Processing Stability of Carbon Nanofiber-Reinforced Glass Fiber/Polypropylene Composites Under Repeated Extrusion for Mechanical Recycling

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

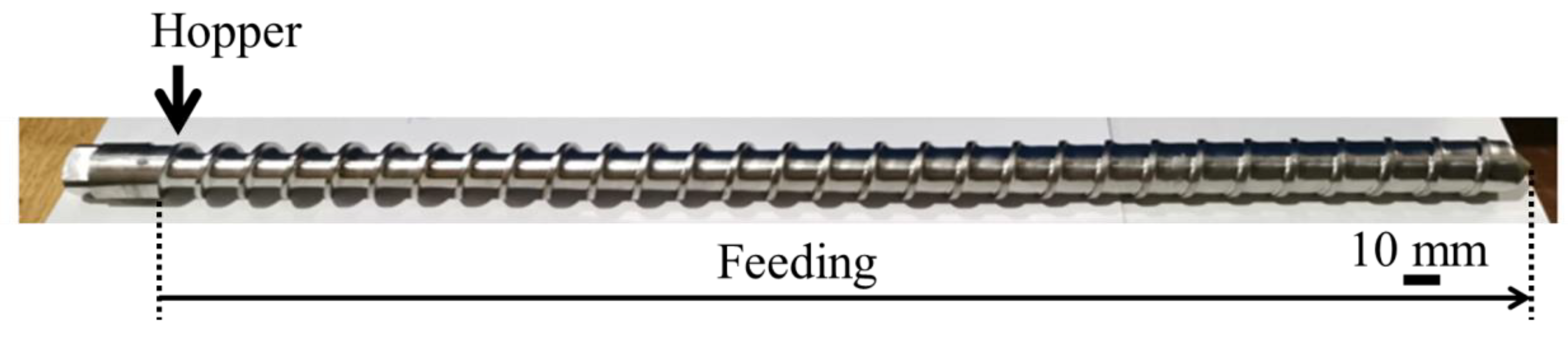

2.2. Melt Compounding

2.3. Repeated Extrusion

2.4. Melt Viscosity Measurement

2.5. Injection Molding

2.6. Fiber Orientation and Fiber Length Analysis

2.7. Interfacial Mechanical Property Evaluation

2.8. Flexural Property Evaluation

2.9. Notched Charpy Impact Test

2.10. Fourier Transform Infrared Spectroscopy

3. Results

3.1. Changes in Melt Viscosity with Repeated Extrusion

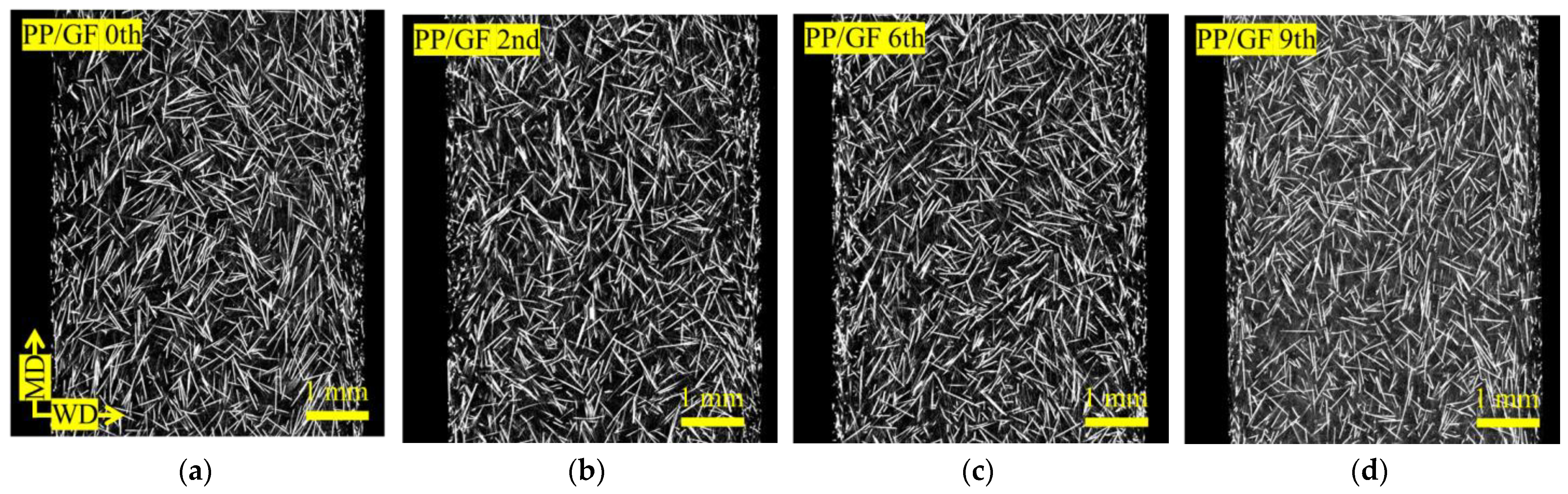

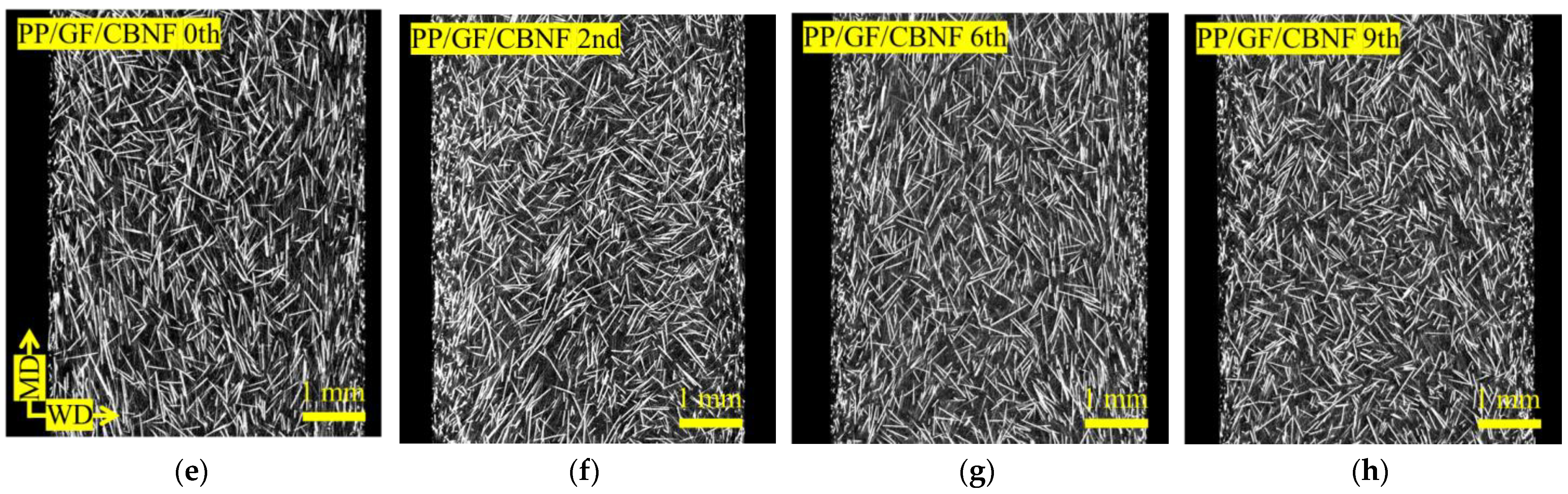

3.2. Changes in Glass Fiber Orientation and Length with Repeated Extrusion

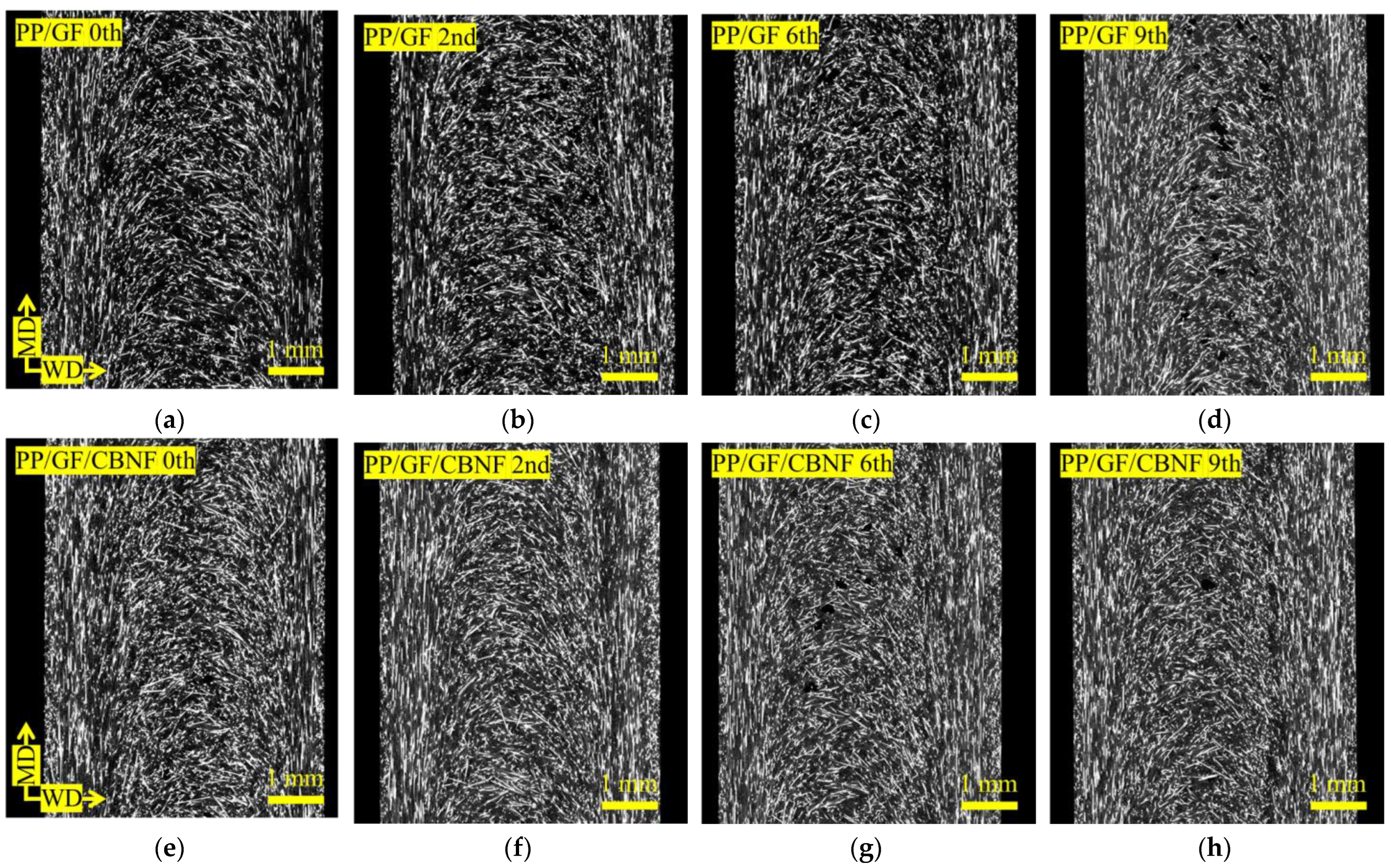

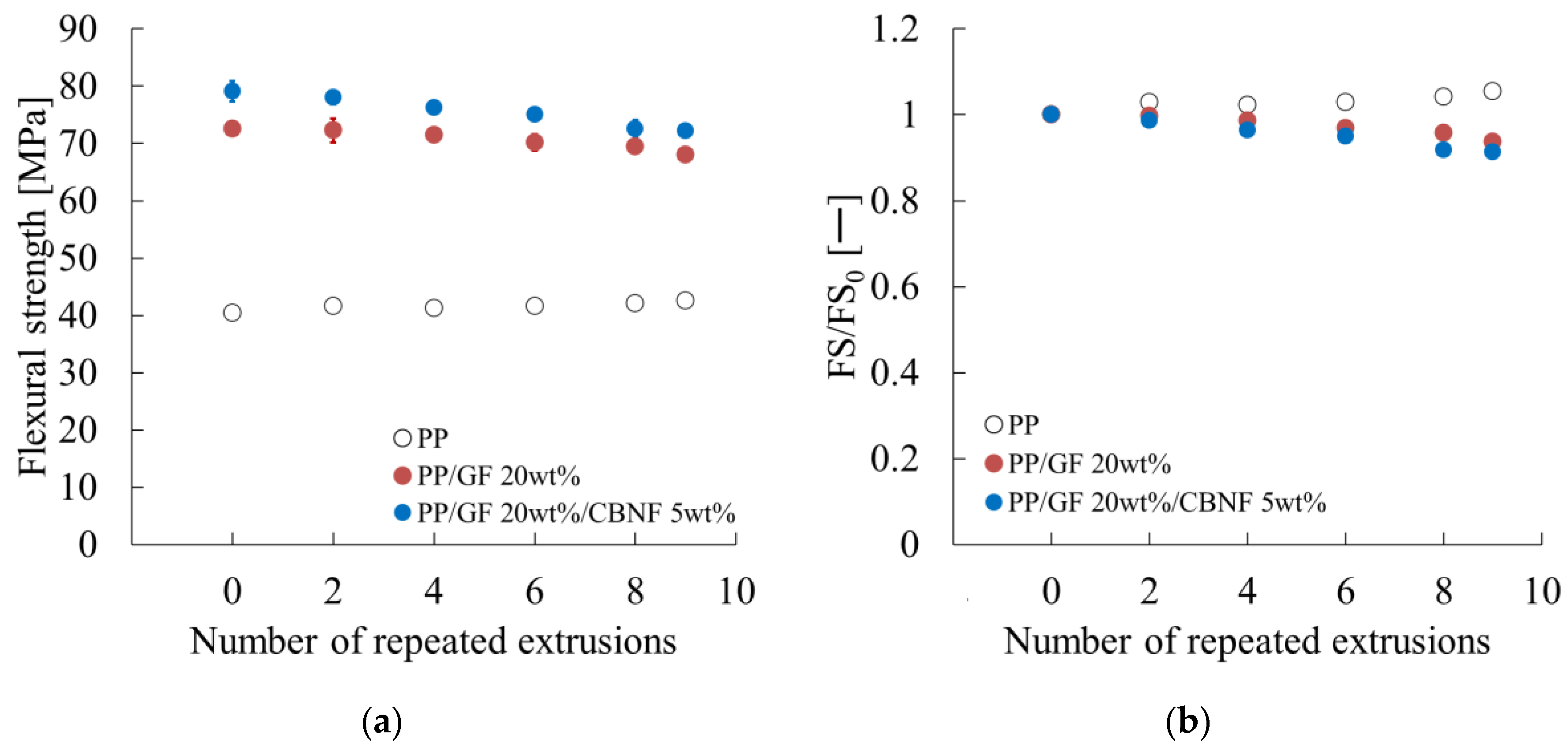

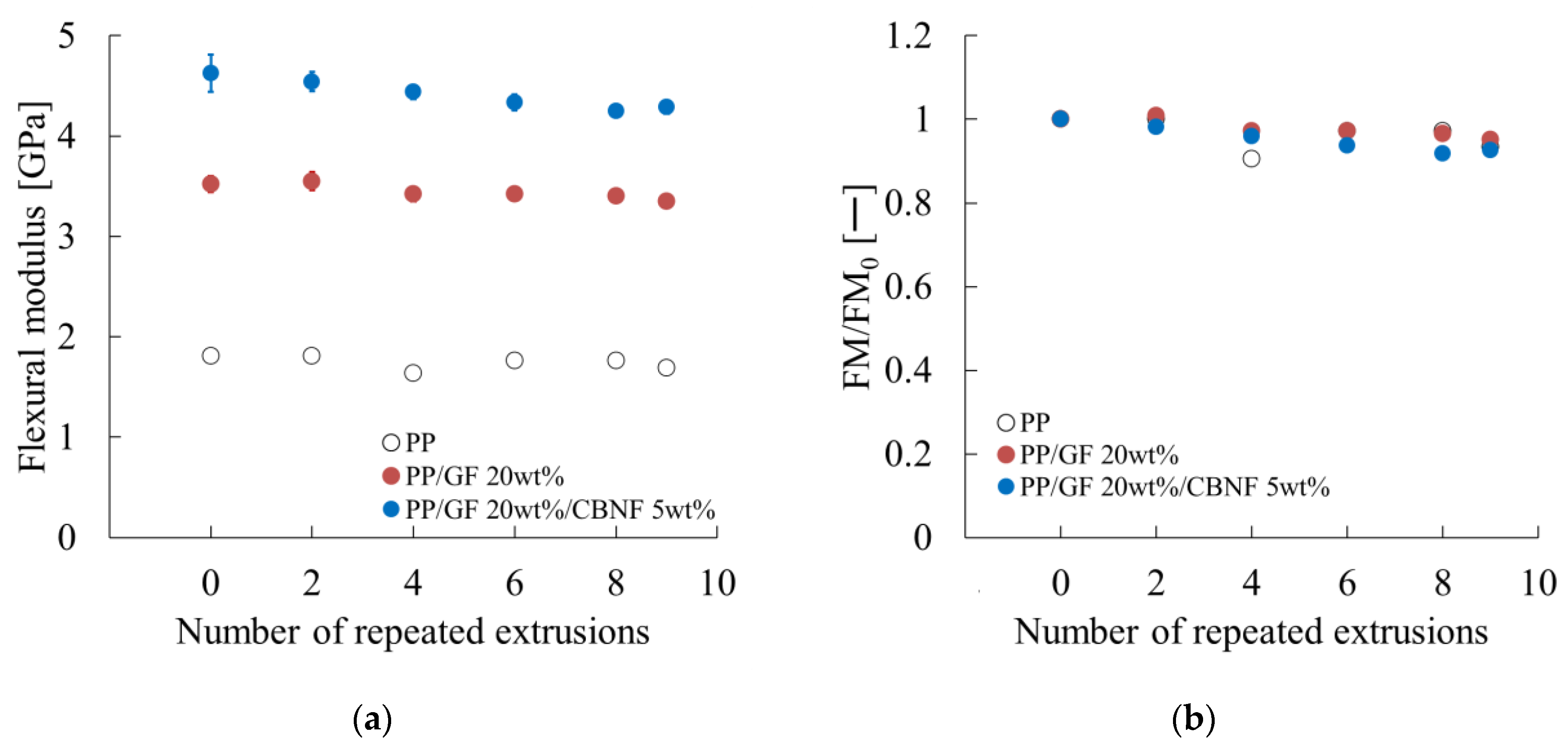

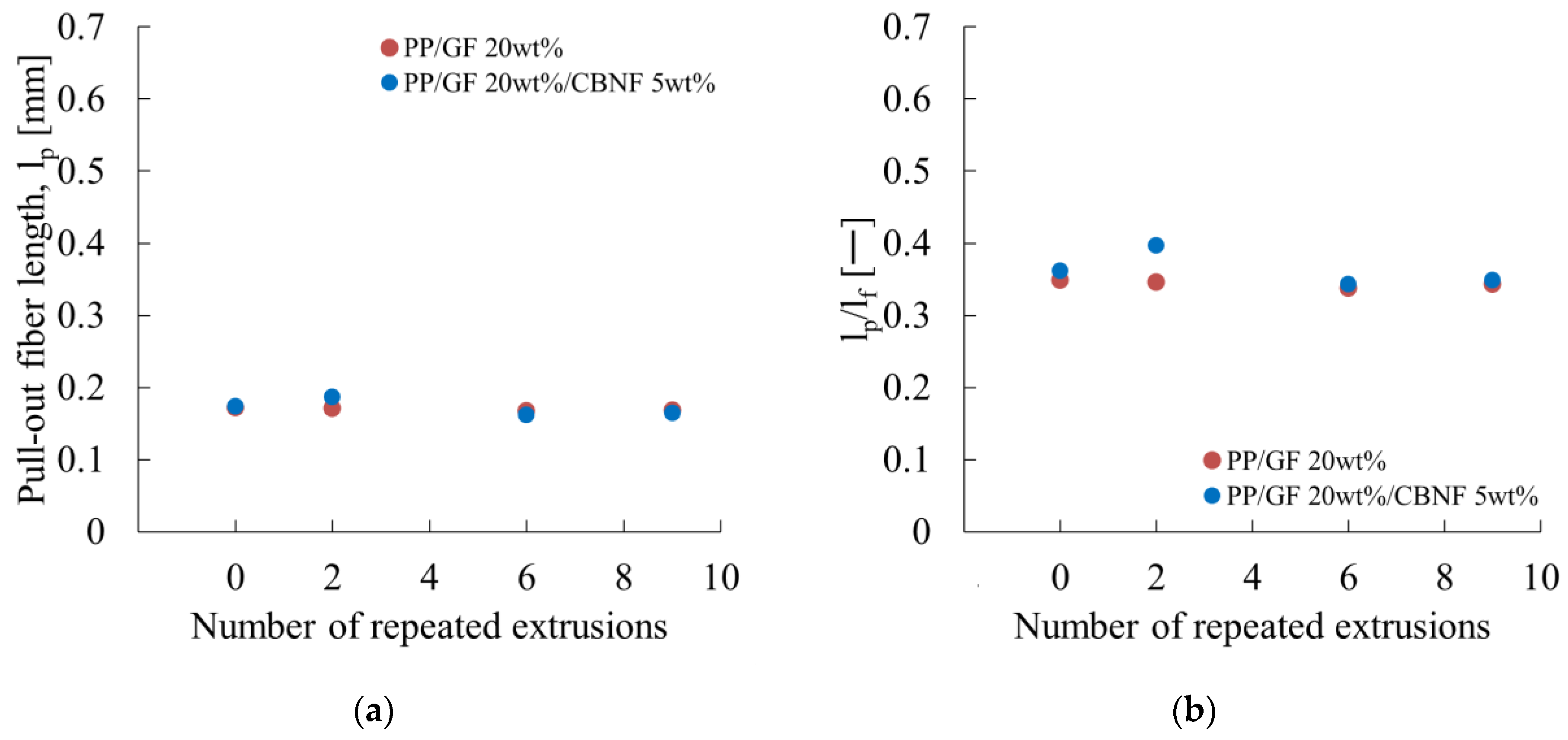

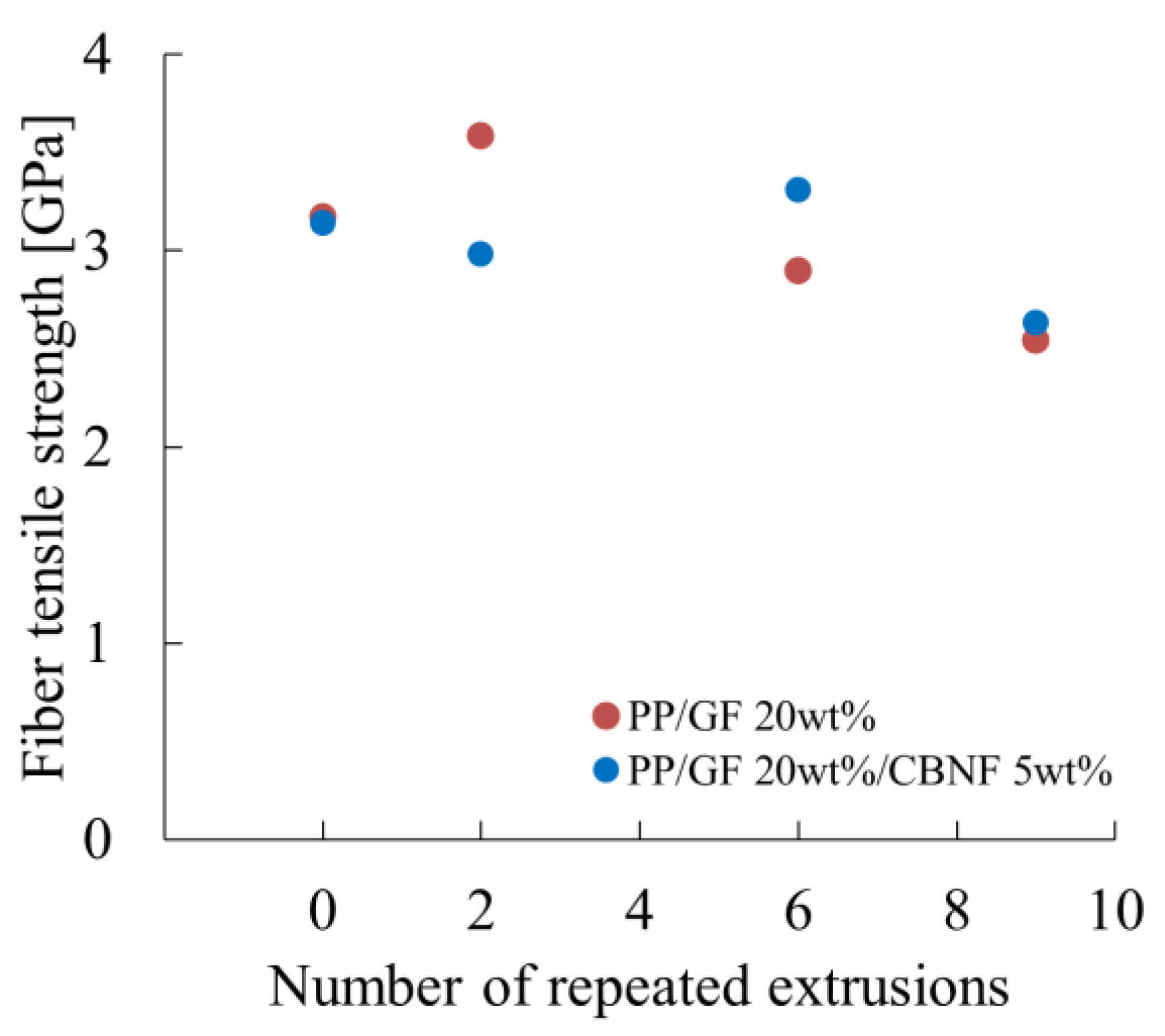

3.3. Changes in Interfacial and Flexural Properties with Repeated Extrusion

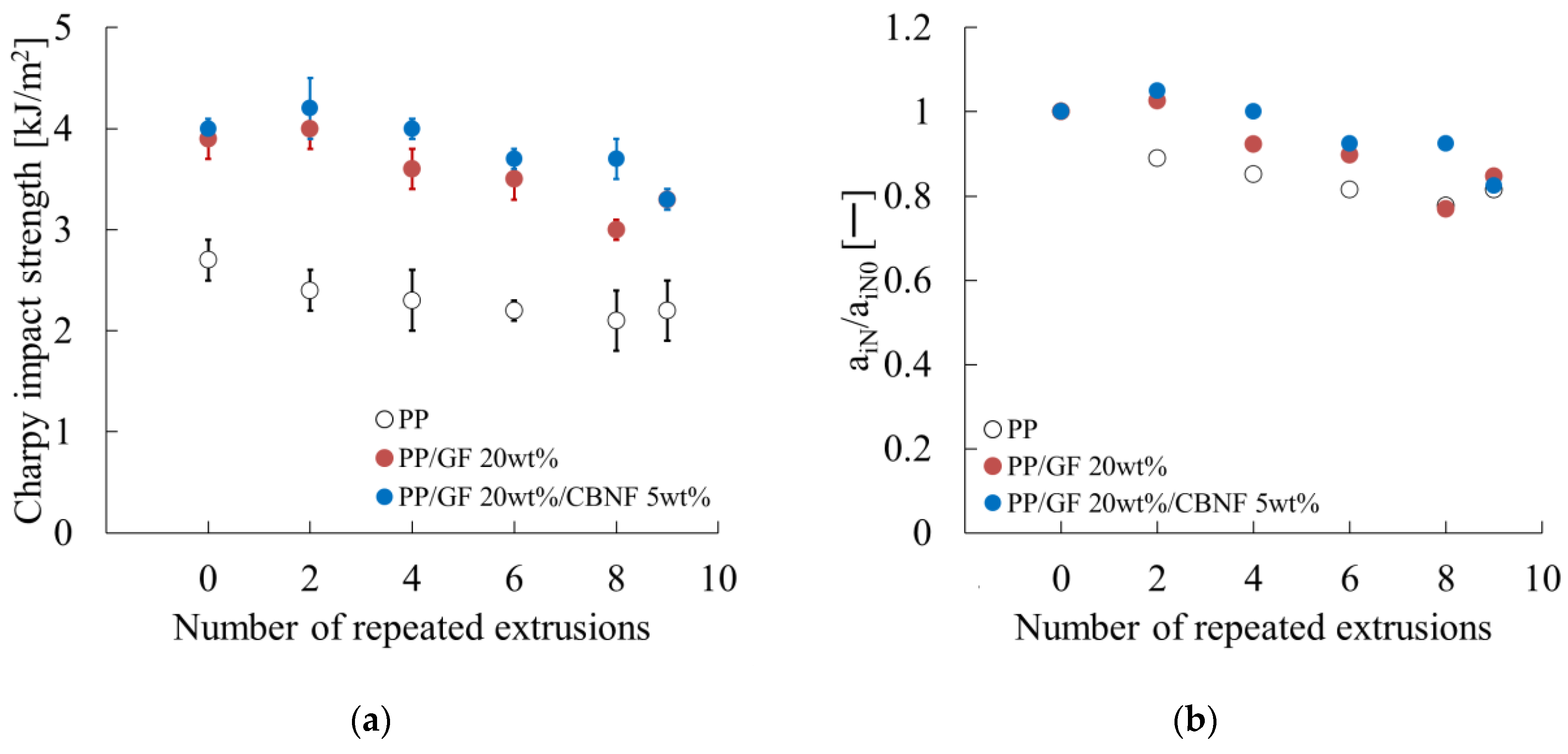

3.4. Changes in Notched Charpy Impact Strength with Repeated Extrusion

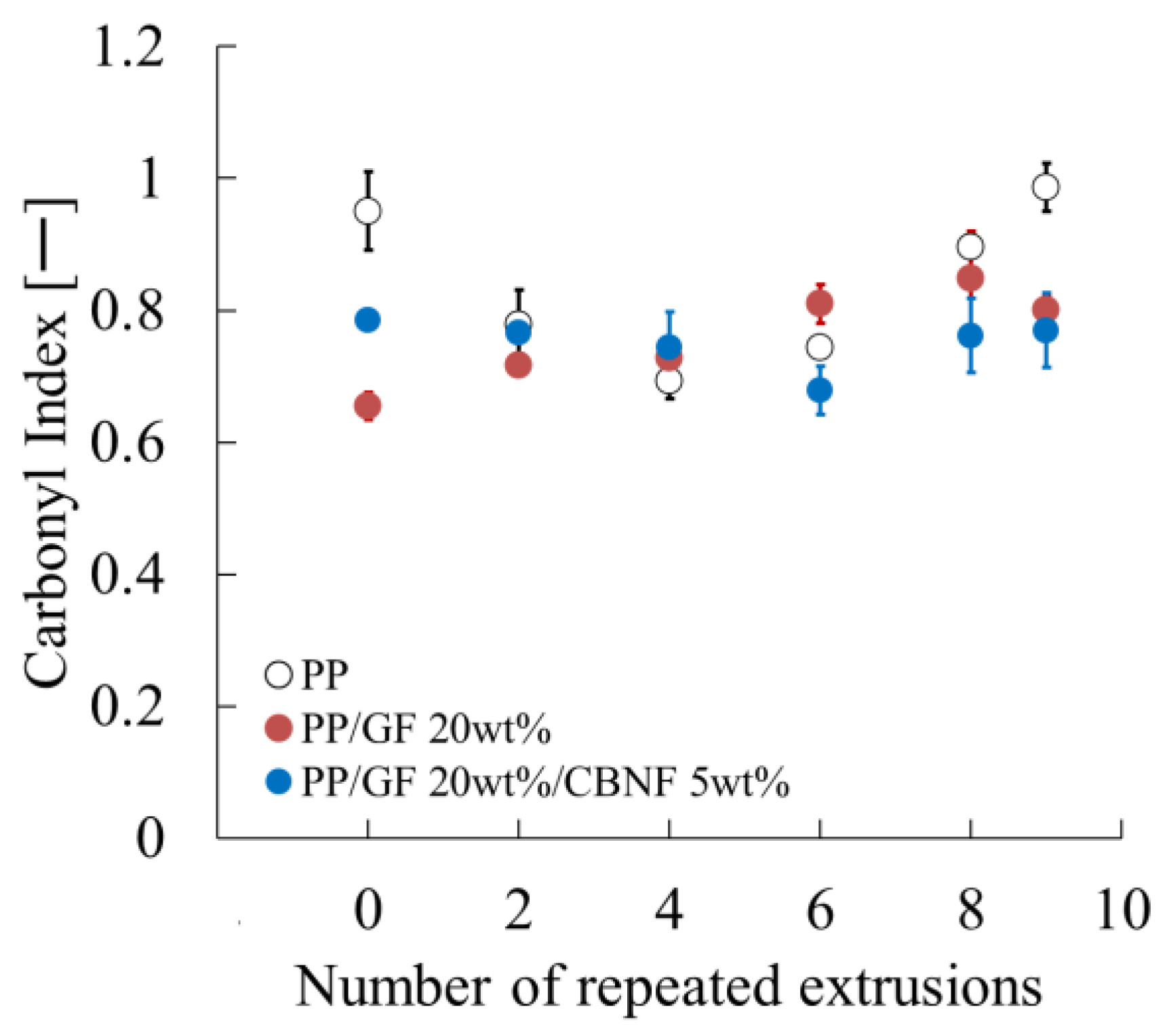

4. Discussion

4.1. Mechanism of Improved Processing Stability by Carbon Nanofiber Addition

4.2. Mechanism of Flexural Property Degradation Under Repeated Extrusion

4.3. Mechanism of Notched Impact Strength Degradation Under Repeated Extrusion

4.4. Recyclability and Practical Challenges of PP/GF/CBNF Hybrid Composites

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Suzuki, G.; Uchida, N.; Tanaka, K.; Higashi, O.; Takahashi, Y.; Kuramochi, H.; Yamaguchi, N.; Osako, M. Global discharge of microplastics from mechanical recycling of plastic waste. Environ. Pollut. 2024, 348, 123855. [Google Scholar] [CrossRef]

- Lamtai, A.; Elkoun, S.; Robert, M.; Mighri, F.; Diez, C. Mechanical Recycling of Thermoplastics: A Review of Key Issues. Waste 2023, 1, 860–883. [Google Scholar] [CrossRef]

- Podara, C.; Termine, S.; Modestou, M.; Semitekolos, D.; Tsirogiannis, C.; Karamitrou, M.; Trompeta, A.; Milickovic, T.; Charitidis, C. Recent Trends of Recycling and Upcycling of Polymers and Composites: A Comprehensive Review. Recycling 2024, 9, 37. [Google Scholar] [CrossRef]

- Uzosike, C.C.; Yee, L.H.; Padilla, R.V. Small-Scale Mechanical Recycling of Solid Thermoplastic Wastes: A Review of PET, PEs, and PP. Energies 2023, 16, 1406. [Google Scholar] [CrossRef]

- Fu, B.; Liu, K.; Chen, J.; Teng, J. Concrete Reinforced with Macro Fibres Recycled from Waste GFRP. Constr. Build. Mater. 2021, 293, 125063. [Google Scholar] [CrossRef]

- Gandi, R.; Parida, S.; Mahato, K.; Bera, M.; Mukherjee, S.; Prusty, R.; Ray, B. Effects of Recycling on the Elevated Temperature Bending and Creep Response of Regenerated Glass Fiber Reinforced Epoxy Composites. Polym. Compos. 2025; in press. [Google Scholar] [CrossRef]

- Sadr Kenari, M.R.; Zolfaghari, A. Experimental Investigation on Mechanical Properties, Shrinkage and Warpage of Injection-Molded Short Glass Fiber Reinforced Polypropylene. J. Compos. Mater. 2023, 57, 3279–3291. [Google Scholar] [CrossRef]

- Chen, T.; Mansfield, C.; Ju, L.; Baird, D. The influence of mechanical recycling on the properties of thermotropic liquid crystalline polymer and long glass fiber reinforced polypropylene. Compos. Part B Eng. 2020, 200, 108316. [Google Scholar] [CrossRef]

- Bernatas, R.; Dagréou, S.; Despax-Ferreres, A.; Barasinski, A. Recycling of Fiber Reinforced Composites with a Focus on Thermoplastic Composites. Clean. Eng. Technol. 2021, 3, 100272. [Google Scholar] [CrossRef]

- Takayama, T.; Kobayashi, S.; Yuasa, Y.; Jiang, Q. Effect of Carbon Nanofiber Distribution on Mechanical Properties of Injection-Molded Aramid-Fiber-Reinforced Polypropylene. Polymers 2024, 16, 1110. [Google Scholar] [CrossRef]

- Takayama, T.; Takahashi, R.; Konno, N.; Sato, N. Evaluation of Polypropylene Reusability Using a Simple Mechanical Model Derived from Injection-Molded Products. Polymers 2025, 17, 2107. [Google Scholar] [CrossRef] [PubMed]

- Nishimoto, T.; Nakagawa, M.; Tsukamoto, M.; Yamamoto, Y. Thermoplastic Resin Composition and Method for Producing the Same. Japan Patent JP2016-222932A, 28 December 2016. [Google Scholar]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M.; Wachowski, M. Mechanical and Material Properties of Mortar Reinforced with Glass Fiber: An Experimental Study. Materials 2021, 14, 698. [Google Scholar] [CrossRef]

- Bacon, R. Growth, Structure, and Properties of Graphite Whiskers. J. Appl. Phys. 1960, 31, 283–290. [Google Scholar] [CrossRef]

- ISO 1133-1:2022; Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method. The British Standards Institution: London, UK, 2022.

- Jiang, Q.; Takayama, T.; Nishioka, A. Improving the Accuracy of the Evaluation Method for Interfacial Shear Strength of FRTP through Short Beam Shear Test. Polymers 2024, 16, 883. [Google Scholar] [CrossRef]

- ISO 178:2019; Plastics—Determination of Flexural Properties. The British Standards Institution: London, UK, 2019.

- ISO 179-1:2023; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test. The British Standards Institution: London, UK, 2023.

- Almond, J.; Sugumaar, P.; Wenzel, M.; Hill, G.; Wallis, C. Determination of the Carbonyl Index of Polyethylene and Polypropylene Using Specified Area Under Band Methodology with ATR-FTIR Spectroscopy. e-Polymers 2020, 20, 369–381. [Google Scholar] [CrossRef]

- Bernagozzi, G.; Arrigo, R.; Ponzielli, G.; Frache, A. Towards effective recycling routes for polypropylene: Influence of a repair additive on flow characteristics and processability. Polym. Degrad. Stab. 2024, 223, 110714. [Google Scholar] [CrossRef]

- Cisneros, F.; Kokini, J. Effect of Extrusion Operating Parameters on Air Bubble Entrapment. J. Food Process Eng. 2002, 25, 251–283. [Google Scholar] [CrossRef]

- Dupuis, A.; Pesce, J.; Ferreira, P.; Régnier, G. Fiber Orientation and Concentration in an Injection-Molded Ethylene–Propylene Copolymer Reinforced by Hemp. Polymers 2020, 12, 2771. [Google Scholar] [CrossRef]

- Yamaguchi, A.; Urushisaki, M.; Uematsu, H.; Sakaguchi, T.; Hashimoto, T. Effects of different types of maleic anhydride-modified polypropylene on the interfacial shear strengths of carbon fiber-reinforced polypropylene composites. Polym. J. 2023, 55, 153–161. [Google Scholar] [CrossRef]

- Xu, B.; Wang, X.; Lu, Y. Surface modification of polyacrylonitrile-based carbon fiber and its interaction with imide. Appl. Surf. Sci. 2006, 253, 2695–2701. [Google Scholar] [CrossRef]

- Yokoi, D.; Tokonami, R.; Sasaki, D.; Takahashi, T. Effect of adding two kinds of acid-terminated polypropylene and surface modification using tannic acid–iron ion complex on the mechanical properties of carbon fiber/polypropylene composites. Polym. Compos. 2025, 46, 13496–13508. [Google Scholar] [CrossRef]

- Takayama, T.; Nagasawa, Y. Poisson’s Ratio Prediction of Injection Molded Thermoplastics Using Differential Scanning Calorimetry. Polymers 2024, 16, 1956. [Google Scholar] [CrossRef]

- Dospisil, D.; Kubát, J.; Plešek, M.; Sáha, P. Extrusion of Short Fibre Reinforced PP: Fibre Length Reduction During Single Screw Extrusion. Int. Polym. Process. 1994, 9, 303–309. [Google Scholar] [CrossRef]

- Jiang, Q.; Takayama, T.; Nishioka, A. Impact Energy Dissipation and Quantitative Models of Injection Molded Short Fiber-Reinforced Thermoplastics. Polymers 2023, 15, 4297. [Google Scholar] [CrossRef]

- Takayama, T.; Yuasa, Y.; Jiang, Q. Polyvinyl Butyral Addition Effects on Notched Charpy Impact Strength of Injection-Molded Glass Fiber-Reinforced Polypropylene. Polymers 2024, 16, 3472. [Google Scholar] [CrossRef]

- Jenkins, P.; Yang, L.; Liggat, J.; Thomason, J. Investigation of the strength loss of glass fibre after thermal conditioning. J. Mater. Sci. 2015, 50, 1050–1057. [Google Scholar] [CrossRef]

- Feih, S.; Manatpon, K.; Mathys, Z.; Gibson, A.; Mouritz, A. Strength degradation of glass fibers at high temperatures. J. Mater. Sci. 2009, 44, 392–400. [Google Scholar] [CrossRef]

- Arbab, S.; Teimoury, A.; Mirbaha, H.; Adolphe, D.; Noroozi, B.; Nourpanah, P. Optimum stabilization processing parameters for polyacrylonitrile-based carbon nanofibers and their difference with carbon (micro) fibers. Polym. Degrad. Stab. 2017, 142, 198–208. [Google Scholar] [CrossRef]

- Yu, C.; Saha, S.; Zhou, J.; Shi, L.; Cassell, A.M.; Cruden, B.A.; Ngo, Q.; Li, J. Thermal Contact Resistance and Thermal Conductivity of a Carbon Nanofiber. J. Heat Transf. 2006, 128, 234–239. [Google Scholar] [CrossRef]

- Salesa, B.; Martí, M.; Frígols, B.; Serrano-Aroca, Á. Carbon Nanofibers in Pure Form and in Calcium Alginate Composites Films: New Cost-Effective Antibacterial Biomaterials against the Life-Threatening Multidrug-Resistant Staphylococcus epidermidis. Polymers 2019, 11, 453. [Google Scholar] [CrossRef] [PubMed]

- Hagnell, M.; Åkermo, M. The Economic and Mechanical Potential of Closed Loop Material Usage and Recycling of Fibre-Reinforced Composite Materials. J. Clean. Prod. 2019, 233, 1650–1659. [Google Scholar] [CrossRef]

- Andrei, R.; Marinoiu, A.; Marin, E.; Enache, S.; Carcadea, E. Carbon Nanofibers Production via the Electrospinning Process. Energies 2020, 13, 3029. [Google Scholar] [CrossRef]

- Ci, L.; Li, Y.; Wei, B.; Liang, J.; Xu, C.; Wu, D. Preparation of carbon nanofibers by the floating catalyst method. Carbon 2000, 38, 1933–1937. [Google Scholar] [CrossRef]

- Lu, X.; Wang, Z. Molecular mechanism for combined toxicity of micro(nano)plastics and carbon nanofibers to freshwater microalgae Chlorella pyrenoidosa. Environ. Pollut. 2024, 337, 123403. [Google Scholar] [CrossRef] [PubMed]

| PP [wt%] | GF [wt%] | MAH-PP [wt%] | CBNF [wt%] | Tinj [°C] | Tmold [°C] | Vinj [m/s] | Phold [MPa] | Tinj [s] | Tcool [s] |

|---|---|---|---|---|---|---|---|---|---|

| 77 | 20 | 3 | - | 230 | 50 | 30 | 56 | 10 | 15 |

| 72 | 20 | 3 | 5 | 230 | 50 | 30 | 70 | 10 | 15 |

| 100 | - | - | - | 230 | 50 | 30 | 70 | 10 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takayama, T.; Shimizu, D.; Kobayashi, S. Processing Stability of Carbon Nanofiber-Reinforced Glass Fiber/Polypropylene Composites Under Repeated Extrusion for Mechanical Recycling. Materials 2025, 18, 4777. https://doi.org/10.3390/ma18204777

Takayama T, Shimizu D, Kobayashi S. Processing Stability of Carbon Nanofiber-Reinforced Glass Fiber/Polypropylene Composites Under Repeated Extrusion for Mechanical Recycling. Materials. 2025; 18(20):4777. https://doi.org/10.3390/ma18204777

Chicago/Turabian StyleTakayama, Tetsuo, Daisuke Shimizu, and Shunsuke Kobayashi. 2025. "Processing Stability of Carbon Nanofiber-Reinforced Glass Fiber/Polypropylene Composites Under Repeated Extrusion for Mechanical Recycling" Materials 18, no. 20: 4777. https://doi.org/10.3390/ma18204777

APA StyleTakayama, T., Shimizu, D., & Kobayashi, S. (2025). Processing Stability of Carbon Nanofiber-Reinforced Glass Fiber/Polypropylene Composites Under Repeated Extrusion for Mechanical Recycling. Materials, 18(20), 4777. https://doi.org/10.3390/ma18204777