Performance of Sustainable Semi-Rigid Pavements: Optimizing High-Content Reclaimed Asphalt Pavement with Rejuvenators and Novel Grout Formulations

Abstract

1. Introduction

2. Materials and Methods

3. Results

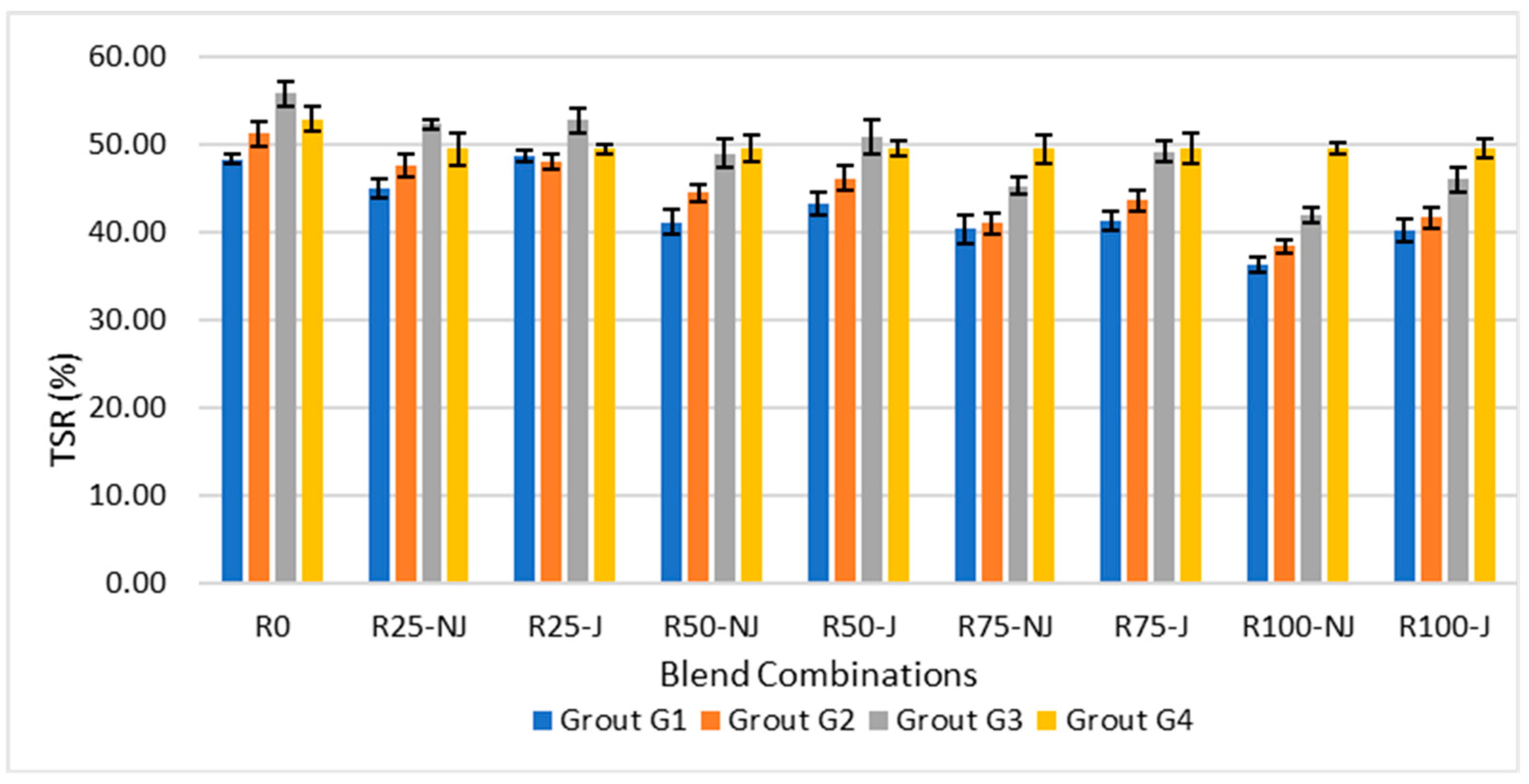

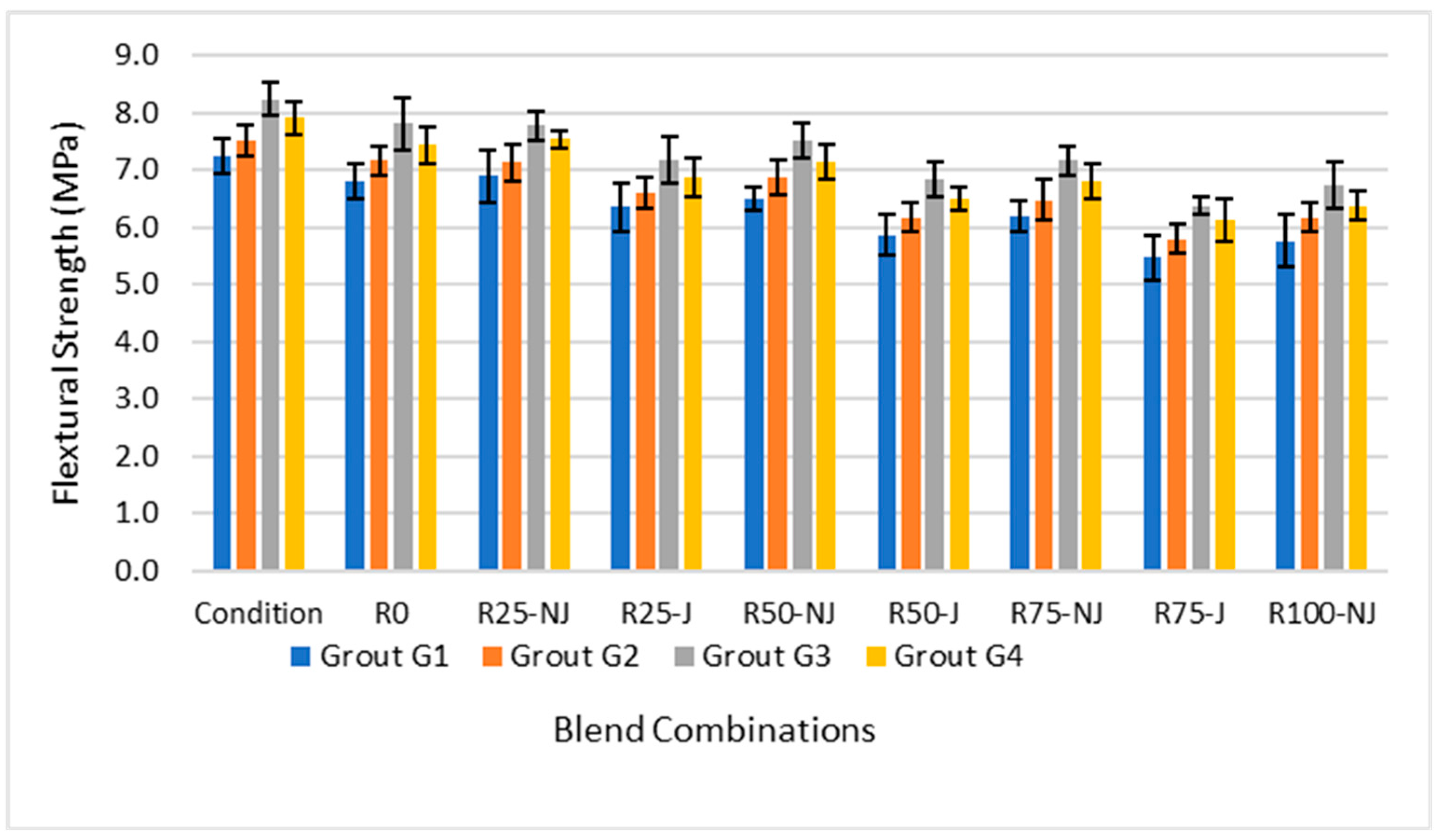

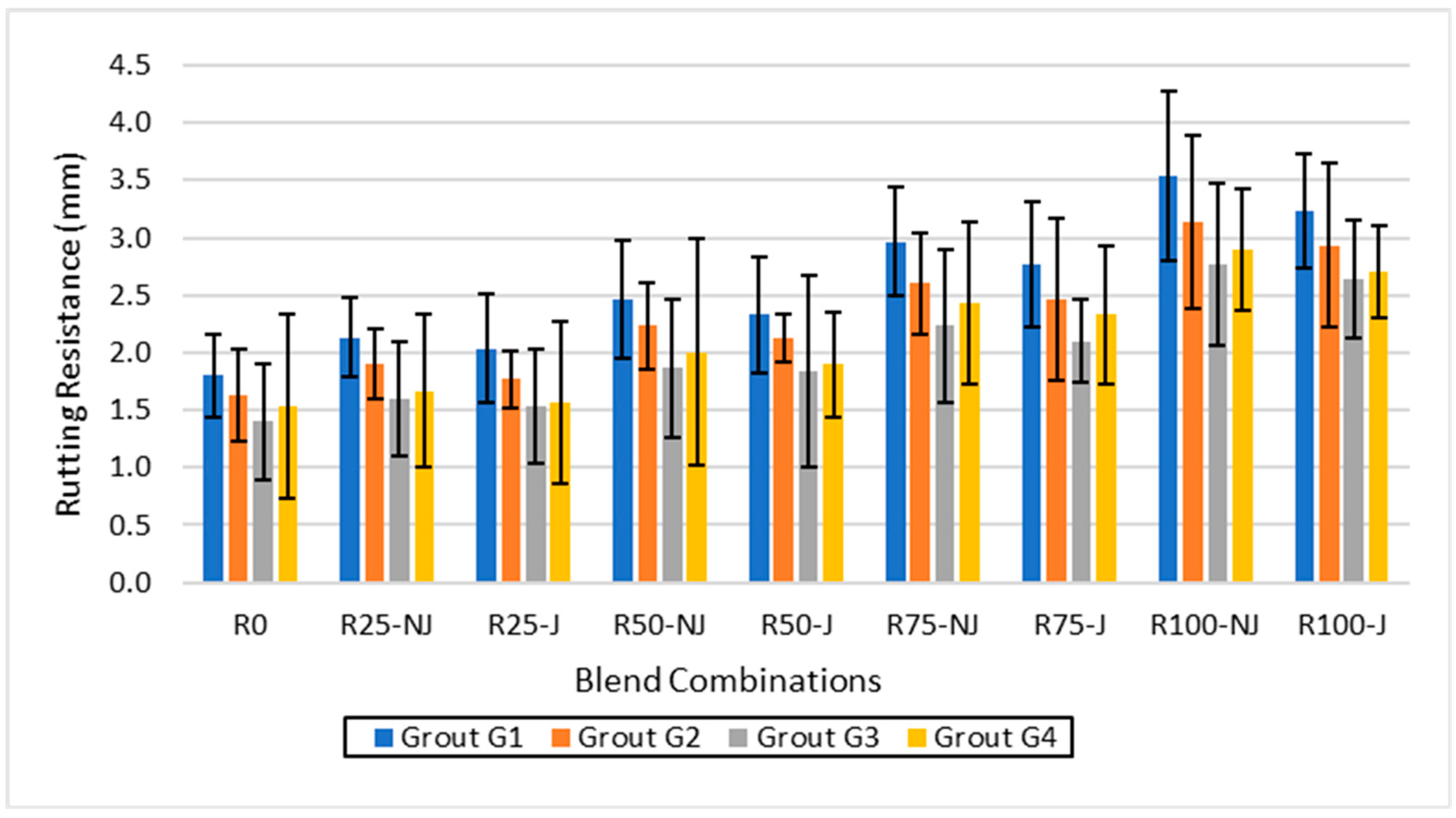

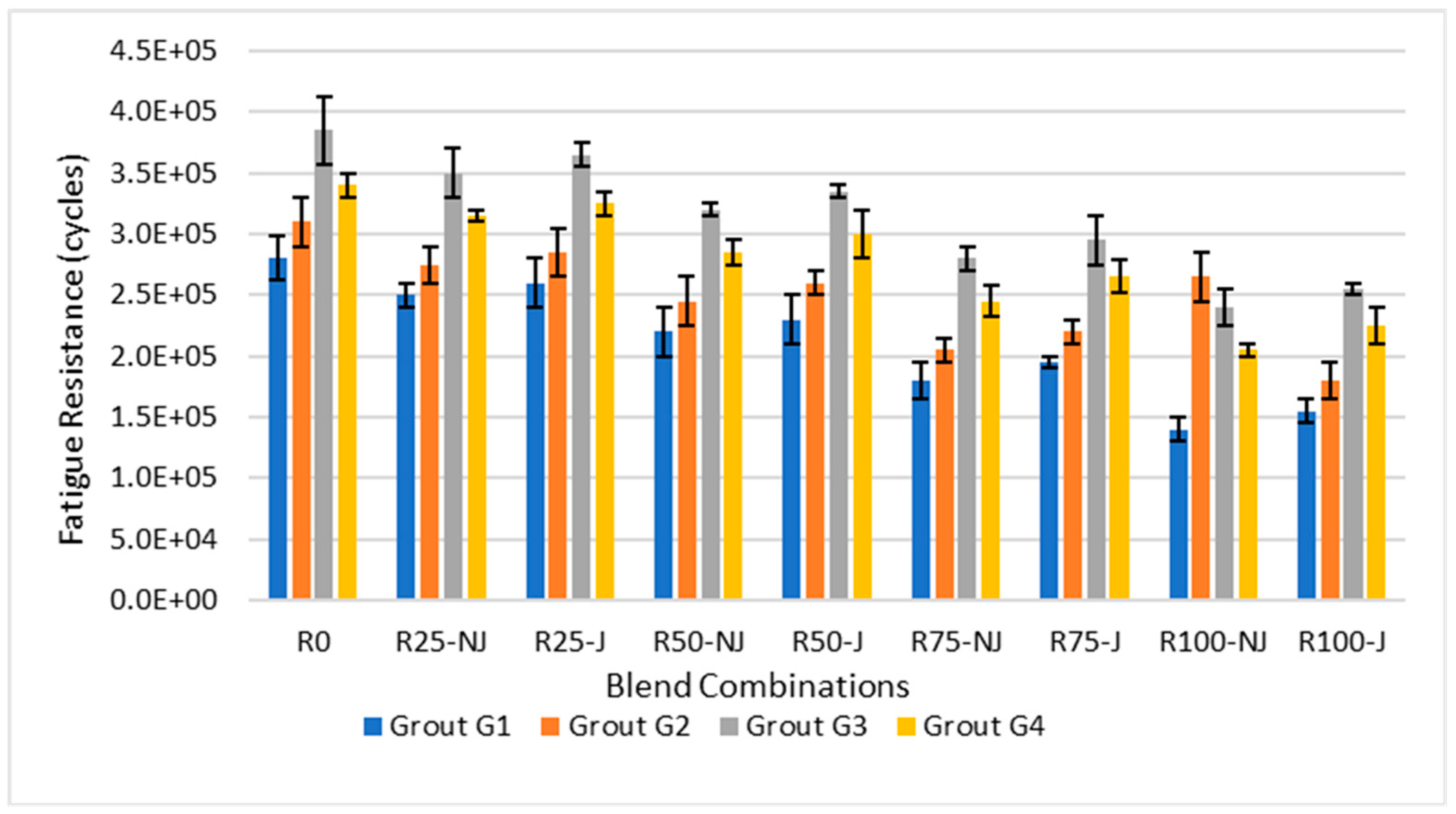

3.1. Experimental Results

3.2. Statistical Significance and Interaction Effects

4. Discussion

5. Conclusions

- Increasing the RAP content was the most dominant factor affecting pavement performance, significantly reducing compressive strength, flexural strength, fatigue life, and moisture resistance.

- The application of the bio-oil-based rejuvenator proved highly effective in mitigating the detrimental effects of the aged RAP binder, with its benefits being most pronounced at higher RAP contents.

- Among the novel grout formulations, G3, which contained a proprietary high-reactivity mineral additive, consistently yielded the best performance across all tested metrics, including compressive strength, rutting resistance, and fatigue life.

- The central finding of this research is the critical synergistic effect between the rejuvenator and grout selection. The optimized combination of the rejuvenator and the G3 grout enabled the 100% RAP mixture to regain over 70% of the virgin control mix’s strength, providing a validated and technically viable pathway for constructing sustainable semi-rigid pavements with complete replacement of virgin materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ITZ | Interfacial Transition Zone |

| TSR | Tensile Strength Ratio |

| RAP | Reclaimed Asphalt Pavement |

| ANOVA | Analysis of Variance |

References

- Sha, A.; Liu, Z.; Jiang, W.; Qi, L.; Hu, L.; Jiao, W.; Barbieri, D.M. Advances and Development Trends in Eco-Friendly Pavements. J. Road Eng. 2021, 1, 1–42. [Google Scholar] [CrossRef]

- Mehmood, S.A.; Khan, M.I.; Ahmed, S.; Al-Nawasir, R.; Choudhry, R.M. From Waste to Roads: Improving Pavement Performance and Achieving Sustainability with Recycled Steel Slag and Low-Density Polyethylene. Buildings 2025, 15, 476. [Google Scholar] [CrossRef]

- Hassan, D.; Memon, N. Rigid Pavement Design Using Recycled Asphaltic Materials. Sindh Univ. Res. J. (Sci. Ser.) 2016, 48, 399–406. [Google Scholar]

- Tarsi, G.; Tataranni, P.; Sangiorgi, C. The Challenges of Using Reclaimed Asphalt Pavement for New Asphalt Mixtures: A Review. Materials 2020, 13, 4052. [Google Scholar] [CrossRef]

- RAP—Recycling-Sustainability-Pavements-Federal Highway Administration. Available online: https://www.fhwa.dot.gov/pavement/recycling/rap.cfm (accessed on 2 September 2025).

- Hasan, U.; Whyte, A.; Al Jassmi, H.; Hasan, A. Lifecycle Cost Analysis of Recycled Asphalt Pavements: Determining Cost of Recycled Materials for an Urban Highway Section. CivilEng 2022, 3, 316–331. [Google Scholar] [CrossRef]

- Milad, A.; Babalghaith, A.M.; Al-Sabaeei, A.M.; Dulaimi, A.; Ali, A.; Reddy, S.S.; Bilema, M.; Yusoff, N.I.M. A Comparative Review of Hot and Warm Mix Asphalt Technologies from Environmental and Economic Perspectives: Towards a Sustainable Asphalt Pavement. Int. J. Environ. Res. Public Health 2022, 19, 14863. [Google Scholar] [CrossRef]

- Tang, W.; Yu, X.; Li, N.; Dong, F.; Wang, Z.; Zhang, Y. Effect of Rejuvenators on the Workability and Performances of Reclaimed Asphalt Mixtures. Materials 2021, 14, 6385. [Google Scholar] [CrossRef]

- Yang, J.; Sun, C.; Tao, W.; Gao, J.; Huang, B.; Zhang, J. Laboratory Investigation of Compaction Characteristics of Plant Recycled Hot-Mix Asphalt Mixture. Sustainability 2021, 13, 3005. [Google Scholar] [CrossRef]

- Sukhija, M.; Saboo, N. A Comprehensive Review of Warm Mix Asphalt Mixtures—Laboratory to Field. Constr. Build. Mater. 2020, 274, 121781. [Google Scholar] [CrossRef]

- Di Mascio, P.; Loprencipe, G.; Moretti, L. Economic Evaluation of Cement Grouted Bituminous Mixes for Airport Pavements. Materials 2021, 14, 7230. [Google Scholar] [CrossRef]

- Moretti, L.; Fabrizi, N.; Fiore, N.; D’Andrea, A. Mechanical Characteristics of Graphene Nanoplatelets-Modified Asphalt Mixes: A Comparison with Polymer- and Not-Modified Asphalt Mixes. Materials 2021, 14, 2434. [Google Scholar] [CrossRef]

- Wang, X.; Ma, B.; Li, S.; Si, W.; Wei, K.; Zhang, H.; Zhou, X.; Yunfeng, F.; Kang, X.; Shi, W. Review on Application of Phase Change Materials in Asphalt Pavement. J. Traffic Transp. Eng. 2023, 10, 185–229. [Google Scholar] [CrossRef]

- Aryal, G.; Yun, J.; Islam, M.A. Review of the Self-Healing Asphalt. 2025. Available online: https://ssrn.com/abstract=5090047 (accessed on 16 October 2025).

- Liu, Y.; Liu, Z.; Zhu, Y.; Zhang, H. A Review of Sustainability in Hot Asphalt Production: Greenhouse Gas Emissions and Energy Consumption. Appl. Sci. 2024, 14, 10246. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% Recycled Hot Mix Asphalt: A Review and Analysis. Resour. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- Milad, A.A.; Ali, A.S.B.; Yusoff, N.I.M. A Review of the Utilisation of Recycled Waste Material as an Alternative Modifier in Asphalt Mixtures. Civ. Eng. J. 2020, 6, 42–60. [Google Scholar] [CrossRef]

- Zhong, H.; Huang, W.; Lin, P.; Zhou, L.; Lv, Q. Critical Considerations and Effective Assessment of Extraction and Recovery Processes of RAP. Constr. Build. Mater. 2023, 403, 133039. [Google Scholar] [CrossRef]

- Steinberger, J.; Krausmann, F.; Eisenmenger, N. Global Patterns of Materials Use: A Socioeconomic and Geophysical Analysis. Ecol. Econ. 2010, 69, 1148–1158. [Google Scholar] [CrossRef]

- Tiza, M.T.; Mogbo, O.N.; Duweni, E.C.; Asawa, J.I. Recycled Asphalt Pavement: A Systematic Literature Review. J. Mod. Technol. Eng. 2020, 5, 242–254. [Google Scholar]

- Sukhija, M.; Coleri, E. A Systematic Review on the Role of Reclaimed Asphalt Pavement Materials: Insights into Performance and Sustainability. Clean. Mater. 2025, 16, 100316. [Google Scholar] [CrossRef]

- Jamshidi, A.; White, G. Evaluation of Performance and Challenges of Use of Waste Materials in Pavement Construction: A Critical Review. Appl. Sci. 2020, 10, 226. [Google Scholar] [CrossRef]

- Jwaida, Z.; Al Quraishy, Q.A.; Almuhanna, R.R.A.; Dulaimi, A.; Bernardo, L.F.A.; Andrade, J.M.d.A. The Use of Waste Fillers in Asphalt Mixtures: A Comprehensive Review. CivilEng 2024, 5, 801–826. [Google Scholar] [CrossRef]

- Jafri, S.F.; Memon, N.A.; Memon, R.A.; Sheeraz, K. Mechanical and Performance Characteristics of Semi-Rigid Mix Design with Recycled Materials and Standardization of Rut Depth Measurements. J. Teknol. (Sci. Eng.) 2024, 86, 179–187. [Google Scholar] [CrossRef]

- Hassan, K.; Setyawan, A.; Zoorob, S. Effect of Cementitious Grouts on the Properties of Semi-Flexible Bituminous Pavements; Routledge: Oxfordshire, UK, 2017; p. 120. [Google Scholar]

- Khan, M.I.; Sutanto, M.H.; Yusoff, N.I.M.; Zoorob, S.E.; Rafiq, W.; Ali, M.; Fediuk, R.; Vatin, N.I. Cementitious Grouts for Semi-Flexible Pavement Surfaces—A Review. Materials 2022, 15, 5466. [Google Scholar] [CrossRef]

- Xiao, R.; Huang, B. Moisture Damage Mechanism and Thermodynamic Properties of Hot-Mix Asphalt Under Aging Conditions. ACS Sustain. Chem. Eng. 2022, 10, 14865–14887. [Google Scholar] [CrossRef]

- Ongel, A.; Hugener, M. Impact of Rejuvenators on Aging Properties of Bitumen. Constr. Build. Mater. 2015, 94, 467–474. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, C.; Chen, T.; Zhang, W.; Yao, K.; Fan, C.; Liang, M.; Guo, C.; Yao, Z. Evaluation on the Mechanical Performance of Recycled Asphalt Mixtures Incorporated with High Percentage of RAP and Self-Developed Rejuvenators. Constr. Build. Mater. 2020, 269, 121337. [Google Scholar] [CrossRef]

- Riccardi, C.; Losa, M. Recent Advances and Perspectives in Circular Bio-Binder Extender to Substitute Part of the Fossil Based Binder in Asphalt Mixture. Constr. Build. Mater. 2024, 410, 134222. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R. Bonding in Cementitious Materials with Asphalt-Coated Particles: Part I—The Interfacial Transition Zone. Constr. Build. Mater. 2017, 130, 171–181. [Google Scholar] [CrossRef]

- Bonicelli, A.; Calvi, P.; Martinez-Arguelles, G.; Fuentes, L.; Giustozzi, F. Experimental Study on the Use of Rejuvenators and Plastomeric Polymers for Improving Durability of High RAP Content Asphalt Mixtures. Constr. Build. Mater. 2017, 155, 37–44. [Google Scholar] [CrossRef]

- Jafri, S.F.; Memon, N.A.; Memon, R.A.; Sheeraz, K.; Khan, K. Parametric Characterization of Semi-Rigid Asphalt Skeleton Using Recycled Materials. Mehran Univ. Res. J. Eng. Technol. 2023, 42, 50. [Google Scholar] [CrossRef]

- ASTM D7064/D7064M; Practice for Open-Graded Friction Course (OGFC) Mix Design. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- Aashto T 164-94 | PDF. Available online: https://it.scribd.com/document/637955545/AASHTO-T-164-94 (accessed on 3 September 2025).

- ASTM C127-01; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2001.

- Penetration Test of Bitumen: (AASHTO T-49, ASTM D-5) | PDF | Asphalt | Temperature. Available online: https://www.scribd.com/document/493438023/Penetration-of-Bitumen (accessed on 3 September 2025).

- T 316-22—Viscosity Determination of Asphalt Binder Using Rotational Viscometer | PDF | Viscosity | Thermometer. Available online: https://www.scribd.com/document/748907840/T-316-22-Viscosity-Determination-of-Asphalt-Binder-Using-Rotational-Viscometer (accessed on 3 September 2025).

- AASHTO T315-20; Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- Aashto T 53-2000 | PDF | Thermometer | Temperature. Available online: https://www.scribd.com/document/735993109/AASHTO-T-53-2000 (accessed on 3 September 2025).

- Tushar, Q.; Salehi, S.; Santos, J.; Zhang, G.; Bhuiyan, M.A.; Arashpour, M.; Giustozzi, F. Application of Recycled Crushed Glass in Road Pavements and Pipeline Bedding: An Integrated Environmental Evaluation Using LCA. Sci. Total Environ. 2023, 881, 163488. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Leng, Z.; Wang, L.; Zhou, P. Effect of Reclaimed Asphalt Pavement Heating Temperature on the Compactability of Recycled Hot Mix Asphalt. Materials 2020, 13, 3621. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Sha, A.; Pei, J.-Z.; Xiao, J.-J. Gyratory Compaction Characteristics of Porous Asphalt Concrete. J. Chang. Univ. 2010, 30, 11–16. [Google Scholar]

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C78-09; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2009.

- Aashto T324 19 | PDF. Available online: https://www.scribd.com/document/773316129/AASHTO-T324-19 (accessed on 3 September 2025).

- AASHTO T 321 Determining the Fatigue Life of Asphalt Mixture Using Flexural Bending Beam. | PDF | Fatigue (Material) | Beam (Structure). Available online: https://www.scribd.com/document/515690169/AASHTO-T-321-Determining-the-Fatigue-Life-of-Asphalt-Mixture-Using-Flexural-Bending-Beam (accessed on 3 September 2025).

- Aashto T 283 | PDF | Asphalt | Road Surface. Available online: https://www.scribd.com/document/483798958/AASHTO-T-283 (accessed on 3 September 2025).

- Dugan, C.R.; Sumter, C.R.; Rani, S.; Ali, S.A.; O’Rear, E.A.; Zaman, M. Rheology of Virgin Asphalt Binder Combined with High Percentages of RAP Binder Rejuvenated with Waste Vegetable Oil. ACS Omega 2020, 5, 15791–15798. [Google Scholar] [CrossRef] [PubMed]

- Karami, M. Application of the Cementitious Grouts on Stability and Durability of Semi Flexible Bituminous Mixtures. In Proceedings of the 3RD International Conference on Construction and Building Engineering (ICONBUILD), Palembang, Indonesia, 14–17 August 2017. Volume 1903. [Google Scholar]

| Sieve Size (mm) | Blended Gradation (% Passing) | Specification Limits (% Passing) |

|---|---|---|

| 19.0 | 100 | 100 |

| 12.5 | 95 | 90–100 |

| 9.5 | 65 | 55–75 |

| 4.75 | 18 | 10–25 |

| 2.36 | 8 | 5–10 |

| 0.075 | 3 | 2–4 |

| Property | Fresh Aggregate | RAP | Test Method |

|---|---|---|---|

| Specific Gravity (Bulk, g/cm3) | 2.65 | 2.58 | ASTM C127 [36] |

| Water Absorption (%) | 0.8 | 1.5 | ASTM C127 [36] |

| Aged Binder Content (%) | --- | 3.7 | AASHTO T164 [35] |

| Property | Virgin Binder PG (58-28) | Recovered RAP Binder | Test Method |

|---|---|---|---|

| Penetration @ 25 °C (0.1 mm) | 75 | 21.5 | AASHTO T49 [37] |

| Viscosity @ 135 °C (Pa·s) | 0.45 | 0.83 | AASHTO T316 [38] |

| DSR (G∗/sinδ) at 64 °C (kPa) | 2.1 | 4.8 | AASHTO T 315 [39] |

| Softening Point (°C) | 48.0 | 72.2 | AASHTO T53 [40] |

| Grout Type | Portland Cement (%) | Class F Fly Ash (%) | Micro-Silica (%) | w/c Ratio | Special Additives |

|---|---|---|---|---|---|

| G1 | 70 | 30 | 0 | 0.50 | None |

| G2 | 65 | 30 | 5 | 0.45 | None |

| G3 | 60 | 30 | 10 | 0.45 | Proprietary Blend |

| G4 | 75 | 25 | 0 | 0.50 | None |

| Factor | Levels | Conditions Applied |

|---|---|---|

| RAP Content (%) | 0, 25, 50, 75, 100 | All levels |

| Rejuvenator | No (NJ), Yes (J) | NJ for R0; NJ and J for R25, R50, R75, and R100 |

| Grout Type | G1, G2, G3, G4 | All combinations |

| Mix Category | Total Binder Content (%) | Added Virgin Binder (%) | N_Design Gyrations |

|---|---|---|---|

| R0 | 4.0 | 4.00 | 53 |

| R25 | 4.0 | 3.08 | 59 |

| R50 | 4.0 | 2.15 | 68 |

| R75 | 4.0 | 1.23 | 73 |

| R100 | 4.0 | 0.30 | 97 |

| Test | Test Standard | Specimen Type |

|---|---|---|

| Compressive Strength | ASTM C39 [44] | Cylindrical (100 mm × 200 mm) |

| Flexural Strength | ASTM C78 [45] | Beam (75 mm × 75 mm × 300 mm) |

| Rutting Resistance | AASHTO T324 [46] | Slab (300 mm × 300 mm × 50 mm) |

| Fatigue | AASHTO T321 [47] | Beam (75 mm × 75 mm × 300 mm) |

| Moisture Sensitivity | AASHTO T283 [48] | Cylindrical (100 mm × 200 mm) |

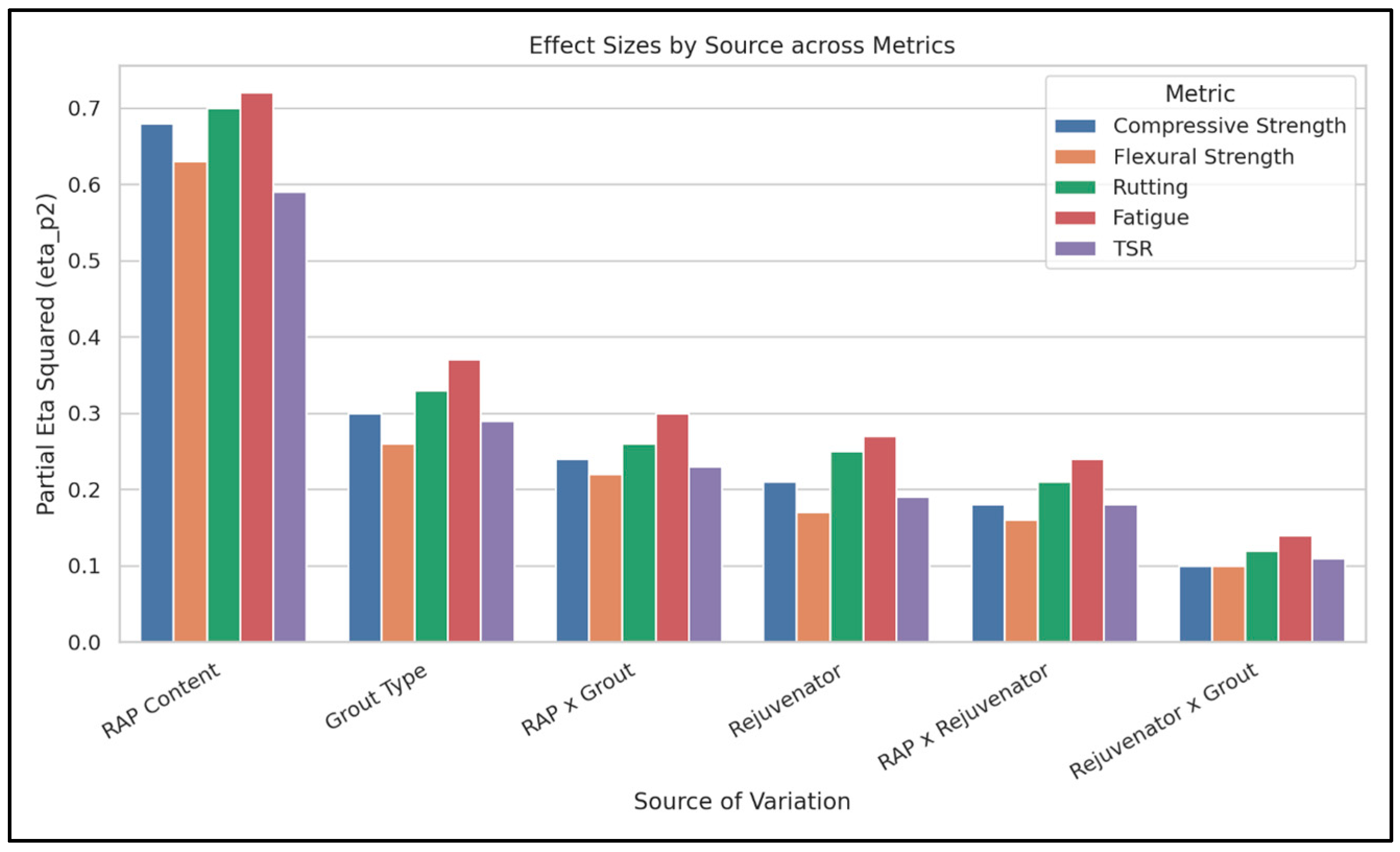

| Source of Variation | DF | Compressive Strength (F, p, ηp2) | Flexural Strength (F, p, ηp2) | Rutting (F, p, ηp2) | Fatigue (F, p, ηp2) | TSR (F, p, ηp2) |

|---|---|---|---|---|---|---|

| RAP Content | 4 | 58.21, <0.001, 0.68 | 45.18, <0.001, 0.63 | 62.55, <0.001, 0.70 | 71.30, <0.001, 0.72 | 38.76, <0.001, 0.59 |

| Rejuvenator | 1 | 28.93, <0.001, 0.21 | 22.70, <0.001, 0.17 | 35.12, <0.001, 0.25 | 40.88, <0.001, 0.27 | 25.41, <0.001, 0.19 |

| Grout Type | 3 | 15.67, <0.001, 0.30 | 12.89, <0.001, 0.26 | 18.03, <0.001, 0.33 | 21.50, <0.001, 0.37 | 14.92, <0.001, 0.29 |

| RAP × Rejuvenator | 4 | 6.12, 0.001, 0.18 | 5.01, 0.003, 0.16 | 7.28, <0.001, 0.21 | 8.55, <0.001, 0.24 | 5.89, 0.001, 0.18 |

| RAP × Grout | 12 | 2.88, 0.008, 0.24 | 2.51, 0.015, 0.22 | 3.15, 0.005, 0.26 | 3.80, 0.001, 0.30 | 2.75, 0.010, 0.23 |

| Rej. × Grout | 3 | 4.50, 0.008, 0.10 | 3.95, 0.015, 0.10 | 5.10, 0.004, 0.12 | 5.90, 0.002, 0.14 | 4.25, 0.011, 0.11 |

| Residuals | 108 | - | - | - | - | - |

| Performance Parameter | Regression Model (R2) | Pearson Correlation Coefficient (r) | p-Value |

|---|---|---|---|

| Compressive Strength | 0.75 | −0.87 | <0.001 |

| Flexural Strength | 0.70 | −0.84 | <0.001 |

| Rutting Resistance | 0.78 | −0.88 | <0.001 |

| Fatigue | 0.82 | −0.90 | <0.001 |

| Moisture Sensitivity | 0.68 | −0.82 | <0.001 |

| Comparison | Mean Difference | Std. Error | Adjusted p-Value | 95% Confidence Interval |

|---|---|---|---|---|

| G3 vs. G1 | 4.55 | 0.89 | <0.001 | [2.79, 6.31] |

| G3 vs. G2 | 2.80 | 0.89 | 0.008 | [1.04, 4.56] |

| G3 vs. G4 | 2.15 | 0.89 | 0.045 | [0.39, 3.91] |

| G4 vs. G1 | 2.40 | 0.89 | 0.021 | [0.64, 4.16] |

| G4 vs. G2 | 0.65 | 0.89 | 0.889 | [−1.11, 2.41] |

| G2 vs. G1 | 1.75 | 0.89 | 0.152 | [−0.01, 3.51] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Memon, N.A.; Jatoi, G.H.; Loprencipe, G.; Moretti, L.; Md. Yusoff, N.I. Performance of Sustainable Semi-Rigid Pavements: Optimizing High-Content Reclaimed Asphalt Pavement with Rejuvenators and Novel Grout Formulations. Materials 2025, 18, 4840. https://doi.org/10.3390/ma18214840

Memon NA, Jatoi GH, Loprencipe G, Moretti L, Md. Yusoff NI. Performance of Sustainable Semi-Rigid Pavements: Optimizing High-Content Reclaimed Asphalt Pavement with Rejuvenators and Novel Grout Formulations. Materials. 2025; 18(21):4840. https://doi.org/10.3390/ma18214840

Chicago/Turabian StyleMemon, Naeem Aziz, Gulzar Hussain Jatoi, Giuseppe Loprencipe, Laura Moretti, and Nur Izzi Md. Yusoff. 2025. "Performance of Sustainable Semi-Rigid Pavements: Optimizing High-Content Reclaimed Asphalt Pavement with Rejuvenators and Novel Grout Formulations" Materials 18, no. 21: 4840. https://doi.org/10.3390/ma18214840

APA StyleMemon, N. A., Jatoi, G. H., Loprencipe, G., Moretti, L., & Md. Yusoff, N. I. (2025). Performance of Sustainable Semi-Rigid Pavements: Optimizing High-Content Reclaimed Asphalt Pavement with Rejuvenators and Novel Grout Formulations. Materials, 18(21), 4840. https://doi.org/10.3390/ma18214840