Numerical Investigation on Effect of Chamfering on Mechanical Behaviors in Continuous Network Composite

Abstract

1. Introduction

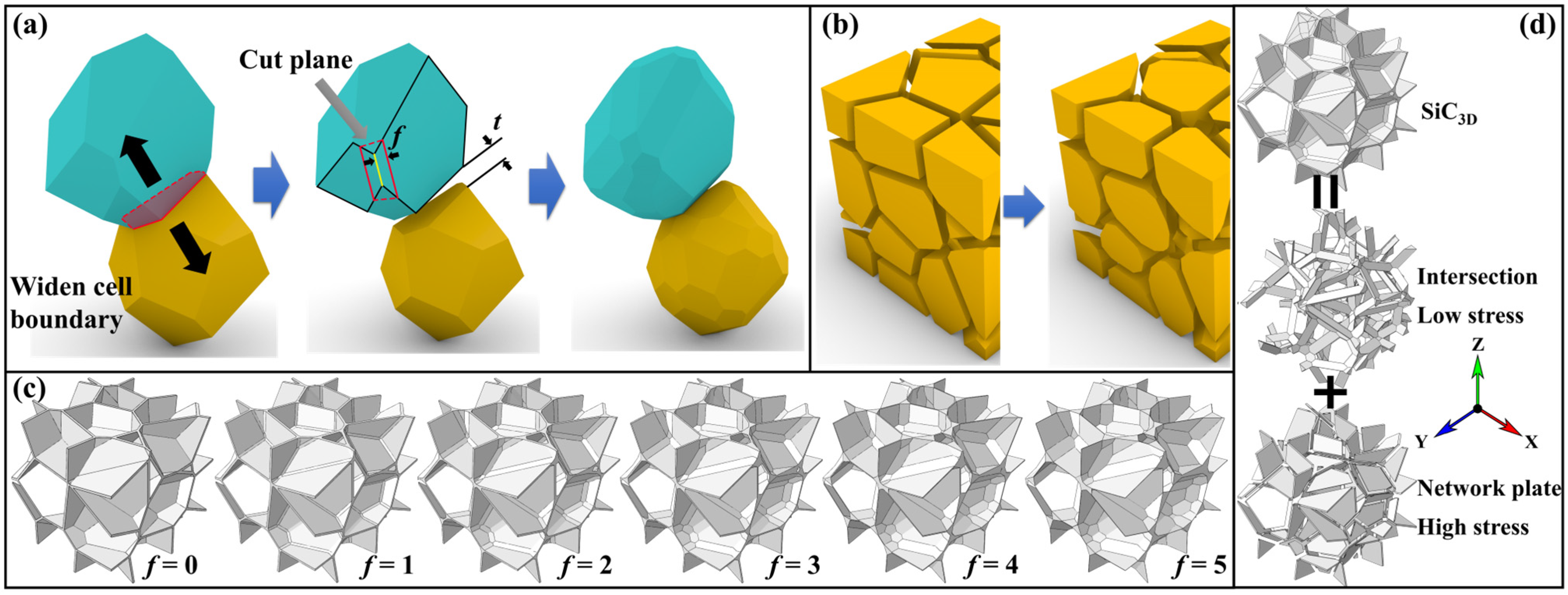

2. Establishment of FEM Models

2.1. Geometrical Modeling Method

2.2. Material Properties

2.3. Boundary Conditions

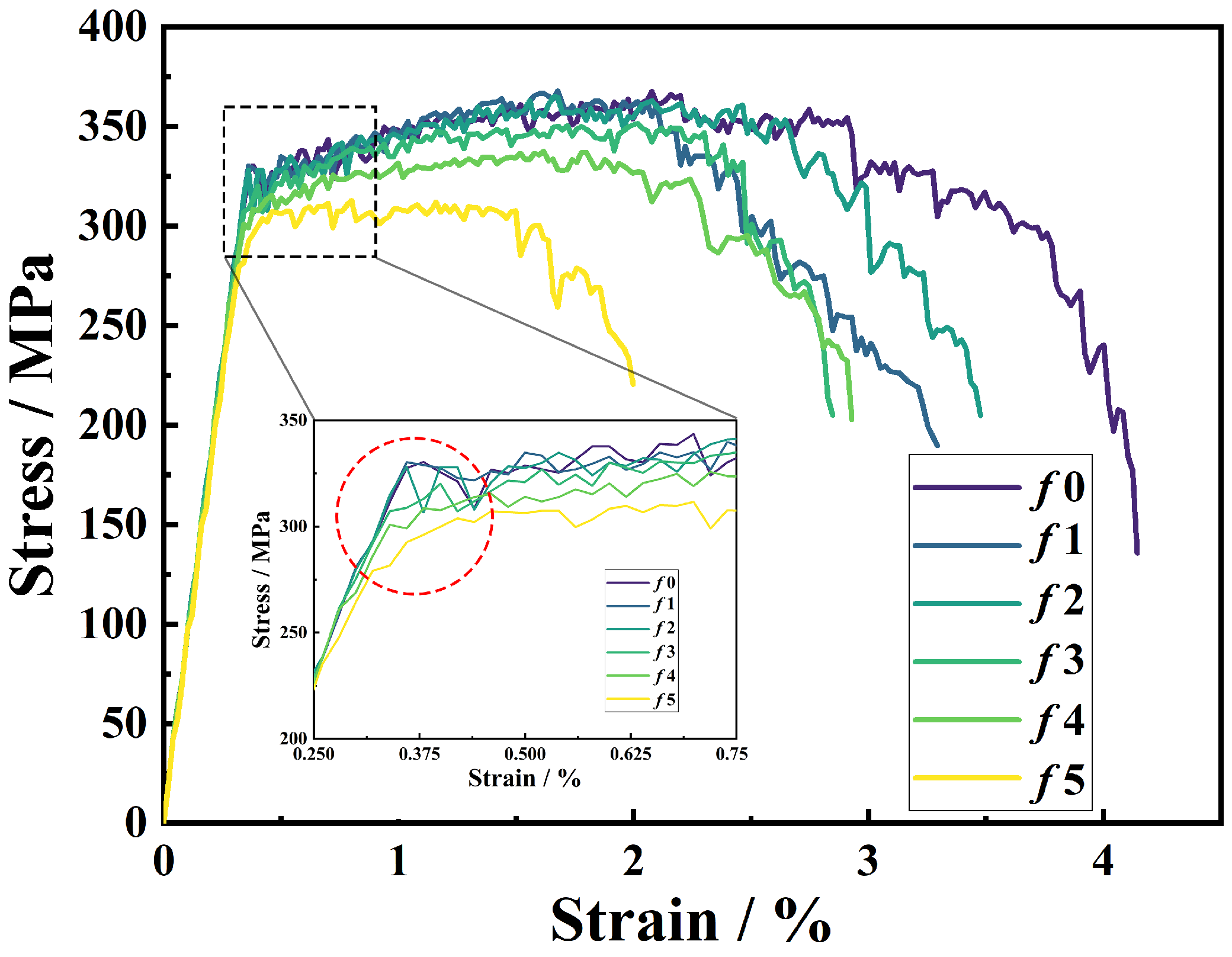

3. Results and Discussion

3.1. Tensile Properties of Composites with Network Architecture

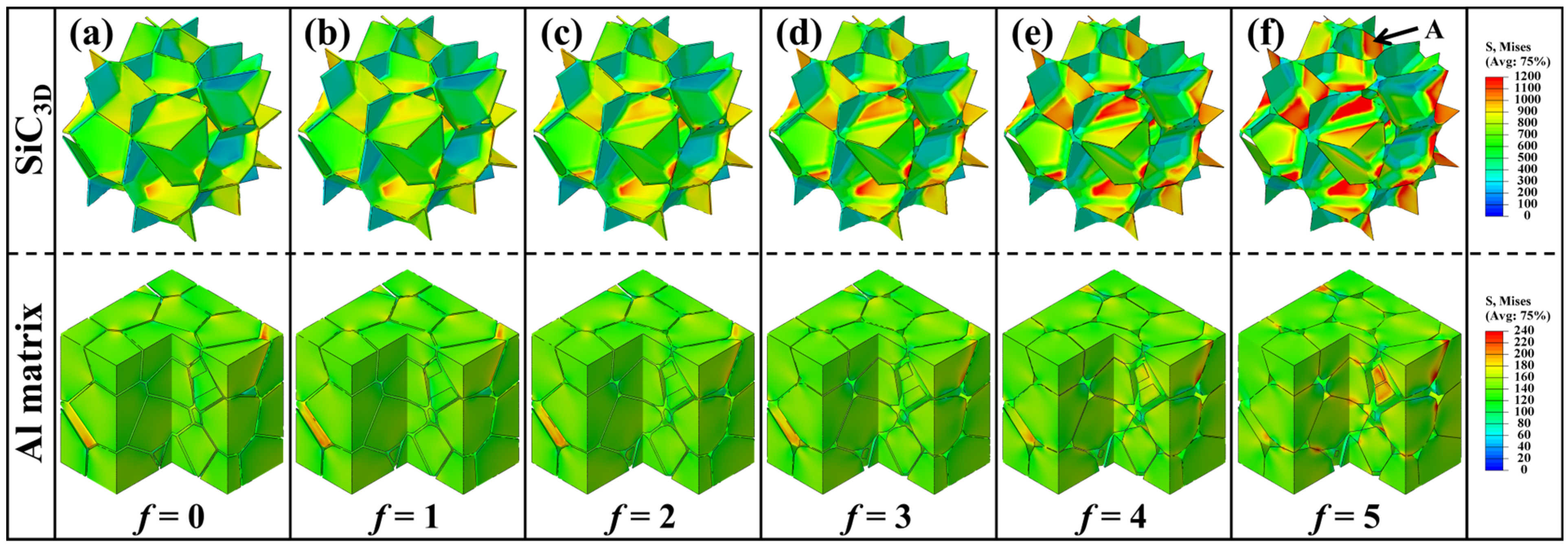

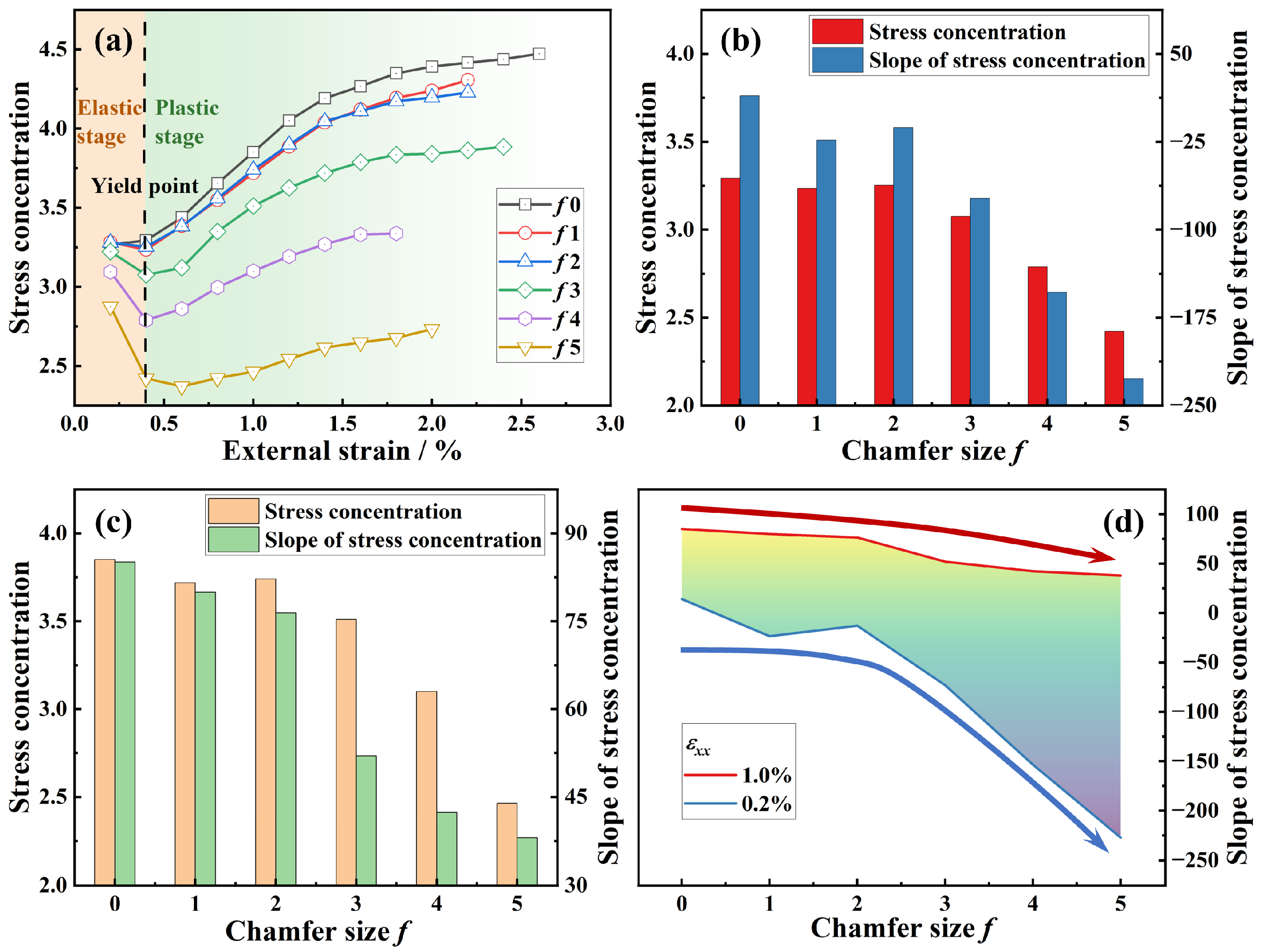

3.2. Load-Bearing Capacity of SiC3D

3.3. Damage Behavior of SiC3D/Al with Network Architecture

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, P.; Cui, Y.A.; Li, J.Y.; Liu, J.X. Theoretical model for the elastic properties of cracked fluid-saturated rocks considering the crack connectivity. Geophys. J. Int. 2024, 239, 1203–1216. [Google Scholar] [CrossRef]

- Samson, S.; Tran, P.; Marzocca, P. Design and modelling of porous gyroid heatsinks: Influences of cell size, porosity and material variation. Appl. Therm. Eng. 2023, 235, 121296. [Google Scholar] [CrossRef]

- Mu, Y.L.; Yao, G.C.; Luo, H.J. Anisotropic damping behavior of closed-cell aluminum foam. Mater. Des. 2010, 31, 610–612. [Google Scholar] [CrossRef]

- Islam, M.A.; Kader, M.A.; Hazell, P.J.; Escobedo, J.P.; Brown, A.D.; Saadatfar, M. Effects of impactor shape on the deformation and energy absorption of closed cell aluminium foams under low velocity impact. Mater. Des. 2020, 191, 108599. [Google Scholar] [CrossRef]

- Huang, B.; Miao, Q.; Zuo, X.Q.; Yi, J.H.; Zhou, Y.; Chen, S. Sound absorption performance and mechanism of aluminum foams with double main pore-porous cell wall structure. Adv. Eng. Mater. 2023, 25, 2300419. [Google Scholar] [CrossRef]

- Islam, M.A.; Kader, M.A.; Escobedo, J.P. Dynamic perforation behavior of closed-cell aluminium foams and foam core sandwich panels with various shaped projectile tips. Mech. Res. Commun. 2025, 148, 104472. [Google Scholar] [CrossRef]

- Karthikeyan, M. A short review of bio-inspired structures prepared using additive manufacturing for energy absorption applications. Prog. Addit. Manuf. 2025, 10, 5813–5828. [Google Scholar] [CrossRef]

- Stephen, D. TPMS-based metamaterials with tuneable elastic anisotropy and mechanical coupling. Mater. Des. 2025, 253, 113866. [Google Scholar] [CrossRef]

- Ding, J.H.; Ma, Q.P.; Li, X.W.; Zhang, L.; Yang, H.; Qu, S.; Wang, M.Y.; Zhai, W.; Gao, H.J.; Song, X. Imperfection-Enabled Strengthening of Ultra-Lightweight Lattice Materials. Adv. Sci. 2024, 11, 2402727. [Google Scholar] [CrossRef]

- Huang, L.J.; Wang, S.; Dong, Y.S.; Zhang, Y.Z.; Pan, F.; Geng, L.; Peng, H.X. Tailoring a novel network reinforcement architecture exploiting superior tensile properties of in situ TiBw/Ti composites. Mater. Sci. Eng. A 2012, 545, 187–193. [Google Scholar] [CrossRef]

- Gao, X.; Peng, M.Y.; Zhang, X.X.; Qian, M.F.; Li, A.B.; Geng, L.; Wang, H.; Peng, H.X. Profound strengthening and toughening effect of reinforcement aspect ratio in composite with network architecture. J. Alloys Compd. 2023, 931, 167444. [Google Scholar] [CrossRef]

- Yu, J.S.; Zhao, Y.Q.; Zhao, Q.Y.; Zhang, W.; Huo, W.T.; Zhang, Y.S. Microstructure and Properties of Titanium Matrix Composites Synergistically Reinforced by Graphene Oxide and Alloying Elements. Adv. Eng. Mater. 2022, 25, 2101778. [Google Scholar] [CrossRef]

- Chen, X.F.; Rong, X.D.; Zhao, D.D.; Zhang, X.; Li, J.J.; He, C.N.; Shi, C.S.; Tao, J.M.; Zhao, N.Q. Regulating microstructure of Al matrix composites with nanocarbon architecture design towards prominent strength-ductility combination. Scr. Mater. 2023, 222, 115037. [Google Scholar] [CrossRef]

- Rong, X.D.; Zhang, X.; Zhao, D.D.; He, C.N.; Shi, C.S.; Liu, E.Z.; Zhao, N.Q. In-situ Al2O3-Al interface contribution towards the strength-ductility synergy of Al-CuO composite fabricated by solid-state reactive sintering. Scr. Mater. 2021, 198, 113825. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Peng, H.X.; Zhang, J. Room temperature tensile fracture characteristics of in situ TiBw/Ti6Al4V composites with a quasi-continuous network architecture. Scr. Mater. 2011, 64, 844–847. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Y.X.; Wang, M.C.; Liu, E.Z.; Zhao, N.Q.; Shi, C.S.; Lin, D.; Zhu, F.L.; He, C.N. A powder-metallurgy-based strategy toward three-dimensional graphene-like network for reinforcing copper matrix composites. Nat. Commun. 2020, 11, 2775. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.F.; Chen, T.J. Synthesis of heterogeneity-improved heterostructured 2024Al alloy with excellent synergy of strength and ductility via powder thixoforming. J. Alloys Compd. 2023, 932, 167661. [Google Scholar] [CrossRef]

- Zhou, X.; Gao, Y.M.; Wang, Y.R.; Huang, X.Y.; Xiao, P. The improved strength and ductility of ZrCp/2024Al composites with a quasi-network microstructure fabricated by spark plasma sintering and T6 heat treatment. Mater. Sci. Eng. A 2022, 841, 142675. [Google Scholar] [CrossRef]

- Liu, P.; Wang, Z.B.; Ye, F.; Hou, B.; Wang, A.Q.; Xie, J.P. Hierarchically heterogeneous strategy for Ti2AlC/TiAl composite with superior mechanical properties. Compos. B Eng. 2024, 273, 111259. [Google Scholar] [CrossRef]

- Mohammad, B.R. In-situ manufacturing of NiAl-TiC composites with three dimensional (3D) discrete particular network and bi-continuous microstructures. Adv. Powder Technol. 2019, 30, 1025–1033. [Google Scholar] [CrossRef]

- Gao, X.; Lu, X.N.; Zhang, X.X.; Qian, M.F.; Li, A.B.; Geng, L.; Wang, H.; Liu, C.; Gong, B.W.; Peng, H.X. Investigation on critical microstructure size for numerical analysis of metal-matrix composites with network reinforcement architecture. Int. J. Appl. Mech. 2024, 16, 2450084. [Google Scholar] [CrossRef]

- Bargmann, S.; Klusemann, B.B.; Markmann, J.; Schnabel, J.E.; Schneider, K.; Soyarslan, C.; Wilmers, J. Generation of 3D representative volume elements for heterogeneous materials: A review. Prog. Mater. Sci. 2018, 96, 322–384. [Google Scholar] [CrossRef]

- Wang, L.L.; Fan, Q.B.; Li, G.J.; Zhang, H.M.; Wang, F.C. Experimental observation and numerical simulation of SiC3D/Al interpenetrating phase composite material subjected to a three-point bending load. Comp. Mater. Sci. 2014, 95, 408–413. [Google Scholar] [CrossRef]

- Li, G.J.; Zhang, X.; Fan, Q.B.; Wang, L.L.; Zhang, H.M.; Wang, F.C.; Wang, Y.W. Simulation of damage and failure processes of interpenetrating SiC/Al composites subjected to dynamic compressive loading. Acta Mater. 2014, 78, 190–202. [Google Scholar] [CrossRef]

- Soyarslan, C.; Bargmann, S.; Pradas, M.; Weissmüller, J. 3D stochastic bicontinuous microstructures: Generation, topology and elasticity. Acta Mater. 2018, 149, 326–340. [Google Scholar] [CrossRef]

- Soyarslan, C.; Pradas, M.; Bargmann, S. Effective elastic properties of 3D stochastic bicontinuous composites. Mech. Mater. 2019, 137, 103098. [Google Scholar] [CrossRef]

- Ghazi, A.; Berke, P.; Kamel, K.E.M.; Sonon, B.; Tiago, C.; Massart, T.J. Multiscale computational modelling of closed cell metallic foams with detailed microstructural morphological control. Int. J. Eng. Sci. 2019, 143, 92–114. [Google Scholar] [CrossRef]

- Ghazi, A.; Tiago, C.; Sonon, B.; Berke, P.; Massart, T.J. Efficient computational modelling of closed cell metallic foams using a morphologically controlled shell geometry. Int. J. Eng. Sci. 2020, 168, 105298. [Google Scholar] [CrossRef]

- Yan, Y.F.; Kou, S.Q.; Yang, H.Y.; Shu, S.L.; Shi, F.J.; Qiu, F.; Jiang, Q.C. Microstructure-based simulation on the mechanical behavior of particle reinforced metal matrix composites with varying particle characteristics. J. Mater. Res. Technol. 2023, 26, 3629–3645. [Google Scholar] [CrossRef]

- Zhang, J.; Ouyang, Q.B.; Guo, Q.; Li, Z.Q.; Fan, G.L.; Su, Y.S.; Jiang, L.; Lavernia, E.J.; Schoenung, J.M.; Zhang, D. 3D Microstructure-based finite element modeling of deformation and fracture of SiCp/Al composites. Compos. Sci. Technol. 2016, 123, 1–9. [Google Scholar] [CrossRef]

- Zhang, J.F.; Zhang, X.X.; Wang, Q.Z.; Xiao, B.L.; Ma, Z.Y. Simulation of anisotropic load transfer and stress distribution in SiCp/Al composites subjected to tensile loading. Mech. Mater. 2018, 122, 96–103. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, X.X.; Geng, L. Strengthening and fracture behaviors in SiCp/Al composites with network particle distribution architecture. Mater. Sci. Eng. A 2019, 740–741, 353–362. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, X.X.; Li, A.B. Numerical study on mechanical properties of quasi-continuous SiCp/Al network composites with various particle size ratios (PSRs). Int. J. Appl. Mech. 2019, 11, 1950065. [Google Scholar] [CrossRef]

- Roy, S.; Gibmeier, J.; Kostov, V.; Weidenmann, K.A.; Nagel, A.; Wanner, A. Internal load transfer in a metal matrix composite with a three-dimensional interpenetrating structure. Acta Mater. 2011, 59, 1424–1435. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, X.X.; Qian, M.F.; Li, A.B.; Geng, L.; Peng, H.X. Fracture behaviour of SiCp/Al composites with network architecture. Materialia 2020, 12, 100725. [Google Scholar] [CrossRef]

- Prasad, V.V.B.; Bhat, B.V.R.; Mahajan, Y.R.; Ramakrishnan, P. Structure–property correlation in discontinuously reinforced aluminium matrix composites as a function of relative particle size ratio. Mater. Sci. Eng. A 2002, 337, 179–186. [Google Scholar] [CrossRef]

- Lin, X.B.; Rong, X.D.; Pu, B.W.; Ma, X.; Wu, Y.S.; Zhao, D.D.; He, C.N.; Zhang, X.; Zhao, N.Q. Gaining strength-ductility combination in Al matrix composites with in-situ synthesized three-dimensional nanocarbon network. J. Alloys Compd. 2024, 970, 172542. [Google Scholar] [CrossRef]

| Parameters/Features | Values | |||||

|---|---|---|---|---|---|---|

| Chamfer size (f)/μm | 0.00 | 1.00 | 2.00 | 3.00 | 4.00 | 5.00 |

| Inter-cell distance (t)/μm | 1.451 | 1.390 | 1.217 | 0.944 | 0.583 | 0.145 |

| Foam volume/μm3 | 100,000 | 99,976 | 99,976 | 99,978 | 99,964 | 99,970 |

| Network plate volume/μm3 | 100,000 | 71,952 | 54,439 | 36,714 | 19,824 | 4331 |

| Intersection volume/μm3 | 0 | 28,024 | 45,537 | 63,264 | 9014 | 95,639 |

| Interface area/μm2 | 133,369 | 130,719 | 128,579 | 126,928 | 125,542 | 124,628 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, T.; Wang, T.; Li, J.; Liu, C.; Gong, B.; Ouyang, W.; Wang, L.; Ma, S.; Zheng, Z.; Yuan, B.; et al. Numerical Investigation on Effect of Chamfering on Mechanical Behaviors in Continuous Network Composite. Materials 2025, 18, 4810. https://doi.org/10.3390/ma18204810

Li T, Wang T, Li J, Liu C, Gong B, Ouyang W, Wang L, Ma S, Zheng Z, Yuan B, et al. Numerical Investigation on Effect of Chamfering on Mechanical Behaviors in Continuous Network Composite. Materials. 2025; 18(20):4810. https://doi.org/10.3390/ma18204810

Chicago/Turabian StyleLi, Tao, Tianzi Wang, Jianchao Li, Cheng Liu, Bowen Gong, Wenting Ouyang, Likun Wang, Sainan Ma, Zhong Zheng, Bo Yuan, and et al. 2025. "Numerical Investigation on Effect of Chamfering on Mechanical Behaviors in Continuous Network Composite" Materials 18, no. 20: 4810. https://doi.org/10.3390/ma18204810

APA StyleLi, T., Wang, T., Li, J., Liu, C., Gong, B., Ouyang, W., Wang, L., Ma, S., Zheng, Z., Yuan, B., Wang, H., & Gao, X. (2025). Numerical Investigation on Effect of Chamfering on Mechanical Behaviors in Continuous Network Composite. Materials, 18(20), 4810. https://doi.org/10.3390/ma18204810