 | 46.5 | 13.5 | 11.6 | 9.3 | 12.8 | 8.3 |

| 0.3 | 12.5 | 21.8 | 9.3 | 7.7 | 6.0 | 7.8 | 4.4 |

| 0.15 | 9.5 | 11.4 | 6.3 | 4.9 | 3.7 | 4.8 | 2.3 |

| 0.075 | 6.0 | 7.0 | 4.8 | 3.4 | 2.5 | 3.3 | 1.3 |

| Sieve Size (mm) | Fraction 1 (%) | Fraction 2 (%) | Fraction 3 (%) | Fraction 4 (%) | Fraction 5 (%) | Fraction 6 (%) |

|---|---|---|---|---|---|---|

| 16 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | 47.6 |

| 13.2 | 16.0 | 16.0 | 16.0 | 16.0 | 40.3 | 46.3 |

| 9.5 | 30.0 | 30.0 | 30.0 | 40.8 | 42.8 | 39.4 |

| 4.75 | 52.0 | 52.0 | 22.5 | 31.1 | 24.7 | 26.0 |

| 2.36 | 66.0 | 11.6 | 18.7 | 20.8 | 13.8 | 18.1 |

| 1.18 | 46.7 | 8.6 | 10.8 | 13.2 | 8.2 | 12.7 |

| 0.6 | 29.0 | 4.0 | 5.9 | 8.2 | 4.7 | 9.2 |

| 0.3 | 9.3 | 3.2 | 4.8 | 6.5 | 4.7 | 8.1 |

| 0.15 | 1.9 | 3.2 | 4.6 | 5.8 | 4.7 | 7.2 |

| 0.075 | 1.0 | 1.2 | 2.6 | 3.5 | 2.7 | 4.7 |

| Material | dmax (%) | dmin (%) |

|---|---|---|

| Reference-2 | 52.0 | 0.3 |

| Reference-3 | 52.0 | 0.1 |

| Reference-4 | 66.0 | 1.0 |

| Quantity | Sieve Size (mm) | Fraction 1 (%) | Fraction 2 (%) | Fraction 3 (%) | Fraction 4 (%) | Fraction 5 (%) | Fraction 6 (%) |

|---|---|---|---|---|---|---|---|

| λj(1) | 16 | 82.0 | 82.0 | 82.0 | 82.0 | 82.0 | 28.1 |

| λj(2) | 13.2 | 54.9 | 54.9 | 54.9 | 54.9 | 31.7 | 28.7 |

| λj(3) | 9.5 | 38.6 | 38.6 | 38.6 | 31.4 | 30.4 | 32.2 |

| λj(4) | 4.75 | 26.3 | 26.3 | 45.9 | 37.7 | 43.5 | 42.2 |

| λj(5) | 2.36 | 21.9 | 63.3 | 50.7 | 48.0 | 58.7 | 51.6 |

| λj(6) | 1.18 | 28.5 | 70.6 | 65.0 | 59.9 | 71.6 | 60.9 |

| λj(7) | 0.6 | 39.4 | 85.8 | 78.9 | 71.7 | 83.2 | 69.0 |

| λj(8) | 0.3 | 68.6 | 89.0 | 82.9 | 76.7 | 83.1 | 71.9 |

| λj(9) | 0.15 | 95.4 | 89.4 | 83.5 | 79.1 | 83.2 | 74.7 |

| λj(10) | 0.075 | 99.7 | 99.0 | 92.1 | 88.0 | 91.5 | 83.2 |

| λj | — | 55.5 | 69.9 | 67.4 | 62.9 | 65.9 | 54.2 |

| ρj | — | 14.8 | 18.6 | 17.9 | 16.7 | 17.5 | 14.4 |

| Reference RAP | Replicate | mw (g) | md (g) | w (%) |

|---|---|---|---|---|

| 1 | 1 | 2000.0 | 1983.0 | 0.86 |

| 2 | 2000.0 | 1982.1 | 0.90 | |

| 3 | 2000.0 | 1981.6 | 0.93 | |

| 4 | 2000.0 | 1978.3 | 1.10 | |

| 5 | 2000.0 | 1976.5 | 1.19 | |

| 2 | 1 | 2000.0 | 1985.5 | 0.73 |

| 2 | 2000.9 | 1987.3 | 0.68 | |

| 3 | 2001.3 | 1986.9 | 0.72 | |

| 4 | 2001.2 | 1988.3 | 0.65 | |

| 5 | 2001.2 | 1989.3 | 0.60 | |

| 3 | 1 | 2001.7 | 1996.1 | 0.28 |

| 2 | 2000.8 | 1995.0 | 0.29 | |

| 3 | 2000.7 | 1995.6 | 0.26 | |

| 4 | 2000.9 | 1995.6 | 0.27 | |

| 5 | 2000.0 | 1995.1 | 0.25 | |

| 4 | 1 | 2001.2 | 1996.1 | 0.26 |

| 2 | 2003.0 | 1997.6 | 0.27 | |

| 3 | 2003.2 | 1998.0 | 0.26 | |

| 4 | 2004.1 | 1998.2 | 0.30 | |

| 5 | 2001.5 | 1996.1 | 0.27 |

| Material | S (%) | (%) | COV (%) | Ra (%) |

|---|---|---|---|---|

| Reference-1 | 0.47 | 4.47 | 10.46 | 1.07 |

| Reference-2 | 0.16 | 4.58 | 3.49 | 0.44 |

| Reference-3 | 0.09 | 4.09 | 2.10 | 0.21 |

| Reference-4 | 0.07 | 4.00 | 1.83 | 0.18 |

| Reference RAP | Replicate | m1 (g) | m1–m2 (g) | Pb (%) |

|---|---|---|---|---|

| 1 | 1 | 1905.9 | 76.4 | 3.85 |

| 2 | 1887.2 | 88.5 | 4.48 | |

| 3 | 1899.7 | 74.2 | 3.76 | |

| 4 | 1879.7 | 94.3 | 4.78 | |

| 5 | 1881.6 | 88.0 | 4.47 | |

| 2 | 1 | 1887.0 | 87.5 | 4.43 |

| 2 | 1892.5 | 87.3 | 4.41 | |

| 3 | 1892.0 | 85.7 | 4.33 | |

| 4 | 1899.5 | 82.7 | 4.17 | |

| 5 | 1893.0 | 90.7 | 4.57 | |

| 3 | 1 | 1914.4 | 78 | 3.91 |

| 2 | 1914.5 | 79.7 | 4.00 | |

| 3 | 1909.7 | 79 | 3.97 | |

| 4 | 1907.2 | 78.8 | 3.97 | |

| 5 | 1919.6 | 75.8 | 3.80 | |

| 4 | 1 | 1919.7 | 75 | 3.76 |

| 2 | 1916.3 | 78.1 | 3.92 | |

| 3 | 1918.8 | 76 | 3.81 | |

| 4 | 1918.1 | 77.5 | 3.88 | |

| 5 | 1916.1 | 77.1 | 3.87 |

| Material | S (%) | COV (%) | Ra (%) | |

|---|---|---|---|---|

| Reference-1 | 0.44 | 4.27 | 10.31 | 1.02 |

| Reference-2 | 0.15 | 4.38 | 3.34 | 0.40 |

| Reference-3 | 0.08 | 3.93 | 2.02 | 0.20 |

| Reference-4 | 0.06 | 3.85 | 1.62 | 0.16 |

| Reference RAP | Replicate | Percentage Retained (%) at Sieve Size (mm) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | <0.075 | ||

| 1 | 1 | 1.8 | 4.5 | 21.9 | 35.1 | 17.0 | 6.9 | 5.0 | 4.2 | 1.9 | 0.6 | 1.1 |

| 2 | 1.6 | 5.3 | 17.3 | 30.5 | 20.4 | 8.8 | 6.7 | 5.8 | 2.5 | 0.7 | 0.5 | |

| 3 | 1.8 | 7.5 | 17.1 | 21.8 | 24.6 | 10.9 | 6.5 | 5.7 | 2.6 | 0.9 | 0.4 | |

| 4 | 0.3 | 4.0 | 13.7 | 28.7 | 19.0 | 10.2 | 9.1 | 8.9 | 4.1 | 1.3 | 0.7 | |

| 5 | 1.6 | 5.8 | 13.0 | 31.1 | 19.0 | 9.4 | 7.9 | 7.5 | 3.1 | 1.0 | 0.6 | |

| 2 | 1 | 2.6 | 2.5 | 12.7 | 30.3 | 24.6 | 10.3 | 7.2 | 5.8 | 2.4 | 0.9 | 0.8 |

| 2 | 2.0 | 5.1 | 14.4 | 26.6 | 23.3 | 10.8 | 7.2 | 6.1 | 2.6 | 0.9 | 0.9 | |

| 3 | 2.2 | 3.9 | 15.1 | 27.1 | 26.4 | 9.4 | 6.6 | 5.1 | 2.3 | 0.9 | 0.9 | |

| 4 | 2.6 | 3.9 | 11.5 | 30.2 | 29.0 | 9.2 | 6.0 | 4.4 | 1.8 | 0.7 | 0.7 | |

| 5 | 1.0 | 5.3 | 17.7 | 24.1 | 22.6 | 10.2 | 7.1 | 6.2 | 3.2 | 1.2 | 1.3 | |

| 3 | 1 | 8.1 | 12.1 | 20.9 | 28.7 | 13.3 | 5.1 | 4.1 | 4.7 | 1.9 | 0.6 | 0.4 |

| 2 | 5.9 | 16.5 | 20.3 | 28.3 | 12.6 | 4.5 | 3.5 | 5.0 | 1.8 | 0.8 | 0.8 | |

| 3 | 7.3 | 13.6 | 20.9 | 28.2 | 14.2 | 4.8 | 3.9 | 4.3 | 1.8 | 0.6 | 0.5 | |

| 4 | 8.0 | 13.3 | 20.6 | 28.1 | 14.5 | 5.1 | 3.7 | 4.1 | 1.6 | 0.5 | 0.4 | |

| 5 | 7.1 | 14.6 | 20.8 | 27.6 | 14.7 | 4.4 | 3.6 | 4.1 | 1.9 | 0.6 | 0.6 | |

| 4 | 1 | 14.5 | 17.5 | 17.4 | 17.9 | 18.7 | 4.7 | 3.9 | 3.2 | 1.3 | 0.5 | 0.5 |

| 2 | 14.4 | 17.8 | 16.9 | 17.8 | 18.5 | 4.4 | 3.8 | 3.5 | 1.4 | 0.6 | 0.8 | |

| 3 | 14.6 | 17.8 | 17.0 | 18.1 | 18.6 | 5.1 | 3.7 | 2.9 | 1.1 | 0.4 | 0.5 | |

| 4 | 14.4 | 17.5 | 16.8 | 18.0 | 18.9 | 4.9 | 3.9 | 3.2 | 1.2 | 0.5 | 0.6 | |

| 5 | 14.4 | 17.9 | 16.8 | 18.0 | 18.4 | 4.8 | 3.7 | 3.1 | 1.5 | 0.6 | 0.8 | |

| Reference Material | Replicate | Percentage Retained (%) at Sieve Size (mm) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | <0.075 | ||

| 1 | 1 | 1.1 | 2.6 | 16.1 | 31.9 | 16.3 | 6.8 | 6.2 | 7.4 | 4.6 | 2.4 | 4.6 |

| 2 | 1.1 | 3.3 | 13.2 | 26.8 | 18.6 | 7.7 | 7.3 | 8.9 | 5.3 | 2.8 | 4.8 | |

| 3 | 0.4 | 5.6 | 12.7 | 27.0 | 17.9 | 7.8 | 7.1 | 8.8 | 5.1 | 3.3 | 4.3 | |

| 4 | 0.3 | 2.3 | 10.3 | 24.7 | 17.7 | 9.2 | 9.6 | 11.5 | 6.6 | 2.8 | 5.0 | |

| 5 | 1.4 | 3.5 | 9.8 | 26.8 | 18.1 | 8.7 | 8.5 | 10.1 | 5.8 | 3.2 | 4.2 | |

| 2 | 1 | 1.6 | 2.2 | 9.1 | 25.8 | 21.6 | 9.2 | 8.1 | 8.8 | 5.0 | 3.8 | 4.6 |

| 2 | 0.8 | 3.4 | 11.2 | 23.3 | 20.8 | 9.7 | 7.6 | 9.2 | 5.3 | 4.2 | 4.4 | |

| 3 | 1.8 | 2.8 | 10.9 | 23.5 | 23.2 | 8.8 | 7.4 | 8.1 | 5.0 | 4.2 | 4.2 | |

| 4 | 2.1 | 2.0 | 8.2 | 25.9 | 25.6 | 8.9 | 7.1 | 7.7 | 4.4 | 3.9 | 4.3 | |

| 5 | 0.9 | 2.8 | 12.3 | 22.5 | 20.1 | 9.1 | 7.7 | 9.5 | 5.9 | 4.3 | 4.9 | |

| 3 | 1 | 3.2 | 7.1 | 17.1 | 26.7% | 14.6 | 6.0 | 5.6 | 8.1 | 4.8 | 3.4 | 3.3 |

| 2 | 3.8 | 7.6 | 17.6 | 25.7 | 13.9 | 5.5 | 4.9 | 8.3 | 5.4 | 3.8 | 3.6 | |

| 3 | 2.7 | 7.1 | 15.9 | 27.1 | 15.0 | 6.1 | 6.2 | 8.0 | 4.8 | 3.7 | 3.4 | |

| 4 | 2.3 | 7.5 | 18.1 | 25.8 | 15.3 | 6.4 | 5.4 | 7.6 | 4.6 | 3.5 | 3.4 | |

| 5 | 4.6 | 8.6 | 15.8 | 26.6 | 15.0 | 5.4 | 5.0 | 7.6 | 4.6 | 4.0 | 2.9 | |

| 4 | 1 | 6.9 | 11.0 | 16.2 | 18.8 | 17.9 | 6.2 | 5.2 | 6.6 | 4.0 | 3.8 | 3.4 |

| 2 | 5.8 | 13.0 | 15.5 | 18.5 | 17.9 | 5.8 | 5.2 | 6.9 | 4.2 | 4.0 | 3.3 | |

| 3 | 6.6 | 10.8 | 15.6 | 19.6 | 18.1 | 6.4 | 5.5 | 6.6 | 4.1 | 4.6 | 2.1 | |

| 4 | 6.2 | 10.6 | 16.5 | 18.9 | 18.1 | 6.1 | 5.7 | 6.9 | 4.3 | 4.1 | 2.6 | |

| 5 | 5.6 | 12.1 | 15.8 | 19.3 | 17.7 | 5.7 | 5.4 | 6.8 | 4.3 | 4.3 | 3.0 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, J.; Sun, Y. Evaluation and Control of Variability in RAP Properties Through Refined Fractionation Processing Methods. Materials 2025, 18, 4944. https://doi.org/10.3390/ma18214944

Zhang Y, Li J, Sun Y. Evaluation and Control of Variability in RAP Properties Through Refined Fractionation Processing Methods. Materials. 2025; 18(21):4944. https://doi.org/10.3390/ma18214944

Chicago/Turabian StyleZhang, Yan, Jiyang Li, and Yiren Sun. 2025. "Evaluation and Control of Variability in RAP Properties Through Refined Fractionation Processing Methods" Materials 18, no. 21: 4944. https://doi.org/10.3390/ma18214944

APA StyleZhang, Y., Li, J., & Sun, Y. (2025). Evaluation and Control of Variability in RAP Properties Through Refined Fractionation Processing Methods. Materials, 18(21), 4944. https://doi.org/10.3390/ma18214944