The Influence of Wide-Directional Asymmetric Spraying on Machining Deformation of Aluminum Alloy Plates

Abstract

1. Introduction

2. Materials and Methods

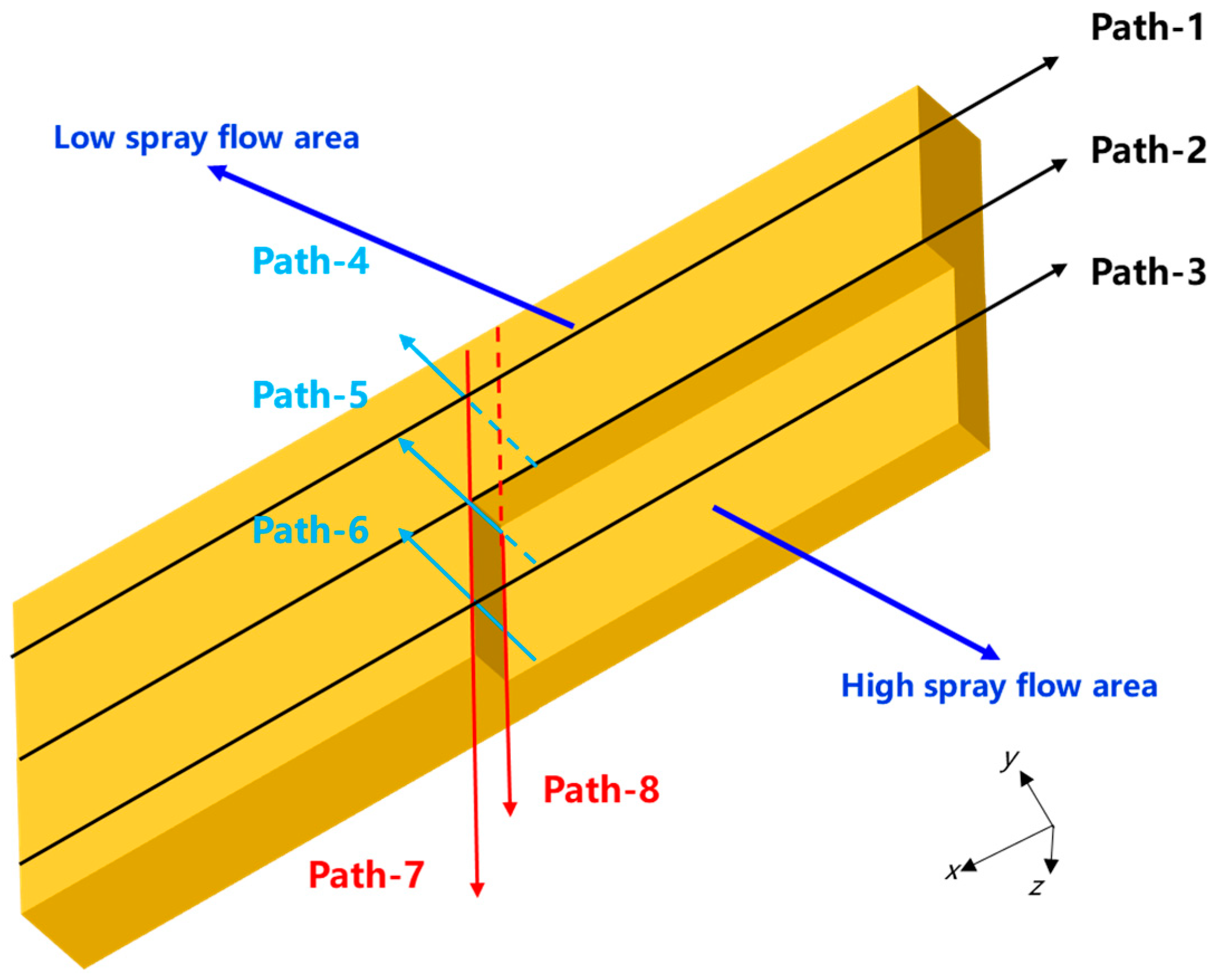

2.1. Finite Element Simulation

2.1.1. Simulated Hypothesis

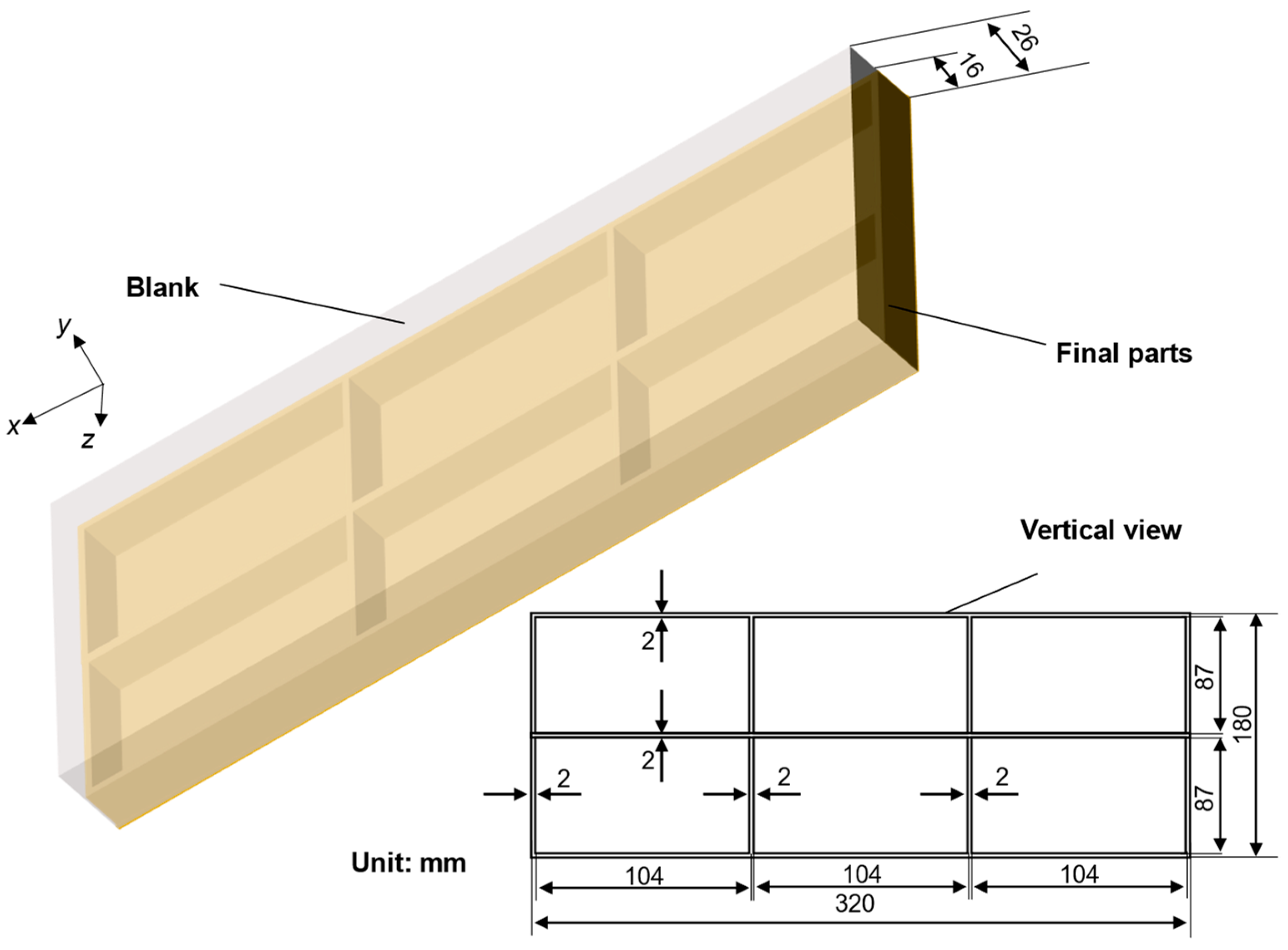

2.1.2. Model and Parameters of Simulation

2.2. Experimental Section

2.2.1. Materials for Experimentation

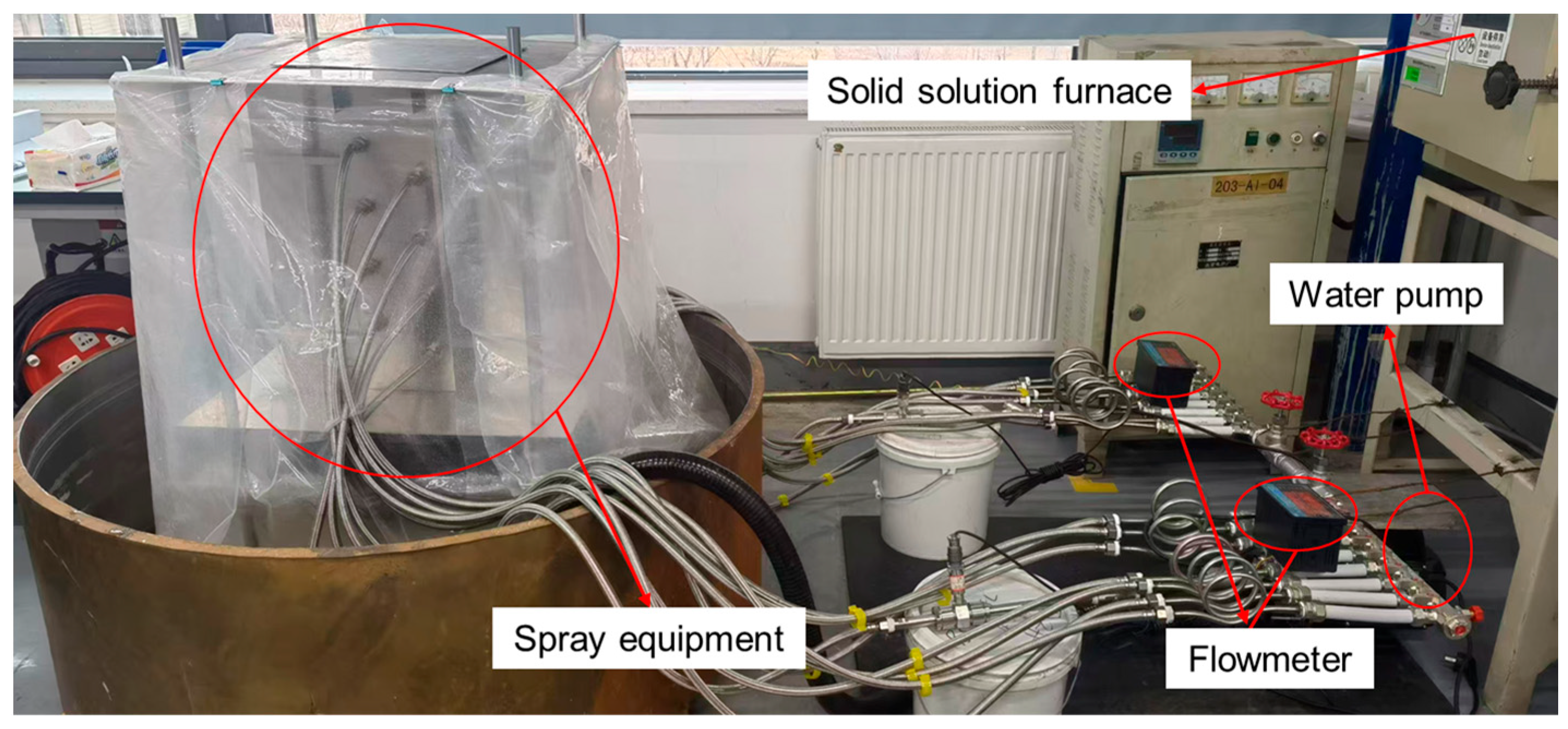

2.2.2. Spray Quenching Experiment

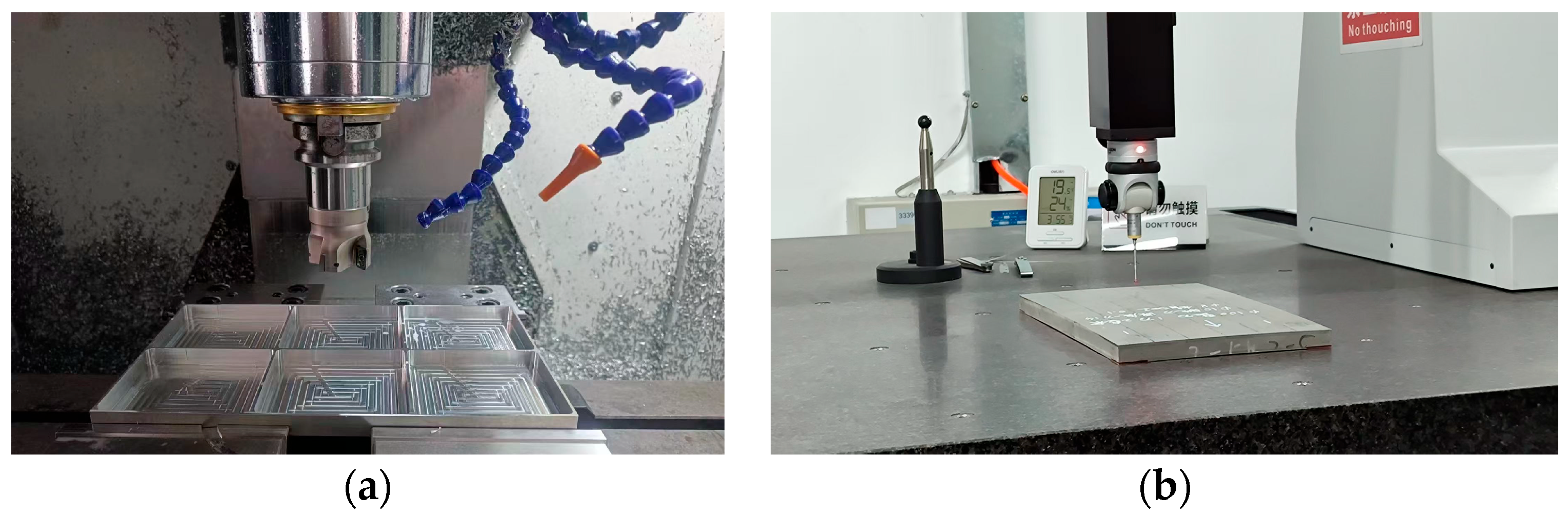

2.2.3. Machining Experiment and Characterization Method of Deformation

3. Results and Discussions

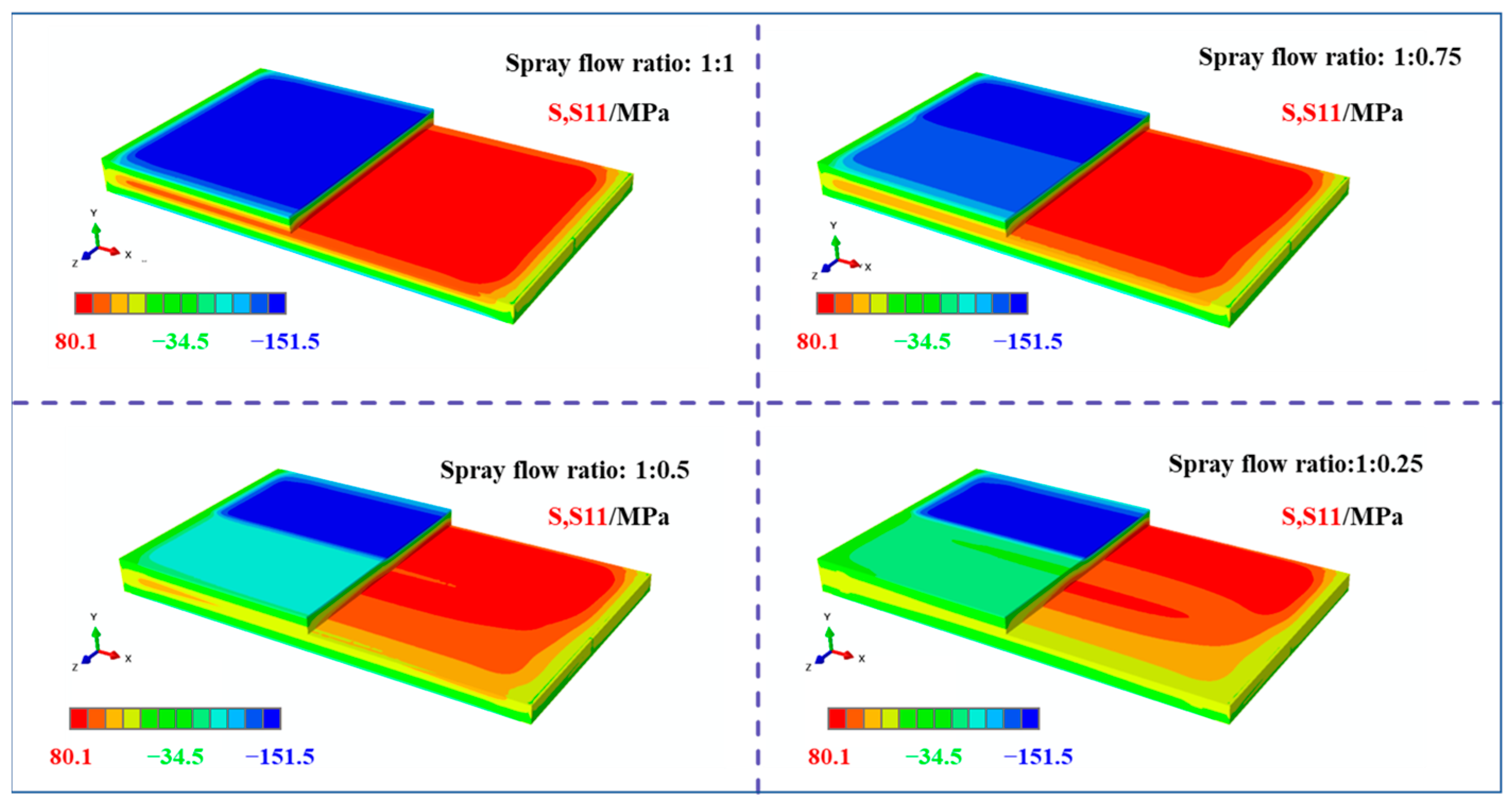

3.1. Residual Stress Distribution Under Asymmetric Spray Conditions

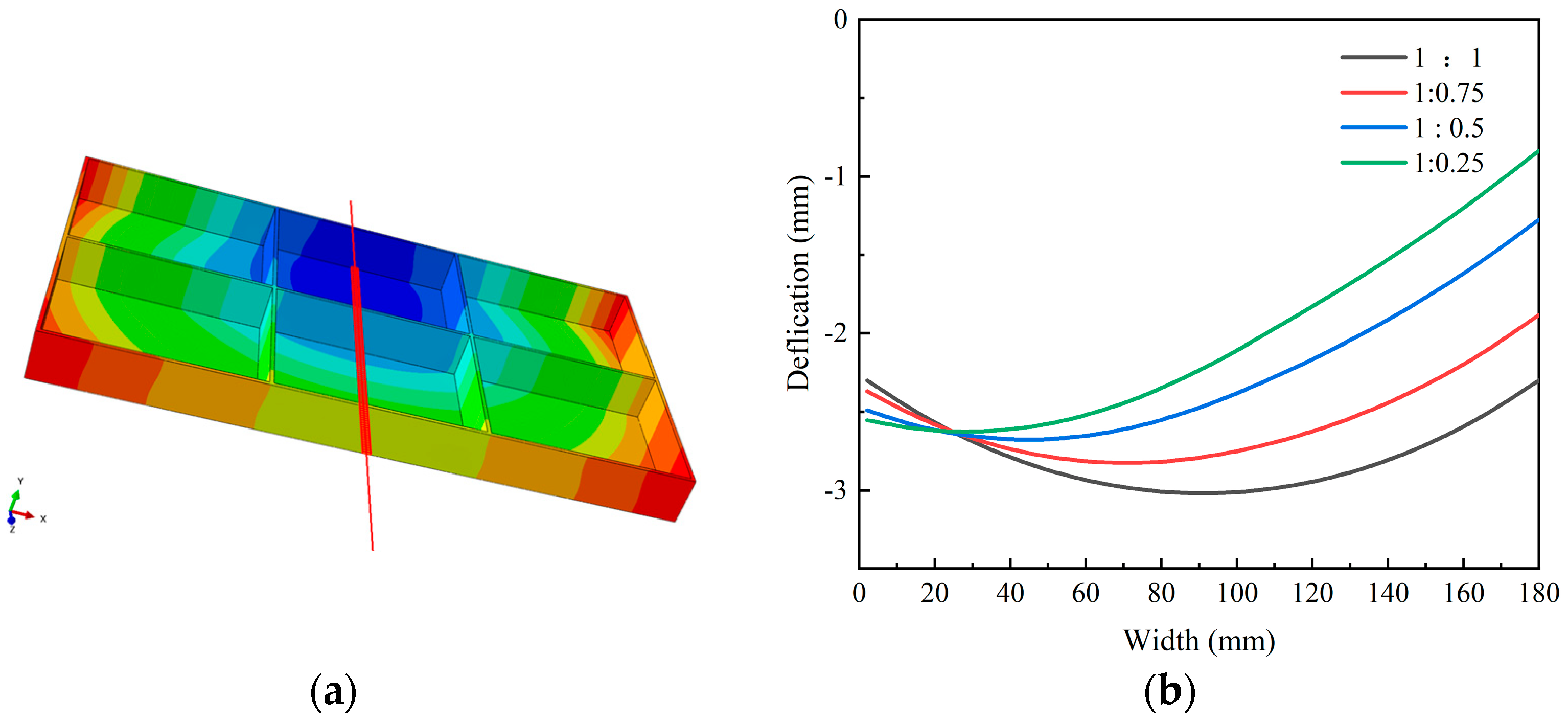

3.2. Influence of Initial Residual Stress State on Machining Deformation

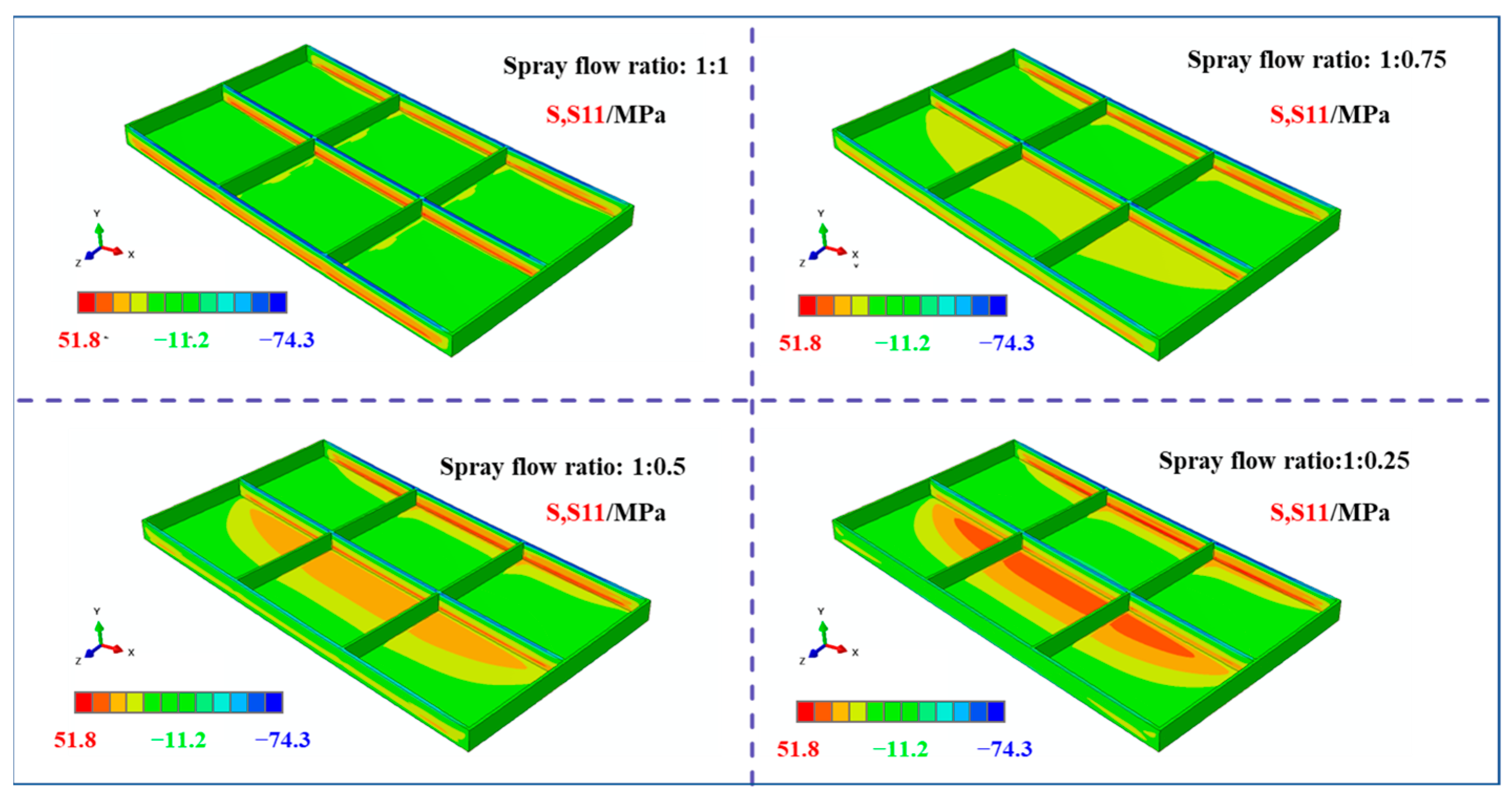

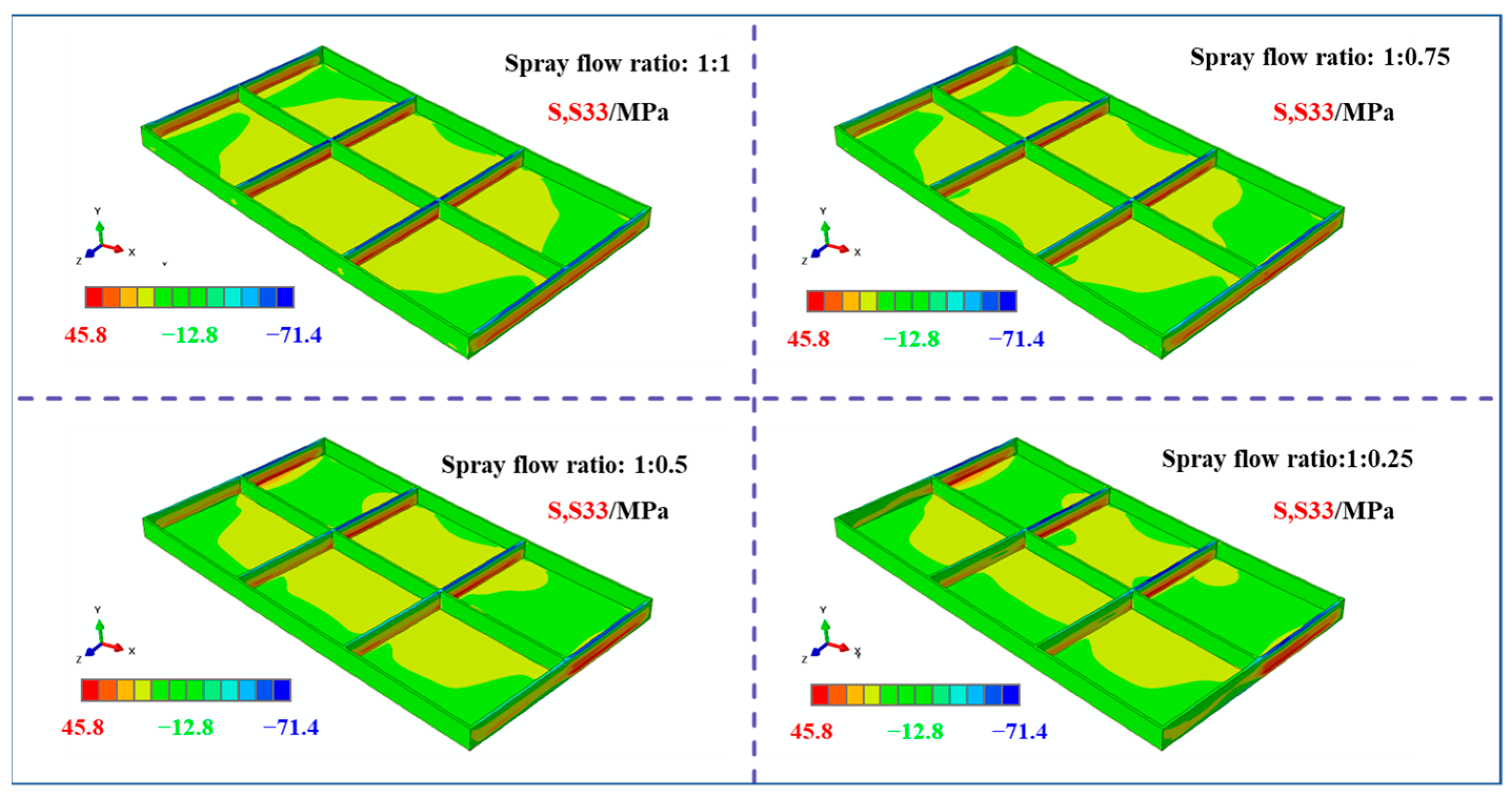

3.2.1. Stress Results of Machined Frame Parts Under Different Initial Stress Conditions

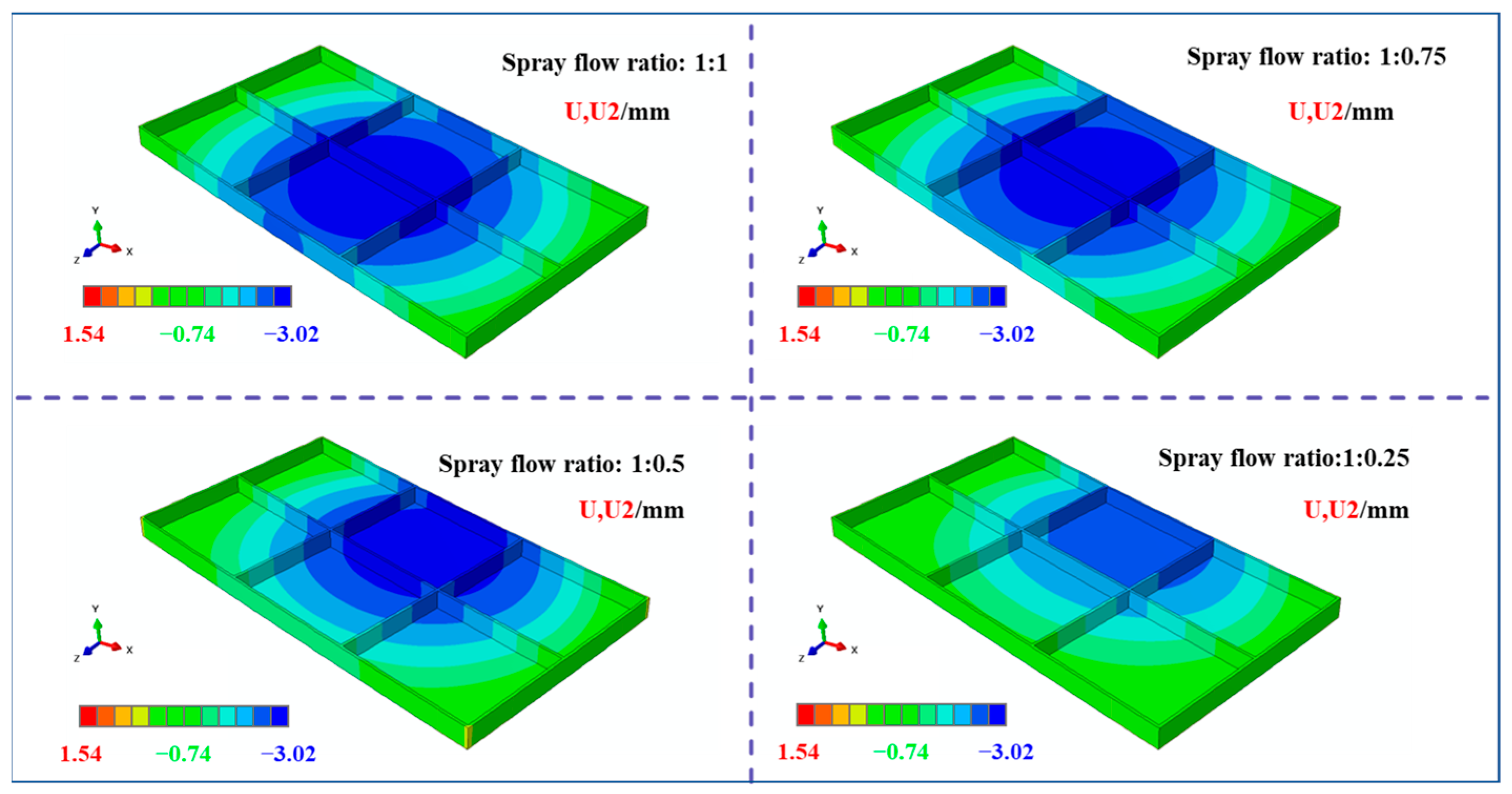

3.2.2. Results of Internal Displacement Field of Machined Frame Parts Under Different Initial Stresses

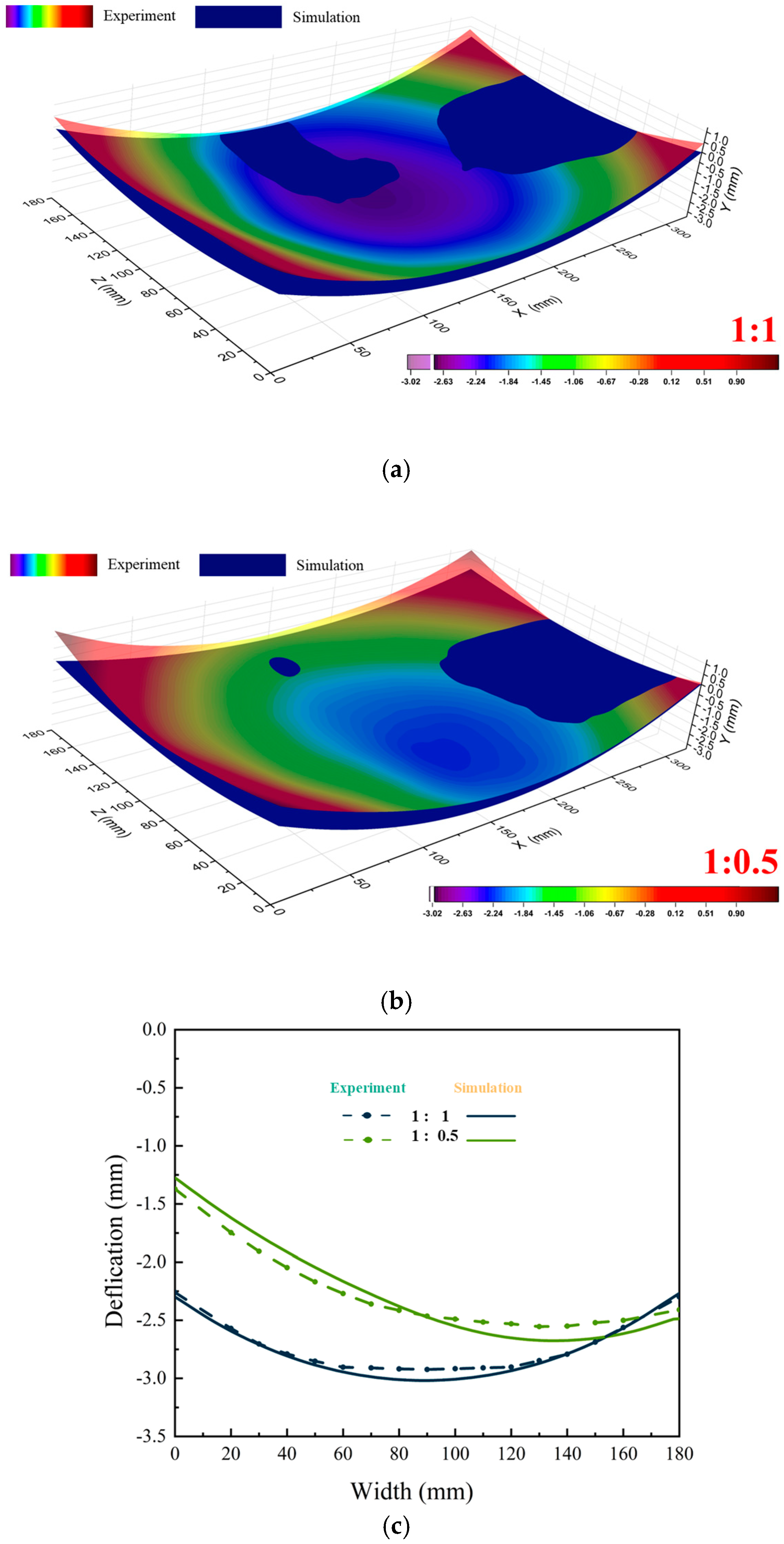

3.2.3. Machining Experiment Verification

3.3. Influence of Machining Strategy on Machining Deformation

3.3.1. Machining Strategies

3.3.2. Stress Results of Machined Frame Parts Under Different Machining Strategies

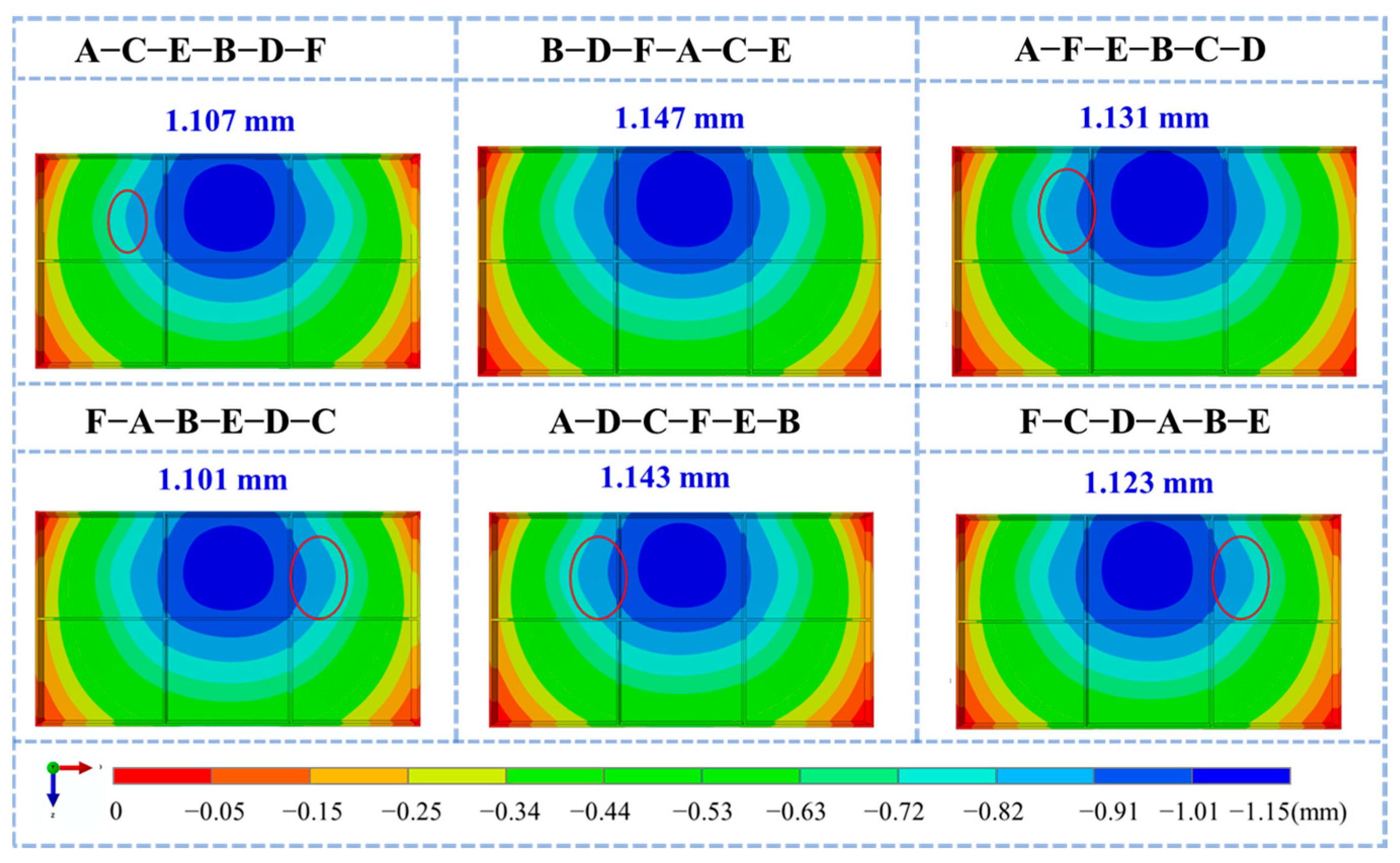

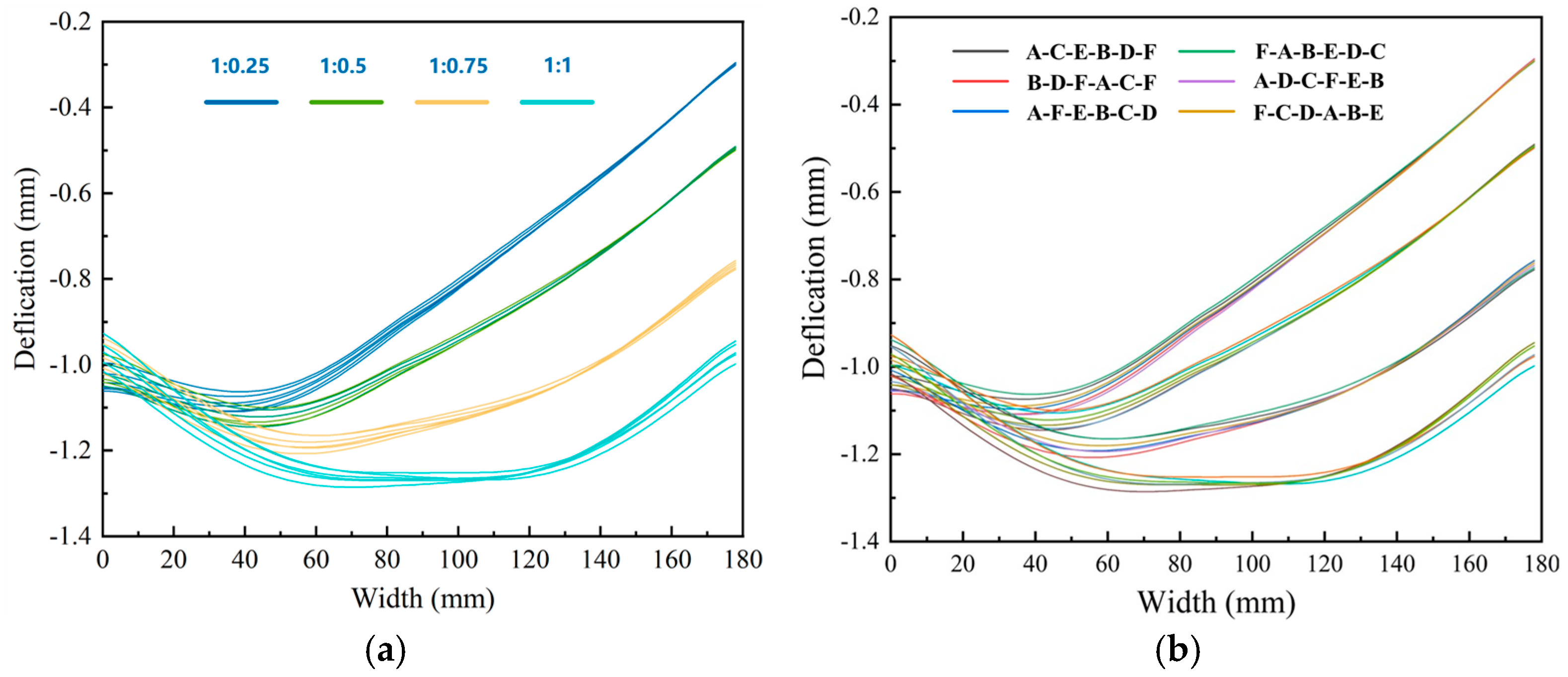

3.3.3. Results of Internal Displacement Field of Machined Frame Parts Under Different Machining Strategies

4. Conclusions

- (1)

- Influence of the Initial Stress State: Lower initial stress asymmetry consistently resulted in reduced post-machining stress levels and diminished overall deformation in the frame components. Deformation in the bottom region (U2 direction) predominantly exhibited a concave pattern. As the stress level on one side progressively decreased, the total deformation magnitude of the frame decreased correspondingly, and the location of the maximum bottom deformation shifted towards the side retaining higher stress.

- (2)

- Machining Sequence Impact: While fundamental deformation patterns remained consistent across different machining sequences, the specific sequence governing the residual stress release during material removal significantly altered the final distortion state. Among the strategies evaluated, the Diagonal Milling sequence F-A-B-E-D-C yielded the minimal overall deformation, achieving a magnitude as low as 1.101 mm.

- (3)

- Coupled Stress-State and Strategy Effects: Deformation patterns exhibited subtle variations depending on the initial stress state. Crucially, the magnitude of the initial stress asymmetry had a pronounced influence, with higher initial stress asymmetry directly correlating with increased final deformation in the assembled structure. The Diagonal Milling sequence F-A-B-E-D-C consistently demonstrated optimal performance across the evaluated stress states.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gloria, A.; Montanari, R.; Richetta, M.; Varone, A. Alloys for aeronautic applications: State of the art and perspectives. Metals 2019, 9, 662. [Google Scholar] [CrossRef]

- Heinz, A.; Haszler, A.; Keidel, C.; Moldenhauer, S.; Benedictus, R.; Miller, W.S. Recent development in aluminium alloys for aerospace applications. Mater. Sci. Eng. A 2000, 280, 102–107. [Google Scholar] [CrossRef]

- Pantelakis, S.G.; Alexopoulos, N.D. Assessment of the ability of conventional and advanced wrought aluminum alloys for mechanical performance in light-weight applications. Mater. Des. 2008, 29, 80–91. [Google Scholar] [CrossRef]

- Fereiduni, E.; Ghasemi, A.; Elbestawi, M. Selective laser melting of aluminum and titanium matrix composites: Recent progress and potential applications in the aerospace industry. Aerospace 2020, 7, 77. [Google Scholar] [CrossRef]

- Liu, L.; Sun, J.; Chen, W.; Sun, P. Study on the machining distortion of aluminum alloy parts induced by forging residual stresses. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2016, 231, 618–627. [Google Scholar] [CrossRef]

- Bi, Y.-B.; Cheng, Q.-L.; Dong, H.-Y.; Ke, Y.-L. Machining distortion prediction of aerospace monolithic components. J. Zhejiang Univ.-Sci. A 2009, 10, 661–668. [Google Scholar] [CrossRef]

- Li, J.; Wang, S. Distortion caused by residual stresses in machining aeronautical aluminum alloy parts: Recent advances. Int. J. Adv. Manuf. Technol. 2017, 89, 997–1012. [Google Scholar] [CrossRef]

- Gao, H.; Li, X.; Wu, Q.; Zhang, W.; Dai, G.; Zhang, G. The optimization of friction disc gear-shaping process aiming at residual stress and machining deformation. Rev. Adv. Mater. Sci. 2021, 60, 921–935. [Google Scholar] [CrossRef]

- Husson, R.; Dantan, J.-Y.; Baudouin, C.; Silvani, S.; Scheer, T.; Bigot, R. Evaluation of process causes and influences of residual stress on gear distortion. CIRP Ann. 2012, 61, 551–554. [Google Scholar] [CrossRef]

- Fu, S.; Feng, P.; Ma, Y.; Wang, L. Initial residual stress measurement based on piecewise calculation methods for predicting machining deformation of aeronautical monolithic components. Int. J. Adv. Manuf. Technol. 2020, 108, 2063–2078. [Google Scholar] [CrossRef]

- Li, X.; Li, L.; Yang, Y.; Zhao, G.; He, N.; Ding, X.; Shi, Y.; Fan, L.; Lan, H.; Jamil, M. Machining deformation of single-sided component based on finishing allowance optimization. Chin. J. Aeronaut. 2020, 33, 2434–2444. [Google Scholar] [CrossRef]

- Fan, N.; Li, Z.; Li, Y.; Li, X.; Zhang, Y.; Xiong, B. Residual stress with asymmetric spray quenching for thick aluminum alloy plates. Int. J. Miner. Met. Mater. 2023, 30, 2200–2211. [Google Scholar] [CrossRef]

- Songmene, V.; Khettabi, R.; Zaghbani, I.; Kouam, J.; Djebara, A. Machining and machinability of aluminum alloys. Alum. Alloys Theory Appl. 2011, 377, 400. [Google Scholar]

- Zhang, Y.; Kang, R.; Dong, Z.; Bao, Y.; Guo, D.; Bai, Q. Effect of dislocation density distribution in work-hardened layer on cutting characteristics in the multi-cutting of 49Fe49Co2V alloy. J. Manuf. Process. 2023, 85, 1187–1196. [Google Scholar] [CrossRef]

- Dong, H.; Ke, Y. Study on machining deformation of aircraft monolithic component by FEM and experiment. Chin. J. Aeronaut. 2006, 19, 247–254. [Google Scholar] [CrossRef]

- Wu, Q.; Li, D.P.; Zhang, Y.D. Detecting milling deformation in 7075 aluminum alloy aeronautical monolithic components using the quasi-symmetric machining method. Metals 2016, 6, 80. [Google Scholar] [CrossRef]

- Li, B.; Jiang, X.; Yang, J.; Liang, S.Y. Effects of depth of cut on the redistribution of residual stress and distortion during the milling of thin-walled part. J. Mater. Process. Technol. 2025, 216, 223–233. [Google Scholar] [CrossRef]

- Srivastava, V.S.; Gupta, T.K.; Srivastava, A.K.; Chauhan, S.; Chauhan, P.K. Effects of cutting parameters on aluminium alloys-A review. Mater. Today Proc. 2021, 47, 3823–3827. [Google Scholar] [CrossRef]

- Yue, Q.; He, Y.; Li, Y.; Tian, S. Investigation on effects of single- and multiple-pass strategies on residual stress in machining Ti-6Al-4V alloy. J. Manuf. Process. 2022, 77, 272–281. [Google Scholar] [CrossRef]

- Han, F.; Wang, J.; Gao, W.; Wang, S.; Jia, B.; Xue, C.-Y.; Zhang, W.; Ju, B.-F.; Zhu, W. Insights into hydrodynamic self-balancing mechanics in adaptive float machining process for nanometric form error control. Int. J. Mach. Tools Manuf. 2025, 212, 104333. [Google Scholar] [CrossRef]

- Chen, H.X.; Li, H.; Feng, H.T.; Du, M.J. Aero-engine blade deformation control of milling process. Adv. Mat. Res. 2011, 308, 1198–1204. [Google Scholar]

- Li, B.; Feng, P.; Zeng, L.; Xu, C.; Zhang, J. Path planning method for on-machine inspection of aerospace structures based on adjacent feature graph. Robot. Comput. Integr. Manuf. 2018, 54, 17–34. [Google Scholar] [CrossRef]

- Lim, E.E.M.; Menq, C.H. Integrated planning for precision machining of complex surfaces. Part 1: Cutting-path and feedrate optimization. Int. J. Mach. Tools Manuf. 1997, 37, 61–75. [Google Scholar] [CrossRef]

- Akhtar, W.; Lazoglu, I.; Liang, S.Y. Prediction and control of residual stress-based distortions in the machining of aerospace parts: A review. J. Manuf. Process. 2022, 76, 106–122. [Google Scholar] [CrossRef]

- Li, Y.N.; Zhang, Y.A.; Li, X.W.; Li, Z.H.; Wang, G.J.; Jin, L.B.; Huang, S.H.; Xiong, B.Q. Quenching residual stress distributions in aluminum alloy plates with different dimensions. Rare Met. 2019, 38, 1051–1061. [Google Scholar] [CrossRef]

- Huang, X.; Sun, J.; Li, J. Effect of initial residual stress and machining-induced residual stress on the deformation of aluminium alloy plate. Stroj. Vestn.-J. Mech. Eng. 2015, 61, 131–137. [Google Scholar] [CrossRef]

- Huang, X.; Sun, J.; Li, J. Finite element simulation and experimental investigation on the residual stress-related monolithic component deformation. Int. J. Adv. Manuf. Technol. 2015, 77, 1035–1041. [Google Scholar] [CrossRef]

- Duan, Z.; Li, C.; Ding, W.; Zhang, Y.; Yang, M.; Gao, T.; Cao, H.; Xu, X.; Wang, D.; Mao, C.; et al. Milling force model for aviation aluminum alloy: Academic insight and perspective analysis. Chin. J. Mech. Eng. 2021, 34, 18. [Google Scholar] [CrossRef]

- Li, C.; Che, G.; Xiao, W.; Zang, C.; Zhang, X.; Fu, Y.; Ma, C. Study on the inhomogeneity of Al–Zn–Cu–Mg aluminum alloy plates with different thickness. J. Mater. Sci. 2022, 57, 21460–21474. [Google Scholar] [CrossRef]

- Li, B.; Ouyang, W.; Dong, Y. Investigating the effects and mechanisms of thermal–vibration-coupled stress relief treatment on residual stress in SiC/Al composites. Metals 2024, 14, 1195. [Google Scholar] [CrossRef]

- Solberg, J.K.; Thon, H. Stress relaxation and creep of some aluminium alloys. Mater. Sci. Eng. 1985, 75, 105–116. [Google Scholar] [CrossRef]

- Shang, B.C.; Yin, Z.M.; Wang, G.; Liu, B.; Huang, Z.Q. Investigation of quench sensitivity and transformation kinetics during isothermal treatment in 6082 aluminum alloy. Mater. Des. 2011, 32, 3818–3822. [Google Scholar] [CrossRef]

- Silva, E.P.; Pacheco, P.M.C.L.; Savi, M.A. Finite element analysis of the phase transformation effect in residual stresses generated by quenching in notched steel cylinders. J. Strain Anal. Eng. Des. 2005, 40, 151–160. [Google Scholar] [CrossRef]

| Temperature (°C) | (kg·m−3) | (W·m−1·°C−1) | (10−6·°C−1) | (J·kg−1∙K−1) | Rp0.2 (MPa) | E (GPa) |

|---|---|---|---|---|---|---|

| 20 | 2841 | 145 | 22.7 | 913 | 266 | 73 |

| 100 | 2828 | 152 | 24 | 983 | 223 | 61 |

| 200 | 2807 | 160 | 24.2 | 1025 | 154 | 56 |

| 300 | 2787 | 167 | 25.2 | 1113 | 73 | 38 |

| 400 | 2761 | 171 | 26 | 1292 | 23 | 32 |

| 500 | 2735 | 178 | 27.5 | 1158 | 10 | 25 |

| Normalized Flow Rates | ||

|---|---|---|

| 1 | 0.64 | 10,000 |

| 0.75 | 0.48 | 8000 |

| 0.5 | 0.32 | 5500 |

| 0.25 | 0.16 | 4000 |

| Zn | Cu | Mg | Zr | Fe | Si | Al |

|---|---|---|---|---|---|---|

| 7.6~8.4 | 2.0~2.6 | 1.8~2.3 | 0.05~0.25 | ≤0.15 | ≤0.10 | Bal. |

| Rotation Speed (r·min−1) | Feed Speed (mm·min−1) | Axial Cutting Depth (mm) | Radial Cutting Width (mm) | Tool Inclination Angle | Tool Clearance Angle |

|---|---|---|---|---|---|

| 1200 | 150 | 1 | 4 | 30° | 8° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Lin, Z.; Li, Y.; Li, X.; Zhu, K.; Yu, M.; Li, Y.; Yan, H. The Influence of Wide-Directional Asymmetric Spraying on Machining Deformation of Aluminum Alloy Plates. Materials 2025, 18, 4802. https://doi.org/10.3390/ma18204802

Li Y, Lin Z, Li Y, Li X, Zhu K, Yu M, Li Y, Yan H. The Influence of Wide-Directional Asymmetric Spraying on Machining Deformation of Aluminum Alloy Plates. Materials. 2025; 18(20):4802. https://doi.org/10.3390/ma18204802

Chicago/Turabian StyleLi, Yang, Zhongkun Lin, Yanan Li, Xiwu Li, Kai Zhu, Mingyang Yu, Ying Li, and Hongwei Yan. 2025. "The Influence of Wide-Directional Asymmetric Spraying on Machining Deformation of Aluminum Alloy Plates" Materials 18, no. 20: 4802. https://doi.org/10.3390/ma18204802

APA StyleLi, Y., Lin, Z., Li, Y., Li, X., Zhu, K., Yu, M., Li, Y., & Yan, H. (2025). The Influence of Wide-Directional Asymmetric Spraying on Machining Deformation of Aluminum Alloy Plates. Materials, 18(20), 4802. https://doi.org/10.3390/ma18204802