Study on Seismic Behavior of Earthquake-Damaged Joints Retrofitted with CFRP in Hybrid Reinforced Concrete–Steel Frames

Abstract

1. Introduction

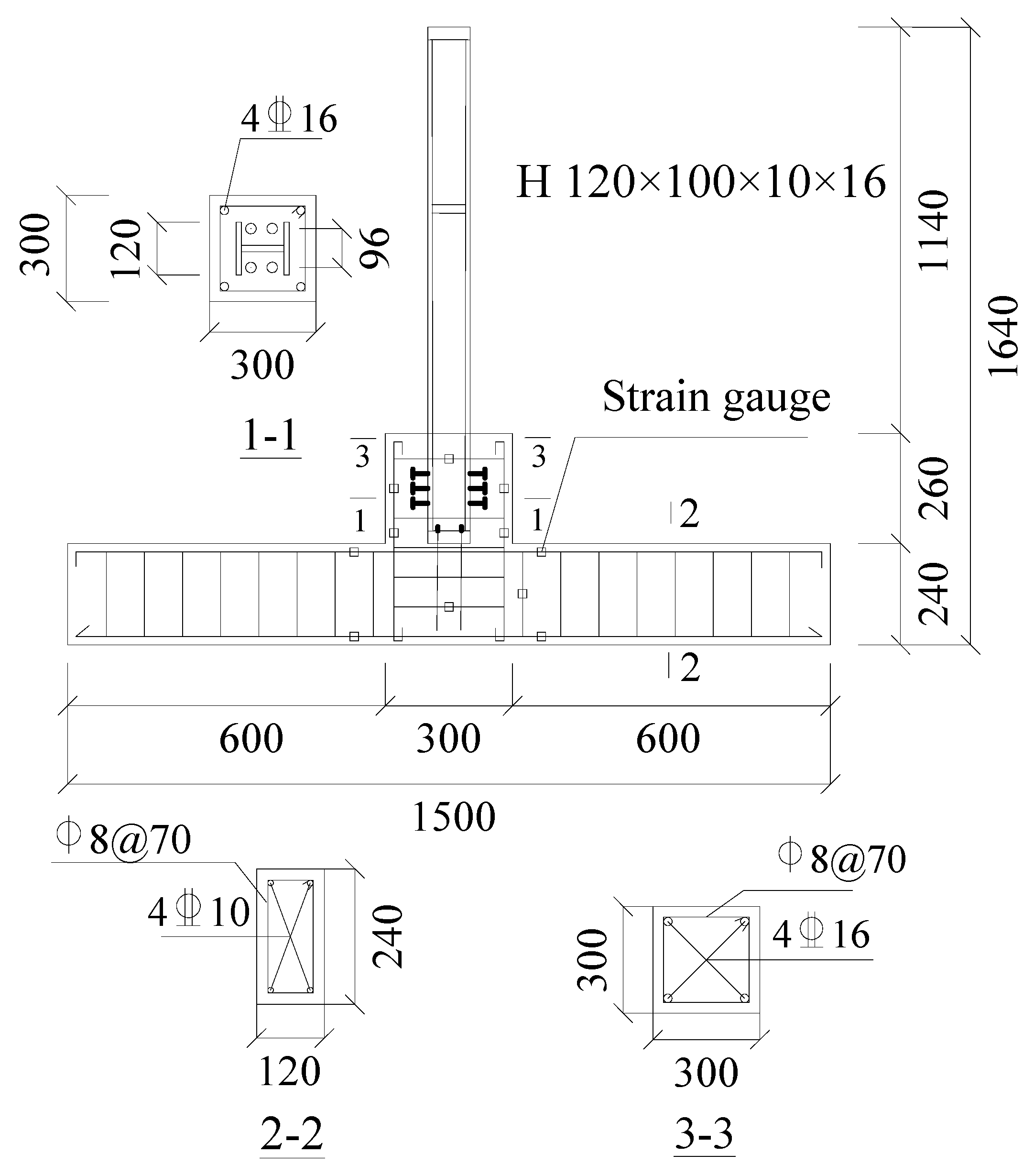

2. Specimen Preparation and Test Methods

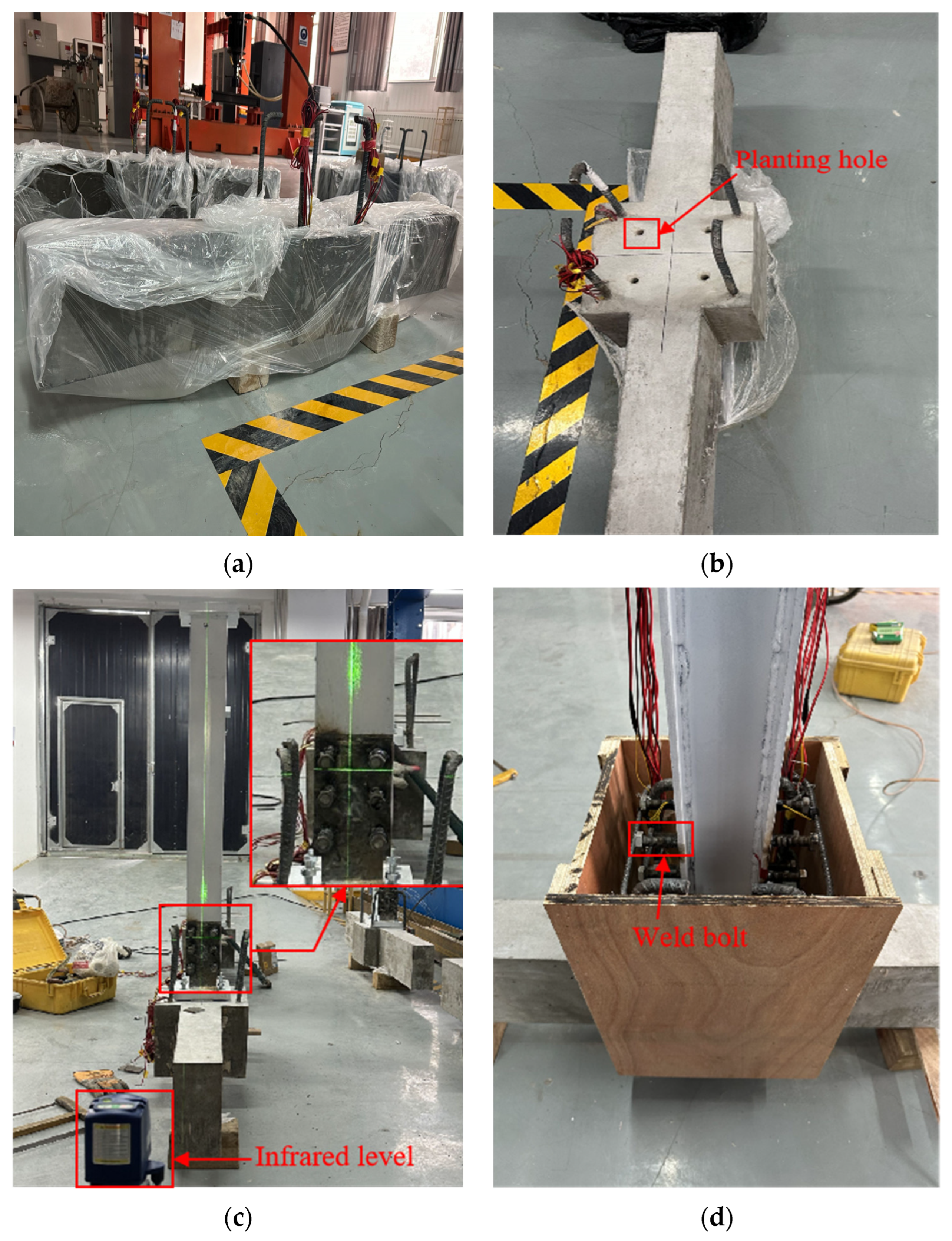

2.1. Specimen Preparation

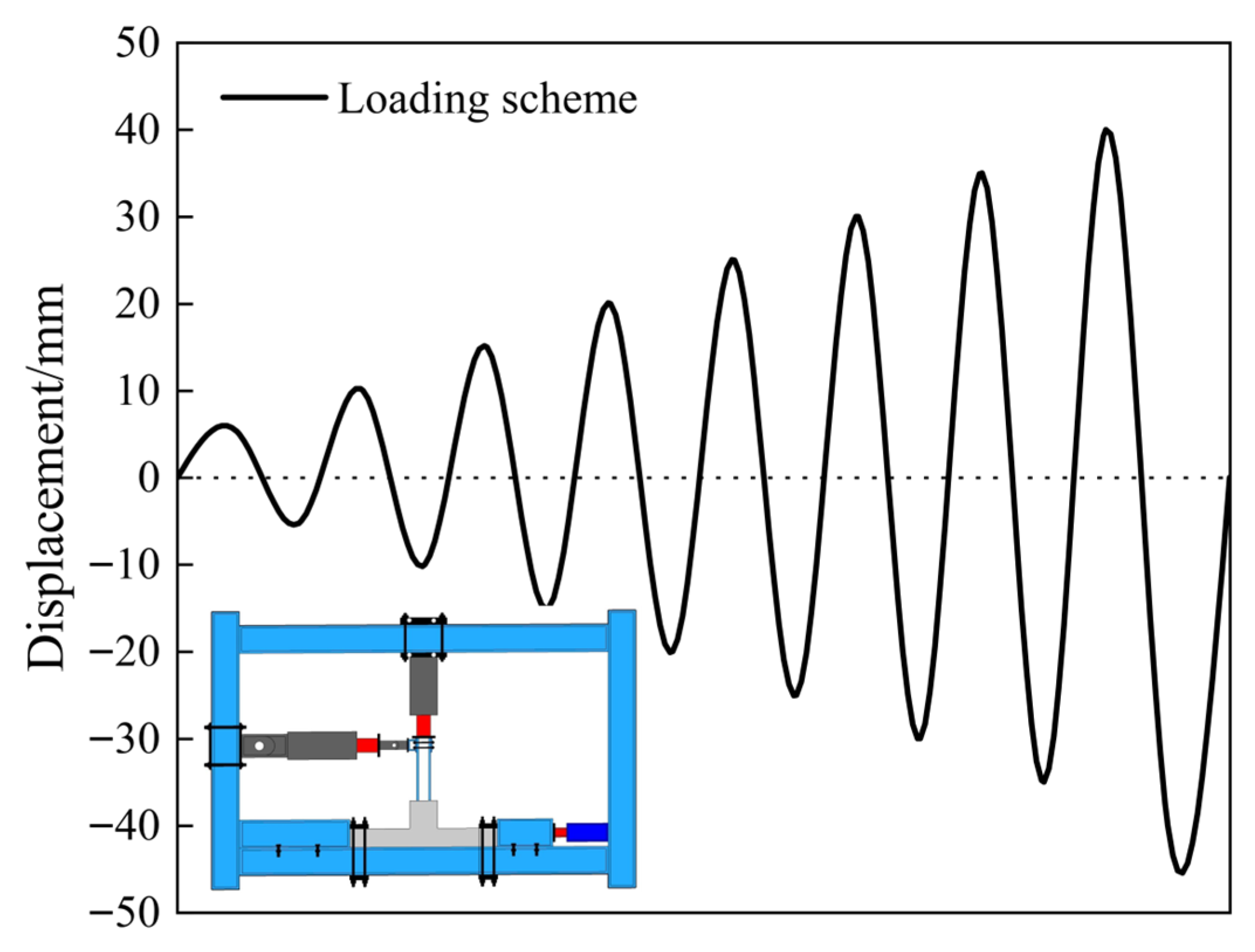

2.2. Test Methods

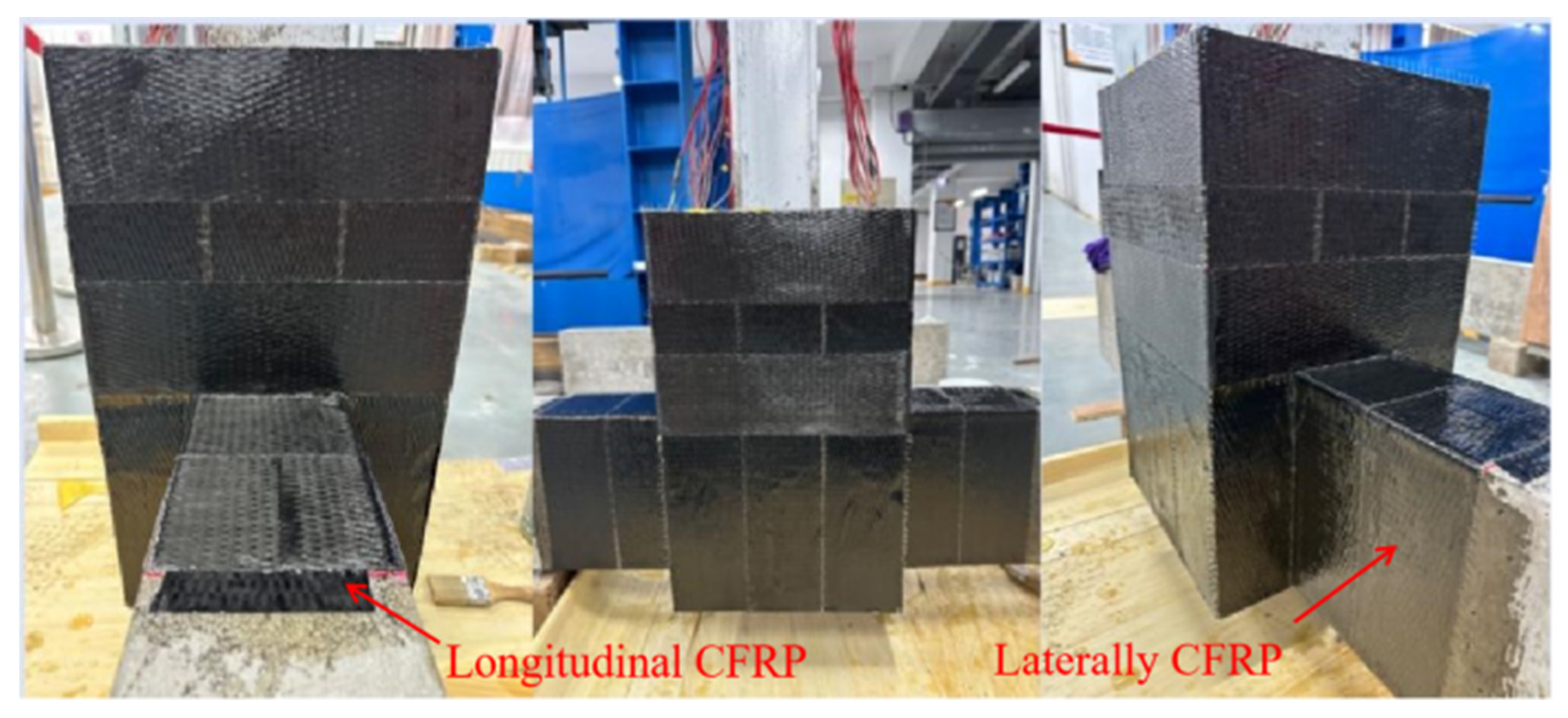

2.3. Reinforcement and Repair

3. Test Results and Evaluation

3.1. Test Observation

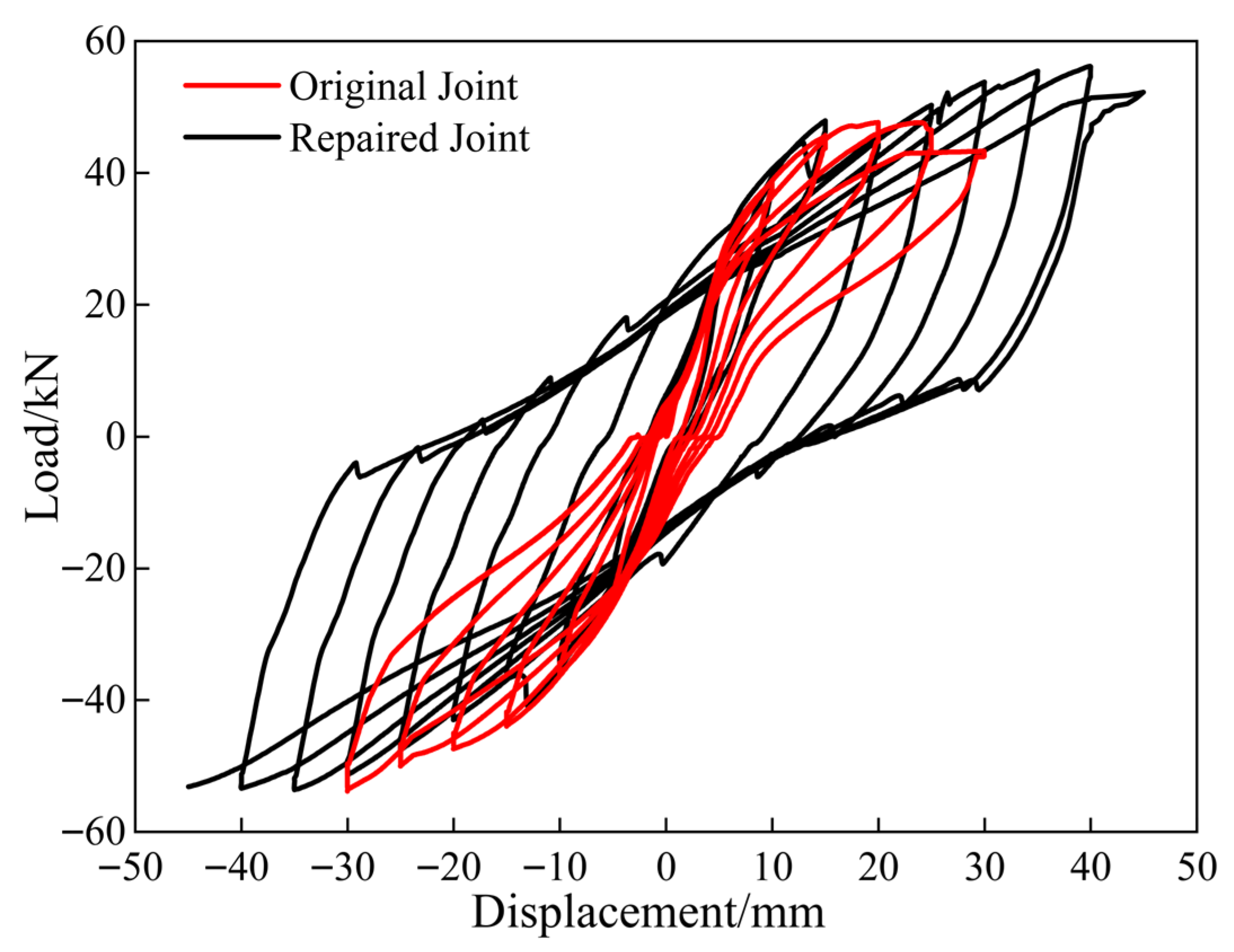

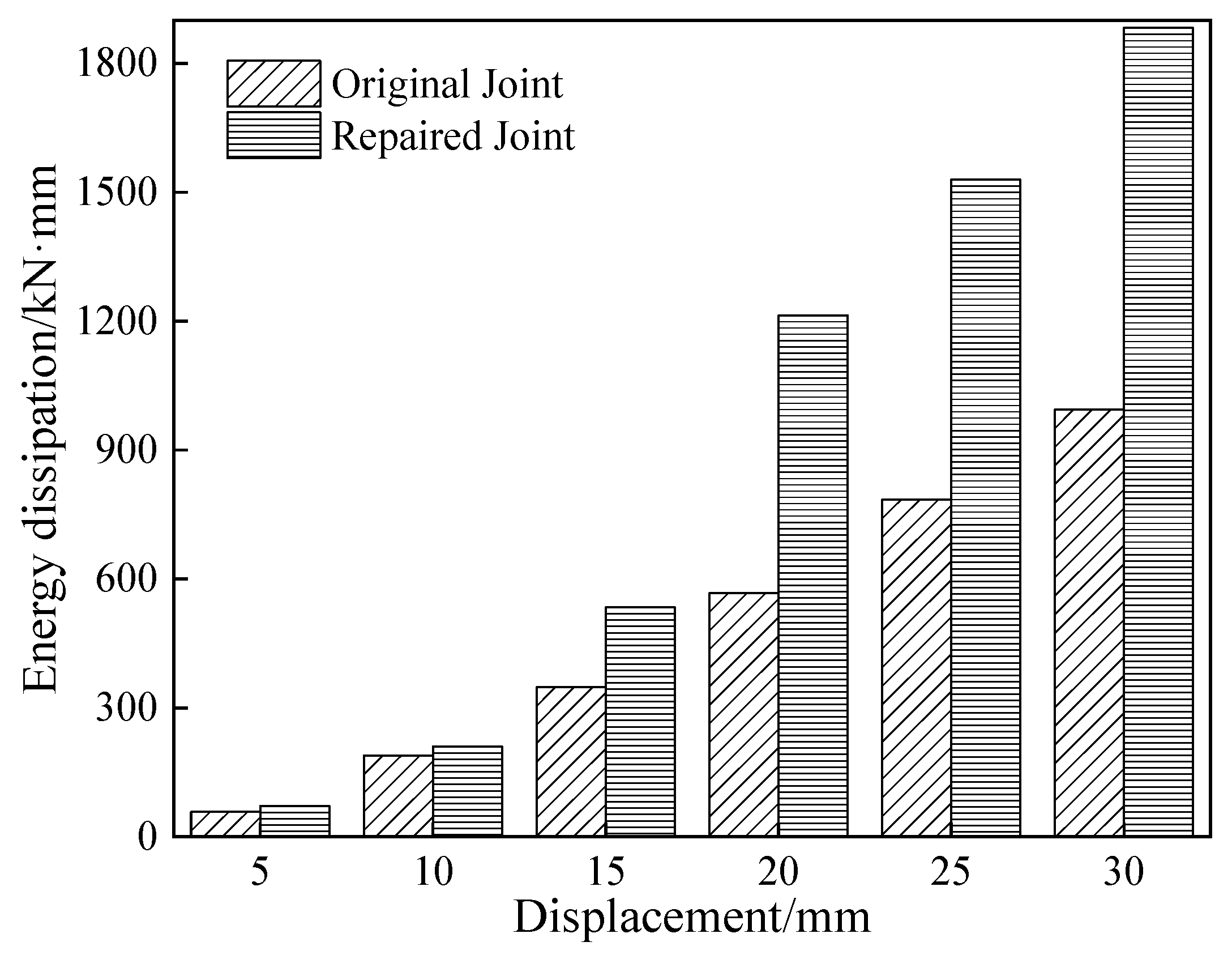

3.2. Hysteresis Curve

3.3. Skeleton Curve

3.4. Stiffness Degradation Curve

4. Detection and Analysis Based on Digital Image Correlation Techniques

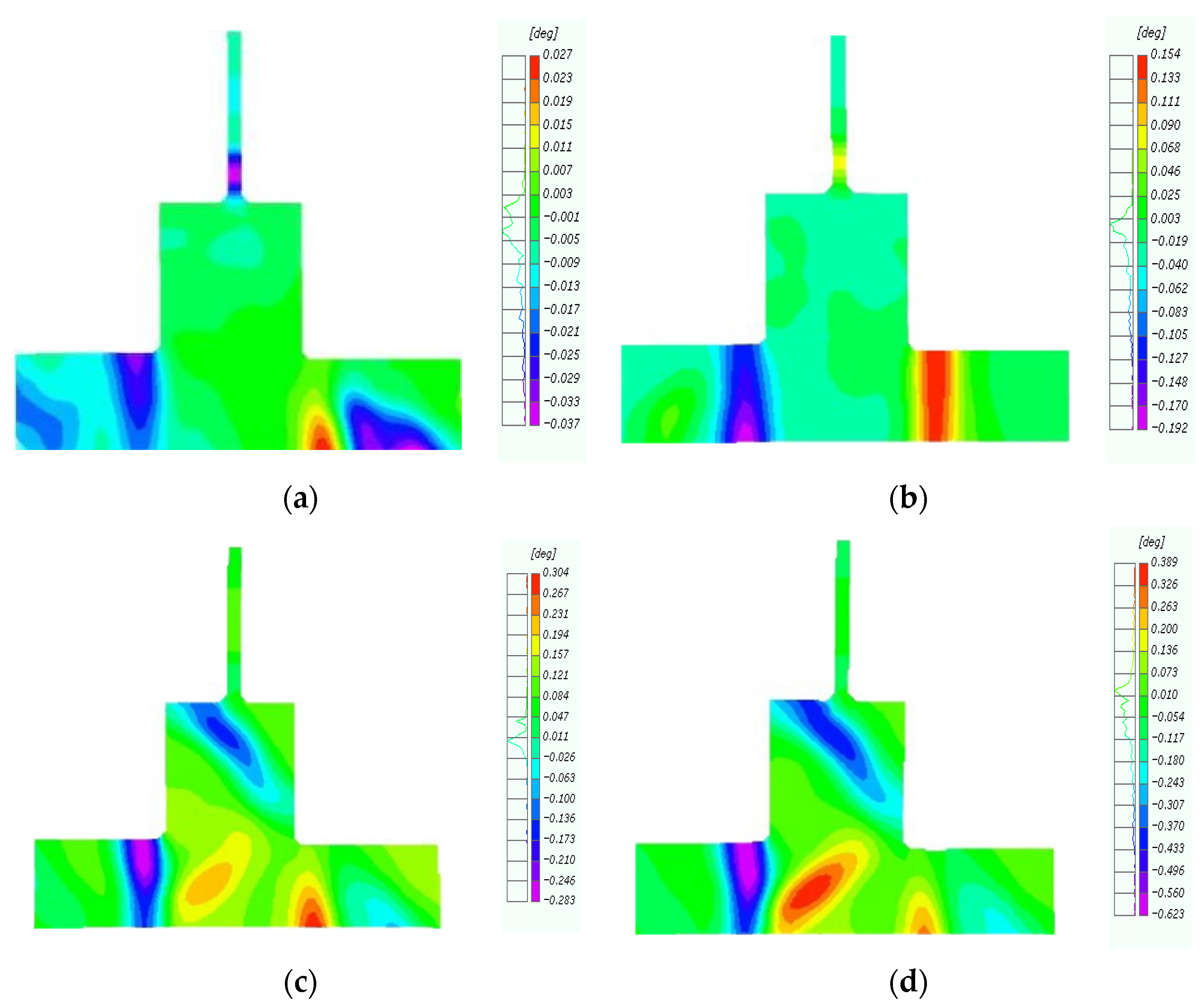

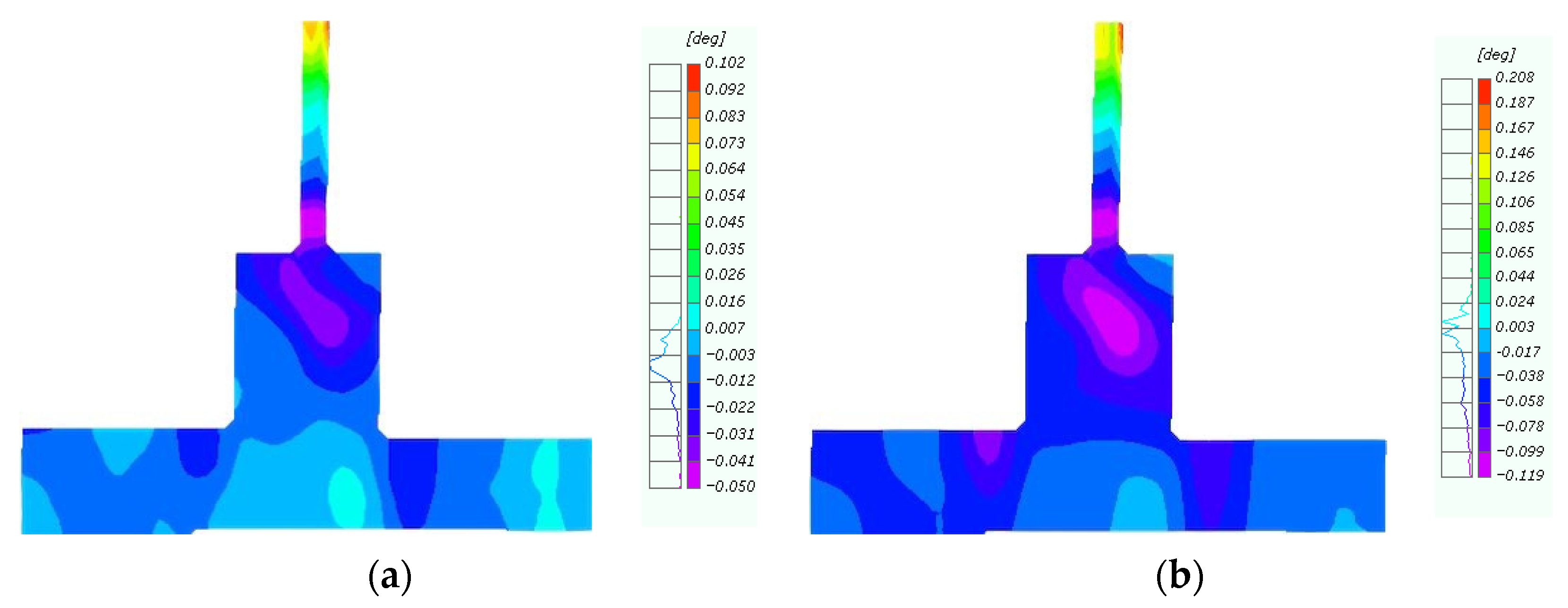

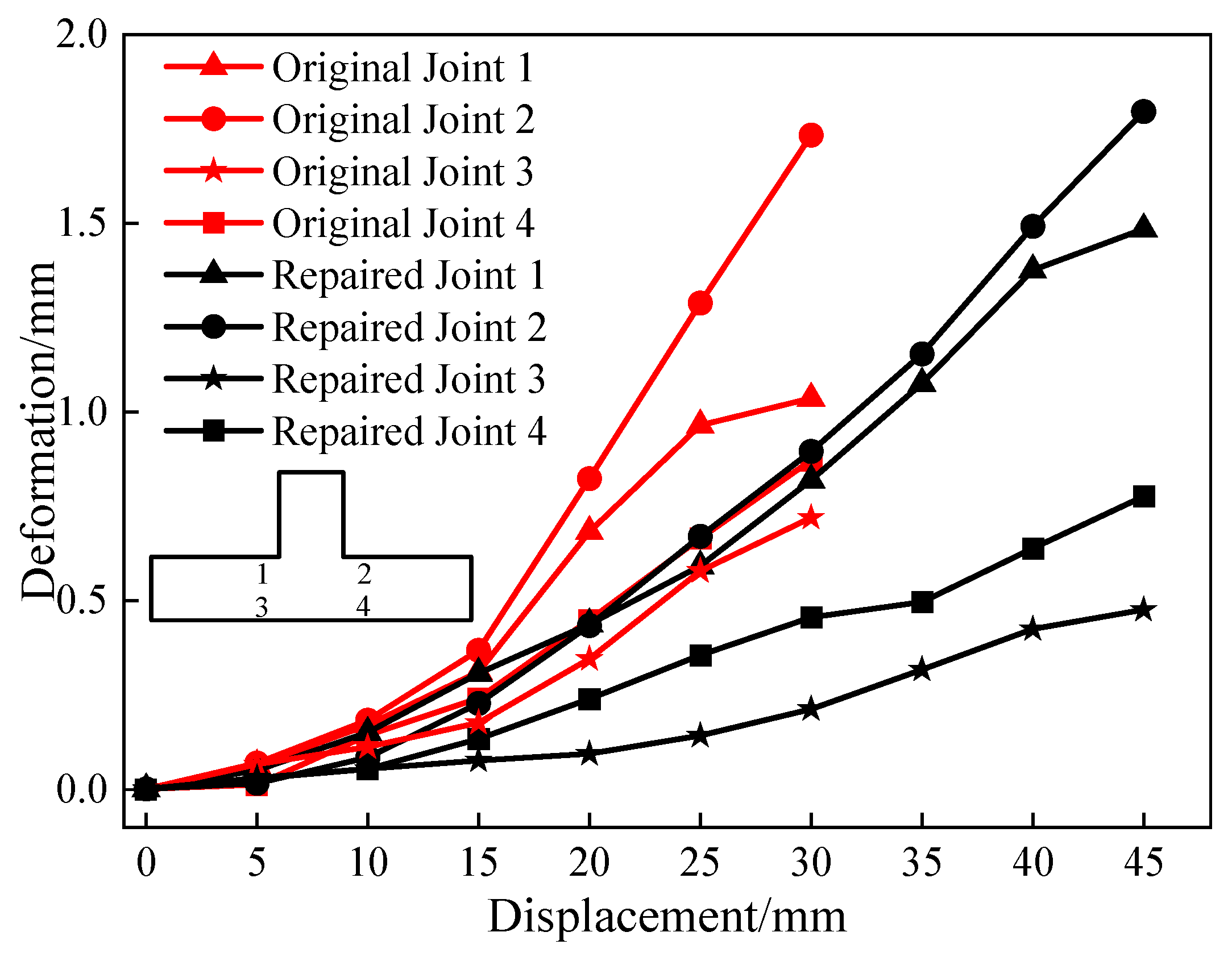

4.1. Shear Deformation

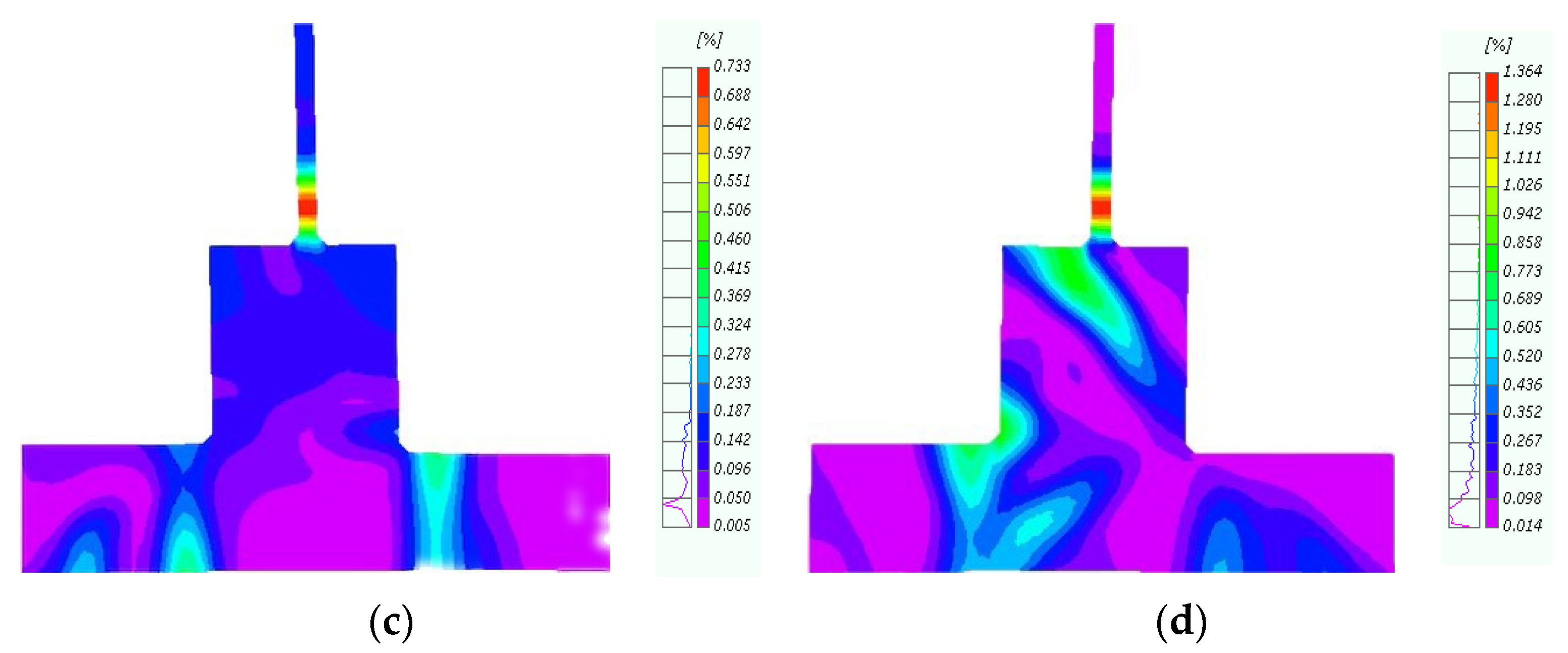

4.2. Damage Analysis

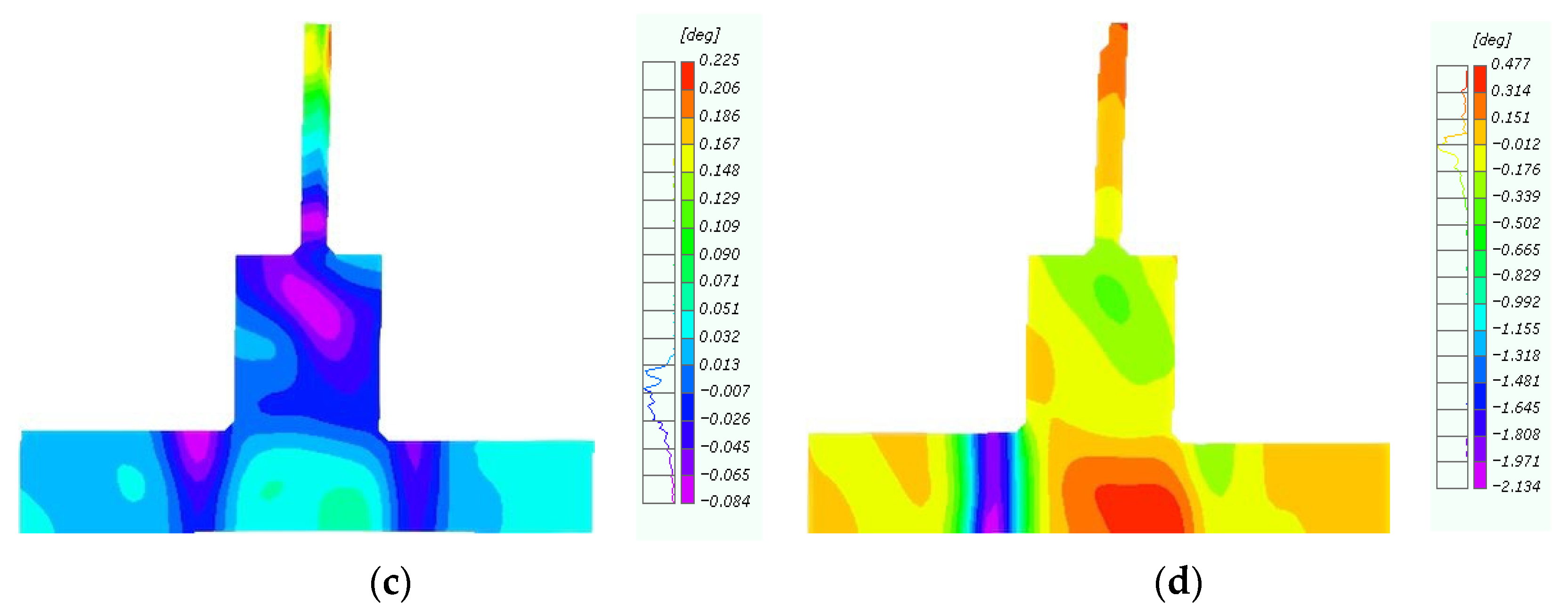

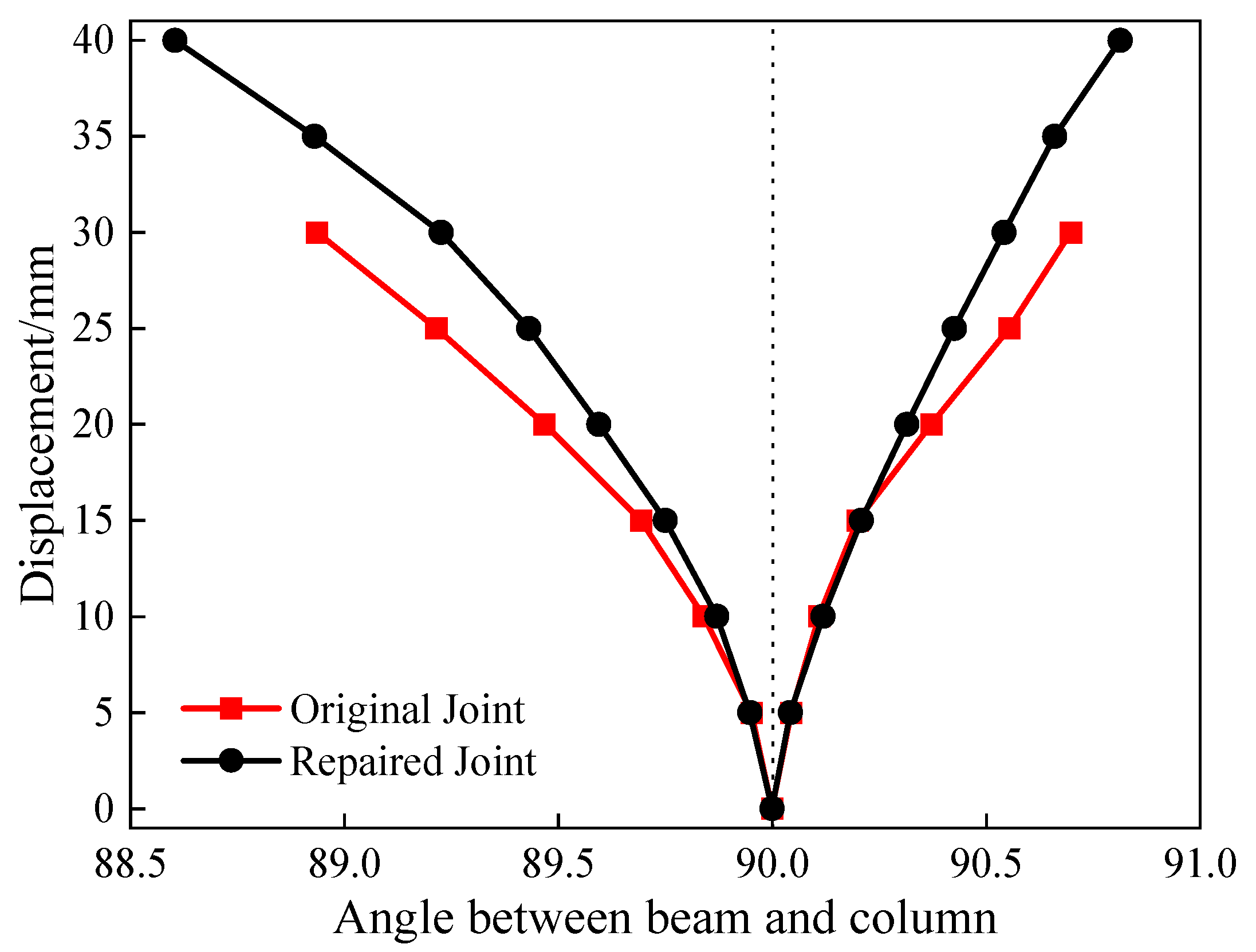

4.3. Angle Between Beam and Column

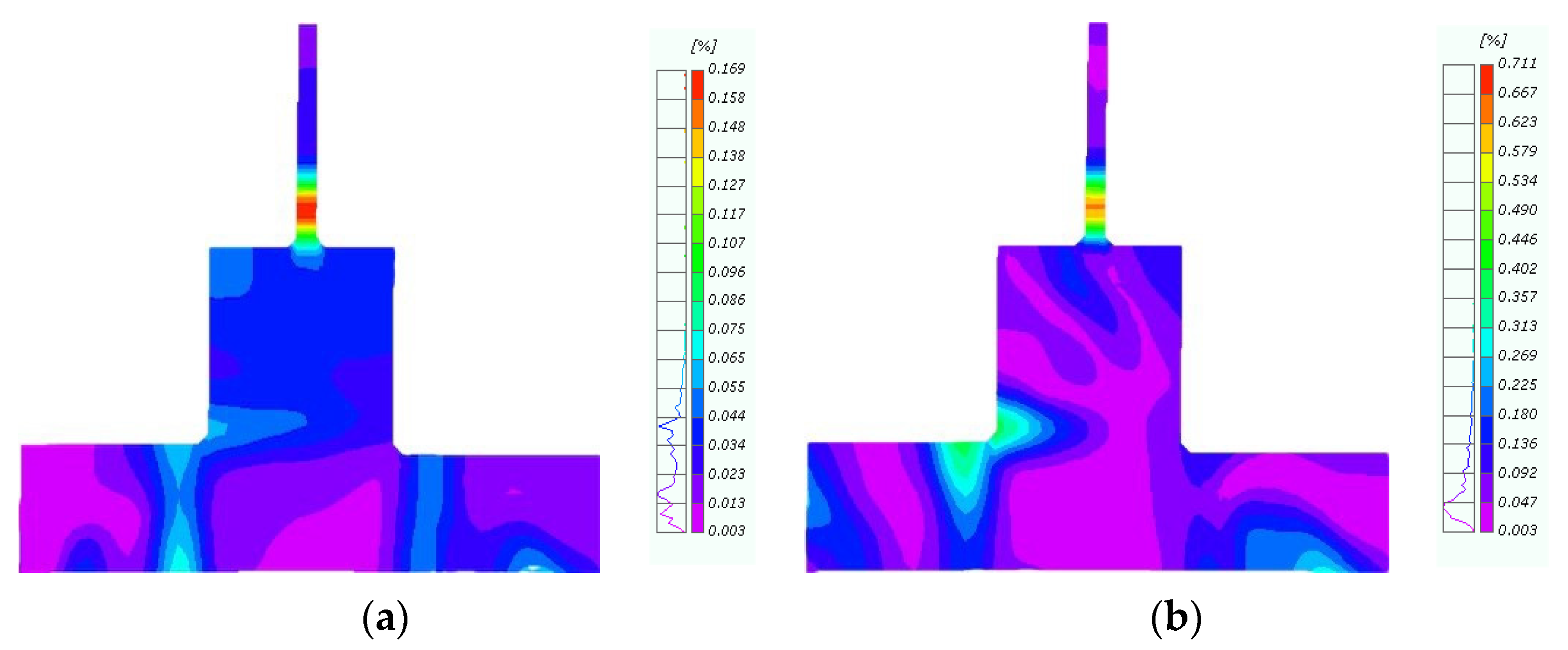

4.4. Concrete Strain

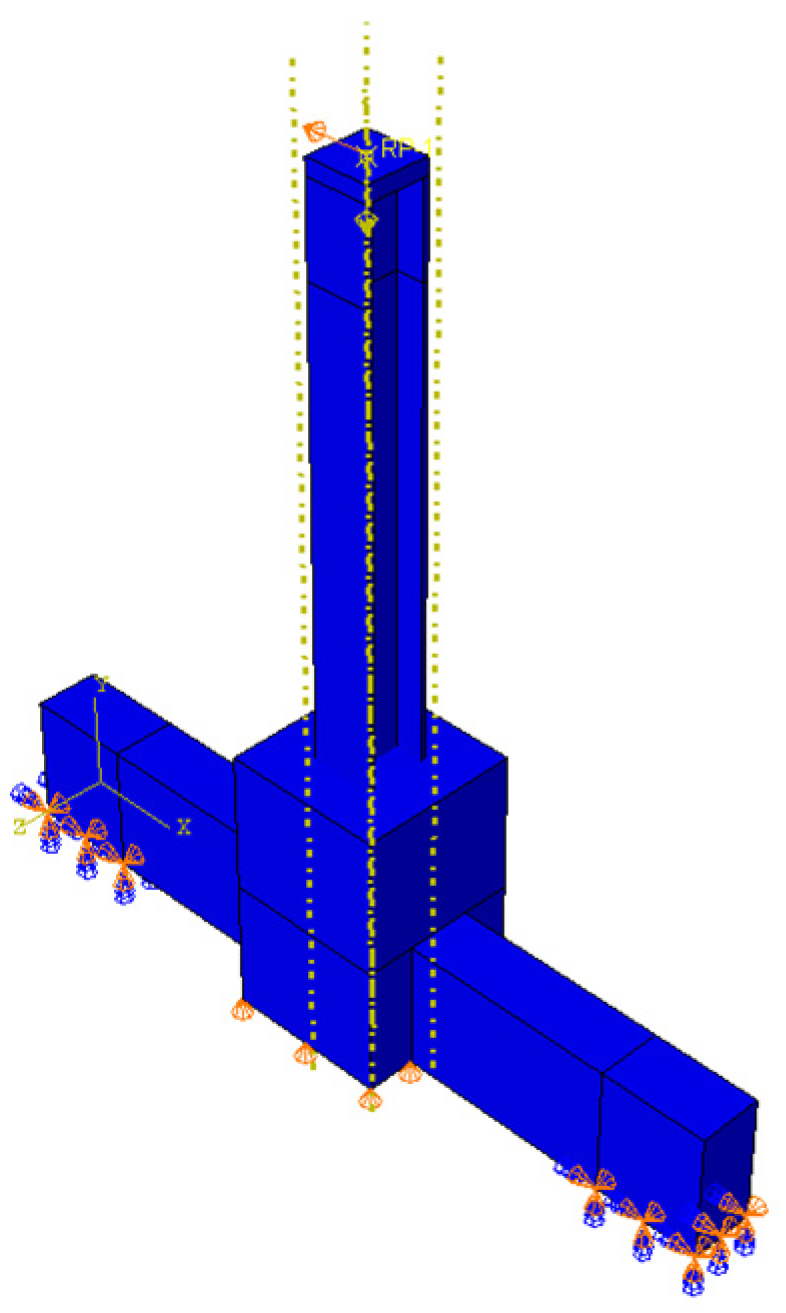

5. Numerical Simulation Analysis

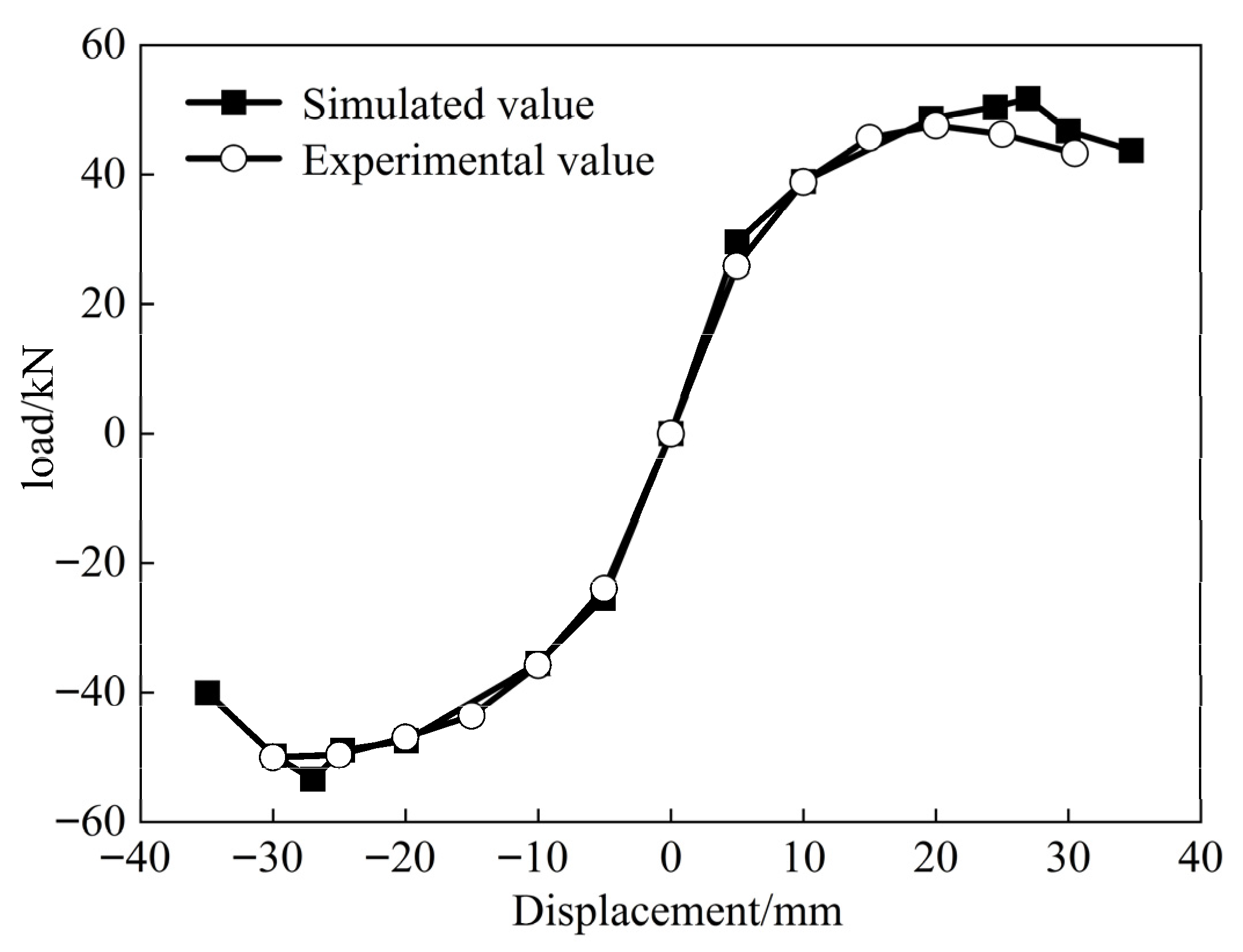

5.1. Validation of the Finite Element Model

5.2. Influence Analysis of the Number of CFRP Layers

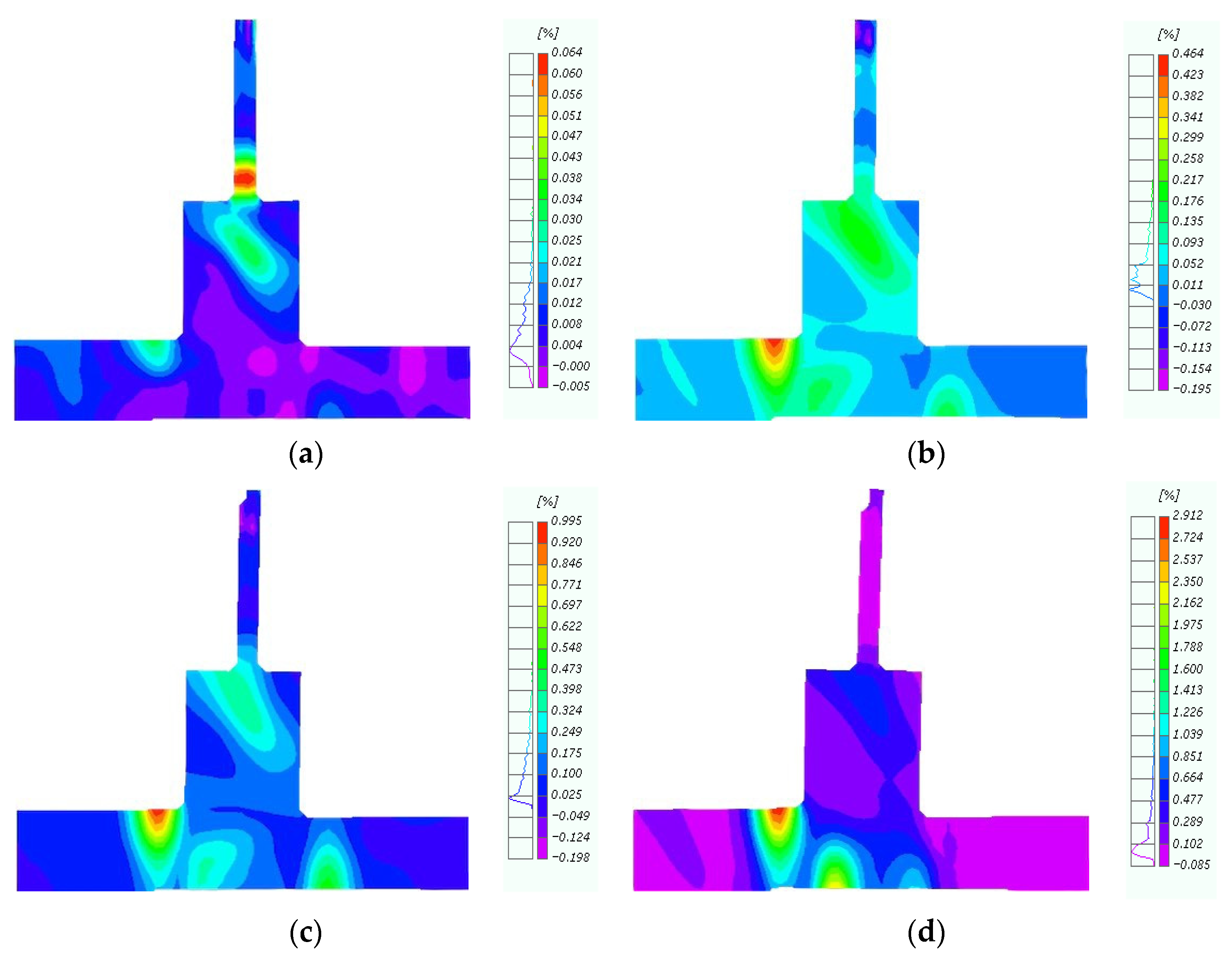

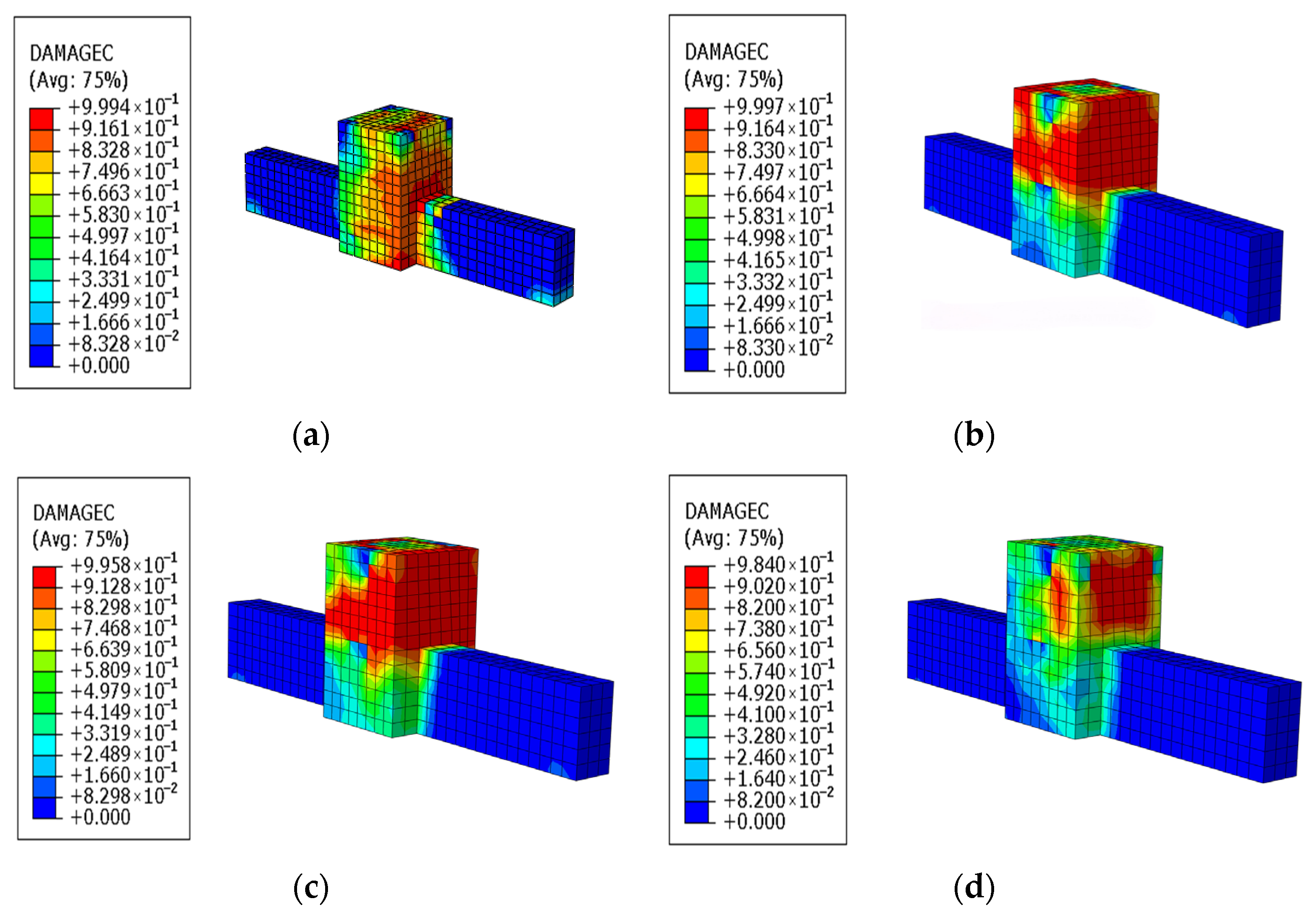

5.3. Evaluation of the Effect of the CFRP Layers on Concrete Damage

6. Conclusions

- (1)

- The seismic capacity of the damaged mixed reinforced concrete–steel frame structure was significantly enhanced through CFRP retrofitting. After retrofitting, all mechanical properties of the repaired joints, except for stiffness, showed improvement compared to the original joints. Specifically, compared with their pre-retrofitting state, the CFRP-reinforced joints exhibited increased ductility and enhanced energy dissipation capacity.

- (2)

- For the mixed reinforced concrete–steel frame structure with severely damaged joints subjected to reciprocal loading, CFRP retrofitting effectively restored and improved the seismic capacity of the joints.

- (3)

- The proposed CFRP seismic retrofit design method, which accounts for the strength degradation of concrete in damaged joints due to earthquake-induced damage, has proven to be feasible, straightforward, and easily implementable.

- (4)

- When joints are reinforced with both vertical and horizontal CFRP layers, the lateral load-bearing capacity increases significantly when two CFRP layers are used compared to one. However, once the CFRP reinforcement meets the required strength, further increases in the number of layers yield only marginal improvements in the lateral load-bearing capacity of the joints and the concrete protection effect.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Julistiono, E.K.; Oldfield, P.; Cardellicchio, L. Up on the roof: A review of design, construction, and technology trends in vertical extensions. Archit. Sci. Rev. 2024, 67, 63–77. [Google Scholar] [CrossRef]

- Argenziano, M.; Faiella, D.; Bruni, F.; De Angelis, C.; Fraldi, M.; Mele, E. Upwards-Vertical extensions of masonry built heritage for sustainable and antifragile urban densification. J. Build. Eng. 2021, 44, 102885. [Google Scholar] [CrossRef]

- Julistiono, E.K.; Oldfield, P.; Cardellicchio, L. Vertical extensions: Stakeholder perspectives on development decisions and construction strategies. J. Archit. Eng. 2023, 29, 04023010. [Google Scholar] [CrossRef]

- Pan, X.Z.; Li, H.; Chao, H.; Li, S.; Liang, G. Hysteretic behavior of a new type of outsourcing hybrid joint. Structures 2022, 40, 88–108. [Google Scholar] [CrossRef]

- Bahri, F.; Bahri, F.; Moeini, M.E. Numerical investigation of a novel concrete-to-steel column splice in mixed structures in height. Structures 2023, 58, 105526. [Google Scholar] [CrossRef]

- Gao, J.Y.; Nie, X.; Ding, R.; Fan, J.-S. Experimental study on seismic performance of a new transfer joint in the steel-concrete vertical hybrid structure. J. Constr. Steel Res. 2020, 174, 106259. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Ferreira, J.; Pinheiro, M.D.; De Brito, J. Economic and environmental savings of structural buildings refurbishment with demolition and reconstruction—A Portuguese benchmarking. J. Build. Eng. 2015, 3, 114–126. [Google Scholar] [CrossRef]

- Askouni, P.K.; Papagiannopoulos, G.A. The non-linear behavior of mixed reinforced concrete–steel frames under strong earthquakes. Eng. Proc. 2023, 53, 15. [Google Scholar] [CrossRef]

- Askouni, P.K. The influence of soil deformability on the seismic response of 3D mixed R/C–steel buildings. Infrastructures 2024, 9, 80. [Google Scholar] [CrossRef]

- Katsimpini, P.S. Seismic Response of Vertical Hybrid Concrete/Steel Frames Considering Soil–Structure Interaction. Buildings 2024, 14, 972. [Google Scholar] [CrossRef]

- Salameh, M.; Shayanfar, M.; Barkhordari, M.A. Seismic displacements and behaviour factors assessment of an innovative steel and concrete hybrid coupled shear wall system. Structures 2021, 34, 20–41. [Google Scholar] [CrossRef]

- Ghanbari, B.; Fathi, M.; Akhaveissy, A.H. Fragility curves for reinforced concrete (RC)/steel vertical hybrid frame structure under mainshock–aftershock sequences. J. Struct. Integr. Maint. 2023, 8, 179–187. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Huang, B.; Wu, X.; Wu, Z.; Faber, M.H. Dynamic characteristics of vertically irregular structures with random fields of different probability distributions based on stochastic homotopy method. Mech. Syst. Signal Process. 2024, 220, 111638. [Google Scholar] [CrossRef]

- Kiani, A.; Kheyroddin, A.; Kafi, M.A.; Naderpour, H. Seismic fragility assessment for mixed concrete/steel buildings considering the appropriate position of the transition story. Soil Dyn. Earthq. Eng. 2022, 163, 107552. [Google Scholar] [CrossRef]

- Kiani, A.; Kheyroddin, A.; Kafi, M.A.; Naderpour, H. Non-linear study of the method of transition in mixed concrete/steel structures. Soil Dyn. Earthq. Eng. 2023, 170, 107925. [Google Scholar] [CrossRef]

- Kiani, A.; Yang, T.Y.; Kheyroddin, A.; Kafi, M.A.; Naderpour, H. Quantification of seismic performance factors of mixed concrete/steel buildings using the FEMA P695 methodology. Structures 2024, 61, 106144. [Google Scholar] [CrossRef]

- Papagiannopoulos, G.A. On the modal damping ratios of mixed reinforced concrete–steel buildings. Soil Dyn. Earthq. Eng. 2024, 178, 108481. [Google Scholar] [CrossRef]

- Pan, X.; Qiao, S.; Li, H.; Gao, H.; Ma, H.; Yao, L. Seismic behaviour of a new type of external hoop assembled joint for RC Frame-added layer hybrid structure. Structures 2021, 32, 170–193. [Google Scholar] [CrossRef]

- Bahri, F.; Kafi, M.A.; Kheyroddin, A. Full-scale experimental assessment of new connection for columns in vertically mixed structures. Struct. Des. Tall Spec. Build. 2019, 28, e1629. [Google Scholar] [CrossRef]

- Deo, B.D.N.; Datta, A.K. A step toward the development of a user interface (UI) for material calculation and cost analysis of jacketed buildings. Asian J. Civ. Eng. 2023, 24, 2925–2938. [Google Scholar] [CrossRef]

- Hussain, Q.; Ruangrassamee, A.; Jirawattanasomkul, T.; Zhang, D. Stress and strain relations of RC circular, square and rectangular columns externally wrapped with fiber ropes. Sci. Rep. 2024, 14, 4181. [Google Scholar] [CrossRef] [PubMed]

- Helal, Y.; Garcia, R.; Imjai, T.; Aosai, P.; Guadagnini, M.; Pilakoutas, K. Seismic behaviour of exterior RC beam-column joints repaired and strengthened using post-tensioned metal straps. Bull. Earthq. Eng. 2024, 22, 3261–3286. [Google Scholar] [CrossRef]

- Lu, X.; Liu, B.Y.; Sun, W.H.; Xu, L. Seismic performance investigation on self-centering friction frames: Collapse capacity and post-earthquake recovery. Soil Dyn. Earthq. Eng. 2024, 179, 108555. [Google Scholar] [CrossRef]

- Lu, X.; Sun, W.H.; Xu, L.H. Experimental investigation on seismic behavior of damaged self-centering friction beam-column joints after repair. Eng. Struct. 2024, 310, 118135. [Google Scholar] [CrossRef]

- Hung, C.C.; Agrawal, S.; Hsiao, H.J. Rehabilitation of seismically-damaged RC beam-column joints with UHPC and high-strength steel mesh reinforcement. J. Build. Eng. 2024, 84, 108667. [Google Scholar] [CrossRef]

- Hung, C.C.; Lin, C.C.; Do, T.D.D. Seismic rehabilitation of RC frames with innovative precast U-shaped UHPC jackets: Experimental evaluation and computational simulation. Eng. Struct. 2024, 318, 118746. [Google Scholar] [CrossRef]

- Zhang, T.Y.; Xu, W.Z.; Wang, S.G.; Du, D.; Xie, L.; Miao, Q. Seismic behavior of earthquake-damaged hybrid connections reinforced with replaceable energy-dissipating elements. J. Build. Eng. 2023, 80, 108062. [Google Scholar] [CrossRef]

- Zhang, J.W.; Tang, L.; Liu, W.H.; Zhang, M. Seismic performance of earthquake-damaged HSRAC beam-column interior joints rehabilitated by bonding steel plates in the plastic hinge of beams. Structures 2024, 69, 107357. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Tan, K.H. Progressive collapse behaviour of earthquake-damaged interior precast concrete joints with headed bars and plastic hinge relocation. Eng. Struct. 2024, 306, 117817. [Google Scholar] [CrossRef]

- Ren, H.M.; Zhang, F.W.; Mao, C.X.; Fan, Q.; Lu, Z. Numerical and experimental analysis in seismic performance of post-earthquake reinforced concrete frame retrofitted with ECC. Adv. Struct. Eng. 2024, 27, 3–16. [Google Scholar] [CrossRef]

- Zhao, L.; Cao, Z.G.; Feng, J.X.; Hu, X.; Fan, F. Influence of joint assembly errors on stability of prefabricated single-layer reticulated shells. J. Constr. Steel Res. 2023, 207, 107979. [Google Scholar] [CrossRef]

- Obaidat, Y.T.; Heyden, S.; Dahlblom, O. The effect of CFRP and CFRP/concrete interface models when modelling retrofitted RC beams with FEM. Compos. Struct. 2010, 92, 1391–1398. [Google Scholar] [CrossRef]

- Bai, R.; Hajjar, J.F.; Liu, S.W.; Chan, S.-L. A mixed-field timoshenko beam-column element for direct analysis of tapered I-sections members. J. Constr. Steel. Res. 2020, 172, 106157. [Google Scholar] [CrossRef]

- JGJ 145-2013; Technical Specification for Post-Installed Fastenings in Concrete Structures. China Architecture & Building Press: Beijing, China, 2013.

- JGJ/T 101-2015; Specification for Seismic Test of Buildings. China Architecture & Building Press: Beijing, China, 2015.

- GB50010-2010; Design Code for Concrete Structures. China Architecture & Building Press: Beijing, China, 2015.

- GB50011-2010; Code for Seismic Design of Buildings. China Architecture & Building Press: Beijing, China, 2016.

- Golewski, G.L. Measurement of fracture mechanics parameters of concrete containing fly ash thanks to use of Digital Image Correlation (DIC) method. Measurement 2019, 135, 96–105. [Google Scholar] [CrossRef]

- Kalali, S.H.; Eskandari-Naddaf, H.; Kooshkaki, A. Digital image correlation to characterize the tensile behavior of the polypropylene and forta-ferro fiber-reinforced concrete. Arab. J. Sci. Eng. 2023, 48, 14017–14027. [Google Scholar] [CrossRef]

- Wang, F.; Kan, L.L.; Yu, J.T.; Duan, X.-Z. Systematic studies on behaviors of ultra-high performance concrete subject to freezing and thawing cycles combining DIC technology. Constr. Build. Mater. 2023, 388, 131580. [Google Scholar] [CrossRef]

- Tuna, M.; Topkaya, C. Panel zone deformation demands in steel moment resisting frames. J. Constr. Steel Res. 2015, 110, 65–75. [Google Scholar] [CrossRef]

- Pham, H.H.; Kim, S.H.; Dinh, N.H.; Kim, S.-H.; Choi, K.-K. Cyclic Axial Behavior of Rectangular RC Prisms Lightly Confined by CFRP Mesh Simulating Shear Wall Boundary Elements. Int. J. Civ. Eng. 2025, 23, 1847–1863. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, X.; Shi, Z.; Wu, W.; Liu, Z. Damage mode identification of CFRP sheet strengthened coral aggregate reinforced concrete beams based on acoustic emission technology. Eng. Struct. 2025, 343, 121076. [Google Scholar] [CrossRef]

- Rehman, A.U.; Siddiqi, Z.A.; Yasin, M.; Aslam, H.M.S.; Noshin, S.; Aslam, H.M.U. Experimental study on the behavior of damaged CFRP and steel rebars RC columns retrofitted with externally bonded composite material. Adv. Compos. Mater. 2025, 34, 93–139. [Google Scholar] [CrossRef]

| No. | Elasticity Modulus (Es/MPa) | Yield Strength (fy/MPa) | Ultimate Strength (fu/MPa) |

|---|---|---|---|

| A8 | 2.1 × 105 | 299.30 | 440.19 |

| C12 | 2.0 × 105 | 335.64 | 468.71 |

| C16 | 2.0 × 105 | 356.51 | 492.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, X.; Guo, T.; Xing, Y.; Qin, R.; Long, H.; Bao, C.; Cao, F.; Hong, R. Study on Seismic Behavior of Earthquake-Damaged Joints Retrofitted with CFRP in Hybrid Reinforced Concrete–Steel Frames. Materials 2025, 18, 4857. https://doi.org/10.3390/ma18214857

Ma X, Guo T, Xing Y, Qin R, Long H, Bao C, Cao F, Hong R. Study on Seismic Behavior of Earthquake-Damaged Joints Retrofitted with CFRP in Hybrid Reinforced Concrete–Steel Frames. Materials. 2025; 18(21):4857. https://doi.org/10.3390/ma18214857

Chicago/Turabian StyleMa, Xiaotong, Tianxiang Guo, Yuxiao Xing, Ruize Qin, Huan Long, Chao Bao, Fusheng Cao, and Ruixiao Hong. 2025. "Study on Seismic Behavior of Earthquake-Damaged Joints Retrofitted with CFRP in Hybrid Reinforced Concrete–Steel Frames" Materials 18, no. 21: 4857. https://doi.org/10.3390/ma18214857

APA StyleMa, X., Guo, T., Xing, Y., Qin, R., Long, H., Bao, C., Cao, F., & Hong, R. (2025). Study on Seismic Behavior of Earthquake-Damaged Joints Retrofitted with CFRP in Hybrid Reinforced Concrete–Steel Frames. Materials, 18(21), 4857. https://doi.org/10.3390/ma18214857