Analysis of the Fiber Residues Unearthed from the Dabuzi Han Tomb in Xi’an, Shaanxi

Abstract

1. Introduction

2. Materials and Methods

2.1. Sampling

2.2. Instrumental Analysis

2.2.1. Morphological Observation

- (1)

- Ultra-Depth Microscopy Observation

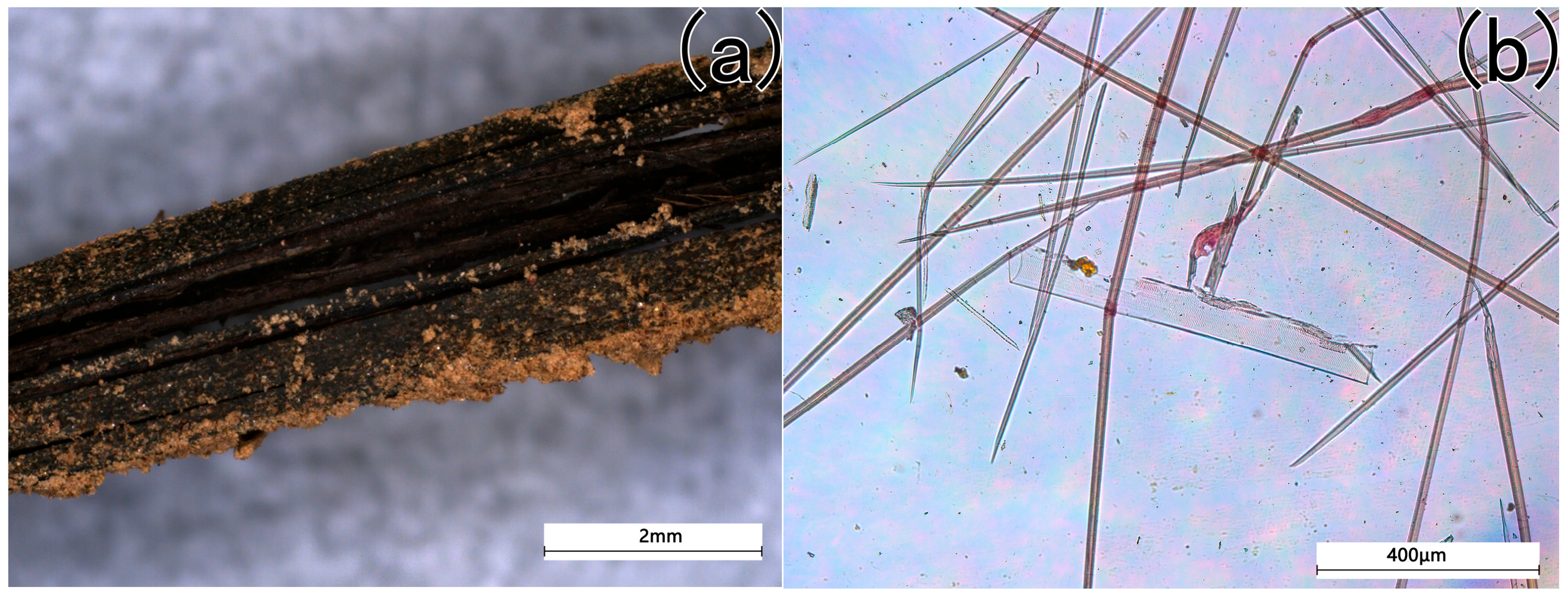

- Portions of the yellow-green fibrous sheet and individual black-brown fibers were extracted and examined under a Zeiss Smartzoom 5 ultra-depth microscope (Germany, Oberkochen, Zeiss). Microscopic images were captured at magnifications of 50×, 100×, 200×, and 300×.

- (2)

- Biological Microscopy Observation

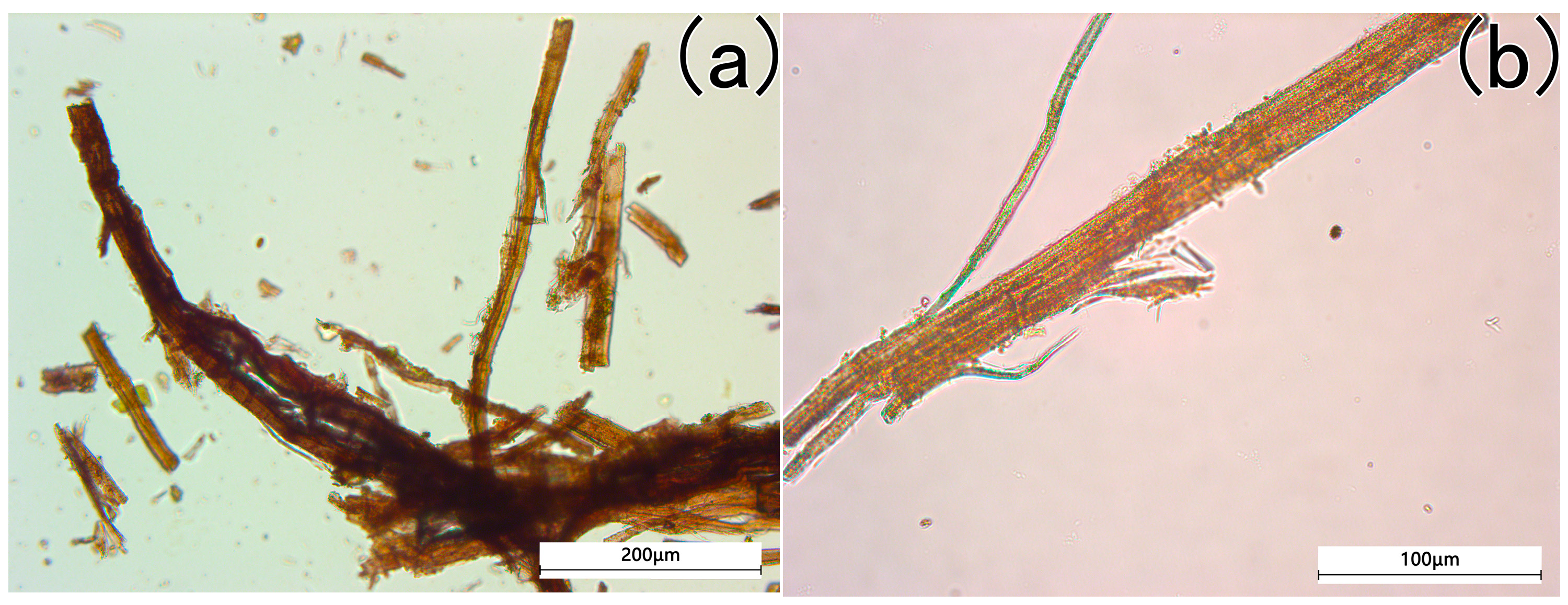

- Following the GB/T 4688-2002 standard [10], small quantities of the two aforementioned samples were placed in stoppered test tubes. A hydrogen peroxide–glacial acetic acid solution (1:1 by volume) was added, and the mixture was incubated in a 60 °C water bath for 24 h. The samples were then filtered through a 300-mesh chemical fiber bag and rinsed. A small amount of the treated sample was placed on a glass slide, stained with 1–2 drops of dye, and evenly dispersed using a dissecting needle. A coverslip was applied, and excess dye was gently absorbed by tilting the slide and using absorbent paper. Observations and imaging were performed under a Leica DM4000B biological microscope (Germany, Wetzlar, Leica Microsystems).

- (3)

- SEM-EDS Observation and Analysis

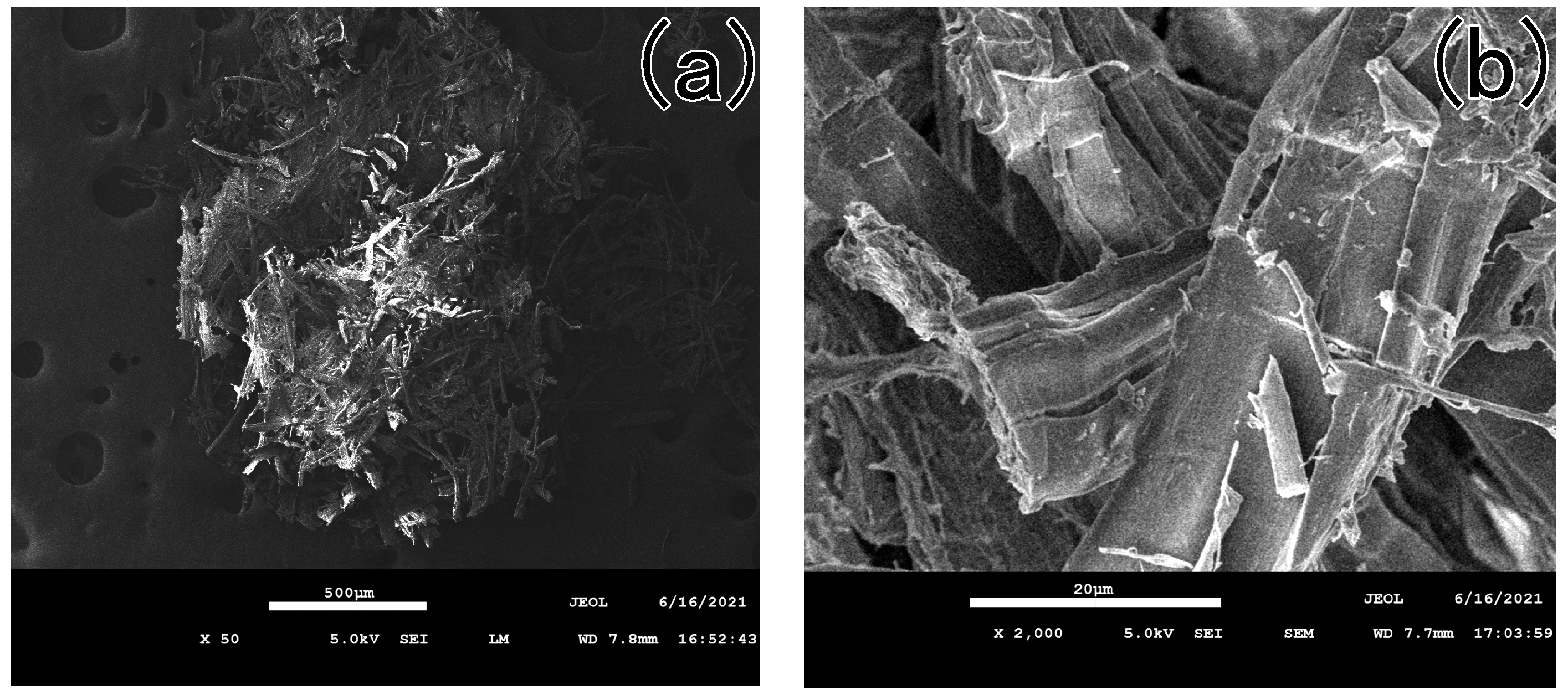

- The structural features of the yellow-green fibers were examined using a JEOL JSM-7500F field-emission scanning electron microscope (Japan, Tokyo, JEOL Ltd.) with a X-Max 50 EDS (England, Oxford, Oxford Instruments). SEM testing conditions included sample coating: ~10 nm of 99.99% gold; accelerating voltage: 5 kV; beam current: 1 × 10−10 A; and working distance: 8 mm. EDS testing conditions were as follows: accelerating voltage: 15 kV; beam current: 3 × 10−10 A; and working distance: 8 mm.

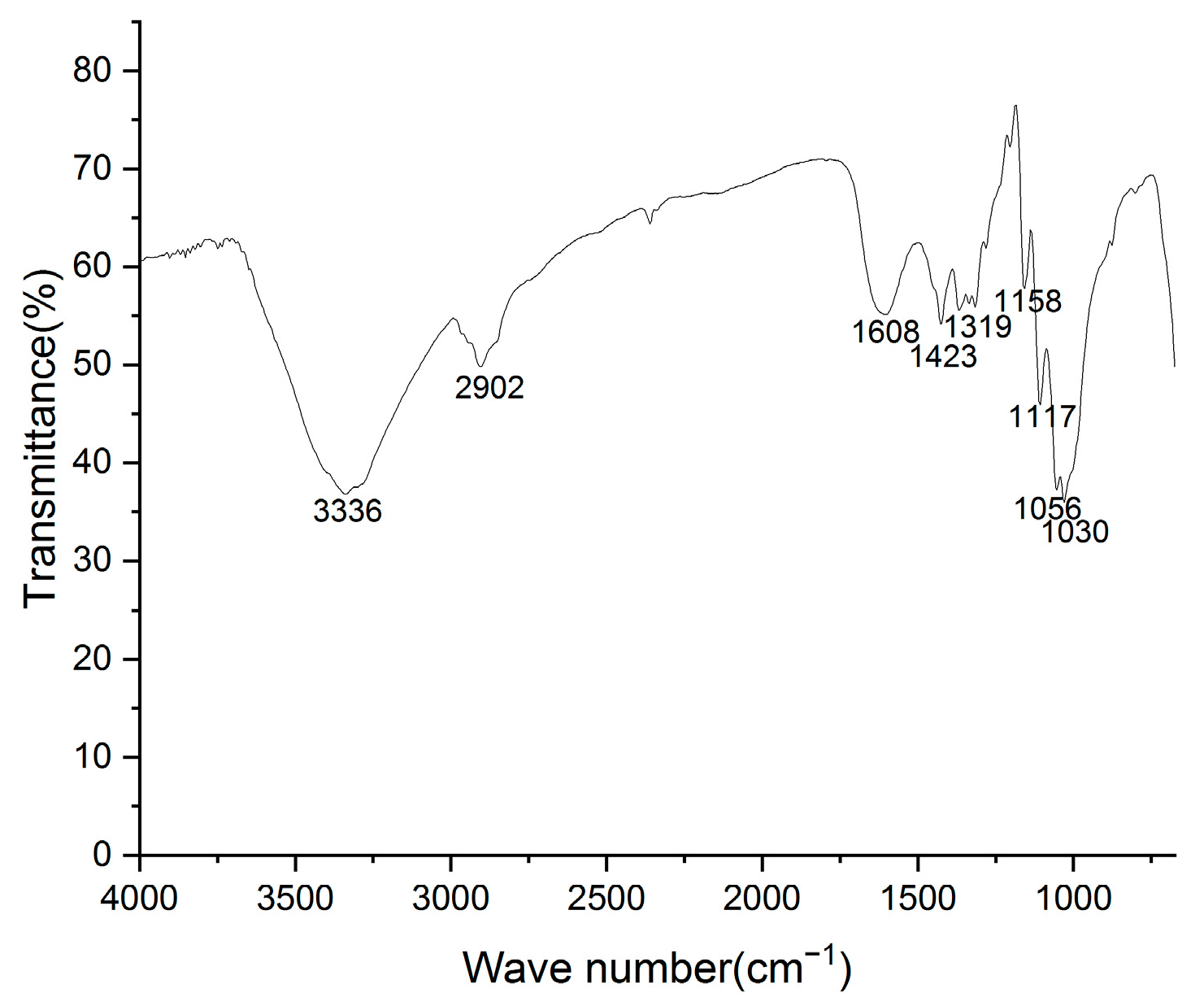

2.2.2. FTIR Analysis

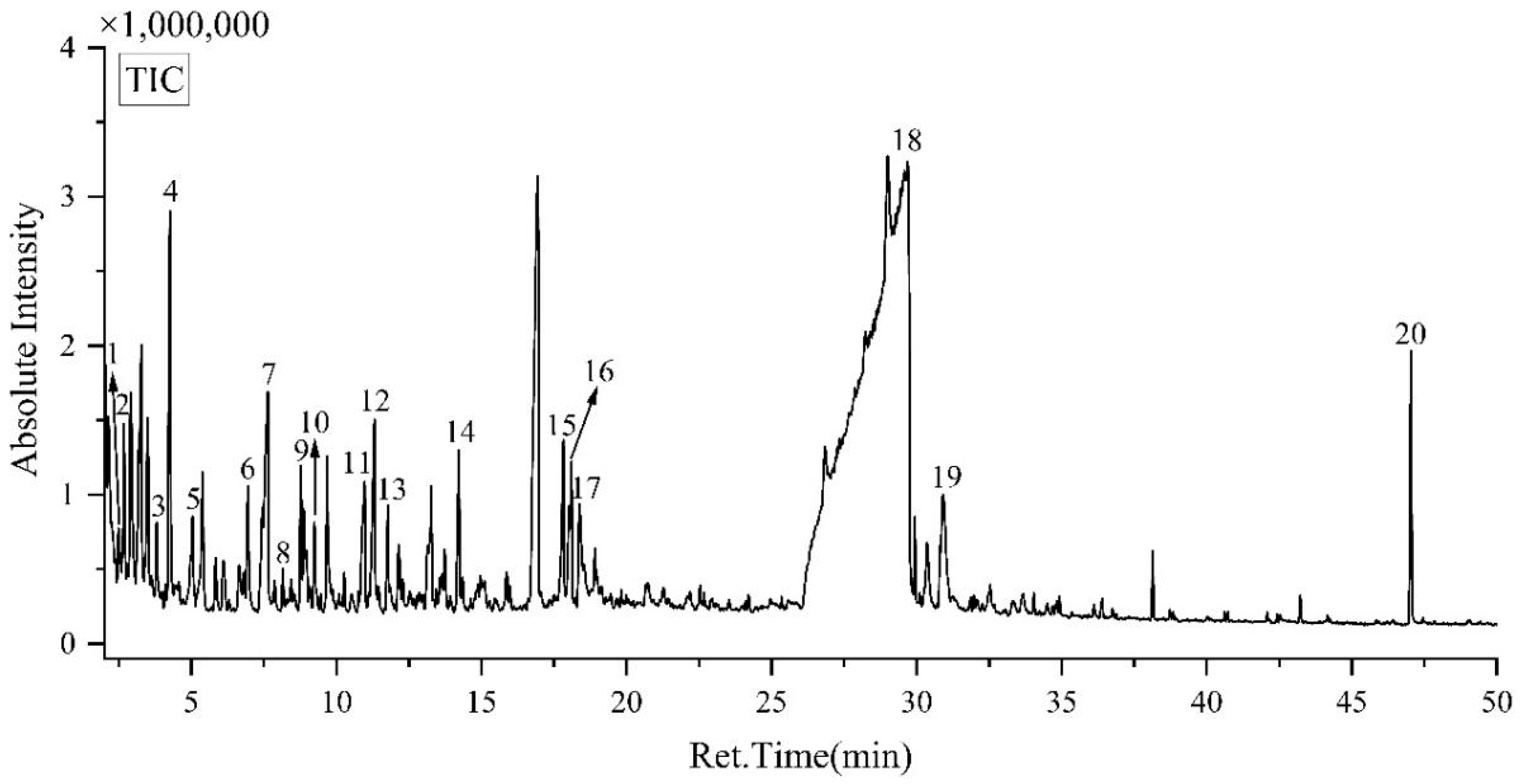

2.2.3. Py-GC/MS Analysis

3. Results and Discussion

3.1. Morphological Observation Analysis

3.2. FTIR Discussion

3.3. Pyrolysis Gas Chromatography–Mass Spectrometry (Py-GC/MS) Analysis

3.4. Discussion of the Sample

4. Conclusions

- (1)

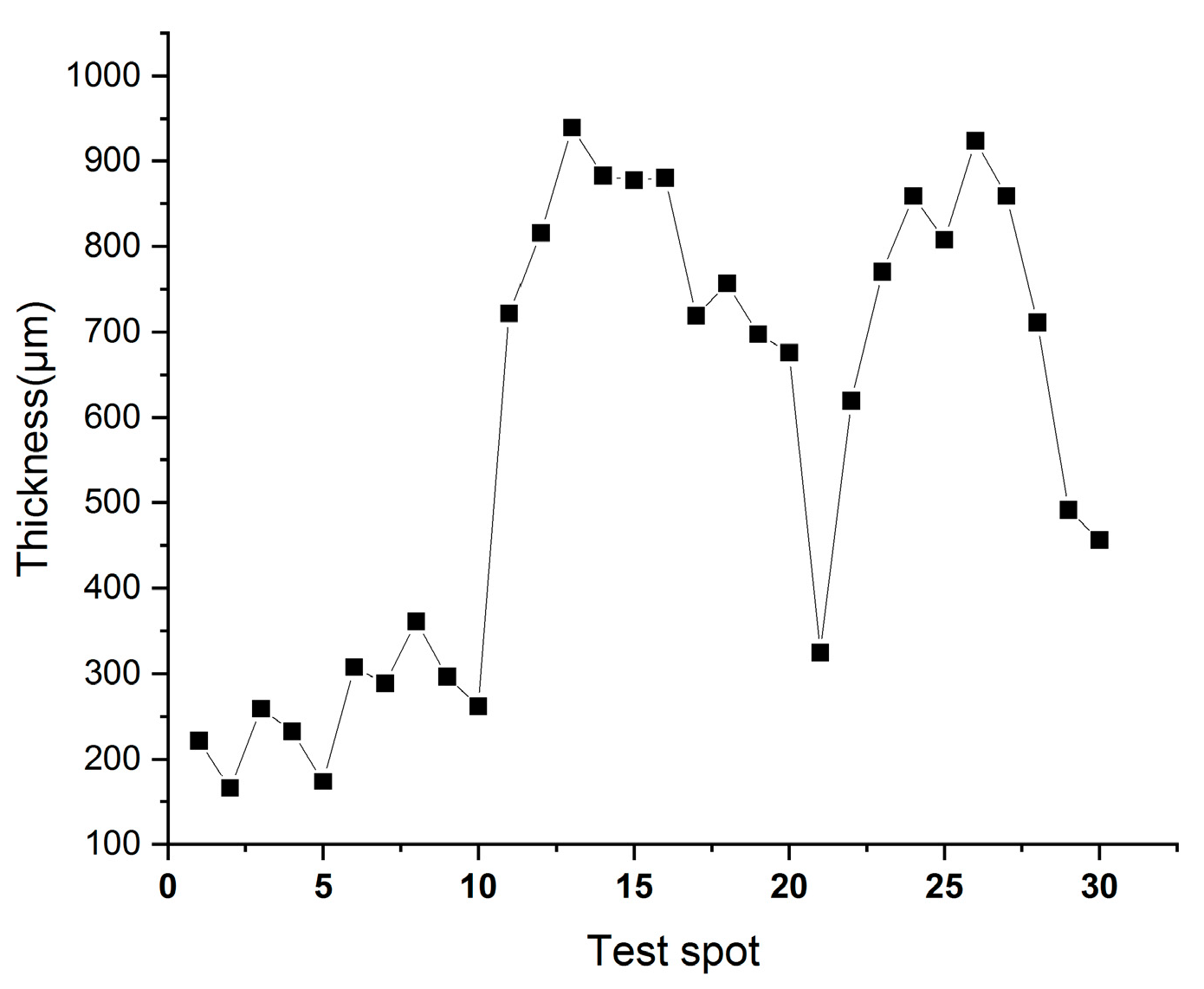

- Combined observations of ultra-depth microscopy, biological microscopy, and scanning electron microscopy revealed that the yellowish-green sheet unearthed from the Han Dynasty tomb at Dabuzi, Xi’an, Shaanxi Province exhibited a rough surface with randomly distributed fibers, showing evidence of shearing and slight fibrillation, which are clear indications of manual beating and cutting processes during production. Its considerable and uneven thickness, along with the absence of screen marks on the surface, are characteristic features consistent with the fixed-mold paper-making technique.

- (2)

- Microscopic examination identified distinct transverse nodes on some fiber cell walls, along with longitudinal striations characteristic of either ramie or hemp fibers. With an average fiber diameter of 20.71 μm, the material was most probably hemp (Cannabis sativa). Complementary analyses using FTIR and Py-GC/MS confirmed cellulose, hemicellulose, and lignin, as the principal components of the paper.

- (3)

- Comprehensive analysis led to the preliminary conclusion that this yellowish-green fibrous sheet represented hemp paper residue manufactured by the fixed-mold making method. Dating based on the tomb’s chronology placed it in the Western Han Dynasty (206 BCE-9 CE). The absence of surface inscriptions suggested its primary function was wrapping material for bronze mirrors. This discovery and its subsequent study hold significant implications for understanding the origins and developmental trajectory of ancient paper-making technology.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cao, X.J. Application of modern analysis and detecting technology in the research of paper cultural relics protection. Pap. Papermak. 2022, 41, 25. [Google Scholar]

- Yao, J.J.; Yan, Y.E.; Zhang, R.H.; Luo, C.; Liu, J.; Bi, N.; Tang, Y. Spectroscopic detection and analysis for micro structure of aged traditional handmade paper. Spectrosc. Spectr. Anal. 2021, 41, 1559. [Google Scholar]

- Qu, Y.J.; Gu, A.; Zhao, L.H.; Lei, Y. Research on microscopic non-destructive in-situ analysis methods for paper-based cultural relics. China Cult. Herit. Sci. Res. 2023, 2, 73. [Google Scholar]

- Zhang, J.F.; Xin, M.M.; Wen, X.D.; Zhang, Q.W. Non-destructive and micro-destructive analysis technologies for paper cultural relics and review on their applications. Sci. Conserv. Archaeol. 2024, 36, 180–188. [Google Scholar]

- Wang, K.Q.; Zhang, P.; Zhou, Y.; Cha, R.T. Research progress of spectroscopy in scientific analysis of paper cultural relics. Trans. China Pulp Pap. 2023, 28, 120–126. [Google Scholar]

- Yan, C.S.; Huang, C.; Han, S.T.; Han, X.L.; Ying, C.N.; Du, Y.D. Review on scientific detection technologies for ancient paper relics. Chin. Opt. 2020, 13, 936–964. [Google Scholar] [CrossRef]

- Han, B.; Niang, J.J.; Rao, H.Y.; Lyu, N.N.; Oda, H.; Sakamoto, S.; Yang, Y.M.; Sablier, M. Paper fragments from the Tibetan Samye Monastery: Clues for an unusual sizing recipe implying wheat starch and milk in early Tibetan papermaking. J. Archaeol. Sci. Rep. 2021, 36, 102793. [Google Scholar] [CrossRef]

- Ortiz-Herrero, L.; Blanco, M.E.; Garcia-Ruiz, C.; Bartolome, L. Direct and indirect approaches based on paper analysis by Py-GC/MS for estimating the age of documents. J. Anal. Appl. Pyrolysis 2018, 131, 9–16. [Google Scholar] [CrossRef]

- Hassan, R.R.A.; Ali, M.F.; Fahmy, A.G.A.; Ali, H.M.; Salem, M.Z.M. Documentation and evaluation of an ancient paper manuscript with leather binding using spectrometric methods. J. Chem. 2020, 2020, 6847910. [Google Scholar] [CrossRef]

- GB/T 4688-2002; Paper, Board and Pulps-Analysis of Fiber Furni. Standards Press of China: Beijing, China, 2002.

- National Institute of Standards and Technology (NIST). *NIST/EPA/NIH Mass Spectral Library (NIST17)* and NIST Tandem Mass Spectral Library (NIST17s). Standard Reference Data Program. 2017. Available online: https://www.nist.gov/programs-projects/nist-standard-reference-database-1a-v23 (accessed on 2 June 2025).

- Rusch, F.; Hillig, E.; Paula, E.A.D.; Melo, R.R.; Pimenta, A.S. Typological classification of bamboo: From the advent of microscopy to artificial intelligence. Pesqui. Agropecu. Trop. 2025, 55, e81998. [Google Scholar] [CrossRef]

- Gong, D.C.; Yang, T.Y.; Li, X.C. Research on the production process and filler composition of Xuanquan paper in Dunhuang, Gansu. Cult. Relics 2014, 9, 85–90. [Google Scholar]

- Li, X.C.; Wang, H.; He, C.H. The Era and relevant problems on ancient paper unearthed in Xuanquan Site, Gansu. Stud. Hist. Nat. Sci. 2012, 31, 277. [Google Scholar]

- Zhao, X.X.; Wang, Y.M.; Zhang, S.Q.; Huang, H.G.; Huang, J.P. Research on identification of flax, ramie and hemp Fiber. China Fiber Insp. 2010, 15, 65–67. [Google Scholar]

- Yan, H.N.; Zhao, F.; Xing, M.Y.; Wu, Z.Y. Research on identification of two historical hemp fibers. J. Zhejiang Sci-Tech Univ. (Nat. Sci.) 2017, 37, 185–189. [Google Scholar]

- Lv, S.X. A Study on the non-destructive method of identifying Chinese traditional handmade paper with attenuated total reflection fourier transform infrared spectroscopy. Spectrosc. Spectr. Anal. 2024, 44, 2450–2458. [Google Scholar]

- Ge, M.F.; Han, B.; Shi, J.T.; Shi, J.L.; Yang, Y.M. Pyrolysis Characterization of Nepalese Handmade Paper. Chin. Papermak. Tech. 2024, 43, 12–18. [Google Scholar]

- Zhao, H.S. Technology and Science in Chinese History—From Ancient Times to the Present Day; People’s University of China Press: Beijing, China, 1997. [Google Scholar]

- Liu, R.Q.; Hu, Y.X. Preliminary study of ancient paper in China. Cult. Relics 1976, 5, 74. [Google Scholar]

- Li, X.C. Preliminary study of Han Dynasty paper unearthed in Fufeng, Shaanxi. Cult. Relics 2012, 7, 93. [Google Scholar]

- Li, X.C. Study on the unearthed ancient paper from Xuanquan Site of Han Dynasty in Gansu. J. Guangxi Minzu Univ. (Nat. Sci. Ed.) 2010, 16, 7. [Google Scholar]

- Li, X.C. The Investigation and analysis of ancient paper of West-Han dynasty. J. Guangxi Minzu Univ. (Nat. Sci. Ed.) 2009, 15, 59. [Google Scholar]

- Li, X.C. Fixed-Mould Paper Making Method, 3rd ed.; Encyclopedia of China: Beijing, China, 2024. [Google Scholar]

- Li, X.C. Fixed-mould papermaking method and movable-mould papermaking method: Two different papermaking method systems conserved in mainland China. J. Dialectics Nat. 2011, 33, 76. [Google Scholar]

- Li, X.C.; Wang, S. The application of ethnic investigation in archaeology. J. Guangxi Minzu Univ. (Philos. Soc. Sci. Ed.) 2018, 40, 10. [Google Scholar]

- Yang, D.C.; Yang, W. On the years of the invention of Chinese paper and its technological improvements. J. Hunan City Univ. 2003, 2, 79. [Google Scholar]

| Element | wt.% |

|---|---|

| C | 18.47 |

| O | 33.35 |

| Al | 2.58 |

| P | 4.14 |

| Cu | 41.47 |

| Total | 100.00 |

| No. | Retention Time (min) | Peak Area (%) | Compounds |

|---|---|---|---|

| 1 | 2.48 | 0.41 | 2,3-Dihydro-3-methylfuran |

| 2 | 2.67 | 0.87 | 2-methylfuran |

| 3 | 3.80 | 0.41 | furfural |

| 4 | 4.26 | 2.71 | furfural |

| 5 | 5.04 | 0.44 | 2-butanone |

| 6 | 6.95 | 0.86 | 2(5H)-Furanone |

| 7 | 7.64 | 2.68 | 2-methylcyclopentanone |

| 8 | 8.15 | 0.21 | 3-Methyl-2,5-furandione |

| 9 | 8.77 | 0.86 | 5-methyl-2-furanyl-ethanone |

| 10 | 9.24 | 0.42 | 3-Methyl-2,5-furandione |

| 11 | 10.97 | 1.44 | 2-Hydroxy-3-methyl-2-cyclopenten-1-ketone |

| 12 | 11.31 | 1.7 | 3-methyl-1,2-cyclopentanedione |

| 13 | 11.77 | 0.53 | 4-Methyl-5H-furan-2-ketone |

| 14 | 14.22 | 1.08 | maltol |

| 15 | 17.82 | 1.01 | 1,4:3,6-Dihydro-α-d-glucopyranose |

| 16 | 18.02 | 1.34 | 2,3-dehydro-d-galactose |

| 17 | 18.38 | 0.84 | 5-Hydroxymethylfurfural |

| 18 | 29.00 | 78.86 | 1,6-dehydro-β-D-glucopyranose |

| 19 | 30.90 | 1.78 | 1,6-dehydro-β-D-glucopyranose |

| 20 | 47.04 | 1.55 | 2-((2H-benzotriazole)-2-yl)-4-(1,1,3,3-tetramethylbutyl) phenol |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Z.; Zhu, Y.; Shao, J.; Hou, X.; Cui, M.; Zhang, B.; Li, J.; Xia, Q. Analysis of the Fiber Residues Unearthed from the Dabuzi Han Tomb in Xi’an, Shaanxi. Materials 2025, 18, 4812. https://doi.org/10.3390/ma18204812

Ma Z, Zhu Y, Shao J, Hou X, Cui M, Zhang B, Li J, Xia Q. Analysis of the Fiber Residues Unearthed from the Dabuzi Han Tomb in Xi’an, Shaanxi. Materials. 2025; 18(20):4812. https://doi.org/10.3390/ma18204812

Chicago/Turabian StyleMa, Zhenzhen, Yingpei Zhu, Jing Shao, Xianting Hou, Menghe Cui, Bei Zhang, Jianxi Li, and Qixing Xia. 2025. "Analysis of the Fiber Residues Unearthed from the Dabuzi Han Tomb in Xi’an, Shaanxi" Materials 18, no. 20: 4812. https://doi.org/10.3390/ma18204812

APA StyleMa, Z., Zhu, Y., Shao, J., Hou, X., Cui, M., Zhang, B., Li, J., & Xia, Q. (2025). Analysis of the Fiber Residues Unearthed from the Dabuzi Han Tomb in Xi’an, Shaanxi. Materials, 18(20), 4812. https://doi.org/10.3390/ma18204812