High Energy Storage Performance in Bi0.46Sr0.06Na0.5TiO3/CaTiO3 Relaxor Ferroelectric Ceramics

Abstract

1. Introduction

2. Materials and Methods

Preparation of BSNT-xCT Samples

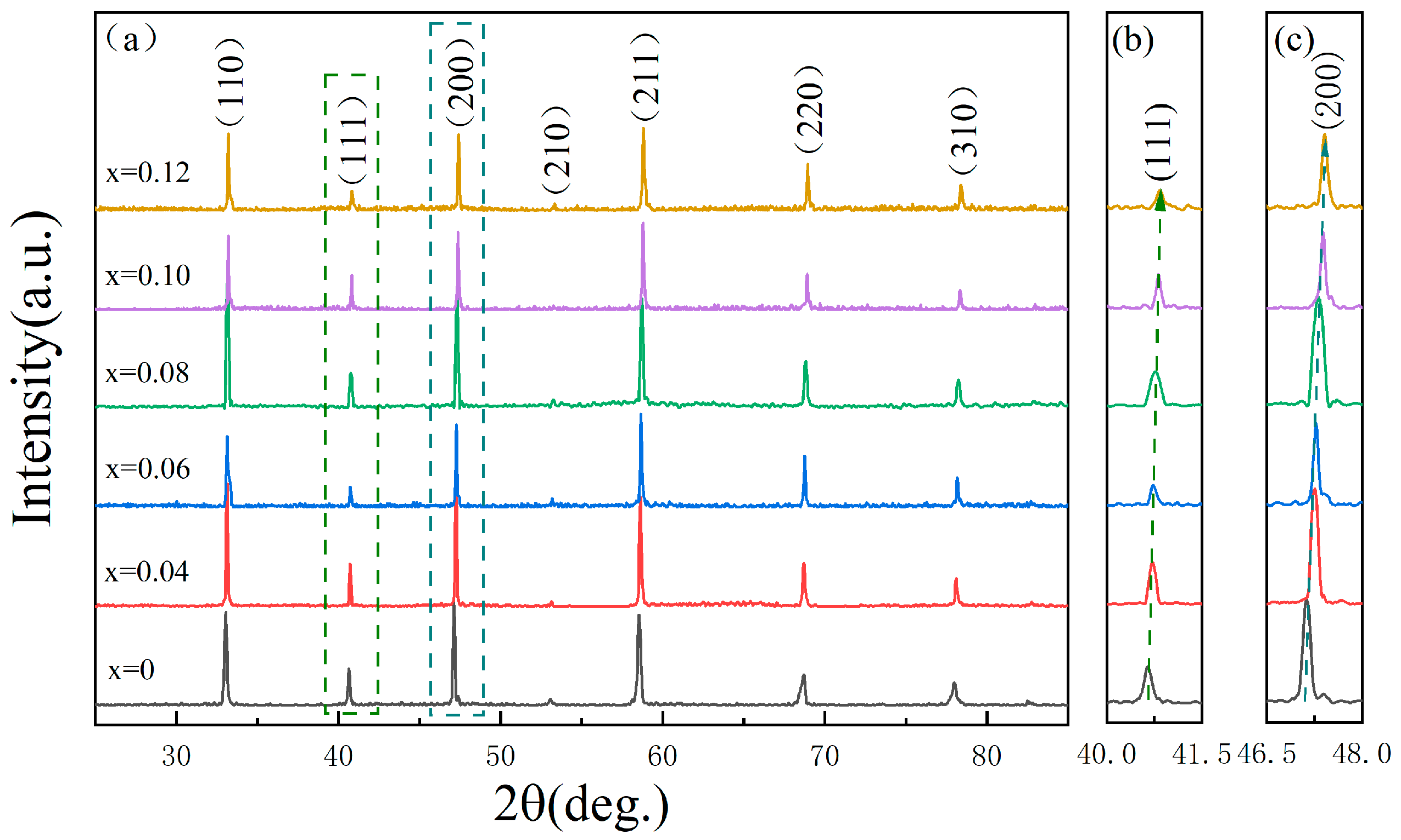

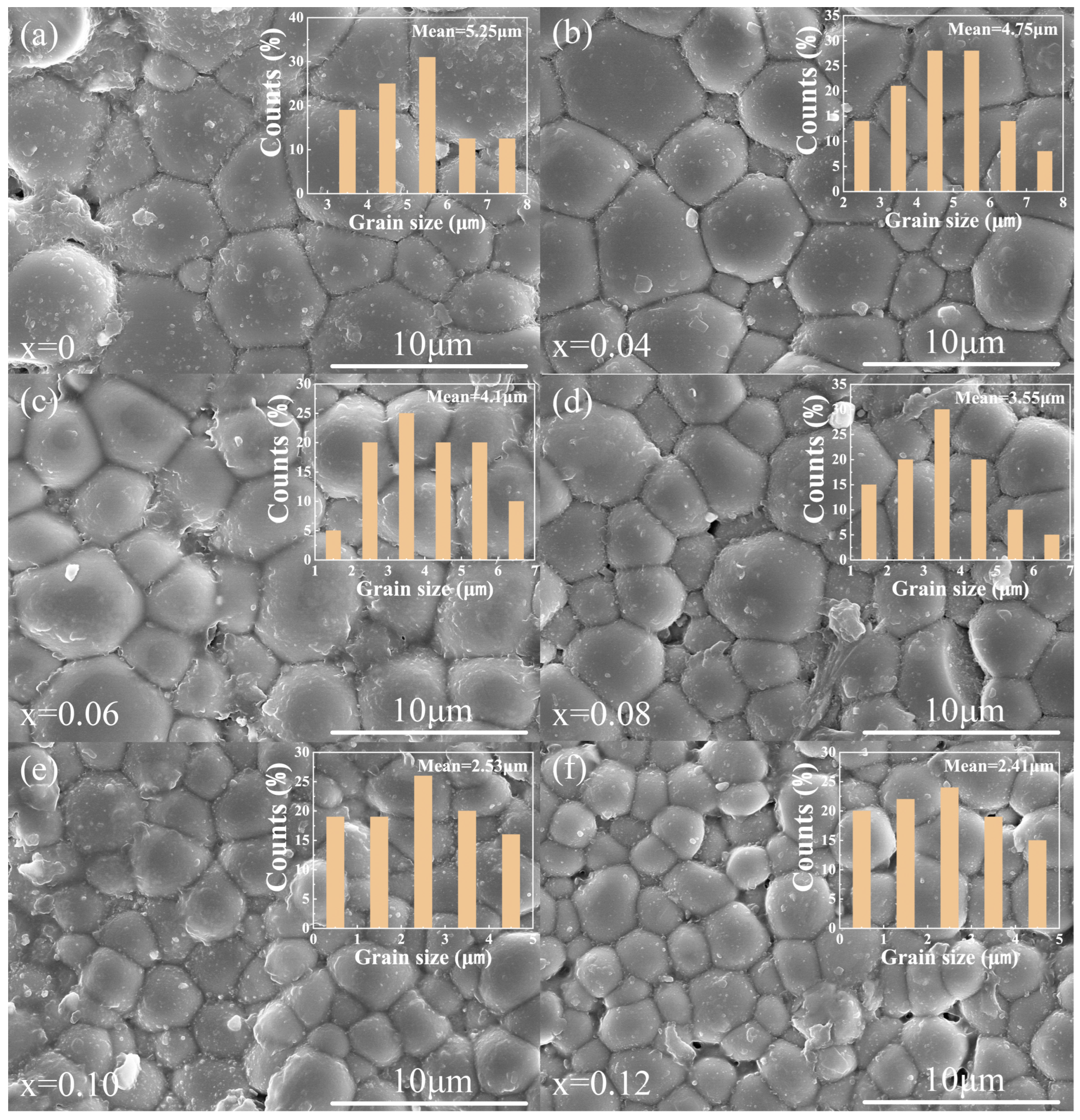

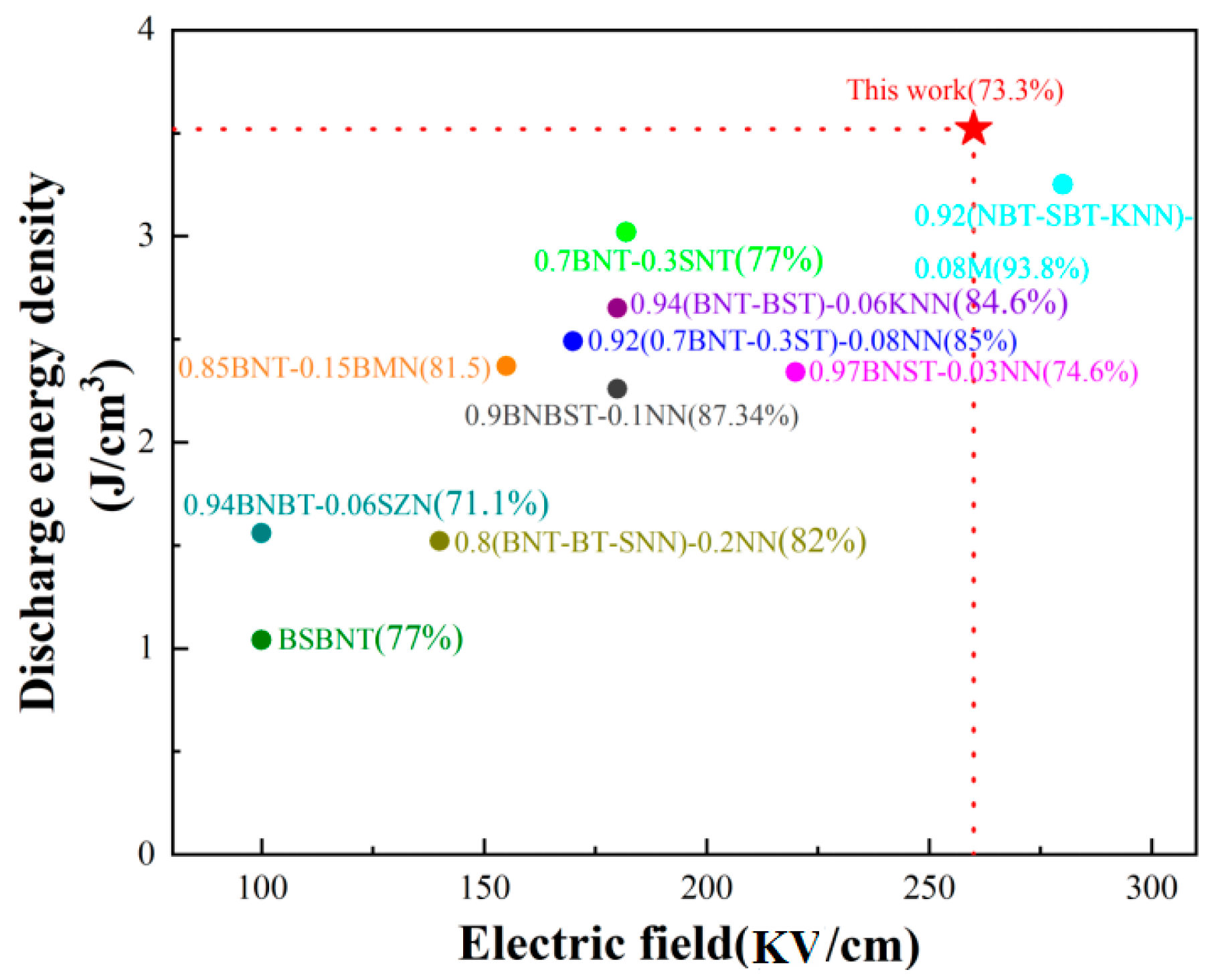

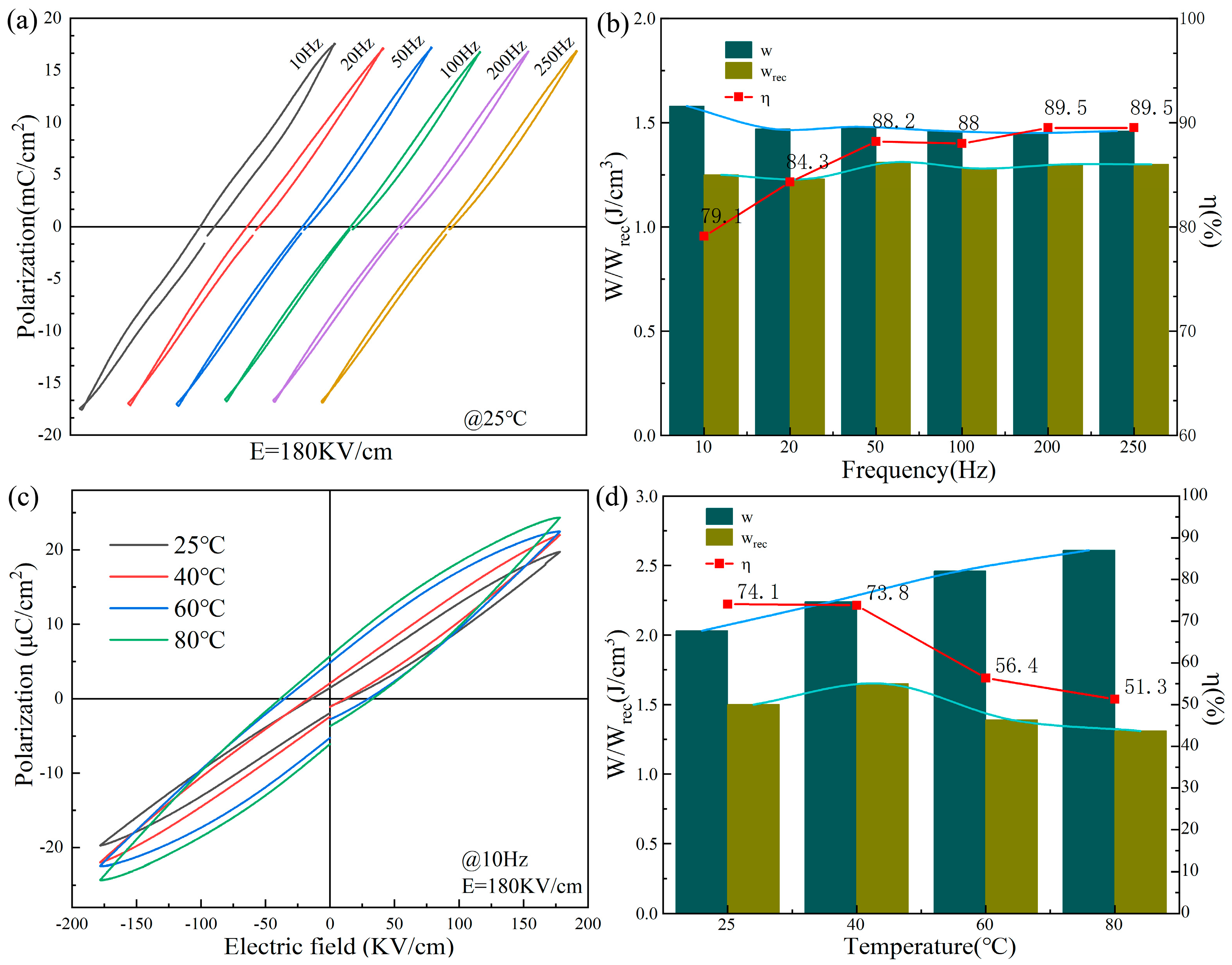

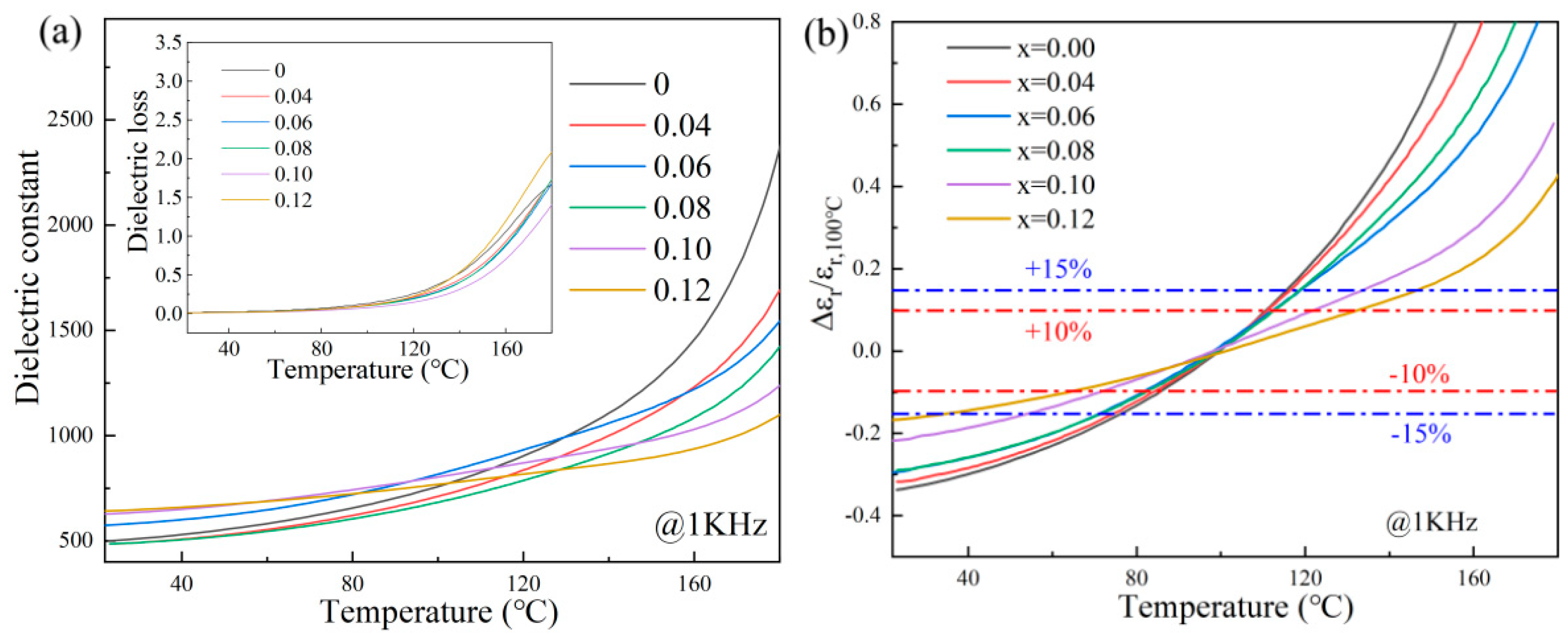

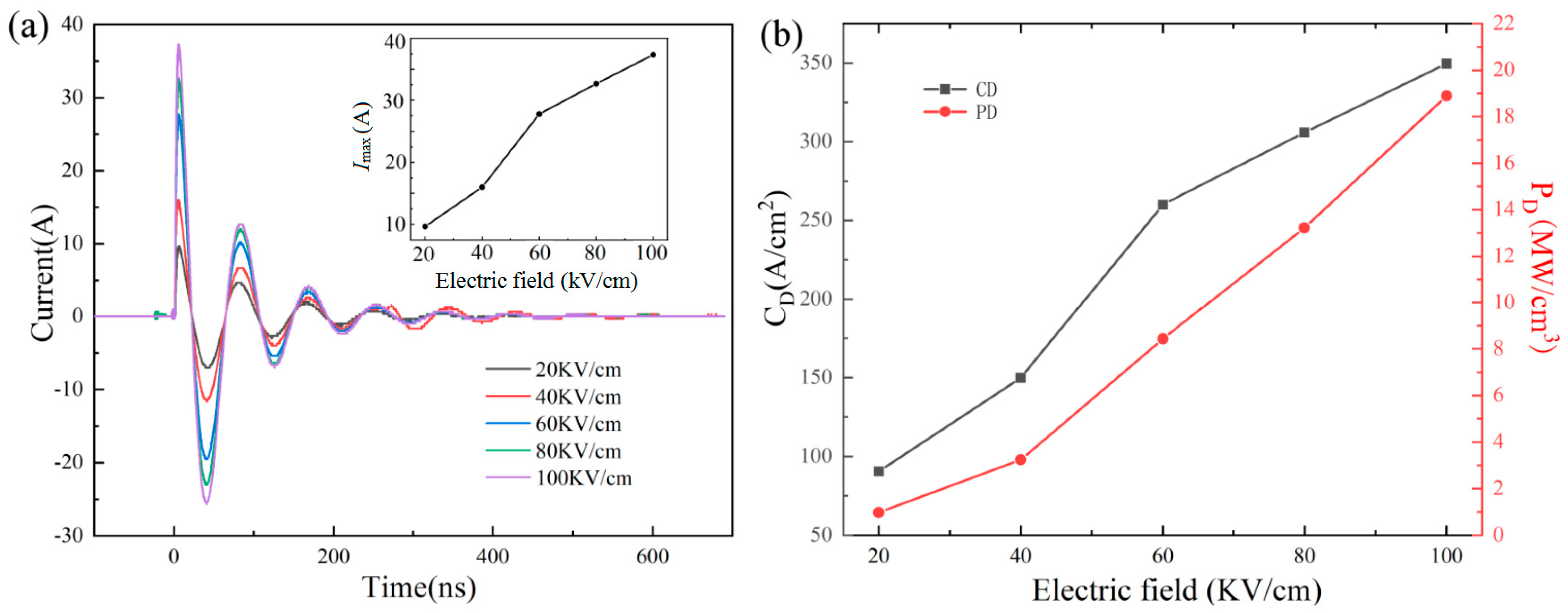

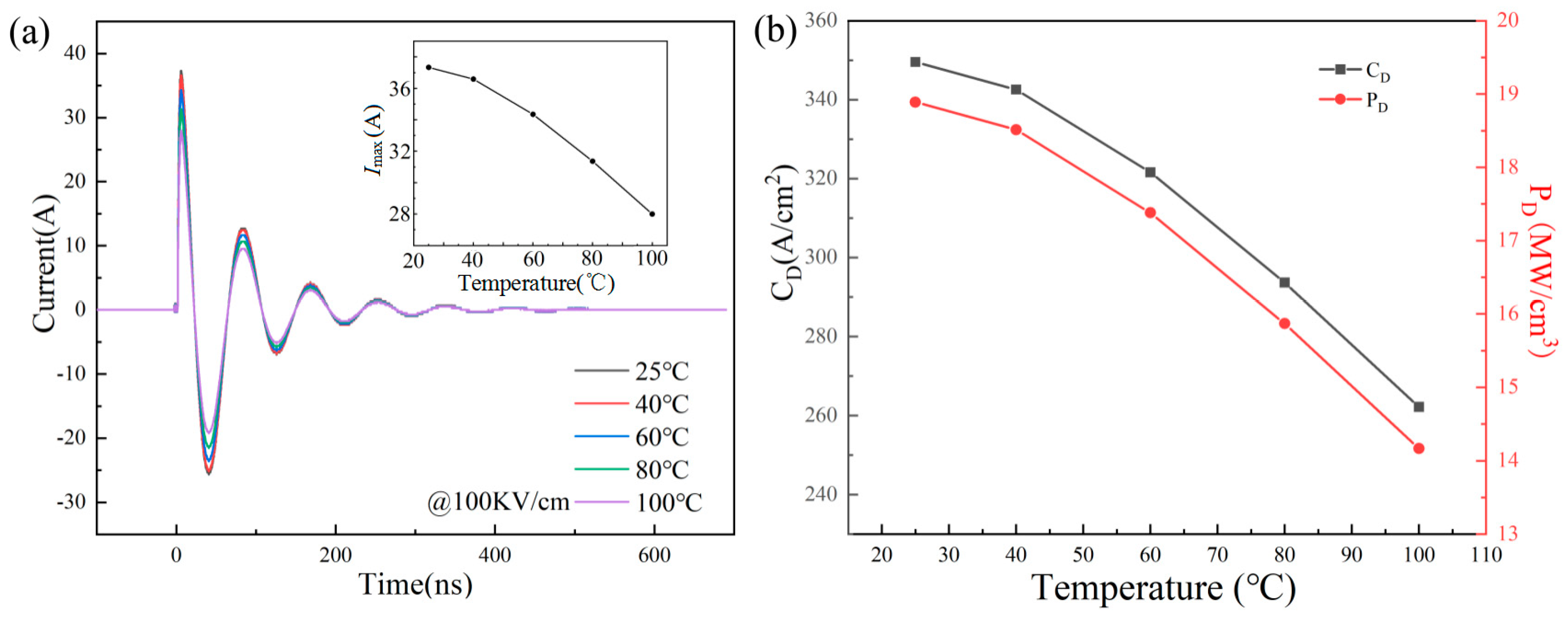

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oh, H.; Kim, H.; Park, Y.; Ko, J.; Lee, H. Influence of starting Y2O3 and Nd2O3 powders characteristics on optical properties of highly transparent Nd: Y2O3 ceramics. J. Opt. Mater. 2021, 121, 111562. [Google Scholar] [CrossRef]

- Wang, Z.; Kang, R.; Liu, W.; Zhang, L.; He, L.; Zhao, S.; Duan, H.; Yu, Z.; Kang, F.; Sun, Q. (Bi0.5Na0.5)TiO3-based relaxor ferroelectrics with medium permittivity featuring enhanced energy-storage density and excellent thermal stability. J. Chem. Eng. 2022, 427, 131989. [Google Scholar] [CrossRef]

- Hou, L.; Zhou, C.; Li, Q.; Li, R.; Yuan, C.; Xu, J.; Rao, G. Giant strain with ultra-low hysteresis by tailoring relaxor temperature and PNRs dynamic in BNT-based lead-free piezoelectric ceramics. J. Ceram. Int. 2022, 48, 13125–13133. [Google Scholar] [CrossRef]

- Vignaswaran, V.; Federica, B.; Theresa, G.; Marco, D. Strategies to improve the energy storage properties of perovskite lead-free relaxor ferroelectrics: A review. Materials 2020, 13, 5742. [Google Scholar] [CrossRef] [PubMed]

- Streich, F.; Martin, A.; Webber, K.; Kamlah, M. Structures, Macroscopic constitutive model for ergodic and non-ergodic lead-free relaxors. J. Intell. Mater. Syst. Struc. 2022, 33, 1002–1017. [Google Scholar] [CrossRef]

- Muhammad, R.; Khalil, M.; Castro, M. Structure and dielectric characteristics of Ba1−xCaxTi1−xO3−δ ceramics. J. Ceram. Int. 2020, 46, 1059–1064. [Google Scholar] [CrossRef]

- Nayak, S.; Venkateshwarlu, S.; Budisuharto, A.; Jørgensen, M.; Borkiewicz, O.; Beyer, K.; Pramanick, A. Effect of A-site substitutions on energy storage properties of BaTiO3-BiScO3 weakly coupled relaxor ferroelectrics. J. Am. Ceram. Soc. 2019, 102, 5919–5933. [Google Scholar] [CrossRef]

- Dai, Z.; Li, D.; Zhou, Z.; Zhou, S.; Liu, W.; Liu, J.; Wang, X.; Ren, X. A strategy for high performance of energy storage and transparency in KNN-based ferroelectric ceramics. J. Chem. Eng. 2022, 427, 131959. [Google Scholar] [CrossRef]

- Anjali, K.; Ajithkumar, T.; Joy, P. Correlation between the structure and dielectric constant of Bi0.5(Na1−xLix)0.5TiO3 (0 ≤ x ≤ 0.20) solid solutions. Int. J. Ceram. Eng. Sci. 2021, 3, 49–56. [Google Scholar] [CrossRef]

- Zhao, X.; Soh, A. The grain boundary effect on electromechanical property of ferroelectric ceramics. J. Scr. Mater. 2020, 178, 313–317. [Google Scholar] [CrossRef]

- Luo, L.; Du, P.; Li, W.; Tao, W.; Chen, H. Effects of er doping site and concentration on piezoelectric, ferroelectric, and optical properties of ferroelectric Bi0.5Na0.5TiO3. J. Appl. Phys. 2013, 114, 124104. [Google Scholar] [CrossRef]

- Wu, K.; Wang, H.; Miao, Z.; Ding, S.; Lin, D. Improved energy storage properties of Sr(Zr0.8Nb0.16)O3-doped Bi0.47Na0.47Ba0.06TiO3 ceramics with excellent temperature/frequency stability. J. Ceram. Int. 2020, 9, 13159–13169. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, N.; Shi, Y.; Chen, Y.; Peng, Y.; Hu, J.; Gao, Q.; Li, Z. Energy storage properties and stability in Nd3+/Ta5+ modified 0.6Na0.5Bi0.5TiO3-0.4Sr0.7Bi0.2TiO3 lead-free relaxor ferroelectric ceramics under a low electric field. J. Ceram. Int. 2024, 50, 13053–13060. [Google Scholar] [CrossRef]

- Chen, J.; Qi, H.; Zuo, R. Realizing Stable Relaxor Antiferroelectric and Superior Energy Storage Properties in (Na1−x/2Lax/2)(Nb1−xTix)O3 Lead-Free Ceramics through A/B-Site Complex Substitution. J. ACS Appl. Mater. Interfaces 2020, 12, 32871–32879. [Google Scholar] [CrossRef] [PubMed]

- Pan, Z.; Hu, D.; Zhang, Y.; Liu, J.; Shen, B.; Zhai, J. Achieving high discharge energy density and efficiency with NBT-based ceramics for application in capacitors. J. Mater. Chem. C 2019, 7, 4072–4078. [Google Scholar] [CrossRef]

- Jones, G.; Kreisel, J.; Jennings, V.; Geday, M.; Thomas, P.; Glazer, A. Investigation of a peculiar relaxor ferroelectric: Na0.5Bi0.5TiO3. J. Ferroelectr. 2002, 270, 191–196. [Google Scholar] [CrossRef]

- Xu, Q.; Li, T.; Hao, H.; Zhang, S.; Wang, Z.; Cao, M.; Yao, Z.; Liu, H. Enhanced energy storage properties of NaNbO3 modified Bi0.5Na0.5TiO3 based ceramics. J. Eur. Ceram. Soc. 2015, 35, 545–553. [Google Scholar] [CrossRef]

- Yuan, X.; Zhang, Y.; Gong, L.; Li, B.; Zhang, L. High energy storage performance of Na(Nb0.95Ta0.05)O3/Na0.5Bi0.5TiO3 lead-free ferroelectric ceramics. J. Ceram. Int. 2022, 48, 13244–13249. [Google Scholar] [CrossRef]

- Furuse, H.; Horiuchi, N.; Kim, B. Transparent non-cubic laser ceramics with fine microstructure. J. Sci. Rep. 2019, 9, 10300. [Google Scholar] [CrossRef] [PubMed]

- Pattipaka, S.; Dobbidi, P.; Goud, J.; James, K.; Pradhan, G.; Sridhar, V. Investigation of surface scaling, optical and microwave dielectric studies of Bi0.5Na0.5TiO3 thin films. J. Mater. Sci. Mater. Electron. 2022, 11, 33. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Guo, H.; Zhai, S.; Yue, L.; Zhang, J.; He, S.; Fu, R.; Yin, C.; Zhang, L. High Energy Storage Performance in Bi0.46Sr0.06Na0.5TiO3/CaTiO3 Relaxor Ferroelectric Ceramics. Materials 2025, 18, 4932. https://doi.org/10.3390/ma18214932

Zhang Y, Guo H, Zhai S, Yue L, Zhang J, He S, Fu R, Yin C, Zhang L. High Energy Storage Performance in Bi0.46Sr0.06Na0.5TiO3/CaTiO3 Relaxor Ferroelectric Ceramics. Materials. 2025; 18(21):4932. https://doi.org/10.3390/ma18214932

Chicago/Turabian StyleZhang, Yangyang, Haizhou Guo, Shuyao Zhai, Liqin Yue, Juqin Zhang, Suxia He, Ruiling Fu, Chiyu Yin, and Ling Zhang. 2025. "High Energy Storage Performance in Bi0.46Sr0.06Na0.5TiO3/CaTiO3 Relaxor Ferroelectric Ceramics" Materials 18, no. 21: 4932. https://doi.org/10.3390/ma18214932

APA StyleZhang, Y., Guo, H., Zhai, S., Yue, L., Zhang, J., He, S., Fu, R., Yin, C., & Zhang, L. (2025). High Energy Storage Performance in Bi0.46Sr0.06Na0.5TiO3/CaTiO3 Relaxor Ferroelectric Ceramics. Materials, 18(21), 4932. https://doi.org/10.3390/ma18214932